The Effect of Temper Condition and Feeding Speed on the Additive Manufacturing of AA2011 Parts Using Friction Stir Deposition

Abstract

:1. Introduction

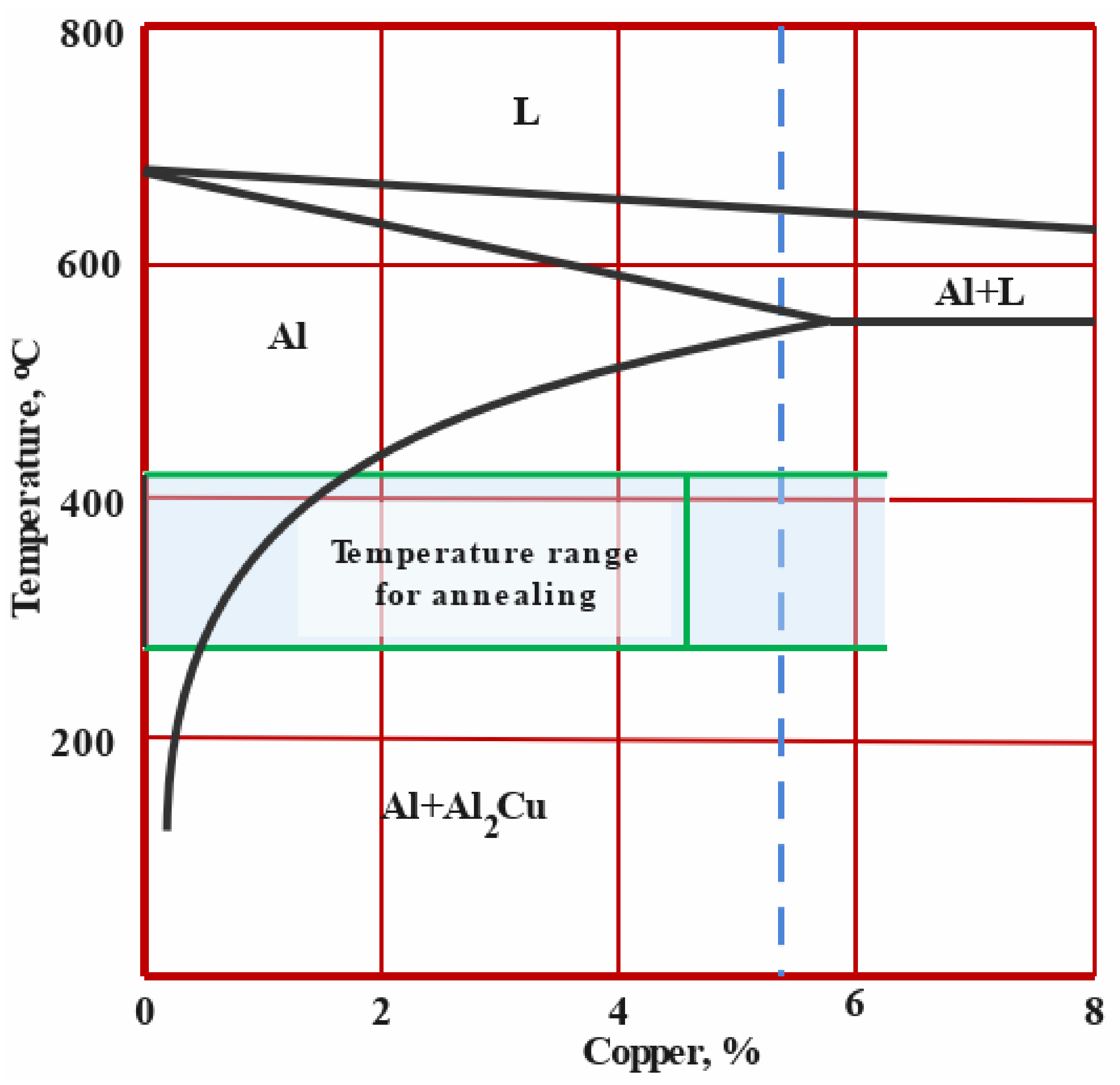

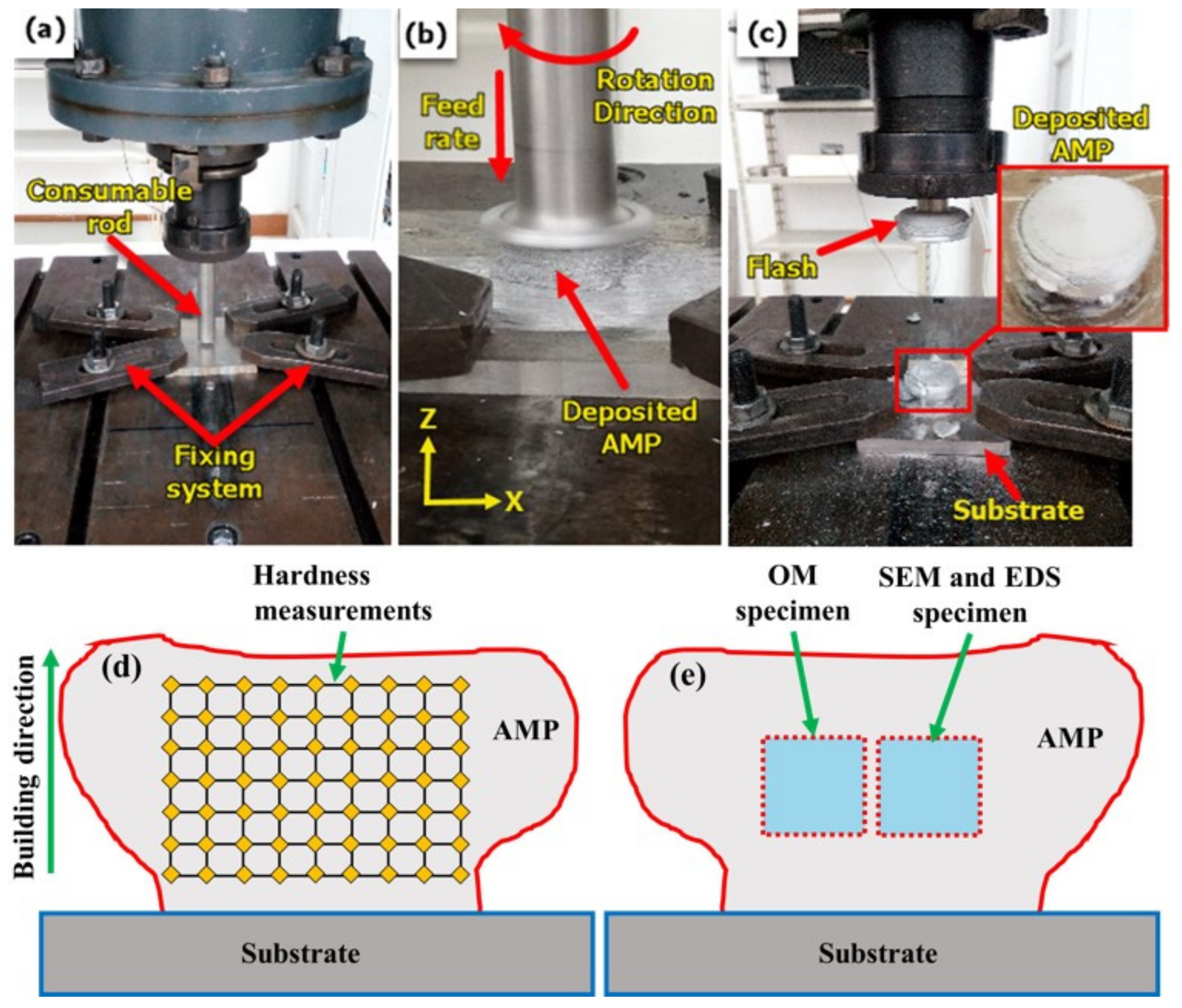

2. Materials and Methods

3. Results and Discussions

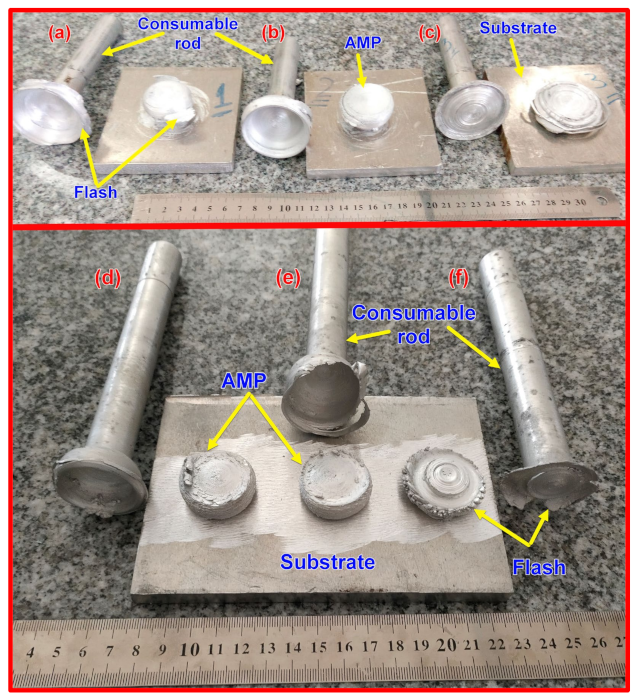

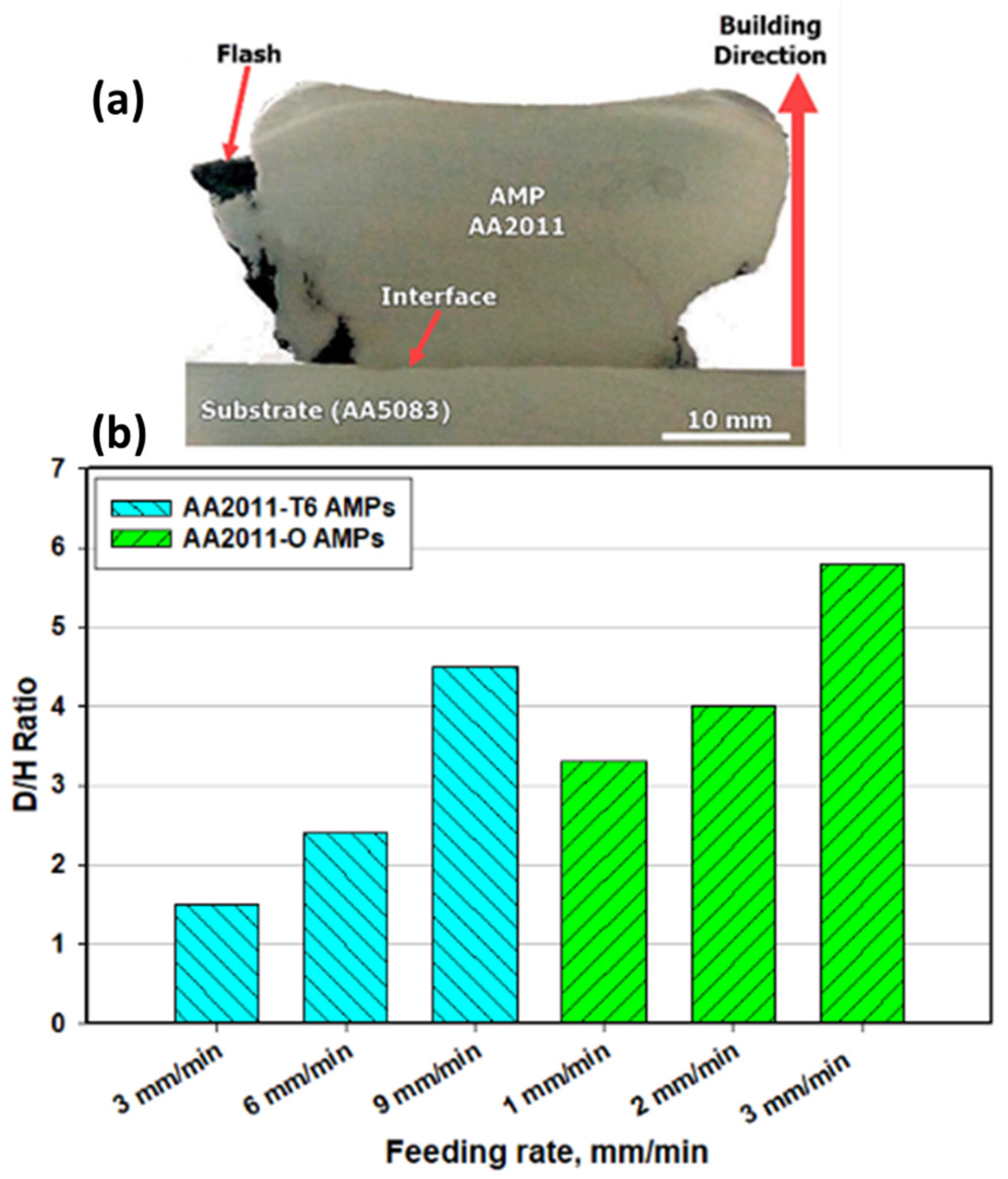

3.1. Fabrication of AMPs

3.2. Macrostructure Examination

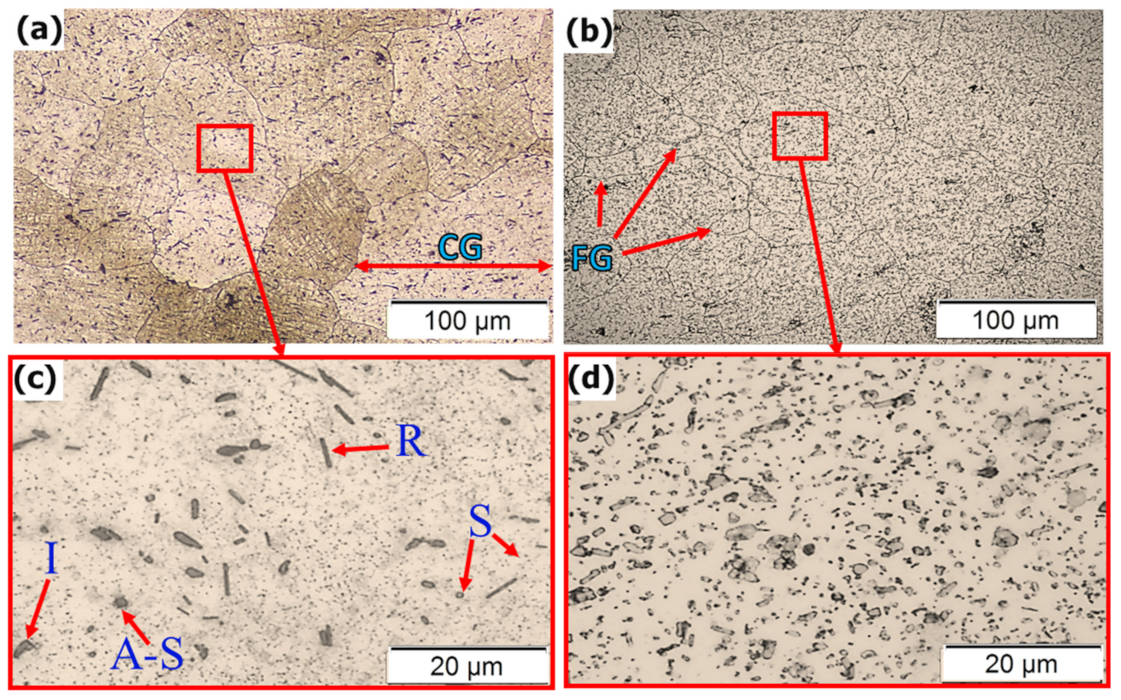

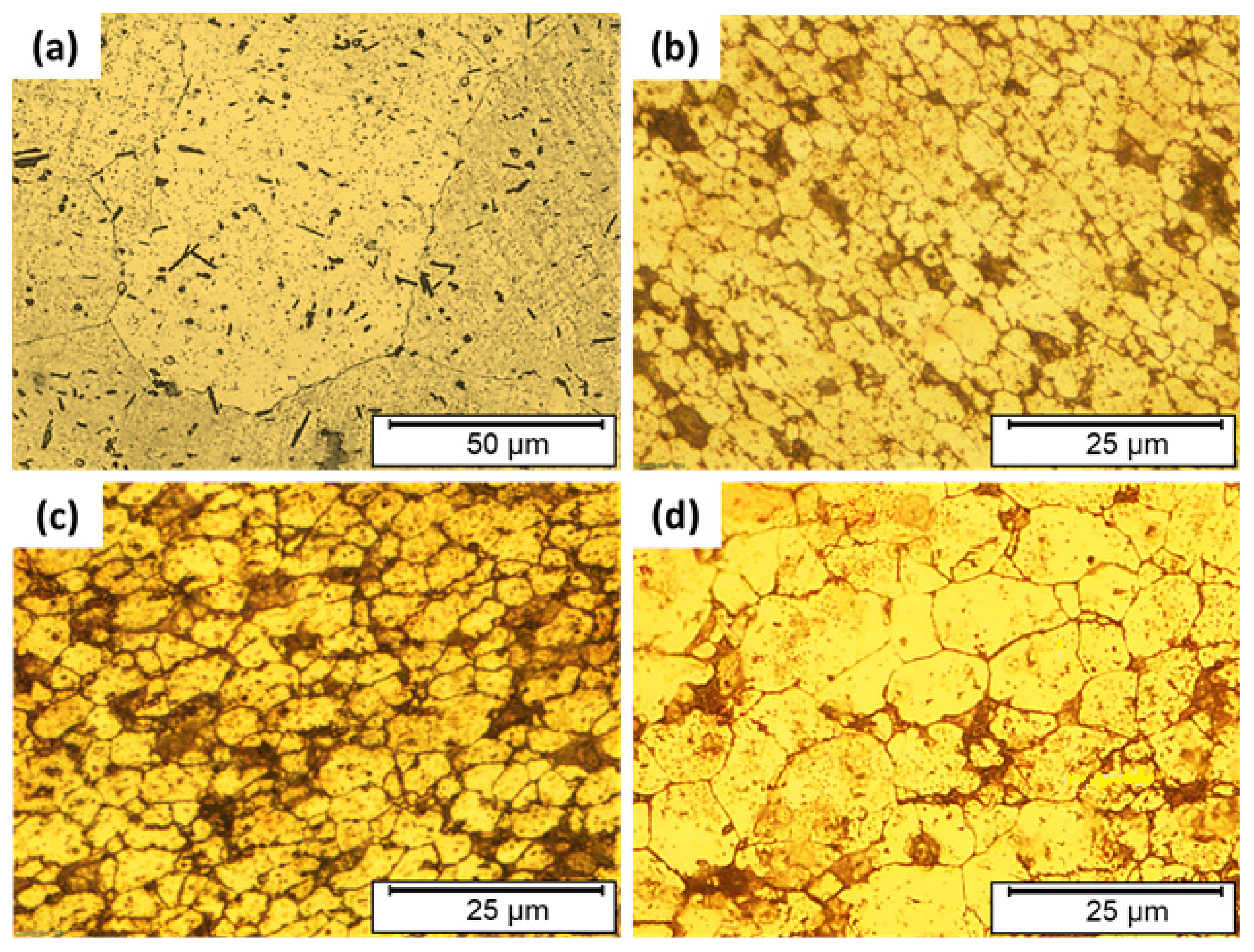

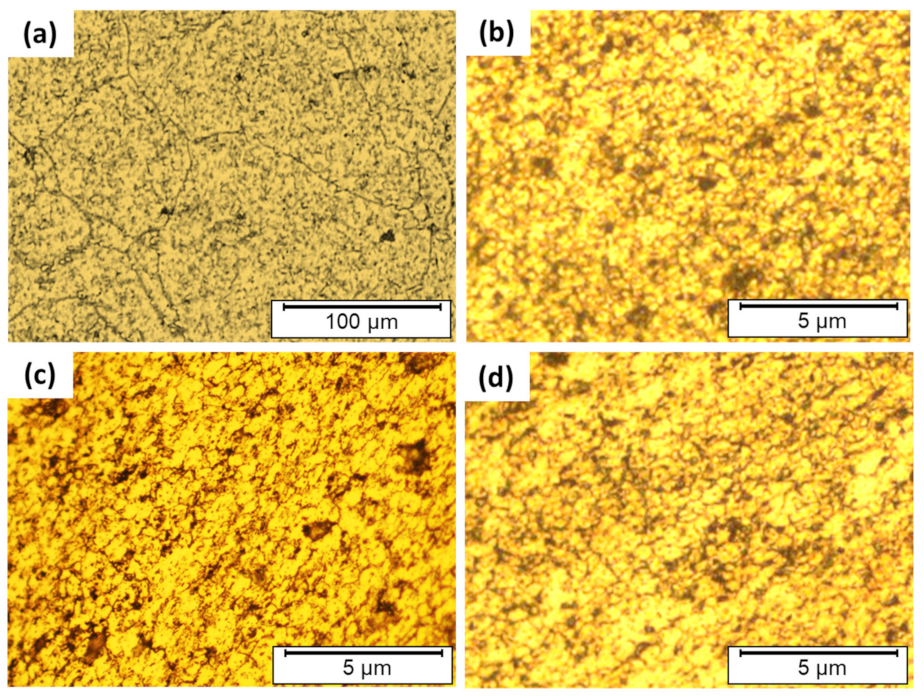

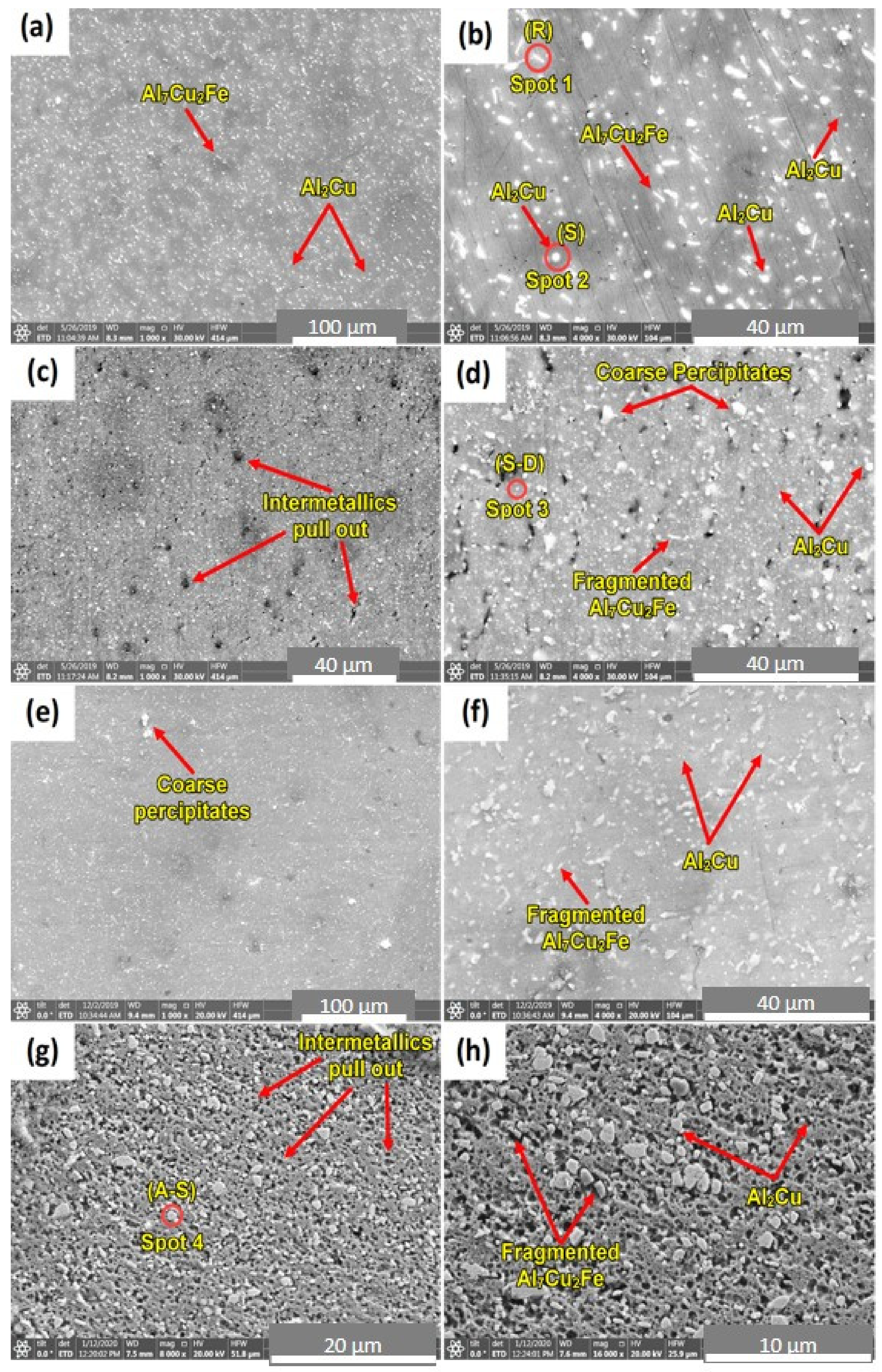

3.3. Microstructure Examination

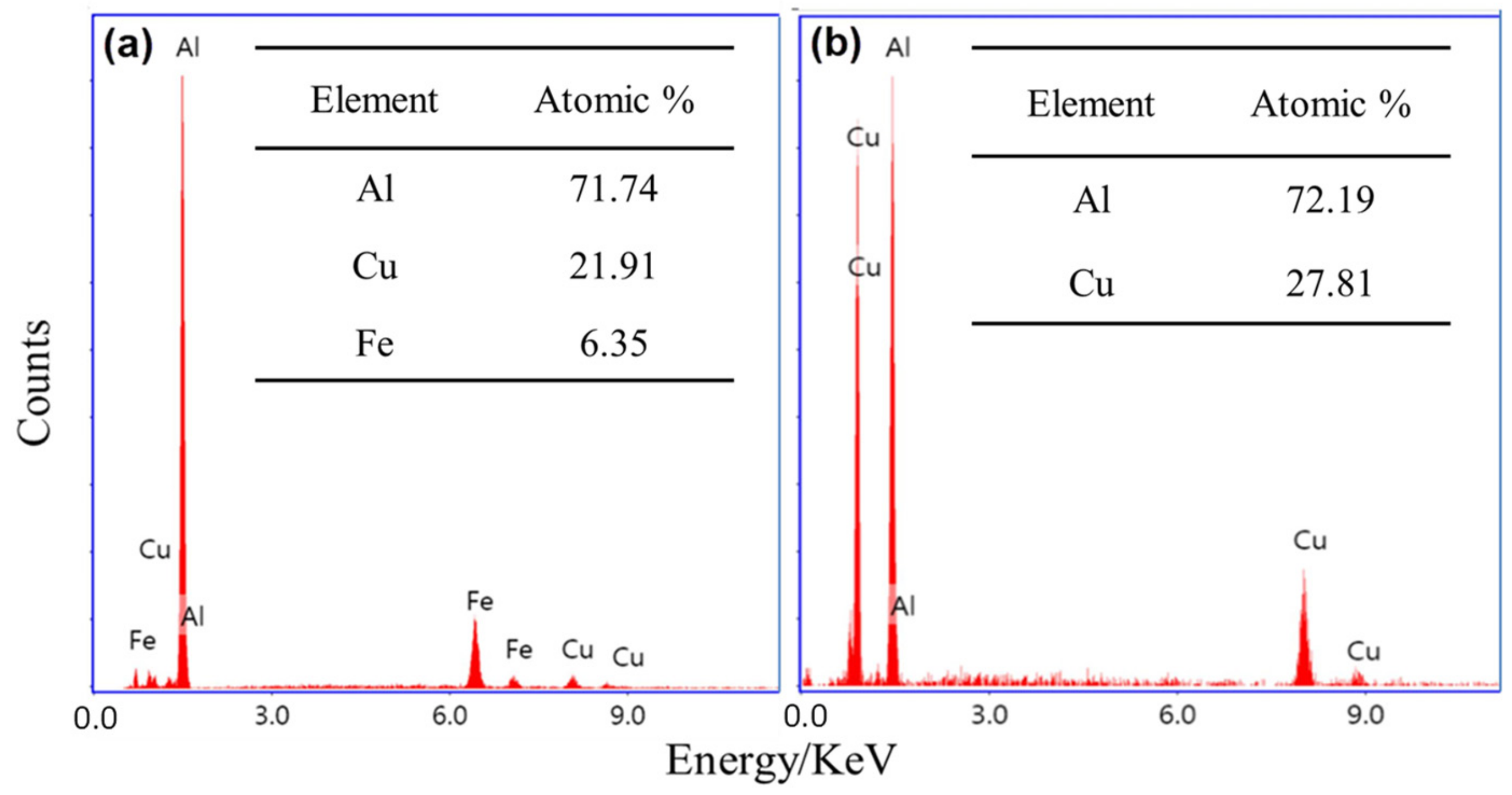

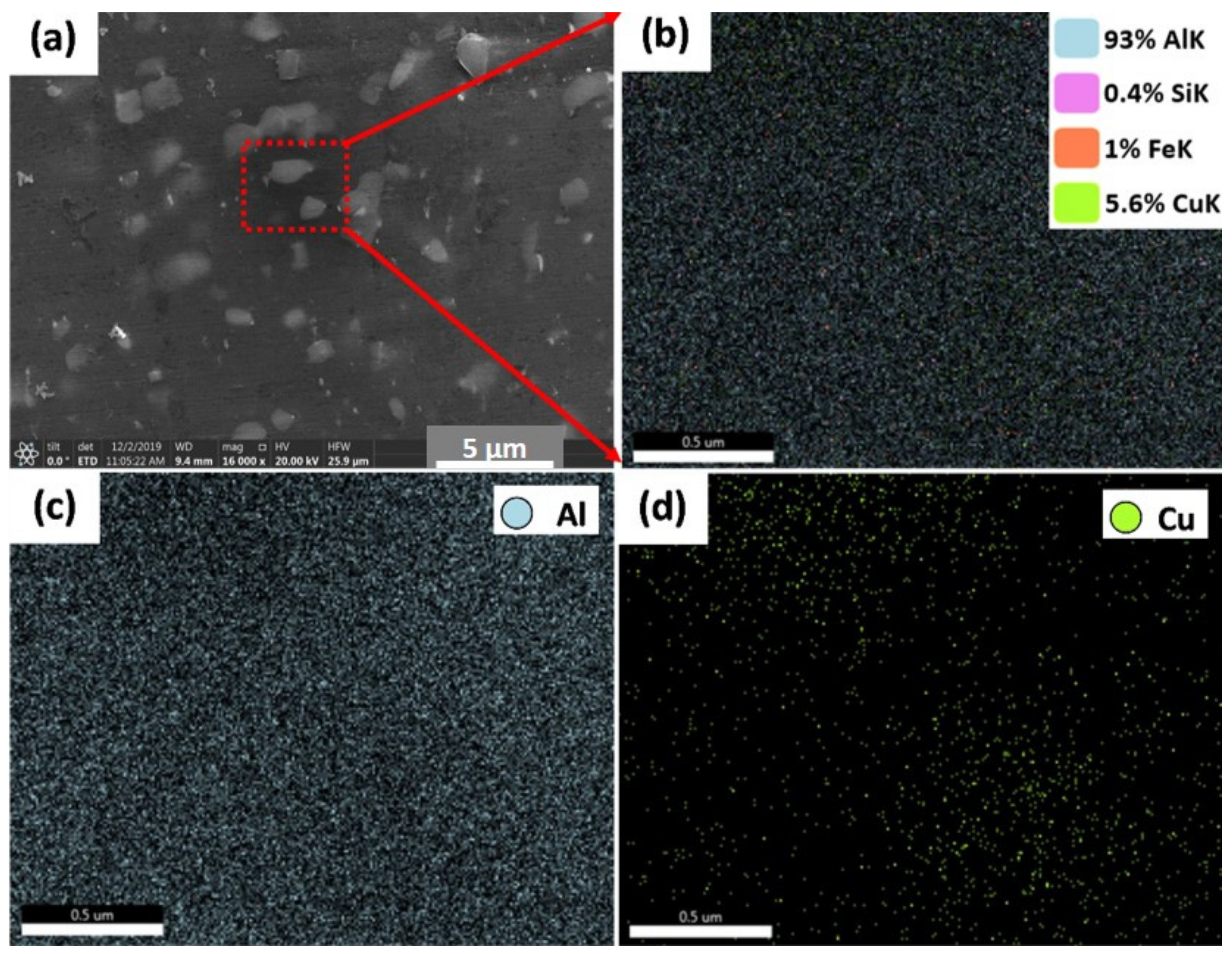

3.3.1. AMPs Parts Produced from AA2011-T6 Alloy

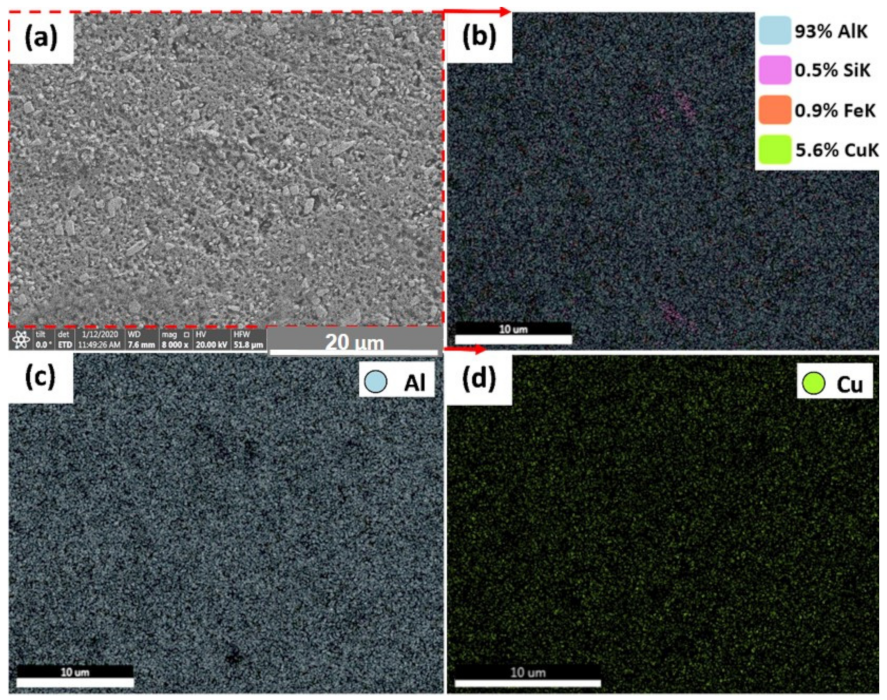

3.3.2. AMPs Parts Produced from AA2011-O

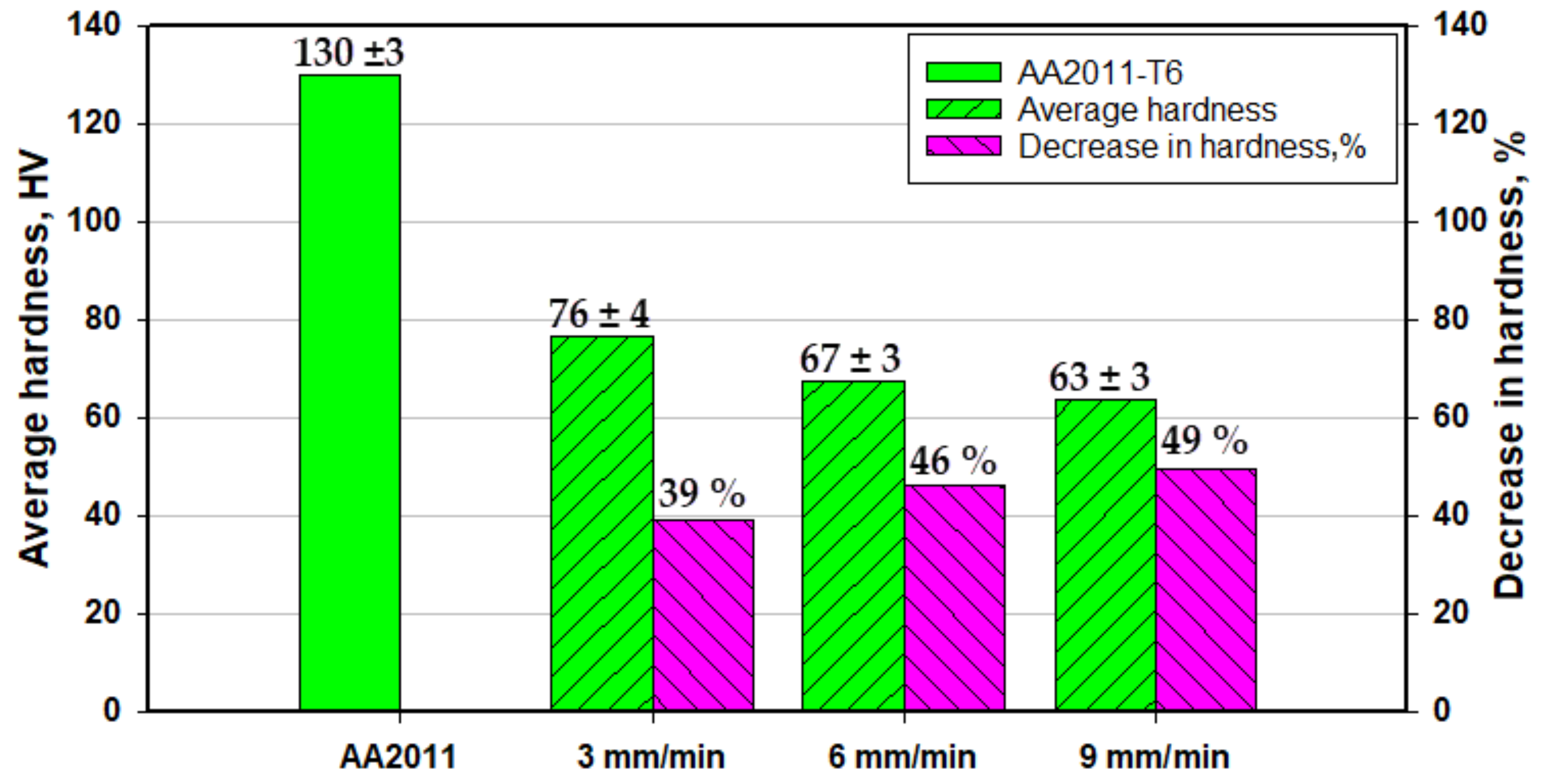

3.4. Hardness

4. Conclusions

- The friction stir deposition technique successfully produced sound continuous multi-layered AA2011 AMPs without any physical discontinuities or interfacial defects between layers along the vertical direction.

- The temper condition of the alloy affects the behavior during FSD, and the parameters that worked with the T6 condition does not work with the O condition alloy. The hard condition alloy required high heat input to reach the state of a good deposition, while the soft condition alloy required low heat input to reach the FSD state.

- The optimum condition for FSD of AA2011-T6 was a rotational rate of 1200 rpm at feeding speeds between 3 and 9 mm/min, while the optimum condition for FSD of AA2011-O was a rotational rate of 200 rpm at feeding speeds between 1 and 3 mm/min.

- Microstructural analysis showed that significant grain refining and intermetallic particle fragmentation have been observed in the AMPs from the two temper conditions of AA2011.

- The fine grain formation is mainly dominated by dynamic recrystallization where the average grain size is reduced by decreasing the feeding speed at a constant rotation rate. The use of a lower rotation rate resulted in more refining due to the lower heat input experienced.

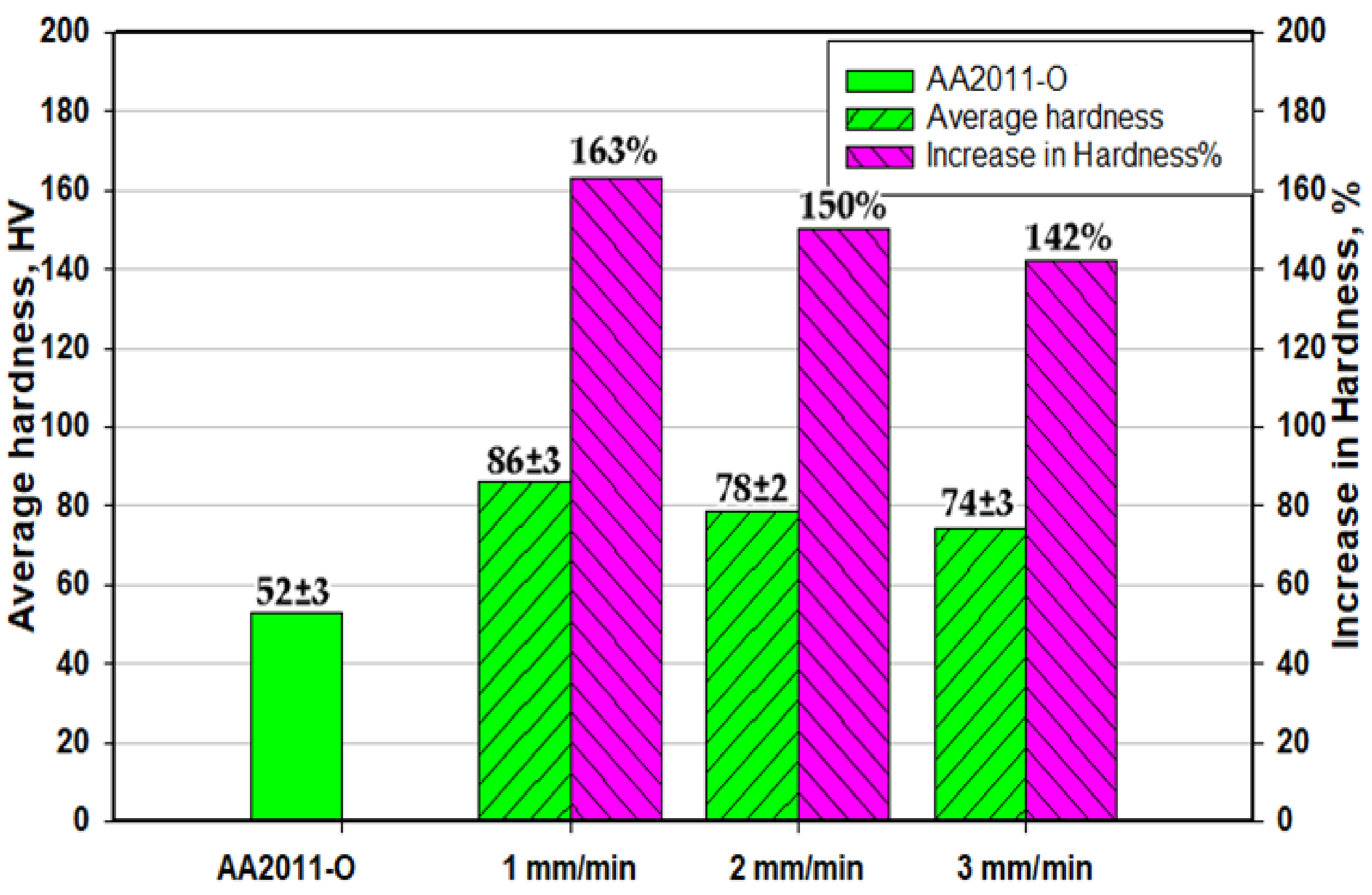

- The use of T6 temper alloy has resulted in AMPs with a lower hardness than the starting material that reached about 61% and 51% of the starting material hardness at feeding rates of 3 and 9 mm/min, respectively. However, the use of O temper alloy has resulted in AMPs with higher hardness than the starting material by about 163% hardness enhancement compared to the starting material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar Srivastava, A.; Kumar, N.; Rai Dixit, A. Friction stir additive manufacturing—An innovative tool to enhance mechanical and microstructural properties. Mater. Sci. Eng. B Solid-State Mater. Adv. Technol. 2021, 263, 114832. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Gerlich, A.P.P. Potentials and strategies of solid-state additive friction-stir manufacturing technology: A critical review. J. Manuf. Process. 2018, 36, 77–92. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, S.; Qiu, D.; Gibson, M.A.; Dargusch, M.S.; Brandt, M.; Qian, M.; Easton, M. Metal Alloys for Fusion-Based Additive Manufacturing. Adv. Eng. Mater. 2018, 20, 1–20. [Google Scholar] [CrossRef]

- Dilip, J.J.S.; Rafi, H.K.; Ram, G.D.J. A new additive manufacturing process based on friction deposition. Trans. Indian Inst. Met. 2011, 64, 27–30. [Google Scholar] [CrossRef]

- Karthik, G.M.; Ram, G.D.J.; Kottada, R.S. Friction deposition of titanium particle reinforced aluminum matrix composites. Mater. Sci. Eng. A 2016, 653, 71–83. [Google Scholar] [CrossRef]

- Dilip, J.J.S.; Ram, G.D.J. Microstructure evolution in aluminum alloy AA 2014 during multi-layer friction deposition. Mater. Charact. 2013, 86, 146–151. [Google Scholar] [CrossRef]

- Harun, W.S.W.; Kamariah, M.S.I.N.; Muhamad, N.; Ghani, S.A.C.; Ahmad, F.; Mohamed, Z. A review of powder additive manufacturing processes for metallic biomaterials. Powder Technol. 2018, 327, 128–151. [Google Scholar] [CrossRef]

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Rutherford, B.A.; Avery, D.Z.; Phillips, B.J.; Rao, H.M.; Doherty, K.J.; Allison, P.G.; Brewer, L.N.; Brian Jordon, J. Effect of thermomechanical processing on fatigue behavior in solid-state additive manufacturing of Al-Mg-Si alloy. Metals 2020, 10, 947. [Google Scholar] [CrossRef]

- Griffiths, R.J.; Perry, M.E.J.J.; Sietins, J.M.; Zhu, Y.; Hardwick, N.; Cox, C.D.; Rauch, H.A.; Yu, H.Z. A Perspective on Solid-State Additive Manufacturing of Aluminum Matrix Composites Using MELD. J. Mater. Eng. Perform. 2019, 28, 648–656. [Google Scholar] [CrossRef]

- Dilip, J.J.S.; Babu, S.; Varadha Rajan, S.; Rafi, K.H.; Janaki Ram, G.; Stucker, B.E. Use of friction surfacing for additive manufacturing. Mater. Manuf. Process. 2013, 28, 189–194. [Google Scholar] [CrossRef]

- Su, J.Q.; Nelson, T.W.; Sterling, C.J. Grain refinement of aluminum alloys by friction stir processing. Philos. Mag. 2006, 86, 1–24. [Google Scholar] [CrossRef]

- Gandra, J. Friction stir processing. In Surface Modification by Solid State Processing; Woodhead Publishing: Sawston, UK, 2014; pp. 73–111. ISBN 9780857094698. [Google Scholar]

- Gupta, G.R.; Parkhurst, J.O.; Ogden, J.A.; Aggleton, P.; Mahal, A. Structural approaches to HIV prevention. Lancet 2008, 372, 764–775. [Google Scholar] [CrossRef]

- Karthik, G.M.; Panikar, S.; Ram, G.D.J.; Kottada, R.S. Additive manufacturing of an aluminum matrix composite reinforced with nanocrystalline high-entropy alloy particles. Mater. Sci. Eng. A 2017, 679, 193–203. [Google Scholar] [CrossRef]

- Andrade, D.G.; Leitão, C.; Rodrigues, D.M. Influence of base material characteristics and process parameters on frictional heat generation during Friction Stir Spot Welding of steels. J. Manuf. Process. 2019, 43, 98–104. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; Seleman, M.M.E.S.; Allam, T.; Alsaleh, N.A.; Ahmed, E. Grain structure, crystallographic texture, and hardening behavior of dissimilar friction stir welded aa5083-o and aa5754-h14. Metals 2021, 11, 181. [Google Scholar] [CrossRef]

- Guru, P.R.; Khan MD, F.; Panigrahi, S.K.; Ram, G.D.J. Enhancing strength, ductility and machinability of a Al-Si cast alloy by friction stir processing. J. Manuf. Process. 2015, 18, 67–74. [Google Scholar] [CrossRef]

- Jahangir, M.N.; Mamun, M.A.H.; Sealy, M.P. A review of additive manufacturing of magnesium alloys. In AIP Conference Proceedings; American Institute of Physics Inc.: College Park, MD, USA, 2018; Volume 1980, p. 030026. [Google Scholar]

- Mishra, R.S.; Palanivel, S. Building without melting: A short review of friction-based additive manufacturing techniques. Int. J. Addit. Subtractive Mater. Manuf. 2017, 1, 82. [Google Scholar] [CrossRef]

- Bose, S.; Ke, D.; Sahasrabudhe, H.; Bandyopadhyay, A. Additive manufacturing of biomaterials. Prog. Mater. Sci. 2018, 93, 45–111. [Google Scholar] [CrossRef]

- Palanivel, S.; Nelaturu, P.; Glass, B.; Mishra, R.S.S. Friction stir additive manufacturing for high structural performance through microstructural control in an Mg based WE43 alloy. Mater. Des. 2015, 65, 934–952. [Google Scholar] [CrossRef]

- Padhy, G.K.; Wu, C.S.; Gao, S. Friction stir based welding and processing technologies—Processes, parameters, microstructures and applications: A review. J. Mater. Sci. Technol. 2018, 34, 1–38. [Google Scholar] [CrossRef]

- Elfishawy, E.; Ahmed, M.M.Z.; El-Sayed Seleman, M.M. Additive manufacturing of aluminum using friction stir deposition. In TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings; The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Boyer, H.E. Heat Treating of Nonferrous Alloys. Metallogr. Microstruct. Anal. 2013, 2, 190–195. [Google Scholar] [CrossRef]

- Committee, A.H. Heat Treating of Aluminum Alloys. In ASM Handbook, Volume 4: Heat Treating; ASM Handbook Committee: Russell Township, OH, USA, 1991; pp. 841–879. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; El-Sayed Seleman, M.M.; Ammar, H.R.; Ahmed, E. Friction stir welding of similar and dissimilar AA7075 and AA5083. J. Mater. Process. Technol. 2017, 242, 77–91. [Google Scholar] [CrossRef]

- Hoziefa, W.; Toschi, S.; Ahmed, M.M.Z.; Morri, A.; Mahdy, A.A.; El-Sayed Seleman, M.M.; El-Mahallawi, I.; Ceschini, L.; Atlam, A. Influence of friction stir processing on the microstructure and mechanical properties of a compocast AA2024-Al2O3 nanocomposite. Mater. Des. 2016, 106, 273–284. [Google Scholar] [CrossRef]

- Alzahrani, B.; El-Sayed Seleman, M.M.; Ahmed, M.M.Z.; Elfishawy, E.; Ahmed, A.M.Z.; Touileb, K.; Jouini, N.; Habba, M.I.A. The Applicability of Die Cast A356 Alloy to Additive Friction Stir Deposition at Various Feeding Speeds. Materials 2021, 14, 6018. [Google Scholar] [CrossRef] [PubMed]

- Lukács, J.; Meilinger, Á.; Pósalaky, D. High cycle fatigue and fatigue crack propagation design curves for 5754-H22 and 6082-T6 aluminium alloys and their friction stir welded joints. Weld. World 2018, 62, 737–749. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Ataya, S.; El-Sayed Seleman, M.M.; Mahdy, A.M.A.; Alsaleh, N.A.; Ahmed, E. Heat input and mechanical properties investigation of friction stir welded aa5083/aa5754 and aa5083/aa7020. Metals 2021, 11, 1–20. [Google Scholar]

- Ahmed, M.M.Z.; Jouini, N.; Alzahrani, B.; Seleman, M.M.E.-S.; Jhaheen, M. Dissimilar Friction Stir Welding of AA2024 and AISI 1018: Microstructure and Mechanical Properties. Metals 2021, 11, 330. [Google Scholar] [CrossRef]

- Zayed, E.M.; El-Tayeb, N.S.M.; Ahmed, M.M.; Rashad, R.M. Development and Characterization of AA5083 Reinforced with SiC and Al2O3 Particles by Friction Stir Processing. In Engineering Design Applications; Öchsner, A., Altenbach, H., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 11–26. ISBN 978-3-319-79005-3. [Google Scholar]

- Hamada, A.S.; Järvenpää, A.; Ahmed, M.M.Z.; Jaskari, M.; Wynne, B.P.; Porter, D.A.; Karjalainen, L.P. The microstructural evolution of friction stir welded AA6082-T6 aluminum alloy during cyclic deformation. Mater. Sci. Eng. A 2015, 642. [Google Scholar] [CrossRef]

- Tonelli, L.; Morri, A.; Toschi, S.; Shaaban, M.; Ammar, H.R.; Ahmed, M.M.Z.; Ramadan, R.M.; El-Mahallawi, I.; Ceschini, L. Effect of FSP parameters and tool geometry on microstructure, hardness, and wear properties of AA7075 with and without reinforcing B4C ceramic particles. Int. J. Adv. Manuf. Technol. 2019, 102, 366–376. [Google Scholar] [CrossRef]

- Kang, J.; Feng, Z.C.; Frankel, G.S.; Huang, I.W.; Wang, G.Q.; Wu, A.P. Friction Stir Welding of Al Alloy 2219-T8: Part I-Evolution of Precipitates and Formation of Abnormal Al2Cu Agglomerates. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2016, 47, 4553–4565. [Google Scholar] [CrossRef]

- Proni, C.T.W.; D’Ávila, M.A.; Zoqui, E.J. Thixoformability evaluation of AA2011 and AA2014 alloys. Int. J. Mater. Res. 2013, 104, 1182–1196. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Rivera, O.G.; Allison, P.G.; Brewer, L.N.; Rodriguez, O.L.; Jordon, J.B.; Liu, T.; Whittington, W.R.; Martens, R.L.; McClelland, Z.; Mason, C.J.T.; et al. Influence of texture and grain refinement on the mechanical behavior of AA2219 fabricated by high shear solid state material deposition. Mater. Sci. Eng. A 2018, 724, 547–558. [Google Scholar] [CrossRef]

- Fouad, D.M.; El-Garaihy, W.H.; Ahmed, M.M.Z.; Albaijan, I.; Seleman, M.M.E.; Salem, H.G. Grain Structure Evolution and Mechanical Properties of Multi-Channel Spiral Twist Extruded AA5083. Metals 2021, 11, 1276. [Google Scholar] [CrossRef]

- Rathee, S.; Srivastava, M.; Maheshwari, S.; Kundra, T.K.; Siddiquee, A.N. Friction Based Additive Manufacturing Technologies; CRC Press: Boca Raton, FL, USA, 2018; ISBN 9780815392361. [Google Scholar]

- Mishra, R.S.; Mahoney, M.W.; McFadden, S.X.; Mara, N.A.; Mukherjee, A.K. 32-High strain rate superplasticity in a friction stir processed 7075 Al alloy. Scr. Mater. 1999, 42, 163–168. [Google Scholar] [CrossRef]

- Niclas, Å. A calorimetric analysis and solid-solubility examination of aluminium alloys containing low-melting-point elements. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2012. [Google Scholar]

- Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Zidan, Z.A.; Ramadan, R.M.; Ataya, S.; Alsaleh, N.A. Microstructure and mechanical properties of dissimilar friction stir welded AA2024-T4/AA7075-T6 T-butt joints. Metals 2021, 11, 128. [Google Scholar] [CrossRef]

- Zhang, W.W.; Lin, B.; Zhang, D.T.; Li, Y.Y. Microstructures and mechanical properties of squeeze cast Al-5.0Cu-0.6Mn alloys with different Fe content. Mater. Des. 2013, 52, 225–233. [Google Scholar] [CrossRef]

- Xu, D.; Zhu, C.; Xu, C.; Chen, K. Microstructures and tensile fracture behavior of 2219 wrought al–cu alloys with different impurity of fe. Metals 2021, 11, 174. [Google Scholar] [CrossRef]

- Zhang, W.; Lin, B.; Fan, J.; Zhang, D.; Li, Y. Microstructures and mechanical properties of heat-treated Al-5.0Cu-0.5Fe squeeze cast alloys with different Mn/Fe ratio. Mater. Sci. Eng. A 2013, 588, 366–375. [Google Scholar] [CrossRef]

| Cu | Fe | Si | Ti | Zn | Bi | Pb | Ni | Mn | Bal. |

|---|---|---|---|---|---|---|---|---|---|

| 5.60 | 0.72 | 0.40 | 0.35 | 0.30 | 0.25 | 0.20 | 0.02 | 0.05 | Al |

| Consumable Rod | FSD Parameters | |||||

|---|---|---|---|---|---|---|

| Material | Initial Length (mm) | Rod Diameter (mm) | Rotation Rate (rpm) | Feeding Speeds (mm/min) | ||

| AA2011-T6 | 200 | 20 | 1200 | 3 | 6 | 9 |

| AA2011-O | 110 | 20 | 200 | 1 | 2 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmed, M.M.Z.; El-Sayed Seleman, M.M.; Elfishawy, E.; Alzahrani, B.; Touileb, K.; Habba, M.I.A. The Effect of Temper Condition and Feeding Speed on the Additive Manufacturing of AA2011 Parts Using Friction Stir Deposition. Materials 2021, 14, 6396. https://doi.org/10.3390/ma14216396

Ahmed MMZ, El-Sayed Seleman MM, Elfishawy E, Alzahrani B, Touileb K, Habba MIA. The Effect of Temper Condition and Feeding Speed on the Additive Manufacturing of AA2011 Parts Using Friction Stir Deposition. Materials. 2021; 14(21):6396. https://doi.org/10.3390/ma14216396

Chicago/Turabian StyleAhmed, Mohamed M. Z., Mohamed M. El-Sayed Seleman, Ebtessam Elfishawy, Bandar Alzahrani, Kamel Touileb, and Mohamed I. A. Habba. 2021. "The Effect of Temper Condition and Feeding Speed on the Additive Manufacturing of AA2011 Parts Using Friction Stir Deposition" Materials 14, no. 21: 6396. https://doi.org/10.3390/ma14216396

APA StyleAhmed, M. M. Z., El-Sayed Seleman, M. M., Elfishawy, E., Alzahrani, B., Touileb, K., & Habba, M. I. A. (2021). The Effect of Temper Condition and Feeding Speed on the Additive Manufacturing of AA2011 Parts Using Friction Stir Deposition. Materials, 14(21), 6396. https://doi.org/10.3390/ma14216396