Study of Pavement Micro- and Macro-Texture Evolution Due to Traffic Polishing Using 3D Areal Parameters

Abstract

:1. Introduction

1.1. Background

1.2. Research Need

- (1)

- Many previous studies evaluated pavement wear performance in the laboratory using polishing machines. In laboratory studies, it is challenging to repeat the actual pavement polish process in the field involving traffic polishing from various vehicle types under different environmental conditions such as temperature, precipitation, or freeze-thaw cycles.

- (2)

- In previous studies, 2D texture profiles were typically collected at the macro-texture level to evaluate pavement texture variation under traffic polish. With the advancement of pavement data collection, high-resolution 3D texture data should be applied to understand better the evolution of asphalt pavement micro- and macro-texture under traffic polish.

- (3)

- Traditional pavement texture parameters only consider texture height distribution while miss other texture characteristics (such as spatial, hybrid, and so on). Hence, different categories of 3D areal parameters should be explored to characterize pavement micro- and macro-texture under traffic polishing from different aspects.

1.3. Objective

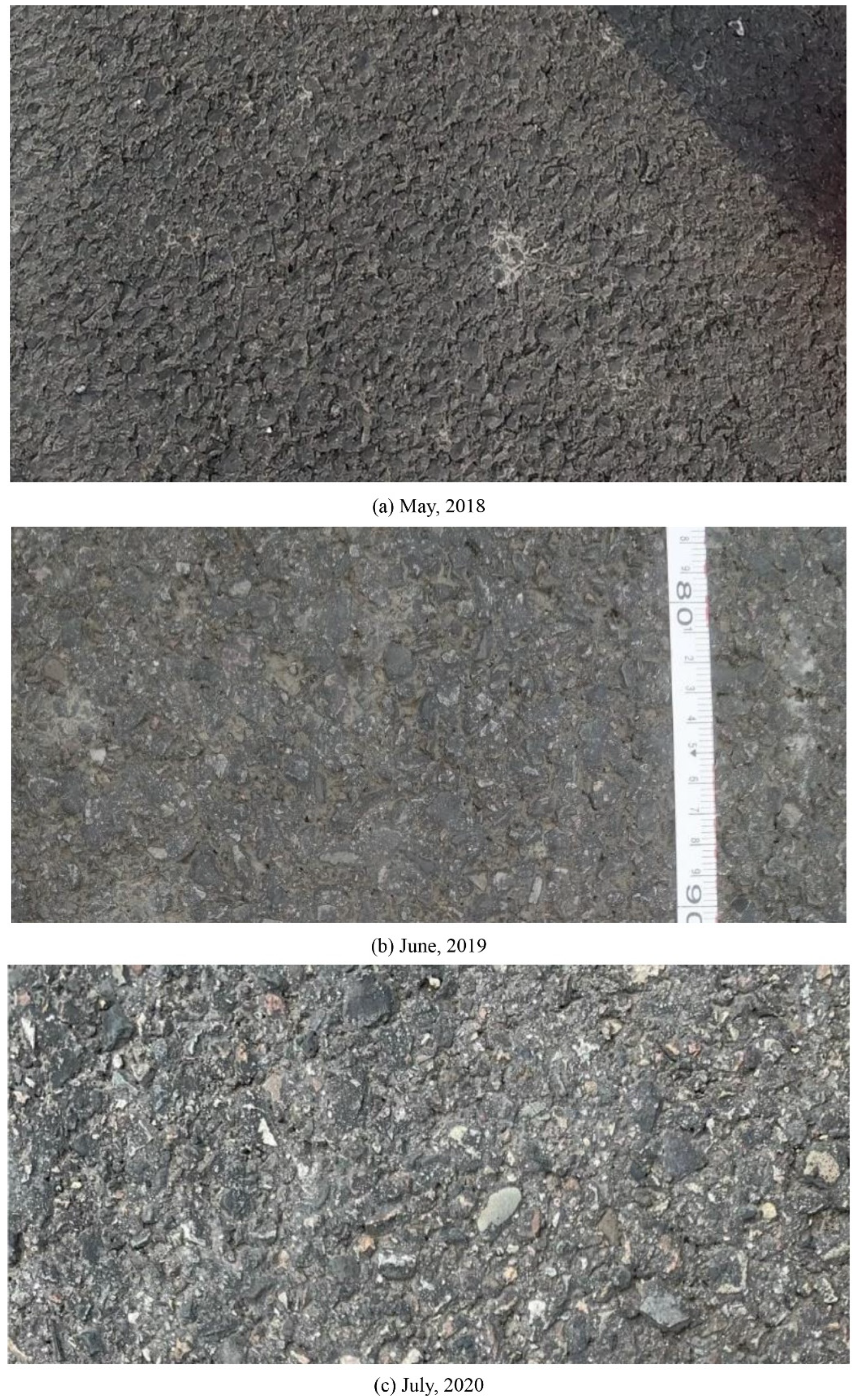

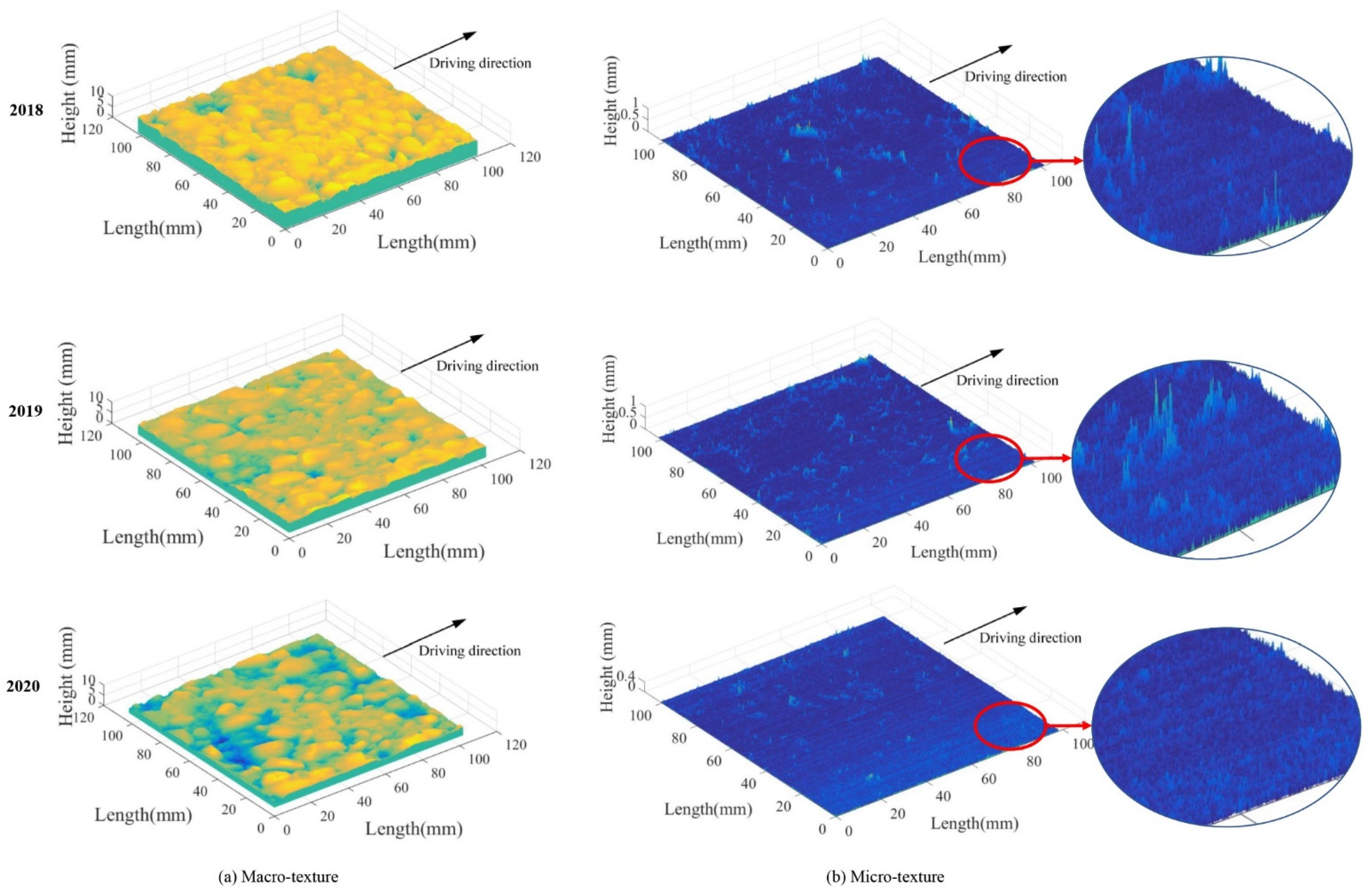

2. Field Data Collection

3. Three Dimensional Areal Parameters

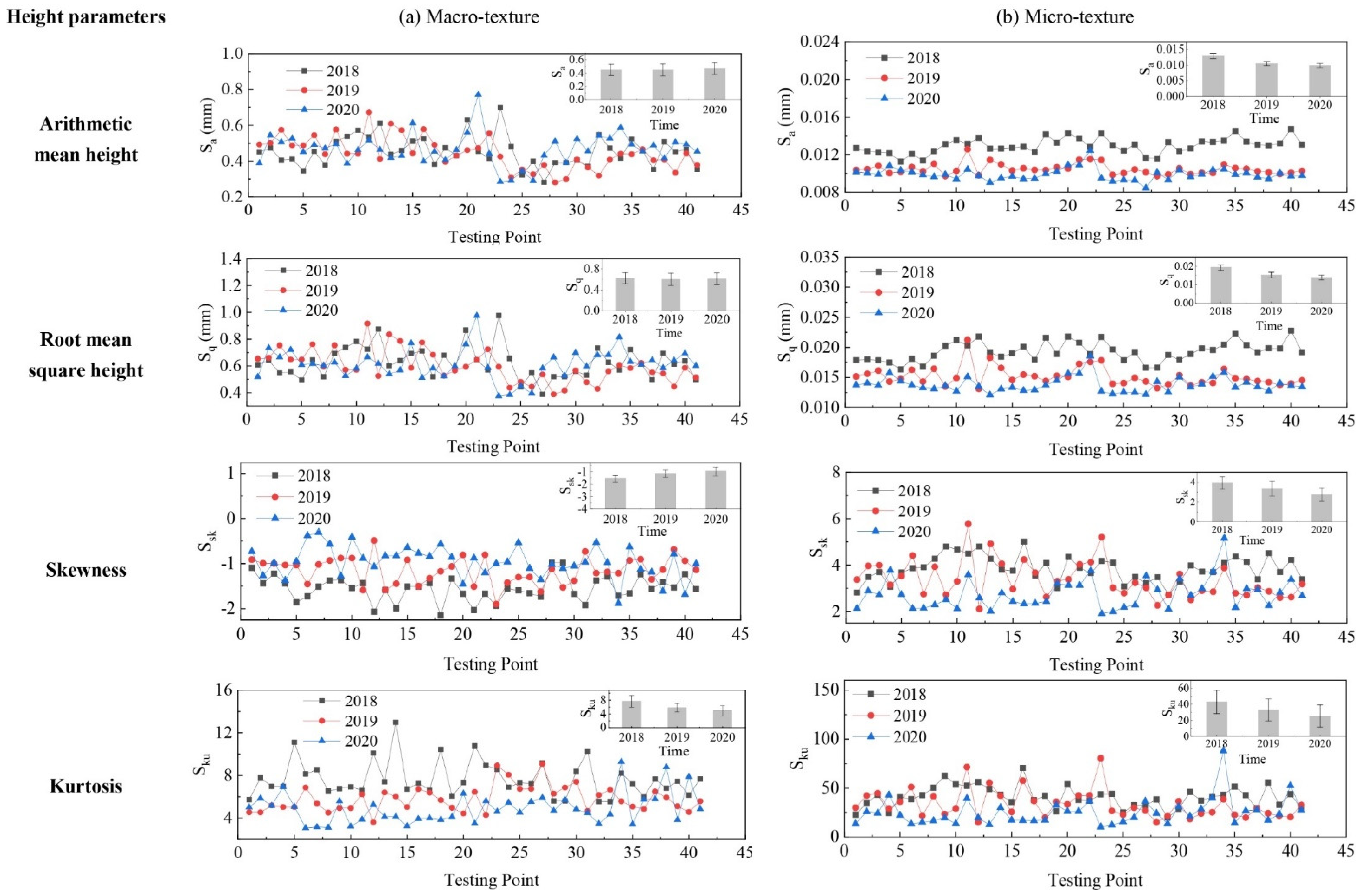

3.1. Height Parameters

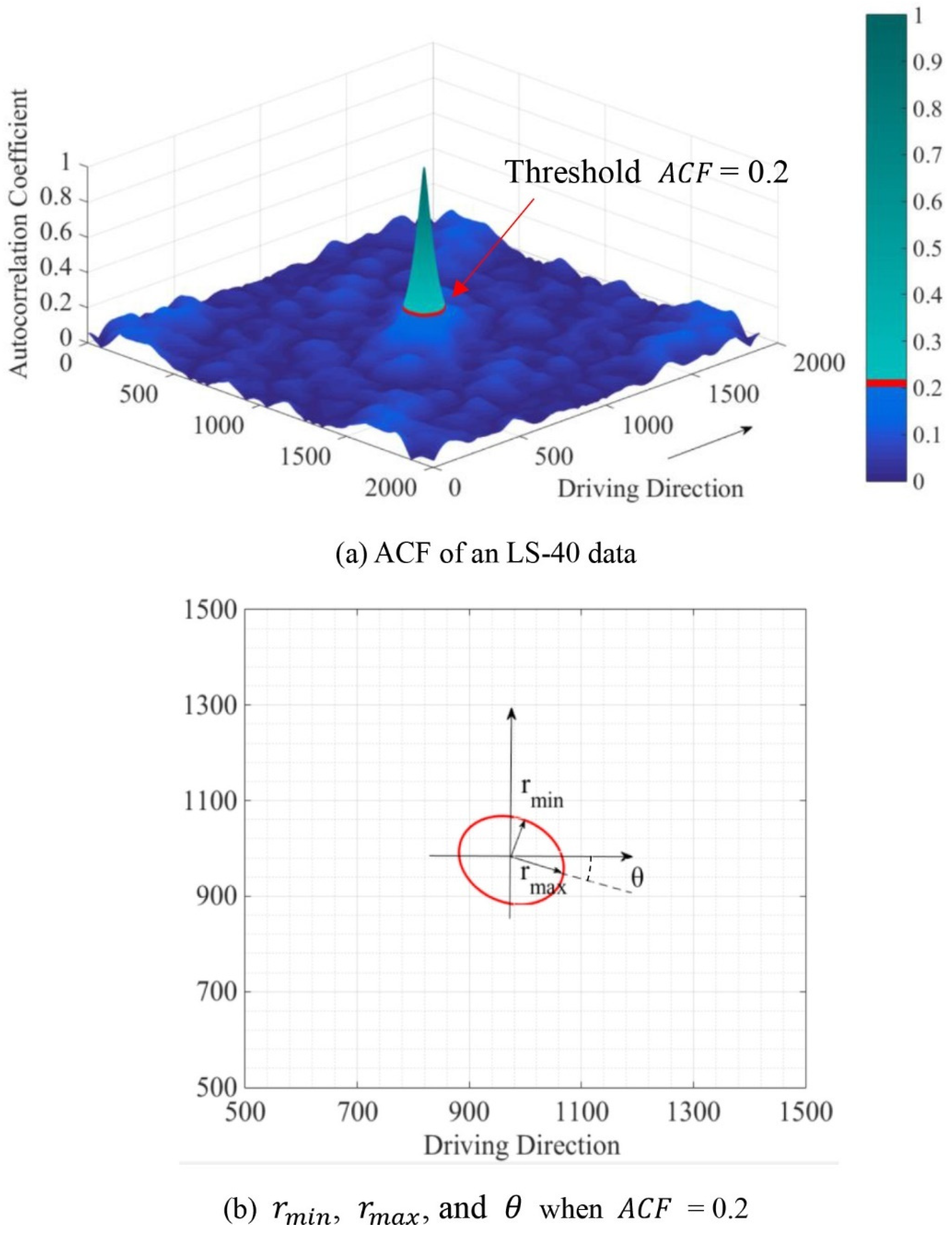

3.2. Spatial Parameters

3.3. Hybrid Parameters

3.4. Function Parameters

3.4.1. Material Ratio Parameters

3.4.2. Stratified Parameters

- First, a straight line is plotted tangent to the middle part of the dashed cumulative height distribution curve. The tangent line intersects the vertical axes of percentage 0% and 100% at two points, A and B. The corresponding height of A and B are peak and valley thresholds.

- Then, points C and D are projected on the cumulative height distribution curve for heights A and B to define percentages of Smr1 and Smr2. The height difference of A and B is defined as Sk.

- The area enclosed below the cumulative height distribution curve and above AC is represented by the triangle ACE that has an equivalent area. The height difference of E and A is defined as Spk.

- The area enclosed above the cumulative height distribution curve and below BD is represented by the triangle BDF that has an equivalent area. The height difference of F and B is defined as Svk.

3.4.3. Volume Parameters

3.5. Feature Parameters

4. Evolution of Micro- and Macro-Texture

4.1. Evolution of Height Parameters

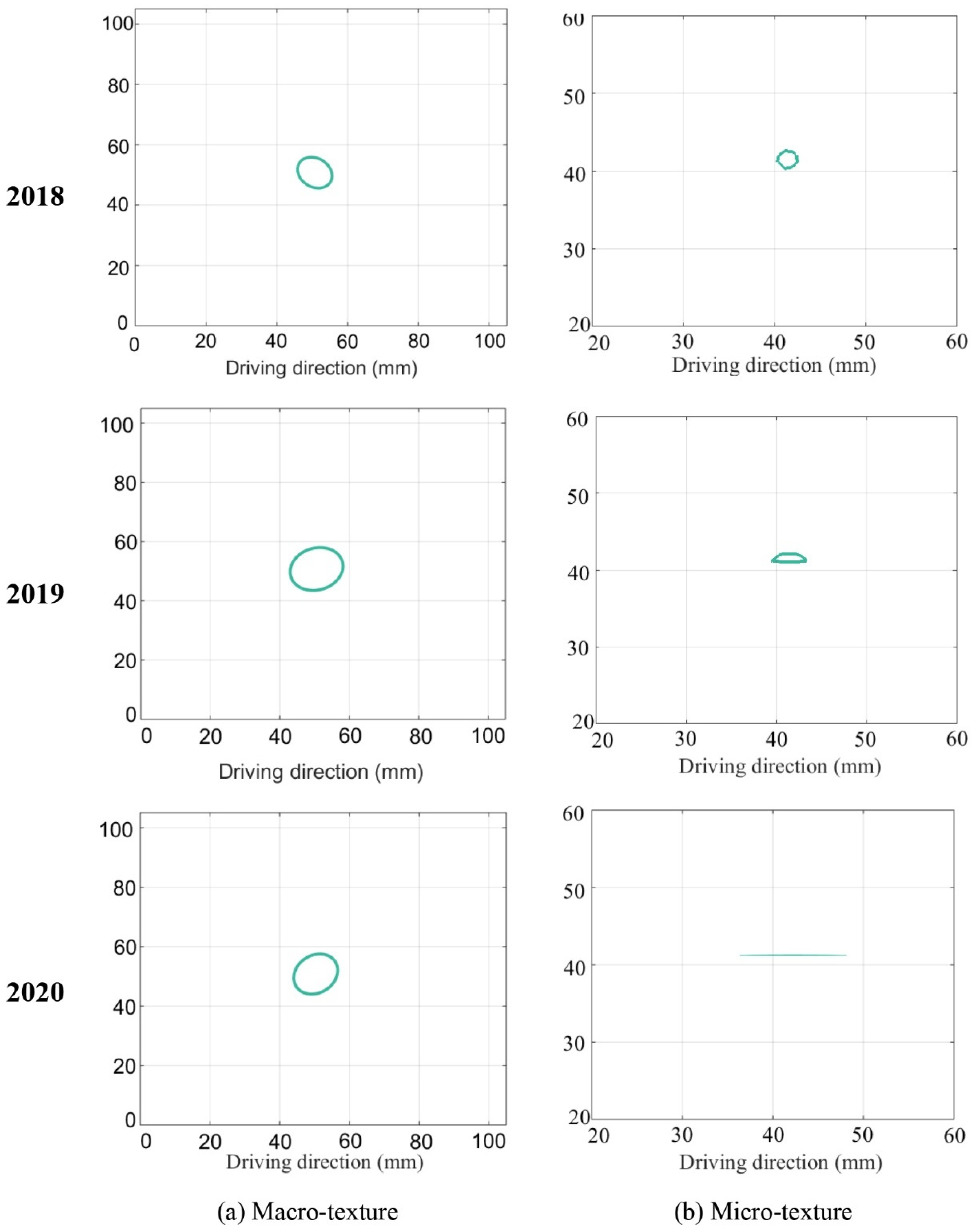

4.2. Evolution of Spatial Parameters

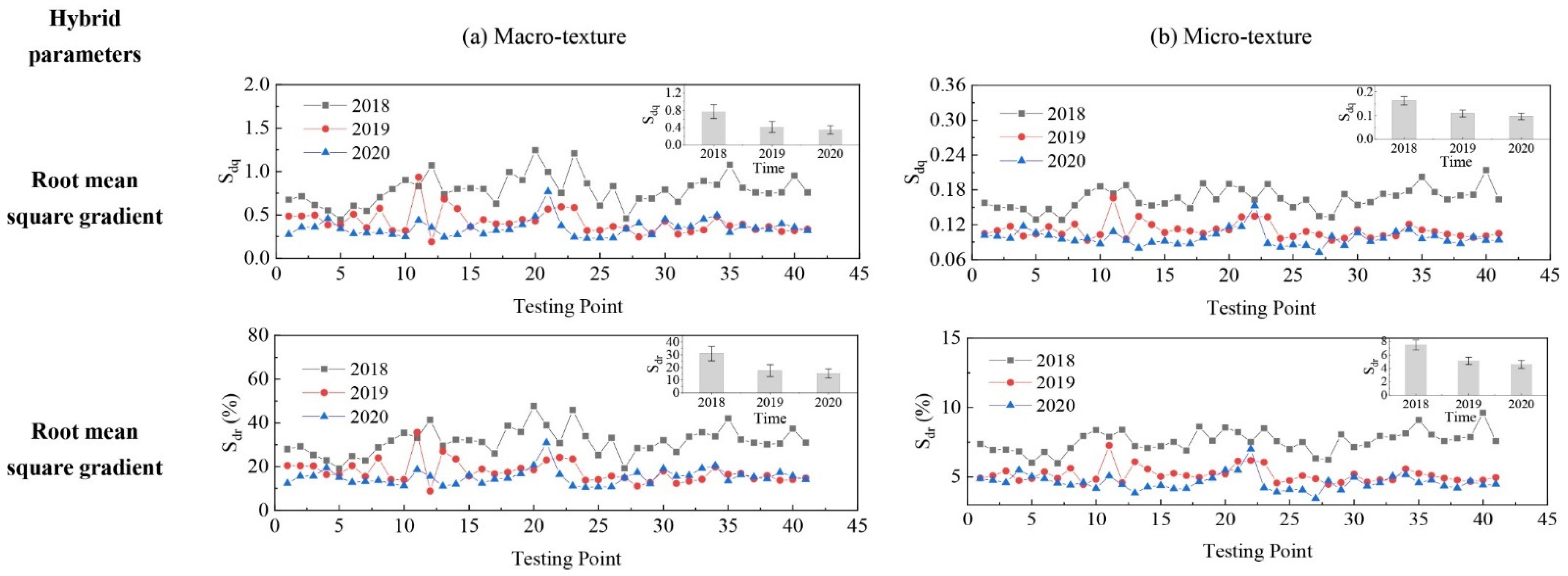

4.3. Evolution of Hybrid Parameters

4.4. Evolution of Function Parameters

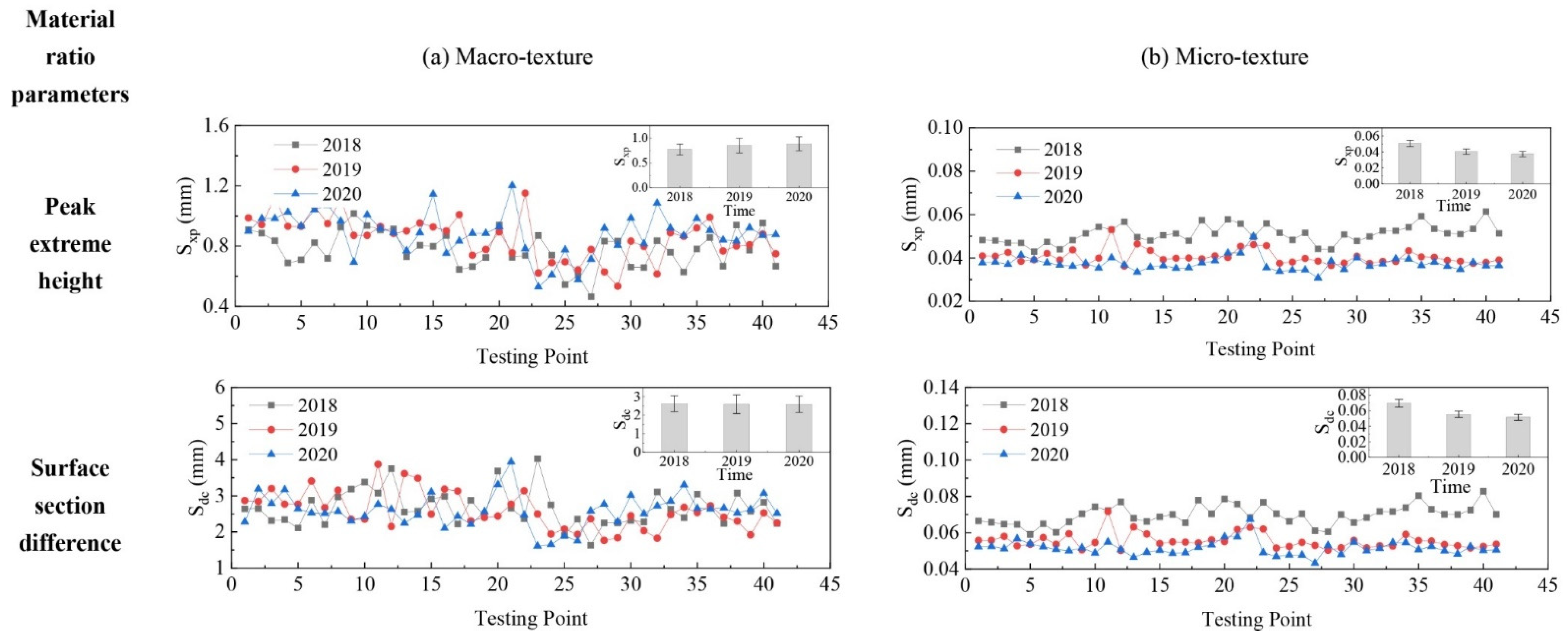

4.4.1. Evolution of Material Ratio Parameters

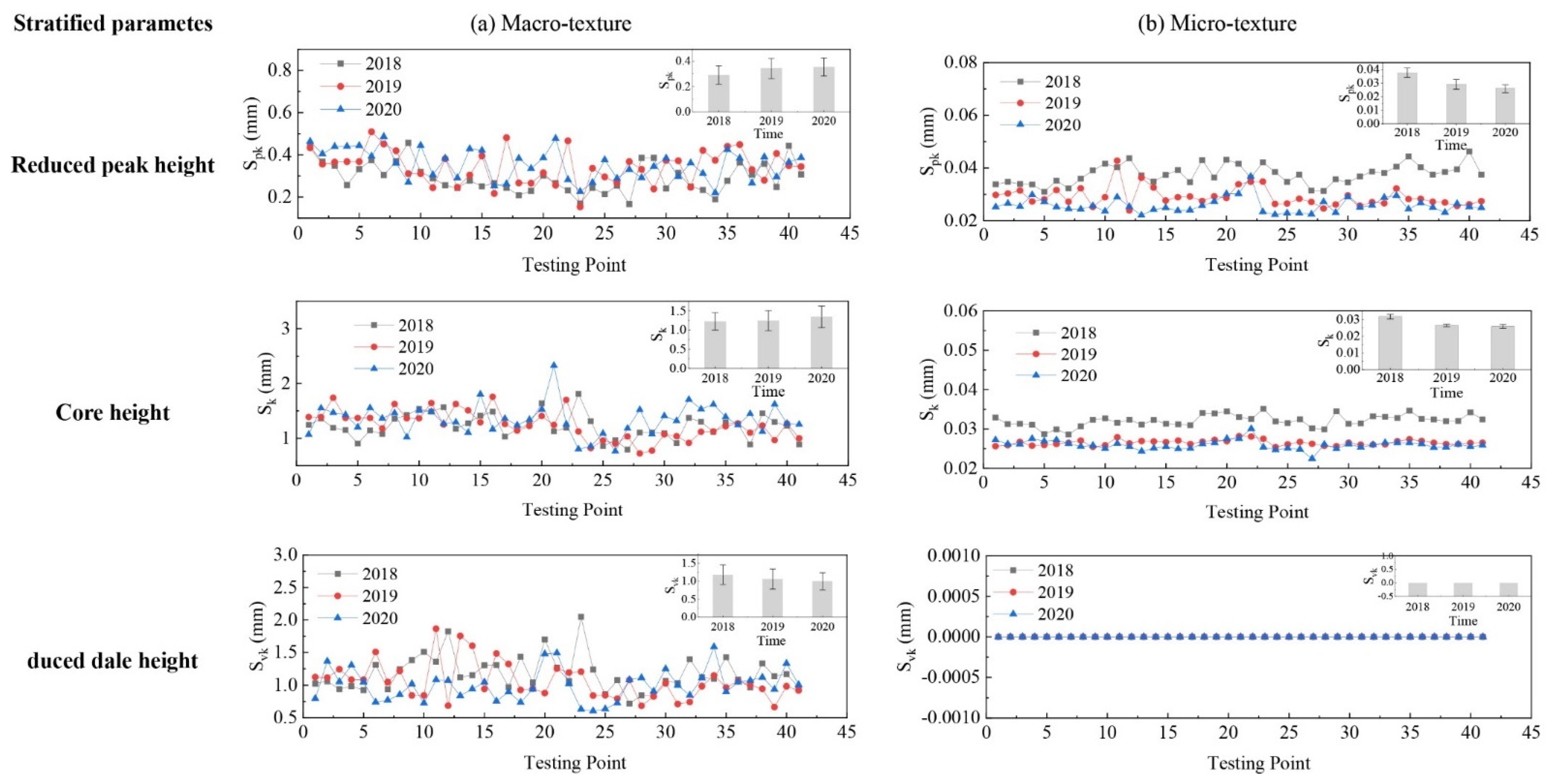

4.4.2. Evolution of Stratified Parameters

4.4.3. Evolution of Volume Parameters

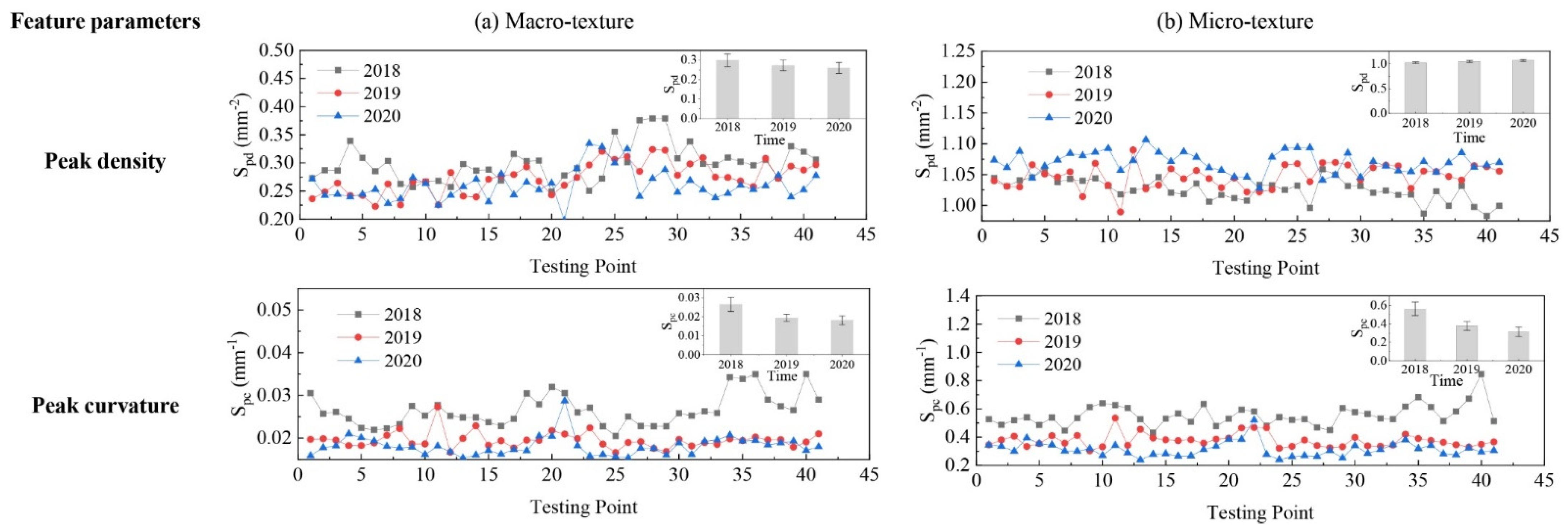

4.5. Evolution of Feature Parameters

5. Conclusions

- the traffic polish and environmental conditions change the pavement micro-texture as follows: (1) the spike structure was gradually shrunk; (2) the spatial characterization evolved from isotropic to anisotropic; (3) the steepness and the developed interfacial area were decreased; (4) the height or volume of the peak, core, and valley layers reduced consistently; and (5) the peak density increased but peak curvature decrease.

- the traffic polish and environmental conditions change the pavement macro-texture as follows: (1) the had valley structure and the height variation of surface peaks decreased; (2) the spatial characteristics were not changed under traffic polish; (3) its steepness and the developed interfacial area were decreased; (4) the material of the peak layer removed, and the valley layer filled up with dust, debris, or residue, and (5) the peak density and peak curvature were all decreased.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fwa, T. Skid resistance determination for pavement management and wet-weather road safety. Int. J. Transp. Sci. Technol. 2017, 6, 217–227. [Google Scholar] [CrossRef]

- Giles, C.G.; Sabey, B.E. Skidding as a factor in accidents on the roads of Great Britain. In Proceedings of the First International Skid Prevention Conference, Charlottesville, VA, USA, 1959; pp. 27–40. [Google Scholar]

- Xiao, J.; Kulakowski, B.T.; Ei-Gindy, M. Prediction of Risk of Wet-Pavement Accidents: Fuzzy Logic Model. Transp. Res. Rec. 2000, 1717, 28–36. [Google Scholar] [CrossRef]

- Chu, L.; Fwa, T.F. Incorporating pavement skid resistance and hydroplaning risk considerations in asphalt mix design. J. Transp. Eng. 2016, 142, 04016039. [Google Scholar] [CrossRef]

- Wang, D.; Liu, P.; Xu, H.; Kollmann, J.; Oeser, M. Evaluation of the polishing resistance characteristics of fine and coarse aggregate for asphalt pavement using Wehner/Schulze test. Constr. Build. Mater. 2018, 163, 742–750. [Google Scholar] [CrossRef]

- Chu, L.; Zhou, B.; Fwa, T.F. Directional characteristics of traffic polishing effect on pavement skid resistance. Int. J. Pavement Eng. 2021, 1–17. [Google Scholar] [CrossRef]

- Do, M.-T.; Tang, Z.; Kane, M.; de Larrard, F. Evolution of road-surface skid-resistance and texture due to polishing. Wear 2009, 266, 574–577. [Google Scholar] [CrossRef]

- Kanafi, M.M.; Kuosmanen, A.; Pellinen, T.K.; Tuononen, A.J. Macro- and micro-texture evolution of road pavements and correlation with friction. Int. J. Pavement Eng. 2015, 16, 168–179. [Google Scholar] [CrossRef]

- Ueckermann, A.; Wang, D.; Oeser, M.; Steinauer, B. Calculation of skid resistance from texture measurements. J. Traffic Transp. Eng. (Engl. Ed.) 2015, 2, 3–16. [Google Scholar] [CrossRef] [Green Version]

- ISO. Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters; ISO 25178-2:2012(en); ISO: London, UK, 2012. [Google Scholar]

- Gheni, A.; Abdelkarim, O.I.; AbdulAzeez, M.M.; ElGawady, M. Texture and design of green chip seal using recycled crumb rubber aggregate. J. Clean. Prod. 2017, 166, 1084–1101. [Google Scholar] [CrossRef]

- Flintsch, G.W.; De León, E.; McGhee, K.K.; Ai-Qadi, I.L. Pavement Surface Macrotexture Measurement and Applications. Transp. Res. Rec. 2003, 1860, 168–177. [Google Scholar] [CrossRef]

- Abe, H.; Tamai, A.; Henry, J.J.; Wambold, J. Measurement of Pavement Macrotexture with Circular Texture Meter. Transp. Res. Rec. 2001, 1764, 201–209. [Google Scholar] [CrossRef]

- Chen, J.; Huang, X.; Zheng, B.; Zhao, R.; Liu, X.; Cao, Q.; Zhu, S. Real-time identification system of asphalt pavement texture based on the close-range photogrammetry. Constr. Build. Mater. 2019, 226, 910–919. [Google Scholar] [CrossRef]

- Meegoda, J.N.; Gao, S. Evaluation of pavement skid resistance using high speed texture measurement. J. Traffic Transp. Eng. (Engl. Ed.) 2015, 2, 382–390. [Google Scholar] [CrossRef] [Green Version]

- Zuniga-Garcia, N.; Prozzi, J.A. Contribution of Micro- and Macro-Texture for Predicting Friction on Pavement Surfaces (No. CHPP Report-UTA# 3-2016). Available online: https://www.chpp.egr.msu.edu/wp-content/uploads/2018/03/CHPP-Report-UTA3-2017_Texture.pdf (accessed on 12 September 2021).

- Leach, R. Characterisation of Areal Surface Texture; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Li, L.; Wang, K.C.; Li, Q. Geometric texture indicators for safety on AC pavements with 1 mm 3D laser texture data. Int. J. Pavement Res. Technol. 2016, 9, 49–62. [Google Scholar] [CrossRef] [Green Version]

- Li, Q.; Yang, G.; Wang, K.C.P.; Zhan, Y.; Wang, C. Novel Macro- and Microtexture Indicators for Pavement Friction by Using High-Resolution Three-Dimensional Surface Data. Transp. Res. Rec. 2017, 2641, 164–176. [Google Scholar] [CrossRef]

- Yang, G.; Yu, W.; Li, Q.J.; Wang, K.; Peng, Y.; Zhang, A. Random Forest–Based Pavement Surface Friction Prediction Using High-Resolution 3D Image Data. J. Test. Eval. 2019, 49, 1141–1152. [Google Scholar] [CrossRef]

- Zou, Y.; Yang, G.; Cao, M. Neural network-based prediction of sideway force coefficient for asphalt pavement using high-resolution 3D texture data. Int. J. Pavement Eng. 2021. [Google Scholar] [CrossRef]

- Dunford, A.M.; Parry, A.R.; Shipway, P.H.; Viner, H.E. Three-dimensional characterisation of surface texture for road stones undergoing simulated traffic wear. Wear 2012, 292, 188–196. [Google Scholar] [CrossRef]

- BS EN 12697-49: Bituminous Mixtures–Test Methods for Hot Mix Asphalt. Part 49: Determination of Friction after Polishing; BSI: London, UK, 2014.

- Wang, D.; Chen, X.; Xie, X.; Stanjek, H.; Oeser, M.; Steinauer, B. A study of the laboratory polishing behavior of granite as road surfacing aggregate. Constr. Build. Mater. 2015, 89, 25–35. [Google Scholar] [CrossRef]

- Lei, C. Study on Pavement Surface Function Accelerated Loading System; Graduate Faculty of South China University of Technology: Guangzhou, China, 2010. [Google Scholar]

- Liang, R.Y. Long Term Validation of an Accelerated Polishing Test Procedure for HMA Pavements; Technical Report; Ohio Department of Transportation and the U.S. Department of Transportation, Federal Highway Administration: Columbus, OH, USA, 2013. [Google Scholar]

- Ren, W.; Han, S.; He, Z.; Li, J.; Wu, S. Development and testing of a multivariable accelerated abrasion machine to characterize the polishing wear of pavement by tires. Surf. Topogr. Metrol. Prop. 2019, 7, 035006. [Google Scholar] [CrossRef]

- Vollor, T.W.; Hanson, D.I. Development of laboratory procedure for measuring friction of HMA mixtures–PHASE I. In Final Report of NCAT; North Carolina Agricultural and Technical State University: Greensboro, NC, USA, 2006. [Google Scholar]

- Kane, M.; Do, M.T.; Piau, J.M. On the Study of Polishing of Road Surface under Traffic Load. J. Transp. Eng. 2010, 136, 45–51. [Google Scholar] [CrossRef]

- Druta, C.; Wang, L.; Lane, D.S. Evaluation of the MMLS3 for Accelerated Wearing of Asphalt Pavement Mixtures Containing Carbonate Aggregates. Available online: https://www.virginiadot.org/vtrc/main/online_reports/pdf/14-r17.pdf (accessed on 12 September 2021).

- Wu, Z.; Abadie, C. Laboratory and field evaluation of asphalt pavement surface friction resistance. Front. Struct. Civ. Eng. 2018, 12, 372–381. [Google Scholar] [CrossRef]

- Plati, C.; Pomoni, M. Impact of Traffic Volume on Pavement Macrotexture and Skid Resistance Long-Term Performance. Transp. Res. Rec. 2019, 2673, 314–322. [Google Scholar] [CrossRef]

- Blunt, L.; Jiang, X. Advanced Techniques for Assessment Surface Topography: Development of a Basis for 3D Surface Texture Standards "Surfstand"; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Barányi, I.; Czifra, Á.; Kalácska, G. Height-independent topographic parameters of worn surfaces. Int. J. Sustain. Constr. Des. 2011, 2, 35–40. [Google Scholar] [CrossRef]

- Franco, L.A.; Sinatora, A. 3D surface parameters (ISO 25178-2): Actual meaning of Spk and its relationship to Vmp. Precis. Eng. 2015, 40, 106–111. [Google Scholar] [CrossRef]

- Salguero, J.; Del Sol, I.; Vazquez-Martinez, J.; Schertzer, M.; Iglesias, P. Effect of laser parameters on the tribological behavior of Ti6Al4V titanium microtextures under lubricated conditions. Wear 2019, 426–427, 1272–1279. [Google Scholar] [CrossRef]

- Bush, A.; Gibson, R.; Thomas, T. The elastic contact of a rough surface. Wear 1975, 35, 87–111. [Google Scholar] [CrossRef]

| Category | Parameters | Unit | |

|---|---|---|---|

| Height Parameters | arithmetic mean height (Sa) | mm | |

| root mean square height (Sq) | mm | ||

| skewness (Ssk) | - | ||

| kurtosis (Sku) | - | ||

| Spatial Parameters | autocorrelation length (Sal) | mm | |

| texture aspect ratio (Str) | - | ||

| texture direction (Std) | rad | ||

| Hybrid Parameters | root mean square gradient (Sdq) | - | |

| developed interfacial area ratio (Sdr) | % | ||

| Function Related Parameters | Material Ratio Parameters | peak extreme height (Sxp) | mm |

| surface section difference (Sdc) | mm | ||

| Stratified Parameters | reduced peak height (Spk) | mm | |

| core height (Sk) | mm | ||

| reduced dale height (Svk) | mm | ||

| Volume Parameters | peak material volume (Vmp) | mm3 | |

| core material volume (Vmc) | mm3 | ||

| core void volume (Vvc) | mm3 | ||

| dales void volume (Vvv) | mm3 | ||

| Feature Parameters | peak density (Spd) | mm−2 | |

| peak curvature (Spc) | mm−1 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, Y.; Yang, G.; Huang, W.; Lu, Y.; Qiu, Y.; Wang, K.C.P. Study of Pavement Micro- and Macro-Texture Evolution Due to Traffic Polishing Using 3D Areal Parameters. Materials 2021, 14, 5769. https://doi.org/10.3390/ma14195769

Zou Y, Yang G, Huang W, Lu Y, Qiu Y, Wang KCP. Study of Pavement Micro- and Macro-Texture Evolution Due to Traffic Polishing Using 3D Areal Parameters. Materials. 2021; 14(19):5769. https://doi.org/10.3390/ma14195769

Chicago/Turabian StyleZou, Yiwen, Guangwei Yang, Wanqing Huang, Yang Lu, Yanjun Qiu, and Kelvin C. P. Wang. 2021. "Study of Pavement Micro- and Macro-Texture Evolution Due to Traffic Polishing Using 3D Areal Parameters" Materials 14, no. 19: 5769. https://doi.org/10.3390/ma14195769

APA StyleZou, Y., Yang, G., Huang, W., Lu, Y., Qiu, Y., & Wang, K. C. P. (2021). Study of Pavement Micro- and Macro-Texture Evolution Due to Traffic Polishing Using 3D Areal Parameters. Materials, 14(19), 5769. https://doi.org/10.3390/ma14195769