Thermal Conductivity of Polybutadiene Rubber from Molecular Dynamics Simulations and Measurements by the Heat Flow Meter Method

Abstract

:1. Introduction

2. Simulation and Experimental Details

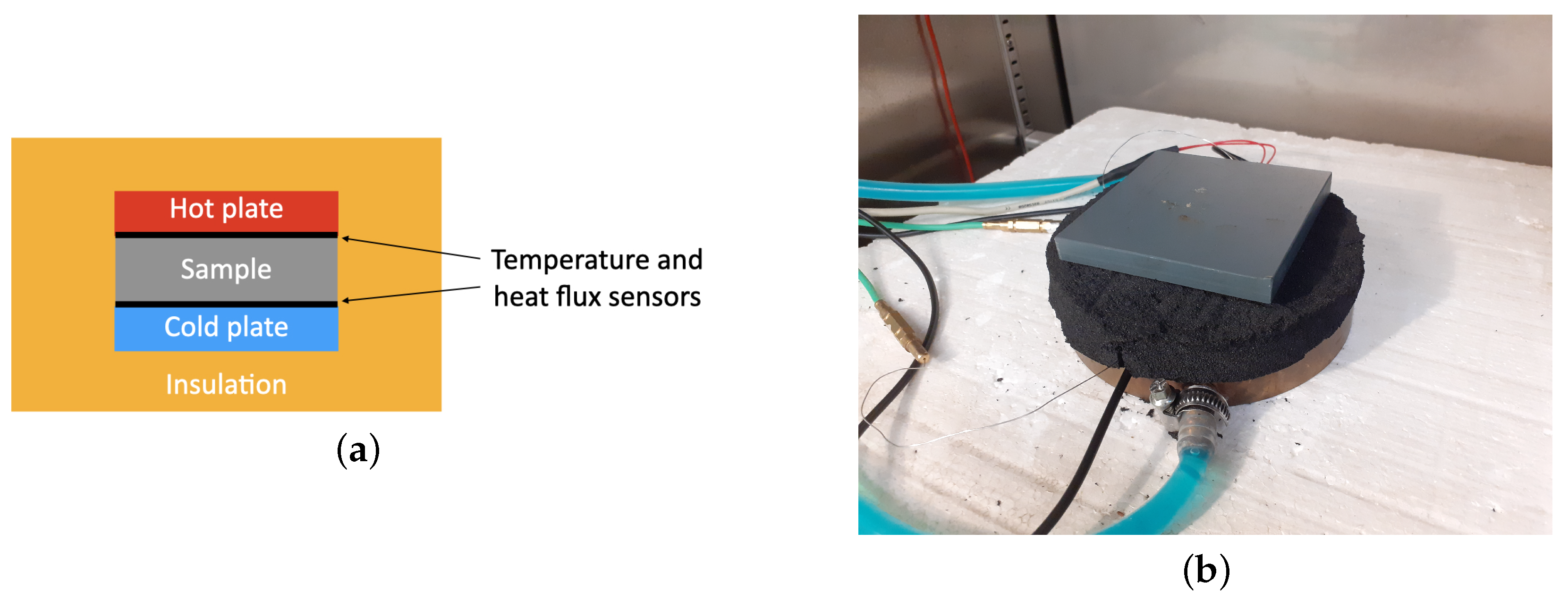

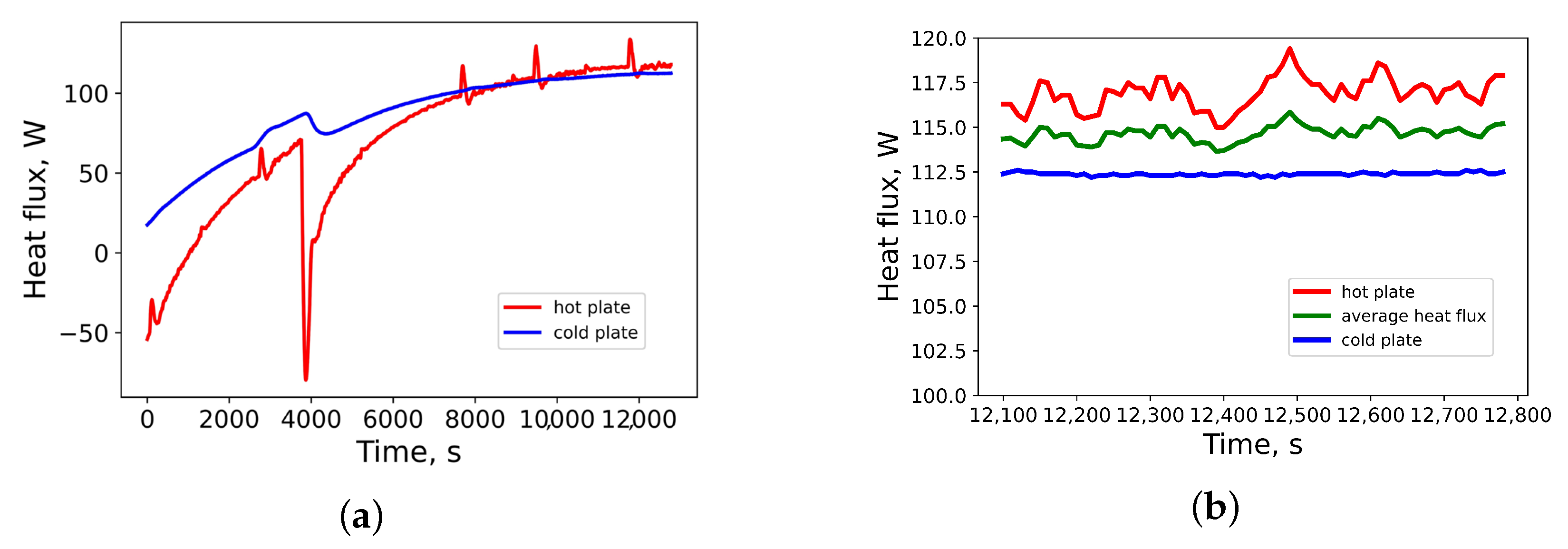

2.1. Simulation Details and Description of the Experimental Setup for Measurement of the Thermal Conductivity

2.2. Preparation of Samples for Experiments

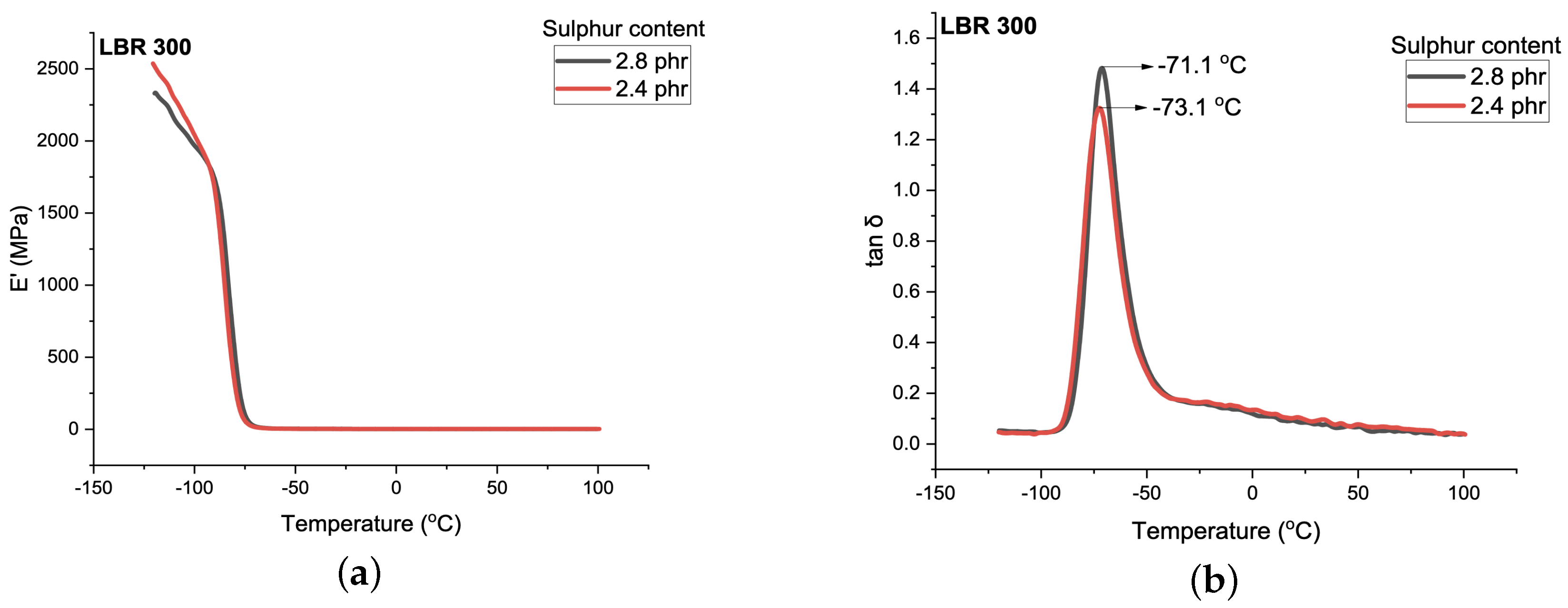

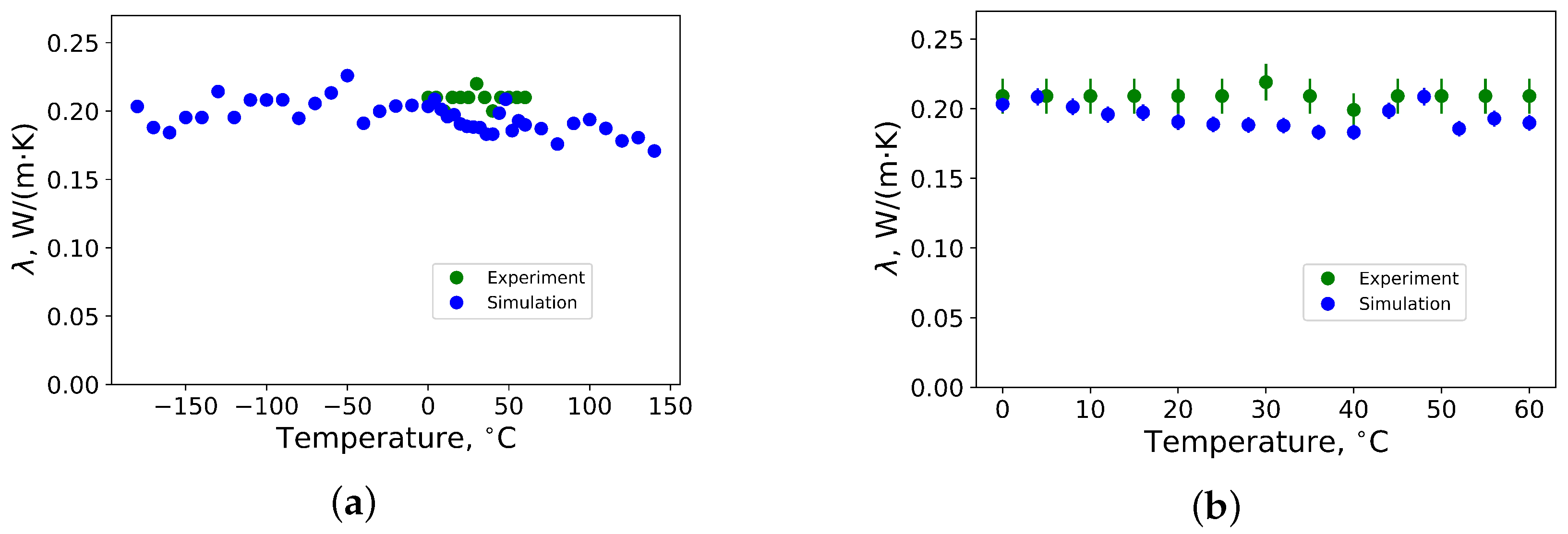

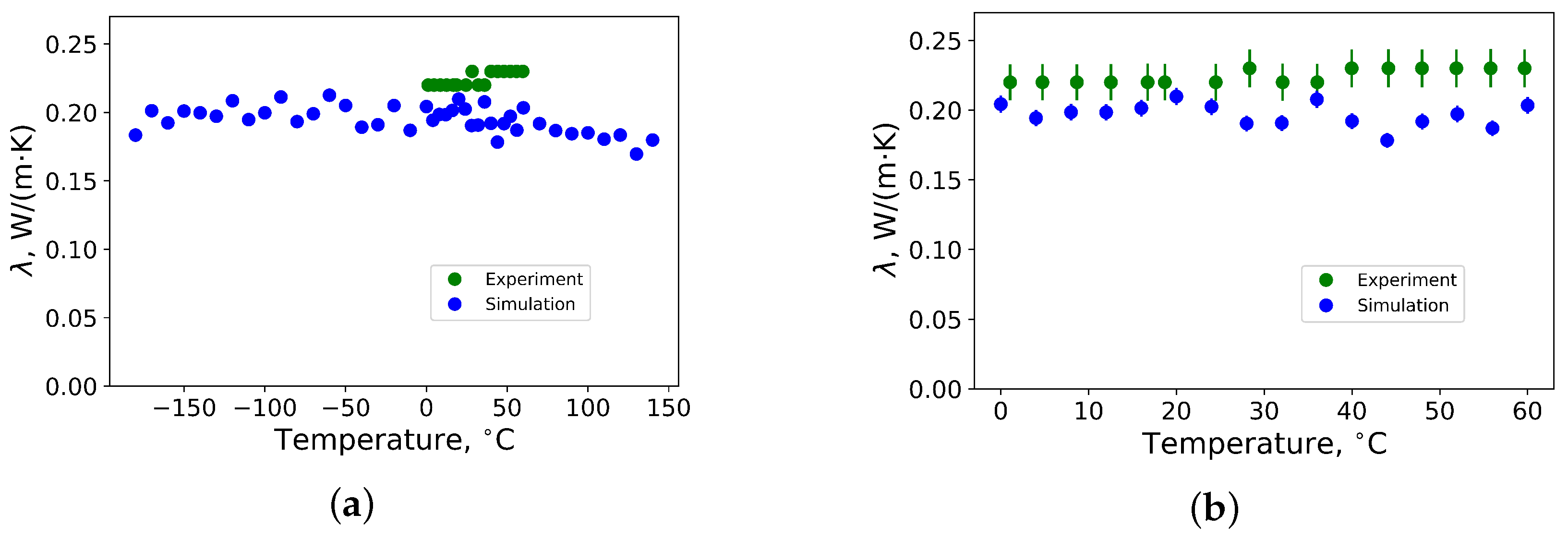

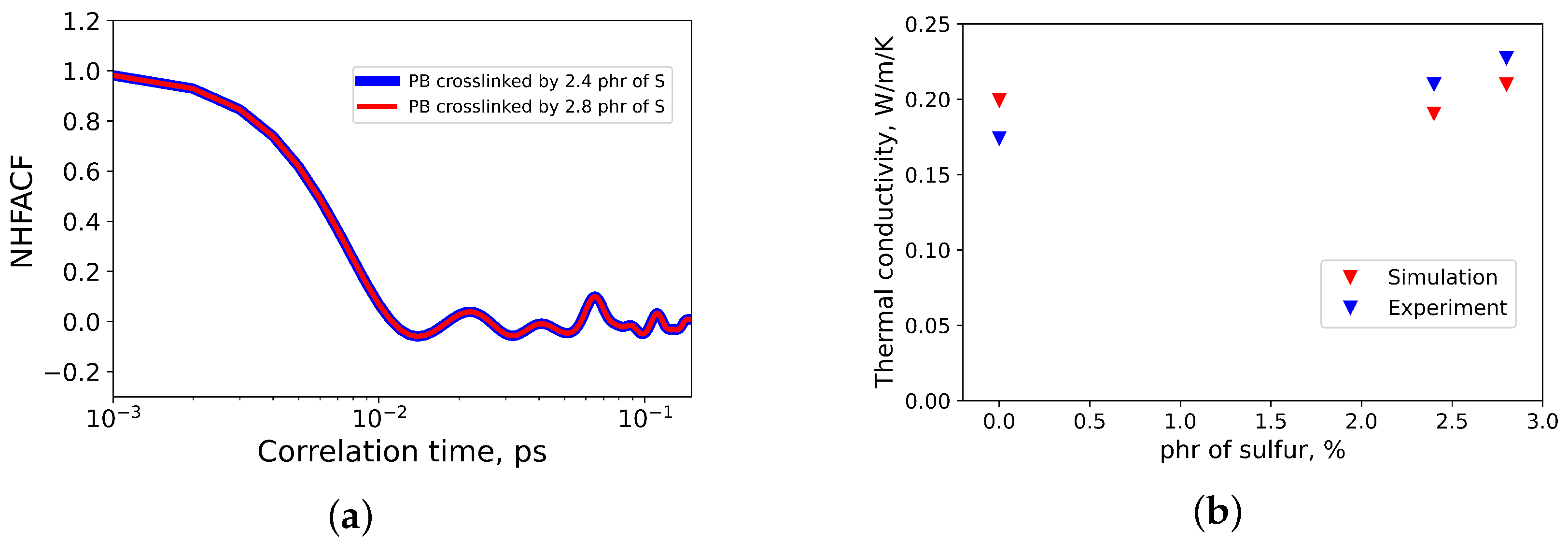

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Sienkiewicz, M.; Janik, H.; Borzędowska-Labuda, K.; Kucińska-Lipka, J. Environmentally friendly polymer-rubber composites obtained from waste tyres: A review. J. Clean. Prod. 2017, 147, 560–571. [Google Scholar] [CrossRef]

- Stelescu, M.D.; Manaila, E.; Craciun, G.; Dumitrascu, M. New green polymeric composites based on hemp and natural rubber processed by electron beam irradiation. Sci. World J. 2014, 2014, 684047. [Google Scholar] [CrossRef]

- Gracia, L.; Liarte, E.; Pelegay, J.; Calvo, B. Finite element simulation of the hysteretic behaviour of an industrial rubber. Application to design of rubber components. Finite Elem. Anal. Des. 2010, 46, 357–368. [Google Scholar] [CrossRef]

- Cugliari, J. Investigation of Contact Mechanics and Friction of Rubber Compounds by Experimental Techniques and Numerical Simulations. Ph.D. Thesis, Institutionelles Repositorium der Leibniz Universität Hannover, Hannover, Germany, 2021. [Google Scholar]

- Kerschbaumer, R.C.; Stieger, S.; Gschwandl, M.; Hutterer, T.; Fasching, M.; Lechner, B.; Meinhart, L.; Hildenbrandt, J.; Schrittesser, B.; Fuchs, P.F.; et al. Comparison of steady-state and transient thermal conductivity testing methods using different industrial rubber compounds. Polym. Test. 2019, 80, 106121. [Google Scholar] [CrossRef]

- Benazzouk, A.; Douzane, O.; Mezreb, K.; Laidoudi, B.; Quéneudec, M. Thermal conductivity of cement composites containing rubber waste particles: Experimental study and modelling. Constr. Build. Mater. 2008, 22, 573–579. [Google Scholar] [CrossRef]

- Sandberg, O.; Bäckström, G. Thermal properties of natural rubber versus temperature and pressure. J. Appl. Phys. 1979, 50, 4720–4724. [Google Scholar] [CrossRef]

- Wilk, J.; Smusz, R.; Filip, R.; Chmiel, G.; Bednarczyk, T. Experimental investigations on graphene oxide/rubber composite thermal conductivity. Sci. Rep. 2020, 10, 15533. [Google Scholar] [CrossRef]

- Tian, L.; Wang, Y.; Li, Z.; Mei, H.; Shang, Y. The thermal conductivity-dependant drag reduction mechanism of water droplets controlled by graphene/silicone rubber composites. Exp. Therm. Fluid Sci. 2017, 85, 363–369. [Google Scholar] [CrossRef]

- Gschwandl, M.; Kerschbaumer, R.C.; Schrittesser, B.; Fuchs, P.F.; Stieger, S.; Meinhart, L. Thermal conductivity measurement of industrial rubber compounds using laser flash analysis: Applicability, comparison and evaluation. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2019; Volume 2065, p. 030041. [Google Scholar]

- Wang, F.; Drzal, L.T.; Qin, Y.; Huang, Z. Enhancement of fracture toughness, mechanical and thermal properties of rubber/epoxy composites by incorporation of graphene nanoplatelets. Compos. Part A Appl. Sci. Manuf. 2016, 87, 10–22. [Google Scholar] [CrossRef]

- Song, J.; Ma, L.; He, Y.; Yan, H.; Wu, Z.; Li, W. Modified graphite filled natural rubber composites with good thermal conductivity. Chin. J. Chem. Eng. 2015, 23, 853–859. [Google Scholar] [CrossRef]

- Song, J.p.; Tian, K.y.; Ma, L.x.; Li, W.; Yao, S.c. The effect of carbon black morphology to the thermal conductivity of natural rubber composites. Int. J. Heat Mass Transf. 2019, 137, 184–191. [Google Scholar] [CrossRef]

- Xue, Y.; Li, X.; Wang, H.; Zhao, F.; Zhang, D.; Chen, Y. Improvement in thermal conductivity of through-plane aligned boron nitride/silicone rubber composites. Mater. Des. 2019, 165, 107580. [Google Scholar] [CrossRef]

- Kobari, T.; Okajima, J.; Komiya, A.; Maruyama, S. Development of guarded hot plate apparatus utilizing Peltier module for precise thermal conductivity measurement of insulation materials. Int. J. Heat Mass Transf. 2015, 91, 1157–1166. [Google Scholar] [CrossRef]

- Yang, I.; Kim, D.; Lee, S. Construction and preliminary testing of a guarded hot plate apparatus for thermal conductivity measurements at high temperatures. Int. J. Heat Mass Transf. 2018, 122, 1343–1352. [Google Scholar] [CrossRef]

- Headley, A.J.; Hileman, M.B.; Robbins, A.S.; Piekos, E.S.; Stirrup, E.K.; Roberts, C.C. Thermal conductivity measurements and modeling of ceramic fiber insulation materials. Int. J. Heat Mass Transf. 2019, 129, 1287–1294. [Google Scholar] [CrossRef]

- Cha, J.; Seo, J.; Kim, S. Building materials thermal conductivity measurement and correlation with heat flow meter, laser flash analysis and TCi. J. Therm. Anal. Calorim. 2012, 109, 295–300. [Google Scholar] [CrossRef]

- Song, J.; Li, X.; Tian, K.; Ma, L.; Li, W.; Yao, S. Thermal conductivity of natural rubber nanocomposites with hybrid fillers. Chin. J. Chem. Eng. 2019, 27, 928–934. [Google Scholar] [CrossRef]

- Eiermann, K.; Hellwege, K.X. Thermal conductivity of high polymers from -180 °C to 90 °C. J. Polym. Sci. 1962, 57, 99–106. [Google Scholar] [CrossRef]

- Carwile, L.C.; Hoge, H.J. Thermal conductivity of soft vulcanized natural rubber, selected values. Rubber Chem. Technol. 1966, 39, 126–131. [Google Scholar] [CrossRef]

- Vasilev, A.; Lorenz, T.; Breitkopf, C. Thermal conductivity of polyisoprene and polybutadiene from molecular dynamics simulations and transient measurements. Polymers 2020, 12, 1081. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Fu, B.; Zhang, W.; Li, H.; Lu, Y.; Gao, Y.; Zhang, L. Increasing the thermal conductivity of styrene butadiene rubber: Insights from molecular dynamics simulation. RSC Adv. 2020, 10, 23394–23402. [Google Scholar] [CrossRef]

- Engelmann, S.; Meyer, J.; Hentschke, R. Computer simulation of thermal conductivity in vulcanized polyisoprene at variable strain and temperature. Phys. Rev. B 2017, 96, 054110. [Google Scholar] [CrossRef]

- Jewett, A.I.; Zhuang, Z.; Shea, J.E. Moltemplate a coarse-grained model assembly tool. Biophys. J. 2013, 104, 169. [Google Scholar] [CrossRef] [Green Version]

- Vasilev, A.; Lorenz, T.; Breitkopf, C. Thermal Conductivities of Crosslinked Polyisoprene and Polybutadiene from Molecular Dynamics Simulations. Polymers 2021, 13, 315. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef] [Green Version]

- Hager, J.; Hentschke, R.; Hojdis, N.W.; Karimi-Varzaneh, H.A. Computer simulation of particle–particle interaction in a model polymer nanocomposite. Macromolecules 2015, 48, 9039–9049. [Google Scholar] [CrossRef]

- Compute Heat/Flux Command. Available online: https://docs.lammps.org/compute_heat_flux.html (accessed on 25 October 2021).

- Compute Centroid/Stress/Atom Command. Available online: https://docs.lammps.org/compute_stress_atom.html (accessed on 20 October 2021).

- Schelling, P.K.; Phillpot, S.R.; Keblinski, P. Comparison of atomic-level simulation methods for computing thermal conductivity. Phys. Rev. B 2002, 65, 144306. [Google Scholar] [CrossRef] [Green Version]

- Bandzierz, K.; Reuvekamp, L.; Dryzek, J.; Dierkes, W.; Blume, A.; Bielinski, D. Influence of network structure on glass transition temperature of elastomers. Materials 2016, 9, 607. [Google Scholar] [CrossRef] [Green Version]

- Rivera, M.R.; Nájera, R.H.; Tapia, J.J.B.; Guerrero, L.R. Structure and properties of model polybutadienes-Effect of microstructure on the dynamic mechanical properties of rubber. J. Elastomers Plast. 2005, 37, 267–278. [Google Scholar] [CrossRef]

- Lewandowska, K.; Furtos, G. Study of apatite layer formation on SBF-treated chitosan composite thin films. Polym. Test. 2018, 71, 173–181. [Google Scholar] [CrossRef]

- Nallasamy, P.; Anbarasan, P.; Mohan, S. Vibrational spectra and assignments of cis-and trans-1, 4-polybutadiene. Turk. J. Chem. 2002, 26, 105–112. [Google Scholar]

- Zhao, J.; Jiang, J.W.; Wei, N.; Zhang, Y.; Rabczuk, T. Thermal conductivity dependence on chain length in amorphous polymers. J. Appl. Phys. 2013, 113, 184304. [Google Scholar] [CrossRef]

- Cheheb, Z.; Mousseau, P.; Sarda, A.; Deterre, R. Thermal conductivity of rubber compounds versus the state of cure. Macromol. Mater. Eng. 2012, 297, 228–236. [Google Scholar] [CrossRef]

| Ingredient | Quantity (phr) |

|---|---|

| Liquid butadiene rubber (LBR) | 100 |

| Zinc Oxide | 3 |

| Stearic acid | 2 |

| TBzTD | 1 |

| CBS | 1.5 |

| Sulfur | 2.4 and 2.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasilev, A.; Lorenz, T.; Kamble, V.G.; Wießner, S.; Breitkopf, C. Thermal Conductivity of Polybutadiene Rubber from Molecular Dynamics Simulations and Measurements by the Heat Flow Meter Method. Materials 2021, 14, 7737. https://doi.org/10.3390/ma14247737

Vasilev A, Lorenz T, Kamble VG, Wießner S, Breitkopf C. Thermal Conductivity of Polybutadiene Rubber from Molecular Dynamics Simulations and Measurements by the Heat Flow Meter Method. Materials. 2021; 14(24):7737. https://doi.org/10.3390/ma14247737

Chicago/Turabian StyleVasilev, Aleksandr, Tommy Lorenz, Vikram G Kamble, Sven Wießner, and Cornelia Breitkopf. 2021. "Thermal Conductivity of Polybutadiene Rubber from Molecular Dynamics Simulations and Measurements by the Heat Flow Meter Method" Materials 14, no. 24: 7737. https://doi.org/10.3390/ma14247737

APA StyleVasilev, A., Lorenz, T., Kamble, V. G., Wießner, S., & Breitkopf, C. (2021). Thermal Conductivity of Polybutadiene Rubber from Molecular Dynamics Simulations and Measurements by the Heat Flow Meter Method. Materials, 14(24), 7737. https://doi.org/10.3390/ma14247737