Mechanical Properties of Furnace Slag and Coal Gangue Mixtures Stabilized by Cement and Fly Ash

Abstract

:1. Introduction

2. Materials and Methods

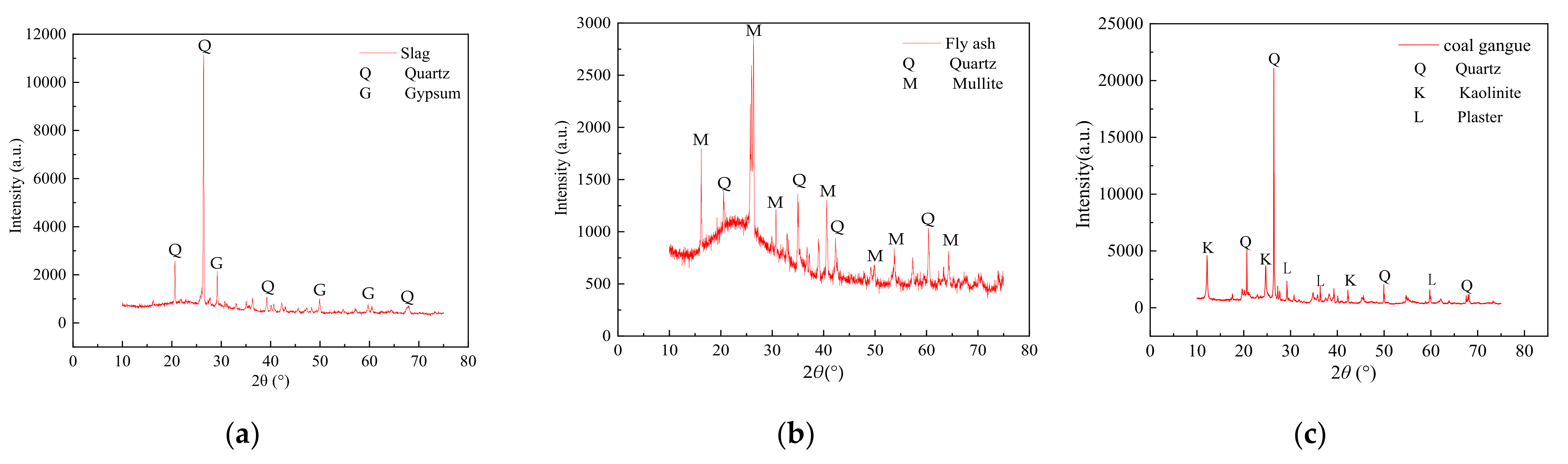

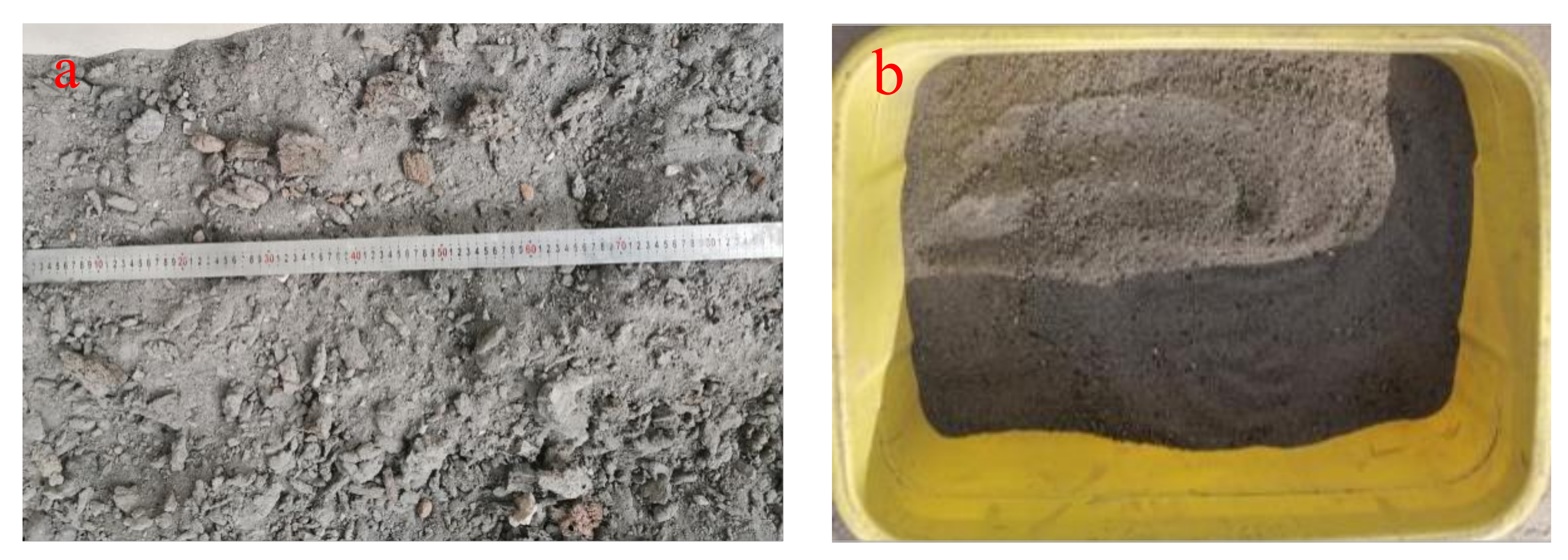

2.1. Materials

2.2. Methods

2.3. Test Schemes

2.3.1. Compaction Testing

2.3.2. Mechanical Property Testing

2.3.3. Triaxial Test

2.3.4. SEM Test

3. Results and Discussion

3.1. Analysis of Compaction Test Law

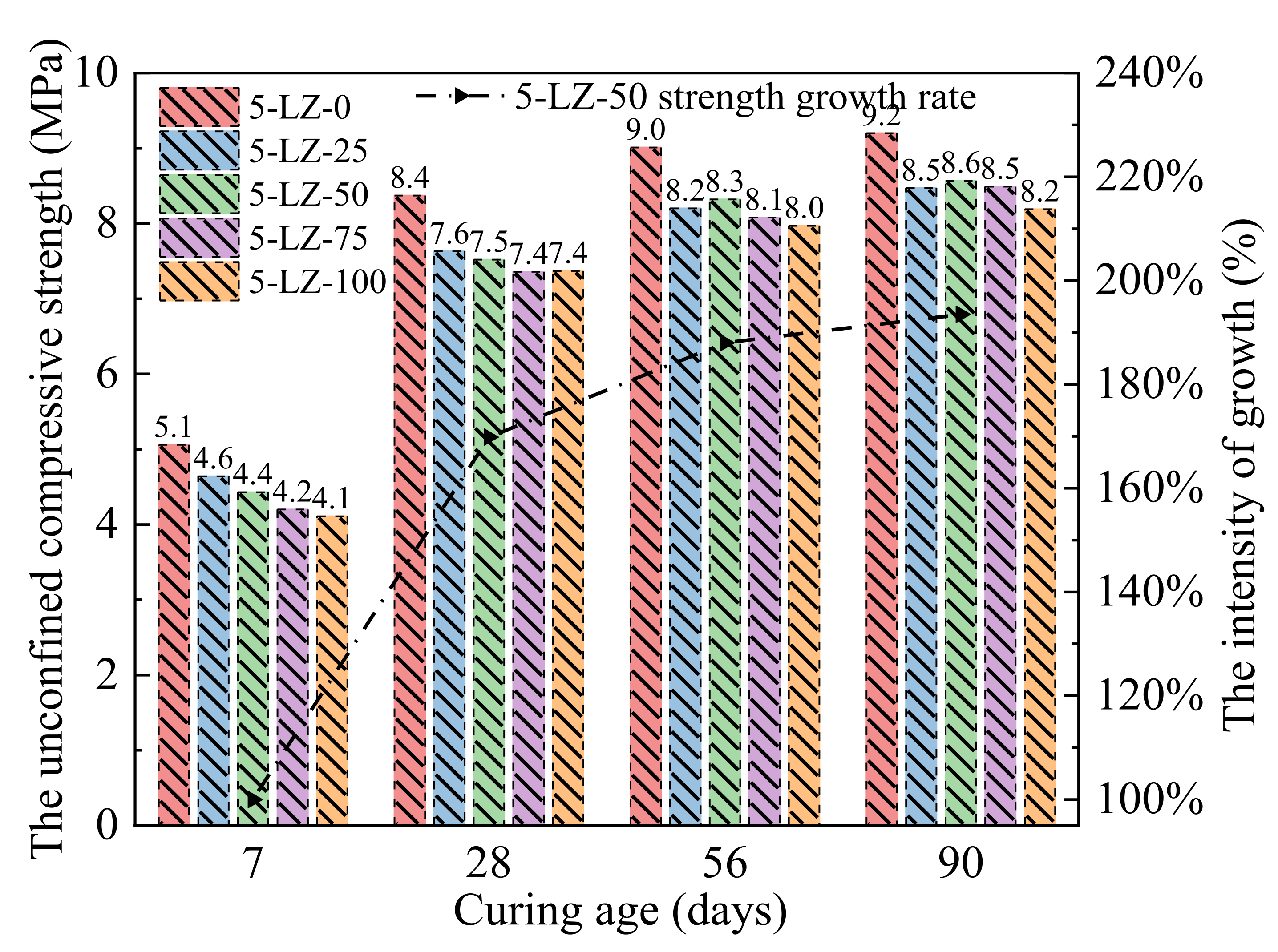

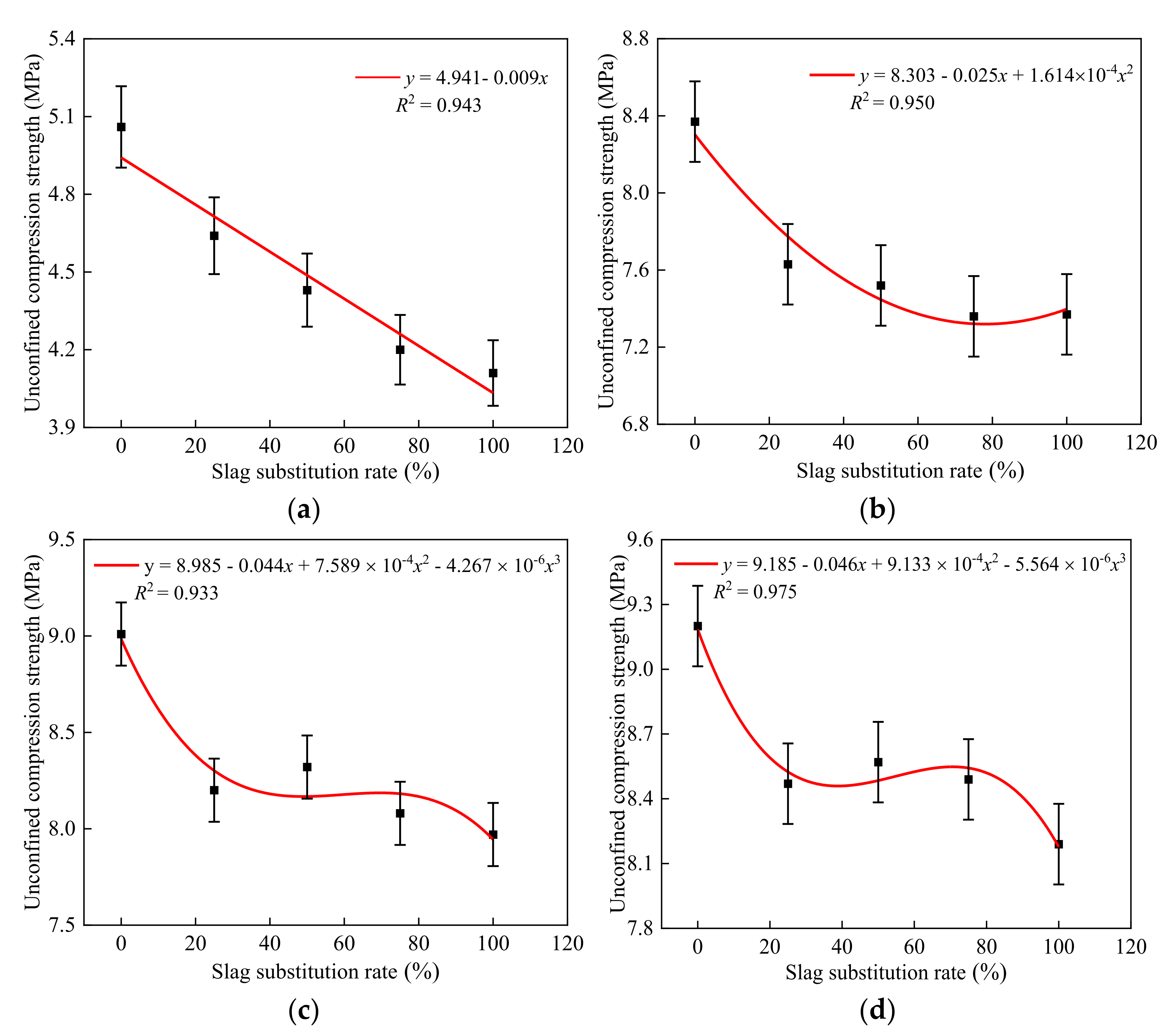

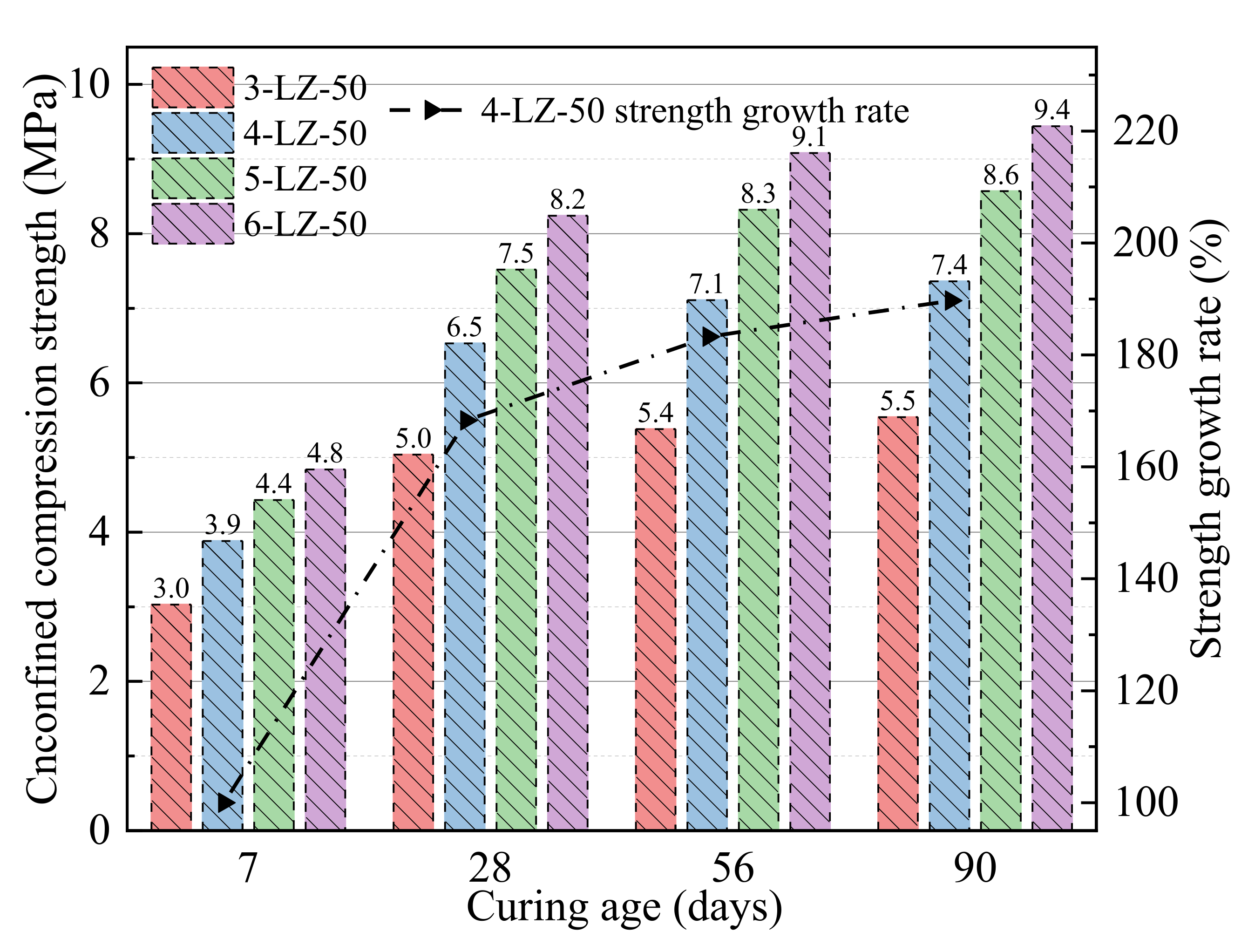

3.2. Analysis of the Unconfined Compressive Strength

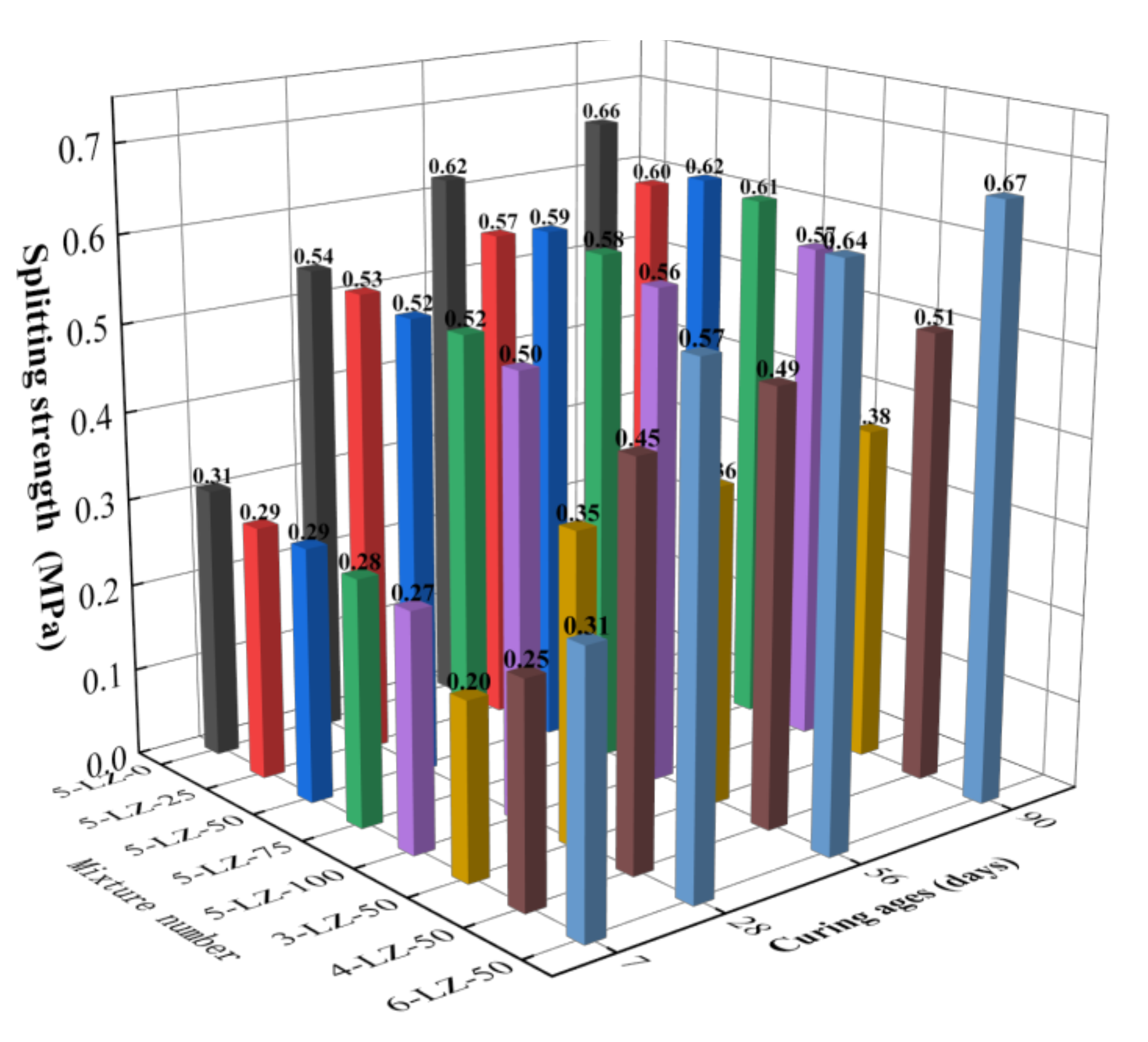

3.3. Analysis of the Splitting Test Law

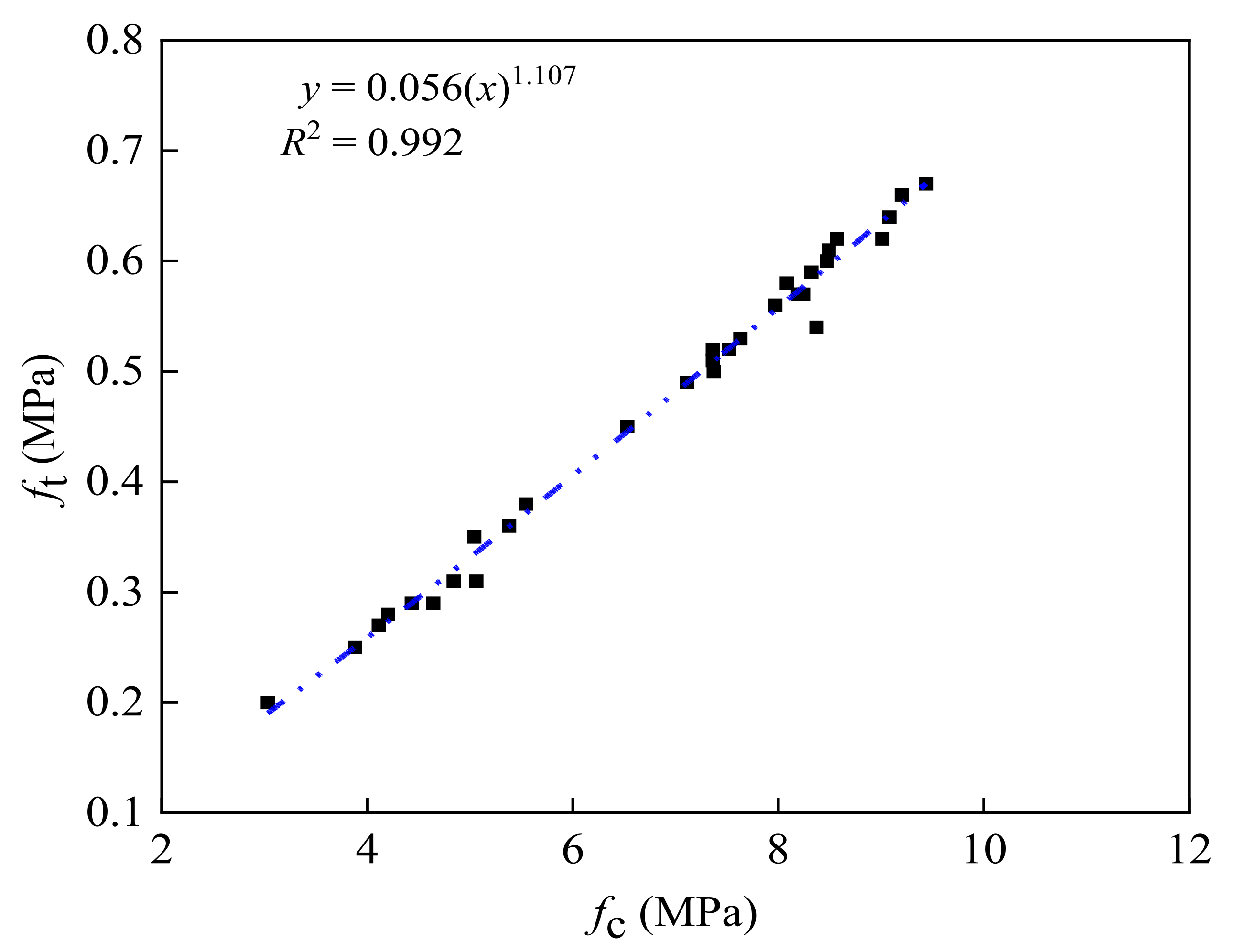

3.4. Analysis of Unconfined Compressive Strength and Splitting Strength

3.5. Analysis of Triaxial Test Law

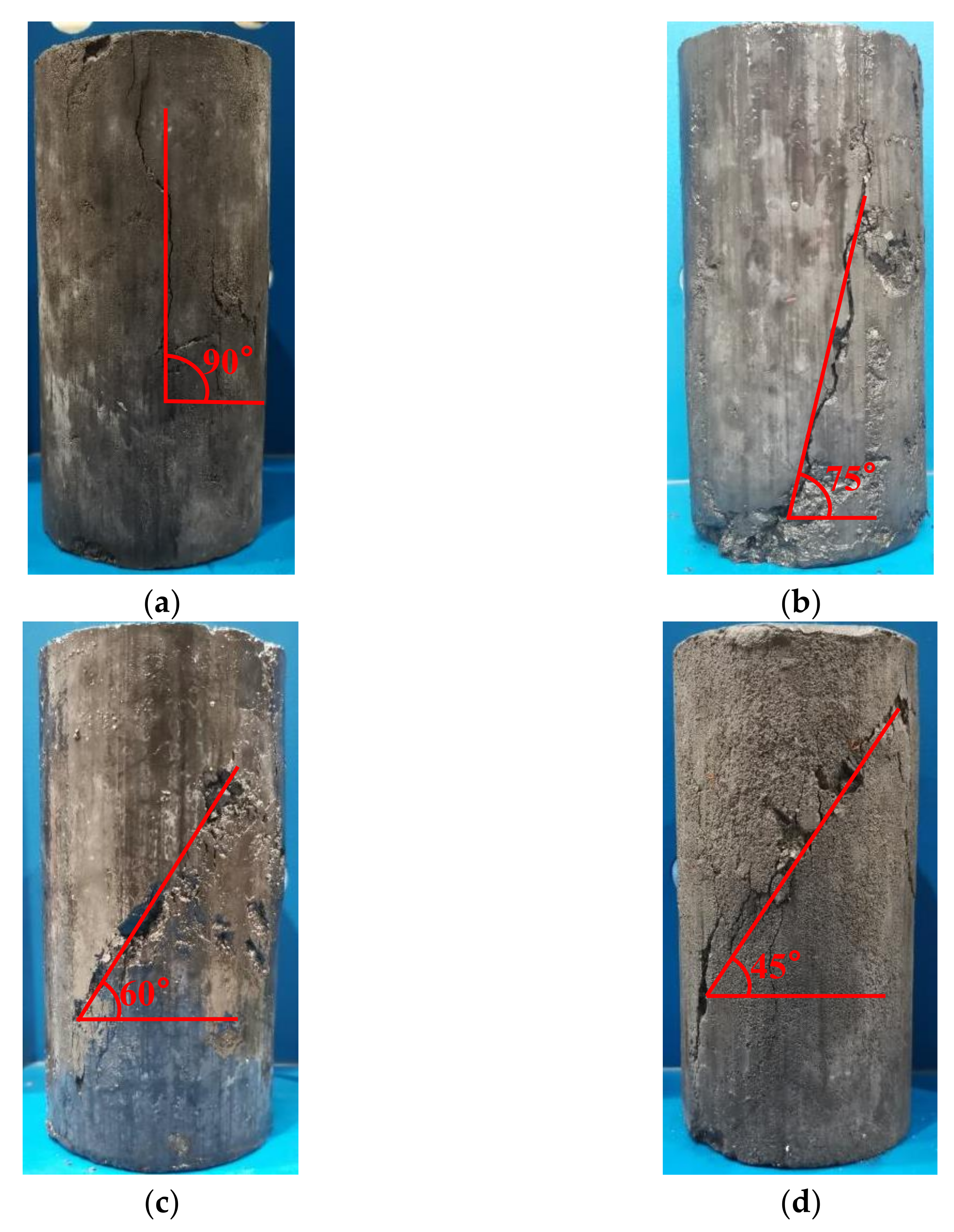

3.5.1. Failure Analysis

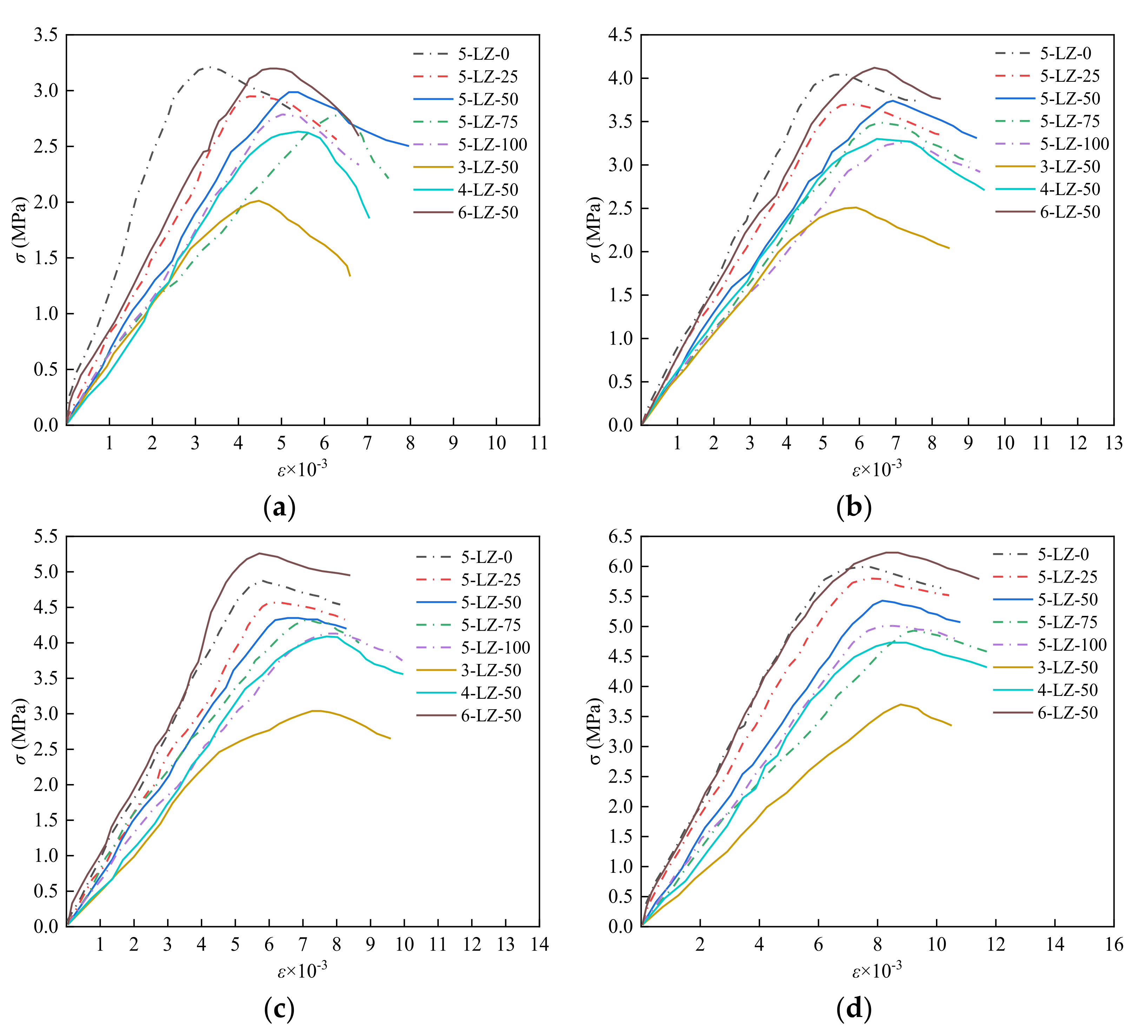

3.5.2. Stress–Strain Curve Analysis

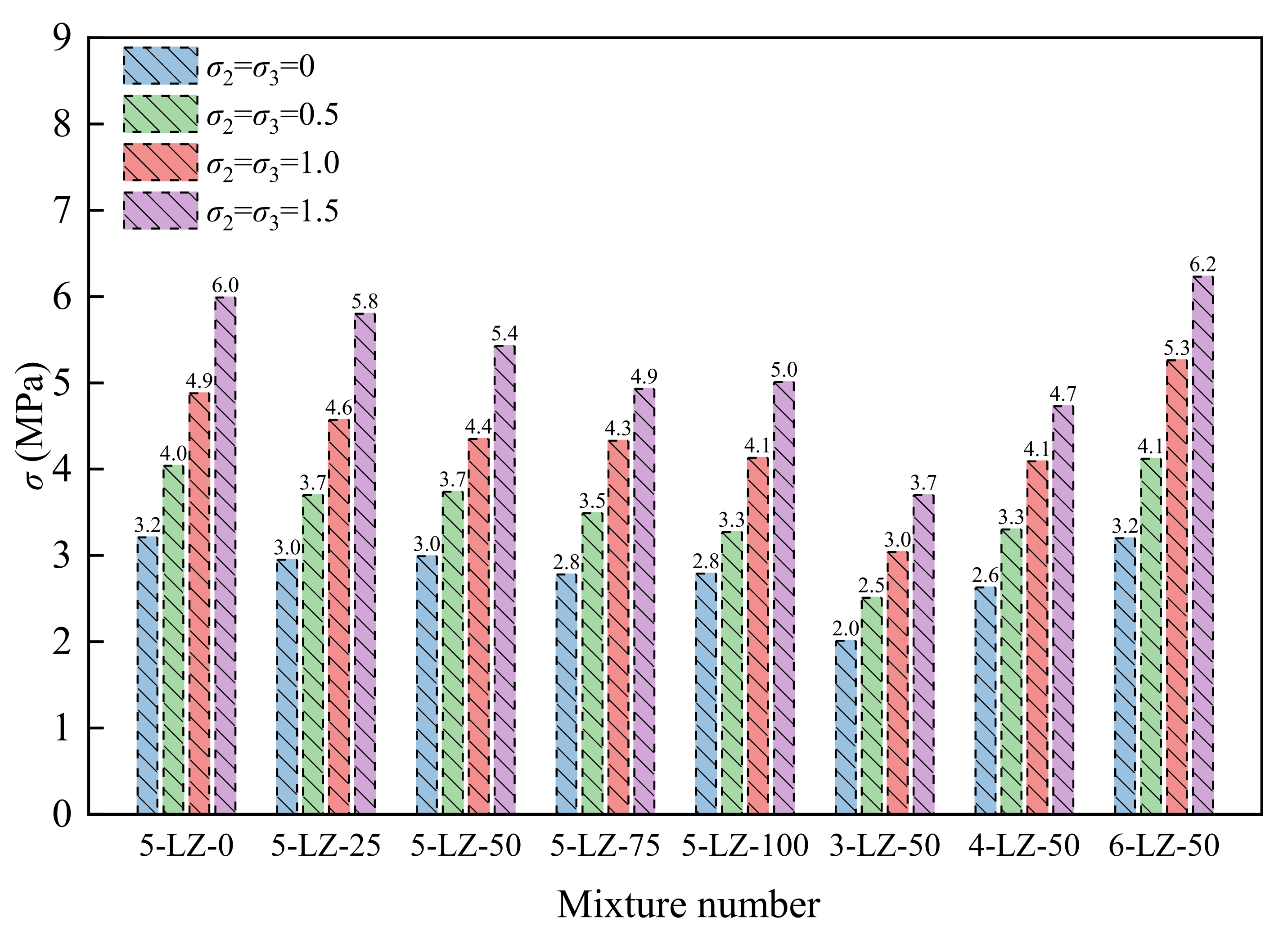

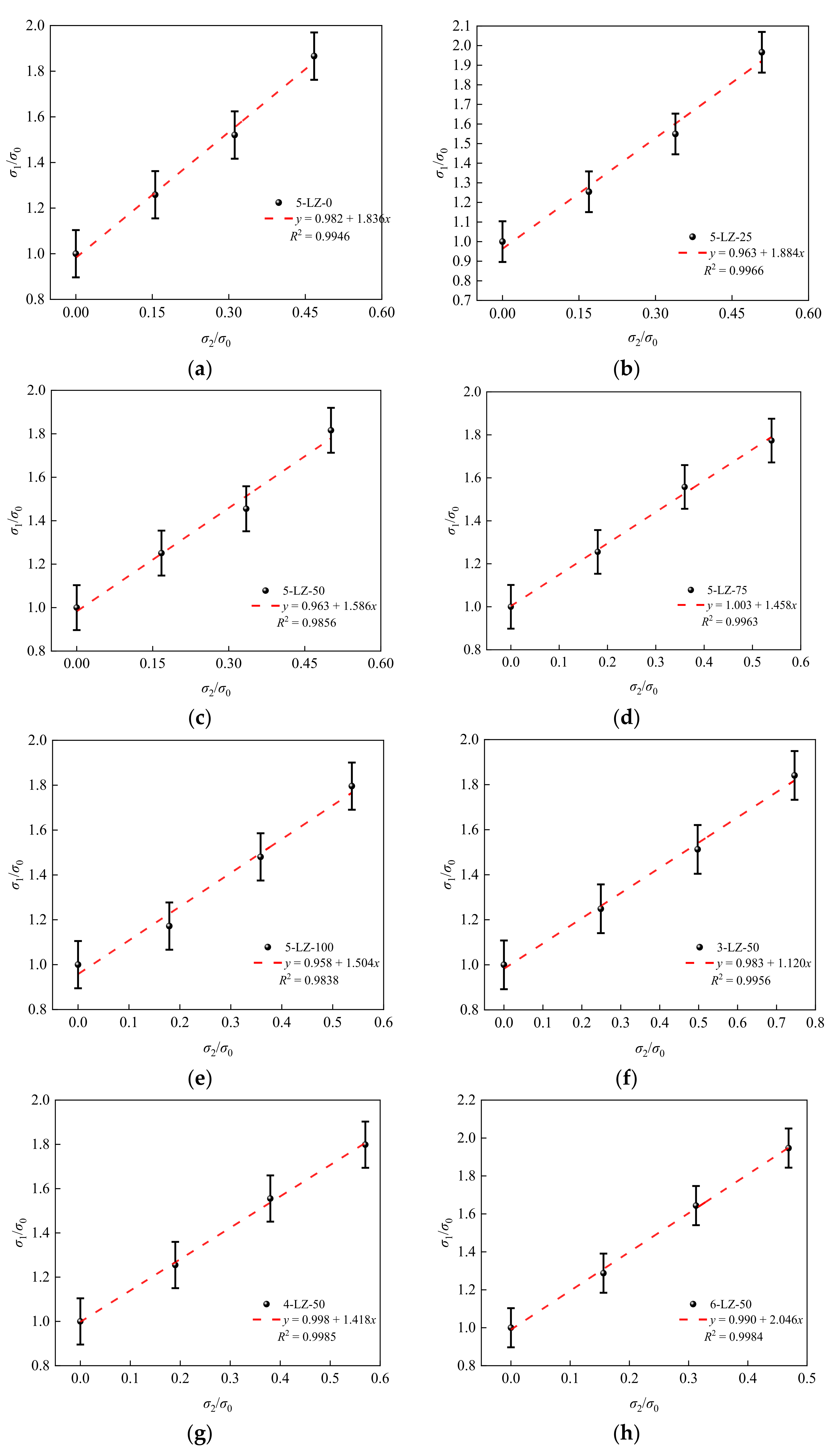

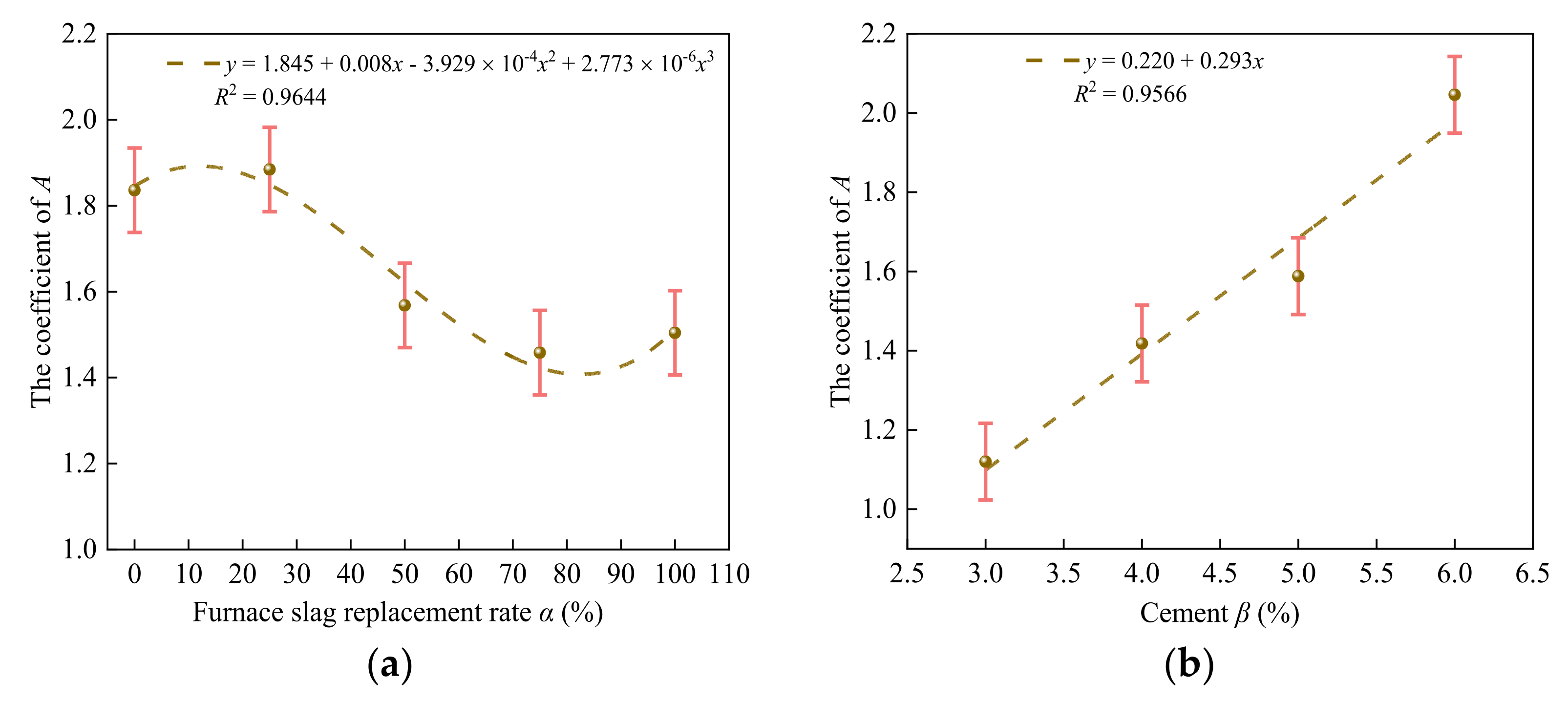

3.5.3. Stress Peak Law Analysis

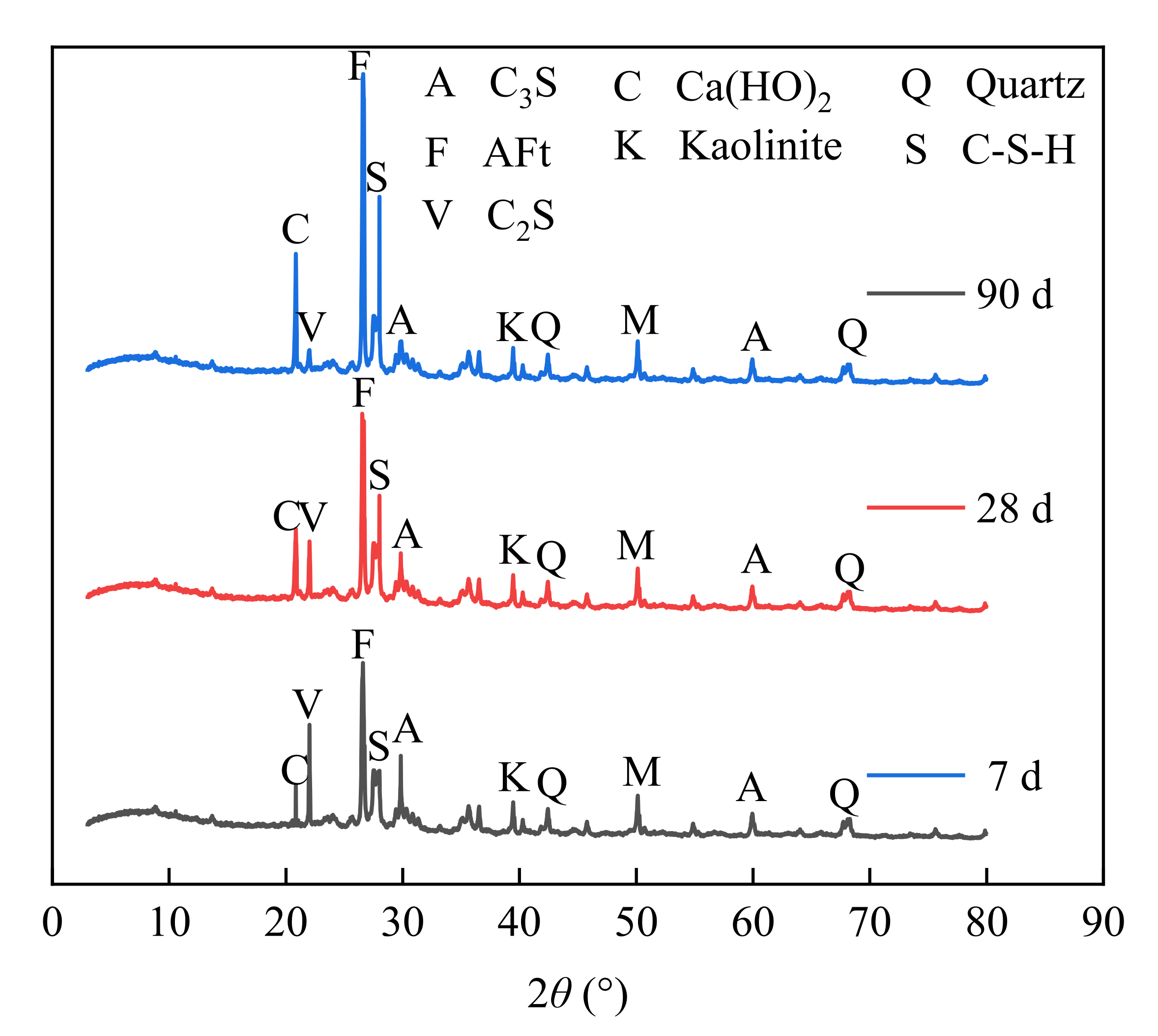

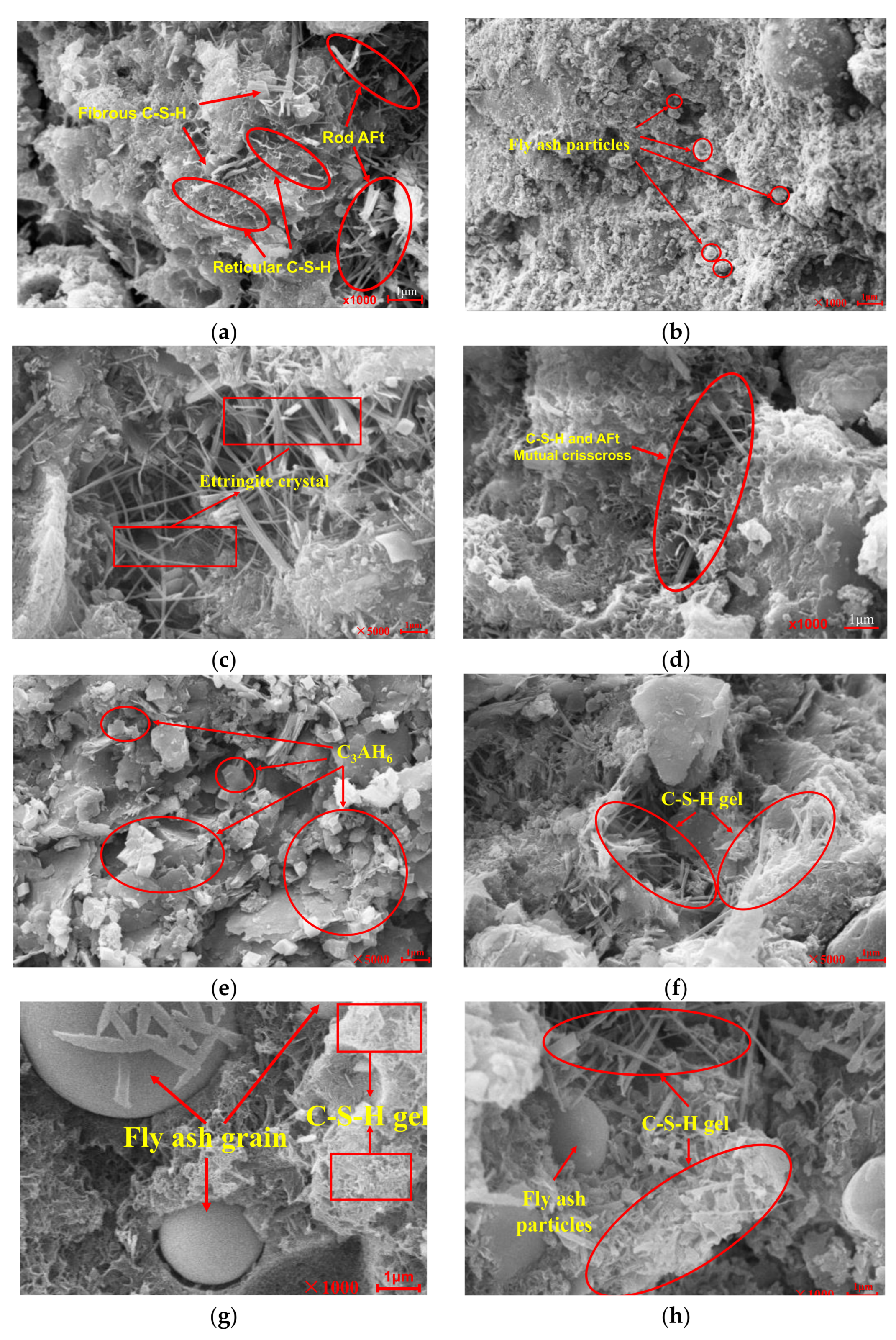

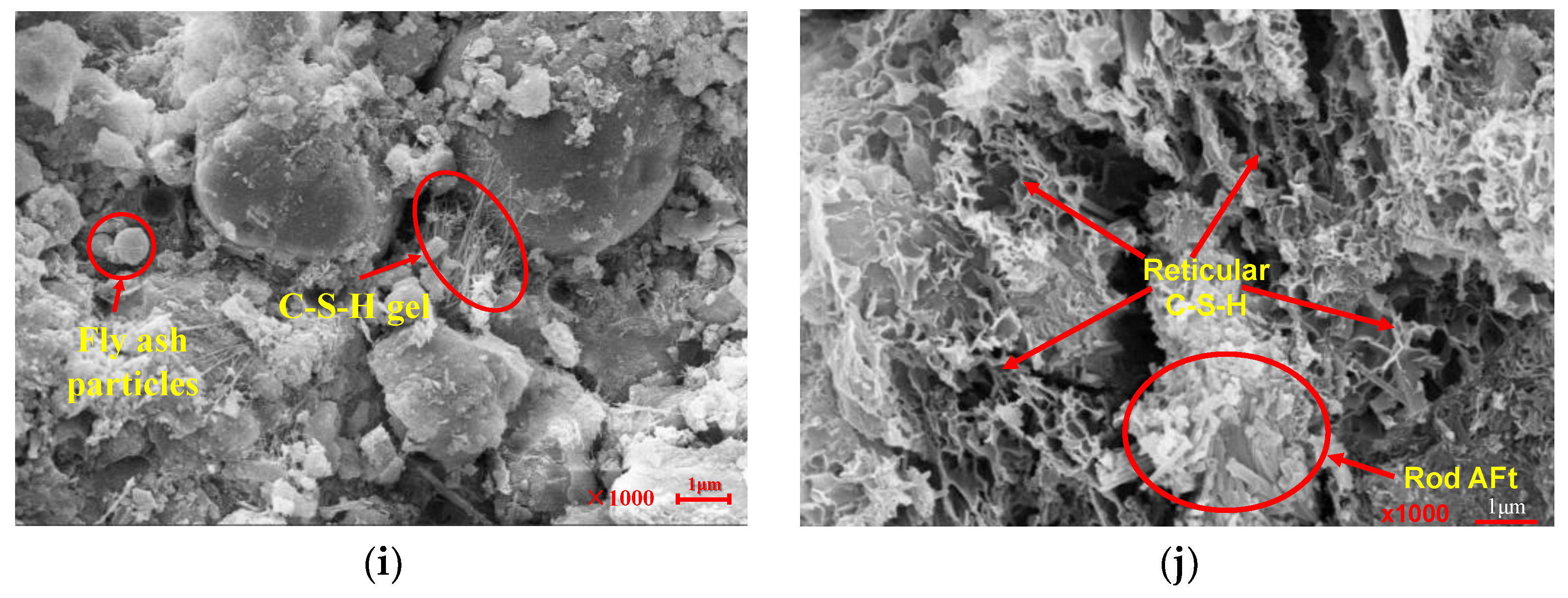

3.6. Strength Formation Mechanism

4. Conclusions

- (1)

- With the increase in the furnace slag substitution rate, the optimal water content of the specimen increased and the maximum dry density decreased. The addition of the furnace slag reduced the unconfined compressive strength of the specimen, where the greater the substitution rate of the furnace slag, the lower the unconfined compressive strength of the specimen. However, with an extended curing period, the effect of the furnace slag on the unconfined compressive strength of the specimen gradually weakened. With the increase in cement ratio, the unconfined compressive strength of the specimen increased. Considering the principle of mechanical properties and economic concerns, it is suggested that the replacement rate of furnace slag in actual construction should be about 50% and should not exceed 75%.

- (2)

- The results showed that the power function agreed well with the experimental results and can be used in practical engineering applications.

- (3)

- The triaxial test results were analyzed in terms of the failure mode, stress–strain relationship curve, peak stress, and failure criterion of the specimens. The results showed that (i) under the triaxial stress, the failure mode of the specimens was greatly affected by confining pressure and they showed typical shear failure, and (ii) according to the test results, the formulas for the relationship between the furnace slag substitution rate, cement ratio, peak stress, and confining pressure were obtained.

- (4)

- The SEM results showed that the hydration products of the mixture included colloidal C-S-H, needle-like ettringite (AFt), unhydrated cement clinker particles, and fly ash particles. The strength of the mixture was a comprehensive embodiment of the microaggregate effect, secondary hydration reaction, and the characteristics of the materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hubiao, Z.; Fei, T.Y.; Changyu, Y.; Shudong, H.; Hongbo, L. Study on road performance of fly ash and gangue mixture. Ningxia Eng. Technol. 2021, 20, 54–57. [Google Scholar]

- Sun, H.; Xu, Q.; Yan, P.; Yin, J.; Lou, P. A Study on Axial Compression Performance of Concrete-Filled Steel-Tubular Shear Wall with a Multi-Cavity T-Shaped Cross-Section. Energies 2020, 13, 4831. [Google Scholar] [CrossRef]

- Ding, F.X.; Wang, W.J.; Lu, D.R.; Liu, X.M. Study on the behavior of concrete-filled square double-skin steel tubular stub columns under axial loading. Structures 2020, 23, 665–676. [Google Scholar] [CrossRef]

- Lu, D.R.; Wang, W.J.; Ding, F.X.; Liu, X.M.; Fang, C.J. The impact of stirrups on the composite action of concrete-filled steel tubular stub columns under axial loading. Structures 2021, 30, 786–802. [Google Scholar] [CrossRef]

- Wang, X.; Yang, X.; Ren, J.; Han, N.; Xing, F. A novel treatment method for recycled aggregate and the mechanical prop-erties of recycled aggregate concrete. J. Mater. Res. Technol. 2020, 10, 1389–1401. [Google Scholar] [CrossRef]

- Reis, G.S.D.; Quattrone, M.; Ambrós, W.M.; Grigore Cazacliu, B.; Hoffmann Sampaio, C. Current Applications of Recycled Aggregates from Construction and Demolition: A Review. Materials 2021, 14, 1700. [Google Scholar] [CrossRef] [PubMed]

- Revilla-Cuesta, V.; Ortega-López, V.; Skaf, M.; Manso, J.M. Effect of fine recycled concrete aggregate on the mechanical behavior of self-compacting concrete. Constr. Build. Mater. 2020, 263, 120671. [Google Scholar] [CrossRef]

- Agrela, F.; Díaz-López, J.L.; Rosales, J.; Cuenca-Moyano, G.M.; Cano, H.; Cabrera, M. Environmental assessment, mechanical behavior and new leaching impact proposal of mixed recycled aggregates to be used in road construction. J. Clean. Prod. 2021, 280, 124362. [Google Scholar] [CrossRef]

- Zhu, K.; Ma, X.; Yao, L.; Zhao, L.; Luo, C. Effect of Polypropylene Fiber on the Strength and Dry Cracking of Mortar with Coal Gangue Aggregate. Adv. Mater. Sci. Eng. 2021, 280, 124362. [Google Scholar] [CrossRef]

- Guangyu, Y.; Mingkai, Z.; Xiao, C. Application of gangue aggregate pavement. J. Wuhan Univ. Technol. (Transp. Sci. Eng. Ed.) 2021, 45, 568–573. [Google Scholar]

- Zhang, Y.; Meng, W.; Zhang, Z. Experimental study of indirect tensile strength of calcareous coal gangue mix-ture. World J. Eng. 2013, 10, 457–462. [Google Scholar] [CrossRef]

- Liao, J.G.; Ma, Q.; Zhang, Y.S.; Song, Z.Y.; Liu, K.H.; Hu, Y.W. Research on Solid Wastes of Gangue, Slag, Fly Ash Used as Cement Composite Mixing Materials. Adv. Mater. Res. 2012, 415, 1583. [Google Scholar] [CrossRef]

- Zhou, M.; Li, Z.G.; Wu, Y.Q.; Zhang, X.F.; Ai, L. Study on lime-fly ash-cement stabilized gangue mixture. J. Build. Mater. 2010, 13, 213–217. [Google Scholar]

- Chalangaran, N.; Farzampour, A.; Paslar, N.; Fatemi, H. Experimental investigation of sound transmission loss in concrete containing recycled rubber crumbs. Adv. Concr. Constr. 2021, 11, 447–454. [Google Scholar]

- Jisheng, Q.; Yunxian, Z.; Minhuang, W. Damage characteristics and constitutive relationship of coal gangue con-crete under freeze-melting cycle. Int. J. Civ. Environ. Eng. 2020, 264, 1–10. [Google Scholar]

- Chalangaran, N.; Farzampour, A.; Paslar, N. Nano Silica and Metakaolin Effects on the Behavior of Concrete Containing Rubber Crumbs. CivilEng 2020, 1, 264–274. [Google Scholar] [CrossRef]

- Wensheng, S. Performance Control for Highway Coal Gangue Filling Subgrade Road; People’s Transportation Press: Beijing, China, 2011; pp. 1–7. [Google Scholar]

- Yan, Z.; Hassan, B.; Rong, Z. Evaluation for the Leaching of Cr from Coal Gangue Using Expansive Soils. Processes 2019, 7, 478. [Google Scholar]

- Fan, X.H.; Xue, Z.H. Study on road performance of recycled aggregate from construction waste. Highway 2020, 65, 40–45. [Google Scholar]

- Qiu, J.S.; Zhou, Y.S.; Wang, M.H.; Houbo, W. Damage characteristics and constitutive relationship of gangue concrete under freeze-thaw cycles. J. Civ. Environ. Eng. 2020, 149–157. [Google Scholar]

- Ozcan, T.; Gokhan, G.; Zaimoglu, A.S. Effect of Bentonite, Fly Ash and Silica Fume cement injections on uniaxial compressive strength of granular bases. KSCE J. Civ. Eng. 2014, 18, 1650–1654. [Google Scholar]

- Khatib, J.M.; Mangat, P.S.; Wright, L. Pore size distribution of cement pastes containing fly ashgypsum blends cured for 7 days. KSCE J. Civ. Eng. 2014, 18, 1091–1096. [Google Scholar] [CrossRef]

- Xiangdong, Z.; Kun, K. Study on base strength and thermal conductivity of cement stable cinder surface. Non-Met. Mine 2017, 40, 47–49. [Google Scholar]

- Changxuan, H. Fatigue characteristics of cement-stabilized slag gravel mixture. Highw. Traffic Technol. 2020, 37, 32–38. [Google Scholar]

- Ministry of Housing and Urban-Rural Development of the People’s Republic of China. CJJ1–2008.

- Meng, S.; Liu, J.; Zhong, P.; Wang, G.; Wang, C. Study on granulation process of uranium containing Coal-fired Fly Ash. Uranium Min. Metall. 2021, 40, 284–289. [Google Scholar]

- Peng, G. Research and Application of Cement Stable Gasized Porous Slag Pavement; Wuhan University of Technology: Wuhan, China, 2020. [Google Scholar]

- Ministry of Communications of the People’s Republic of China. Test Regulations for Inorganic Bonded Stability Materials of JTG E51–2009, Highway Engineering; People’s Transportation Publishing House: Beijing, China, 2009. [Google Scholar]

- Jia, L.; von Deluan, A. A multiscale coupled finite element analysis method considering the microscopic motion of soil particles. Rock Earth Mech. 2021, 42, 1186–1199. [Google Scholar]

- Shabab, M.E.; Shahzada, K.; Gencturk, B.; Ashraf, M.; Fahad, M. Synergistic effect of fly ash and bentonite as partial replacement of cement in mass concrete. KSCE J. Civ. Eng. 2016, 20, 1987–1995. [Google Scholar] [CrossRef]

- Kheradmand, M.; Abdollahnejad, Z.; Pacheco-Torgal, F. Shrinkage Performance of Fly Ash Alkali-activated Cement Based Binder Mortars. KSCE J. Civ. Eng. 2018, 22, 1854–1864. [Google Scholar] [CrossRef] [Green Version]

- Nordine, L.; Van-Huong, N.; Pierre, M. The effect of the partial cement substitution with fly ash on Delayed Ettringite Formation in heat-cured mortars. KSCE J. Civ. Eng. 2017, 21, 1359–1366. [Google Scholar]

- Farzampour, A. Compressive Behavior of Concrete under Environmental Effects; IntechOpen: London, UK, 2019. [Google Scholar]

- Avic, D.; Zhen, H. Numerical Implementation and Application of a Corcorner Model for generalized double-shear stress criterion. J. Rock Mech. Eng. 2021, 40, 2320–2329. [Google Scholar]

- Ding, S.; Niv, D.T.; Wang, J.B. Experimental Study on Micro-structure and Mechanical Properties of Shotcrete with Fly Ash. Bull. Chin. Ceram. Soc. 2015, 34, 1187–1192. [Google Scholar]

- Li, H.; Wang, J.B.; Guo, Q.J. Mechanical Properties of Recycled Aggregate Concrete with Mineral Admixture. Bull. Chin. Ceram. Soc. 2020, 39, 2608–2614. [Google Scholar]

- Ding, F.X.; Wang, W.; Liu, X.M.; Wang, L.; Sun, Y. Mechanical behavior of outer square inner circular concrete filled dual steel tubular stub columns. Steel Compos. Struct. 2021, 38, 305–317. [Google Scholar] [CrossRef]

- Farzampour, A. Temperature and humidity effects on behavior of grouts. Adv. Concr. Constr. 2017, 5, 659. [Google Scholar]

| Raw Materials | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | TiO2 | SO3 | Loss on Ignition |

|---|---|---|---|---|---|---|---|---|---|---|

| Furnace slag | 47.47 | 22.69 | 8.77 | 8.57 | 1.84 | 2.23 | 1.09 | 1.56 | 1.21 | 4.52 |

| Fly ash | 45.16 | 32.91 | 7.47 | 4.95 | 1.20 | 2.12 | 0.78 | 1.77 | 0.80 | 2.63 |

| Coal gangue | 54.65 | 28.28 | 4.81 | 5.06 | 1.03 | 3.02 | 0.32 | 1.52 | 0.64 | 1.51 |

| Sample | Particle Size (mm) | Crush Value (%) | Apparent Density (g·cm−3) | Packing Density (g·cm−3) | Water Absorption (%) |

|---|---|---|---|---|---|

| Furnace slag aggregate | 0–2.36 | / | 2.353 | 0.786 | 11.1 |

| 2.36–4.75 | 38.4 | 2.414 | 0.758 | ||

| Grade coal gangue | 19.0–37.5 | / | 2.568 | 1.396 | 3.0 |

| 9.5–19 | 29.5 | 2.574 | 1.461 | ||

| 4.75–9.5 | / | 2.562 | 1.432 | ||

| 0–4.75 | / | 2.543 | 1.468 |

| Screening Size (mm) | Screening Quality (g) | Grade Screening (%) | Accumulated Screening (%) | By Percentage (%) |

|---|---|---|---|---|

| >19 | 14.1 | 4.7 | 4.7 | 95.3 |

| 16 | 16.8 | 1.9 | 6.6 | 93.4 |

| 13.2 | 32.5 | 3.7 | 10.3 | 89.7 |

| 9.5 | 38.9 | 4.4 | 14.7 | 85.3 |

| 4.75 | 82.2 | 9.3 | 24.0 | 76.0 |

| 2.36 | 67.9 | 7.6 | 31.6 | 68.4 |

| 1.18 | 44.6 | 5.0 | 36.6 | 63.4 |

| 0.6 | 59.9 | 6.7 | 43.3 | 56.7 |

| 0.075 | 99.4 | 11.2 | 97.4 | 2.6 |

| <0.075 | 23.2 | 2.6 | 100 | 0 |

| Mixture Number | Mass Fraction of the Material (%) | ||||||

|---|---|---|---|---|---|---|---|

| Coal Gangue Grading (mm) | Furnace Slag (mm) | Fly Ash | Cement | ||||

| 16–26.5 | 9.5–16 | 4.75–9.5 | 0–4.75 | 0–4.75 | |||

| 5-LZ-0 | 18 | 19 | 15 | 28 | 0 | 15 | 5 |

| 5-LZ-25 | 18 | 19 | 15 | 21 | 7 | 5 | |

| 5-LZ-50 | 18 | 19 | 15 | 14 | 14 | 5 | |

| 5-LZ-75 | 18 | 19 | 15 | 7 | 21 | 5 | |

| 5-LZ-100 | 18 | 19 | 15 | 0 | 28 | 5 | |

| 3-LZ-y | 18 | 19 | 16 | 28-x | x | 3 | |

| 4-LZ-y | 18 | 19 | 17 | 28-x | x | 4 | |

| 6-LZ-y | 18 | 19 | 18 | 28-x | x | 6 | |

| Mix Number | Optimal Moisture Content (%) | Maximum Dry Density (g·cm−3) |

|---|---|---|

| 5-LZ-0 | 8.7 | 2.018 |

| 5-LZ-25 | 9.7 | 1.966 |

| 5-LZ-50 | 10.9 | 1.910 |

| 5-LZ-75 | 12.2 | 1.853 |

| 5-LZ-100 | 13.6 | 1.804 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Zhang, H.; Yan, P.; Yan, C.; Tong, Y. Mechanical Properties of Furnace Slag and Coal Gangue Mixtures Stabilized by Cement and Fly Ash. Materials 2021, 14, 7103. https://doi.org/10.3390/ma14227103

Li H, Zhang H, Yan P, Yan C, Tong Y. Mechanical Properties of Furnace Slag and Coal Gangue Mixtures Stabilized by Cement and Fly Ash. Materials. 2021; 14(22):7103. https://doi.org/10.3390/ma14227103

Chicago/Turabian StyleLi, Hongbo, Hubiao Zhang, Pengfei Yan, Changyu Yan, and Yufei Tong. 2021. "Mechanical Properties of Furnace Slag and Coal Gangue Mixtures Stabilized by Cement and Fly Ash" Materials 14, no. 22: 7103. https://doi.org/10.3390/ma14227103

APA StyleLi, H., Zhang, H., Yan, P., Yan, C., & Tong, Y. (2021). Mechanical Properties of Furnace Slag and Coal Gangue Mixtures Stabilized by Cement and Fly Ash. Materials, 14(22), 7103. https://doi.org/10.3390/ma14227103