Influence of C and N on Strain-Induced Martensite Formation in Fe-15Cr-7Mn-4Ni-0.5Si Austenitic Steel

Abstract

:1. Introduction

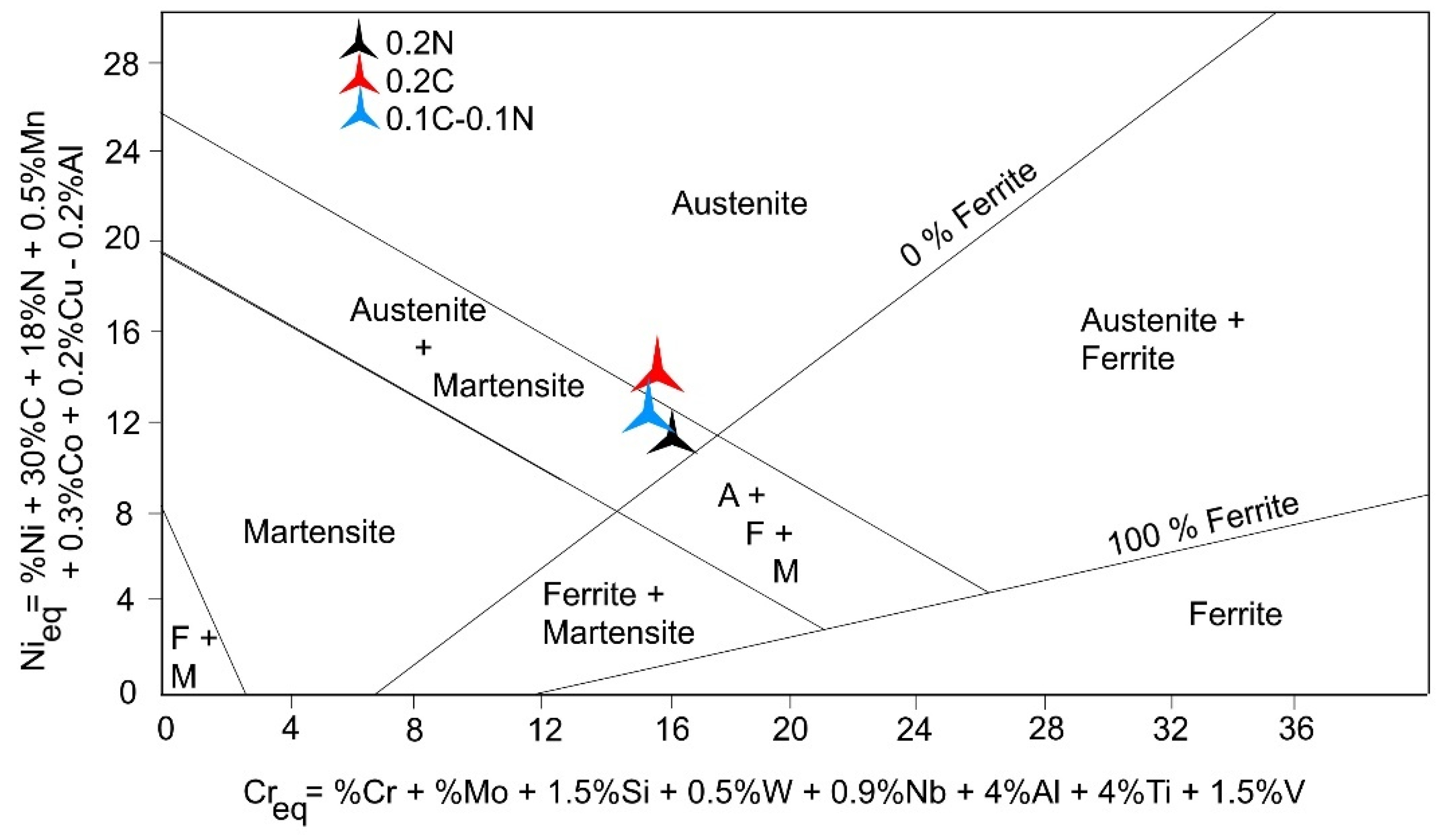

2. Materials and Methods

3. Results

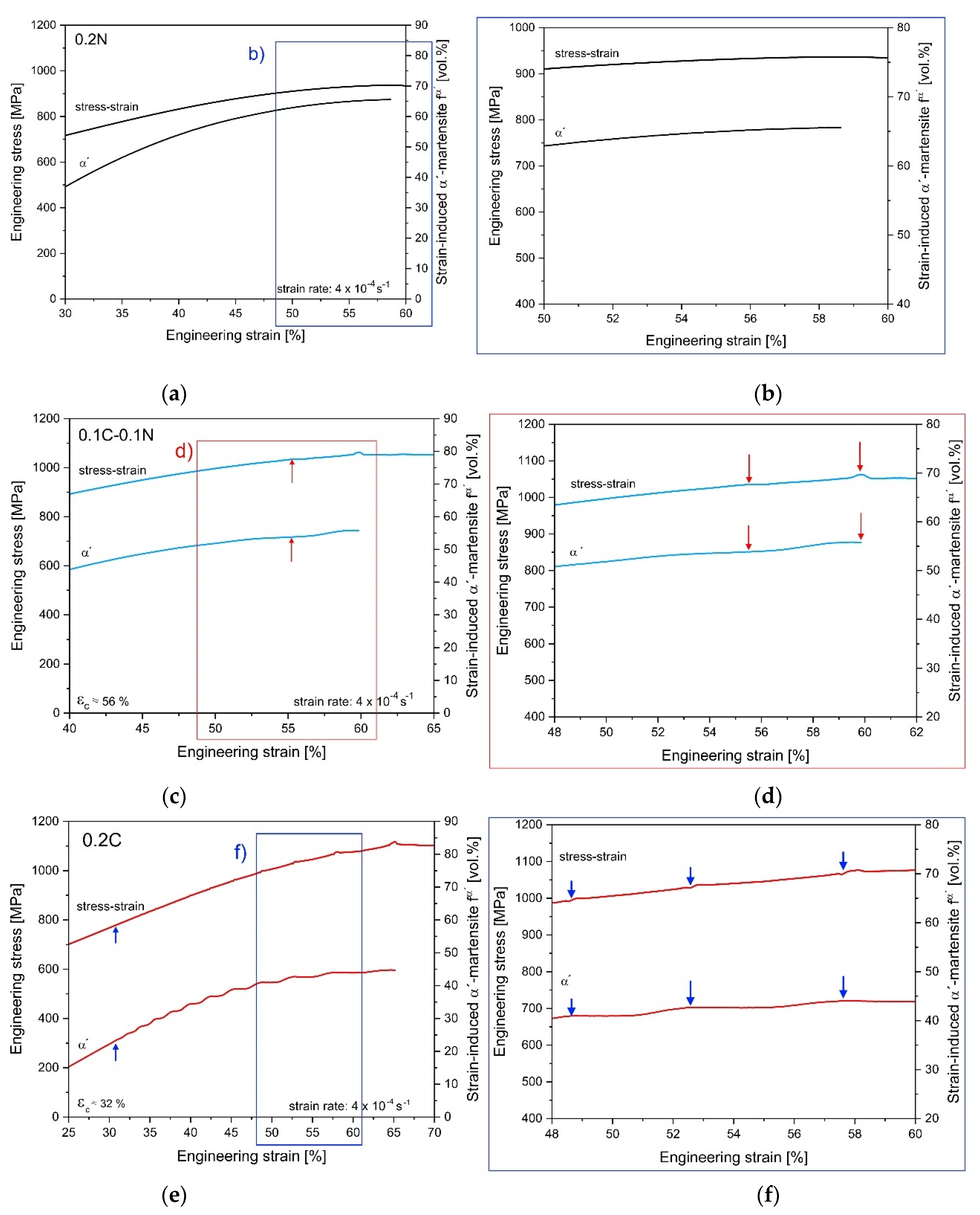

3.1. In Situ Tensile Tests

3.2. Evaluation of the Influence of C and N on Short-Range Ordering and Clustering

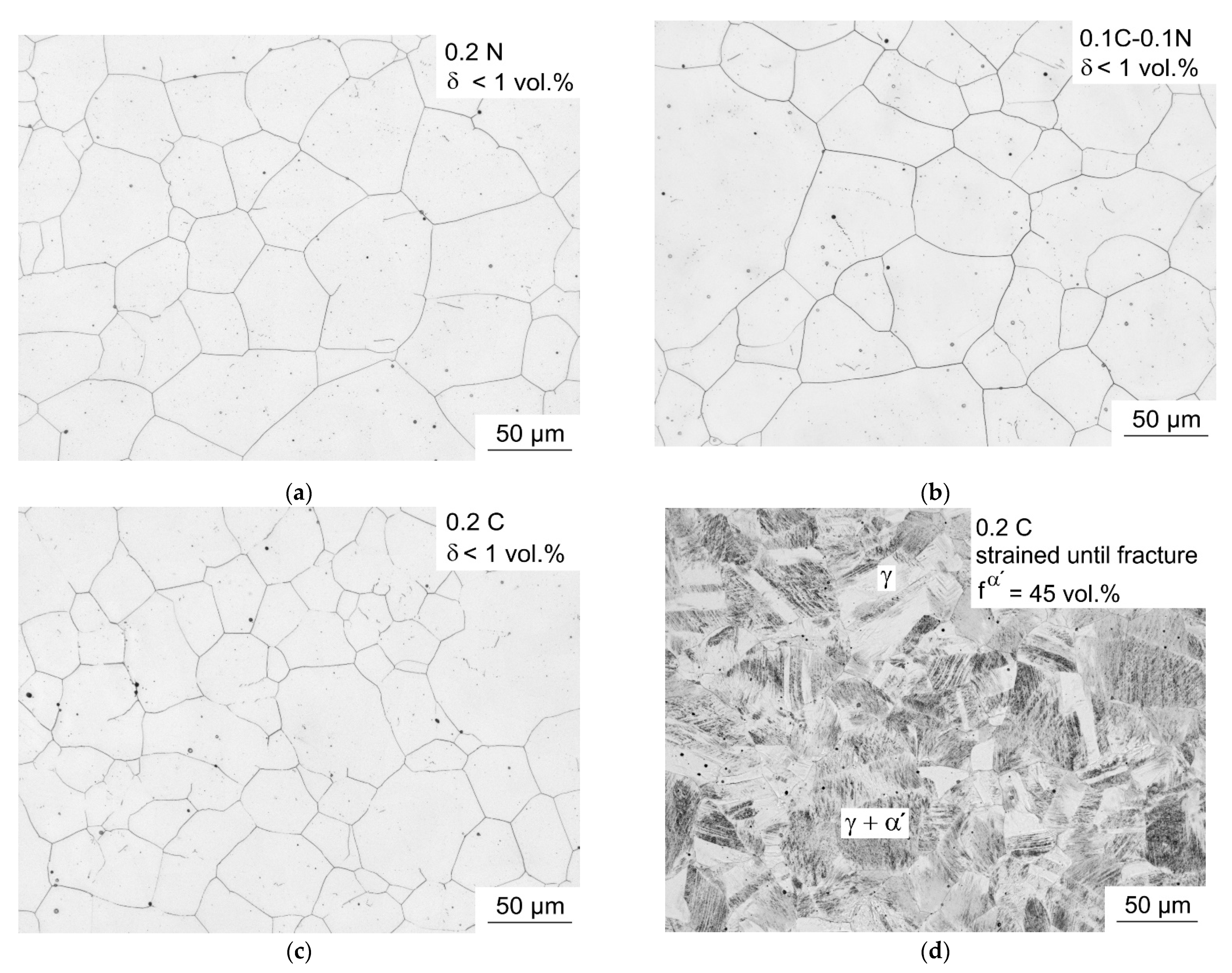

3.3. Average Austenite Grain Size, Microhardness, and Microstructure

4. Discussion

4.1. Strain Hardening and Triggering Stress of the α′-Martensite Formation

4.2. Dynamic Strain Aging

5. Conclusions

- The 0.2C steel achieved the highest ultimate tensile strength (1114 MPa), uniform elongation (63%), and total elongation (68%) in contrast to the other studied steels, despite the lowest formation rate and total volume fraction of strain-induced α′-martensite.

- The highest strain-induced α′-martensite fraction was obtained in steel 0.2N, which showed the lowest UTS and TE values.

- The true triggering stress for the strain-induced α′-martensite formation slightly increased from 583 MPa to 619 MPa with the increasing carbon content. In 0.2N steel, martensite formation started slightly earlier, indicating the lower austenite stability compared with the other steels.

- The different contents of C and N influence the potential of short-range ordering and clustering of atoms. The semi-empirical parameter, the TOI value, shows a favorable Cr-N short-range order in 0.2N steel, which affects SFE and dislocation glide. With increasing C content, the hardening increases and the strain-induced α′-martensite fraction decreases. For the 0.2C steel, the lowest strain-induced martensite formation (45 vol.%) and DSA phenomena were observed during tensile deformation.

- The in situ magnetic measurement equipment is capable of detecting DSA phenomena in the steels. The serrations in the stress–strain curve caused by inhomogeneous plastic flow were also evident in the martensite formation curve.

- DSA occurred in the 0.2C steel and 0.1C-0.1N steel. With the increasing C content, the critical strain for triggering DSA decreased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bogers, A.J.; Burgers, W.G. Partial dislocations on the {110} planes in the B.C.C. lattice and the transition of the F.C.C. into the B.C.C. lattice. Acta Metall. 1964, 12, 255–261. [Google Scholar] [CrossRef]

- Zhang, S.Y.; Compagnon, E.; Godin, B.; Korsunsky, A.M. Investigation of Martensite Transformation in 316L Stainless Steel. Mater. Today Proc. 2015, 2, S251–S260. [Google Scholar] [CrossRef]

- Kovalev, A.; Wendler, M.; Jahn, A.; Weiß, A.; Biermann, H. Thermodynamic-Mechanical Modeling of Strain-Induced α′- Martensite Formation in Austenitic Cr-Mn-Ni As-Cast Steel. Adv. Eng. Mater. 2013, 15, 609–617. [Google Scholar] [CrossRef]

- Saenarjhan, N.; Kang, J.H.; Kim, S.J. Effects of carbon and nitrogen on austenite stability and tensile deformation behavior of 15Cr-15Mn-4Ni based austenitic stainless steels. Mater. Sci. Eng. A 2019, 742, 608–616. [Google Scholar] [CrossRef]

- Breedis, J.F. Influence of dislocation substructure on the martensitic transformation in stainless steel. Acta Metall. 1965, 13, 239–250. [Google Scholar] [CrossRef]

- Lee, W.S.; Lin, C.F. Morphologies and characteristics of impact-induced martensite in 304L stainless steel. Scr. Mater. 2000, 43, 777–782. [Google Scholar] [CrossRef]

- Irvine, K.J.; Llewellyn, D.T.; Pickering, F.B. High-strength austenitic stainless steels. J. Iron Steel Inst. 1961, 199, 153–175. [Google Scholar]

- Beneke, R.; Sandenbergh, R.F. The influence of nitrogen and molybdenum on the sensitization properties of low-carbon austenitic stainless steels. Corros. Sci. 1989, 29, 543–555. [Google Scholar] [CrossRef]

- Berns, H. Stainless steels suited for solution nitriding. Materialwissenschaft und Werkstofftechnik 2002, 33, 5–11. [Google Scholar] [CrossRef]

- Gavriljuk, V.G.; Shanina, B.D.; Berns, H. On the correlation between electron structure and short range atomic order in iron-based alloys. Acta Mater. 2000, 48, 3879–3893. [Google Scholar] [CrossRef]

- Gavriljuk, V.; Rawers, J.; Shanina, B.; Berns, H. Nitrogen and carbon in austenitic and martensitic steels: Atomic interactions and structural stability. Mater. Sci. Forum 2003, 426–432, 943–950. [Google Scholar] [CrossRef]

- Berns, H.; Gavriljuk, V.; Shanina, B. Intensive interstitial strengthening of stainless steels. Adv. Eng. Mater. 2008, 10, 1083–1093. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Kwon, O.; Chin, K.G. State-of-the-knowledge on TWIP steel. Mater. Sci. Technol. 2012, 28, 513–527. [Google Scholar] [CrossRef]

- Dierke, H.; Fischer, M.; Tutsch, R.; Casarotto, L. Optisches extensometer zur verfolgung propagierender verformungsbänder. Technisches Messen 2011, 78, 211–217. [Google Scholar] [CrossRef]

- Kubin, L.P.; Estrin, Y. Evolution of Dislocation Densities and Portevin-Le Chatelier Effect. Acta. Met. Mater. 1990, 38, 697–708. [Google Scholar] [CrossRef]

- Chihab, K.; Estrin, Y.; Kubin, L.P.; Vergnol, J. The Kinetics of the Portevin-Le Chatelier Bands in an Al-5at%Mg Alloy. Scr. Metall. 1987, 28, 203–208. [Google Scholar] [CrossRef]

- Lee, S.J.; Kim, J.; Kane, S.N.; De Cooman, B.C. On the origin of dynamic strain aging in twinning-induced plasticity steels. Acta Mater. 2011, 59, 6809–6819. [Google Scholar] [CrossRef]

- Oda, K.; Kondo, N. X-ray Absorption Fine Structure Analysis of Interstitial (C, N)-Substitutional (Cr) complexes in Austenitic stainless steels. ISIJ Int. 1990, 30, 625–631. [Google Scholar] [CrossRef]

- Sevsek, S.; Bleck, W. Ab initio-based modelling of the yield strength in high-manganese steels. Metals 2018, 8, 34. [Google Scholar] [CrossRef] [Green Version]

- De Cooman, B.C. High Mn TWIP steel and medium Mn steel. In Automotive Steels: Design, Metallurgy, Processing and Applications; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; pp. 317–385. ISBN 9780081006535. [Google Scholar]

- Karlsen, W.; Ivanchenko, M.; Ehrnstén, U.; Yagodzinskyy, Y.; Hänninen, H. Microstructural manifestation of dynamic strain aging in AISI 316 stainless steel. J. Nucl. Mater. 2009, 395, 156–161. [Google Scholar] [CrossRef]

- Ehrnstén, U.; Toivonen, A.; Ivanchenko, M.; Nevdacha, V.; Yagozinskyy, Y.; Hänninen, H. Dynamic strain ageing of deformed nitrogen-alloyed AISI 316 stainless steels. In Proceedings of the EUROCORR 2004: Long Term Prediction and Modeling of Corrosion, Nice, France, 12–16 September 2004; pp. 103–118. [Google Scholar]

- Christopher, J.; Choudhary, B.K. Kinetics of Uniaxial Tensile Flow and Work Hardening Behavior of Type 316L(N) Austenitic Stainless Steel in the Framework of Two-Internal-Variable Approach. Metall. Mater. Trans. A 2015, 46, 674–687. [Google Scholar] [CrossRef]

- Hänninen, H.; Seifert, H.-P.; Yagodzinskyy, Y.; Ehrstén, U.; Tarasenko, O.; Aaltonen, P. Effect of dynmaic strain aging on environment-assisted cracking of low alloy pressure vessel and piping steels. In Proceedings of the VTT Symposium (Valtion Teknillinen Tutkimuskeskus); Solin, J., Ed.; Technical Research Center of Finland: Espoo, Finland, 2003; pp. 199–221. [Google Scholar]

- Cunningham, S. Effect of Substitutional Elements on Dynamic Strain Aging in Steel. Ph.D. Thesis, McGill University, Montréal, QC, Canada, 1999. [Google Scholar]

- Dai, Q.X.; Wang, A.D.; Cheng, X.N. Stacking fault energy of cryogenic austenitic steels. J. Iron Steel Res. 2002, 14, 34–37. [Google Scholar] [CrossRef]

- Wendler, M.; Hauser, M.; Fabrichnaya, O.; Krüger, L.; Weiß, A.; Mola, J. Thermal and deformation-induced phase transformation behavior of Fe-15Cr-3Mn-3Ni-0.1N-(0.05-0.25)C austenitic and austenitic-martensitic cast stainless steels. Mater. Sci. Eng. A 2015, 645, 28–39. [Google Scholar] [CrossRef]

- Wendler, M.; Reichel, B.; Weiß, A.; Krüger, L.; Mola, J. Influence of Carbon on the Microstructure and Mechnical Properties of Cast Austenitic Fe-19Cr-4Ni-3Mn-0.15N Steels. In Proceedings of the 12th International Conference on High Nitrogen Steels, Hamburg, Germany, 16–19 September 2014; pp. 154–161. [Google Scholar]

- Hauser, M.; Wendler, M.; Chowdhury, S.G.; Weiß, A.; Mola, J. Quantification of deformation induced α′-martensite in Fe-19Cr-3Mn-4Ni-0.15C- 0.15N austenitic steel by in situ magnetic measurements. Mater. Sci. Technol. 2015, 31, 1473–1478. [Google Scholar] [CrossRef]

- Hauser, M.; Wendler, M.; Mola, J.; Fabrichnaya, O.; Volkova, O.; Weiß, A. Thermodynamic-Mechanical Modeling of Metastable High Alloy Austenitic CrMnNi Steels. In Austenitic TRIP/TWIP Steels and Steel-Zirconia Composites; Biermann, H., Aneziris, C.G., Eds.; Springer International Publishing: Cham, Switzerland, 2020; Volume 298, pp. 651–678. ISBN 9783030426033. [Google Scholar]

- Rodriguez, P. Serrated plastic flow. Bull. Mater. Sci. 1984, 6, 653–663. [Google Scholar] [CrossRef]

- De Almeida, L.H.; Le May, I.; Emygdio, P.R.O. Mechanistic Modeling of Dynamic Strain Aging in Austenitic Stainless Steels. Mater. Charact. 1998, 41, 137–150. [Google Scholar] [CrossRef]

- Kim, S.J.; Lee, T.H.; Oh, C.S. Effect of Nitrogen on the Deformation Behaviour of High-Nitrogen Austenitic Stainless Steels. Steel Res. Int. 2009, 80, 467–472. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Mosecker, L.; Schwedt, A.; Bleck, W. Characterization and Prediction of Flow Behavior in High-Manganese Twinning Induced Plasticity Steels: Part I. Mechanism Maps and Work-Hardening Behavior. Metall. Mater. Trans. A 2012, 43, 1688–1704. [Google Scholar] [CrossRef]

- Mosecker, L.; Pierce, D.T.; Schwedt, A.; Beighmohamadi, M.; Mayer, J.; Bleck, W.; Wittig, J.E. Temperature effect on deformation mechanisms and mechanical properties of a high manganese C+N alloyed austenitic stainless steel. Mater. Sci. Eng. A 2015, 642, 71–83. [Google Scholar] [CrossRef]

- Pranke, K.; Wendler, M.; Weidner, A.; Guk, S.; Weiß, A.; Kawalla, R. Formability of strong metastable Fe-15Cr-3Mn-3Ni-0.2C-0.1N austenitic TRIP/(TWIP) steel—A comparison of different base materials. J. Alloy. Compd. 2015, 648, 783–793. [Google Scholar] [CrossRef]

- Gussev, M.N.; Leonard, K.J. In situ SEM-EBSD analysis of plastic deformation mechanisms in neutron-irradiated austenitic steel. J. Nucl. Mater. 2019, 519, 45–56. [Google Scholar] [CrossRef]

- Humbert, M.; Petit, B.; Bolle, B.; Gey, N. Analysis of the γ-ε-α′ variant selection induced by 10% plastic deformation in 304 stainless steel at −60 °C. Mater. Sci. Eng. A 2007, 454–455, 508–517. [Google Scholar] [CrossRef]

- Talonen, J.; Nenonen, P.; Pape, G.; Hänninen, H. Effect of Strain Rate on the Strain-Induced γ → α′-Martensite Transformation and Mechanical Properties of Austenitic Stainless Steels. Metall. Mater. Trans. A 2005, 36, 421–432. [Google Scholar] [CrossRef]

- Perdahcioǧlu, E.S.; Geijselaers, H.J.M.; Groen, M. Influence of plastic strain on deformation-induced martensitic transformations. Scr. Mater. 2008, 58, 947–950. [Google Scholar] [CrossRef]

- Perdahcioǧlu, E.S.; Geijselaers, H.J.M. A macroscopic model to simulate the mechanically induced martensitic transformation in metastable austenitic stainless steels. Acta Mater. 2012, 60, 4409–4419. [Google Scholar] [CrossRef]

- Olson, G.B.; Azrin, M. Transformation Behavior of TRIP Steels. Metall. Trans. A 1978, 9, 713–721. [Google Scholar] [CrossRef]

- Olson, G.B.; Cohen, M. Stress-Assisted Isothermal Martensitic Transformation: Application to TRIP Steels. Metall. Trans. A 1982, 13, 1907–1914. [Google Scholar] [CrossRef]

- Hauser, M.; Wendler, M.; Weiß, A.; Mola, J. Quantification of deformation-induced α′-martensite content in Fe-19Cr-3Mn-4Ni-0.15C-0.17N austenitic stainless steel by in-situ magnetic measurements. In Proceedings of the 8th European Stainless Steel and Duplex Stainless Steel Conference, Graz, Austria, 28–30 April 2015; pp. 19–26. [Google Scholar]

- Alsultan, S.; Quitzke, C.; Cheng, Z.; Krüger, L.; Volkova, O.; Wendler, M. Strain-Induced Martensite Formation and Mechanical Properties of Fe-19Cr-4Ni-3Mn-0.15N-0.15C Austenitic Stainless Steel at Cryogenic Temperature. Steel Res. Int. 2021, 92, 2000611. [Google Scholar] [CrossRef]

- Quitzke, C.; Schröder, C.; Ullrich, C.; Mandel, M.; Krüger, L.; Volkova, O.; Wendler, M. Evaluation of strain-induced martensite formation and mechanical properties in N-alloyed austenitic stainless steels by in situ tensile tests. Mater. Sci. Eng. A 2021, 808, 140930. [Google Scholar] [CrossRef]

- Talonen, J. Effect of Strain-Induced α′-Martensite Transformation on Mechanical Properties of Metastable Austenitic Stainless Steels. Ph.D. Thesis, Helsinki University of Technology, Helsinki, Finland, 2007. [Google Scholar]

- Talonen, J.; Hänninen, H. Damping properties of austenitic stainless steels containing strain-induced martensite. Metall. Mater. Trans. A 2004, 35, 2401–2406. [Google Scholar] [CrossRef]

- Wittig, J.E.; Pozuelo, M.; Jiménez, J.A.; Frommeyer, G. Temperature Dependent Deformation Mechanisms of a High Nitrogen-Manganese Austenitic Stainless steel. Steel Res. Int. 2009, 80, 66–70. [Google Scholar] [CrossRef]

- Martin, S.; Wolf, S.; Martin, U.; Krüger, L.; Rafaja, D. Deformation Mechanisms in Austenitic TRIP/TWIP Steel as a Function of Temperature. Metall. Mater. Trans. A 2014, 47, 49–58. [Google Scholar] [CrossRef] [Green Version]

- Naraghi, R.; Hedström, P.; Borgenstam, A. Spontaneous and deformation-induced martensite in austenitic stainless steels with different stability. Steel Res. Int. 2011, 82, 337–345. [Google Scholar] [CrossRef]

- Martin, S.; Wolf, S.; Decker, S.; Krüger, L.; Martin, U. Deformation Bands in High-Alloy Austenitic 16Cr6Mn6Ni TRIP Steel: Phase Transformation and Its Consequences on Strain Hardening at Room Temperature. Steel Res. Int. 2015, 86, 1187–1196. [Google Scholar] [CrossRef]

- Gey, N.; Petit, B.; Humbert, M. Electron Backscattered Diffraction Study of ε/α′ Martensitic Variants Induced by Plastic Deformation in 304 Stainless Steel. Metall. Mater. Trans. A 2005, 36, 3291–3299. [Google Scholar] [CrossRef]

- Fang, X.F.; Dahl, W. Strain hardening and transformation mechanism of deformation-induced martensite transformation in metastable austenitic stainless steels. Mater. Sci. Eng. A 1991, 141, 189–198. [Google Scholar] [CrossRef]

- Hedström, P.; Lienert, U.; Almer, J.; Odén, M. Stepwise transformation behavior of the strain-induced martensitic transformation in a metastable stainless steel. Scr. Mater. 2007, 56, 213–216. [Google Scholar] [CrossRef]

- Staudhammer, K.P.; Murr, L.E.; Hecker, S.S. Nucleation and evolution of strain-induced martensitic (b.c.c.) embryos and substructure in stainless steel: A transmission electron microscope study. Acta Metall. 1983, 31, 267–274. [Google Scholar] [CrossRef]

- Masumura, T.; Nakada, N.; Tsuchiyama, T.; Takaki, S.; Koyano, T.; Adachi, K. The difference in thermal and mechanical stabilities of austenite between carbon- and nitrogen-added metastable austenitic stainless steels. Acta Mater. 2015, 84, 330–338. [Google Scholar] [CrossRef]

- Gerold, V.; Karnthaler, H.P. On the origin of planar slip in f.c.c. alloys. Acta Metall. 1989, 37, 2177–2183. [Google Scholar] [CrossRef]

- Zhou, X.W.; Grujicic, M. Thermodynamic analysis of the short range order strengthening in Fe-Ni-Cr-N austenite. Calphad 1996, 20, 257–272. [Google Scholar] [CrossRef]

- Gavriljuk, V.G.; Berns, H. High Nitrogen Steels; Springer: Berlin/Heidelberg, Germany, 1999; ISBN 9974-42-052-0. [Google Scholar]

- Terazawa, Y.; Ando, T.; Tsuchiyama, T.; Takaki, S. Relationship between work hardening behaviour and deformation structure in Ni-free high nitrogen austenitic stainless steels. Steel Res. Int. 2009, 80, 473–476. [Google Scholar] [CrossRef]

- Simmons, J.W. Overview: High-nitrogen alloying of stainless steels. Mater. Sci. Eng. A 1996, 207, 159–169. [Google Scholar] [CrossRef]

- Chen, L.; Kim, H.S.; Kim, S.K.; De Cooman, B.C. Localized deformation due to Portevin-LeChatelier effect in 18Mn-0.6C TWIP austenitic steel. ISIJ Int. 2007, 47, 1804–1812. [Google Scholar] [CrossRef] [Green Version]

- Field, D.M.; Van Aken, D.C. Dynamic Strain Aging Phenomena and Tensile Response of Medium-Mn TRIP Steel. Metall. Mater. Trans. A 2018, 49, 1152–1166. [Google Scholar] [CrossRef] [Green Version]

- Kubin, L.P.; Estrin, Y. Dynamic strain ageing and the mechanical response of alloys. J. Phys. III 1991, 1, 929–943. [Google Scholar] [CrossRef]

- Lee, S.; Kim, J.; Lee, S.J.; De Cooman, B.C. Effect of nitrogen on the critical strain for dynamic strain aging in high-manganese twinning-induced plasticity steel. Scr. Mater. 2011, 65, 528–531. [Google Scholar] [CrossRef]

- McCormick, P.G. Theory of flow localisation due to dynamic strain ageing. Acta Metall. 1988, 36, 3061–3067. [Google Scholar] [CrossRef]

- Müller, A.; Segel, C.; Linderov, M.; Vinogradov, A.; Weidner, A.; Biermann, H. The Portevin–Le Châtelier Effect in a Metastable Austenitic Stainless Steel. Metall. Mater. Trans. A 2016, 47, 59–74. [Google Scholar] [CrossRef]

- Ganesan, V.; Laha, K.; Nandagopal, M.; Parameswaran, P.; Mathew, M.D. Effect of nitrogen content on dynamic strain ageing behaviour of type 316LN austenitic stainless steel during tensile deformation. Mater. High Temp. 2014, 31, 162–170. [Google Scholar] [CrossRef]

- Kim, D.W.; Ryu, W.S.; Hong, J.H.; Choi, S.K. Effect of nitrogen on the dynamic strain ageing behaviour of type 316L stainless steel. J. Mater. Sci. 1998, 33, 675–679. [Google Scholar] [CrossRef]

- Song, W.; Ingendahl, T.; Bleck, W. Control of strain hardening behavior in high-mn austenitic steels. Acta Metall. Sin. Engl. Lett. 2014, 27, 546–556. [Google Scholar] [CrossRef]

- Ivanchenko, M. Dynamic Strain Aging of Austenitic Stainless Steels and Ni Base Alloys. Ph.D. Thesis, Aalto University, Espoo, Finland, 2010. [Google Scholar]

- Ogawa, T.; Koyama, M.; Tasan, C.C.; Tsuzaki, K.; Noguchi, H. Effects of martensitic transformability and dynamic strain age hardenability on plasticity in metastable austenitic steels containing carbon. J. Mater. Sci. 2017, 52, 7868–7882. [Google Scholar] [CrossRef]

- Li, Y.P.; Yu, J.S.; Kurosu, S.; Koizumi, Y.; Matsumoto, H.; Chiba, A. Role of nitrogen addition in stabilizing the γ phase of Biomedical Co-29Cr-6Mo alloy. Mater. Chem. Phys. 2012, 133, 29–32. [Google Scholar] [CrossRef]

- Pierce, D.T.; Jiménez, J.A.; Bentley, J.; Raabe, D.; Oskay, C.; Wittig, J.E. The influence of manganese content on the stacking fault and austenite/ε-martensite interfacial energies in Fe-Mn-(Al-Si) steels investigated by experiment and theory. Acta Mater. 2014, 68, 238–253. [Google Scholar] [CrossRef]

- Koyama, M.; Sawaguchi, T.; Lee, T.; Lee, C.S.; Tsuzaki, K. Work hardening associated with ε-martensitic transformation, deformation twinning and dynamic strain aging in Fe-17Mn-0.6C and Fe-17Mn-0.8C TWIP steels. Mater. Sci. Eng. A 2011, 528, 7310–7316. [Google Scholar] [CrossRef]

| Alloy | C | N | Cr | Ni | Mn | Si | Fe + Others | SFE at RT [mJ/m²] |

|---|---|---|---|---|---|---|---|---|

| 0.2N | 0.01 | 0.22 | 15.0 | 4.0 | 7.1 | 0.5 | bal. | 20 |

| 0.1C-0.1N | 0.10 | 0.12 | 14.7 | 4.1 | 6.9 | 0.5 | bal. | 18 |

| 0.2C | 0.20 | 0.01 | 14.9 | 4.2 | 7.1 | 0.5 | bal. | 17 |

| Alloy | TOI (-) C/Mn | TOI (-) N/Cr |

|---|---|---|

| 0.2N | 0.006 | 0.05 |

| 0.1C-0.1N | 0.07 | 0.03 |

| 0.2C | 0.13 | 0.002 |

| Alloy | True Triggering Stress [MPa] | True Triggering Strain [–] | Strain-Induced α′-Martensite [vol.%] |

|---|---|---|---|

| 0.2N | 583 | 0.10 | 2.0 |

| 0.1C-0.1N | 615 | 0.12 | 3.0 |

| 0.2C | 619 | 0.12 | 3.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quitzke, C.; Huang, Q.; Biermann, H.; Volkova, O.; Wendler, M. Influence of C and N on Strain-Induced Martensite Formation in Fe-15Cr-7Mn-4Ni-0.5Si Austenitic Steel. Materials 2021, 14, 6502. https://doi.org/10.3390/ma14216502

Quitzke C, Huang Q, Biermann H, Volkova O, Wendler M. Influence of C and N on Strain-Induced Martensite Formation in Fe-15Cr-7Mn-4Ni-0.5Si Austenitic Steel. Materials. 2021; 14(21):6502. https://doi.org/10.3390/ma14216502

Chicago/Turabian StyleQuitzke, Caroline, Qiuliang Huang, Horst Biermann, Olena Volkova, and Marco Wendler. 2021. "Influence of C and N on Strain-Induced Martensite Formation in Fe-15Cr-7Mn-4Ni-0.5Si Austenitic Steel" Materials 14, no. 21: 6502. https://doi.org/10.3390/ma14216502

APA StyleQuitzke, C., Huang, Q., Biermann, H., Volkova, O., & Wendler, M. (2021). Influence of C and N on Strain-Induced Martensite Formation in Fe-15Cr-7Mn-4Ni-0.5Si Austenitic Steel. Materials, 14(21), 6502. https://doi.org/10.3390/ma14216502