Ultrasonic Assessment of the Influence of Cold Rolling and Recrystallization Annealing on the Elastic Constants in a TWIP Steel

Abstract

1. Introduction

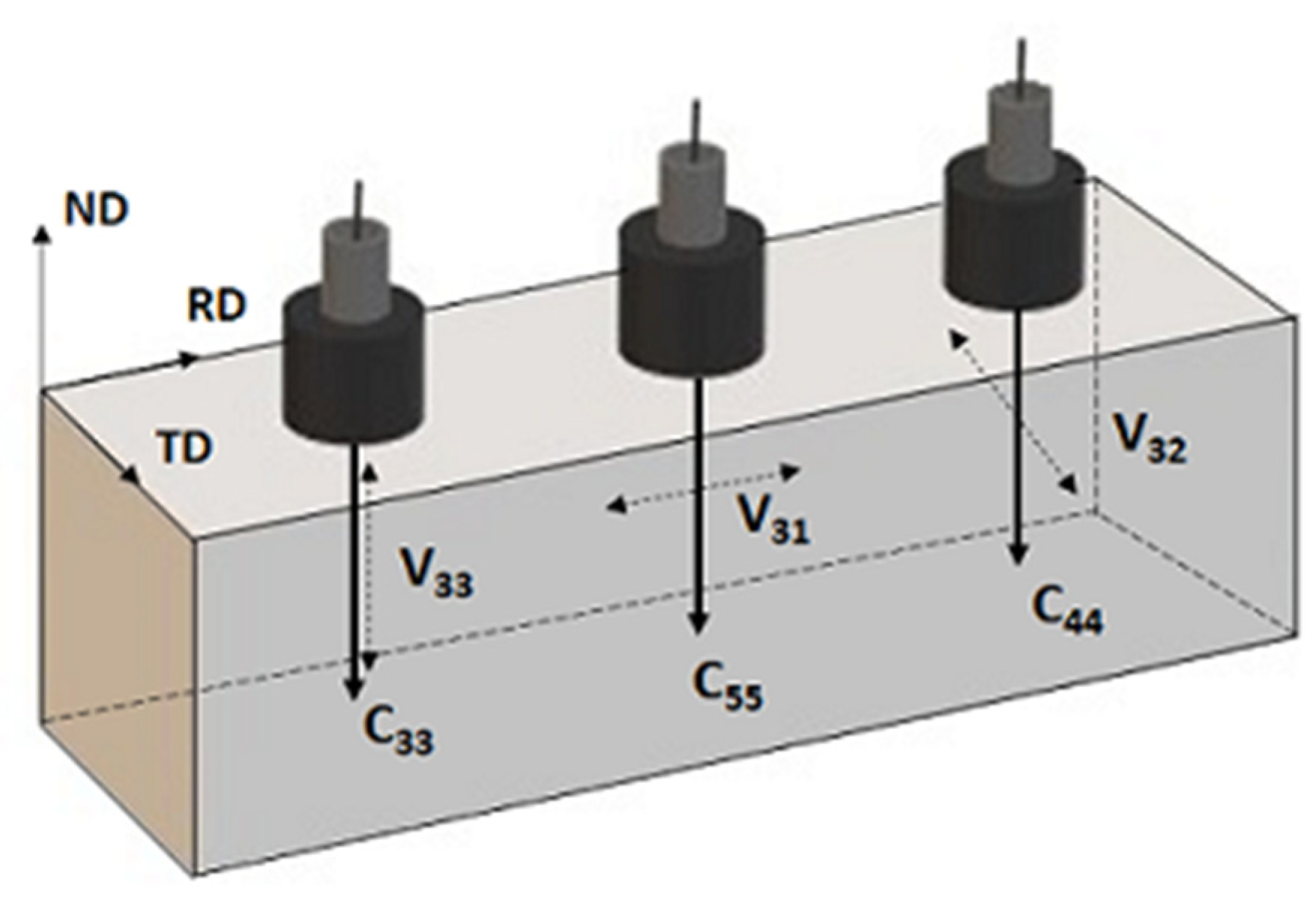

2. Principles of the Ultrasonic Wave Analysis for the Determination of Elastic Constants

3. Materials and Methods

4. Results and Discussion

4.1. Cold Rolling

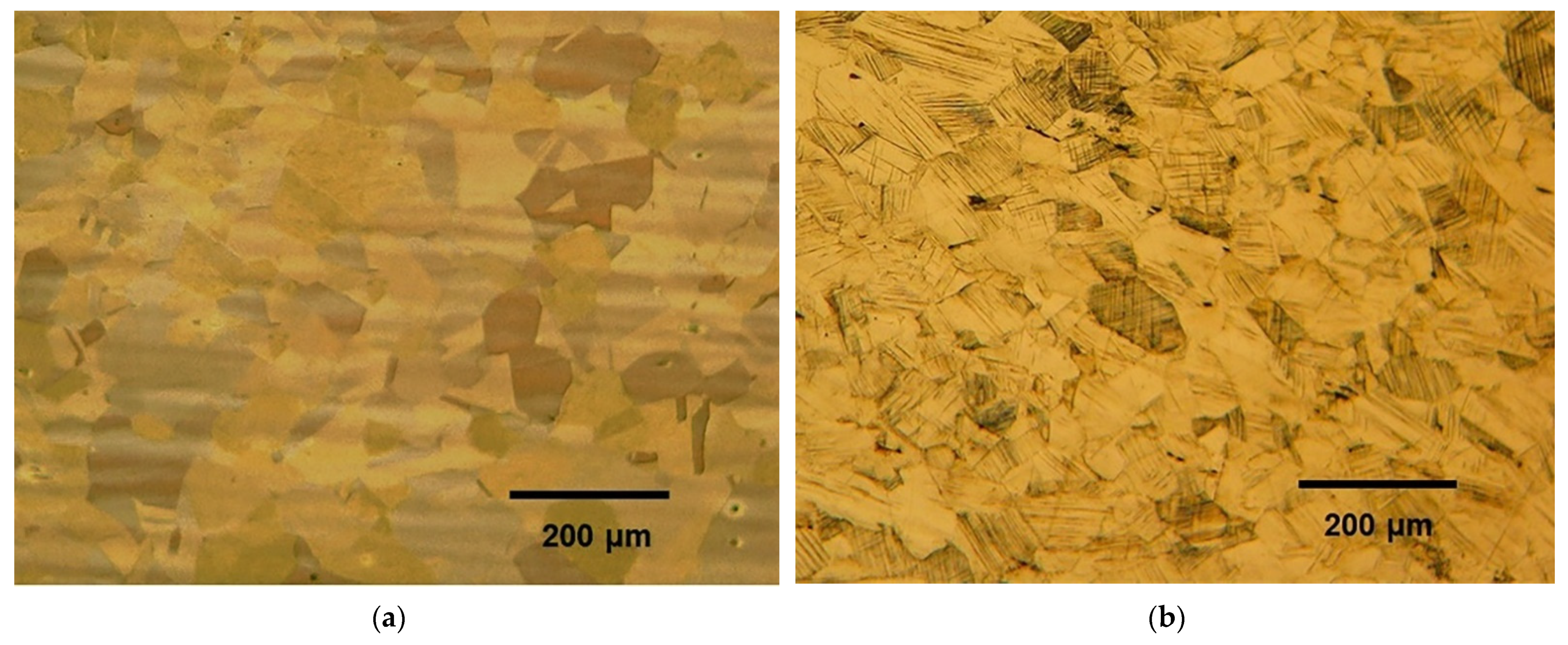

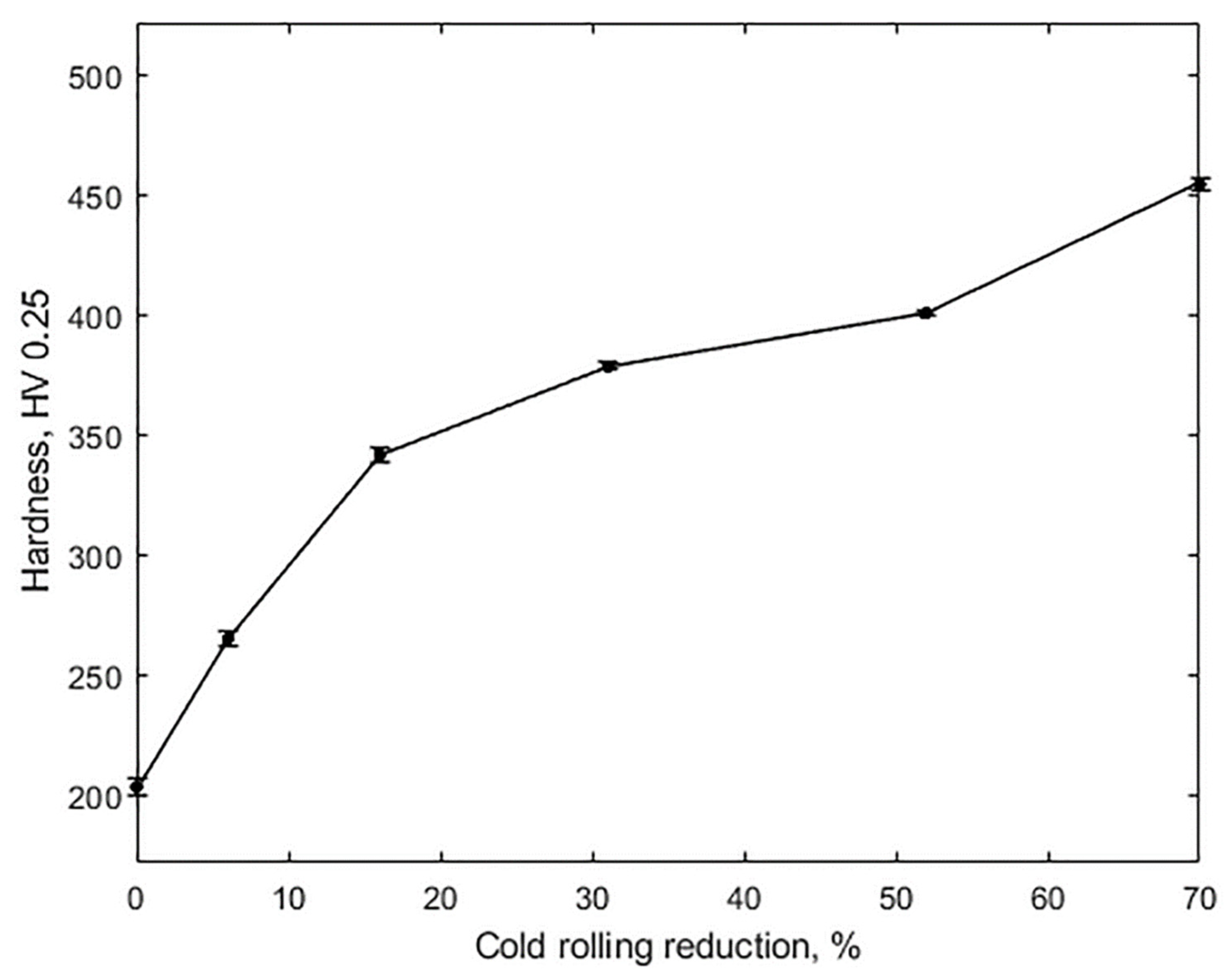

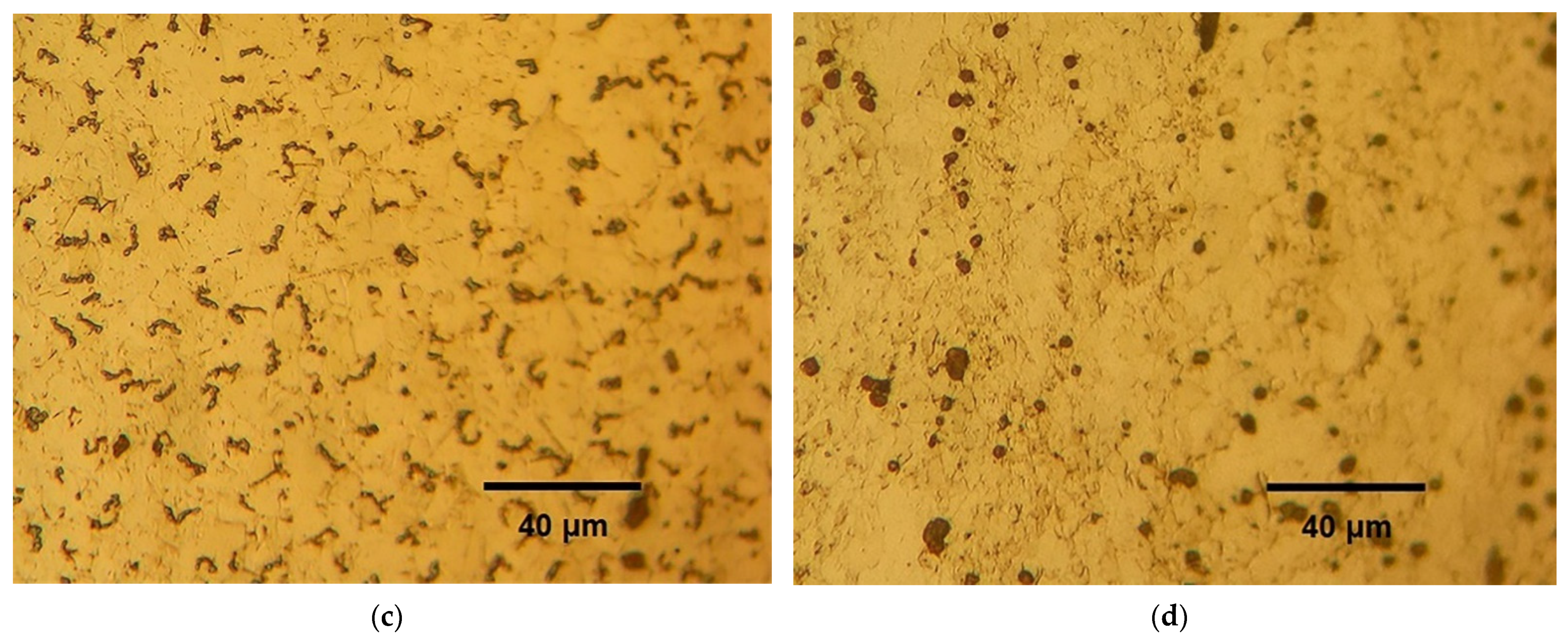

4.1.1. Effect of Cold Rolling on Microstructure and Hardness

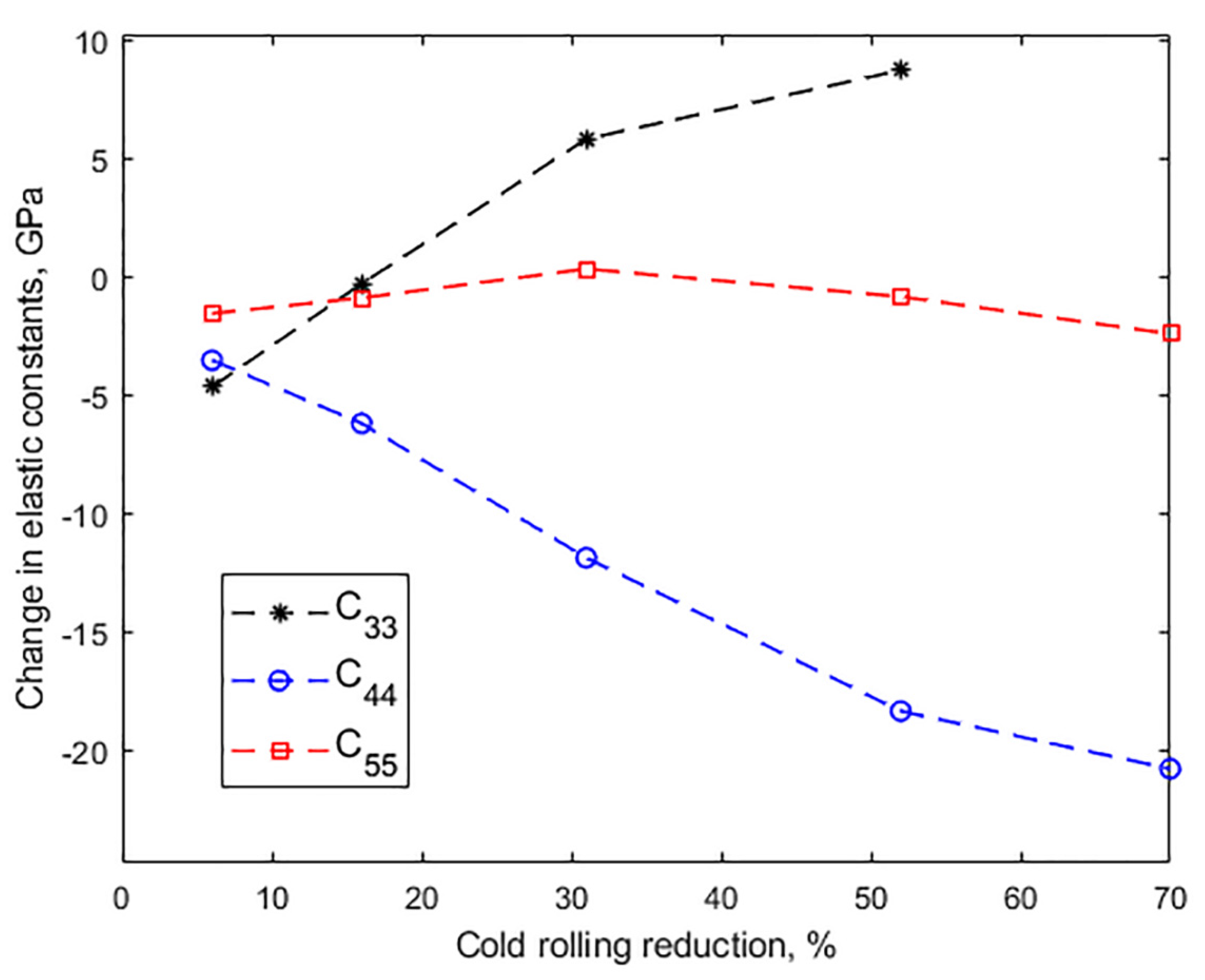

4.1.2. Effect of Cold Rolling on Wave Velocities and Elastic Constants

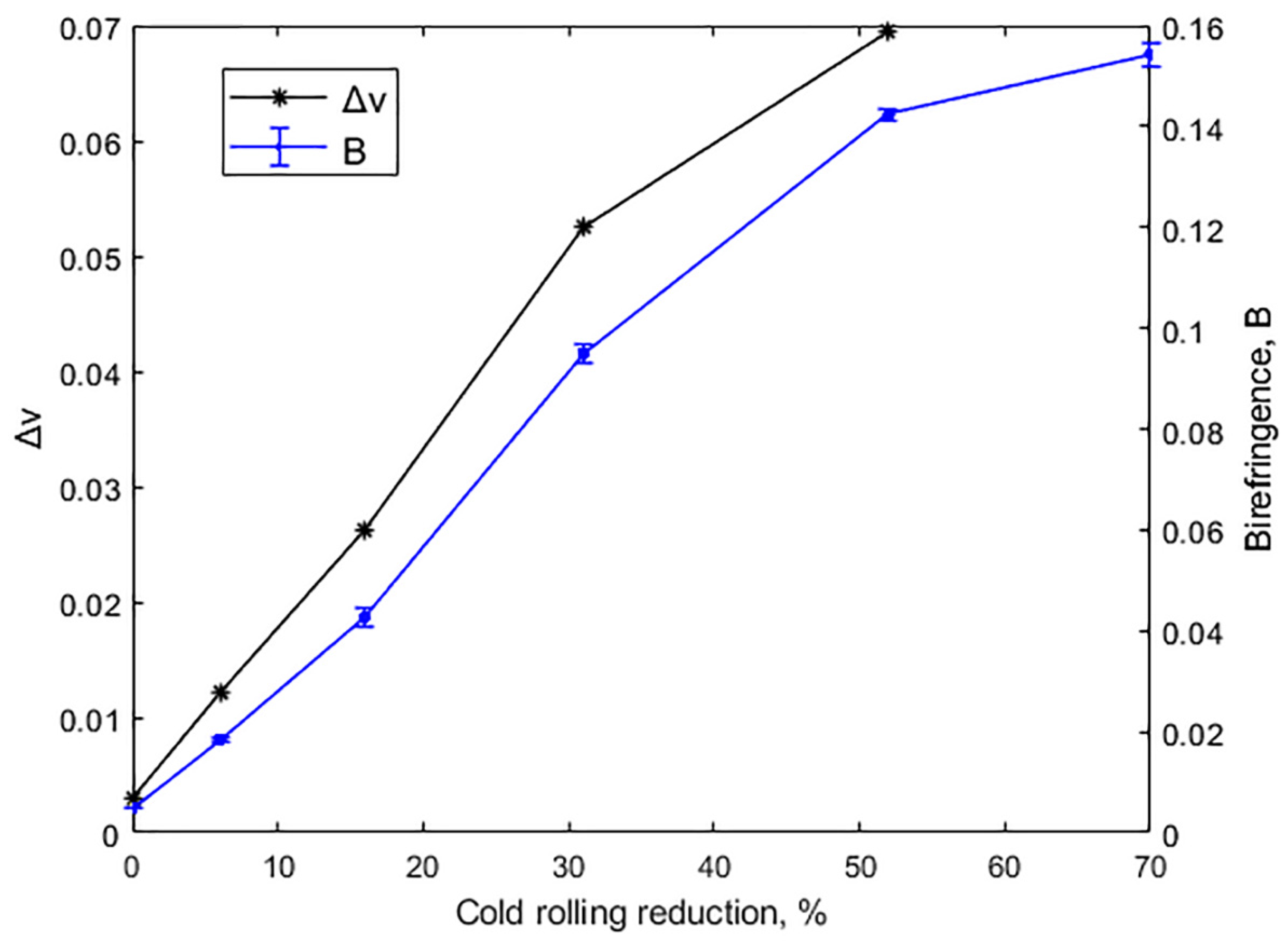

4.1.3. Effect of Cold Rolling on Poisson’s Ratio and Birefringence

4.2. Annealing

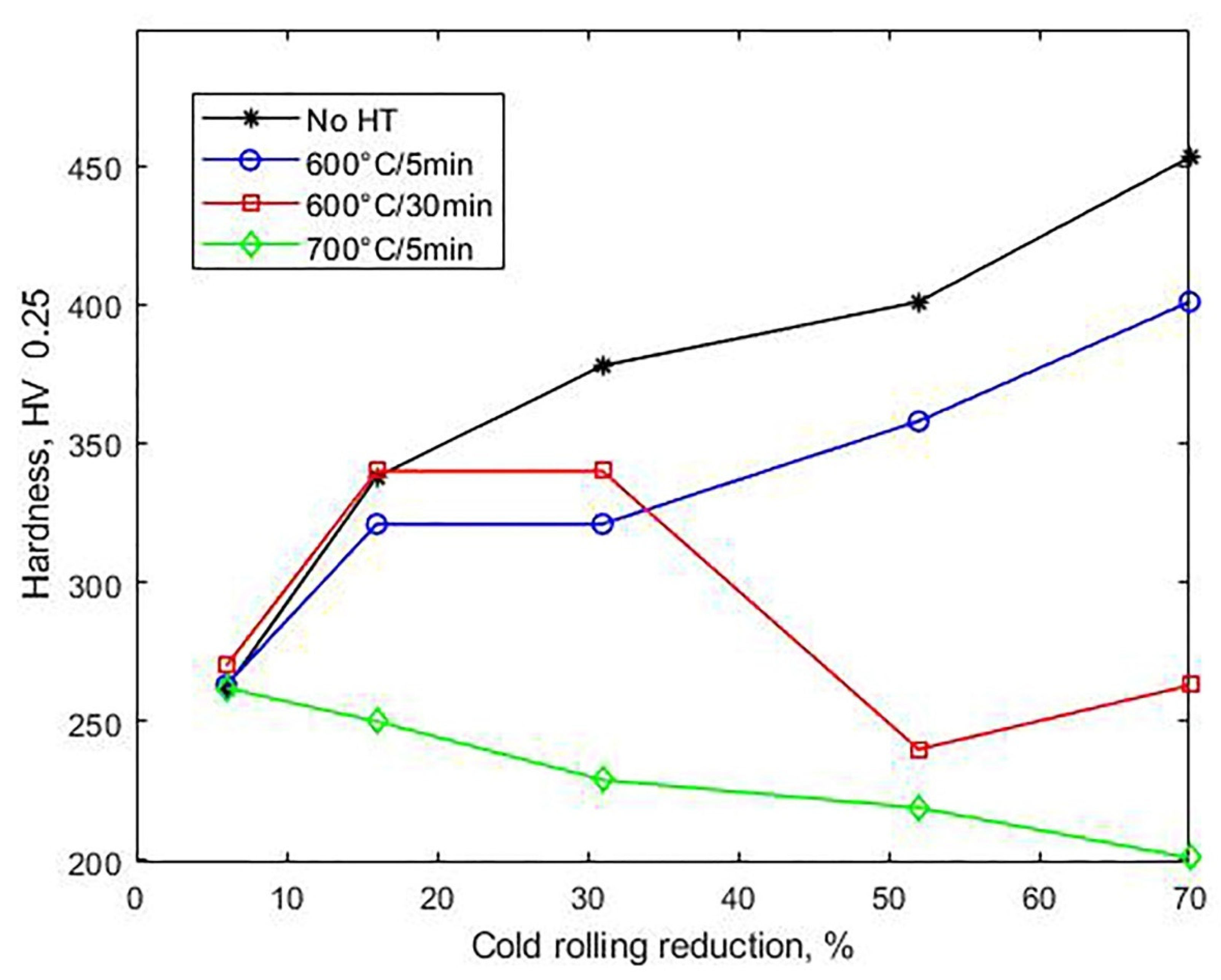

4.2.1. Effect of Annealing on Microstructure and Hardness

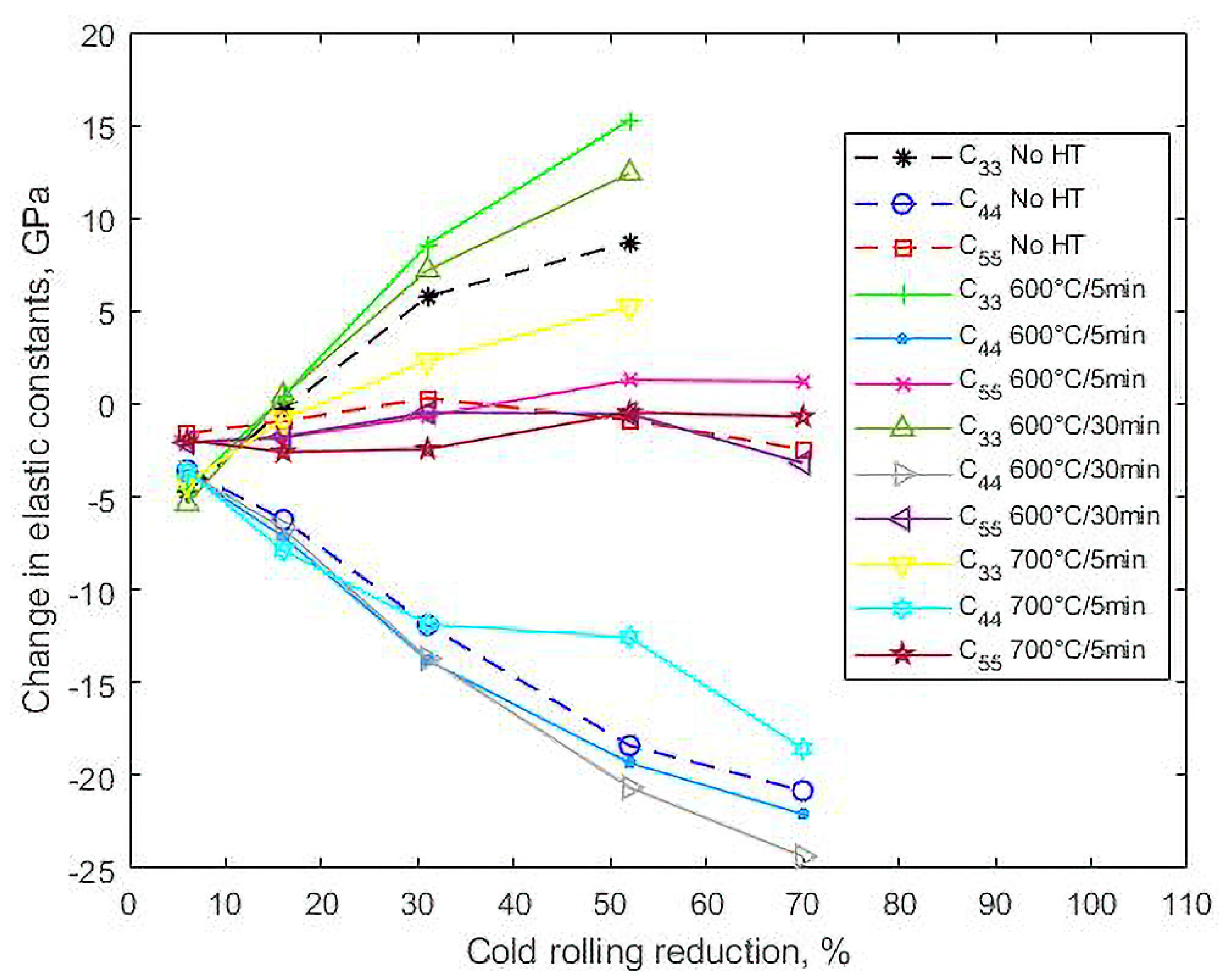

4.2.2. Effect of Annealing on Wave Velocities and Elastic Constants

4.2.3. Effect of Annealing on Poisson’s Ratio and Birefringence

5. Conclusions

- Increasing reduction by cold rolling markedly decreased , had a small effect on and increased , thus increasing the orthotropy, which was reflected in the values of birefringence and the Poisson’s ratio parameter .

- The curve of hardness versus reduction by cold rolling shows a variable slope, which may be related to the deformation mechanisms. This variable slope is also present in the birefringence and curves.

- The effects of the recrystallization annealing temperature and time were reflected in both hardness and the elastic parameters. While the former shows that for medium to high deformation, there was substantial recrystallization at both 600 °C and 700 °C, the latter show that orthotropy was retained after recrystallization.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fonstein, N. Advanced High Strength Sheet Steels; Springer: Berlin/Heidelberg, Germany, 2015. [Google Scholar]

- De Cooman, B.C.; Chin, K.; Kim, J. High Mn TWIP Steels for Automotive Applications. In New Trends and Developments in Automotive System Engineering; InTech: Rijeka, Croatia, 2011. [Google Scholar]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Mater. Sci. Technol. 2011, 23, 707–709. [Google Scholar] [CrossRef]

- Hamada, A.S.; Kisko, A.; Khosravifard, A.; Hassan, M.A.; Karjalainen, L.P.; Porter, D. Ductility and formability of three high-Mn TWIP steels in quasi-static and high-speed tensile and Erichsen tests. Mater. Sci. Eng. A 2018, 712, 255–265. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe-Mn-C alloys. Mater. Sci. Eng. A 2004, 387–389, 158–162. [Google Scholar] [CrossRef]

- Hamada, A.S.; Karjalainen, L.P.; Somani, M.C. The influence of aluminum on hot deformation behavior and tensile properties of high-Mn TWIP steels. Mater. Sci. Eng. A 2007, 467, 114–124. [Google Scholar] [CrossRef]

- Jung, I.-C.; De Cooman, B.C. Temperature dependence of the flow stress of Fe–18Mn–0.6C–xAl twinning-induced plasticity steel. Acta Mater. 2013, 61, 6724–6735. [Google Scholar] [CrossRef]

- De Barbieri, F.; Cerda, F.C.; Pérez-Ipiña, J.; Artigas, A.; Monsalve, A. Temperature dependence of the microstructure and mechanical properties of a twinning-induced plasticity steel. Metals 2018, 8, 262. [Google Scholar] [CrossRef]

- Bordone, M.; Perez-Ipiña, J.; Bolmaro, R.; Artigas, A.; Monsalve, A. Mechanical Properties and Microstructural Aspects of Two High-Manganese Steels with TWIP/TRIP Effects: A Comparative Study. Metals 2021, 11, 24. [Google Scholar] [CrossRef]

- Bracke, L.; Verbeken, K.; Kesten, L. Texture generation and implications in TWIP steels. Scr. Mater. 2012, 66, 1007–1011. [Google Scholar] [CrossRef]

- Gür, C.H.; Tuncer, B.O. Characterization of microstructural phases of steels by sound velocity measurement. Mater. Charact. 2005, 55, 160–166. [Google Scholar] [CrossRef]

- Yu, C.J.; Conway, J.C.; Ruud, C.O.; Kozaczek, K.J. Ultrasonic characterization of the effect of cold work and grain size in copper and 68:32 brass sheets. J. Mater. Sci. 1992, 27, 5174–5180. [Google Scholar] [CrossRef]

- Palanichamy, P.; Joseph, A.; Jayakumar, T.; Raj, B. Ultrasonic velocity measurements for estimation of grain size in austenitic stainless steel. NDT&E Int. 1995, 28, 179–185. [Google Scholar]

- Vasudevan, M.; Palanichamy, P. Characterization of Microstructural Changes During Annealing of Cold Worked Austenitic Stainless Steel Using Ultrasonic Velocity Measurements and Correlation with Mechanical Properties. JMEPEG 2002, 11, 169–179. [Google Scholar] [CrossRef]

- Foster, K.; Fairburn, S.L.; Leisure, R.G.; Kim, S.; Balzar, D.; Alers, G.; Ledbetter, H. Acoustic study of texture in polycrystalline brass. J. Acoust. Soc. Am. 1999, 105, 2663–2668. [Google Scholar] [CrossRef]

- Carvajal, L.; Artigas, A.; Monsalve, A.; Vargas, Y. Acoustic Birefringence and Poisson’s Ratio Determined by Ultrasound: Tools to Follow-Up Deformation by Cold Rolling and Recrystallization. Mater. Res. 2016, 20 (Suppl. 2), 304–310. [Google Scholar] [CrossRef][Green Version]

- Ledbetter, H.; Reed, R. Elastic Properties of Metal and Alloy, I. Iron, Nickel, and Iron-Nickel Alloys. J. Phys. 1973, 2, 531–618. [Google Scholar]

- Haase, C.; Barrales-Mora, L.; Molodov, D.; Gottstein, G. Texture evolution of a cold-rolled Fe-28Mn-0.28C TWIP steel during recrystallization. Mater. Sci. 2013, 753, 213–216. [Google Scholar] [CrossRef]

- Lu, Y.; Molodov, D.; Gottstein, G. Correlation Between Microstructure and Texture Development in a Cold-rolled TWIP Steel. ISIJ Int. 2011, 51, 812–817. [Google Scholar] [CrossRef]

- Duggan, B.; Hatherly, M.; Hutchinson, W.; Wakefield, P. Deformation structures and textures in cold-rolled 70:30 brass. Metal Sci. 1978, 12, 343–351. [Google Scholar] [CrossRef]

- Haase, C.; Barrales-Mora, L.; Roters, F.; Molodov, D.; Gottstein, G. Applying the texture analysis for optimizing thermomechanical treatment of high manganese twinning-induced plasticity steel. Acta Mater. 2014, 80, 327–340. [Google Scholar] [CrossRef]

- El-Danaf, E.; Kalidindi, S.; Doherty, R. Influence of grain size and stacking-fault energy on deformation twinning in fcc metals. Metall. Mater. Trans. 1999, 30, 1223–1233. [Google Scholar] [CrossRef]

- Ferraiuolo, A.; Smith, A.; Sevillano, J.G.; De las Cuevas, F.; Karjalainen, P.; Pratolongo, G.; Gouveia, H.; Rodrigues, M. Metallurgical Design of High-Strength Austenitic Fe-C-Mn Steels with Excellent Formability; Publications Office of the European Union: Luxembourg, 2012. [Google Scholar]

| C (%) | Si (%) | Mn (%) | Al (%) | N (%) |

|---|---|---|---|---|

| 0.51 | 0.296 | 21.47 | 0.0056 | 0.052 |

| Set 1 | Set 2 | Set 3 | |

|---|---|---|---|

| Temperature, °C | 600 | 600 | 700 |

| Time, min | 5 | 30 | 5 |

| Reduction (%) | Wave Velocities (m/s); Elastic Constants (GPa) | ||

|---|---|---|---|

| 0 | 5468.01 ± 0.00 233.81 ± 0.00 | 3065.38 ± 0.00 73.46 ± 0.00 | 3079.42 ± 0.00 74.14 ± 0.00 |

| 6 | 5412.82 ± 5.30 229.12 ± 0.45 | 2989.81 ± 5.77 69.90 ± 0.27 | 3045.63 ± 6.93 72.56 ± 0.33 |

| 16 | 5464.30 ± 6.19 233.49 ± 0.53 | 2932.18 ± 6.25 67.23 ± 0.29 | 3060.16 ± 3.46 73.22 ± 0.17 |

| 31 | 5534.96 ± 3.85 239.6 ± 0.33 | 2805.71 ± 8.33 61.56 ± 0.37 | 3085.42 ± 6.11 74.44 ± 0.30 |

| 52 | 5568.69 ± 13.43 242.5 ± 1.17 | 2654.11 ± 4.58 55.08 ± 0.19 | 3061.00 ± 6.08 73.27 ± 0.29 |

| 70 | * | 2594.37 ± 4.51 52.65 ± 0.18 | 3028.12 ± 4.36 71.70 ± 0.21 |

| Reduction (%) | |||

|---|---|---|---|

| 0 | 0.005 ± 0.000 | 0.271 ± 0.000 | 0.268 ± 0.000 |

| 6 | 0.018 ± 0.000 | 0.280 ± 0.002 | 0.268 ± 0.002 |

| 16 | 0.043 ± 0.002 | 0.298 ± 0.001 | 0.272 ± 0.000 |

| 31 | 0.095 ± 0.002 | 0.327 ± 0.001 | 0.275 ± 0.000 |

| 52 | 0.142 ± 0.001 | 0.353 ± 0.001 | 0.284 ± 0.001 |

| 70 | 0.154 ± 0.002 | * | * |

| Reduction (%) | Wave Velocity (m/s) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 600 °C/5 min | 600 °C/30 min | 700 °C/5 min | |||||||

| 6 | 5414.00 ± 4.24 | 2984.69 ± 8.54 | 3034.69 ± 8.01 | 5405.70 ± 0.99 | 2986.72 ± 3.24 | 3035.71 ± 0.00 | 5418.17 ± 4.00 | 2988.33 ± 3.11 | 3038.17 ± 3.64 |

| 16 | 5473.00 ± 15.55 | 2912.09 ± 10.32 | 3041.28 ± 16.81 | 5473.18 ± 1.66 | 2921,51 ± 3.00 | 3042.38 ± 0.00 | 5458.38 ± 6.18 | 2895.43 ± 2.89 | 3024.77 ± 3.53 |

| 31 | 5567.42 ± 17.55 | 2762.07 ± 4.33 | 3065.13 ± 15.34 | 5551.36 ± 22.12 | 2764.44 ± 16.88 | 3069.53 ± 13.70 | 5495.31 ± 4.68 | 2806.92 ± 18.50 | 3028.11 ± 11.44 |

| 52 | 5643.70 ± 2.55 | 2631.20 ± 11.57 | 3105.79 ± 15.46 | 5611.20 ± 16.80 | 2598.82 ± 2.51 | 3067.90 ± 15.86 | 5531.40 ± 8.71 | 2790.75 ± 4.31 | 3069.52 ± 15.87 |

| 70 | 2563.31 ± 13.55 | 3103.70 ± 4.10 | 2505.94 ± 2.10 | 3012.16 ± 10.23 | 2650.03 ± 27.20 | 3064.53 ± 29.81 | |||

| Reduction (%) | Elastic Constants (GPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 600 °C/5 min | 600 °C/30 min | 700 °C/5 min | |||||||

| 6 | 229.22 ± 0.36 | 69.66 ± 0.40 | 72.02 ± 0.38 | 228.43 ± 0.08 | 69.76 ± 0.15 | 72.07 ± 0.00 | 229.57 ± 0.34 | 69.83 ± 0.15 | 72.18 ± 0.17 |

| 16 | 234.24 ± 1.33 | 66.32 ± 0.47 | 72.33 ± 0.80 | 234.25 ± 0.14 | 66.75 ± 0.14 | 72.38 ± 0.00 | 232.99 ± 0.53 | 65.56 ± 0.13 | 71.55 ± 0.17 |

| 31 | 242.39 ± 1.53 | 59.66 ± 0.19 | 73.47 ± 0.74 | 241.00 ± 1.92 | 59.76 ± 0.73 | 73.68 ± 0.66 | 236.15 ± 0.40 | 61.61 ± 0.81 | 71.71 ± 0.54 |

| 52 | 249.08 ± 0.23 | 54.14 ± 0.48 | 75.43 ± 0.75 | 246.22 ± 1.48 | 52.82 ± 0.10 | 73.60 ± 0.76 | 239.05 ± 0.75 | 60.90 ± 0.19 | 73.68 ± 0.76 |

| 70 | 51.38 ± 0.54 | 75.33 ± 0.20 | 49.11 ± 0.08 | 70.95 ± 0.48 | 54.92 ± 1.13 | 73.45 ± 1.43 | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carvajal, L.; Sosa, M.; Artigas, A.; Luco, N.; Monsalve, A. Ultrasonic Assessment of the Influence of Cold Rolling and Recrystallization Annealing on the Elastic Constants in a TWIP Steel. Materials 2021, 14, 6559. https://doi.org/10.3390/ma14216559

Carvajal L, Sosa M, Artigas A, Luco N, Monsalve A. Ultrasonic Assessment of the Influence of Cold Rolling and Recrystallization Annealing on the Elastic Constants in a TWIP Steel. Materials. 2021; 14(21):6559. https://doi.org/10.3390/ma14216559

Chicago/Turabian StyleCarvajal, Linton, María Sosa, Alfredo Artigas, Nelson Luco, and Alberto Monsalve. 2021. "Ultrasonic Assessment of the Influence of Cold Rolling and Recrystallization Annealing on the Elastic Constants in a TWIP Steel" Materials 14, no. 21: 6559. https://doi.org/10.3390/ma14216559

APA StyleCarvajal, L., Sosa, M., Artigas, A., Luco, N., & Monsalve, A. (2021). Ultrasonic Assessment of the Influence of Cold Rolling and Recrystallization Annealing on the Elastic Constants in a TWIP Steel. Materials, 14(21), 6559. https://doi.org/10.3390/ma14216559