Porous Nanostructured Gadolinium Aluminate for High-Sensitivity Humidity Sensors

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussions

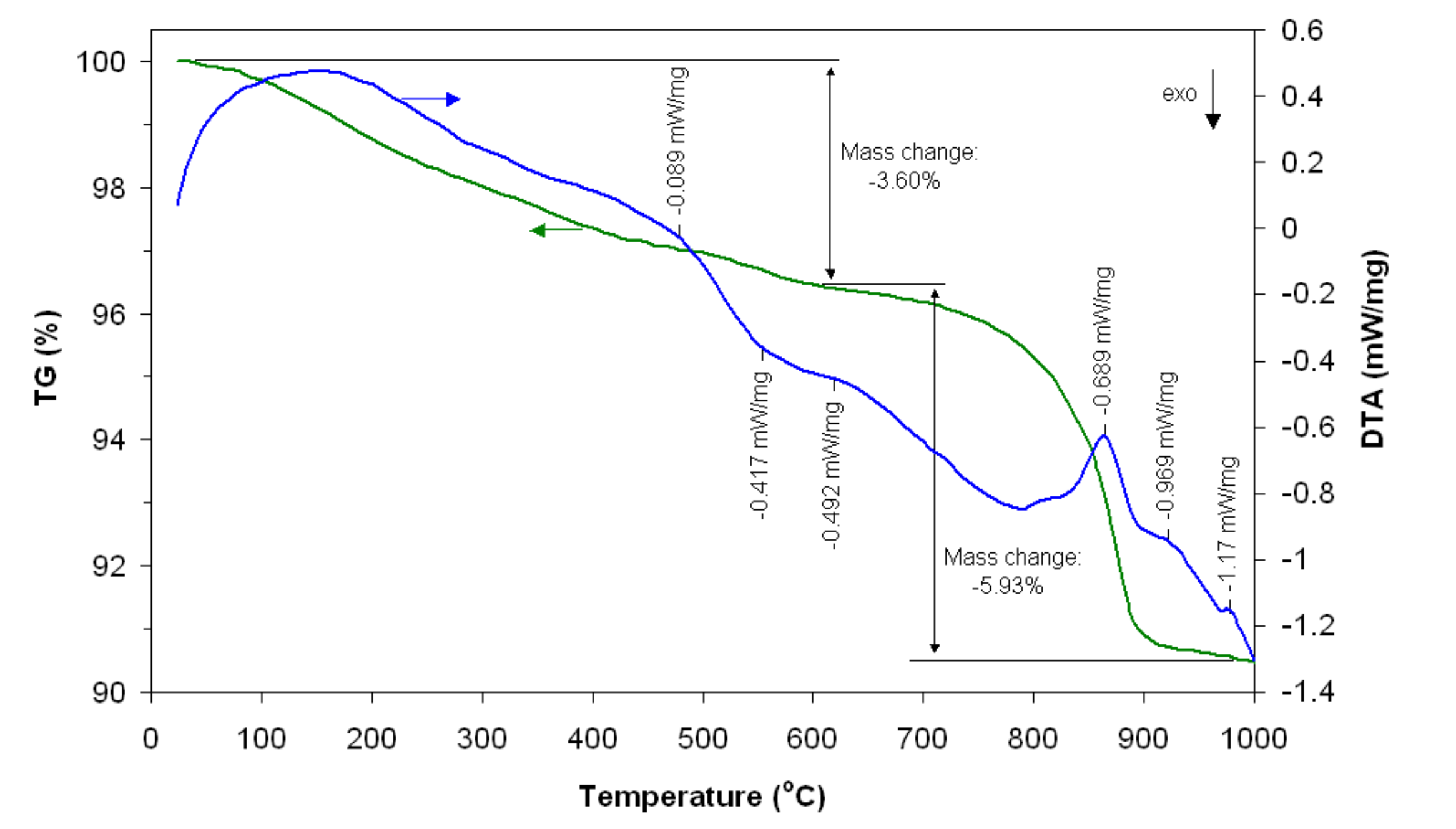

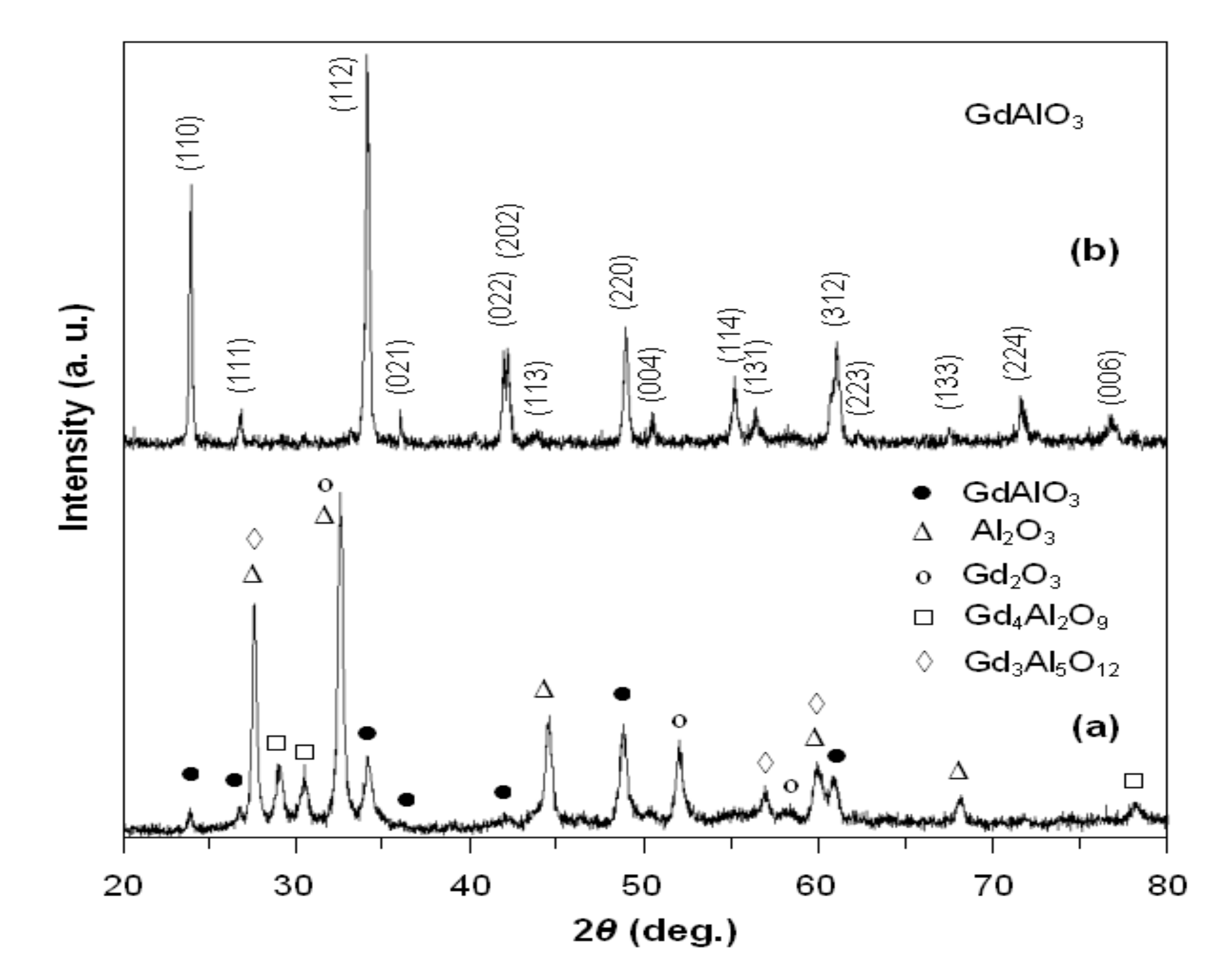

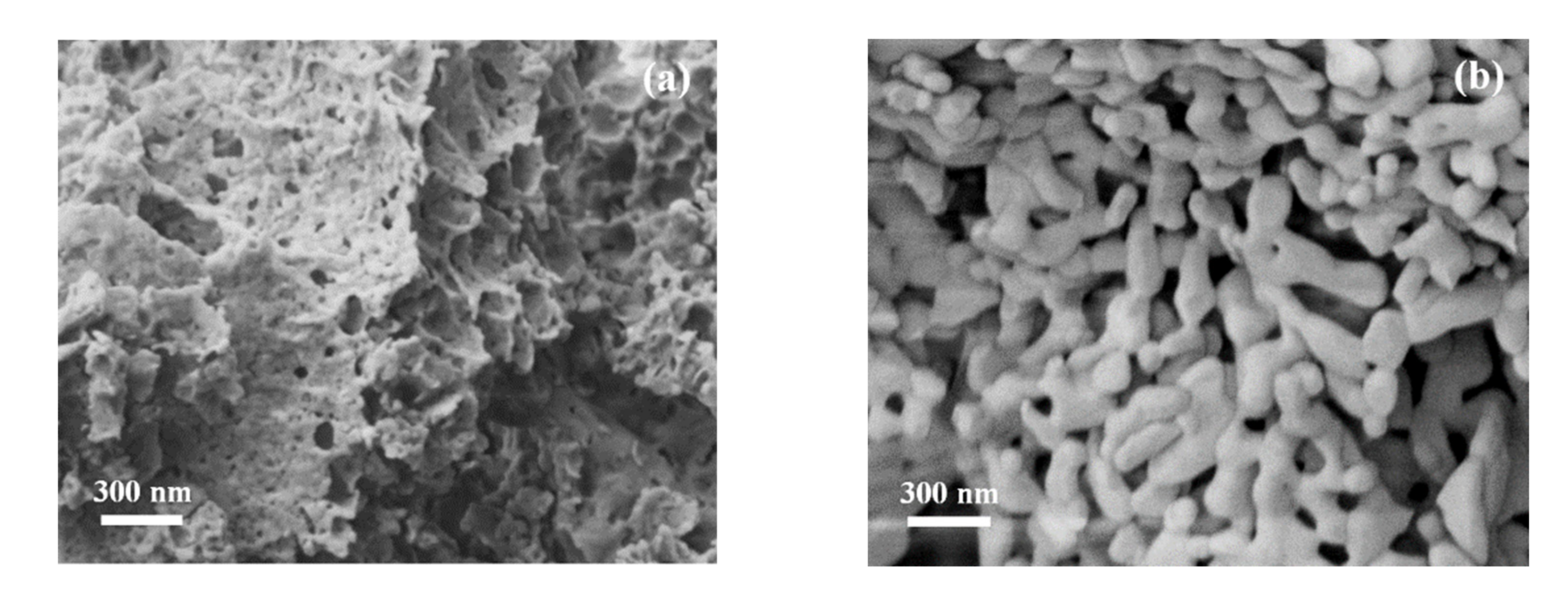

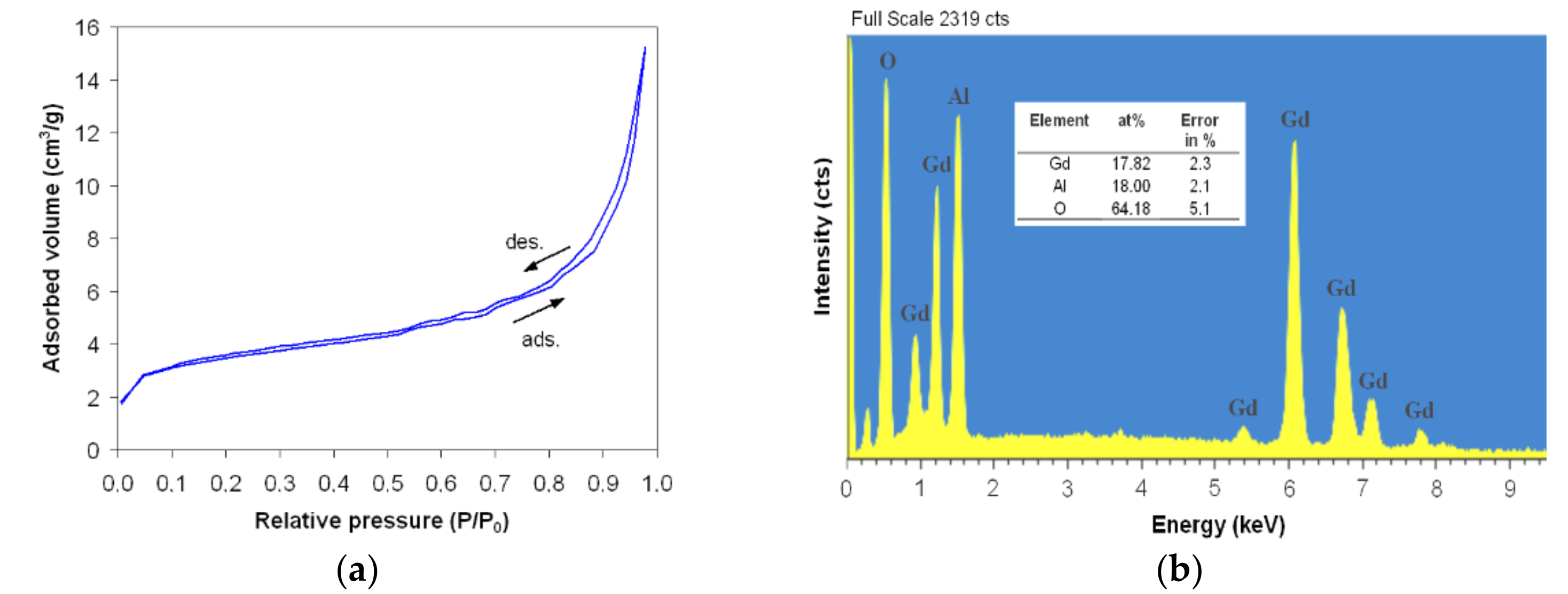

3.1. Structure and Morphology

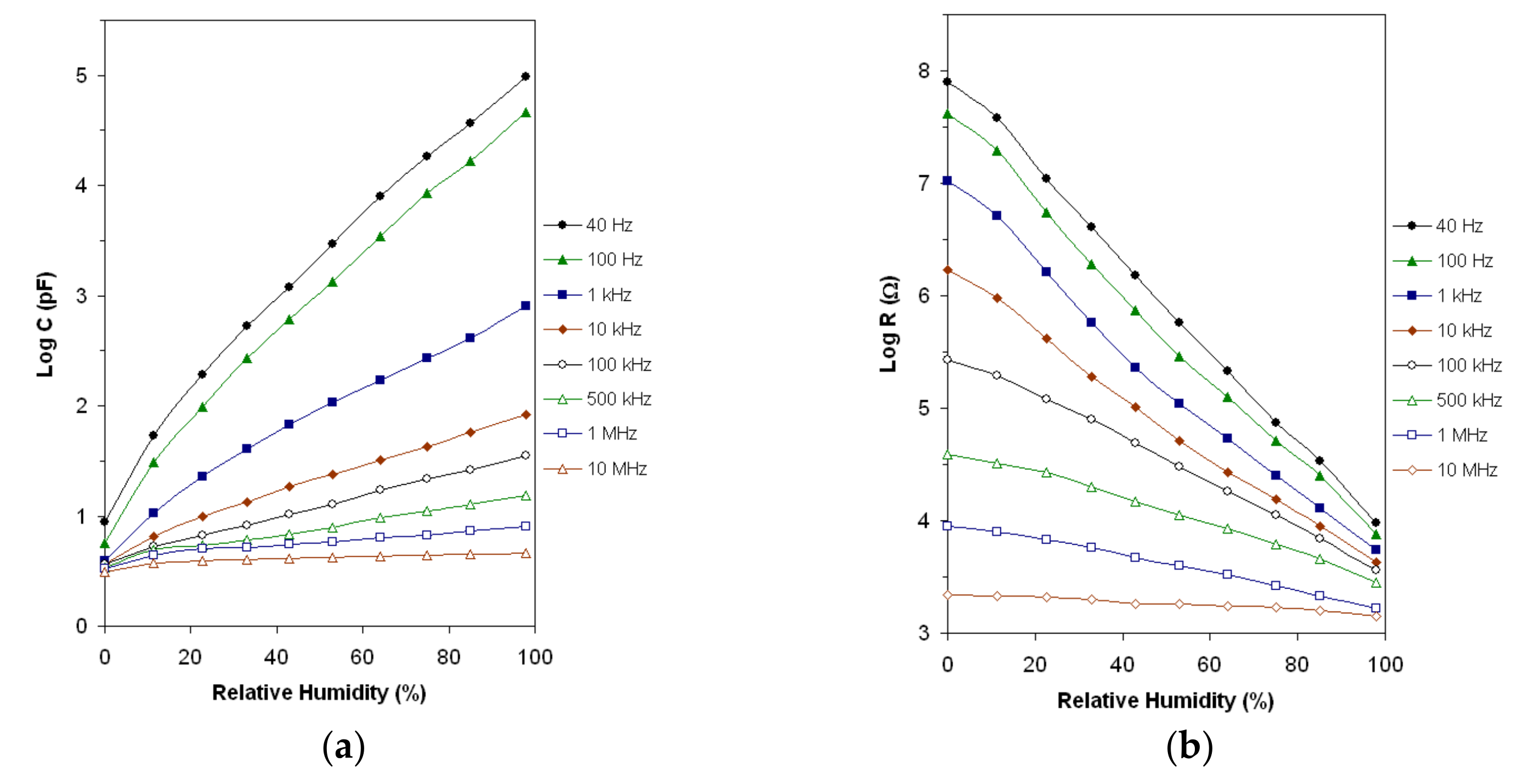

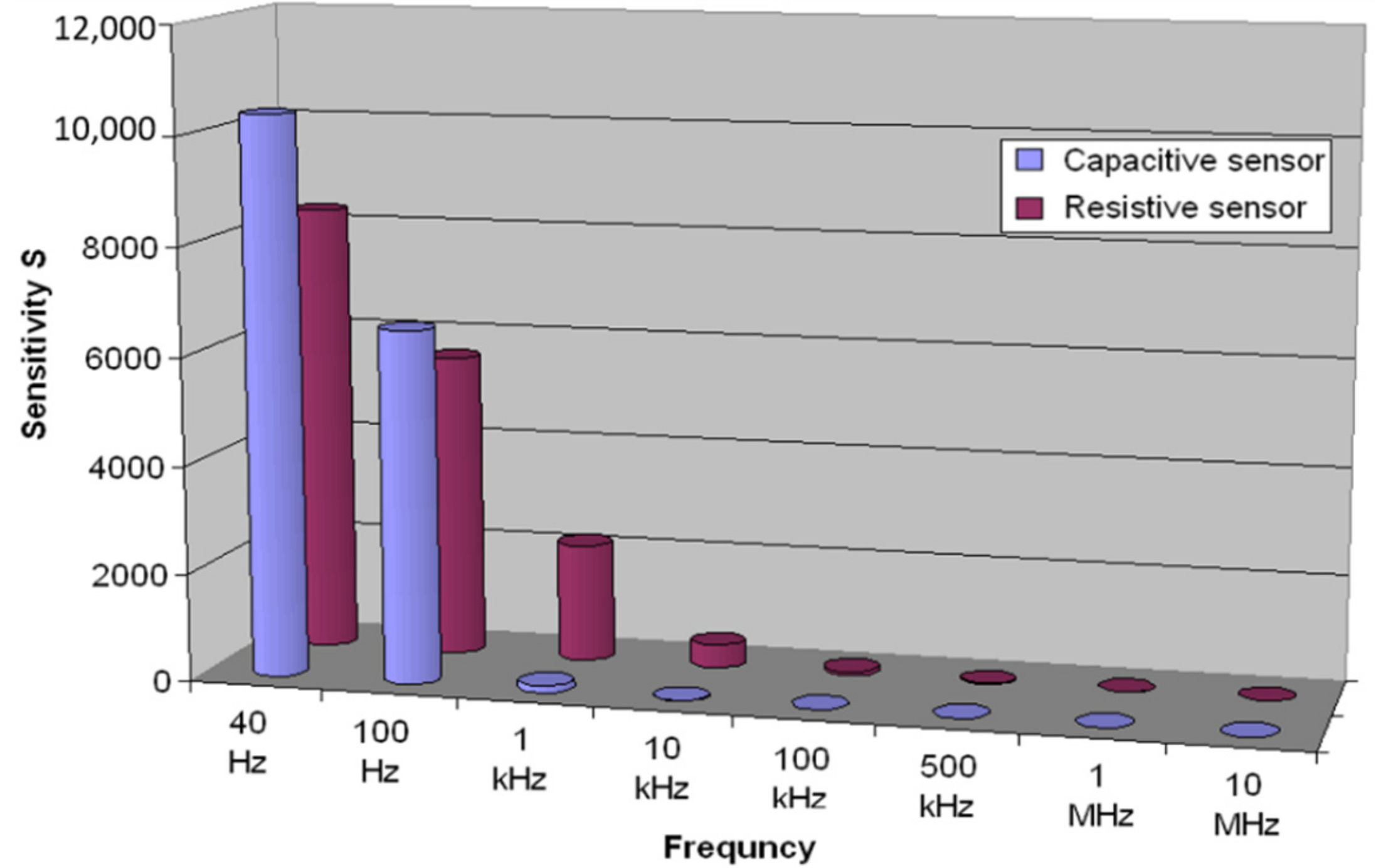

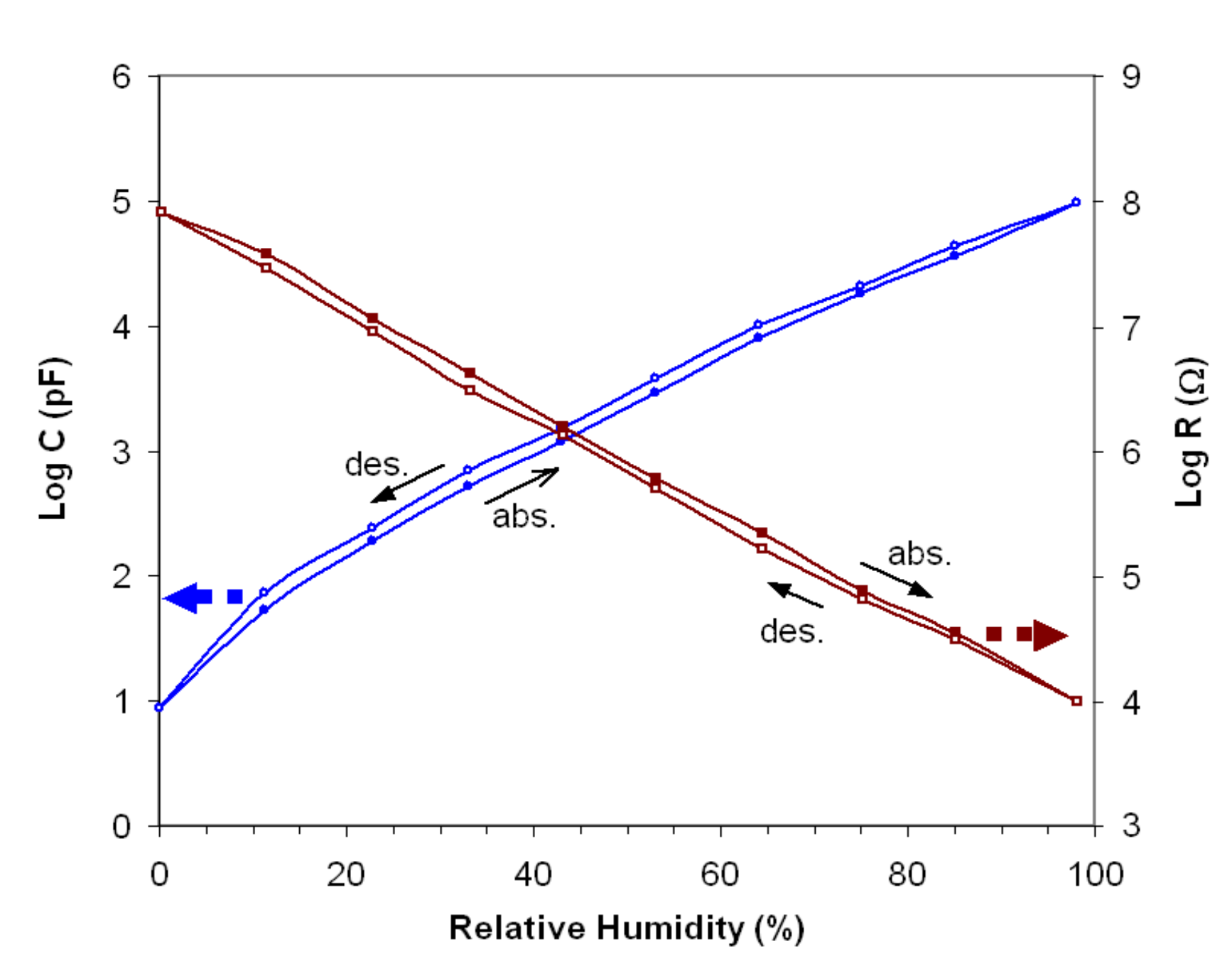

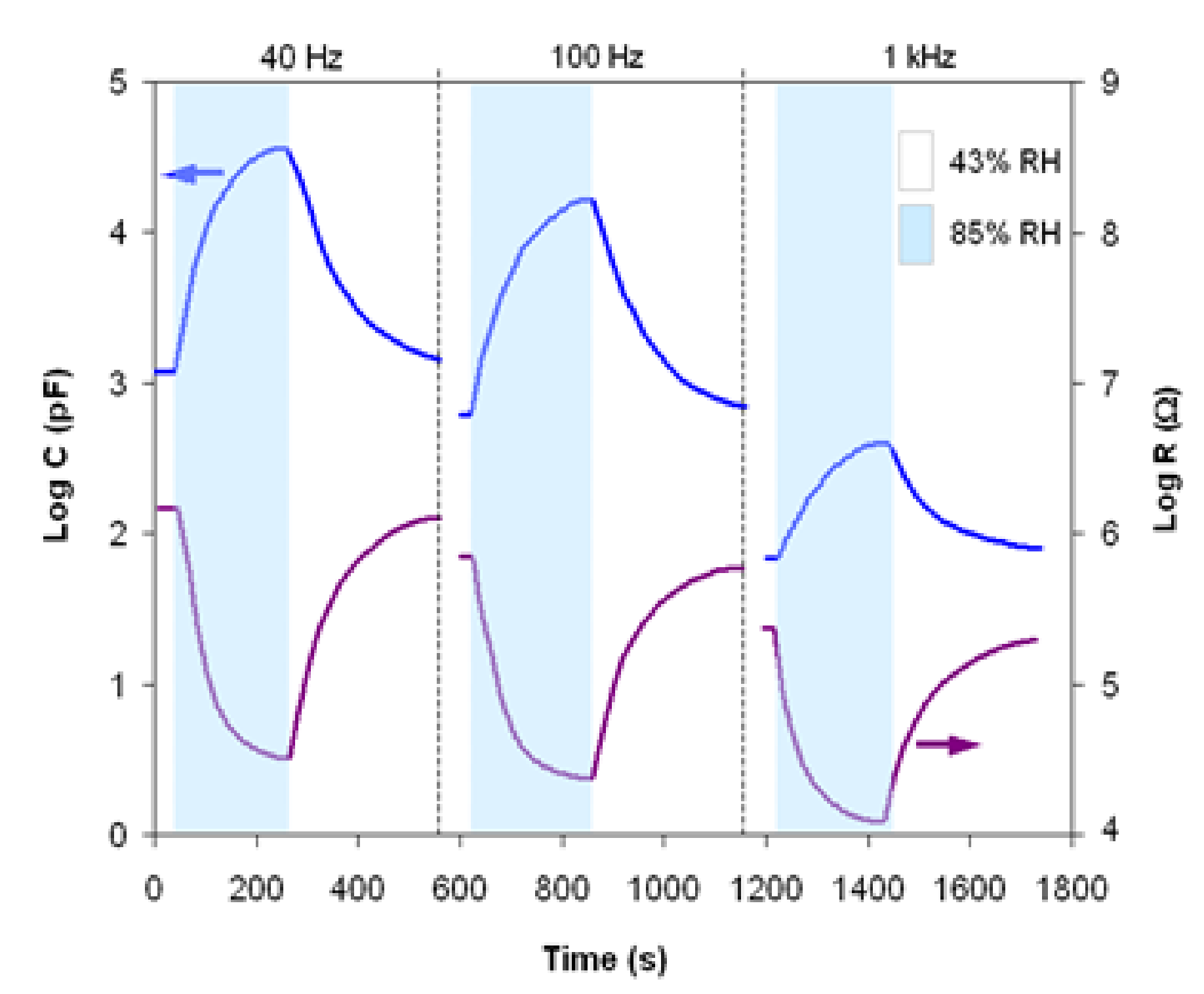

3.2. Sensor Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tripathy, A.; Pramanik, S.; Manna, A.; Bhuyan, S.; Shah, N.F.A.; Radzi, Z.; Abu Osman, N.A. Design and development for capacitive humidity sensor applications of lead-free Ca, Mg, Fe, Ti-oxides-based electro-ceramics with improved sensing properties via physisorption. Sensors 2016, 16, 11352. [Google Scholar] [CrossRef] [PubMed]

- McGhee, J.R.; Sagu, J.S.; Southee, D.J.; Evans, P.S.A.; Upul Wijayantha, K.G. Printed, fully metal oxide, capacitive humidity sensors using conductive indium tin oxide inks. ACS Appl. Electron. Mater. 2020, 2, 3593–3600. [Google Scholar] [CrossRef]

- Agarwal, S.; Sharma, G.L. Humidity sensing properties of (Ba, Sr) TiO3 thin films grown by hydrothermal-electrochemical method. Sens. Actuators B 2002, 85, 205–211. [Google Scholar] [CrossRef]

- Shimizu, Y.; Uemura, K.; Matsuda, H.; Miura, N.; Yamazoe, N. Bi-functional oxygen electrode using large surface area La1−xCaxCoO3 for rechargeable metal-air battery. J. Electrochem. Soc. 1990, 137, 3430–3433. [Google Scholar] [CrossRef]

- Shi, W.; Ding, R.; Li, X.; Xu, Q.; Ying, D.; Huang, Y.; Liu, E. Bimetallic Co-Mn perovskite fluorides as highly-stable electrode materials for supercapacitors. Chem. Eur. J. 2017, 23, 15305–15311. [Google Scholar] [CrossRef]

- Lang, X.; Mo, H.; Hu, X.; Tian, H. Supercapacitor performance of perovskite La1−xSrxMnO3. Dalton Trans. 2017, 46, 13720–13730. [Google Scholar] [CrossRef] [PubMed]

- Arai, H.; Ezeki, S.; Shimizu, Y.; Shippo, O.; Seiyama, T. Semiconductive humidity sensor of perovskite-type oxides. Hyomen Kagaku 1984, 5, 165–166. [Google Scholar] [CrossRef]

- Yeh, Y.C.; Tseng, T.Y. Analysis of the d.c. and a.c. properties of K2O-doped porous Ba0.5Sr0.5TiO3 ceramic humidity sensor. J. Mater. Sci. 1989, 24, 2739–2745. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, C.; Zhang, T.; Guo, H.; Zou, B.; Wang, R.; Wu, F. Humidity sensitive properties of K+ -doped nanocrystalline LaCo0.3Fe0.7O3. Sens. Actuators B 2007, 126, 678–683. [Google Scholar] [CrossRef]

- Doroftei, C.; Popa, P.D.; Iacomi, F. Selectivity between methanol and ethanol gas of La-Pb-Fe-O perovskite synthesized by novel method. Sens. Actuators A 2013, 190, 176–180. [Google Scholar] [CrossRef]

- Hunter, G.W.; Xu, J.C.; Evans, L.J.; Vander Wal, R.L.; Gordon, M. Chemical sensors based on metal oxide nanostructures, applications. Solid State Ion. Devices 2006, 9, 199–209. [Google Scholar]

- Zou, H.; Zhang, Y.; Duan, Z.; Tong, Y.; Peng, J.; Zheng, X. Humidity sensing properties of LnFeO3 nanofibers synthesized by electrospinning (Ln = Sm, Nd, La). Mater. Res. Express 2018, 5, 015022. [Google Scholar] [CrossRef]

- Josephine, B.A.; Manikandan, A.; Teresita, V.M.; Antony, S.A. Fundamental study of LaMgxCr1−xO3−δ perovskites nano-photocatalysts: Sol-gel synthesis, characterization and humidity sensing. Korean J. Chem. Eng. 2016, 33, 1590–1598. [Google Scholar] [CrossRef]

- Upadhyay, S.; Kavitha, P. Lanthanum doped stannate for humidity sensor. Mater. Lett. 2007, 61, 1912–1915. [Google Scholar] [CrossRef]

- Malinowski, M.; Piramidowicz, R.; Frukacz, Z.; Chadeyron, G.; Mahiou, R.; Joubert, M.F. Spectroscopy and upconversion processes in YAlO3:Ho3+ crystals. Opt. Mater. 1999, 12, 409–423. [Google Scholar] [CrossRef]

- Cizauskaite, S.; Reichlova, V.; Nenartaviciene, G.; Beganskiene, A.; Pinkas, J.; Kareiva, A. Sol-gel preparation and characterization of perovskite gadolinium aluminates. Mater. Sci. 2007, 25, 755–765. [Google Scholar]

- Girish, H.N.; Madhusudan, P.; Sajan, C.P.; Suresh Kumar, B.V.; Byrappa, K. Supercritical hydrothermal synthesis of polycrystalline gadolinium aluminum perovskite materials (GdAlO3, GAP). AIMS Mater. Sci. 2017, 4, 540–550. [Google Scholar] [CrossRef] [Green Version]

- Atwood, D.A.; Yearwood, B.C. The future of aluminium chemistry. J. Organomet. Chem. 2000, 600, 186–197. [Google Scholar] [CrossRef]

- Chroma, M.; Pinkas, J.; Pakutinskiene, I.; Beganskiene, A.; Kareiva, A. Processing and characterization of sol-gel fabricated mixed metal aluminates. J. Ceram. Int. 2005, 31, 1123–1130. [Google Scholar] [CrossRef]

- Doroftei, C.; Popa, P.D.; Rezlescu, N. The influence of the heat treatment on the humidity sensitivity of magnesium nanoferrite. J. Optoelectron. Adv. Mater. 2010, 12, 881–884. [Google Scholar]

- Rezlescu, N.; Doroftei, C.; Rezlescu, E.; Popa, P.D. The influence of Sn4+ and/or Mo6+ ions on the structure, electrical and gas sensing properties of Mg-ferrite. Phys. Stat. Sol. A 2006, 203, 306–316. [Google Scholar] [CrossRef]

- Doroftei, C.; Popa, P.D.; Rezlescu, E.; Rezlescu, N. Nanocrystalline SrMnO3 powder as catalyst for hydrocarbon combustion. J. Alloys Comp. 2014, 584, 195–198. [Google Scholar] [CrossRef]

- Doroftei, C.; Leontie, L. Nanocrystalline SrMnO3 perovskite prepared by sol-gel self-combustion method for sensor applications. J. Sol-Gel Sci. Technol. 2021, 97, 146–154. [Google Scholar] [CrossRef]

- Cao, G. Nanostructures and Nanomaterials: Synthesis, Properties and Applications; Imperial College Press: London, UK, 2004. [Google Scholar]

- Upadhyay, K.; Tamrakar, R.K.; Dubey, V. High temperature solid state synthesis and photoluminescence behavior of Eu3+ doped GdAlO3 nanophosphor. Superlattice Microst. 2015, 78, 116–124. [Google Scholar] [CrossRef]

- Kristin, P. Materials Data on GdAlO3 (SG:62) by Materials Project. 2014. Available online: https://materialsproject.org/materials/mp-5223/ (accessed on 20 March 2021). [CrossRef]

- Lowell, S.; Shields, J.E.; Thomas, M.A.; Thommes, M. Characterization of Porous Solids and Powders: Surface Area, Pore Size and Density; Kluwer Academic Publisher: Dordrecht, The Netherlands, 2004. [Google Scholar]

- Tripathy, A.; Pramanik, S.; Cho, J.; Santhosh, J.; Osman, N.A.A. Role of morphological structure, doping, and coating of different materials in the sensing characteristics of humidity sensors. Sensors 2014, 14, 16343–16422. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Wang, X.H.; Wang, X.D. Study on dielectric properties of humidity sensing nanometer materials. Sens. Actuators B 2005, 108, 445–449. [Google Scholar] [CrossRef]

- Bi, H.; Yin, K.; Xie, X.; Ji, J.; Wan, S.; Sun, L.; Terrones, M.; Dresselhaus, M.S. Ultrahigh humidity sensitivity of graphene oxide. Sci. Rep. 2013, 3, 2714. [Google Scholar] [CrossRef] [Green Version]

- Yo, X.; Chen, X.; Ding, X.; Chen, X.; Yo, X.; Zhao, X. High-sensitivity and low-hysteresis humidity sensor based on hydrothermally reduced graphene oxide/nanodiamond. Sens. Actuators B 2019, 283, 761–768. [Google Scholar]

- Yadav, B.C.; Srivastava, R.; Dwivedi, C.D. Synthesis and characterization of ZnO-TiO2 nanocomposite and its application as a humidity sensor. Philos Mag. 2008, 88, 1113–1124. [Google Scholar] [CrossRef]

- Das, J.; Hossain, S.M.; Chahraborty, S. Role of parasitic in humidity sensing by porous silicon. Sens. Actuators A 2001, 94, 44–52. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, L.; Wu, F.; Yuan, S.; Zhao, Y.; Zhang, M. The sol-gel template synthesis of porous TiO2 for a high performance humidity sensor. Nanotechnology 2011, 22, 275502–275509. [Google Scholar] [CrossRef] [PubMed]

- Agmon, N. The Grotthuss mechanism. Chem. Phys. Lett. 1995, 244, 456–462. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Doroftei, C.; Leontie, L. Porous Nanostructured Gadolinium Aluminate for High-Sensitivity Humidity Sensors. Materials 2021, 14, 7102. https://doi.org/10.3390/ma14227102

Doroftei C, Leontie L. Porous Nanostructured Gadolinium Aluminate for High-Sensitivity Humidity Sensors. Materials. 2021; 14(22):7102. https://doi.org/10.3390/ma14227102

Chicago/Turabian StyleDoroftei, Corneliu, and Liviu Leontie. 2021. "Porous Nanostructured Gadolinium Aluminate for High-Sensitivity Humidity Sensors" Materials 14, no. 22: 7102. https://doi.org/10.3390/ma14227102

APA StyleDoroftei, C., & Leontie, L. (2021). Porous Nanostructured Gadolinium Aluminate for High-Sensitivity Humidity Sensors. Materials, 14(22), 7102. https://doi.org/10.3390/ma14227102