Tensile Properties and Deformation of AISI 316L Additively Manufactured with Various Energy Densities

Abstract

:1. Introduction

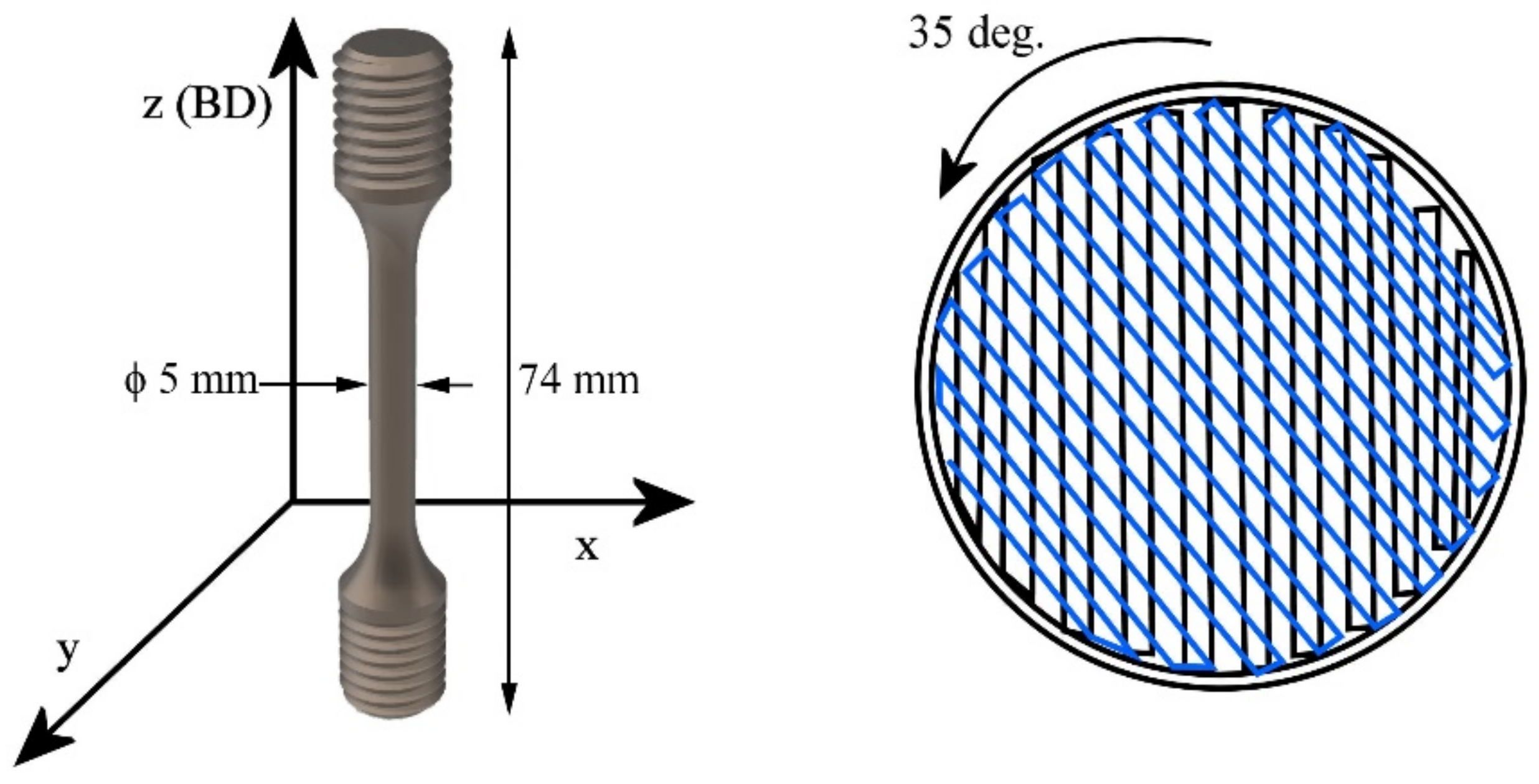

2. Materials and Methods

3. Results and Discussion

3.1. Additively Manufactured and Wrought Microstructures

3.2. Density and Defect Structure

3.3. Mechanical Properties

3.4. Strained Microstructures

3.5. Fracture Behavior

3.6. Associated Failure Micro-Mechanisms

4. Conclusions

- Microstructures and density of the additively manufactured AISI 316L varied according to the used VED. Increase in VED caused substructure coarsening and columnar growth but also an increase in achieved density. The type and distributions of defects observed in the studied structures varied from narrow lack-of-fusion defects to large voids in the low-VED structure, whereas the distribution shifted towards smaller cross-sectional sizes in the higher VED structures. The largest defect size observed was 109, 65, and 21 µm for low-, medium-, and high-VED specimen, respectively.

- The value of VED had no influence on the yield and tensile strength within the applied parameter window, but the elongation was increased with increases in the VED, with the high-VED specimen being almost equal to that of the wrought steel. Decreasing the strain rate enhanced the elongation of both the additively manufactured and wrought structures. All samples showed ductile fracture behavior, but the necking was almost inhibited in the low-VED structure, obviously affected by the high defect density.

- Twinning was found to be an additional deformation mechanism in the last stages of plastic straining in the medium- and high-VED structures as well as in the wrought material, regardless of the strain rate, and it was also found to be orientation-dependent. In the low-VED specimen, twinning was only found locally near the relatively large defects. Presumably, this was a result of low accumulated strain in the matrix before fracture.

- Some ε-martensite was found to form adjacent to the twins in the high-VED structure during necking. This indicates that the effective stacking fault energy of the steel is reduced during straining to become low enough for the formation of ε-martensite and twins, though only in the necking stage in the present steel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, Opportunities, Considerations, and Constraints. CIRP Ann.-Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef] [Green Version]

- Mäntyjärvi, K.; Iso-Junno, T.; Niemi, H.; Mäkikangas, J. Design for Additive Manufacturing in Extended DFMA Process. Key Eng. Mater. 2018, 786, 342–347. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of Selective Laser Melting: Materials and Applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Birnbaum, A.J.; Steuben, J.C.; Barrick, E.J.; Iliopoulos, A.P.; Michopoulos, J.G. Intrinsic Strain Aging, Σ3 Boundaries, and Origins of Cellular Substructure in Additively Manufactured 316L. Addit. Manuf. 2019, 29, 100784. [Google Scholar] [CrossRef]

- Cui, D.; Wikman, S.; Liu, L.; Zhong, Y.; Shen, Z. Intragranular Cellular Segregation Network Structure Strengthening 316L Stainless Steel Prepared by Selective Laser Melting. J. Nucl. Mater. 2015, 470, 170–178. [Google Scholar] [CrossRef]

- Choo, H.; Sham, K.L.; Bohling, J.; Ngo, A.; Xiao, X.; Ren, Y.; Depond, P.J.; Matthews, M.J.; Garlea, E. Effect of Laser Power on Defect, Texture, and Microstructure of a Laser Powder Bed Fusion Processed 316L Stainless Steel. Mater. Des. 2019, 164. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. (Engl. Ed.) 2017, 30, 515–527. [Google Scholar] [CrossRef] [Green Version]

- King, W.E.; Barth, H.D.; Castillo, V.M.; Gallegos, G.F.; Gibbs, J.W.; Hahn, D.E.; Kamath, C.; Rubenchik, A.M. Observation of Keyhole-Mode Laser Melting in Laser Powder-Bed Fusion Additive Manufacturing. J. Mater. Process. Technol. 2014, 214, 2915–2925. [Google Scholar] [CrossRef]

- Li, R.; Liu, J.; Shi, Y.; Wang, L.; Jiang, W. Balling Behavior of Stainless Steel and Nickel Powder during Selective Laser Melting Process. Int. J. Adv. Manuf. Technol. 2012, 59, 1025–1035. [Google Scholar] [CrossRef]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the Effect of Process Parameters on Microstructural and Physical Properties of 316L Stainless Steel Parts by Selective Laser Melting. Int. J. Adv. Manuf. Technol. 2014, 76, 869–879. [Google Scholar] [CrossRef] [Green Version]

- Sun, Z.; Tan, X.; Tor, S.B.; Yeong, W.Y. Selective Laser Melting of Stainless Steel 316L with Low Porosity and High Build Rates. Mater. Des. 2016, 104, 197–204. [Google Scholar] [CrossRef]

- Seifi, M.; Salem, A.; Beuth, J.; Harrysson, O.; Lewandowski, J.J. Overview of Materials Qualification Needs for Metal Additive Manufacturing. JOM 2016, 68, 747–764. [Google Scholar] [CrossRef] [Green Version]

- Im, Y.D.; Kim, K.H.; Jung, K.H.; Lee, Y.K.; Song, K.H. Anisotropic Mechanical Behavior of Additive Manufactured AISI 316L Steel. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2019, 50, 2014–2021. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and Heterogeneity of Microstructure and Mechanical Properties in Metal Additive Manufacturing: A Critical Review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Saeidi, K.; Gao, X.; Zhong, Y.; Shen, Z.J. Hardened Austenite Steel with Columnar Sub-Grain Structure Formed by Laser Melting. Mater. Sci. Eng. A 2015, 625, 221–229. [Google Scholar] [CrossRef]

- Barkia, B.; Aubry, P.; Haghi-Ashtiani, P.; Auger, T.; Gosmain, L.; Schuster, F.; Maskrot, H. On the Origin of the High Tensile Strength and Ductility of Additively Manufactured 316L Stainless Steel: Multiscale Investigation. J. Mater. Sci. Technol. 2020, 41, 209–218. [Google Scholar] [CrossRef]

- Chaubey, A.K.; Scudino, S.; Salman, O.O.; Gammer, C.; Eckert, J. Effect of Heat Treatment on Microstructure and Mechanical Properties of 316L Steel Synthesized by Selective Laser Melting. Mater. Sci. Eng. A 2019, 748, 205–212. [Google Scholar] [CrossRef]

- Pickering, F.B. Physical Metallurgical Development of Stainless Steels; Stainless Steels 84; Institute of Metals: London, UK, 1984; ISBN 0-904357-68-6. [Google Scholar]

- Pham, M.S.; Dovgyy, B.; Hooper, P.A. Twinning Induced Plasticity in Austenitic Stainless Steel 316L Made by Additive Manufacturing. Mater. Sci. Eng. A 2017, 704, 102–111. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Mechanical Behavior of Selective Laser Melted 316L Stainless Steel. Mater. Sci. Eng. A 2017, 696, 113–121. [Google Scholar] [CrossRef]

- Ronneberg, T.; Davies, C.M.; Hooper, P.A. Revealing Relationships between Porosity, Microstructure and Mechanical Properties of Laser Powder Bed Fusion 316L Stainless Steel through Heat Treatment. Mater. Des. 2020, 189, 108481. [Google Scholar] [CrossRef]

- Röttger, A.; Boes, J.; Theisen, W.; Thiele, M.; Esen, C.; Edelmann, A.; Hellmann, R. Microstructure and Mechanical Properties of 316L Austenitic Stainless Steel Processed by Different SLM Devices. Int. J. Adv. Manuf. Technol. 2020, 108, 769–783. [Google Scholar] [CrossRef]

- Wang, X.; Muñiz-Lerma, J.A.; Attarian Shandiz, M.; Sanchez-Mata, O.; Brochu, M. Crystallographic-Orientation-Dependent Tensile Behaviours of Stainless Steel 316L Fabricated by Laser Powder Bed Fusion. Mater. Sci. Eng. A 2019, 766, 138395. [Google Scholar] [CrossRef]

- Woo, W.; Jeong, J.S.; Kim, D.-K.; Lee, M.; Choi, S.-H.; Suh, J.-Y.; Lee, S.Y.; Harjo, S.; Kawasaki, T. Stacking Fault Energy Analyses of Additively Manufactured Stainless Steel 316L and CrCoNi Medium Entropy Alloy Using In Situ Neutron Diffraction. Sci. Rep. 2020, 10, 1350. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Imlau, J.; Prahl, U.; Bleck, W. Derivation and Variation in Composition-Dependent Stacking Fault Energy Maps Based on Subregular Solution Model in High-Manganese Steels. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009, 40, 3076–3090. [Google Scholar] [CrossRef]

- Dong, Z.; Li, W.; Chai, G.; Vitos, L. Strong Temperature–Dependence of Ni -Alloying Influence on the Stacking Fault Energy in Austenitic Stainless Steel. Scr. Mater. 2020, 178, 438–441. [Google Scholar] [CrossRef]

- Latanision, R.M.; Ruff, A.W. The Temperature Dependence of Stacking Fault Energy in Fe-Cr-Ni Alloys. Metall. Trans. 1971, 2, 505–509. [Google Scholar] [CrossRef]

- Jeon, J.M.; Park, J.M.; Yu, J.H.; Kim, J.G.; Seong, Y.; Park, S.H.; Kim, H.S. Effects of Microstructure and Internal Defects on Mechanical Anisotropy and Asymmetry of Selective Laser-Melted 316L Austenitic Stainless Steel. Mater. Sci. Eng. A 2019, 763, 138152. [Google Scholar] [CrossRef]

- Charmi, A.; Falkenberg, R.; Ávila, L.; Mohr, G.; Sommer, K.; Ulbricht, A.; Sprengel, M.; Saliwan Neumann, R.; Skrotzki, B.; Evans, A. Mechanical Anisotropy of Additively Manufactured Stainless Steel 316L: An Experimental and Numerical Study. Mater. Sci. Eng. A 2021, 799, 140154. [Google Scholar] [CrossRef]

- Yang, D.; Yin, Y.; Kan, X.; Zhao, Y.; Zhao, Z.; Sun, J. The Mechanism of Substructure Formation and Grain Growth 316L Stainless Steel by Selective Laser Melting. Mater. Res. Express 2021, 8, 096510. [Google Scholar] [CrossRef]

- Wang, Y.M.; Voisin, T.; McKeown, J.T.; Ye, J.; Calta, N.P.; Li, Z.; Zeng, Z.; Zhang, Y.; Chen, W.; Roehling, T.T.; et al. Additively Manufactured Hierarchical Stainless Steels with High Strength and Ductility. Nat. Mater. 2017, 17, 63–71. [Google Scholar] [CrossRef] [Green Version]

- Yin, Y.J.; Sun, J.Q.; Guo, J.; Kan, X.F.; Yang, D.C. Mechanism of High Yield Strength and Yield Ratio of 316 L Stainless Steel by Additive Manufacturing. Mater. Sci. Eng. A 2019, 744, 773–777. [Google Scholar] [CrossRef]

- Spencer, K.; Embury, J.D.; Conlon, K.T.; Véron, M.; Bréchet, Y. Strengthening via the Formation of Strain-Induced Martensite in Stainless Steels. Mater. Sci. Eng. A 2004, 387–389, 873–881. [Google Scholar] [CrossRef]

- Huang, C.X.; Yang, G.; Gao, Y.L.; Wu, S.D.; Li, S.X. Investigation on the Nucleation Mechanism of Deformation-Induced Martensite in an Austenitic Stainless Steel under Severe Plastic Deformation. J. Mater. Res. 2011, 22, 724–729. [Google Scholar] [CrossRef]

| Material | Element [wt.%] | SFE [mJ/m2] [18] | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Cr | Ni | Mn | Mo | Si | Ti | Nb | N | Fe | ||

| L-PBF | 0.02 | 17.7 | 12.9 | 0.6 | 2.5 | 0.7 | 0.01 | 0.005 | 0.09 | Bal. | 27 |

| Wrought | 0.02 | 17.0 | 10.3 | 1.5 | 2.0 | 0.1 | 0.04 | 0.02 | 0.04 | Bal. | 33 |

| ID | Volume Energy Density [J/mm3] | Laser Power [W] | Scan Speed [mm/s] | Hatch Spacing [µm] | Layer Thickness [µm] |

|---|---|---|---|---|---|

| low-VED | 50.8 | 160 | 875 | 120 | 30 |

| medium-VED | 79.4 | 190 | 800 | 100 | 30 |

| high-VED | 84.3 | 220 | 725 | 120 | 30 |

| VED [J/mm3] | Grain Size [µm] | Melt Pool Size [µm] | Aspect Ratio | Density | |||

|---|---|---|---|---|---|---|---|

| TD | BD | Equivalent Diam. | Width | Height | TD/BD | % | |

| 50.8 | 9.3 | 13.8 | 10.5 | 155 | 54 | 0.67 | 91.9 |

| 79.4 | 15.9 | 23 | 15.3 | 202 | 67 | 0.69 | 94.6 |

| 84.3 | 14.3 | 33.7 | 15.2 | 285 | 62 | 0.42 | 99.6 |

| Wrought | 39.1 | 52.3 | 61.8 | - | - | 0.75 | 100 |

| VED [J/mm3] | 0.008/s | 0.0005/s | ||||||

|---|---|---|---|---|---|---|---|---|

| YS [MPa] | UTS [MPa] | UE | TE | YS [MPa] | UTS [MPa] | UE | TE | |

| 50.8 | 481 | 786 | 0.26 | 0.29 | 479 | 821 | 0.33 | 0.35 |

| 79.4 | 489 | 790 | 0.28 | 0.34 | 478 | 805 | 0.37 | 0.41 |

| 84.3 | 475 | 788 | 0.38 | 0.42 | 460 | 834 | 0.48 | 0.51 |

| Wrought | 390 | 887 | 0.38 | 0.43 | 382 | 935 | 0.47 | 0.54 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jaskari, M.; Ghosh, S.; Miettunen, I.; Karjalainen, P.; Järvenpää, A. Tensile Properties and Deformation of AISI 316L Additively Manufactured with Various Energy Densities. Materials 2021, 14, 5809. https://doi.org/10.3390/ma14195809

Jaskari M, Ghosh S, Miettunen I, Karjalainen P, Järvenpää A. Tensile Properties and Deformation of AISI 316L Additively Manufactured with Various Energy Densities. Materials. 2021; 14(19):5809. https://doi.org/10.3390/ma14195809

Chicago/Turabian StyleJaskari, Matias, Sumit Ghosh, Ilkka Miettunen, Pentti Karjalainen, and Antti Järvenpää. 2021. "Tensile Properties and Deformation of AISI 316L Additively Manufactured with Various Energy Densities" Materials 14, no. 19: 5809. https://doi.org/10.3390/ma14195809

APA StyleJaskari, M., Ghosh, S., Miettunen, I., Karjalainen, P., & Järvenpää, A. (2021). Tensile Properties and Deformation of AISI 316L Additively Manufactured with Various Energy Densities. Materials, 14(19), 5809. https://doi.org/10.3390/ma14195809