Research on the Secondary Forgeability of High Volume Fraction Whisker Reinforced Aluminum Matrix Composites of Original Squeeze Casting

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

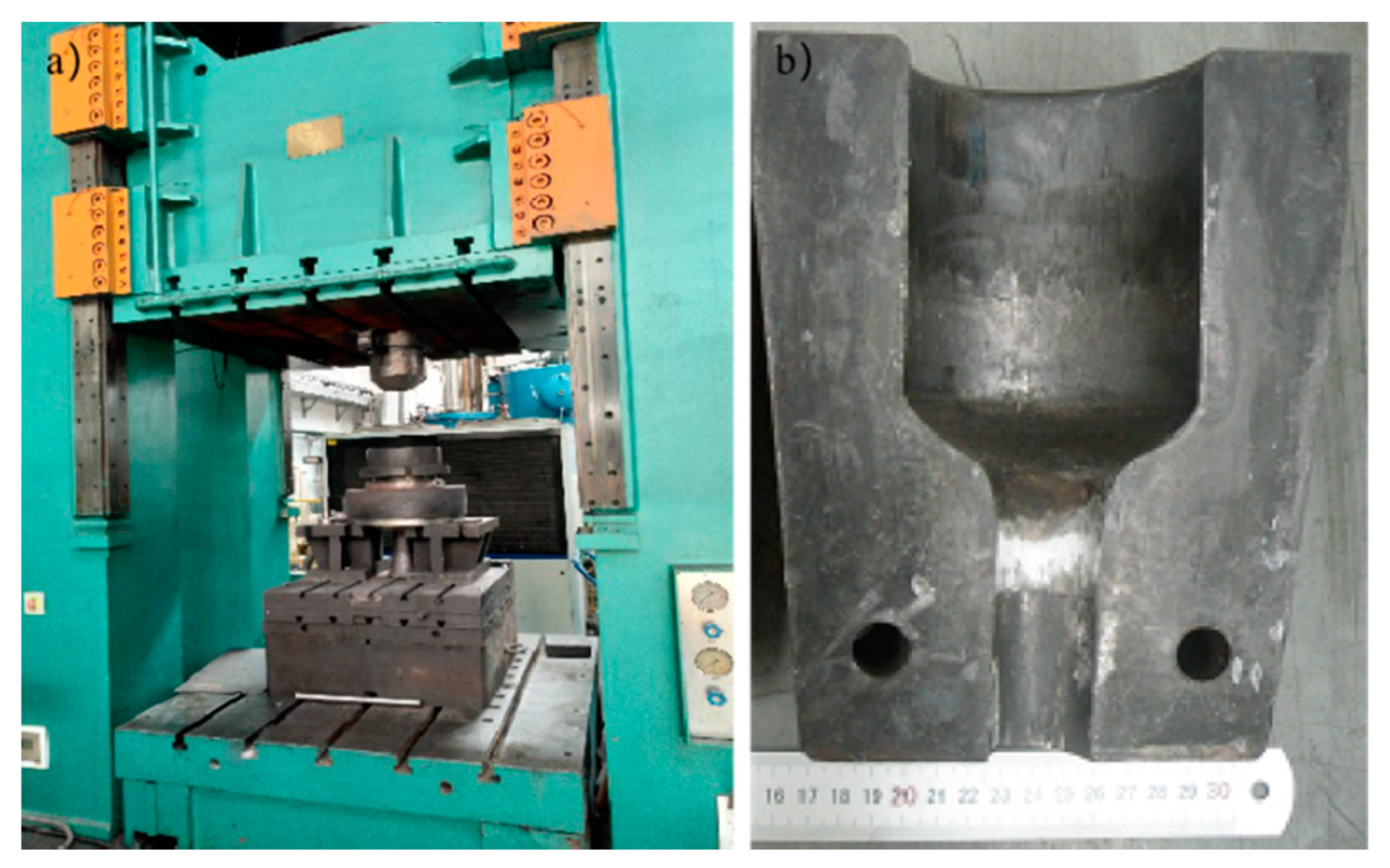

2.2. Methods

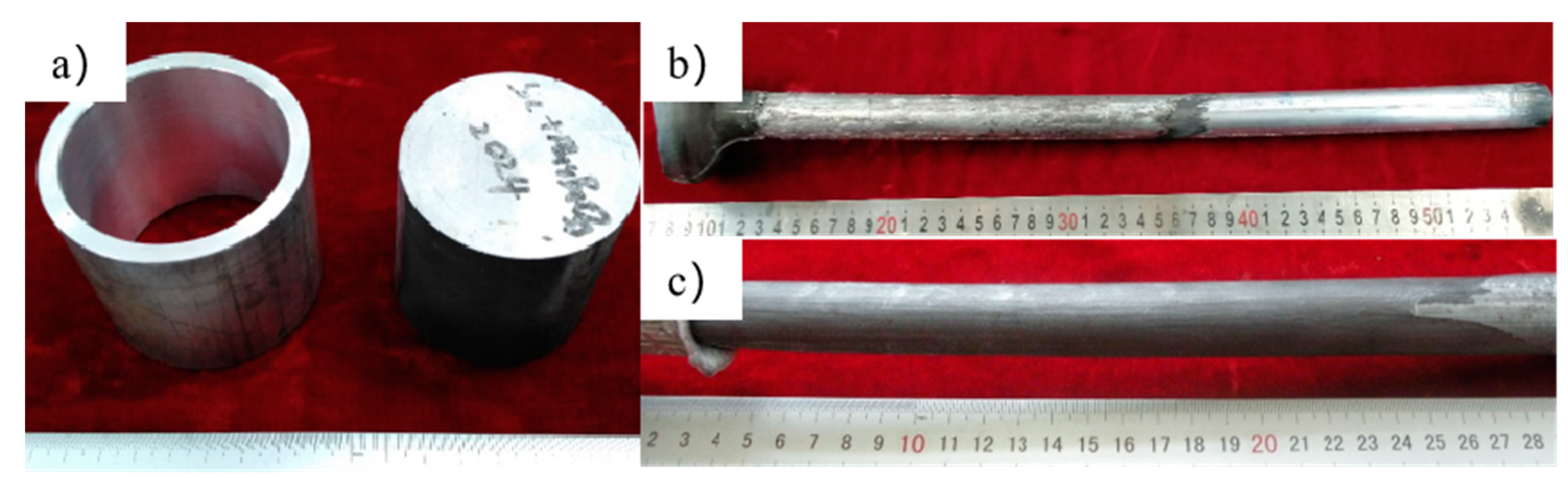

2.2.1. Extrusion Experiment

2.2.2. Upsetting Experiment

3. Results

3.1. The Sheathed Extrusion of the Aluminum Matrix Composites of Original Squeeze Casting Samples

3.2. The Secondary Forgeability of the Aluminum Matrix Composites of Original Squeeze Casting Samples

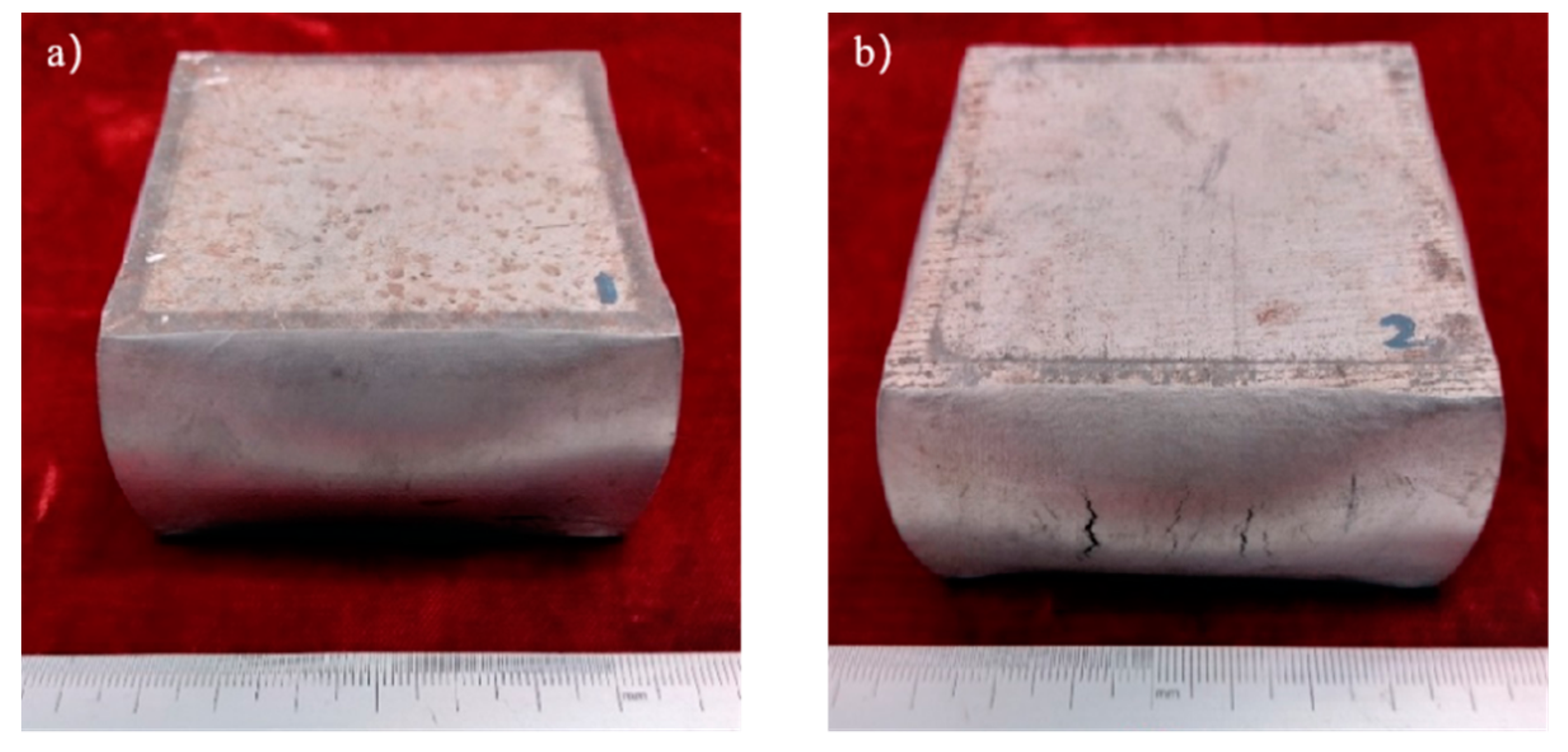

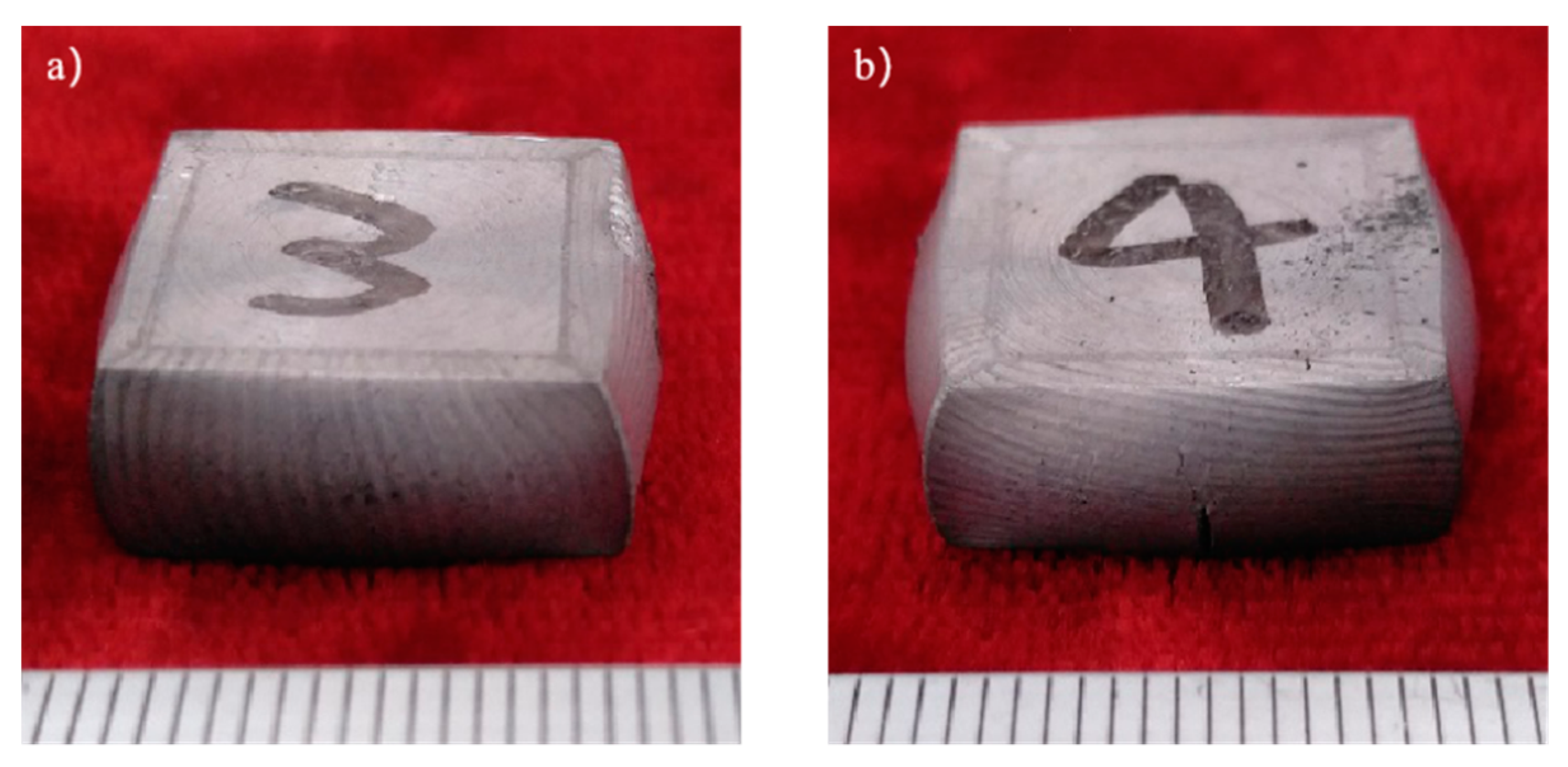

3.2.1. The First Forging Limit of the Original Squeeze Casting Samples

3.2.2. The Secondary Upsetting Experiment of the Original Squeeze Casting Samples

3.3. The Secondary Forgeability of the Aluminum Matrix Composites of Extrusion Samples

3.3.1. The First Forging Limit of the Extrusion Samples

3.3.2. The Secondary Upsetting Experiment of the Extrusion Samples

4. Discussion

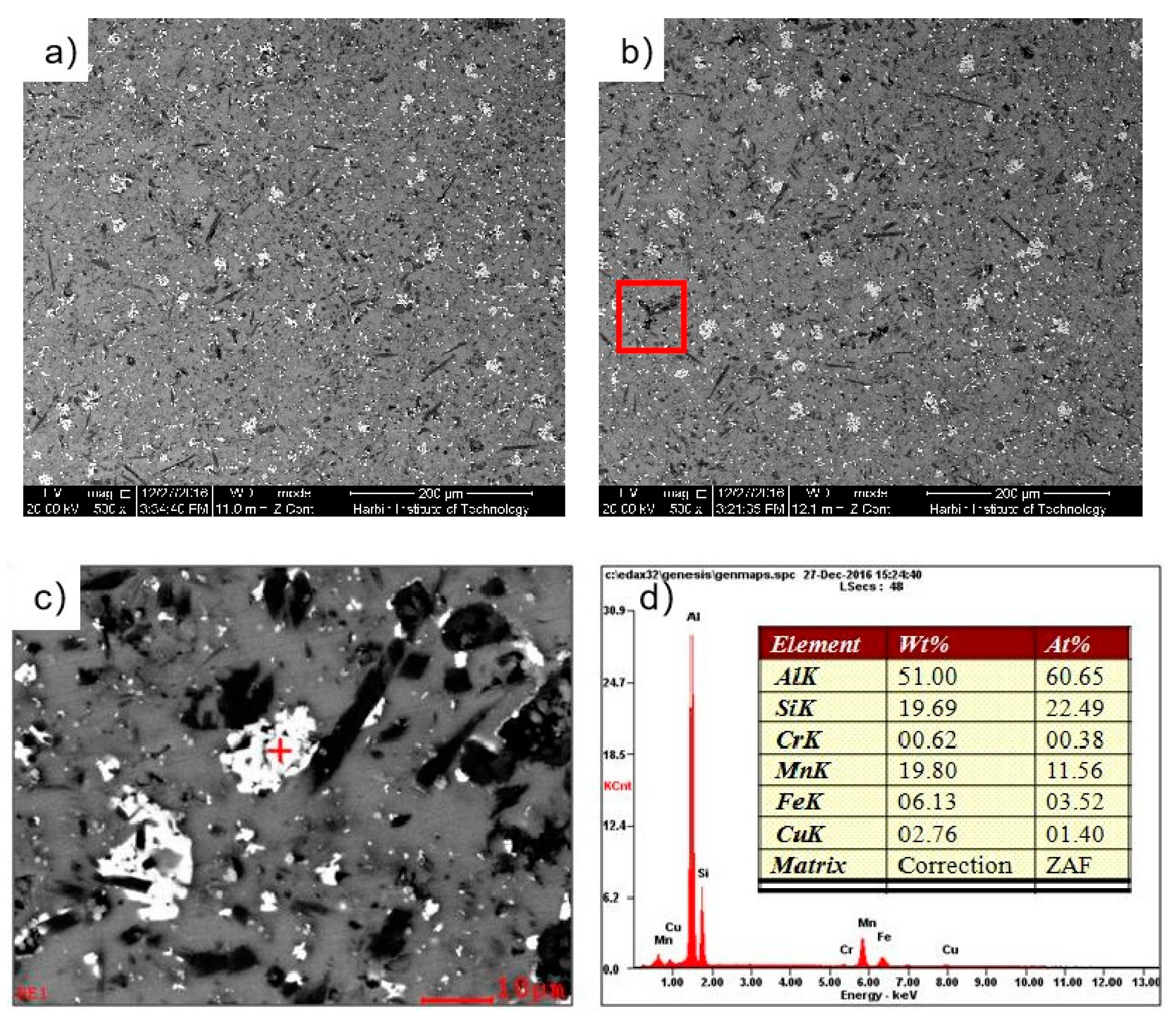

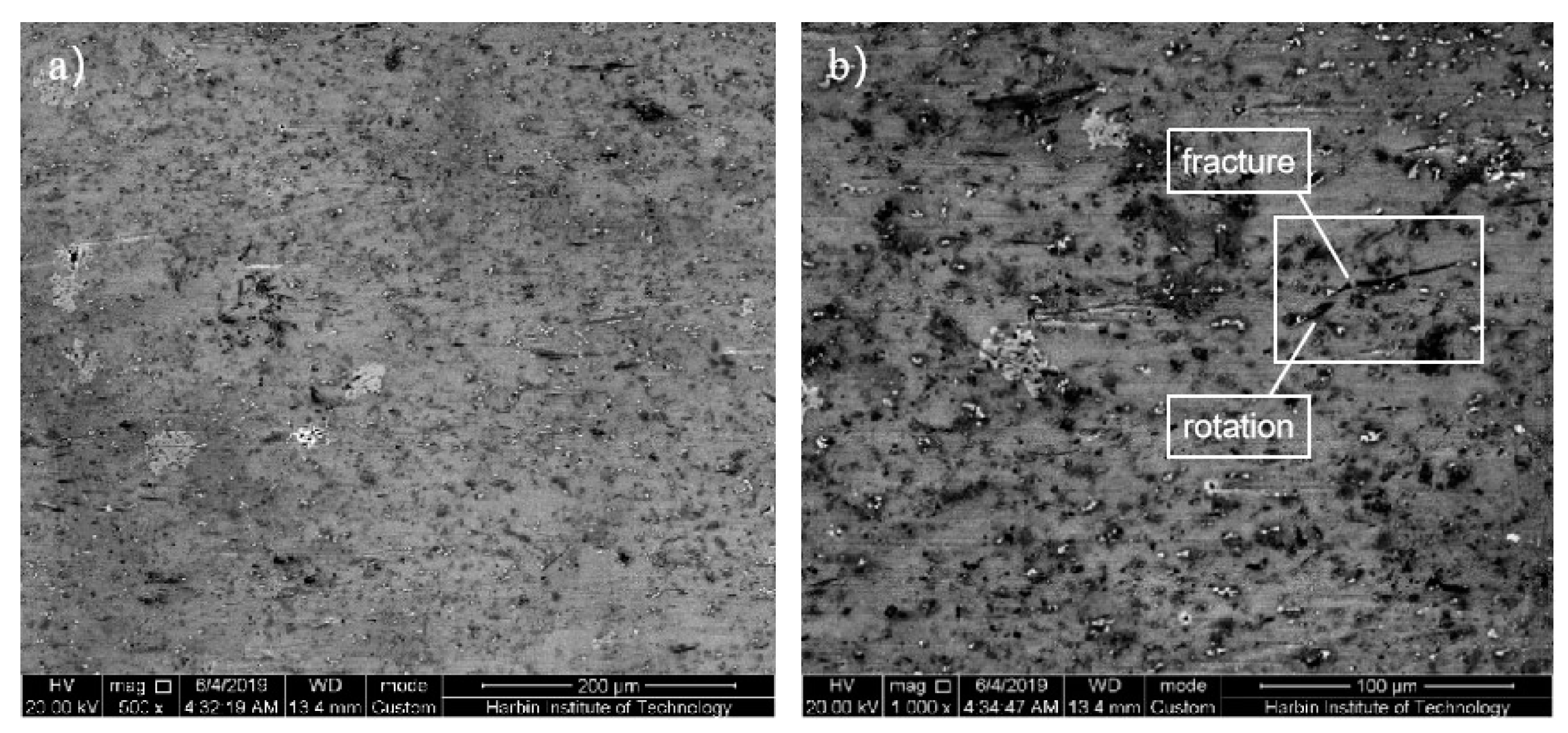

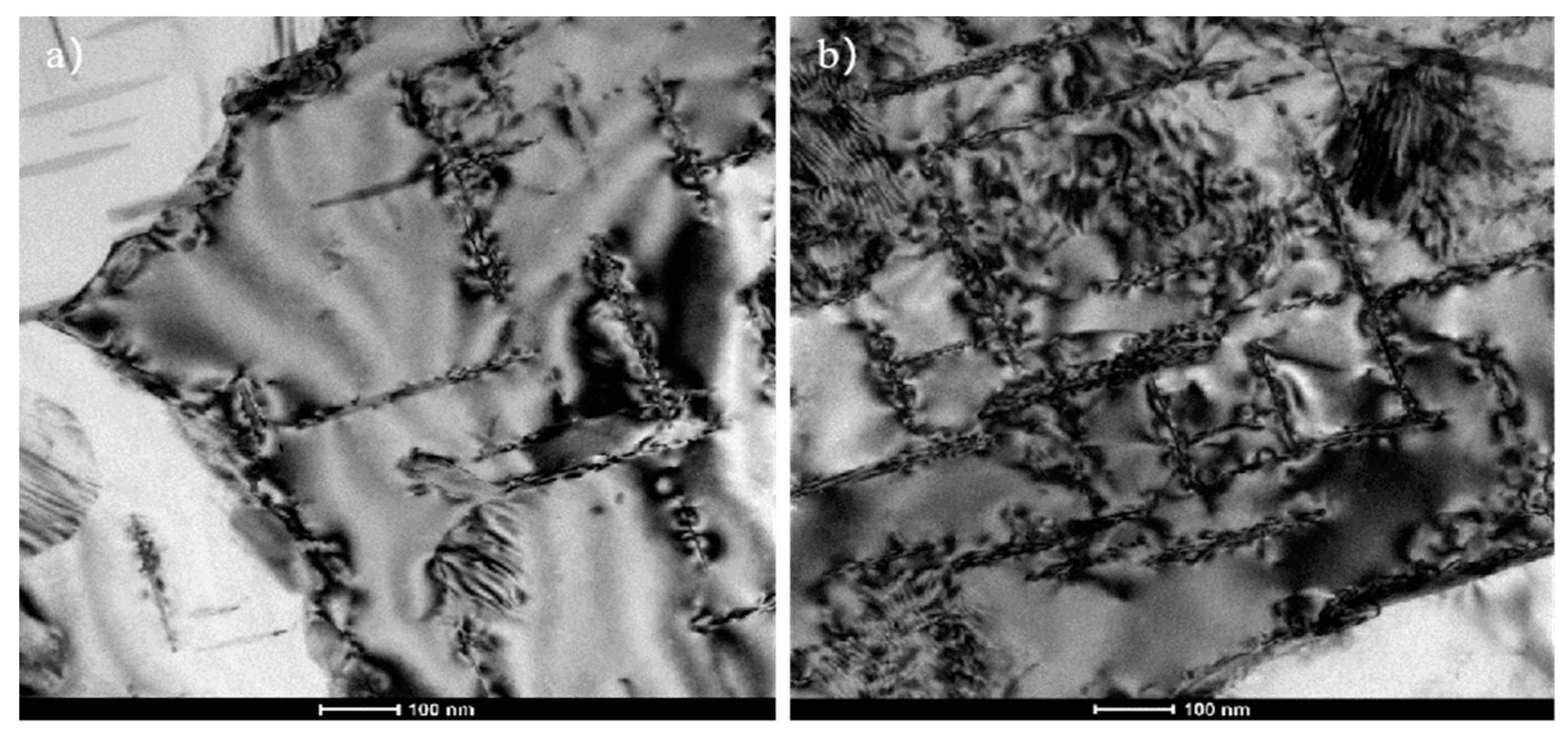

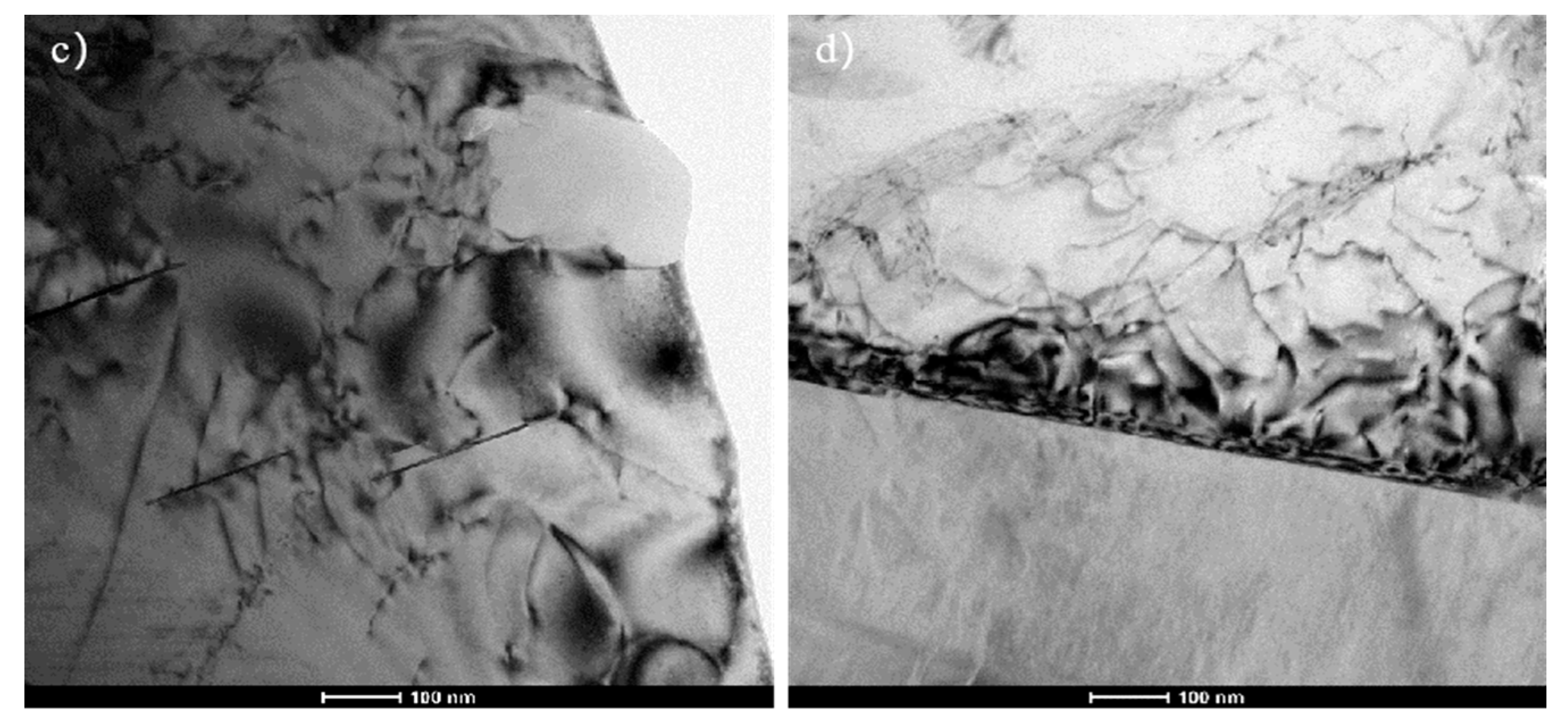

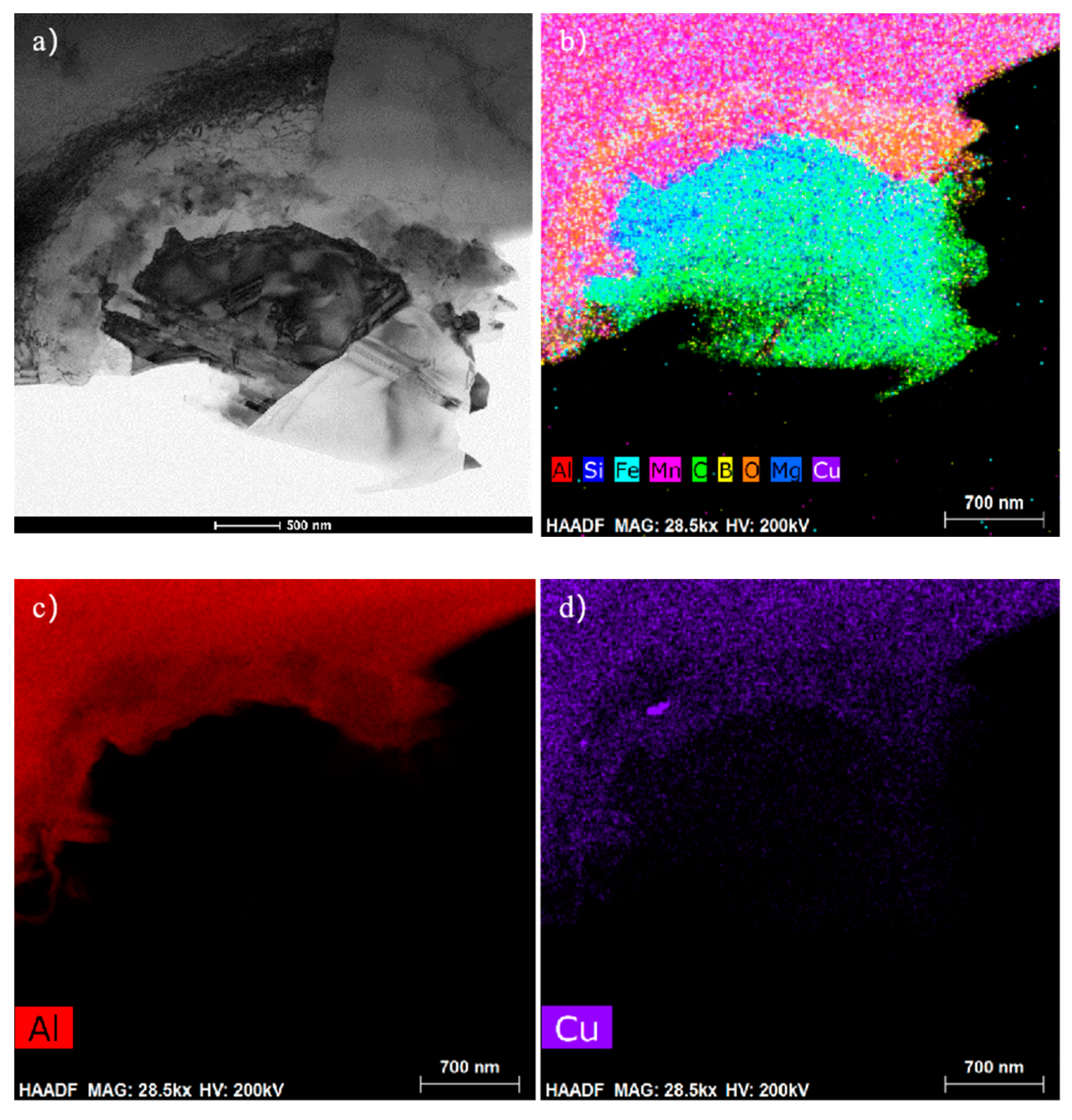

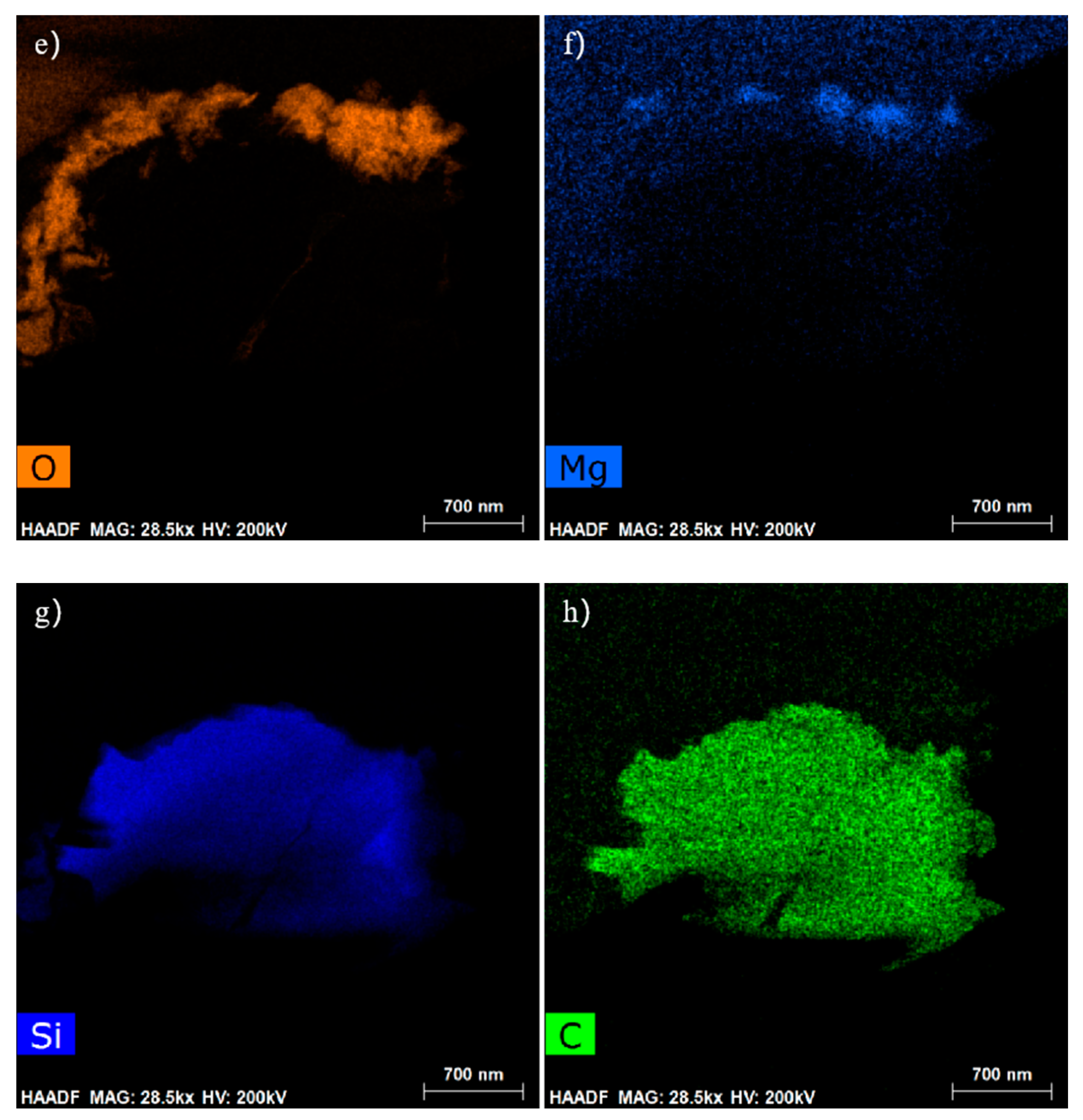

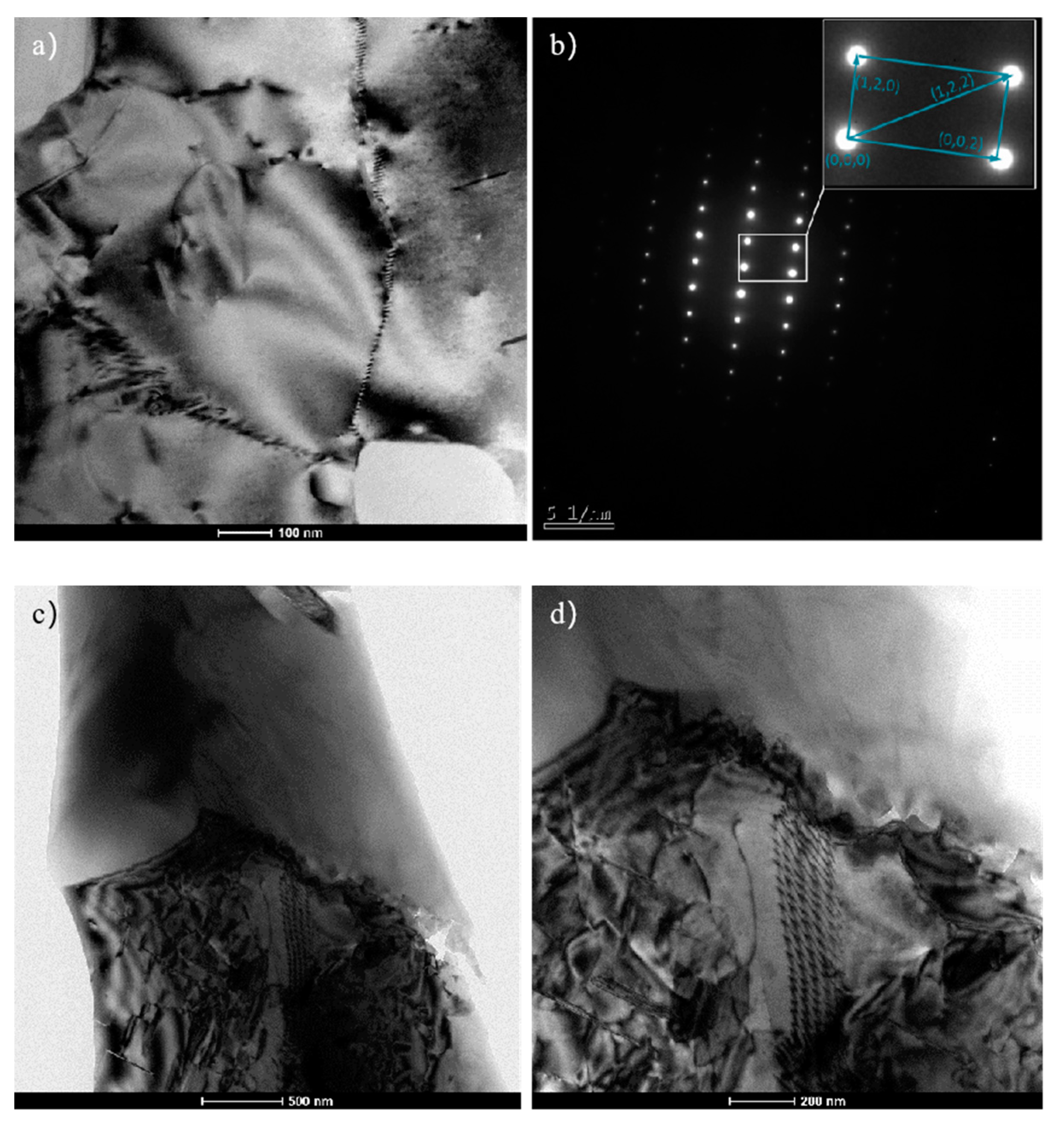

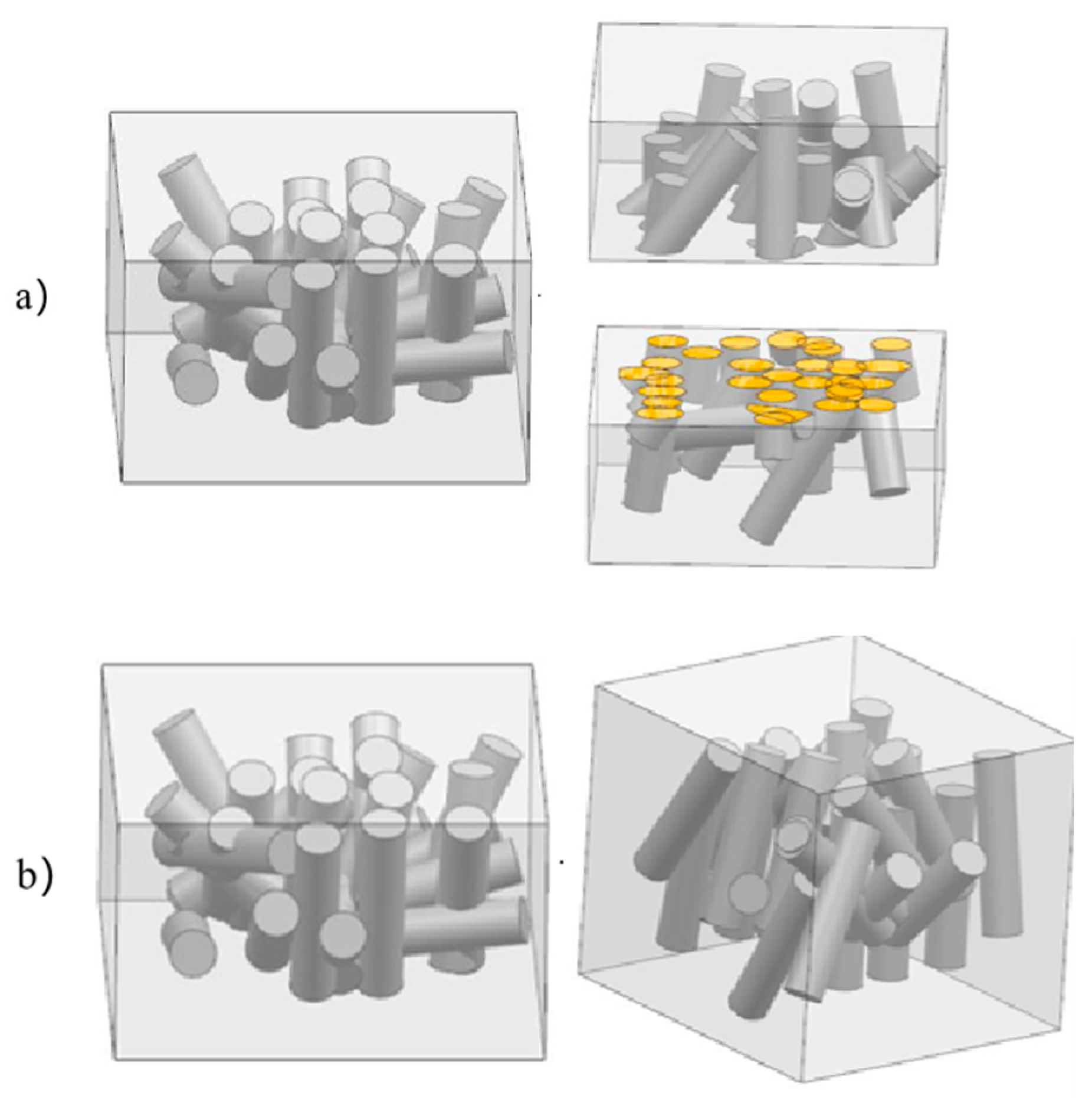

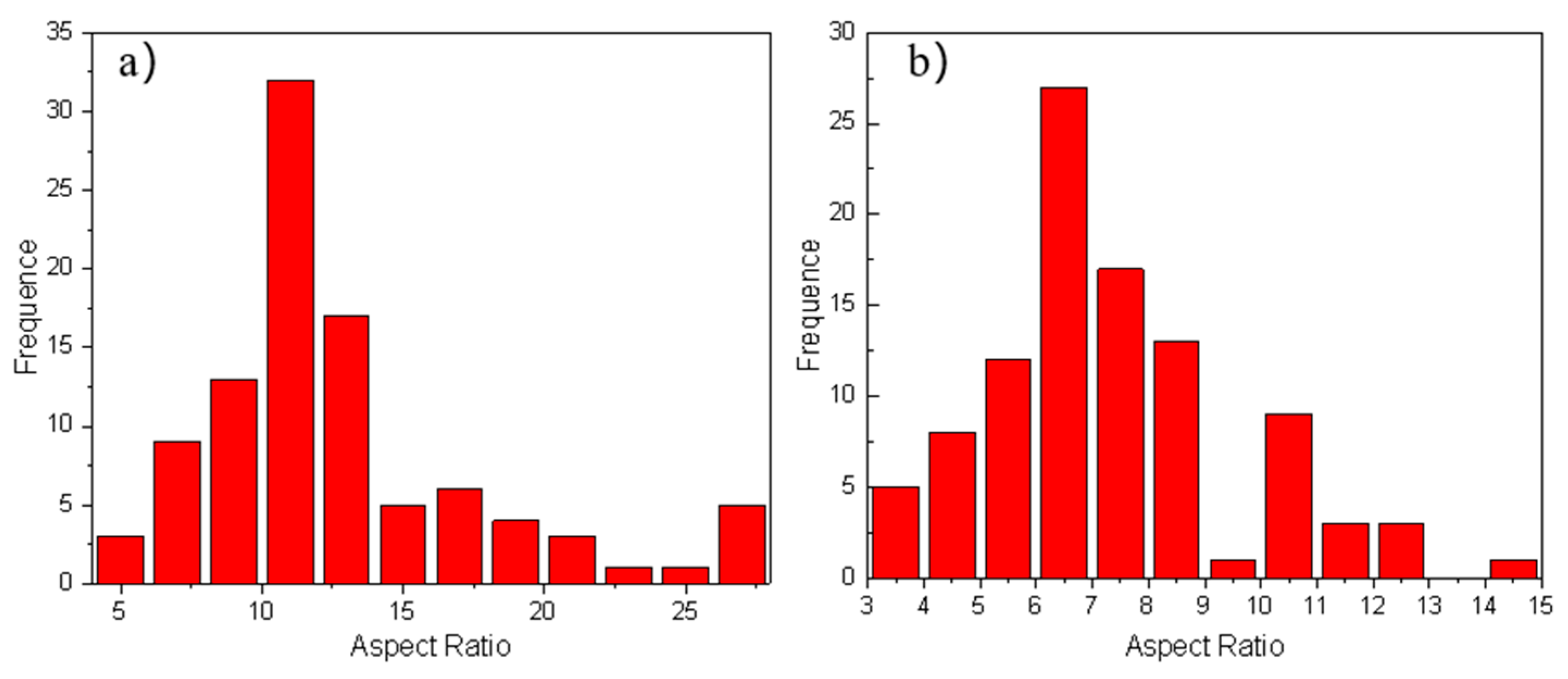

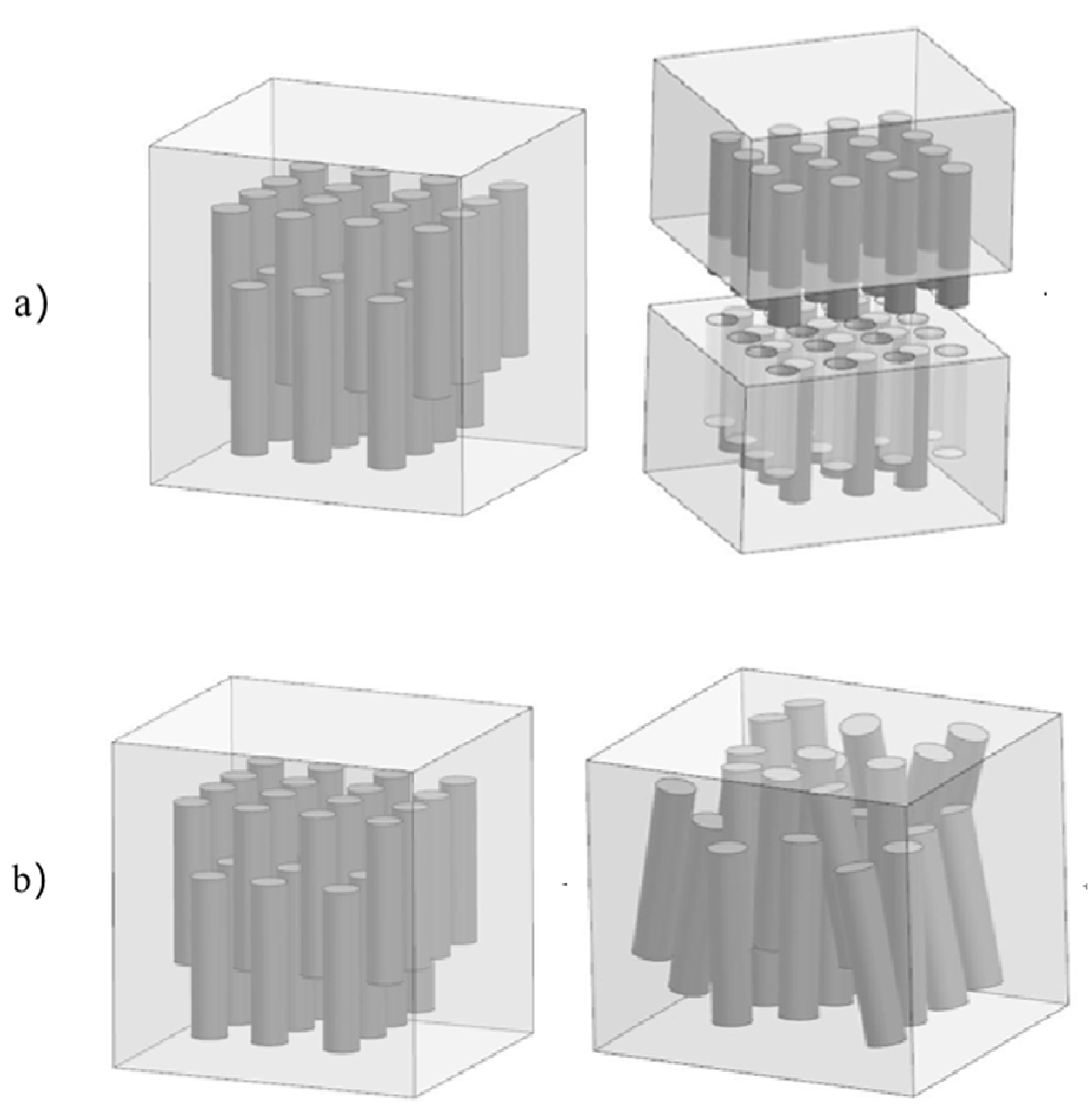

4.1. Microstructure of the Original Squeeze Casting Samples

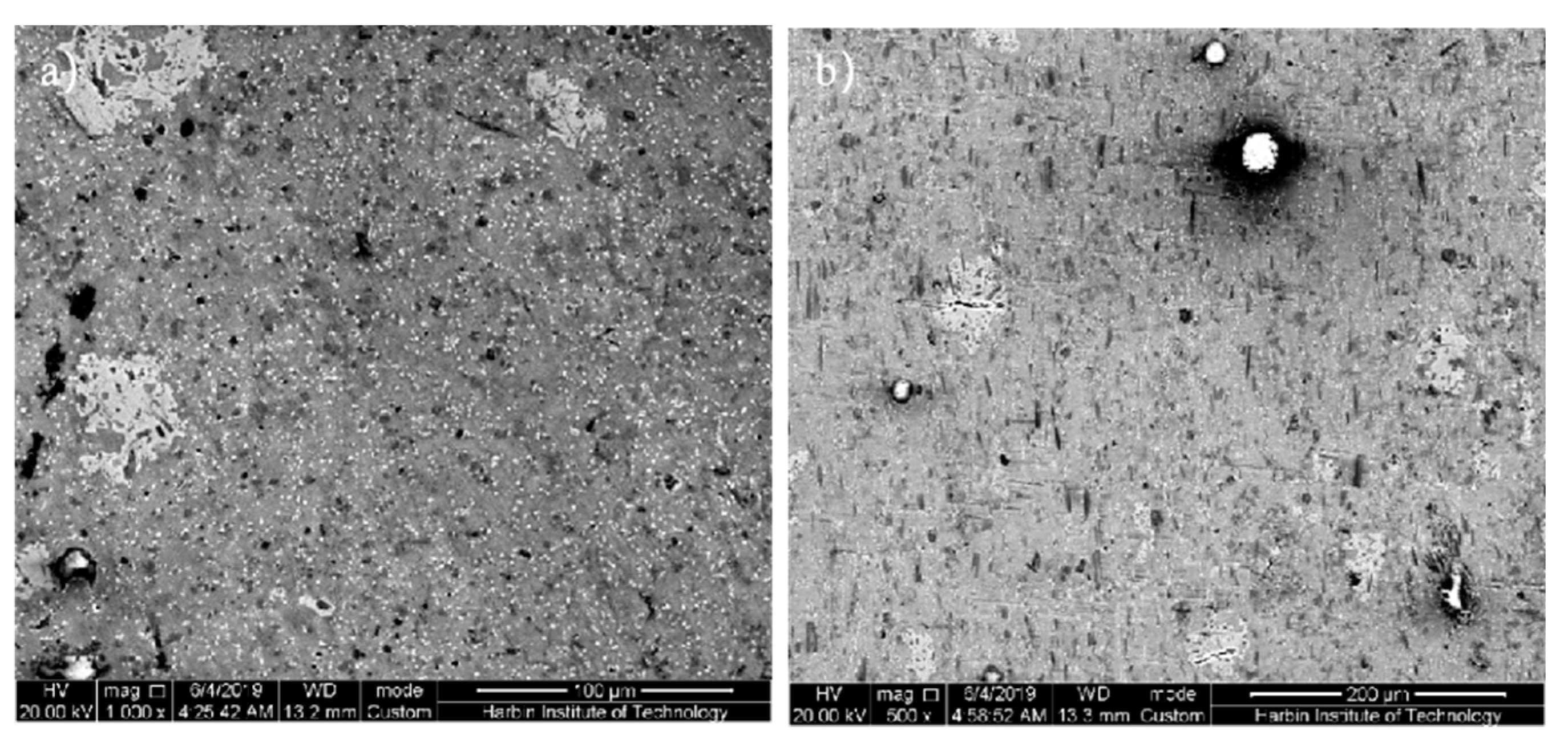

4.2. Microstructure of the Extrusion Samples

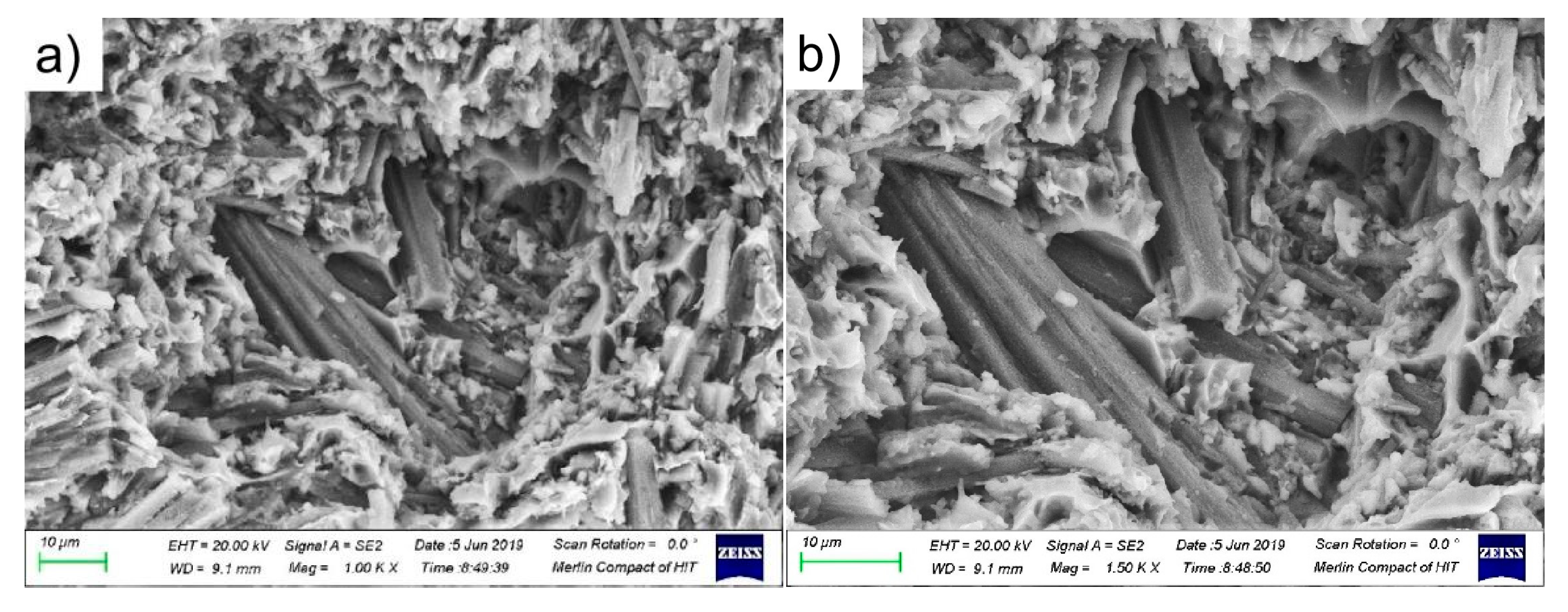

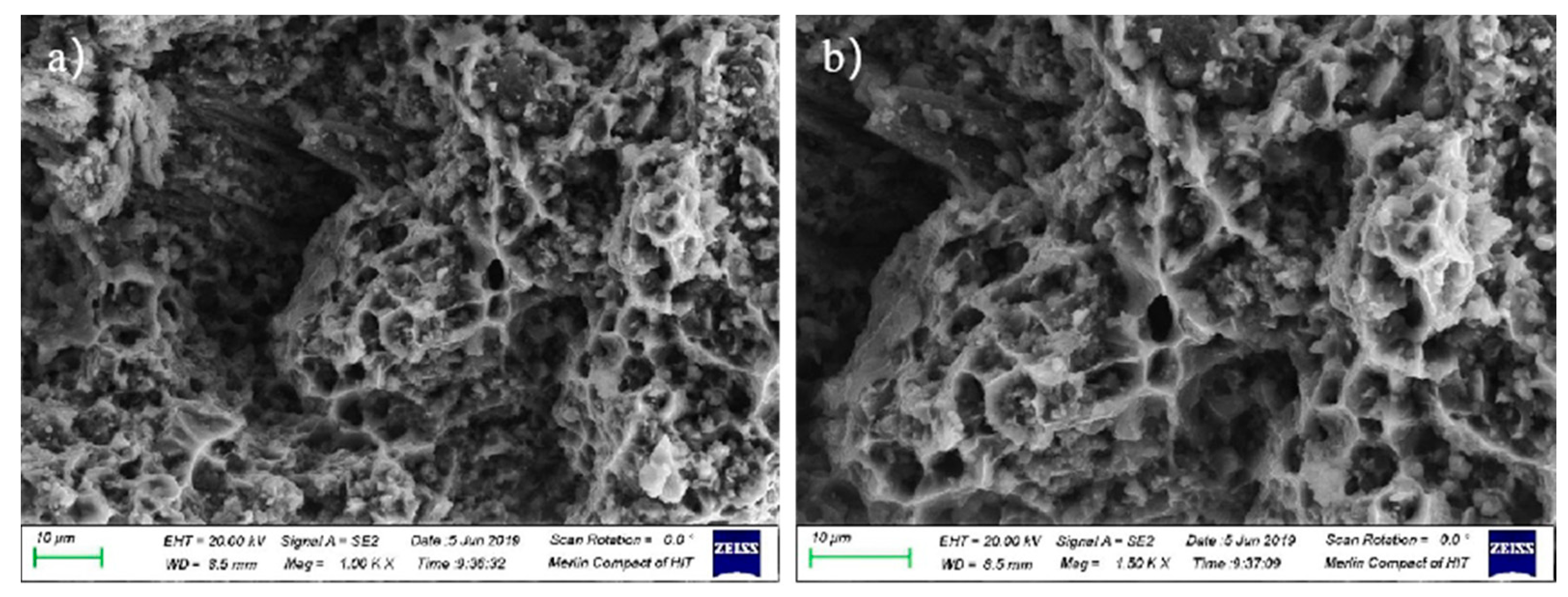

4.3. Fracture Mechanism of the Aluminum Matrix Composite of the Original Squeeze Casting and Extrusion

4.4. Microstructure of the Original Squeeze Casting Samples after Secondary Upsetting

4.5. Microstructure of the Extrusion Samples after Secondary Upsetting

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sharma, P.; Khanduja, D.; Sharma, S. Tribological and mechanical behavior of particulate aluminum matrix composites. J. Reinf. Plast. Compos. 2014, 33, 2192–2202. [Google Scholar] [CrossRef]

- Jin, P.; Liu, Y.; Li, S. Aerospace Applications of Particulate Reinforced Aluminum Matrix Composites. Mater. Rep. 2009, 23, 24–27. [Google Scholar]

- Reddy, M.P.; Manakari, V.; Parande, G.; Shakoor, R.; Mohamed, A.; Gupta, M. Structural, mechanical and thermal characteristics of Al-Cu-Li particle reinforced Al-matrix composites synthesized by microwave sintering and hot extrusion. Compos. Part B-Eng. 2019, 164, 485–492. [Google Scholar] [CrossRef]

- Zhang, C.; Zeng, Y.P.; Yao, D.; Yin, J.; Zuo, K.; Xia, Y.; Liang, H. The improved mechanical properties of Al matrix composites reinforced with oriented beta-Si3N4 whisker. J. Mater. Sci. Technol. 2019, 35, 1345–1353. [Google Scholar] [CrossRef]

- Seleman, M.M.E.; Ahmed, M.M.Z.; Ataya, S. Microstructure and mechanical properties of hot extruded 6016 aluminum alloy/graphite composites. J. Mater. Sci. Technol. 2018, 34, 1580–1591. [Google Scholar] [CrossRef]

- Wang, Z.G.; Li, C.P.; Wang, H.Y. Aging Behavior of Nano-SiC/2014Al Composite Fabricated by Powder Metallurgy and Hot Extrusion Techniques. J. Mater. Sci. Technol. 2016, 32, 1008–1012. [Google Scholar] [CrossRef]

- Ma, K.; Liu, Z.Y.; Bi, S.; Zhang, X.X.; Xiao, B.L.; Ma, Z.Y. Microstructure evolution and hot deformation behavior of carbon nanotube reinforced 2009Al composite with bimodal grain structure. J. Mater. Sci. Technol. 2021, 70, 73–82. [Google Scholar] [CrossRef]

- Asadikiya, M.; Yang, S.; Zhang, Y.; Lemay, C.; Apelian, D.; Zhong, Y. A review of the design of high-entropy aluminum alloys: A pathway for novel Al alloys. J. Mater. Sci. 2021, 56, 12093–12110. [Google Scholar] [CrossRef]

- Chak, V.; Chattopadhyay, H.; Dora, T.L. A review on fabrication methods, reinforcements and mechanical properties of aluminum matrix composites. J. Manuf. Process. 2002, 56, 1059–1074. [Google Scholar] [CrossRef]

- Yi, L.F.; Yoshida, N.; Yamamoto, T.; Onda, T.; Chen, Z.C. Microstructure and thermal/mechanical properties of hot-extruded aluminum/graphite composites with Al–Si alloy addition. J. Mater. Sci. 2019, 54, 9933–9944. [Google Scholar] [CrossRef]

- Sha, J.J.; LÜ, Z.Z.; Sha, R.Y.; Zu, Y.F.; Dai, J.X.; Xian, Y.Q.; Zhang, W.; Ding, C.U.; Yan, C.L. Improved wettability and mechanical properties of metal coated carbon fiber-reinforced aluminum matrix composites by squeeze melt infiltration technique. Trans. Nonferrous Met. Soc. China 2021, 31, 317–330. [Google Scholar] [CrossRef]

- Pandey, N.; Chakrabarty, I.; Barkane, K.; Mehta, N.S.; Majhi, M.R. Microstructure, mechanical and wear properties of aluminum borate whisker reinforced aluminum matrix composites. Trans. Nonferrous Met. Soc. China 2020, 30, 1731–1742. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Recent progress pin aluminum metal matrix composites: A review on processing, mechanical and wear properties. J. Manuf. Process. 2020, 59, 131–152. [Google Scholar] [CrossRef]

- Lau, K.T.; Hui, D. The revolutionary creation of new advanced material-carbon nanotube composites. Compos. Part B Eng. 2002, 33, 263–277. [Google Scholar] [CrossRef]

- Jiang, J.F.; Wang, Y.; Liu, Y.Z.; Xiao, G.F.; Li, H. Microstructure and mechanical properties of 7005 aluminum alloy processed by one-pass equal channel reciprocating extrusion. Trans. Nonferrous Met. Soc. China 2020, 31, 609–625. [Google Scholar] [CrossRef]

- Tzamtzis, S.; Barekar, N.S.; Babu, N.H.; Patel, J.; Dhindaw, B.K.; Fan, Z. Processing of advanced Al/SiC particulate metal matrix composites under intensive shearing–A novel Rheo-process. Compos. Part A Appl. Sci. Manuf. 2009, 40, 144–151. [Google Scholar] [CrossRef]

- Zeng, X.H.; Xu, R.; Tan, Z.Q. Progress of Advanced Aluminum Matrix Composites Research. Mater. China 2015, 34, 417–424. [Google Scholar]

- Ji, Y.M.; Yuan, Y.P.; Zhang, W.Z. Elevated Temperature Tensile Creep Behavior of Aluminum Borate Whisker-Reinforced Aluminum Alloy Composites (ABOw/Al-12Si). Materials 2021, 14, 1217. [Google Scholar] [CrossRef]

- Sitek, R.; Szustecki, M.; Zrodowski, L.; Wysocki, B.; Jaroszewicz, J.; Wisniewski, P.; Mizera, J. Analysis of Microstructure and Properties of a Ti-AlN Composite Produced by Selective Laser Melting. Materials 2020, 13, 2218. [Google Scholar] [CrossRef]

- Fu, X.L.; Li, Y.; Schuh, C.A. Temperature, strain rate and reinforcement volume fraction dependence of plastic deformation in metallic glass matrix composites. Acta Mater. 2007, 55, 3059–3071. [Google Scholar] [CrossRef]

- Wei, S.H.; Nie, J.H.; Liu, Y.Q. Effect of Isothermal Forging on Fracture Toughness of Aluminum Matrix Composites Reinforced by Silicon Carbide Particles. Rare Met. Mat. Eng. 2017, 46, 3464–3468. [Google Scholar]

- Wu, Q.; Xu, W.X.; Zhang, L.C. Microstructure-based modelling of fracture of particulate rein-forced metal matrix composite. Compos. Part B-Eng. 2019, 163, 384–392. [Google Scholar] [CrossRef]

- Narayan, S.; Rajeshkannan, A. Studies on formability of sintered aluminum composites during hot deformation using strain hardening parameters. J. Mater. Res. Technol. 2017, 6, 101–107. [Google Scholar] [CrossRef]

- Fu, M.S.; Xiao, Y.H.; Peng, C.G. Influence of the Two-fold Hot Pressing Deformation Technology on the Uniformity of the Microstructure of Powder Metallurgycal SiCp/Al Composite Material. Hot Work. Technol. 2000, 6, 27–29. [Google Scholar]

- Hu, Y.B.; Wang, J.F.; Pan, F.S. Research on Fracture and Strengthening Mechanisms of SiCp/6066 Aluminum Matrix Composites with Canned Hot Extrusion. Mater. Rep. 2007, 21, 151–153. [Google Scholar]

- Qu, S.J.; Geng, L.; Cao, G.J. Microstructure and Properties of Deformable SiCp/Al Composite Fabricated by Squeeze Casting Method. Acta Mater. Compos. Sin. 2003, 20, 69–73. [Google Scholar]

- Zhang, X.N.; Geng, L.; Wang, G.S. Effect of Hot Extrusion on the Microstructure and Mechanical Properties of (SiCw·SiCp)/2024Al hybrid nanocomposites. Mater. Rep. 2004, 12, 482–485. [Google Scholar]

- Xu, W.; Jin, X.; Xiong, W.; Zeng, X.; Shan, D. Study on hot deformation behavior and workability of squeeze-cast 20vol% SiCw/6061Al composites using processing map. Mater. Charact. 2018, 135, 154–166. [Google Scholar] [CrossRef]

- Yuan, L.; Shi, W.; Shivpuri, R.; Xu, F.; Shan, D. Increased hot forgeability of 2024Al/Al18B4O33 whisker composites at high strain rates. J. Mater. Process. Technol. 2017, 243, 456–464. [Google Scholar] [CrossRef]

- Leng, J.; Wu, G.; Zhou, Q.; Dou, Z.; Huang, X. Mechanical properties of SiC/Gr/Al composites fabricated by squeeze casting technology. Scr. Mater 2008, 59, 619–622. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mn | Mg | Zn | Ti | Cr | Al |

|---|---|---|---|---|---|---|---|---|

| 0.5 | 0.5 | 3.5–4.9 | 0.3–0.9 | 1.2–1.8 | 0.25 | 0.15 | 0.10 | other |

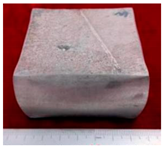

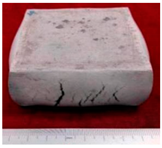

| No. | Morphology of the Samples | Forging Process | Surface Crack |

| 1 |  |

| No macroscopic cracks on the surface |

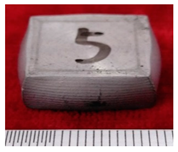

| 2 |  |

| Severe macroscopic cracks on the surface |

| 3 |  |

| Shallow macroscopic cracks on the surface |

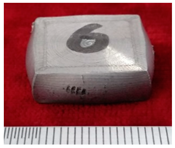

| 4 |  |

| No macroscopic cracks on the surface |

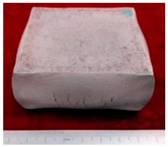

| No. | Morphology of the Samples | Forging Process | Surface Crack |

| 1 |  |

|  Micro-cracks on the surface |

| 2 |  |

|  Micro-cracks on the surface |

| 3 |  |

| No macroscopic cracks on the surface |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, S.; Yuan, L.; Wang, L.; Li, J.; Xu, F.; Zheng, Z.; Shan, D.; Guo, B. Research on the Secondary Forgeability of High Volume Fraction Whisker Reinforced Aluminum Matrix Composites of Original Squeeze Casting. Materials 2021, 14, 7261. https://doi.org/10.3390/ma14237261

Xu S, Yuan L, Wang L, Li J, Xu F, Zheng Z, Shan D, Guo B. Research on the Secondary Forgeability of High Volume Fraction Whisker Reinforced Aluminum Matrix Composites of Original Squeeze Casting. Materials. 2021; 14(23):7261. https://doi.org/10.3390/ma14237261

Chicago/Turabian StyleXu, Shucong, Lin Yuan, Lei Wang, Jinyu Li, Fuchang Xu, Zhenzhu Zheng, Debin Shan, and Bin Guo. 2021. "Research on the Secondary Forgeability of High Volume Fraction Whisker Reinforced Aluminum Matrix Composites of Original Squeeze Casting" Materials 14, no. 23: 7261. https://doi.org/10.3390/ma14237261

APA StyleXu, S., Yuan, L., Wang, L., Li, J., Xu, F., Zheng, Z., Shan, D., & Guo, B. (2021). Research on the Secondary Forgeability of High Volume Fraction Whisker Reinforced Aluminum Matrix Composites of Original Squeeze Casting. Materials, 14(23), 7261. https://doi.org/10.3390/ma14237261