Hardness Prediction of Grind-Hardening Layer Based on Integrated Approach of Finite Element and Cellular Automata

Abstract

:1. Introduction

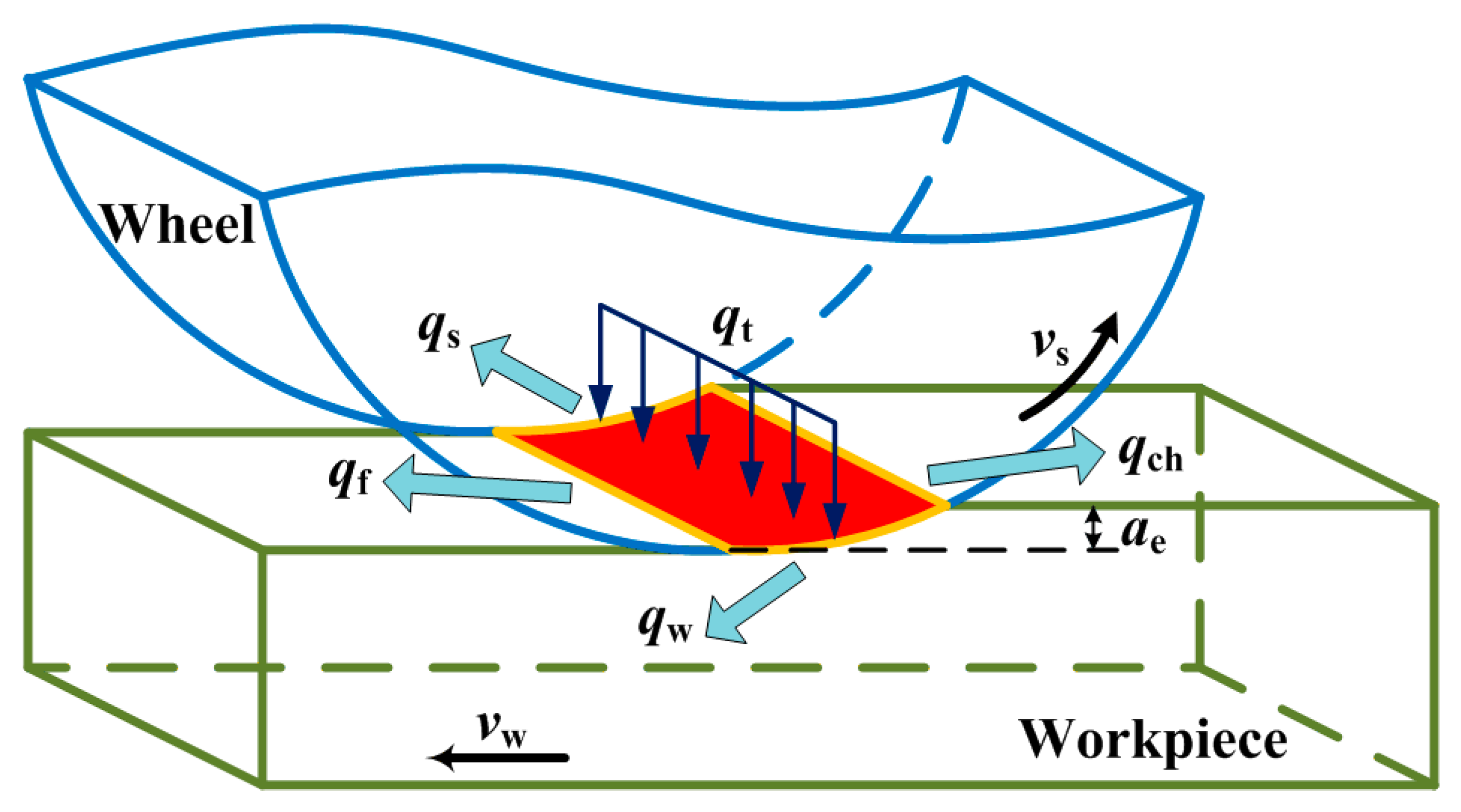

2. Heat Source Modeling and FE Simulation

2.1. Heat Source Model

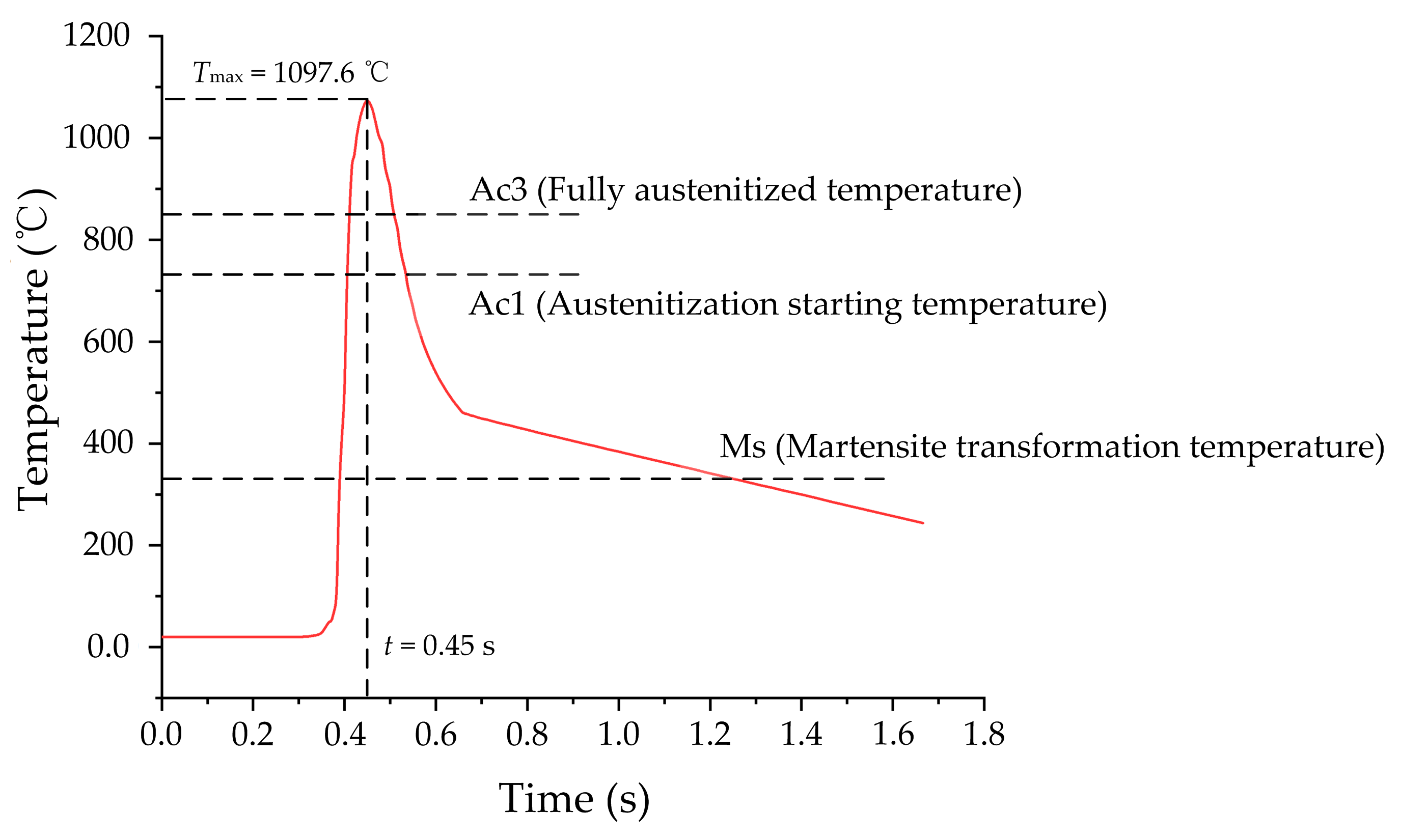

2.2. FE Simulation of Temperature Field

3. Simulation for Microstructure Transformation Based on CA Approach

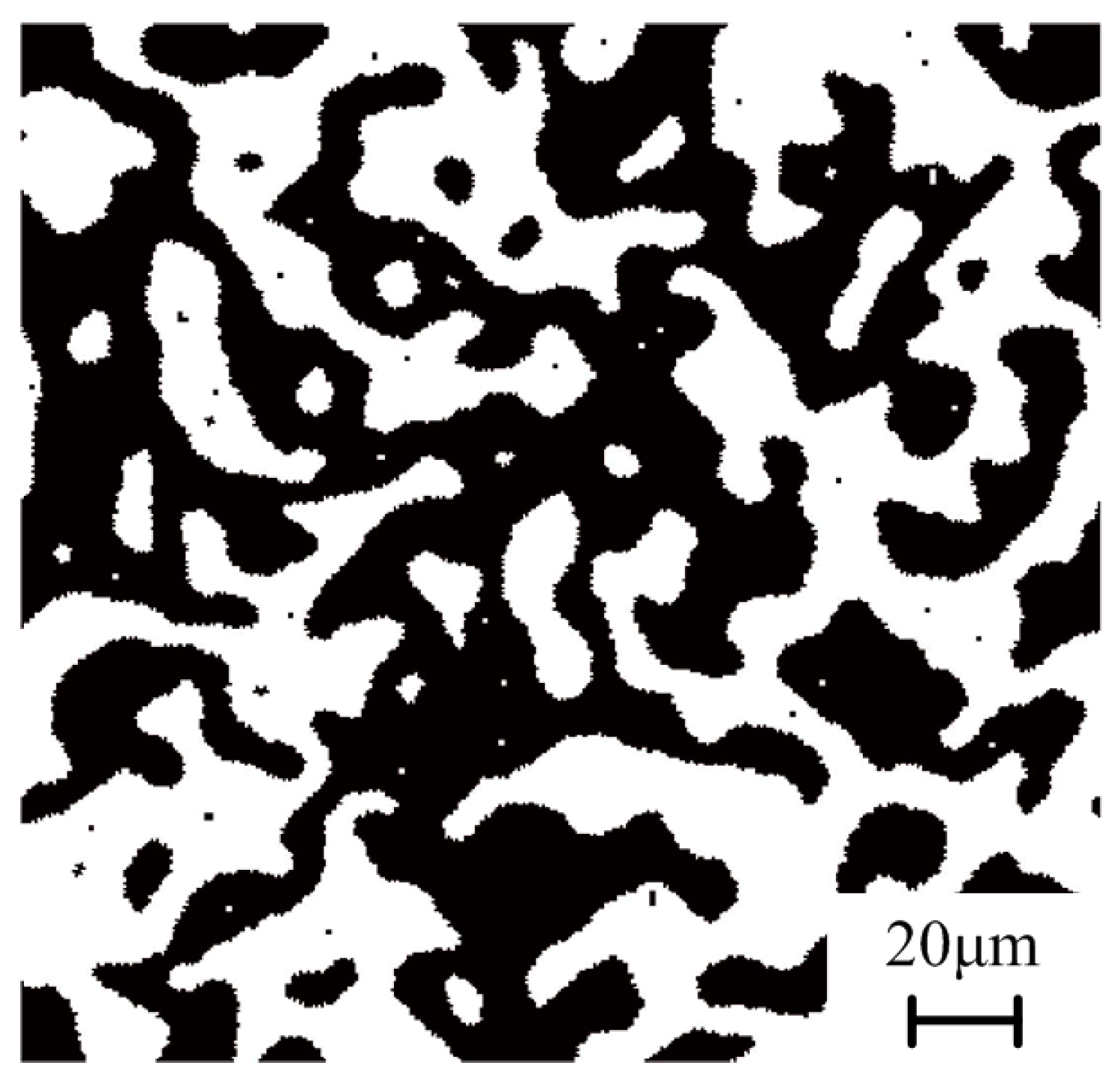

3.1. CA Modeling

3.2. Kinetic Model and Austenite Transformation Rules

3.2.1. Nucleation of Austenite

3.2.2. Growth of Austenite

3.2.3. Coarsening of Austenite

3.3. Kinetic Model of Martensite Transformation

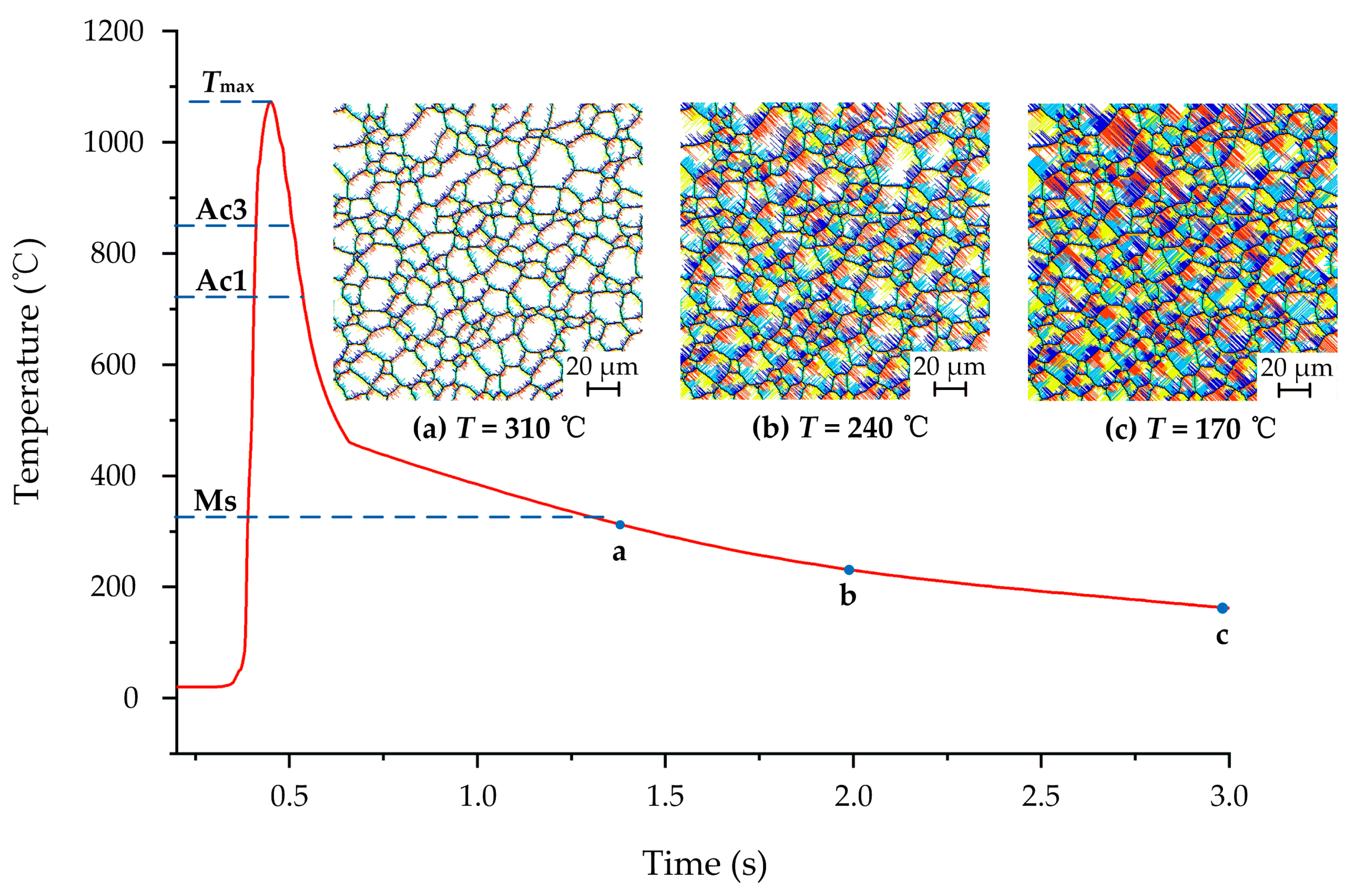

3.4. Simulation and Discuss

4. Hardness Prediction for Hardened Layer

4.1. Hardness Modeling

4.2. Hardness Prediction

5. Grind-Hardening Experiment

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xiu, S.C.; Sun, C.; Duan, J.C.; Lan, D.X.; Li, Q.L. Study on the surface topography in consideration of the dynamic grinding hardening process. Int. J. Adv. Manuf. Technol. 2019, 100, 209–233. [Google Scholar] [CrossRef]

- Zhang, Y.B.; Li, C.H.; Jia, D.Z.; Zhang, D.K.; Zhang, X.W. Experimental evaluation of MoS2 nanoparticles in jet MQL grinding with different types of vegetable oil as base oil. J. Clean. Prod. 2015, 87, 930–940. [Google Scholar] [CrossRef]

- Brockhoff, T.; Brinksmeier, E. Grind-hardening: A Comprehensive View. CIRP Ann. Manuf. Technol. 1999, 48, 255–260. [Google Scholar] [CrossRef]

- Nguyen, T.; Zhang, L.C.; Sun, D.L.; Wu, Q. Characterizing the Mechanical Properties of the Hardened Layer Induced by Grinding-Hardening. Mach. Sci. Technol. 2014, 18, 277–298. [Google Scholar] [CrossRef]

- Nguyen, T.; Zhang, L.C. Grinding-hardening using dry air and liquid nitrogen: Prediction and verification of temperature fields and hardened layer thickness. Int. J. Mach. Tools Manuf. 2010, 50, 901–910. [Google Scholar] [CrossRef]

- Alonso, U.; Ortega, N.; Sanchez, J.A.; Pombo, I.; Plaza, S.; Izquierdo, B. In-process prediction of the hardened layer in cylindrical traverse grind-hardening. Int. J. Adv. Manuf. Technol. 2014, 71, 101–108. [Google Scholar] [CrossRef]

- Salonitis, K.; Kolios, A. Experimental and numerical study of grind-hardening-induced residual stresses on AISI 1045 Steel. Int. J. Adv. Manuf. Technol. 2015, 79, 1443–1452. [Google Scholar] [CrossRef]

- Zhang, X.M.; Xiu, S.C.; Shi, X.L. Study on the distribution of hardening layer of 40Cr and 45 steel workpiece in grind-hardening process based on simulation and experiment. Int. J. Adv. Manuf. Technol. 2017, 93, 4265–4283. [Google Scholar] [CrossRef]

- Huang, X.M.; Ren, Y.H.; Jiang, W.; He, Z.J.; Deng, Z.H. Investigation on grind-hardening annealed AISI5140 steel with minimal quantity lubrication. Int. J. Adv. Manuf. Technol. 2017, 89, 1069–1077. [Google Scholar] [CrossRef]

- Huang, X.M.; Ren, Y.H.; Li, T.; Zhou, Z.X.; Zhang, G.F. Influence of minimum quantity lubrication parameters on grind-hardening process. Mater. Manuf. Process. 2018, 33, 69–76. [Google Scholar] [CrossRef]

- Zinoviev, A.; Zinovieva, O.; Ploshikhin, V.; Romanova, V.; Balokhonov, R. Evolution of grain structure during laser additive manufacturing. Simulation by a cellular automata method. Mater. Design 2016, 106, 321–329. [Google Scholar] [CrossRef]

- Lan, Y.J.; Li, D.Z.; Li, Y.Y. Modeling austenite decomposition into ferrite at different cooling rate in low-carbon steel with cellular automaton method. Acta Mater. 2004, 52, 1721–1729. [Google Scholar] [CrossRef]

- Bos, C.; Mecozz, M.G.; Sietsma, J. A microstructure model for recrystallisation and phase transformation during the dual-phase steel annealing cycle. Comput. Mater. Sci. 2010, 48, 692–699. [Google Scholar] [CrossRef]

- Zhi, Y.; Liu, W.J.; Liu, X.H. Simulation of Martensitic Transformation of High Strength and Elongation Steel by Cellular Automaton. Adv. Mat. Res. 2014, 1004–1005, 235–238. [Google Scholar] [CrossRef]

- Shabaniverki, S.; Serajzadeh, S. Simulation of softening kinetics and microstructural events in aluminum alloy subjected to single and multi-pass rolling operations. Appl. Math. Model. 2016, 40, 7571–7582. [Google Scholar] [CrossRef]

- Liu, M.H.; Zhang, K.; Xiu, S.C. Mechanism investigation of hardening layer hardness uniformity based on grind-hardening process. Int. J. Adv. Manuf. Technol. 2017, 88, 3185–3194. [Google Scholar] [CrossRef]

- Shi, X.L.; Xiu, S.C. Study on the hardness model of grinding for structural steel. Int. J. Adv. Manuf. Technol. 2020, 106, 3563–3573. [Google Scholar] [CrossRef]

- Rowe, W.B. Thermal analysis of high efficiency deep grinding. Int. J. Mach. Tools Manuf. 2011, 41, 1–19. [Google Scholar] [CrossRef]

- Jin, T.; Stephenson, D.J. Analysis of grinding chip temperature and energy partitioning in high-efficiency deep grinding. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2006, 220, 615–625. [Google Scholar] [CrossRef]

- Bok, H.H.; Lee, M.G.; Pavlina, E.J.; Barlat, F.; Kim, H.D. Comparative study of the prediction of microstructure and mechanical properties for a hot-stamped B-pillar reinforcing part. Int. J. Mech. Sci. 2011, 53, 744–752. [Google Scholar] [CrossRef]

- Irani, M.; Chung, S.; Kim, M.; Lee, K.; Joun, M. Adjustment of Isothermal Transformation Diagrams Using Finite-Element Optimization of the Jominy Test. Metals 2020, 10, 931. [Google Scholar] [CrossRef]

- Yang, B.J.; Hattiangadi, A.; Li, W.Z.; Zhou, G.F.; McGreevy, T.E. Simulation of steel microstructure evolution during induction heating. Mater. Sci. Eng. A 2010, 527, 2978–2984. [Google Scholar] [CrossRef]

- Zhu, B.; Zhang, Y.S.; Wang, C.; Liu, P.X.; Liang, W.K.; Li, J. Modeling of the Austenitization of Ultra-high Strength Steel with Cellular Automation Method. Metall. Mater. Trans. A 2014, 45, 3161–3171. [Google Scholar] [CrossRef]

- Yang, B.J.; Chuzhoy, L.; Johson, M.L. Modeling of reaustenitization of hypoeutectoid steels with cellular automaton method. Comput. Mater. Sci. 2007, 41, 186–194. [Google Scholar] [CrossRef]

- Mecozzi, M.G.; Bos, C.; Sietsma, J. A mixed-mode model for the ferrite-to-austenite transformation in a ferrite/pearlite microstructure. Acta Mater. 2015, 88, 302–313. [Google Scholar] [CrossRef]

- Svoboda, J.; Fischer, F.D.; Fratzl, P.; Gamsjäger, E.; Simha, N.K. Kinetics of interfaces during diffusional transformations. Acta Mater. 2011, 49, 1249–1259. [Google Scholar] [CrossRef]

- Lan, Y.J.; Li, D.Z.; Li, Y.Y. A Mesoscale Cellular Automaton Model for Curvature-Driven Grain Growth. Metall. Mater. Trans. B 2006, 37, 119–129. [Google Scholar] [CrossRef]

- Li, D.Z.; Xiao, N.M.; Lan, Y.J.; Zheng, C.W.; Li, Y.Y. Growth modes of individual ferrite grains in the austenite to ferrite transformation of low carbon steels. Acta Mater. 2007, 55, 6234–6249. [Google Scholar] [CrossRef]

- Guimaraes, J.R.C.; Rios, P.R. Modeling Lath Martensite Transformation Curve. Metall. Mater. Trans. A 2013, 44, 2–4. [Google Scholar] [CrossRef]

- Sherman, D.H.; Yang, B.J.; Catalina, A.V.; Hattiangadi, A.A.; Zhao, P.; Chuzhoy, L.; Johnson, M.L. Modeling of Microstructure Evolution of Athermal Transformation of Lath Martensite. Mater. Sci. Forum 2007, 539–543, 4795–4800. [Google Scholar] [CrossRef]

- Guo, Y.; Xiu, S.C.; Liu, M.H. Uniformity mechanism investigation of hardness penetration depth during grind-hardening process. Int. J. Adv. Manuf. Technol. 2017, 89, 2001–2010. [Google Scholar] [CrossRef]

| Component | C | Si | Mn | Cr | Ni | Cu |

|---|---|---|---|---|---|---|

| Fraction (%) | 0.42–0.5 | 0.17–0.37 | 0.5–0.8 | ≤0.25 | ≤0.3 | ≤0.25 |

| Temperature (°C) | 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Density (kg/m3) | 7850 | 7830 | 7800 | 7770 | 7740 | 7700 | 7685 | 7672 | 7660 | 7651 | 7649 |

| Specific Heat (J/kg·°C) | 460 | 480 | 498 | 524 | 524 | 615 | 690 | 720 | 682 | 637 | 602 |

| Heat Conductivity (W/m·°C) | 49.77 | 46.76 | 43.24 | 40.29 | 37.87 | 35.96 | 33.18 | 30.52 | 27.96 | 25.92 | 24.02 |

| Experimental Conditions | Parameters | |

|---|---|---|

| Machine | BLOHM ORBIT 36CNC (Korber Schleifring, Shanghai, China) | |

| Wheel | Size (outer diameter × width) | 350 mm × 40 mm |

| Granularity | F46 | |

| Abrasive material | White alumina | |

| Workpiece | Material | 1045 steel |

| Size | 90 mm × 9 mm × 14 mm | |

| Cooling mode and grinding method | Dry grinding, up grinding | |

| Metallographic observation equipment | OLYMPUS-GX71 (Olympus Corporation, Tokyo, Japan) | |

| Vickers hardness test instrument | THV-5 (Beijing Time High Technology Ltd., Beijing, China) | |

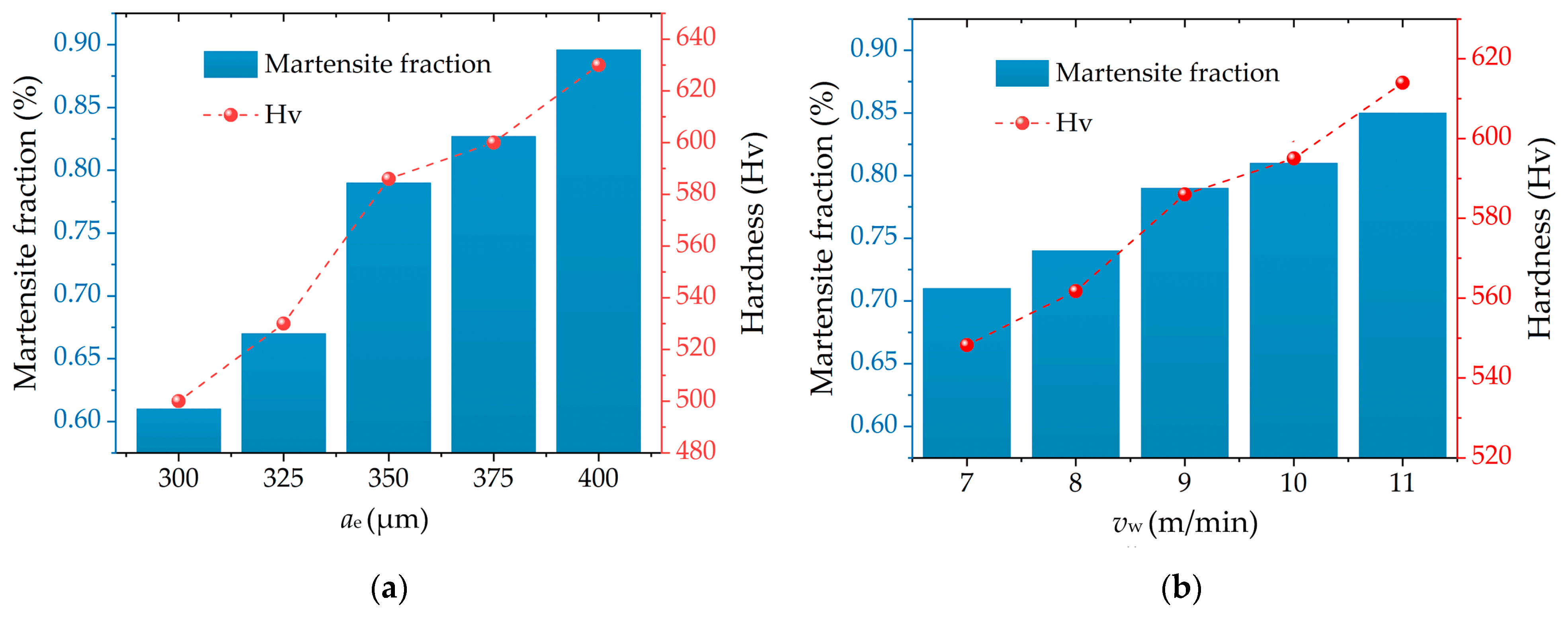

| Grinding parameters | Grinding depth ae (μm) | 300, 325, 350, 375, 400 |

| Feeding speed vw (m/min) | 7, 8, 9, 10, 11 | |

| Wheel speed vs (m/s) | 26.4 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Liu, M.; Yan, Y. Hardness Prediction of Grind-Hardening Layer Based on Integrated Approach of Finite Element and Cellular Automata. Materials 2021, 14, 5651. https://doi.org/10.3390/ma14195651

Guo Y, Liu M, Yan Y. Hardness Prediction of Grind-Hardening Layer Based on Integrated Approach of Finite Element and Cellular Automata. Materials. 2021; 14(19):5651. https://doi.org/10.3390/ma14195651

Chicago/Turabian StyleGuo, Yu, Minghe Liu, and Yutao Yan. 2021. "Hardness Prediction of Grind-Hardening Layer Based on Integrated Approach of Finite Element and Cellular Automata" Materials 14, no. 19: 5651. https://doi.org/10.3390/ma14195651

APA StyleGuo, Y., Liu, M., & Yan, Y. (2021). Hardness Prediction of Grind-Hardening Layer Based on Integrated Approach of Finite Element and Cellular Automata. Materials, 14(19), 5651. https://doi.org/10.3390/ma14195651