Analysis, Synthesis and Characterization of Thin Films of a-Si:H (n-type and p-type) Deposited by PECVD for Solar Cell Applications

Abstract

:1. Introduction

2. Materials and Methods

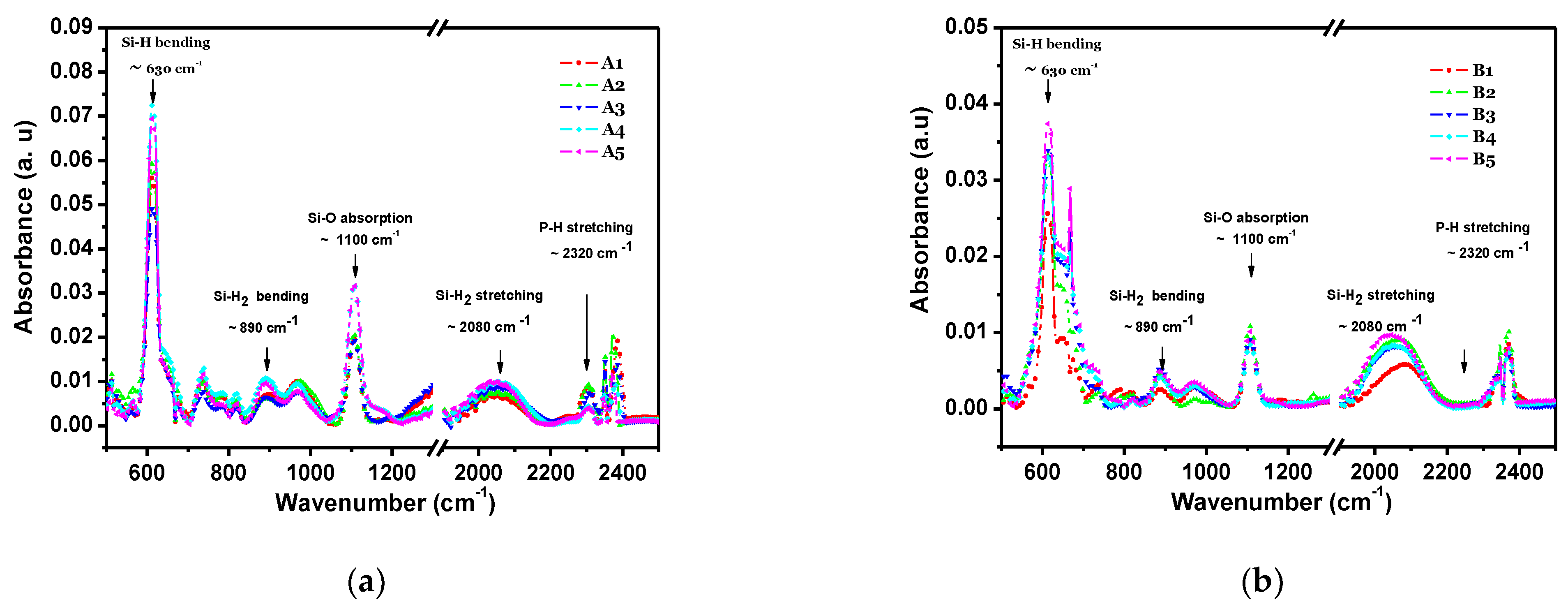

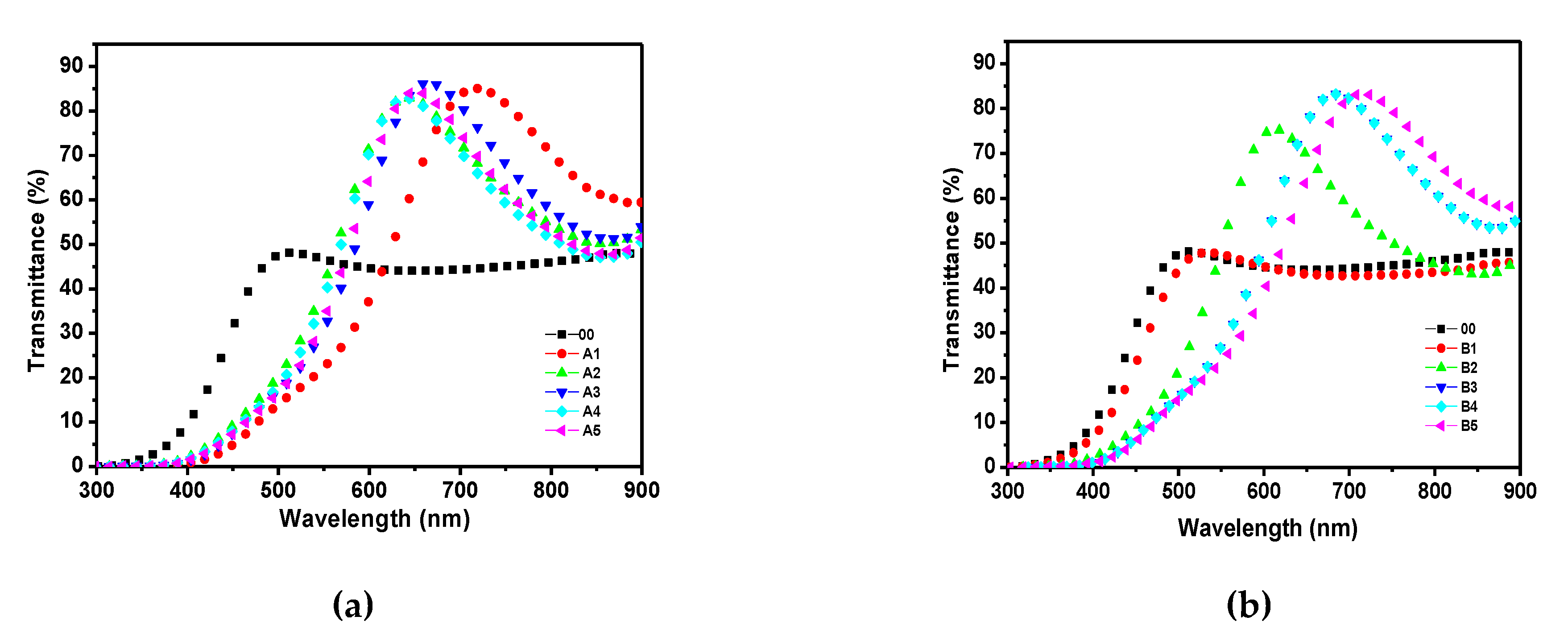

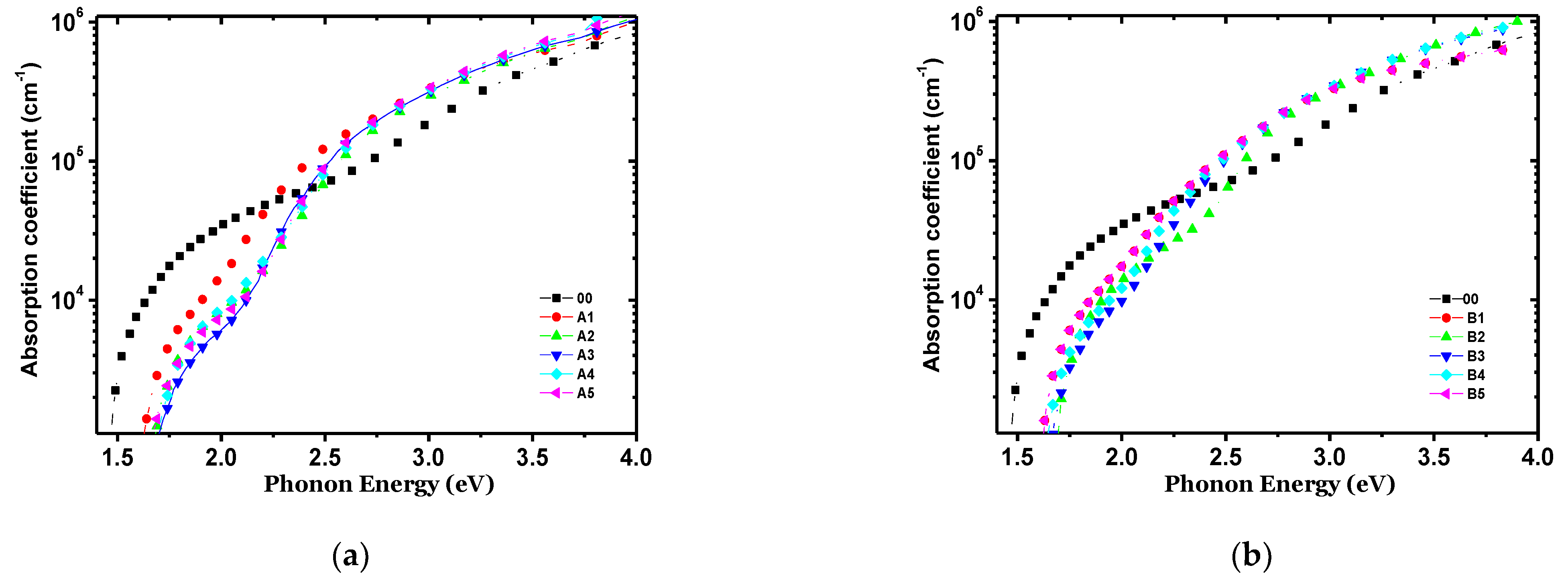

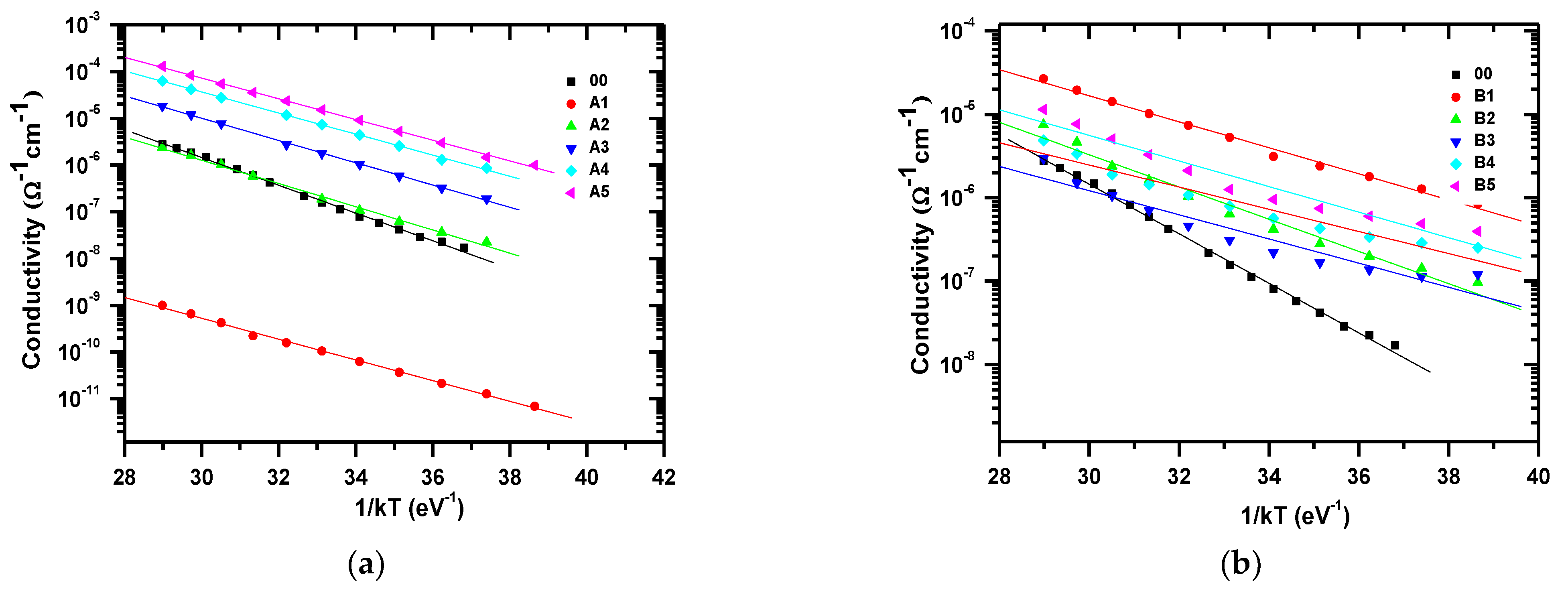

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Müllerová, J.; Fischer, M.; Netrvalová, M.; Zeman, M.; Šutta, P. Influence of deposition temperature on amorphous structure of PECVD deposited a-Si:H thin films. Cent. Eur. J. Phys. 2011, 9, 1301–1308. [Google Scholar] [CrossRef]

- Li, Z.; Li, W.; Jiang, Y.; Cai, H.; Gong, Y.; He, J. Raman characterization of the structural evolution in amorphous and partially nanocrystalline hydrogenated silicon thin films prepared by PECVD. J. Raman Spectrosc. 2011, 42, 415–421. [Google Scholar] [CrossRef]

- Lien, S.Y.; Chang, Y.Y.; Cho, Y.S.; Wang, J.H.; Weng, K.W.; Chao, C.H.; Chen, C.F. Characterization of HF-PECVD a-Si:H thin film solar cells by using OES studies. J. Non-Cryst. Solids 2011, 357, 161–164. [Google Scholar] [CrossRef]

- Yang, G.R.; Zhao, Y.P. Studying low-pressure chemical vapor deposition a-Si:B alloys by optical spectroscopy. J. Vac. Sci. Technol. A 1998, 16, 2267. [Google Scholar] [CrossRef]

- He, J.; Wang, C.; Li, W.; Qi, K.C.; Jiang, Y.D. Effect of gas temperature on the structural and optoelectronic properties of a-Si:H thin films deposited by PECVD. Surf. Coat. Technol. 2013, 214, 131–137. [Google Scholar] [CrossRef]

- Wang, S.H.; Chang, H.E.; Lee, C.C.; Fuh, Y.K.; Li, T.T. Evolution of a-Si:H to nc-Si:H transition of hydrogenated silicon films deposited by trichlorosilane using principle component analysis of optical emission spectroscopy. Mater. Chem. Phys. 2020, 240, 122186. [Google Scholar] [CrossRef]

- Stuckelberger, M.; Biron, R.; Wyrsch, N.; Haug, F.J.; Ballif, C. Review: Progress in solar cells from hydrogenated amorphous silicon. Renew. Sustain. Energy 2017, 76, 1497–1523. [Google Scholar] [CrossRef]

- Meillaud, F.; Boccard, M.; Bugnon, G.; Despeisse, M.; Hänni, S.; Haug, F.J.; Persoz, J.; Schüttauf, J.W.; Stuckelberger, M.; Ballif, C. Recent advances and remaining challenges in thin-film silicon photovoltaic technology. Mater. Today 2015, 18, 378–384. [Google Scholar] [CrossRef]

- Matsui, T.; Sai, H.; Suezaki, T.; Matsumoto, M.; Saito, K.; Yoshida, I.; Kondo, M. Development of highly stable and efficient amorphous silicon based solar cells. In Proceedings of the 28th European Photovoltaic Solar Energy Conference Exhibition, Villepinte, France, 30 September–4 October 2013; pp. 2213–2217. [Google Scholar]

- Matsui, T.; Maejima, K.; Bidiville, A.; Sai, H.; Koida, T.; Suezaki, T.; Matsumoto, M.; Saito, K.; Yoshida, I.; Kondo, M. High-efficiency thin-film silicon solar cells realized by integrating stable a-Si:H absorbers into improved device design. Jpn. J. Appl. Phys. 2015, 54, 1–4. [Google Scholar] [CrossRef]

- Bengali, S.; Borello, D.; Sauvain, E.; Meir, J.; Kroll, U.; Hotzel, J. High efficiency amorphous silicon devices on LPCVD-ZNO TCO prepared in industrial KAI-M R&D reactor. In Proceedings of the 24th European Photovoltaic Solar Energy Conference, Hamburg, Germany, 21–25 September 2009; pp. 2293–2298. [Google Scholar]

- Lambertz, A.; Finger, F.; Schropp, R.E.I.; Rau, U.; Smirnov, V. Preparation and measurement of highly efficient a-Si:H single junction solar cells and the advantages of μc-SiOx:H n-layers. Prog. Photovolt. 2015, 23, 939–948. [Google Scholar] [CrossRef]

- Nelson, B.P.; Iwaniczko, E.; Mahan, A.H.; Wang, Q.; Xu, Y.; Crandall, R.S.; Branz, H.M. High-deposition rate a-Si:H n–i–p solar cells grown by HWCVD. Thin Solid Film. 2001, 395, 292–297. [Google Scholar] [CrossRef]

- Matsui, T.; Bidiville, A.; Maejima, K.; Sai, H.; Koida, T.; Suezaki, T.; Matsumoto, M.; Saito, K.; Yoshida, I.; Kondo, M. High-efficiency amorphous silicon solar cells: Impact of deposition rate on metastability. Appl. Phys. Lett. 2015, 106, 053901. [Google Scholar] [CrossRef]

- Yoon, J.H.; Song, J.; Lee, S.J. Practical application of building integrated photovoltaic (BIPV) system using transparent amorphous silicon thin-film PV module. Sol. Energy 2011, 85, 723–733. [Google Scholar] [CrossRef]

- Kang, D.W.; Ryu, J.; Konagai, M. High-performance amorphous silicon thin film solar cells prepared at 100 °C: Toward flexible building-integrated photovoltaics. Electron. Mater. Lett. 2019, 15, 623–629. [Google Scholar] [CrossRef]

- Nobile, G.; Morana, M. Light soaking effect in a-Si: H based n–i–p and p–i–n solar cells. Sol. Energy Mater. Sol. Cells 2003, 76, 511–520. [Google Scholar] [CrossRef]

- Staebler, D.L.; Wronski, C.R. Reversible conductivity changes in discharge produced amorphous Si. Appl. Phys. Lett. 1977, 31, 292–294. [Google Scholar] [CrossRef]

- Kim, K.; Yue, K. Influence of pin amorphous silicon stack deposition sequence on solar cell performance and degradation. ECS J. Solid State Sci. Technol. 2017, 6, 29–35. [Google Scholar] [CrossRef]

- Schroeder, B. Status report: Solar cell related research and development using amorphous and microcrystalline silicon deposited by HW(Cat)CVD. Thin Solid Film. 2003, 430, 1–6. [Google Scholar] [CrossRef]

- Tan, H.; Santbergen, R.; Smets, A.H.; Zeman, M. Plasmonic light trapping in thin-film silicon solar cells with improved self-assembled silver nanoparticles. Nano Lett. 2012, 12, 4070–4076. [Google Scholar] [CrossRef]

- Hou, G.; Zhang, X.; Han, X.; Li, G.; Geng, X.; Chen, X.; Zhao, Y. High-efficiency a-Si:H/μc-Si:H solar cells by optimizing A-Si:H and μc-Si:H sub-cells. IEEE Int. Conf. Electro-Inf. Technol. 2013, 2013, 1–6. [Google Scholar]

- Luft, W.; Tsuo, Y.S. Hydrogenated Amorphous Silicon Allow Deposition Processes; Dekker: New York, NY, USA, 1993. [Google Scholar]

- Tao, G.; Zeman, M.; Metselaar, J.W. Optical modeling of a-Si:H based solar cells on textured substrates. Proceedings of IEEE 1st World Conference on Photovoltaic Energy Conversion—WCPEC, Waikoloa, HI, USA, 5–9 December 1994; pp. 666–669. [Google Scholar]

- Oliveira, A.R.; Carreño, M.N.P. N and p-type doping of PECVD a-SiC:H obtained under “silane starving plasma” condition with and without hydrogen dilution. Mater. Sci. Eng. B 2006, 128, 2006. [Google Scholar] [CrossRef]

- Global Thin-film Amorphous Silicon Solar Cell Market Report, History and Forecast 2016–2027, Breakdown Data by Manufacturers, Key Regions, Types and Application. Available online: https://www.businessgrowthreports.com/enquiry/request-sample/18398265 (accessed on 9 September 2021).

- Sharma, M.; Panigrahi, J.; Komarala, V.K. Nanocrystalline silicon thin film growth and application for silicon heterojunction solar cells: A short review. Nanoscale Adv. 2021, 3, 3373. [Google Scholar] [CrossRef]

- Dai, Y.; Bai, Y. Performance Improvement for Building Integrated Photovoltaics in Practice: A Review. Energies 2021, 14, 178. [Google Scholar] [CrossRef]

- Saeed, M.A.; Kim, S.H.; Baek, K.; Hyun, J.K.; Lee, S.Y.; Shim, J.W. PEDOT:PSS: CuNW-based transparent composite electrodes for high-performance and flexible organic photovoltaics under indoor lighting. Appl. Surf. Sci. 2021, 567, 150852. [Google Scholar] [CrossRef]

- Cho, Y.S.; Hsu, C.H.; Lien, S.Y.; Wuu, D.S.; Hsieh, I.C. Effect of hydrogen content in intrinsic a-Si:H on performances of heterojunction solar cells. Int. J. Photoenergy 2013, 121875, 1–6. [Google Scholar] [CrossRef]

- Lee, J.H.; You, Y.J.; Saeed, M.A.; Kim, S.H.; Choi, S.H.; Kim, S.; Lee, S.Y.; Park, J.S.; Shim, J.W. Udoped tin dioxide transparent electrodes for efficient and cost-effective indoor organic photovoltaics (SnO2 electrode for indoor organic photovoltaics). NPG Asia Mater. 2021, 13, 43. [Google Scholar] [CrossRef]

| Process 1 | H2 (sccm) | SiH4 (sccm) | PH3 (sccm) | B2H6 (sccm) |

|---|---|---|---|---|

| 00 | 1000 | 50 | 0 | 0 |

| A1 | 200 | 50 | 4 | 0 |

| A2 | 1000 | 50 | 5 | 0 |

| A3 | 1000 | 50 | 6 | 0 |

| A4 | 1000 | 50 | 8 | 0 |

| A5 | 1000 | 50 | 10 | 0 |

| B1 | 200 | 50 | 0 | 4 |

| B2 | 1000 | 50 | 0 | 5 |

| B3 | 1000 | 50 | 0 | 6 |

| B4 | 1000 | 50 | 0 | 8 |

| B5 | 1000 | 50 | 0 | 10 |

| Process | Thickness (Å) | Eg (eV) |

|---|---|---|

| 00 | 583 | 1.97 |

| A1 | 1066 | 1.71 |

| A2 | 941 | 1.71 |

| A3 | 995 | 1.82 |

| A4 | 910 | 1.79 |

| A5 | 955 | 1.78 |

| B1 | 601 | 1.83 |

| B2 | 860 | 1.74 |

| B3 | 985 | 1.70 |

| B4 | 1030 | 1.69 |

| B5 | 1079 | 1.67 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garcia-Barrientos, A.; Bernal-Ponce, J.L.; Plaza-Castillo, J.; Cuevas-Salgado, A.; Medina-Flores, A.; Garcia-Monterrosas, M.S.; Torres-Jacome, A. Analysis, Synthesis and Characterization of Thin Films of a-Si:H (n-type and p-type) Deposited by PECVD for Solar Cell Applications. Materials 2021, 14, 6349. https://doi.org/10.3390/ma14216349

Garcia-Barrientos A, Bernal-Ponce JL, Plaza-Castillo J, Cuevas-Salgado A, Medina-Flores A, Garcia-Monterrosas MS, Torres-Jacome A. Analysis, Synthesis and Characterization of Thin Films of a-Si:H (n-type and p-type) Deposited by PECVD for Solar Cell Applications. Materials. 2021; 14(21):6349. https://doi.org/10.3390/ma14216349

Chicago/Turabian StyleGarcia-Barrientos, Abel, Jose Luis Bernal-Ponce, Jairo Plaza-Castillo, Alberto Cuevas-Salgado, Ariosto Medina-Flores, María Silvia Garcia-Monterrosas, and Alfonso Torres-Jacome. 2021. "Analysis, Synthesis and Characterization of Thin Films of a-Si:H (n-type and p-type) Deposited by PECVD for Solar Cell Applications" Materials 14, no. 21: 6349. https://doi.org/10.3390/ma14216349

APA StyleGarcia-Barrientos, A., Bernal-Ponce, J. L., Plaza-Castillo, J., Cuevas-Salgado, A., Medina-Flores, A., Garcia-Monterrosas, M. S., & Torres-Jacome, A. (2021). Analysis, Synthesis and Characterization of Thin Films of a-Si:H (n-type and p-type) Deposited by PECVD for Solar Cell Applications. Materials, 14(21), 6349. https://doi.org/10.3390/ma14216349