Effect of a Compound Energy Field with Temperature and Ultrasonic Vibration on the Material Properties and Bending Process of TC2 Titanium Alloy

Abstract

:1. Introduction

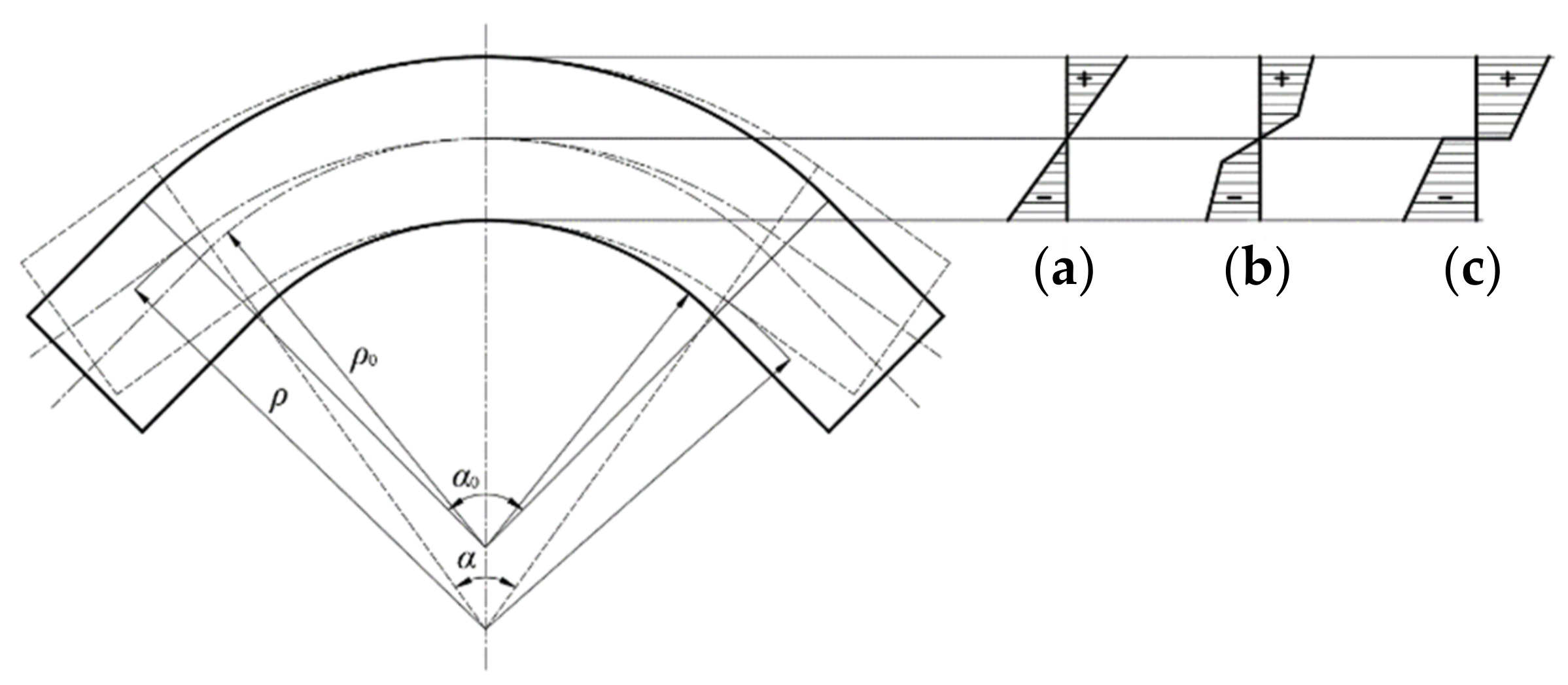

2. Bending Process Analysis

3. Experimental Materials and Scheme

3.1. Experimental Material

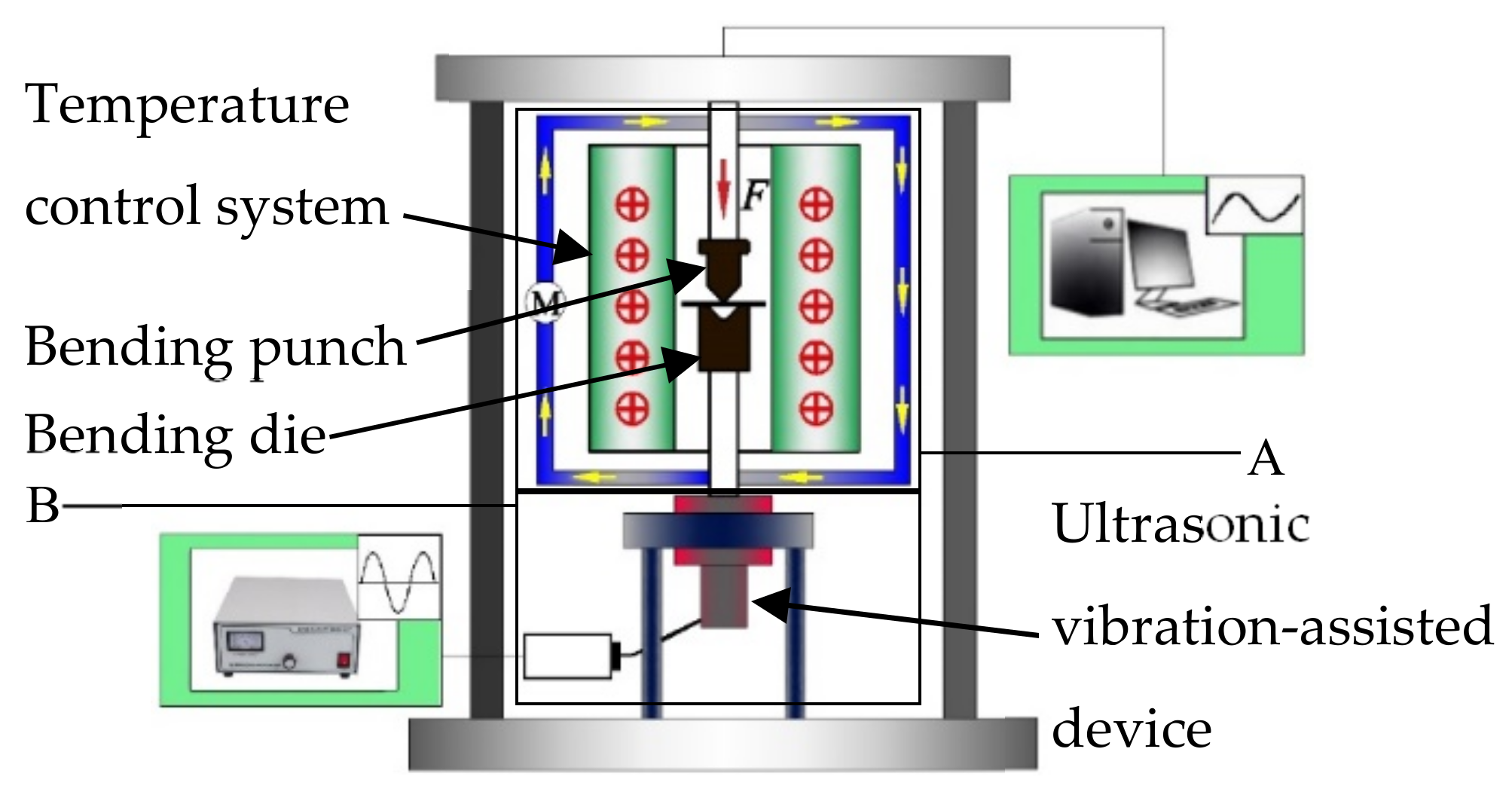

3.2. Experimental Principle and Scheme

4. Experimental Results and Analysis

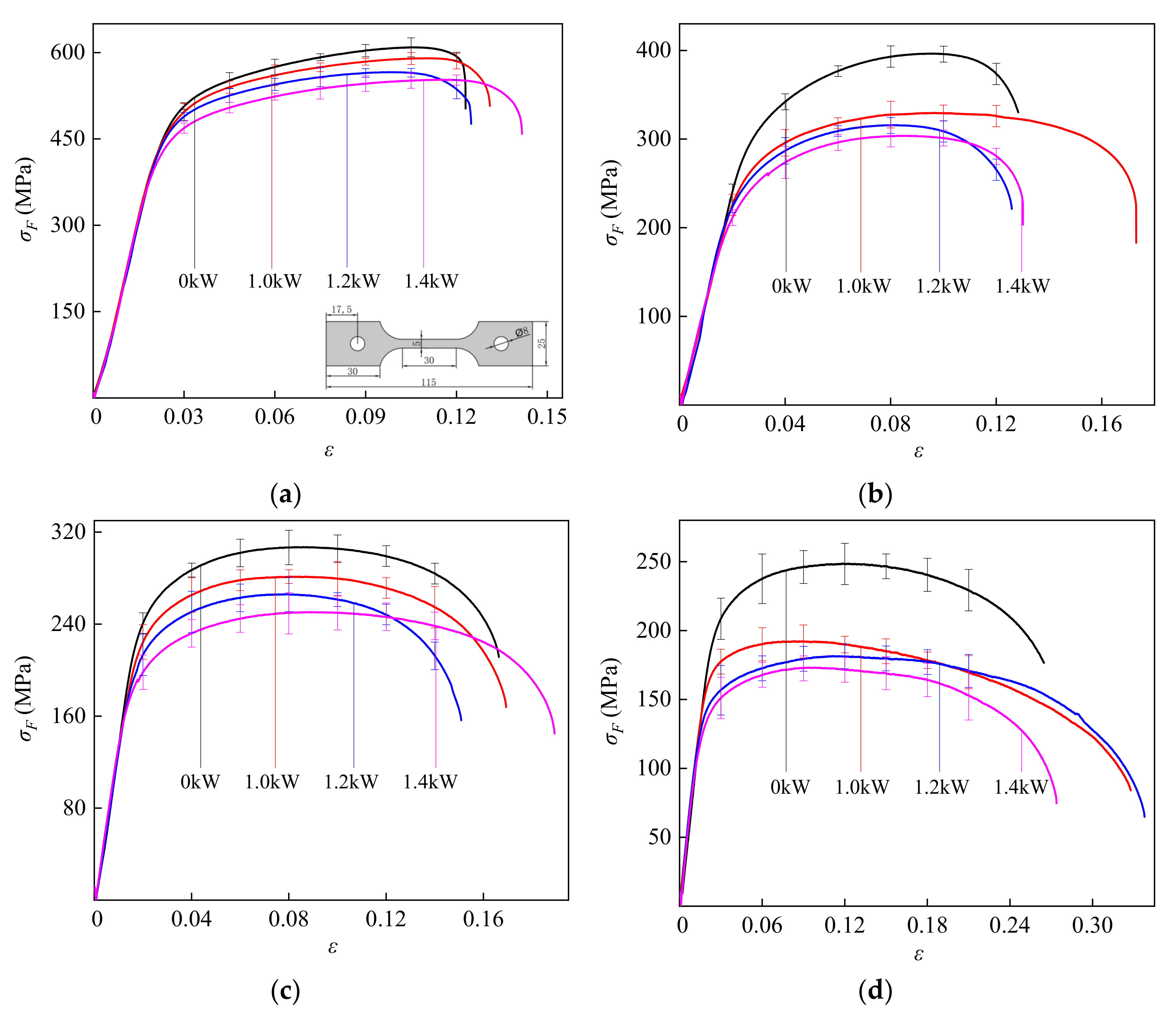

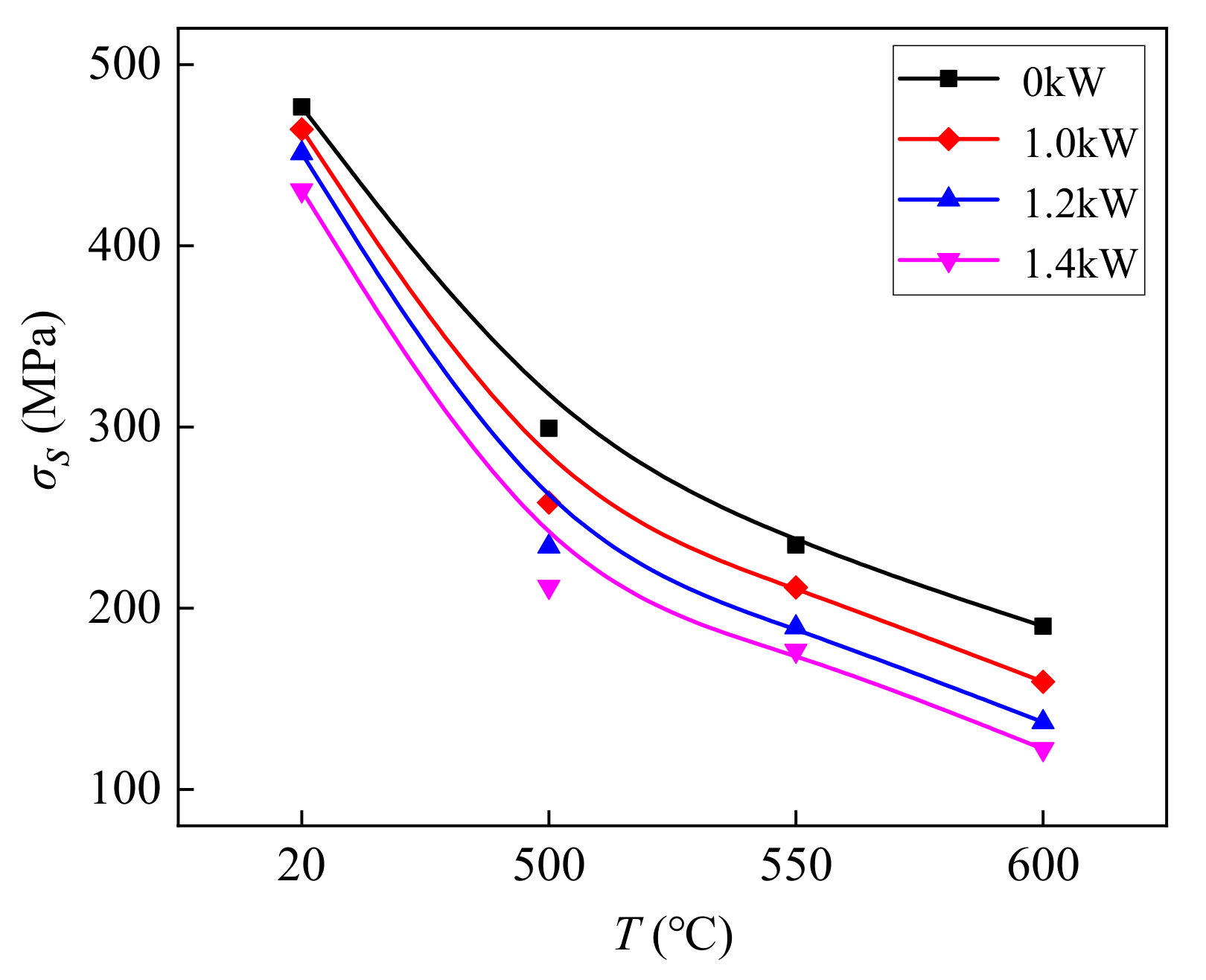

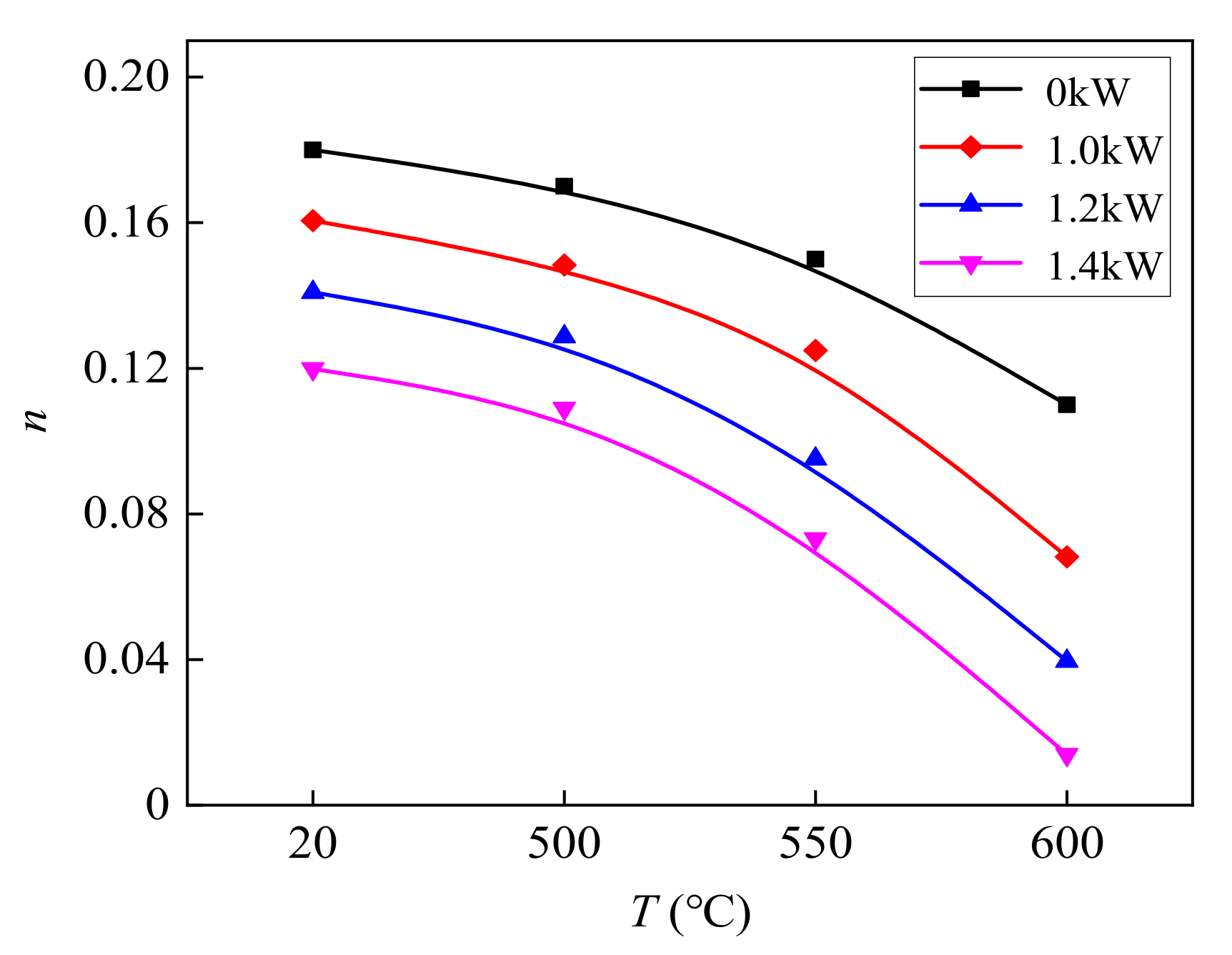

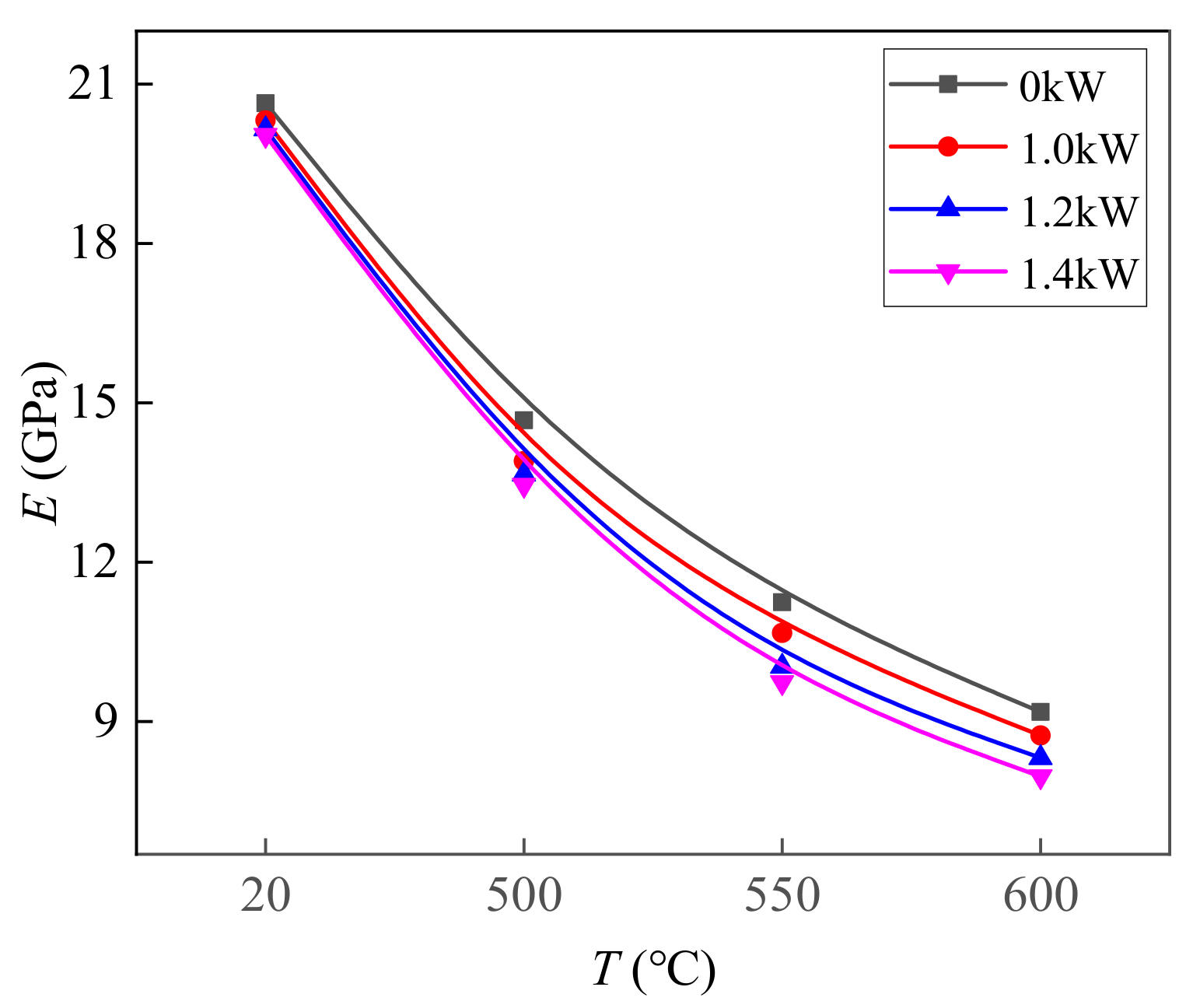

4.1. Tensile Results and Analysis

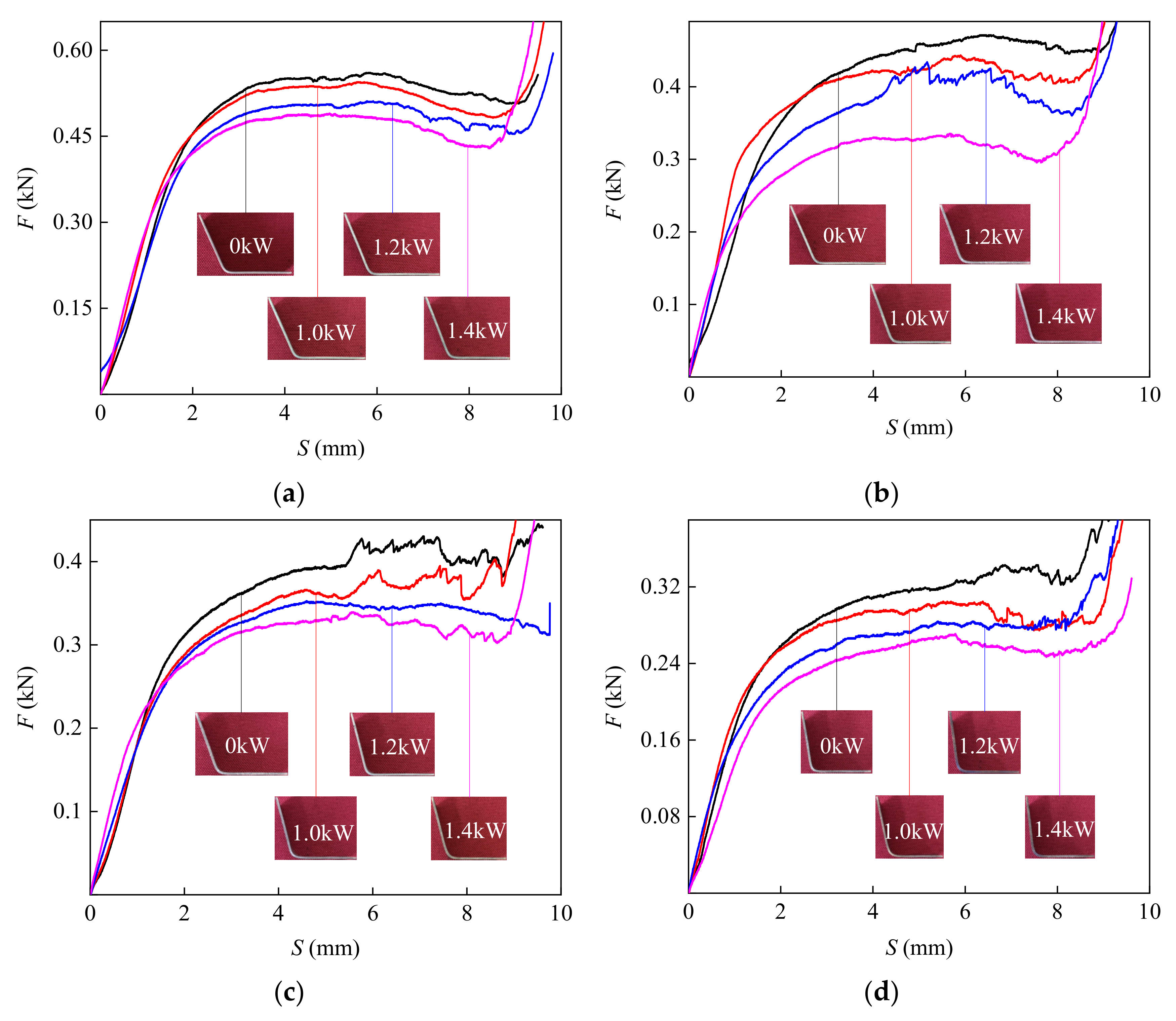

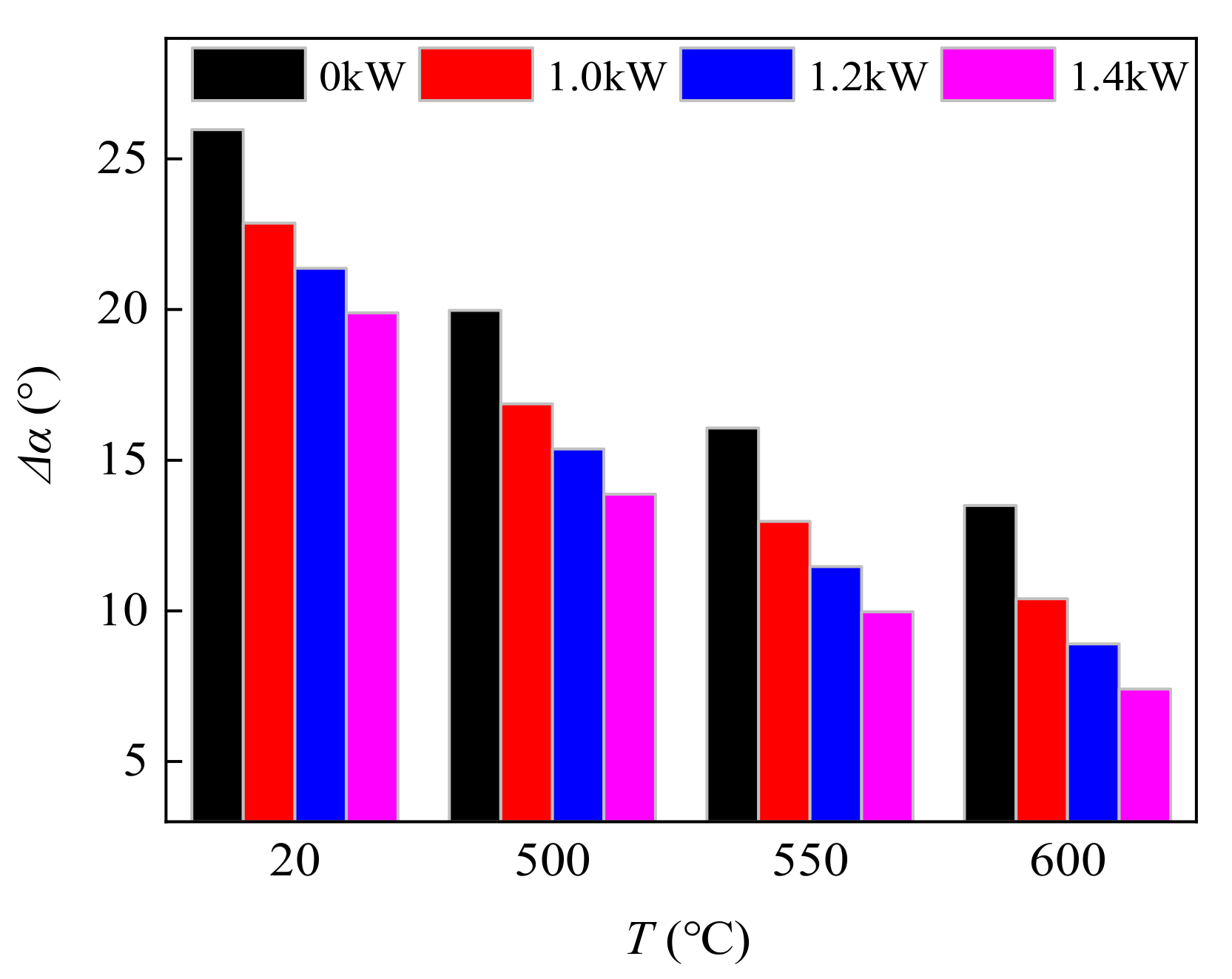

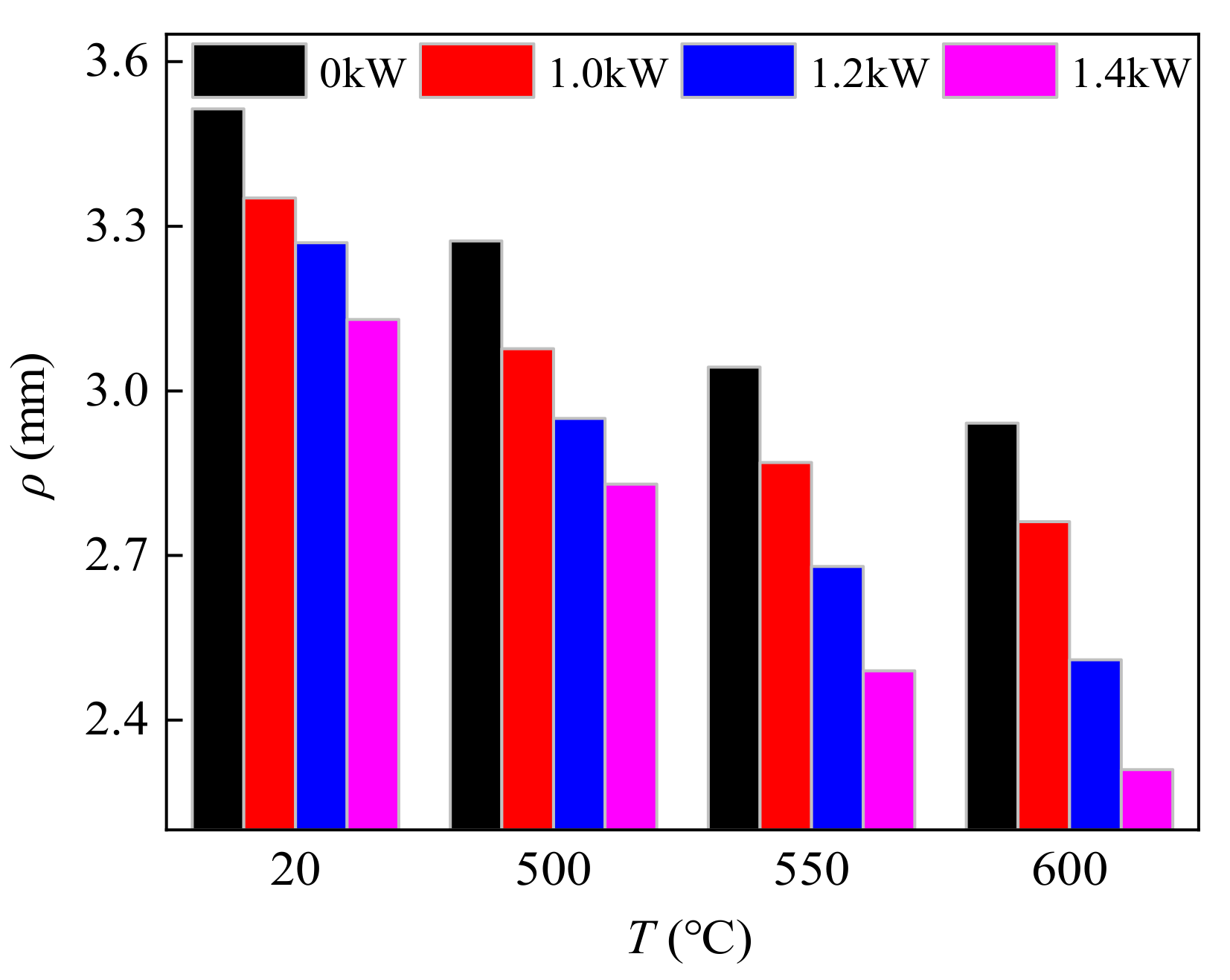

4.2. Bending Results and Analysis

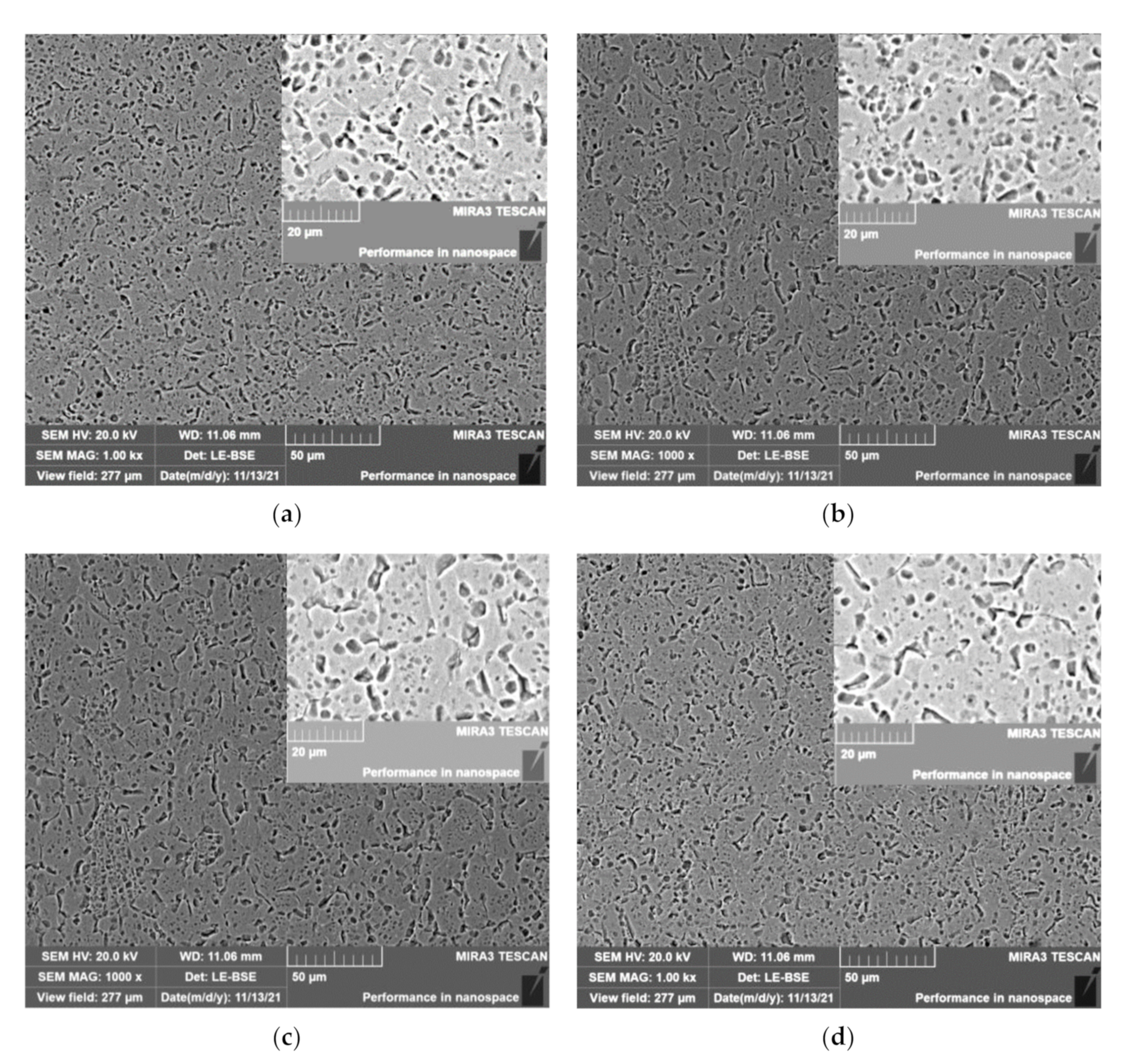

4.3. Effect of the CEF on Microstructure

5. Conclusions

- The results of the tensile tests of TC2 under the CEF show that, compared with a single-temperature field, the strength and the material-hardening exponent decrease due to the high-temperature softening effect increased by the CEF. Therefore, the CEF can effectively enhance the plastic formability of the sheet, and the effect increases with the increase in ultrasonic energy.

- The results of the bending tests for TC2 under the CEF show that, compared with a single-temperature field, the CEF can reduce the bending force and spring-back of the TC2 parts and effectively increase the quality of bending parts.

- Microstructure observation of the TC2 titanium alloy shows that grain size increases under the effect of ultrasonic vibration, which further increases the high-temperature softening effect.

- The combination of the temperature field and ultrasonic vibration can further improve the mechanical properties and bending properties of titanium, which is helpful in improving the quality and properties of titanium alloy parts.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pan, S.; Fu, M.; Liu, H.; Chen, Y.; Yi, D. In Situ Observation of the Tensile Deformation and Fracture Behavior of Ti–5Al–5Mo–5V–1Cr–1Fe Alloy with Different Microstructures. Materials 2021, 14, 5794. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Cheng, L.; Li, D. Experimental Study on Forged TC4 Titanium Alloy Fatigue Properties under Three-Point Bending and Life Prediction. Materials 2021, 14, 5329. [Google Scholar] [CrossRef] [PubMed]

- Bao, X.; Cheng, L.; Ding, J.; Chen, X.; Lu, K.; Cui, W. The Effect of Microstructure and Axial Tension on Three-Point Bending Fatigue Behavior of TC4 in High Cycle and Very High Cycle Regimes. Materials 2020, 13, 68. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, D.; Liu, N.; Chen, Y.; Zhang, G.; Tian, J.; Kong, F.; Xiao, S.; Sun, J. Microstructure Evolution and Mechanical Properties of PM-Ti43Al9V0.3Y Alloy. Materials 2020, 13, 198. [Google Scholar] [CrossRef] [Green Version]

- Gupta, N.K.; Somani, N.; Prakash, C.; Singh, R.; Walia, A.S.; Singh, S.; Pruncu, C.I. Revealing the WEDM Process Parameters for the Machining of Pure and Heat-Treated Titanium (Ti-6Al-4V) Alloy. Materials 2021, 14, 2292. [Google Scholar] [CrossRef]

- Abby, L. Current Status of Titanium Alloys for Aircrafts Application; The International Titanium Association: Las Vegas, NV, USA, 2013. [Google Scholar]

- Vanderhasten, M.; Rabet, L.; Verlinden, B. Ti-6Al-4V: Deformation map and modelisation of tensile behaviour. Mater. Des. 2008, 29, 1090–1098. [Google Scholar] [CrossRef]

- Lang, L.H.; Liu, B.S.; Zeng, Y.S. Titanium Alloy Plate Forming Technology and Its Application in Aviation Industry. Aeronaut. Manuf. Technol. 2009, 10, 28–31. [Google Scholar]

- Lü, Z.D.; Zhang, C.J.; Du, Z.X.; Han, J.C.; Zhang, S.Z.; Yang, F.; Chen, Y.Y. Relationship between microstructure and tensile properties on a near-β titanium alloy after multidirectional forging and heat treatment. Rare Met. 2019, 38, 336–342. [Google Scholar] [CrossRef]

- Li, X.F.; Xu, F.F.; Hu, L.; Zhu, F.H.; Chen, J. Tensile deformation behavior of coarse-grained Ti-55 titanium alloy with different hydrogen additions. Rare Met. 2021, 40, 2092–2098. [Google Scholar] [CrossRef]

- Ashraf Imam, M. The 12th world conference on titanium presents research and applications of “wonder metal”. JOM 2011, 63, 16–23. [Google Scholar] [CrossRef]

- Ulutan, D.; Ozel, T. Machining induced surface integrity in titanium and nickel alloys: A review. Int. J. Mach. Tools Manuf. 2011, 51, 250–280. [Google Scholar] [CrossRef]

- Wang, A.; Zhong, K.; Fakir, O.E.; Liu, J.; Sun, C.Y.; Wang, L.L.; Lin, J.G.; Dean, T.A. Springback analysis of AA5754 after hot stamping: Experiments and FE modelling. Int. J. Adv. Manuf. Technol. 2017, 89, 1339–1352. [Google Scholar] [CrossRef] [Green Version]

- Simonetto, E.; Venturato, G.; Ghiotti, A.; Bruschi, S. Modelling of hot rotary draw bending for thin-walled titanium alloy tubes. Int. J. Mech. Sci. 2018, 148, 698–706. [Google Scholar] [CrossRef]

- Yao, K.; Min, X.H.; Satoshi, E.; Tsuchiya, K. Coupling effect of deformation mode and temperature on tensile properties in TWIP type Ti–Mo alloy. Mater. Sci. Eng. A 2019, 766, 1–10. [Google Scholar] [CrossRef]

- Thomas, P.; Matthias, G.; Marion, M. Numerical modelling approach for the temperature dependent forming behavior of Ti-6Al-4V. Matec Web Conf. 2018, 190, 1–6. [Google Scholar]

- Zhu, Y. Research on Pulse Current-Assisted Bending Forming Law of Titanium and Titanium Alloy. Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2020. [Google Scholar]

- Guang, K.H.; Yao, Y.F.; Wu, T.L.; Liu, B.B. Study on Forming Limit of Incremental Forming of TC4 Titanium Alloy Sheet by Electromagnetic Induction Heating. Hot Work. Technol. 2021, 50, 86–89. [Google Scholar]

- Lang, L.H.; Liu, K.N.; Cai, G.C.; Guo, C. Numerical Research on Forming Technology of Complicated Taper-shaped Part of TC4 Titanium Alloy by Thermal Deep Drawing with Heated Media. Synth. Manuf. Technol. Complex Struct. 2013, 16, 109–112. [Google Scholar]

- Blaha, F.; Langenecker, B. Elongation of zinc monocrystals under ultrasonic action. Die Nat. 1955, 42, 556. [Google Scholar] [CrossRef]

- Langenecker, B. Effects of Ultrasound on Deformation Characteristics of Metals. IEEE Trans. Sonics Ultrason. 1966, 13, 1–8. [Google Scholar] [CrossRef]

- Wang, C.J.; Liu, Y.; Guo, B.; Shan, D.B.; Zhang, B. Acoustic softening and stress superposition in ultrasonic vibration assisted uniaxial tension of copper foil: Experiments and modeling. Mater. Des. 2016, 112, 246–253. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.W.; Wang, C.J.; Liu, Y.; Liu, C.; Wang, Z.L.; Guo, B.; Shan, D.B. An energy based modeling for the acoustic softening effect on the Hall-Petch behavior of pure titanium in ultrasonic vibration assisted micro-tension. Int. J. Plast. 2021, 136, 102879. [Google Scholar] [CrossRef]

- Lin, J.; Li, J.; Liu, T.; Xie, Z.D.; Zhu, L.H.; Wang, Y.; Guan, Y.J. Investigation on ultrasonic vibration effects on plastic flow behavior of pure titanium: Constitutive modeling. J. Mater. Res. Technol. 2020, 9, 4978–4993. [Google Scholar] [CrossRef]

- Ren, Z.J.; Lai, F.Q.; Qu, S.G.; Zhang, Y.L.; Li, X.Q.; Yang, C. Effect of ultrasonic surface rolling on surface layer properties and fretting wear properties of titanium alloy Ti5Al4Mo6V2Nb1Fe. News Sci. 2020, 389, 125612. [Google Scholar] [CrossRef]

- Huang, Y.M.; Wu, Y.S.; Huang, J.Y. The influence of ultrasonic vibration-assisted micro-deep drawing process. Int. J. Adv. Manuf. Technol. 2014, 71, 1455–1461. [Google Scholar] [CrossRef]

- Schinke, B.; Malmberg, T. Dynamic tensile tests with superimposed ultrasonic oscillations for stainless steel type 321 at room temperature. North-Holl. 1987, 100, 281–296. [Google Scholar] [CrossRef]

- Shalvandi, M.; Hojjat, Y.; Abdullah, A.; Asadi, H. Influence of ultrasonic stress relief on stainless steel 316 specimens: A comparison with thermal stress relief. Mater. Des. 2013, 46, 713–723. [Google Scholar] [CrossRef]

- Xu, L.H.; Lei, Y.L.; Zhang, H.O.; Zhang, Z.C.; Sheng, Y.C.; Han, G.C. Research on the Micro-Extrusion Process of Copper T2 with Different Ultrasonic Vibration Modes. Metals 2019, 9, 1209. [Google Scholar] [CrossRef] [Green Version]

- Zha, C.L.; Chen, W. Theories and experiments on effects of acoustic energy field in micro-square cup drawing. Int. J. Adv. Manuf. Technol. 2019, 104, 4791–4802. [Google Scholar] [CrossRef]

- Wu, X.; Li, J.J.; Zheng, Z.Z.; Chen, X.D. Research and application progress of metal plastic forming mechanism under vibration field. J. Plast. Eng. 2015, 22, 1–7. [Google Scholar]

- Ma, W.P.; Wang, B.Y.; Xiao, W.C.; Yang, X.M.; Kang, Y. Springback analysis of 6016 aluminum alloy sheet in hot V-shape stamping. J. Cent. South Univ. 2019, 26, 524–535. [Google Scholar] [CrossRef]

- Yang, X.M.; Dang, L.M.; Wang, Y.Q.; Zhou, J.; Wang, B.Y. Springback prediction of TC4 titanium alloy V-bending under hot stamping condition. J. Cent. South Univ. 2020, 27, 2578–2591. [Google Scholar] [CrossRef]

- Xie, W.; Wei, D.; Chen, B.; Zhang, X. Preliminary study on "striated Groove" on the surface of TC2 titanium alloy sheet. World Nonferrous Met. 2021, 15, 118–119. [Google Scholar]

- Yang, W.J.; Li, D.S.; Li, X.Q.; Li, Y. Hot forming process optimization of a complex titanium alloy part with numerical simulation method. J. Plast. Eng. 2009, 16, 42–46. [Google Scholar]

- Hung, J.C.; Hung, C.G. The influence of ultrasonic-vibration on hot upsetting of aluminum alloy. Ultrasonics 2005, 43, 692–698. [Google Scholar] [CrossRef]

- Hung, J.C.; Lin, C.C. Investigations on the material property changes of ultrasonic-vibration assisted aluminum alloy upsetting. Mater. Des. 2013, 45, 412–420. [Google Scholar] [CrossRef]

- Zheng, J.X.; Du, X.W.; Cheng, J. On the special behavior of ductile metal subjected to ultrasonic action. Acta Aeronaut. Et Astronaut. Sin. 2000, 4, 334–337. [Google Scholar]

- Tong, P.Y.; Zhang, P.; Wang, Y.J.; Han, Y.B.; Liu, B.; Guo, Q.Q. Tensile Properties and Stress-strain Curve Fitting of Aluminum Alloy Sheets Commonly Used for Aviation. Tool Eng. 2019, 53, 41–46. [Google Scholar]

- Shao, W. Research on Hot Forming Properties of TC4 High Strength Titanium Alloy Sheet. Master’s Thesis, Shanghai University of Engineering Science, Shanghai, China, 2020. [Google Scholar]

- Zhang, H.D.; Deng, L.; Wang, X.Y.; Jin, J.S. Research Progress on Mechanism and Application of Vibration Assisted Plastic Forming. Aeronaut. Manuf. Technol. 2020, 63, 22–31. [Google Scholar]

- ASTM E112. Standard Test Methods for Determining Average Grain Size; American Society for Testing and Materials: New York, NY, USA, 2012.

| Fe | C | N | H | O | Al | Mn | Ti |

|---|---|---|---|---|---|---|---|

| ≤0.30 | ≤0.08 | ≤0.05 | ≤0.012 | ≤0.15 | ≤3.5–5.0 | ≤0.8–2.0 | balance |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, T.; Wang, K.; Ling, Z.; Wang, Z. Effect of a Compound Energy Field with Temperature and Ultrasonic Vibration on the Material Properties and Bending Process of TC2 Titanium Alloy. Materials 2021, 14, 7192. https://doi.org/10.3390/ma14237192

Gao T, Wang K, Ling Z, Wang Z. Effect of a Compound Energy Field with Temperature and Ultrasonic Vibration on the Material Properties and Bending Process of TC2 Titanium Alloy. Materials. 2021; 14(23):7192. https://doi.org/10.3390/ma14237192

Chicago/Turabian StyleGao, Tiejun, Kaifeng Wang, Zhiyuan Ling, and Zhongjin Wang. 2021. "Effect of a Compound Energy Field with Temperature and Ultrasonic Vibration on the Material Properties and Bending Process of TC2 Titanium Alloy" Materials 14, no. 23: 7192. https://doi.org/10.3390/ma14237192

APA StyleGao, T., Wang, K., Ling, Z., & Wang, Z. (2021). Effect of a Compound Energy Field with Temperature and Ultrasonic Vibration on the Material Properties and Bending Process of TC2 Titanium Alloy. Materials, 14(23), 7192. https://doi.org/10.3390/ma14237192