Archaeological and Chemical Investigation on Mortars and Bricks from a Necropolis in Braga, Northwest of Portugal

Abstract

:1. Introduction

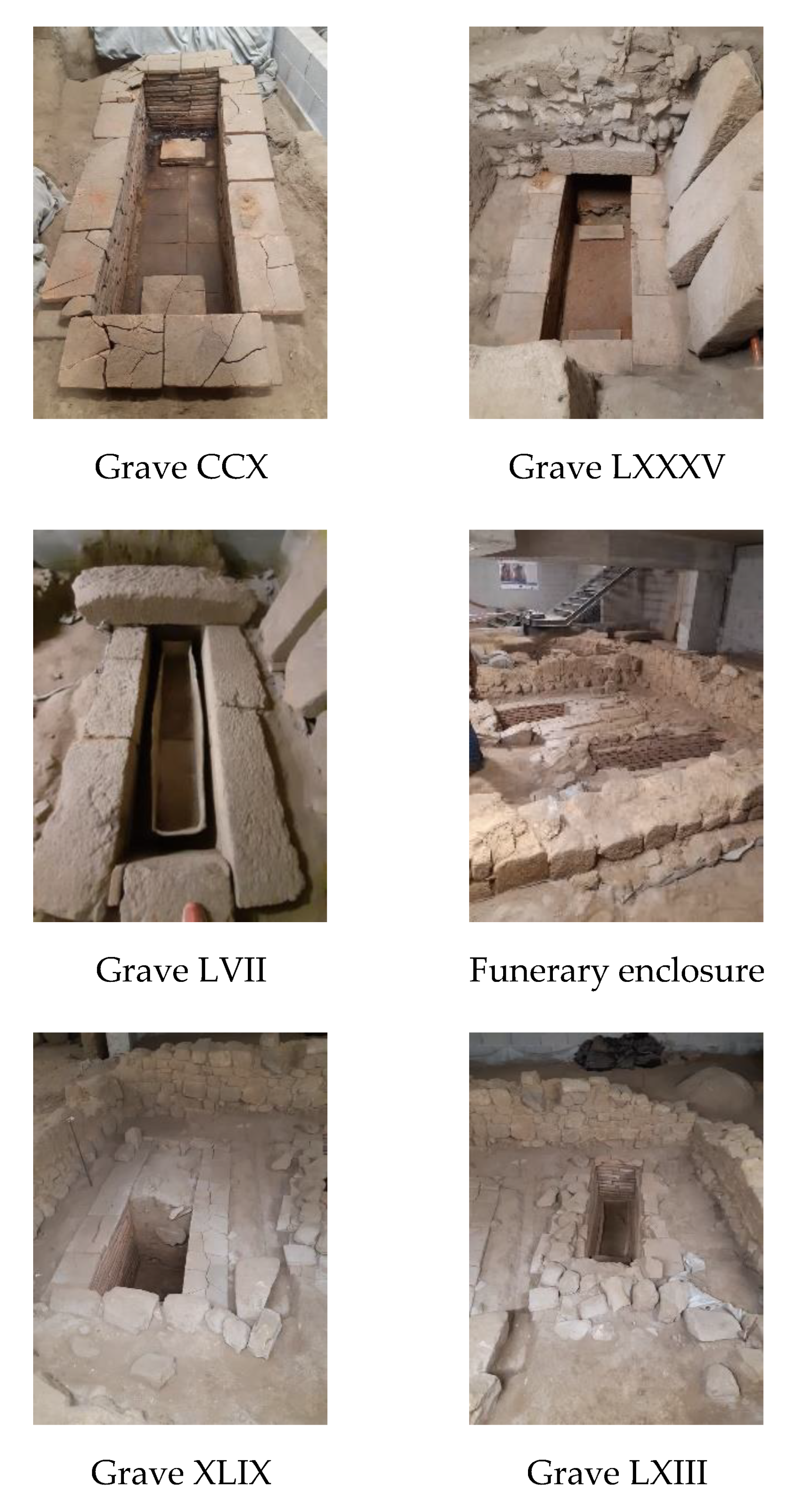

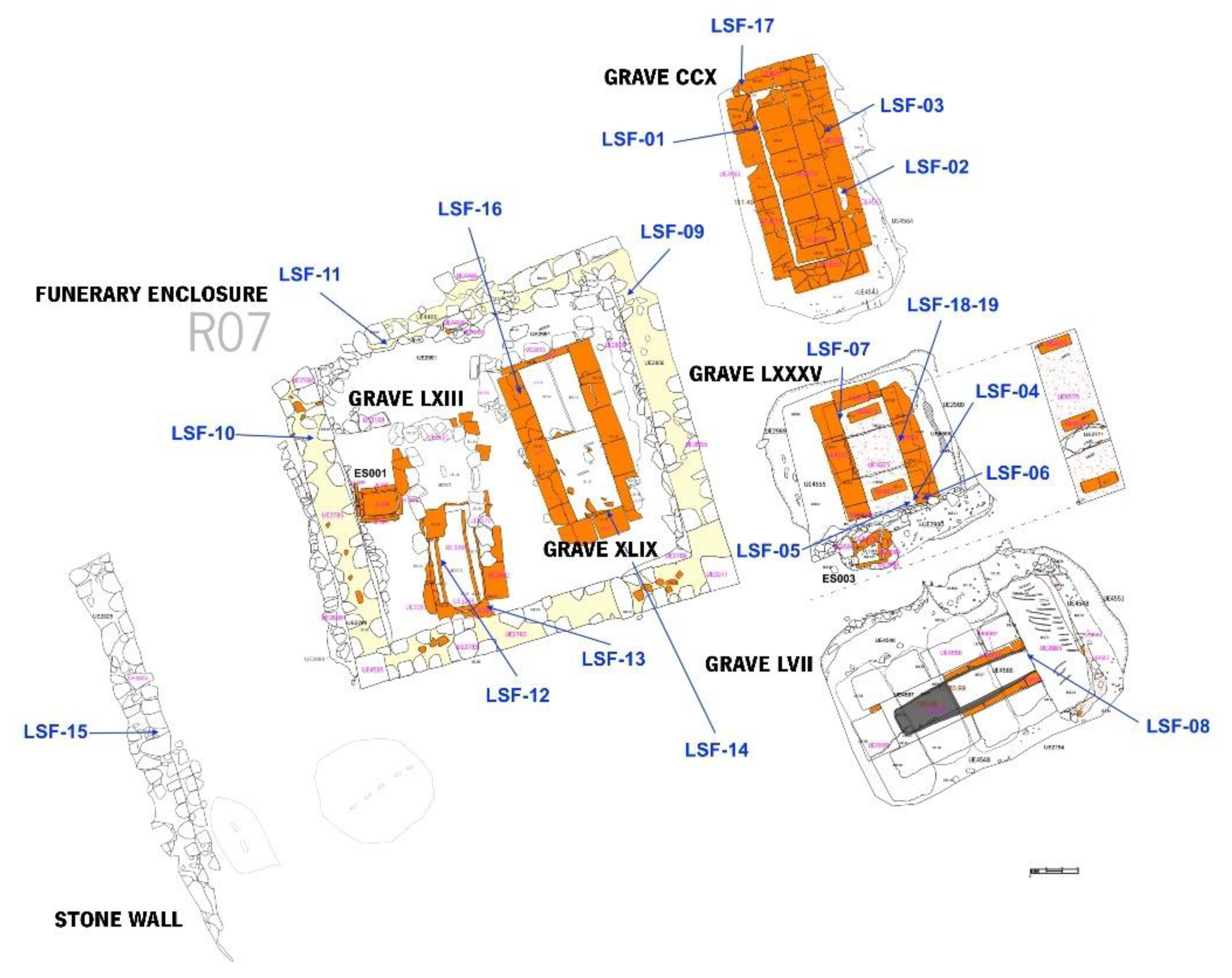

2. Archaeological Setting

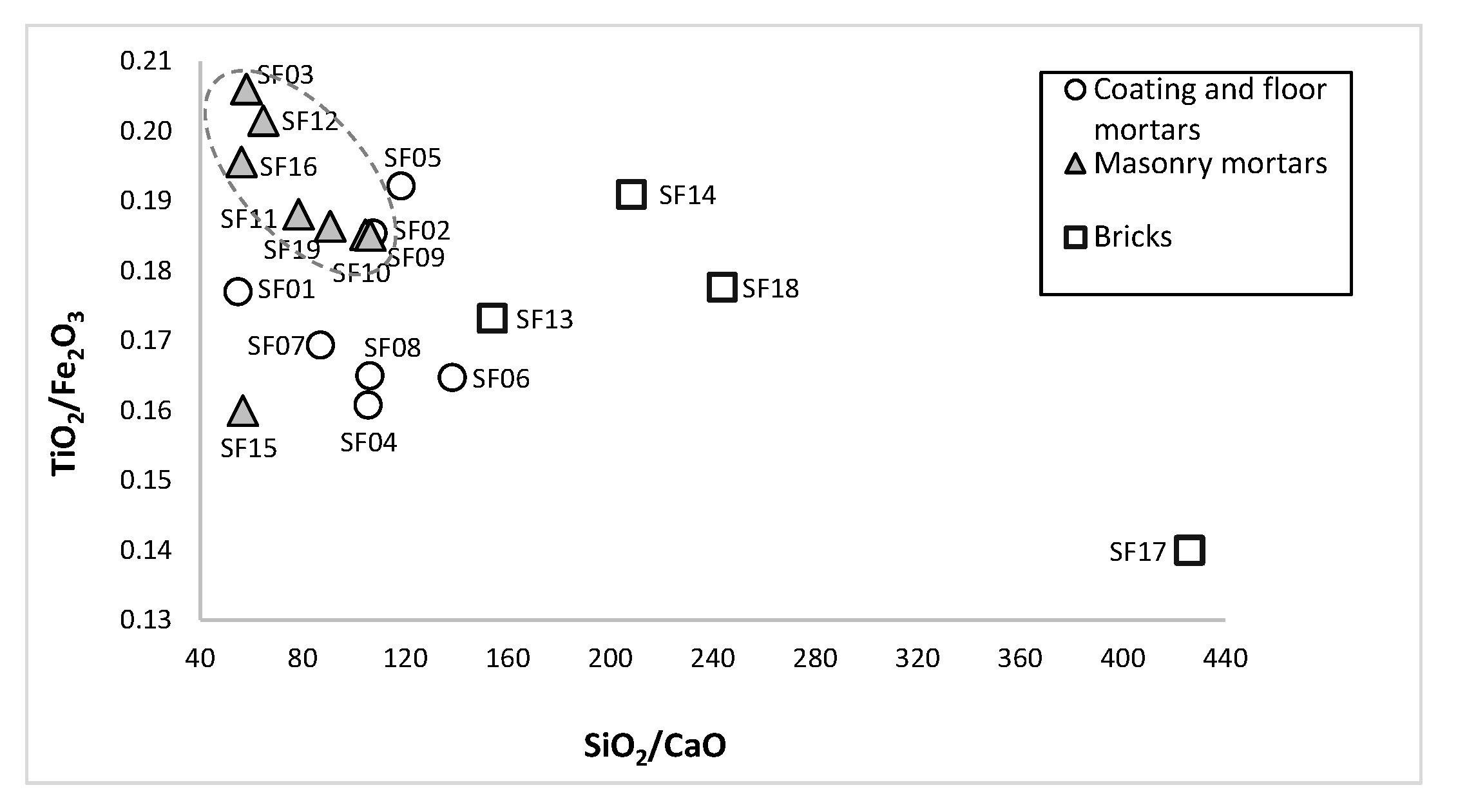

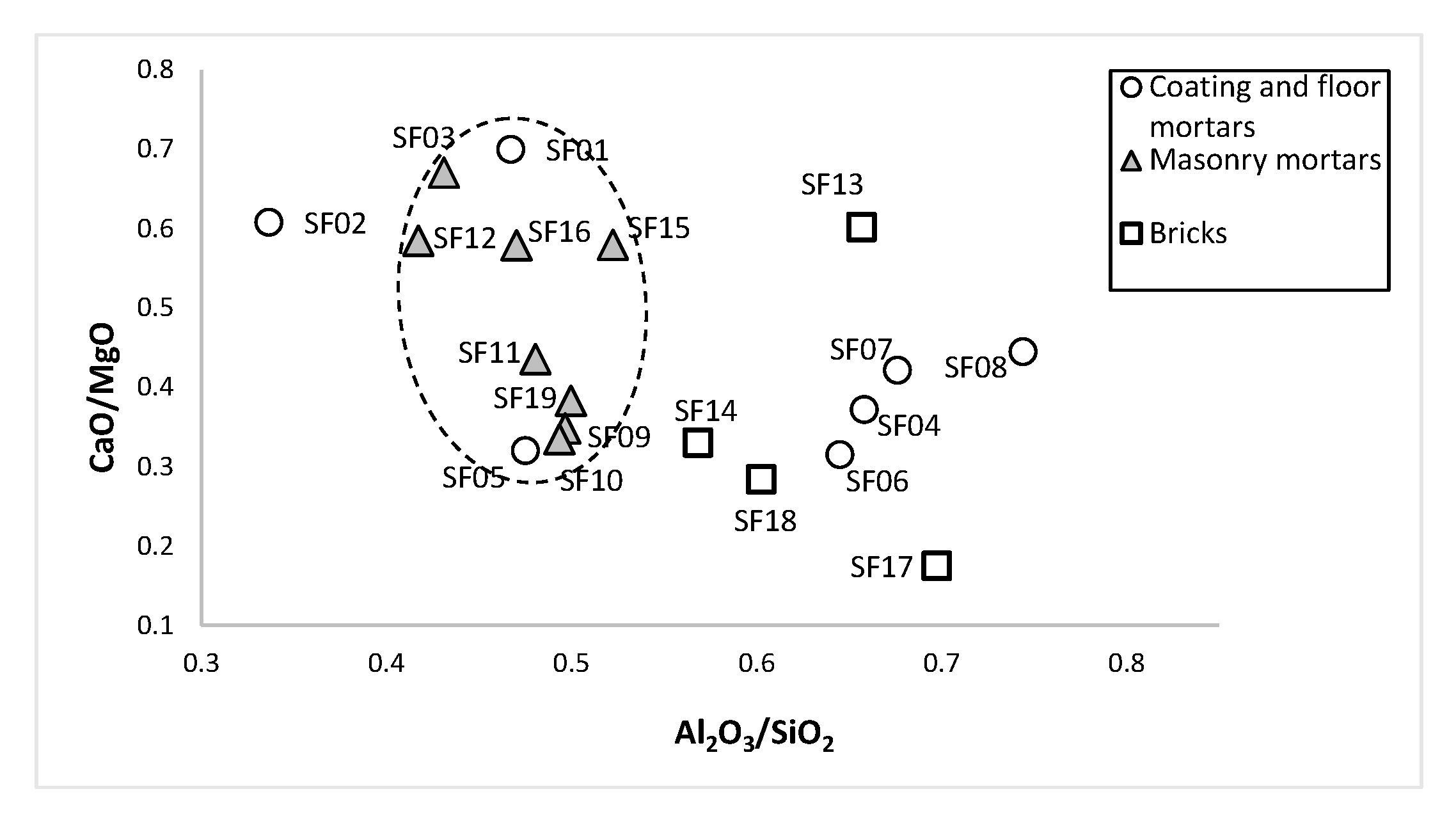

Description of the Structures Identified

3. Materials and Methods

3.1. Samples Collection

3.2. Chemical Analysis by X-ray Fluorescence (XRF)

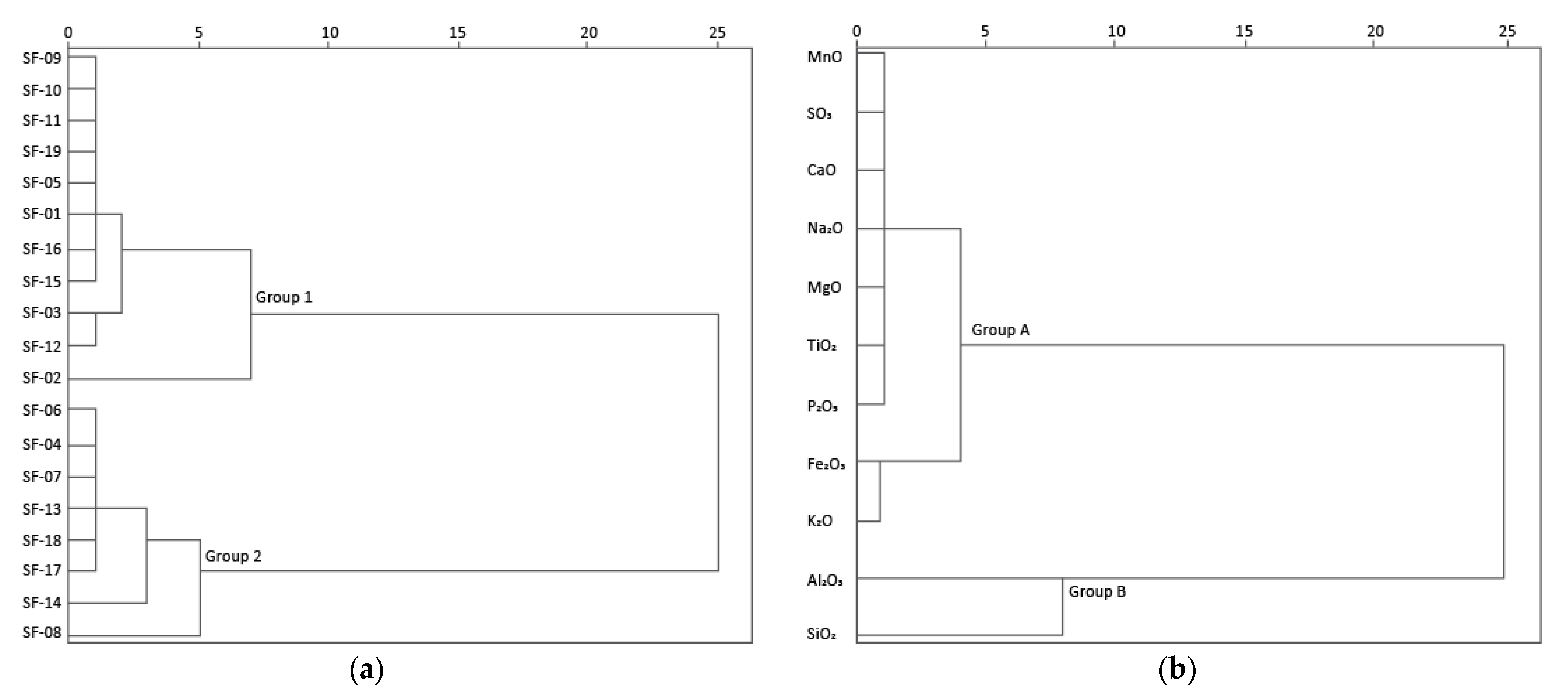

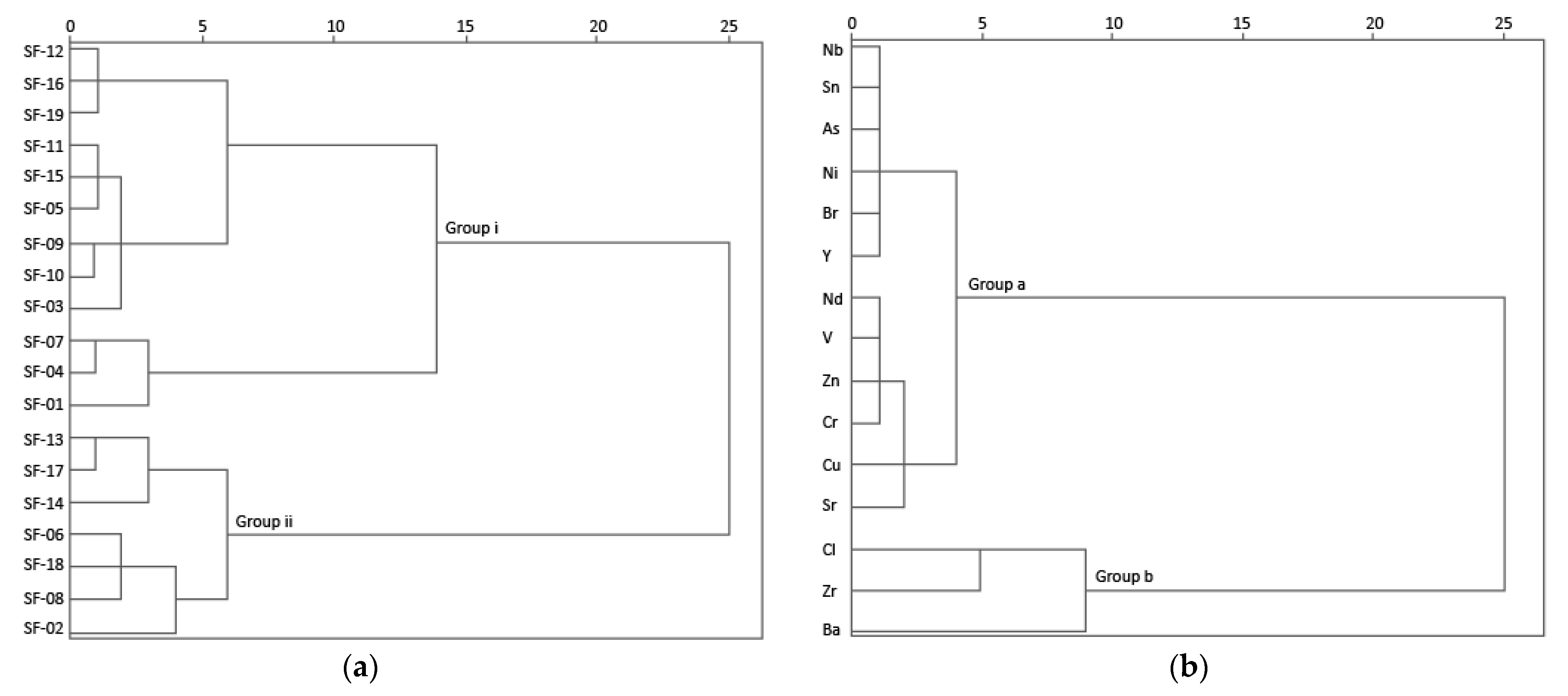

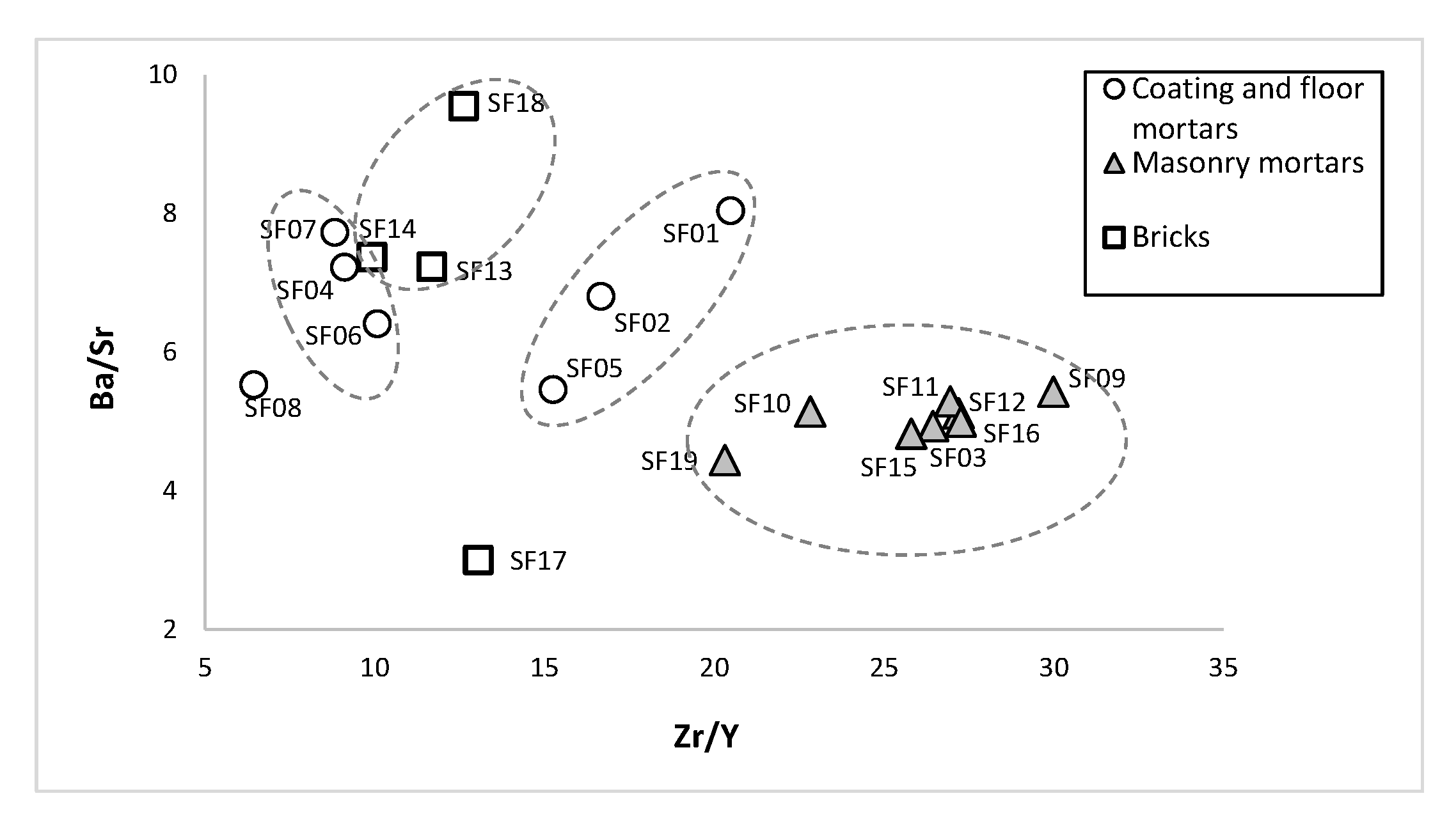

3.3. Chemical Statistical Analysis

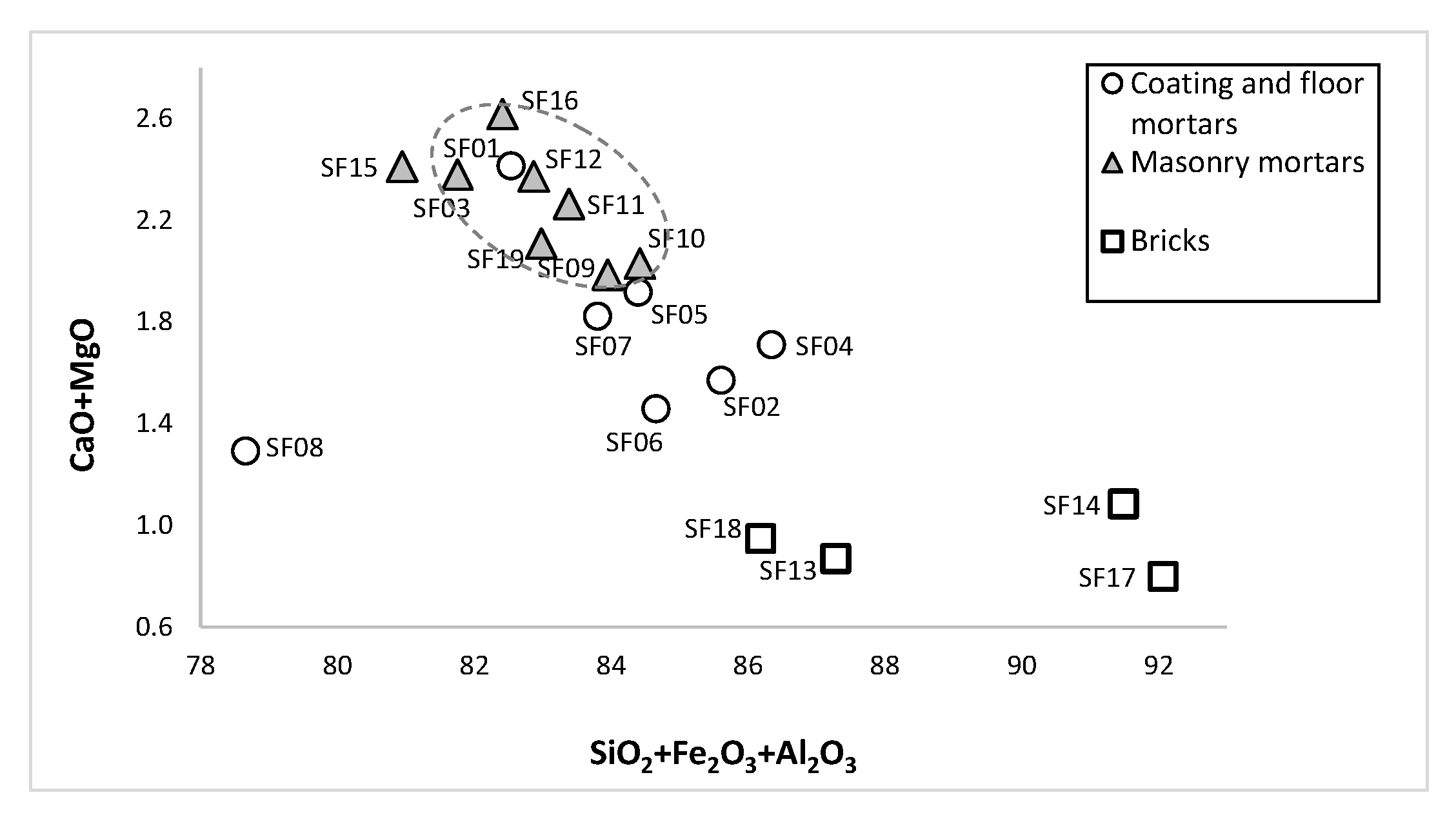

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fragata, A.; Ribeiro, J.; Candeias, C.; Velosa, A.; Rocha, F. Archaeological and Chemical Investigation on the High Imperial Mosaic Floor Mortars of the Domus Integrated in the Museum of Archaeology D. Diogo de Sousa, Braga, Portugal. Appl. Sci. 2021, 11, 8267. [Google Scholar] [CrossRef]

- Silva, A.S.; Paiva, M.; Ricardo, J.; Salta, M.M.; Monteiro, A.M.; Candeias, A.E. Characterisation of Roman mortars from the archaeological site of Tróia (Portugal). Mater. Sci. Forum 2006, 514, 1643–1647. [Google Scholar] [CrossRef]

- Cardoso, I.; Macedo, M.F.; Vermeulen, F.; Corsi, C.; Santos Silva, A.; Rosado, L.; Candeias, A.; Mirao, J. A multidisciplinary approach to the study of archaeological mortars from the town of Ammaia in the Roman province of Lusitania (Portugal). Archaeometry 2014, 56, 1–24. [Google Scholar] [CrossRef] [Green Version]

- Borsoi, G.; Santos Silva, A.; Menezes, P.; Candeias, A.; Mirão, J. Analytical characterization of ancient mortars from the archaeological Roman site of Pisões (Beja, Portugal). Constr. Build Mater. 2019, 204, 597–608. [Google Scholar] [CrossRef] [Green Version]

- Velosa, A.L.; Coroado, J.; Veiga, M.R.; Rocha, F. Characterisation of roman mortars from Conímbriga with respect to their repair. Mater. Charact. 2007, 58, 1208–1216. [Google Scholar] [CrossRef]

- Ribeiro, J. Roman Architecture in Bracara Augusta. Analysis of Building Techniques; Afrontamento: Porto, Portugal, 2013. (In Portuguese) [Google Scholar]

- Fernandes, F.M.; Lourenço, P.B.; Castro, F. Ancient Clay Bricks: Manufacture and Properties. In Materials, Technologies and Practice in Historic Heritage Structures; Dan, M.B., Přikryl, R., Török, Á., Eds.; Springer: Dordrecht, The Netherlands, 2010; pp. 29–48. [Google Scholar]

- Prudêncio, M.I.; Braga, M.A.S.; Oliveira, F.; Dias, M.I.; Delgado, M.; Martins, M. Raw material sources for the Roman Bracarense ceramics (NW Iberian Peninsula). Clays Clay Miner. 2006, 54, 638–649. [Google Scholar] [CrossRef]

- Al-Muheisen, Z. Archaeological Excavations at the Yasileh Site in Northern Jordan: The Necropolis. Syr. Archéologie Art Et Hist. 2018, 85, 315–337. [Google Scholar] [CrossRef]

- Cochet, A.E.; Hansen, J. Conduites et Objects de Plomb Gallo-Romaines de Vienne (Isére); Gallia, 46; Centre National de la Recherche Scientifique: Paris, France, 1986. (In French) [Google Scholar]

- Gillet, P.E.; Mahéo, N. Sarcophages en plomb gallo-romaines découverts à Amiens et dans ses environs (Somme). Rev. Archéologique Picardie 2000, 3, 77–118. (In French) [Google Scholar] [CrossRef]

- Pereira, C. The Roman Necropolis of Algarve (Portugal): About the Spaces of Death in the South of Lusitania; Archaeopress Publishing Ltd.: Oxford, UK, 2015. [Google Scholar]

- Di Benedetto, C.; Graziano, S.F.; Guarino, V.; Rispoli, C.; Munzi, P.; Morra, V.; Cappelletti, P. Romans’ established skills: Mortars from D46b mausoleum, Porta Mediana Necropolis, Cuma (Naples). Mediterr. Archaeol. Ar. 2018, 18, 131–146. [Google Scholar]

- Alberghina, M.F.; Germinario, C.; Bartolozzi, G.; Bracci, S.; Grifa, C.; Izzo, F.; La Russa, M.F.; Magrini, D.; Massa, E.; Mercurio, M.; et al. The Tomb of the Diver and the frescoed tombs in Paestum (southern Italy): New insights from a comparative archaeometric study. PLoS ONE 2020, 15, e0232375. [Google Scholar] [CrossRef] [Green Version]

- Sanchez-Moral, S.; Cañaveras, J.C.; Benavente, D.; Fernandez-Cortes, A.; Cuezva, S.; Elez, J.; Jurado, V.; Rogerio-Candelera, M.A.; Saiz-Jimenez, C. A study on the state of conservation of the Roman Necropolis of Carmona (Sevilla, Spain). J. Cult. Herit. 2018, 34, 185–197. [Google Scholar] [CrossRef] [Green Version]

- Martins, M.; Carvalho, H. Roman city of Bracara Augusta (Hispania Citerior Tarraconensis): Urbanism and territory occupation. Agri Centuriate 2017, 14, 79–98. [Google Scholar]

- Braga, C.; Martins, M. The funerary topography of the Via XVII necropolis in Late Antiquity (Braga). Agira 2016, VIII, 17–34. [Google Scholar]

- Vaz, F.C.; Braga, C.; Tereso, J.P.; Oliveira, C.; Carretero, L.G.; Detry, C.; Marcos, B.; Fontes, L.; Martins, M. Food for the dead, fuel for the pyre: Symbolism and function of plant remains in provincial Roman cremation rituals in the necropolis of Bracara Augusta (NW Iberia). Quatern. Int. 2021, 593, 372–383. [Google Scholar] [CrossRef]

- Braga, C. A new sector of Via XVII necropolis in Bracara Augusta: The High Empire phase. In Proceedings of the XVIII CIAC: Centro y Periferia en el Mundo Clásico, Mérida, Spain, 13–17 May 2013; Martínez, J.M., Trinidad, N.B., Llanza, I., Eds.; Museo Nacional de Arte Romano: Mérida, Spain, 2014; pp. 1253–1257. [Google Scholar]

- Fontes, L.; Braga, C. Archaeological nucleus of Liberdade Street Fashion, Braga. Forum 2015, 49–50, 71–84. (In Portuguese) [Google Scholar]

- Braga, C. Death, Memory and Identity: An analysis of Bracara Augusta’s Funerary Practices. Ph.D. Thesis, University of Minho, Braga, Portugal, 2018. (In Portuguese). [Google Scholar]

- Özkaya, O.A.; Böke, H. Properties of Roman bricks and mortars used in Serapis temple in the city of Pergamon. Mater. Charact. 2009, 60, 995–1000. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, N. Geological Chart of Portugal in Scale 1:50,000—Sheet 5-D, Braga; Ministério da Economia, Instituto Geológico Mineiro, Departamento de Geologia: Lisboa, Portugal, 2000. [Google Scholar]

- Lourenço, P.B.; Fernandes, F.M.; Castro, F. Handmade Clay Bricks: Chemical, Physical and Mechanical Properties. Int. J. Archit. Herit. 2010, 4, 38–58. [Google Scholar] [CrossRef] [Green Version]

- Ontiveros-Ortega, E.; Rodríguez-Gutiérrez, O.; Navarro, A. Mineralogical and physical-chemical characterization of Roman mortars used for monumental substrates on the hill of San Antonio, in the Roman city of Italica (prov. Baetica, Santiponce, Seville, Spain). J. Archaeol. Sci. Rep. 2016, 7, 205–223. [Google Scholar]

- Fragata, A.; Veiga, R.; Velosa, A. Substitution ventilated render systems for historic masonry: Salt crystallization tests evaluation. Const. Build. Mater. 2016, 102, 592–600. [Google Scholar] [CrossRef]

- Ergenç, D.; Fort, R. Multi-technical characterization of Roman mortars from Complutum, Spain. Measurement 2019, 147, 106876. [Google Scholar] [CrossRef]

- Baronio, G.; Binda, L. Study of the pozzolanicity of some bricks and clays. Const. Build. Mater. 1997, 11, 41–46. [Google Scholar] [CrossRef]

- Miriello, D.; Bloise, A.; Crisci, G.M.; Apollaro, C.; La Marca, A. Characterisation of archaeological mortars and plasters from kyme (Turkey). J. Archaeol. Sci. 2011, 38, 794–804. [Google Scholar] [CrossRef]

| Sample | Location Description | Brick or Mortar Function in the Structure/Construction Technique | Construction Phase (Century) | Color/Consolidation/Conservation State | |

|---|---|---|---|---|---|

| Masonry mortars (MM) | SF03 | Grave CCX; brick wall | Bedding mortar | IV–V | Greyish Brown/no/cohesion loss |

| SF09 | Funerary enclosure; East stone wall | Bedding mortar | V–VII | Light brown/no/cohesion loss | |

| SF10 | Funerary enclosure; West stone wall | Bedding mortar | V–VII | Light brown/no/cohesion loss | |

| SF11 | Funerary enclosure; North stone wall | Bedding mortar from foundations | V–VII | Light brown/no/cohesion loss | |

| SF12 | Grave LXIII (inside funerary enclosure); brick wall | Bedding mortar | V–VII | Light brown/no/cohesion loss | |

| SF15 | Stone wall | Bedding mortar | II | Brown/no/cohesion loss | |

| SF16 | Grave XLIX (inside funerary enclosure); brick wall | Bedding mortar | IV–V | Light brown/no/cohesion loss | |

| SF19 | Grave LXXXV; brick wall | Bedding mortar | V–VII | Greyish brown/no/cohesion loss | |

| Coating and floor mortars (CFM) | SF01 | Grave CCX; brick wall | Opus signinum; coating mortar—from the wall | IV–V | Reddish/cohesion loss |

| SF02 | Grave CCX; brick wall | Opus signinum; coating mortar with brick fragments from the top of the cover (may act as impermeabilization render) | IV–V | Pink or reddish brown/paraloid 10%/cohesion loss | |

| SF04 | Grave LXXXV | Opus signinum; floor mortar, uppermost layer | V–VII | Reddish/cohesion loss | |

| SF05 | Grave LXXXV | Preparatory layer; floor mortar, lowermost layer | V–VII | Reddish/no/cohesion loss | |

| SF06 | Grave LXXXV; brick wall | Opus signinum; coating mortar from the top of the cover (may act as impermeabilization render) | V–VII | Orange or reddish/no/cohesion loss | |

| SF07 | Grave LXXXV; brick wall | Opus signinum; coating mortar from the wall | V–VII | Reddish/cohesion loss | |

| SF08 | Grave LVII; stone wall | Opus signinum; coating mortar from the wall | V–VII | Reddish brown/no/cohesion loss | |

| Bricks (B) | SF13 | Grave LXIII (inside funerary enclosure); brick wall | Brick from cover | IV–V | Orange/no |

| SF14 | Grave XLIX (inside funerary enclosure); brick wall | Brick from the wall | IV–V | Orange/no | |

| SF17 | Grave CCX; brick wall | Brick (lydion type) from the wall | IV–V | Orange/no | |

| SF18 | Grave LXXXV; brick wall | Brick from the wall | V–VII | Orange/no |

| Group | Al2O3 | CaO | Fe2O3 | MgO | K2O | MnO | Na2O | P2O5 | SiO2 | SO3 | TiO2 | LOI | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Masonry mortars (MM) | Min | 20.77 | 0.51 | 5.37 | 1.43 | 5.80 | 0.06 | 0.33 | 0.38 | 50.07 | 0.03 | 1.11 | 4.78 |

| Max | 23.99 | 0.96 | 7.23 | 1.66 | 6.73 | 0.11 | 0.89 | 1.82 | 56.57 | 0.11 | 1.19 | 6.54 | |

| Mean | 22.88 | 0.75 | 6.16 | 1.53 | 6.30 | 0.08 | 0.62 | 0.94 | 53.80 | 0.07 | 1.15 | 5.31 | |

| SD | 1.29 | 0.19 | 0.58 | 0.07 | 0.31 | 0.02 | 0.22 | 0.54 | 1.88 | 0.03 | 0.03 | 0.56 | |

| Coating and floor mortars (CFM) | Min | 18.28 | 0.35 | 3.51 | 0.90 | 3.82 | 0.07 | 0.28 | 0.36 | 42.26 | 0.05 | 0.65 | 3.61 |

| Max | 29.78 | 0.99 | 7.61 | 1.45 | 6.61 | 0.11 | 0.75 | 4.53 | 63.83 | 0.32 | 1.25 | 7.89 | |

| Mean | 25.96 | 0.54 | 6.35 | 1.20 | 4.94 | 0.08 | 0.45 | 1.86 | 51.41 | 0.17 | 1.09 | 5.35 | |

| SD | 4.52 | 0.21 | 1.48 | 0.21 | 1.07 | 0.01 | 0.22 | 1.33 | 7.00 | 0.11 | 0.21 | 1.38 | |

| Bricks (B) | Min | 28.27 | 0.12 | 6.33 | 0.54 | 3.70 | 0.02 | 0.14 | 0.31 | 50.38 | 0.02 | 1.10 | 1.36 |

| Max | 32.83 | 0.33 | 8.52 | 0.82 | 3.85 | 0.04 | 0.20 | 1.03 | 56.01 | 0.12 | 1.23 | 6.04 | |

| Mean | 30.17 | 0.23 | 7.02 | 0.69 | 3.80 | 0.03 | 0.17 | 0.68 | 52.07 | 0.05 | 1.18 | 3.63 | |

| SD | 2.01 | 0.09 | 1.02 | 0.11 | 0.07 | 0.01 | 0.03 | 0.35 | 2.65 | 0.05 | 0.06 | 2.48 | |

| Group | As | Ba | Br | Cl | Cr | Cu | Nb | Nd | Ni | Pb 1 | Sn | Sr | V | Y | Zn | Zr | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Masonry mortars (MM) | Min | 5.9 | 720.0 | 6.8 | 120.0 | 21.9 | 32.3 | 15.7 | 61.1 | 8.1 | 46.9 | 10.4 | 140.0 | 56.4 | 13.0 | 57.5 | 370.0 |

| Max | 21.4 | 900.0 | 16.9 | 370.0 | 89.8 | 210.0 | 18.4 | 80.8 | 9.8 | 220.0 | 21.4 | 180.0 | 70.1 | 18.7 | 78.9 | 410.0 | |

| Mean | 10.9 | 820.0 | 10.5 | 222.5 | 38.2 | 85.7 | 17.1 | 69.1 | 8.8 | 94.5 | 12.8 | 163.8 | 64.7 | 15.1 | 66.6 | 386.3 | |

| SD | 4.3 | 61.4 | 3.2 | 98.8 | 20.5 | 58.4 | 0.9 | 5.5 | 0.6 | 64.8 | 3.6 | 14.9 | 4.0 | 1.7 | 5.6 | 13.2 | |

| Coating and floor mortars (CFM) | Min | 5.4 | 400.0 | 3.9 | 160.0 | 28.4 | 27.9 | 11.7 | 24.3 | 6.3 | 43.5 | 8.1 | 67.6 | 27.3 | 10.8 | 46.0 | 180.0 |

| Max | 28.1 | 820.0 | 62.0 | 610.0 | 65.4 | 160.0 | 28.8 | 91.5 | 16.1 | 180.0 | 34.1 | 150.0 | 90.0 | 71.5 | 110.0 | 460.0 | |

| Mean | 14.9 | 565.7 | 22.5 | 357.1 | 50.8 | 67.8 | 21.3 | 62.1 | 11.5 | 81.6 | 19.7 | 85.6 | 62.1 | 35.0 | 72.2 | 348.6 | |

| SD | 7.5 | 136.3 | 17.9 | 166.2 | 11.0 | 41.5 | 6.8 | 20.0 | 3.4 | 46.7 | 7.7 | 26.9 | 18.0 | 19.7 | 21.1 | 90.5 | |

| Bricks (B) | Min | 11.9 | 270.0 | 6.3 | 40.0 | 46.5 | 20.3 | 27.5 | 38.6 | 9.9 | 42.6 | 19.8 | 35.6 | 51.7 | 30.1 | 56.7 | 370.0 |

| Max | 34.7 | 340.0 | 16.7 | 280.0 | 54.3 | 31.4 | 34.4 | 56.9 | 13.6 | 63.6 | 35.1 | 89.8 | 67.6 | 45.2 | 74.7 | 590.0 | |

| Mean | 22.4 | 307.5 | 10.8 | 146.7 | 50.4 | 28.6 | 32.0 | 48.5 | 12.5 | 51.6 | 28.1 | 52.6 | 56.7 | 39.3 | 65.3 | 465.0 | |

| SD | 8.2 | 32.7 | 4.4 | 99.8 | 2.8 | 4.8 | 2.6 | 6.6 | 1.5 | 7.9 | 5.7 | 21.8 | 6.4 | 6.1 | 7.2 | 93.4 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fragata, A.; Candeias, C.; Ribeiro, J.; Braga, C.; Fontes, L.; Velosa, A.; Rocha, F. Archaeological and Chemical Investigation on Mortars and Bricks from a Necropolis in Braga, Northwest of Portugal. Materials 2021, 14, 6290. https://doi.org/10.3390/ma14216290

Fragata A, Candeias C, Ribeiro J, Braga C, Fontes L, Velosa A, Rocha F. Archaeological and Chemical Investigation on Mortars and Bricks from a Necropolis in Braga, Northwest of Portugal. Materials. 2021; 14(21):6290. https://doi.org/10.3390/ma14216290

Chicago/Turabian StyleFragata, Ana, Carla Candeias, Jorge Ribeiro, Cristina Braga, Luís Fontes, Ana Velosa, and Fernando Rocha. 2021. "Archaeological and Chemical Investigation on Mortars and Bricks from a Necropolis in Braga, Northwest of Portugal" Materials 14, no. 21: 6290. https://doi.org/10.3390/ma14216290

APA StyleFragata, A., Candeias, C., Ribeiro, J., Braga, C., Fontes, L., Velosa, A., & Rocha, F. (2021). Archaeological and Chemical Investigation on Mortars and Bricks from a Necropolis in Braga, Northwest of Portugal. Materials, 14(21), 6290. https://doi.org/10.3390/ma14216290