The Relationship of Compressive Strength and Chemically Bound Water Content of High-Volume Fly Ash-Cement Mortar

Abstract

:1. Introduction

2. Materials and Methods

2.1. Research Program

- Step 1: Reveal the effect of FA content, water-to-binder ratio, and curing age on the compressive strength and chemically bound water contents of HVFA-cement mortars with experimental studies;

- Step 2: Propose and verify the prediction formula for the chemically bound water content of HVFA-cement mortars based on the FA content, water-to-binder ratio, and curing age, according to the test results;

- Step 3: Establish the relationship between the compressive strength and chemically bound water content, then the compressive strength of HVFA-cement mortars could be predicted based on the chemically bound water content.

2.2. Materials and Mix Proportions

2.3. Compressive Strength Tests

2.4. Chemically Bound Water Content Test

3. Results and Discussions

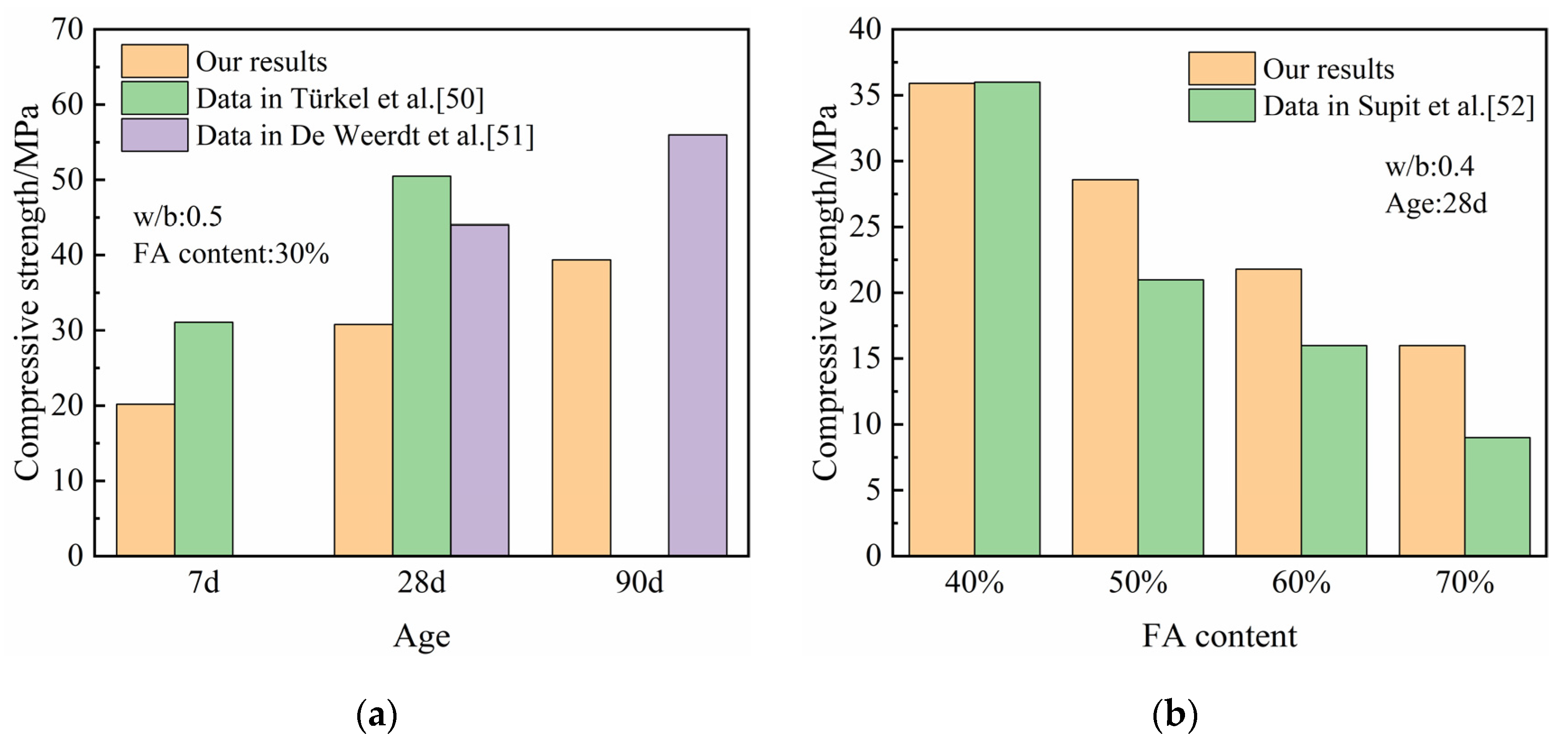

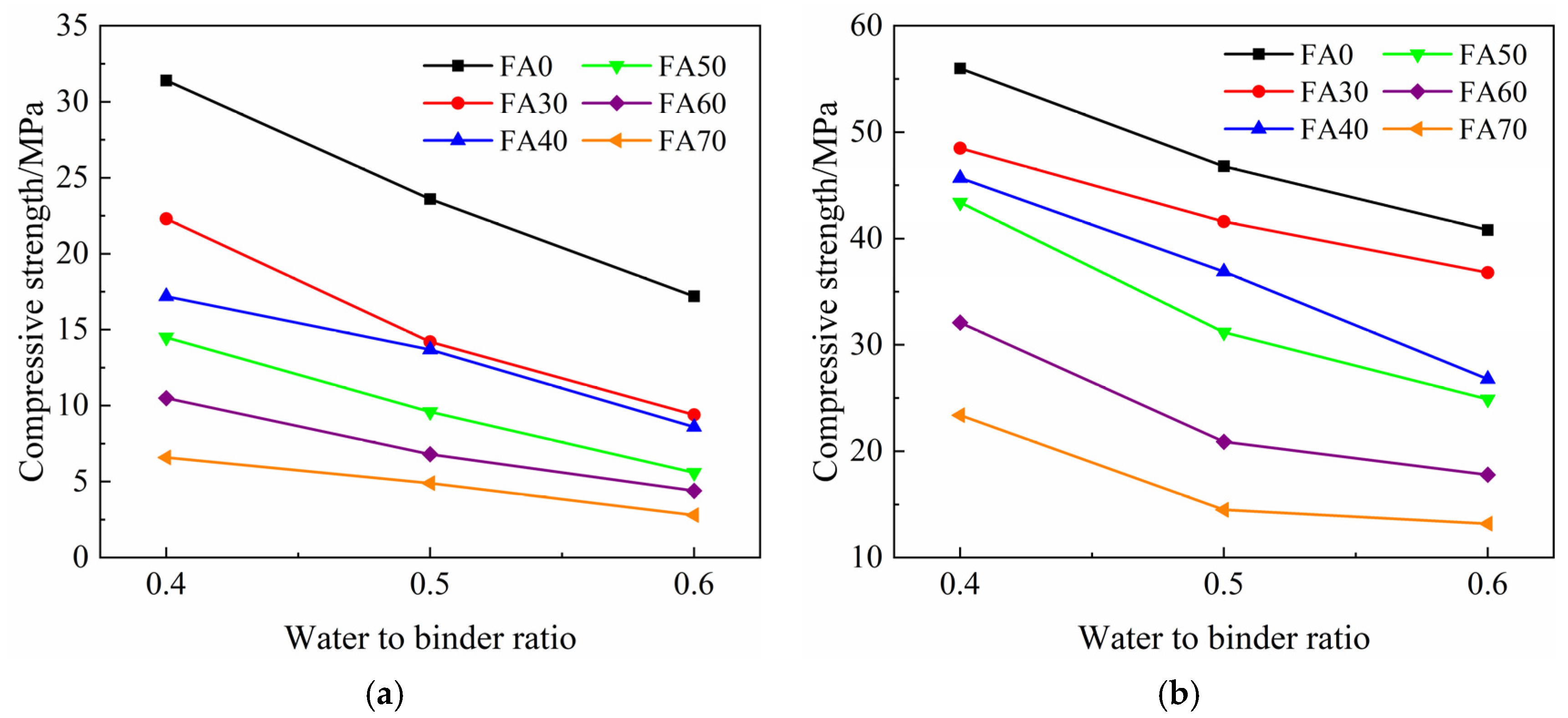

3.1. Compressive Strength of HVFA-Cement Mortars

- (1).

- The compressive strength of the mortars improved along with the curing age, and the compressive strength grew fast at early ages and relatively slowly at late ages. When the FA content grew higher, the compressive strength development of mortars at early ages was slower, but the growth of compressive strength at late ages was generally faster. In other words, with the increase of FA content, the growth rate of the compressive strength of mortars decreased at early ages, but increased at late ages. For example, from 3 d to 7 d, the compressive strengths of FA0-0.5 and FA70-0.5 increased by 8.2 MPa and 1.2 MPa respectively, while from 60 d to 90 d, the compressive strengths of FA0-0.5 and FA70-0.5 increased by 0.1 MPa and 1.7 MPa, respectively. The pozzolanic reactivity of FA contributed to the long-term strength improvement of the HVFA-cement mortar.

- (2).

- With the increase of FA content, the compressive strength of HVFA-cement mortar decreased. When the FA content was low (e.g., 30%), the compressive strength of HVFA-cement mortar at 90 d can be close to that of pure cement mortar. For instance, the compressive strength of FA30-0.6 at 90 d was 90.2% of the compressive strength of FA0-0.6, and for FA30-0.4 and FA30-0.5, their 90 d compressive strengths were 86.6% and 88.9% of the pure cement mortars under the same circumstances. When the FA content was high (i.e., >50%), the compressive strength of HVFA-cement mortar decreased remarkably. The compressive strengths of FA70-0.4, FA70-0.5 and FA70-0.6 at 90 d was only 41.8%, 31.0% and 32.4% of the corresponding pure cement mortars. This was mainly because the reactivity of FA was much lower than cement. With the increase of cement replaced by FA, the actual water-to-cement ratio in the paste increased, and the overall reaction degree decreased, resulting in the loose microstructure of the paste and the decrease of the compressive strength [49].

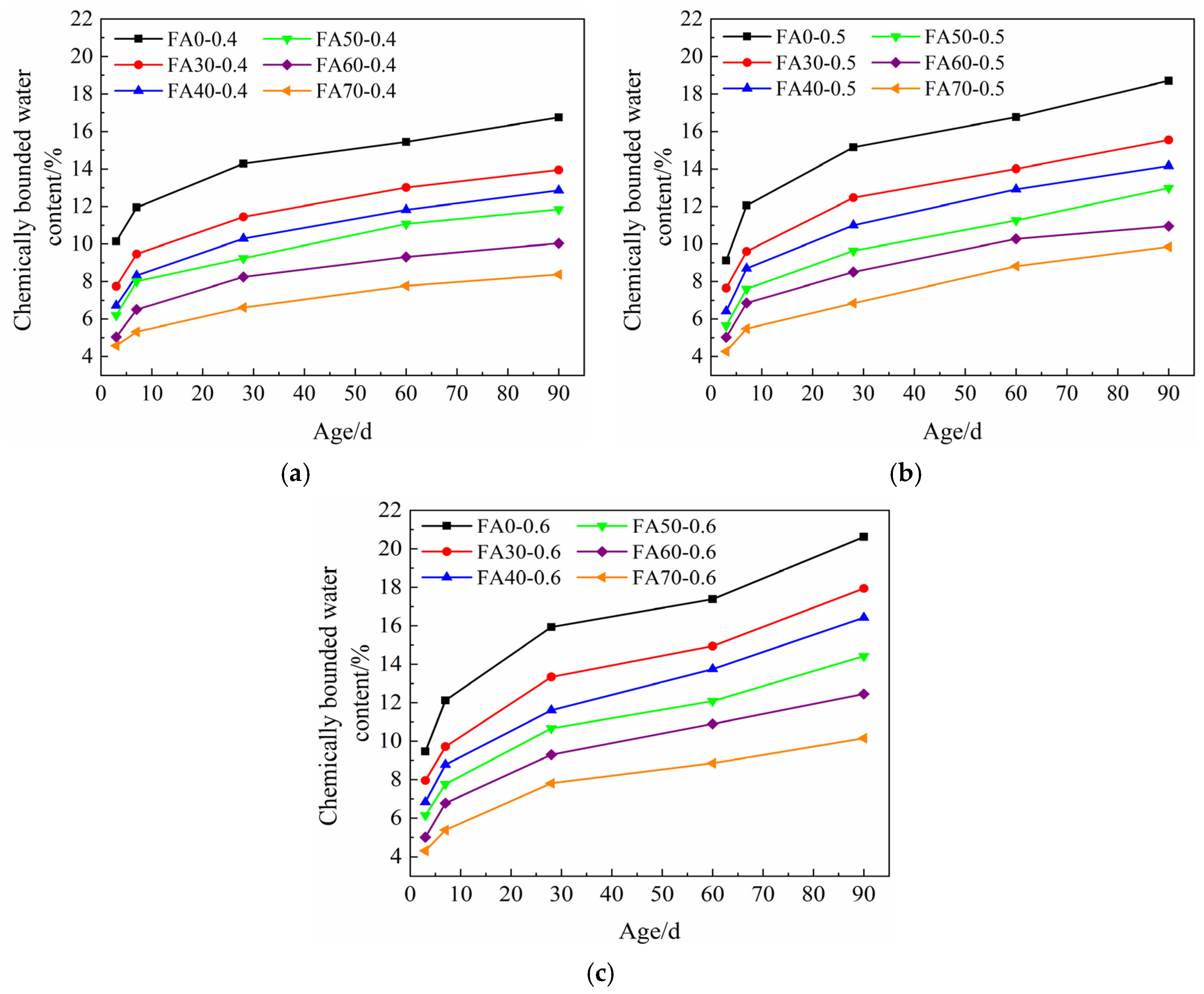

3.2. Chemically Bound Water Content of HVFA-Cement Mortars

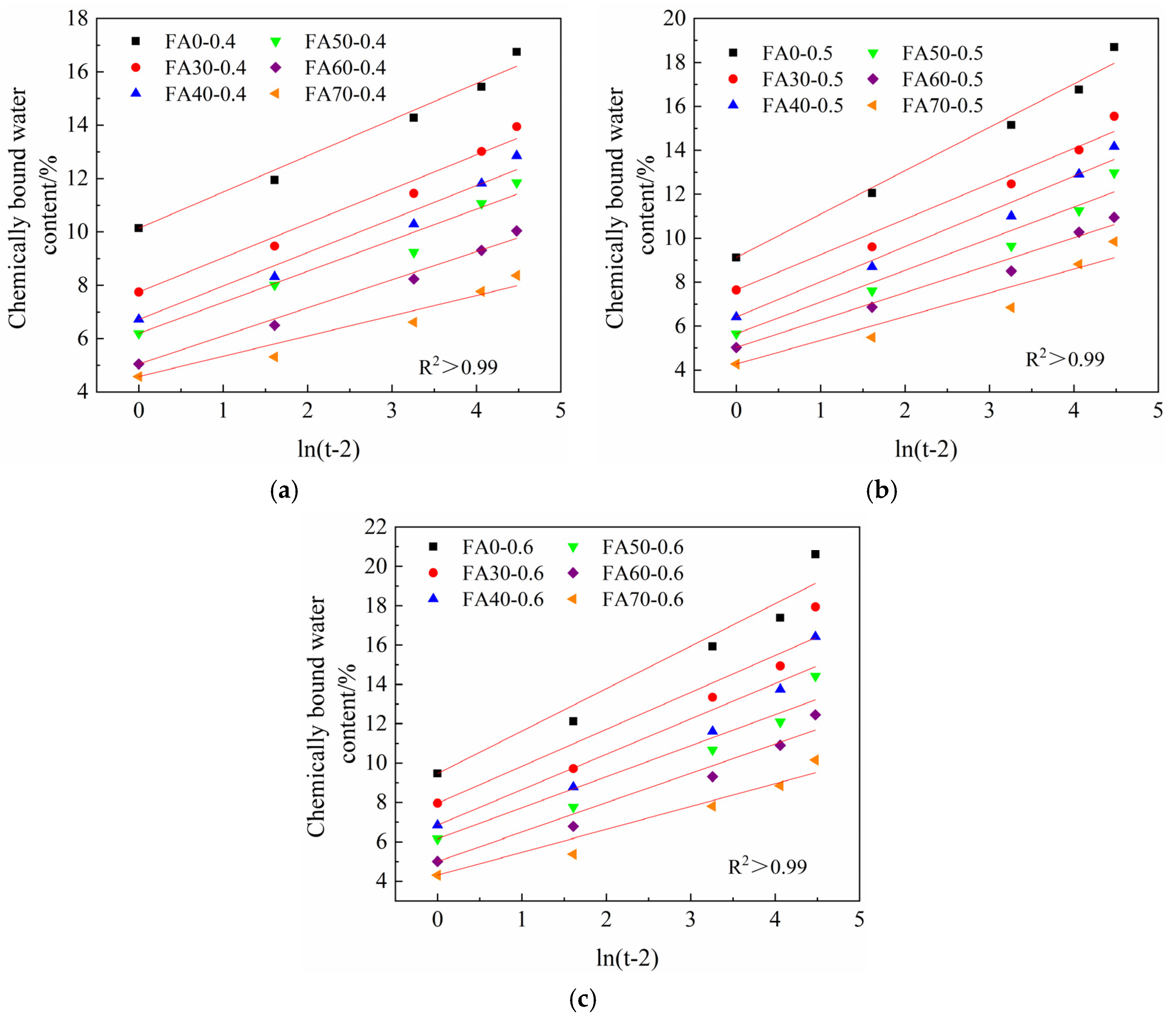

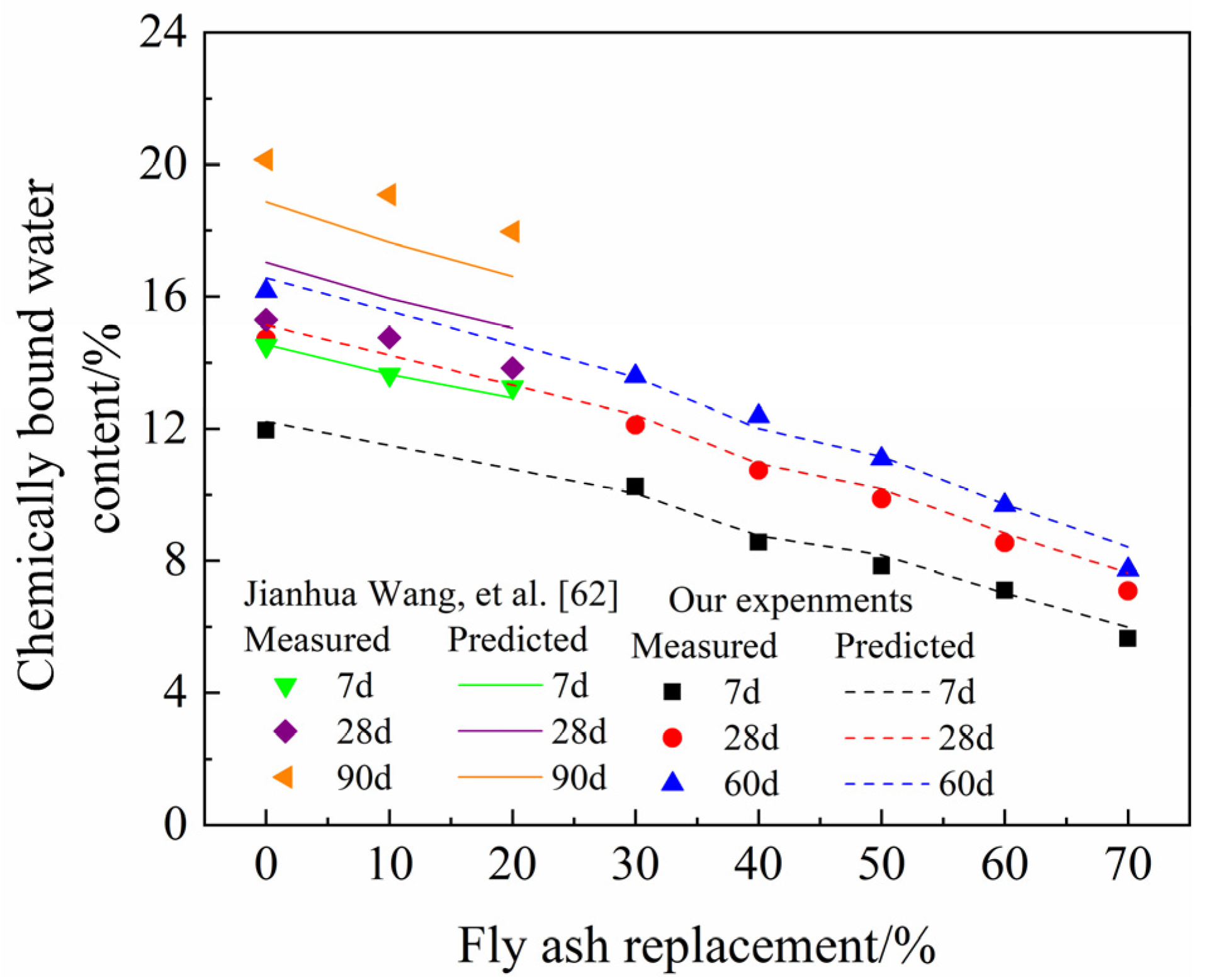

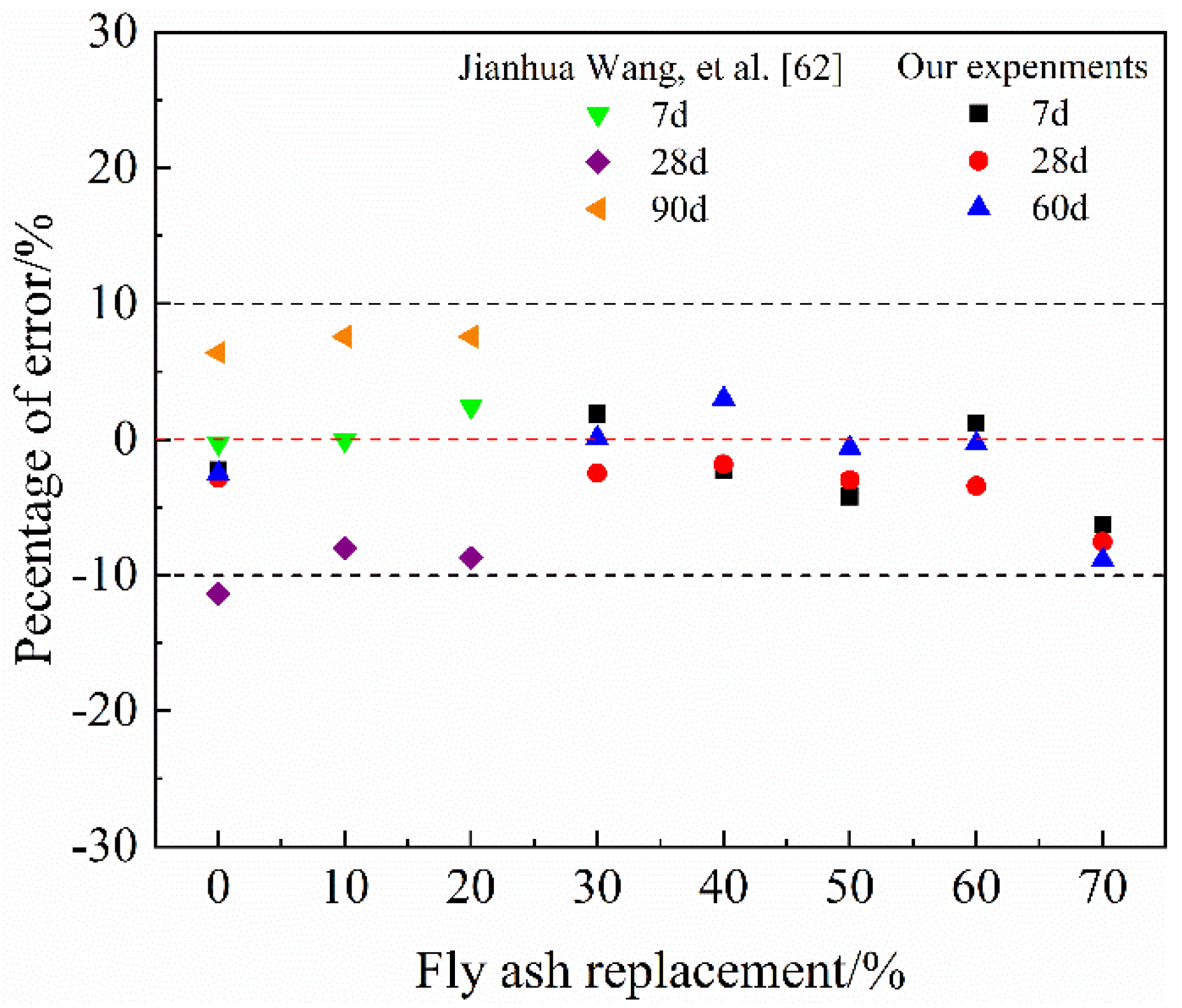

3.3. Prediction of Chemically Bound Water Content Based on Curing Age, w/b and FA Content

3.4. The Relationship between the Compressive Strength and Chemically Bound Water Content

4. Conclusions

- The compressive strength development of HVFA-cement mortar was rapid at early ages and tended to be slow at late ages. However, with the increase of FA content, the compressive strength grew faster at late ages. With the increase of w/b and FA content, the compressive strength of HVFA-cement mortar decreased. With the decrease of w/b, the effect of FA content on the compressive strength of mortar was more significant.

- The chemically bound water content of HVFA-cement paste increased rapidly at early ages, and became slowly at late ages. The incorporation of FA reduced the chemically bound water content in HVFA-cement pastes. With the increase of w/b, the chemically bound water content increased, but w/b showed less influence at early ages and more significant influence at late ages.

- The quantitative prediction formula for chemically bound water content was established based on w/b, FA content, and curing age. The equation could accurately predict the chemically bound water content of HVFA-cement-based materials.

- There is a linear relationship between the chemically bound water content and compressive strength of HVFA-cement mortar. The compressive strength of HVFA-cement mortars could be predicted based on the chemically bound water content, within the scope of this study.

5. Limitations and Further Research Needs

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmaruzzaman, M. A review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Yao, Z.; Ji, X.; Sarker, P.; Tang, J.; Ge, L.; Xia, M.; Xi, Y. A comprehensive review on the applications of coal fly ash. Earth-Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef] [Green Version]

- Herath, C.; Gunasekara, C.; Law, D.W.; Setunge, S. Performance of high volume fly ash concrete incorporating additives: A systematic literature review. Constr. Build. Mater. 2020, 258, 120606. [Google Scholar] [CrossRef]

- Singh, N.; Kumar, P.; Goyal, P. Reviewing the behaviour of high volume fly ash based self compacting concrete. J. Build. Eng. 2019, 26, 100882. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. A comparative study of the mechanical and life cycle assessment of high-content fly ash and recycled aggregates concrete. J. Build. Eng. 2020, 29, 101173. [Google Scholar] [CrossRef]

- Hemalatha, T.; Ramaswamy, A. A review on fly ash characteristics—Towards promoting high volume utilization in devel-oping sustainable concrete. J. Clean. Prod. 2017, 147, 546–559. [Google Scholar] [CrossRef]

- Giergiczny, Z. Fly ash and slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Kim, H.-S.; Kim, K.-S.; Jung, S.S.; Hwang, J.I.; Choi, J.-S.; Sohn, I. Valorization of electric arc furnace primary steelmaking slags for cement applications. Waste Manag. 2015, 41, 85–93. [Google Scholar] [CrossRef] [PubMed]

- Herrmann, A.; Koenig, A.; Dehn, F. Structural concrete based on alkali-activated binders: Terminology, reaction mechanisms, mix designs and performance. Struct. Concr. 2017, 19, 918–929. [Google Scholar] [CrossRef]

- Dueramae, S.; Tangchirapat, W.; Sukontasukkul, P.; Chindaprasirt, P.; Jaturapitakkul, C. Investigation of compressive strength and microstructures of activated cement free binder from fly ash—calcium carbide residue mixture. J. Mater. Res. Technol. 2019, 8, 4757–4765. [Google Scholar] [CrossRef]

- Hwang, S.; Shahsavari, S. High calcium cementless fly ash binder with low environmental footprint: Optimum Taguchi design. J. Am. Ceram. Soc. 2019, 102, 2203–2217. [Google Scholar] [CrossRef]

- Sankar, K.; Sutrisno, A.; Kriven, W. Slag-fly ash and slag-metakaolin binders: Part II-Properties of precursors and NMR study of poorly ordered phases. J. Am. Ceram. Soc. 2019, 102, 3204–3227. [Google Scholar] [CrossRef]

- Sankar, K.; Stynoski, P.; Kriven, W. Sodium silicate activated slag-fly ash binders: Part III-Composition of soft gel and calo-rimetry. J. Am. Ceram. Soc. 2019, 102, 3175–3190. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Garcia-Lodeiro, I.; Maltseva, O.; Palomo, A. Hydration mechanisms of hybrid cements as a function of the way of addition of chemicals. J. Am. Ceram. Soc. 2018, 102, 427–436. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Z.; Wang, K.; Lange, D.A.; Zhou, H.; Wang, W.; Zhu, D. Creep and thermal cracking of ultra-high volume fly ash mass concrete at early age. Cem. Concr. Compos. 2019, 99, 191–202. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.; Biswas, W. Effect of fly ash on the service life, carbon footprint and embodied energy of high strength concrete in the marine environment. Energy Build. 2018, 158, 1694–1702. [Google Scholar] [CrossRef] [Green Version]

- Jun, L.; Wang, X.; Qiu, Q.; Ou, G.; Xing, F. Understanding the effect of curing age on the chloride resistance of fly ash blended concrete by rapid chloride migration test. Mater. Chem. Phys. 2017, 196, 315–323. [Google Scholar]

- Zhao, Q.; He, X.; Zhang, J.; Jiang, J. Long-age wet curing effect on performance of carbonation resistance of fly ash concrete. Constr. Build. Mater. 2016, 127, 577–587. [Google Scholar] [CrossRef] [Green Version]

- Bendapudi, S.; Saha, P. Contribution of Fly ash to the properties of Mortar and Concrete. Int J. Earth. Sci. 2011, 04, 974–5904. [Google Scholar]

- Yan, B.; Kouame, K.J.A.; Lv, W.; Yang, P.; Cai, M. Modification and in-place mechanical characteristics research on cement mortar with fly ash and lime compound admixture in high chlorine environment. J. Mater. Res. Technol. 2018, 8, 1451–1460. [Google Scholar] [CrossRef]

- Kim, T.; Davis, J.M.; Ley, M.T.; Kang, S.; Amrollahi, P. Fly ash particle characterization for predicting concrete compressive strength. Constr. Build. Mater. 2018, 165, 560–571. [Google Scholar] [CrossRef]

- Yu, J.; Li, G.; Leung, C. Hydration and physical characteristics of ultrahigh-volume fly ash-cement systems with low wa-ter/binder ratio. Construct. Build. Mater. 2018, 161, 509–518. [Google Scholar] [CrossRef]

- Gao, Y.; He, B.; Li, Y.; Tang, J.; Qu, L. Effects of nano-particles on improvement in wear resistance and drying shrinkage of road fly ash concrete. Constr. Build. Mater. 2017, 151, 228–235. [Google Scholar] [CrossRef]

- Yu, Z.; Ye, G. New perspective of service life prediction of fly ash concrete. Constr. Build. Mater. 2013, 48, 764–771. [Google Scholar] [CrossRef]

- Yu, Z.; Ye, G.; Van, B. A Review of the Effects of Fly Ash on Durability of Concrete: Hydration Chemistry and Microstructure. Technol J. Wuhan Univ. 2010, 32, 235–240. [Google Scholar]

- Yang, S.; Zhang, J.; An, X.; Qi, B.; Shen, D.; Lv, M. Effect of fly ash and limestone on the paste rheological thresholds of self-compacting concrete. Constr. Build. Mater. 2021, 281, 122560. [Google Scholar] [CrossRef]

- Gnanaraj, S.C.; Chokkalingam, R.B.; Thankam, G.L.; Pothinathan, S. Durability properties of self-compacting concrete developed with fly ash and ultra fine natural steatite powder. J. Mater. Res. Technol. 2021, 13, 431–439. [Google Scholar] [CrossRef]

- Gunasekera, C.; Zhou, Z.; Sofi, M.; Law, D.; Setunge, S.; Mendis, P. Hydration and strength evolution of ternary-blend high-volume fly ash concretes. ACI Mater. J. 2019, 116, 251–261. [Google Scholar] [CrossRef]

- Poon, C.; Lam, L.; Wong, Y. A study on high strength concrete prepared with large volumes of low calcium fly ash. Cem. Concr. Res. 2000, 30, 447–455. [Google Scholar] [CrossRef]

- Jiang, Y.; Yang, Y.; Wang, Y.; Zhou, Y.; Ma, C. Autogenous shrinkage of high performance concrete containing mineral ad-mixtures under different curing temperatures. Construct. Build. Mater. 2014, 61, 260–269. [Google Scholar] [CrossRef]

- Liu, B.; Xie, Y.; Zhou, S.; Yuan, Q. Influence of ultrafine fly ash composite on the fluidity and compressive strength of concrete. Cem. Concr. Res. 2000, 30, 1489–1493. [Google Scholar] [CrossRef]

- de Matos, P.; Junckes, R.; Graeff, E.; Prudêncio, L. Effectiveness of fly ash in reducing the hydration heat release of mass concrete. J. Build. Eng. 2020, 28, 101063. [Google Scholar] [CrossRef]

- Lam, L.; Wong, Y.; Poon, C.S. Degree of hydration and gel/space ratio of high-volume fly ash/cement systems. Cem. Concr. Res. 2000, 30, 747–756. [Google Scholar] [CrossRef]

- Xu, G.; Shi, X. Characteristics and applications of fly ash as a sustainable construction material: A state-of-the-art review. Resour. Conserv. Recycl. 2018, 136, 95–109. [Google Scholar] [CrossRef]

- Durán-Herrera, A.; Juárez, C.; Valdez, P.; Bentz, D. Evaluation of sustainable high-volume fly ash concretes. Cem. Concr. Compos. 2011, 33, 39–45. [Google Scholar] [CrossRef]

- Zhang, G.; Wei, Q.; Ding, Q.; Wang, A.; Liu, K. Effect of curing temperature and fly ash content on the hydration and micro-structure of fly ash–cement pastes. J. Sustain. Cem-Based. Mater. 2018, 7, 372–383. [Google Scholar]

- De la Varga, I.; Castro, J.; Bentz, D.; Zunino, F.; Weiss, J. Evaluating the hydration of high volume fly ash mixtures using chemically inert fillers. Constr. Build. Mater. 2018, 161, 221–228. [Google Scholar] [CrossRef]

- Batog, M.; Giergiczny, Z. Influence of mass concrete constituents on its properties. Constr. Build. Mater. 2017, 146, 221–230. [Google Scholar] [CrossRef]

- Huang, C.-H.; Lin, S.-K.; Chang, C.-S.; Chen, H.-J. Mix proportions and mechanical properties of concrete containing very high-volume of Class F fly ash. Constr. Build. Mater. 2013, 46, 71–78. [Google Scholar] [CrossRef]

- Sun, J.; Shen, X.; Tan, G.; Tanner, J.E. Compressive strength and hydration characteristics of high-volume fly ash concrete prepared from fly ash. J. Therm. Anal. Calorim. 2018, 136, 565–580. [Google Scholar] [CrossRef]

- Kearsley, E.; Wainwright, P. The effect of high fly ash content on the compressive strength of foamed concrete. Cem. Concr. Res. 2001, 31, 105–112. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Sun, W.; Yan, H.D. Hydration of high-volume fly ash cement pastes. Cem. Concr. Compos. 2000, 22, 445–452. [Google Scholar] [CrossRef]

- Reiner, M.; Rens, K. High-Volume Fly Ash Concrete: Analysis and Application. Pr. Period. Struct. Des. Constr. 2006, 11, 58–64. [Google Scholar] [CrossRef]

- Standardization Administration of the People’s Republic of China, Common Portland Cement, GB 175-2007; China Quality and Standards Publishing & Media Co., Ltd.: Beijing, China, 2007.

- Standardization Administration of the People’s Republic of China, Fly Ash Used for Cement and Concrete, GB/T 1596-2017; China Quality and Standards Publishing & Media Co., Ltd.: Beijing, China, 2017.

- American Society of Testing Materials, Standard Specification for Standard Sand, ASTM C778-17; ASTM International: West Conshohocken, PA, USA, 2017.

- Standardization Administration of the People’s Republic of China, Test Method for Fluidity of Cement Mortar, GB 2419-2005; China Quality and Standards Publishing & Media Co., Ltd.: Beijing, China, 2005.

- International Organization for Standardization, Cement-Test method-Determination of Strength, ISO 679-2009; ISO Copyright Office: Geneva, Switzerland, 2009.

- Zhang, Y.; Sun, W.; Zheng, K.; Jia, Y. Hydration process of Portland cement-fly ash pastes. J. Southeast Univ. 2006, 36, 118–123. [Google Scholar]

- Türkel, S.; Altunta, Y. The effect of limestone powder, fly ash and silica fume on the properties of self-compacting repair mortars. Sadhana 2009, 34, 331–343. [Google Scholar] [CrossRef]

- Weerdt, K.; Kjellevold, K.; Sellevold, E.; Justnes, H. Synergy between fly ash and limestone powder in ternary cements. Cem. Concr. Compos. 2011, 33, 30–38. [Google Scholar] [CrossRef]

- Supit, S.; Shaikh, F.; Sarker, P. Effect of ultrafine fly ash on mechanical properties of high volume fly ash mortar. Constr. Build. Mater. 2014, 51, 278–286. [Google Scholar] [CrossRef]

- Rahla, K.M.; Mateus, R.; Bragança, L. Comparative sustainability assessment of binary blended concretes using Supplementary Cementitious Materials (SCMs) and Ordinary Portland Cement (OPC). J. Clean. Prod. 2019, 220, 445–459. [Google Scholar] [CrossRef]

- Ramezanianpour, A.; Hooton, R. A Study on Hydration, Compressive Strength, and Porosity of Portland-Limestone Cement Mixes Containing SCMs. Cem. Con. Compos. 2014, 51, 1–13. [Google Scholar] [CrossRef]

- Duval, R.; Kadri, E. Influence of Silica Fume on the Workability and the Compressive Strength of High-Performance Con-cretes. Cem. Concr. Res. 1998, 28, 533–547. [Google Scholar] [CrossRef]

- Jiang, D.; Li, X.; Lv, Y.; Zhou, M.; He, C.; Jiang, W.; Li, C. Utilization of limestone powder and fly ash in blended cement: Rhe-ology, strength and hydration characteristics. Construct. Build. Mater. 2020, 232, 117228. [Google Scholar] [CrossRef]

- Marsh, B.; Day, R. Pozzolanic and cementitious reactions of fly ash in blended cement pastes. Cem. Concr. Res. 1998, 18, 301–310. [Google Scholar] [CrossRef]

- Bentz, D.; Coveney, P.; Garboczi, E.; Kleyn, M. Cellular automaton simulations of cement hydration and microstructure de-velopment. Model. Simul. Mater. Sci. Eng. 1994, 2, 783–808. [Google Scholar] [CrossRef]

- Bentz, D.; Jensen, O.; Coats, A.; Glasser, F. Influence of silica fume on diffusivity in cement-based materials: I. Experimental and computer modeling studies on cement pastes. Cem. Concr. Res. 2000, 30, 953–962. [Google Scholar] [CrossRef]

- Tang, S.; Cai, X.; He, Z.; Shao, H.; Li, Z.; Chen, E. Hydration process of fly ash blended cement pastes by impedance meas-urement. Construct. Build. Mater. 2016, 113, 939–950. [Google Scholar] [CrossRef]

- Dzaye, E.D.; De Schutter, G.; Aggelis, D.G. Monitoring early-age acoustic emission of cement paste and fly ash paste. Cem. Concr. Res. 2020, 129, 105964. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Jia, X.; Lei, C. Influence on Cement Hydration and Strength of Fly Ash. Fly Ash Compr. Utilization 2009, 5, 34–36. (In Chinese) [Google Scholar]

- Gu, C.; Ye, G.; Wang, Q.; Sun, W. Modeling of the chloride diffusivity of ultra-high performance concrete with a multi-scale scheme. Model. Simul. Mater. Sci. Eng. 2019, 27, 055002. [Google Scholar] [CrossRef]

- Kocak, Y.; Nas, S. The effect of using fly ash on the strength and hydration characteristics of blended cements. Constr. Build. Mater. 2014, 73, 25–32. [Google Scholar] [CrossRef]

- van Breugel, K. Numerical simulation of hydration and microstructural development in hardening cement-based materials (I) theory. Cem. Concr. Res. 1995, 25, 319–331. [Google Scholar] [CrossRef]

| Material | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Loss |

|---|---|---|---|---|---|---|---|

| Cement | 22.19 | 4.48 | 3.23 | 63.10 | 2.41 | 2.57 | 2.03 |

| FA | 47.12 | 36.92 | 3.97 | 6.79 | 0.93 | 0.69 | 1.99 |

| Sample | Mix Proportions/g | ||||

|---|---|---|---|---|---|

| Cement | FA | Sand | Water | Superplasticizer | |

| FA0-0.4/0.5/0.6 | 450 | 0 | 1350 | 180/225/270 | 2.0/0.3/0 |

| FA30-0.4/0.5/0.6 | 315 | 135 | 1350 | 180/225/270 | 2.0/0.3/0 |

| FA40-0.4/0.5/0.6 | 270 | 180 | 1350 | 180/225/270 | 2.0/0.3/0 |

| FA50-0.4/0.5/0.6 | 225 | 225 | 1350 | 180/225/270 | 2.0/0.3/0 |

| FA60-0.4/0.5/0.6 | 180 | 270 | 1350 | 180/225/270 | 2.0/0.3/0 |

| FA70-0.4/0.5/0.6 | 135 | 315 | 1350 | 180/225/270 | 2.0/0.3/0 |

| w/b | Fitted Equation | R2 | x-Axis Intersection |

|---|---|---|---|

| 0.4 | σ = 4.38 wcbw-12.70 | 0.97 | 2.90% |

| 0.5 | σ = 3.41 wcbw-12.00 | 0.94 | 3.52% |

| 0.6 | σ = 2.56 wcbw-10.52 | 0.95 | 4.11% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, C.; Yao, J.; Yang, Y.; Huang, J.; Ma, L.; Ni, T.; Liu, J. The Relationship of Compressive Strength and Chemically Bound Water Content of High-Volume Fly Ash-Cement Mortar. Materials 2021, 14, 6273. https://doi.org/10.3390/ma14216273

Gu C, Yao J, Yang Y, Huang J, Ma L, Ni T, Liu J. The Relationship of Compressive Strength and Chemically Bound Water Content of High-Volume Fly Ash-Cement Mortar. Materials. 2021; 14(21):6273. https://doi.org/10.3390/ma14216273

Chicago/Turabian StyleGu, Chunping, Jikai Yao, Yang Yang, Jie Huang, Linhao Ma, Tongyuan Ni, and Jintao Liu. 2021. "The Relationship of Compressive Strength and Chemically Bound Water Content of High-Volume Fly Ash-Cement Mortar" Materials 14, no. 21: 6273. https://doi.org/10.3390/ma14216273

APA StyleGu, C., Yao, J., Yang, Y., Huang, J., Ma, L., Ni, T., & Liu, J. (2021). The Relationship of Compressive Strength and Chemically Bound Water Content of High-Volume Fly Ash-Cement Mortar. Materials, 14(21), 6273. https://doi.org/10.3390/ma14216273