1. Introduction

The generation of municipal solid waste (MSW) is inextricably linked with the everyday existence of a human being. Every year, an increase in the stream of MSW is observed. In 2019, 225 million Mg of MSW was generated in the EU–27 [

1], corresponding to 512 kg per capita, increasing 3.3% compared to 2018. The amount of MSW per capita in individual countries varies significantly, from 280 kg per capita inhabitant in Romania to 844 kg per inhabitant in Denmark [

1]. On the other hand, in Poland, 336 kg was produced per capita in 2019. While Poland is in the group of countries with the lowest rates, it does not change that we are becoming a more and more consumption and waste based society [

2].

In Poland, in 2019, 3.19 million Mg of generated MSW (25%) was directed to recycling (material and organic). Forty-three percent of generated MSW (5.48 million Mg) was landfilled. On the other hand, thermal transformation with energy recovery was subjected to 22% (2.72 million Mg), and 0.20 million Mg (approximately 1% of generated municipal waste) was sent for disposal by a thermal transformation without energy recovery. It should be added that since 2013 there has been an upward trend in the thermal treatment of waste with energy recovery [

2].

Due to the growing amount of municipal waste generated, several executive acts have been introduced, which deal with, among other things, the level of recycling or recovery of, e.g., energy. An important document seems to be the European Commission (EC) Communication of 2017 on energy recovery from waste in the Circular Economy (CE is a concept aimed at the rational use of resources and limiting the negative environmental impact of manufactured products [

3]). The current waste management system, by Directive (EU) 2018/851 of the European Parliament and of the Council of May 30 2018 [

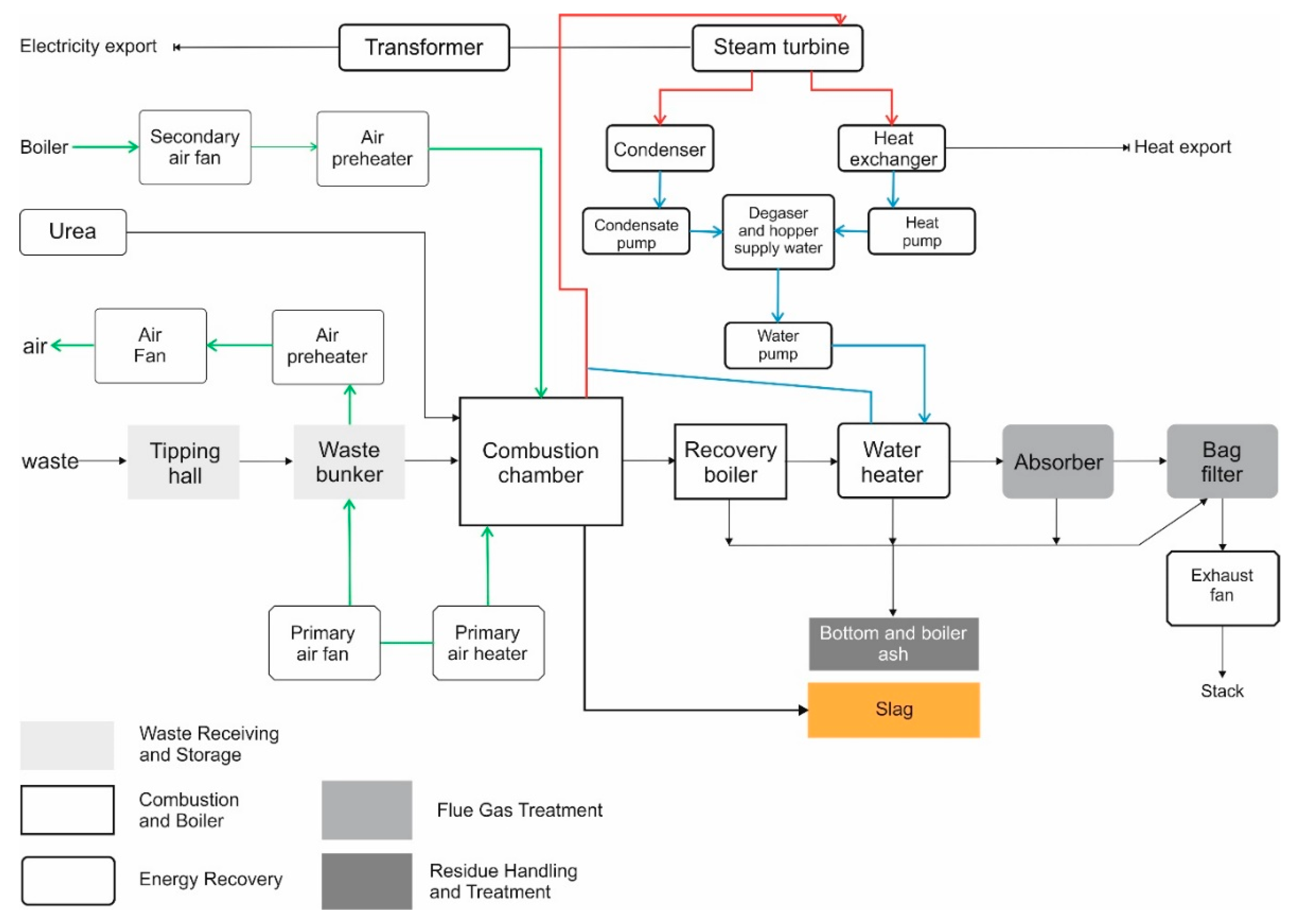

4] provides for energy recovery, which, following the waste management hierarchy, covers only those wastes that have lost their properties, qualifying them for recycling and reuse. One of the elements of the waste management system is Municipal Waste Thermal Treatment Installations (MSWIs).

The act on maintaining cleanliness and order in municipalities (Journal of Laws of 2021, item 888) [

5] abolished the 30% limit on thermal treatment wasted from municipal waste processing. The introduced change freed the market of waste incineration plants, which had been limited so far. Local governments see the introduced amendment as the possibility of managing the combustible fraction of municipal waste in local heating systems. Currently, we have a big problem with the optimal management of the municipal waste stream because it contains a lot of high-calorific fractions. The introduced changes may contribute to comprehensive waste management.

On the one hand, the amendment will contribute to the optimal management of the combustible fraction. Still, on the other hand, it will contribute to the formation of significant amounts of secondary waste, including slags, which should be reused to achieve the objectives of the circular economy (circular economy). The idea of the circular economy does not support thermal degradation because it is a loss of material but says that waste for one sector may be a raw material for the other sector [

3]. Such an approach is close to the discussed case. For example, waste for MSWI can be a valuable raw material for cement plants. However, this requires research and cooperation between MSWI and the cement industry.

While incineration, in line with the current waste hierarchy [

4], is the final disposal element and should not be treated as an alternative to recycling, it should be the worst alternative to storage. Incineration of waste brings several advantages, including reducing the mass and volume of waste and producing heat or electricity. As a result of combustion processes, secondary waste is generated, which in recent years has become the subject of many studies in the context of economic use [

6,

7]. About 0.25 Mg of slag per 1 ton of incinerated waste is produced and about 0.075 Mg per 1 ton of incinerated fly ash waste, dust from dust removal, filter cakes and gypsum from flue gas cleaning processes [

6,

7].

Recently, the interest in the use of waste from thermal processes in construction has increased significantly. This direction of using post-process waste is consistent with the principles of sustainable development and the idea of a Circular Economy (CE) implemented in Europe. After appropriate preparation, wastes generated in the combustion process (i.e., slag, fly ash and bottom ash) meet the requirements set by the construction industry. Additionally, they enable economic and environmental benefits to be achieved. Using this type of waste (e.g., slags) reduces the consumption of ordinary cement, which significantly affects the consumption of non-renewable, natural raw materials needed for its production. It also reduces anthropogenic CO2 emissions to the atmosphere and reduces the energy consumption needed for its production. The factors mentioned above improve the condition of the environment in Poland, which ultimately translates into global effects.

Additionally, studies [

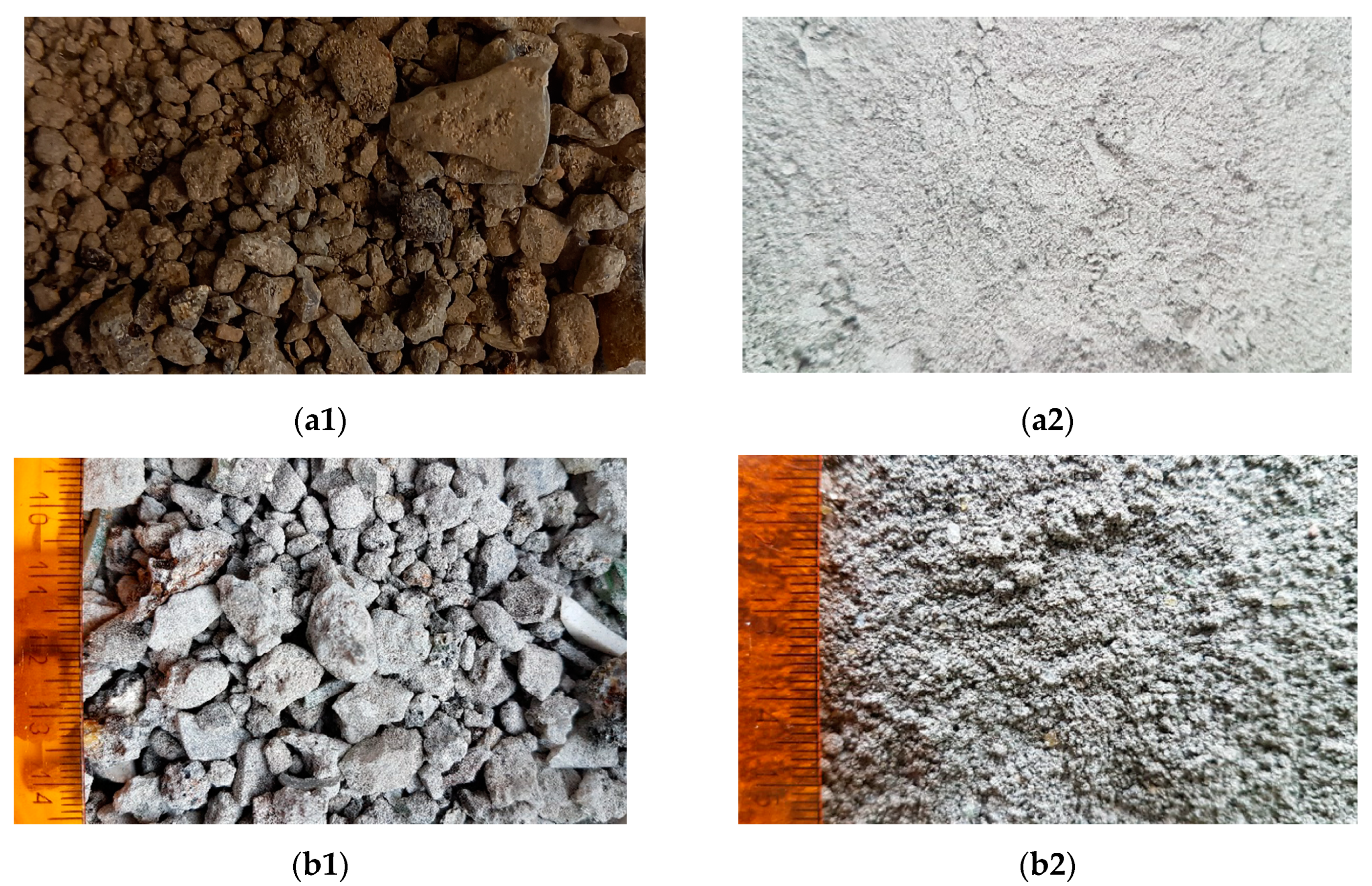

8] confirm the possibility of using slag from the incineration of MSW as an artificial aggregate. According to publication [

8], the dominant direction in using slags in Poland in 2016 is mostly storage. To a lesser extent, they are used as an additive for the production of road aggregates.

Slags resulting from combustion can be used in construction, saving natural resources. However, it is worth remarking that the building materials produced based on such slags are most often characterised by low strength and therefore are mainly used in local construction roads. Regardless of their use, the resulting final product must not be harmful to the environment. Based on the literature, it can be concluded that the content of chlorides and heavy metals in slags from municipal garbage incinerators is relatively not great. In addition, it is assumed that any undesirable substances will be somewhat sunk in the structure of concrete.

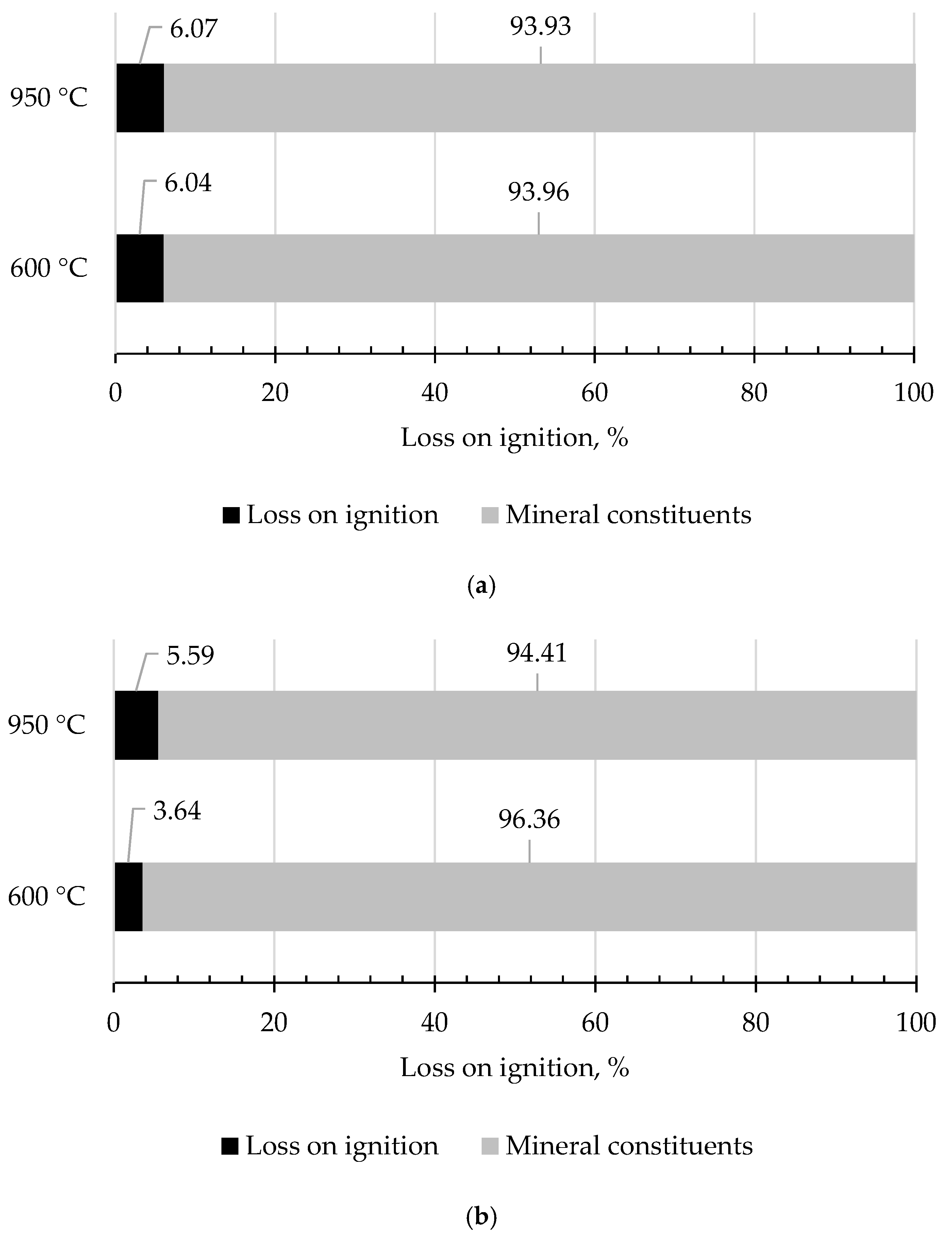

Nevertheless, any even minor risk of leakage of harmful substances should be assessed at the production stage of the materials produced and during their operation and subsequent degradation. When preparing concretes, based on aggregate sew from the incinerator, the relationship between cement and the aluminium and zinc contained in the waste is particularly undesirable. It is known that these reactions cause the phenomenon of swelling and even cracking of concrete. To counteract these phenomena, slags from the incinerator, before being used in the production of building materials, should most often be seasoned and processed. Waste treatment can take various forms depending on the initial composition and future importance (seasoning, rinsing, washing, sodium hydroxide action, heavy metal removal, glazing). Many studies emphasise the need to use such treatments, or at least to pre-wash the obtained slag. Numerous studies show that only the processed (cleaned) combustion product has the appropriate chemical and physical properties ensuring the expected quality of concrete. However, while environmentally friendly, the materials often obtained by the authors were characterised by low strength. One of the most common problems was reducing the aluminium and the glass contained in the waste after incineration. The furnace slag from current production contained particles of unburned coal and sometimes significant amounts of sulphur oxides. Therefore, it should not be applied to the concrete. Burnt furnace slag aggregate should be applied to concretes provided that the sulphur content does not exceed 3%. The search for an environmentally friendly concrete mix with good mechanical properties is still valid. Because the waste treatment represents a highly actual topic, several researchers have studied the possibility of recycling MSWIA materials in concrete and cement manufacturing, both as aggregates or mineral additions [

9,

10,

11,

12,

13,

14,

15,

16,

17]. MSWI bottom ash and fly ash have also been used as raw materials for manufacturing cement, ceramics, bricks or tiles.

Publications [

18,

19] analysed the possibilities of using MSWI ashes as a component of cement. Paper [

20] describes the results of research aimed at studying the effect of replacing part of Portland cement with fly ash and bottom ash, both from municipal solid waste incinerators (MSWIs). The studied MSWI ashes exhibit a high concentration of chlorides and sulfates, which is an unfavourable feature for a potential concrete additive [

21,

22]. Publication [

23] indicated that the MSWI slag structure is loose and irregular, and its main component is SiO

2. The SiO

2 and Al

2O

3 in fly ash and slag participate in the hydration reaction of cement and can increase concrete strength. It is thus confirmed that fly ash and slag generated by waste incineration can replace cement and coarse aggregate in appropriate proportions. This is an effective method to solve the problem of scarcity of solid waste landfill space.

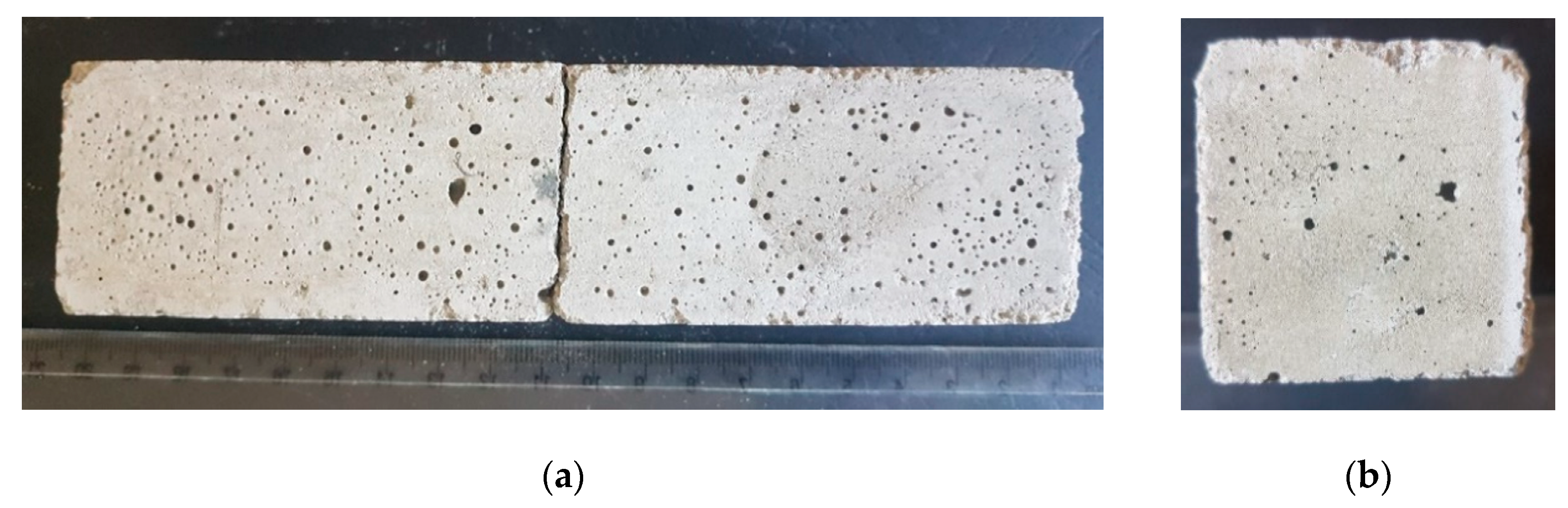

However, there are still few studies in the literature on the effect of ground slag as a component of cement. The reactions between cement, aluminium and zinc in the waste are particularly undesirable [

24,

25,

26,

27]. The reasons and course of these reactions have been described in detail in the literature. It is known that these reactions cause concrete swelling and even cracking. To counteract these phenomena, slags and ashes from incineration plants are mostly seasoned and processed before using them for the production of building materials. Depending on the initial composition and future destination, waste treatment may vary forms (seasoning, rinsing, washing, treatment with sodium hydroxide, removal of heavy metals, glazing). Many studies emphasise the need to use such treatments, or at least preliminary rinsing of the obtained slag. Numerous studies show that only the processed (cleaned) combustion product has the appropriate chemical and physical properties, ensuring the expected quality of concrete. However, while environmentally friendly, the materials often received by authors were characterised by low-level endurance. One of the most common problems was the need to reduce the aluminium and the amount of glass contained in the waste after incineration and limit the release into the environment of potentially harmful substances. The authors concluded that improperly selected, unseasoned slag may cause concrete swelling based on the conducted research. Therefore, the authors propose to use alkaline activation of slag to eliminate the swelling of the mortar with its participation. The results of the trials are analysed in this article. Similar research of this scope has not been conducted so far.

4. Conclusions

Slag from thermal treatment of municipal waste is not an accessible raw material to use. Still, after appropriate treatment, it can be a good and valuable alternative to non-renewable natural resources. To use MSWI furnace slags in the construction industry, e.g., for the production of building materials or roads, it is necessary, together with manufacturers, to develop a procedure for their cleaning, processing and seasoning. Depending on the input stream to the Installation and its future use, their preparation may take various forms, such as seasoning, rinsing, washing or treatment with sodium hydroxide. Furnace slags require systematic analyses, mainly concerning the chemical composition. Then, it will be possible to make the right decision regarding their use, e.g., for concrete production. After preliminary tests, the furnace slag, formed in the combustion process, analysed in the article, can be successfully used as a substitute for some cement (e.g., 30%) in the so-called lean concrete. Additionally, they can be used in the construction of road foundations.

Reactions between cement and aluminium and zinc contained in the slags may be a barrier to the use of furnace slags. An additional difficulty may be caused by the heterogeneity of the furnace slag and a significant content of harmful components (i.e., unburned coal, sulfur compounds). The mentioned components may cause reduced strength of concrete with the addition of furnace slag, consequently translating into a limited scope of application. However, it has been proven that the alkaline activation of the slag reduces the swelling of the mortars. Moreover, low-alkali cement is recommended as a complement to MSWI slag mortars. The obtained results allow environmentally friendly use of furnace slags with the possibility of obtaining tight and durable concretes. This method of use may be the best and cheapest long-term solution in waste management and fill the market gap in this area. The search for mineral additives for concrete, including secondary waste from thermal degradation, is still valid. Currently, we are obliged to look for recyclable raw materials to use waste that can be given another life cycle. Thermal degradation of municipal waste is one of the elements of modern waste management, which aims to abandon landfilling completely.

Additionally, they can support local heating installations. Finally, post-process waste, such as slags, can be a valuable aggregate or cement component. The result presented in the article is an introduction to further research and discussion because the problem is will continue in the future, is global and is interdisciplinary.