The Influence of CNC Turning with VBMT, RCMX, 3ER, and MGMN Type Indexable Inserts on West African Ebony/Diospyros crassiflora, San Domingo Boxwood/Phyllostylon brasiliense, Rio Rosewood/Dalbergia nigra, Beechwood/Fagus sylvatica, Oakwood/Quercus robur, and Pinewood/Pinus silvestris Surface Roughness

Abstract

1. Introduction

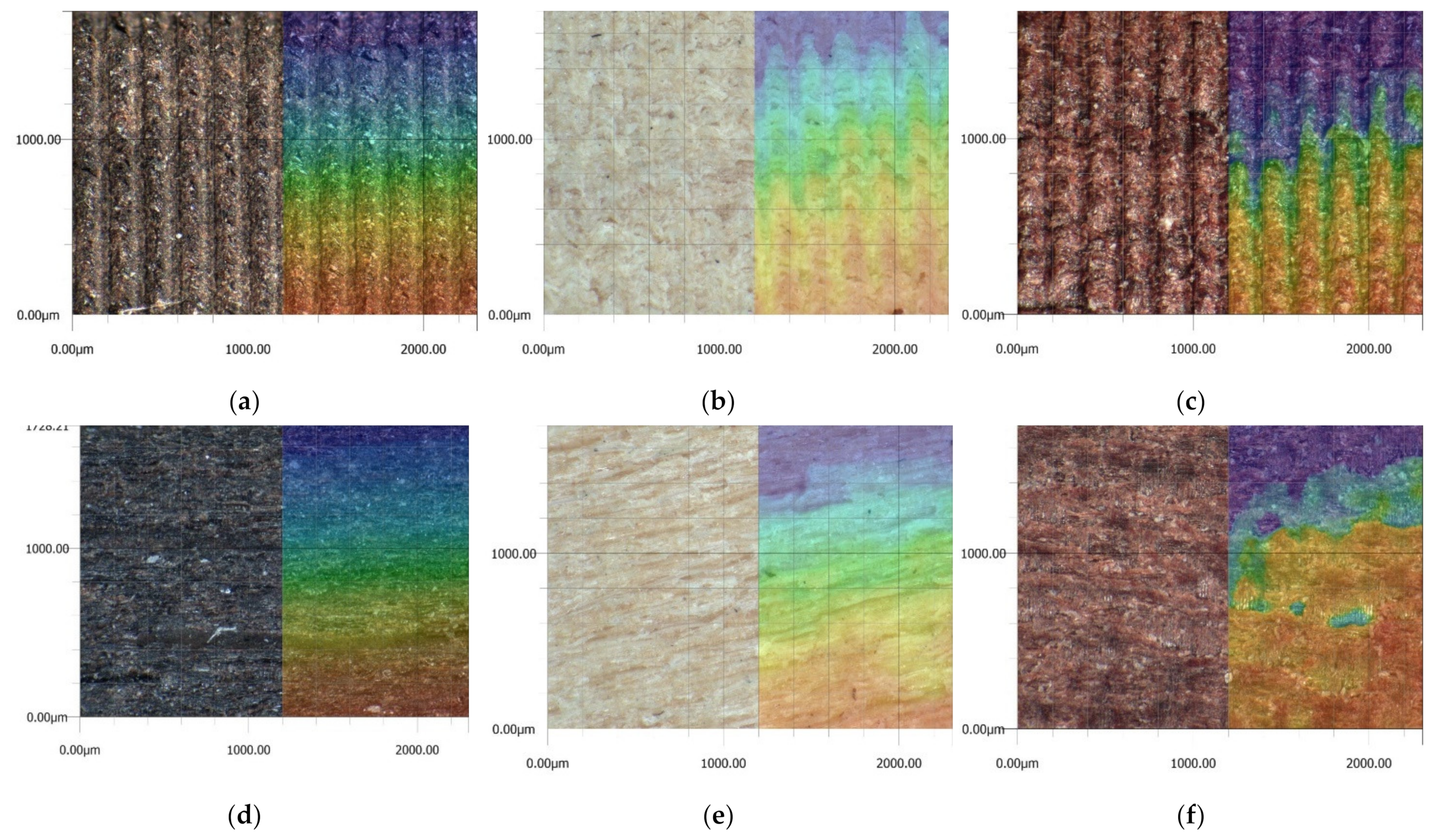

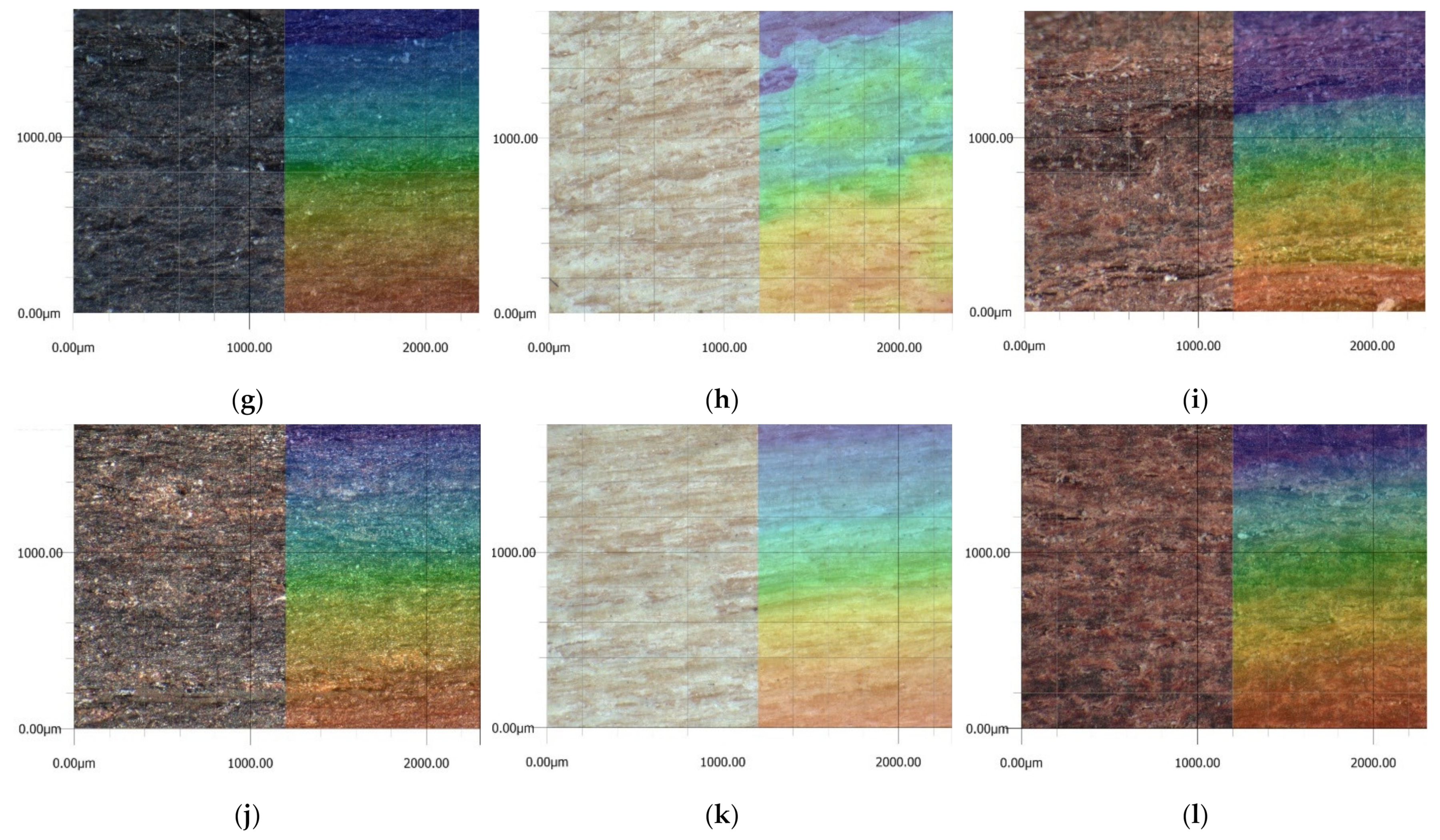

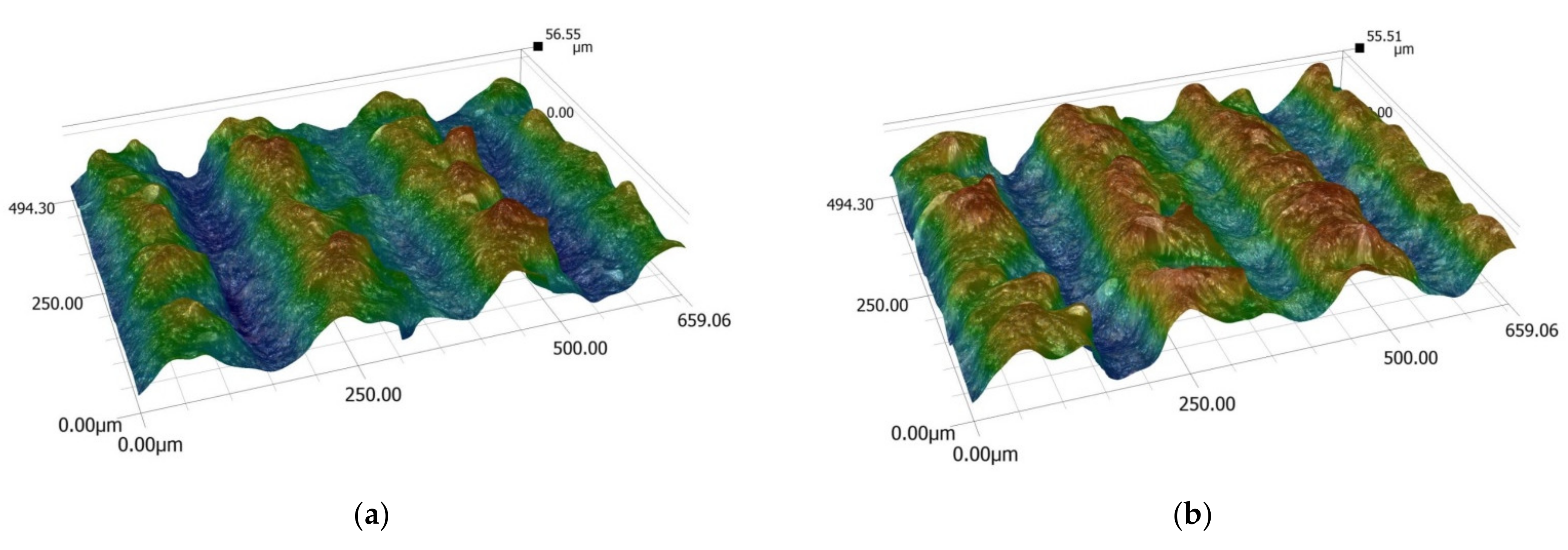

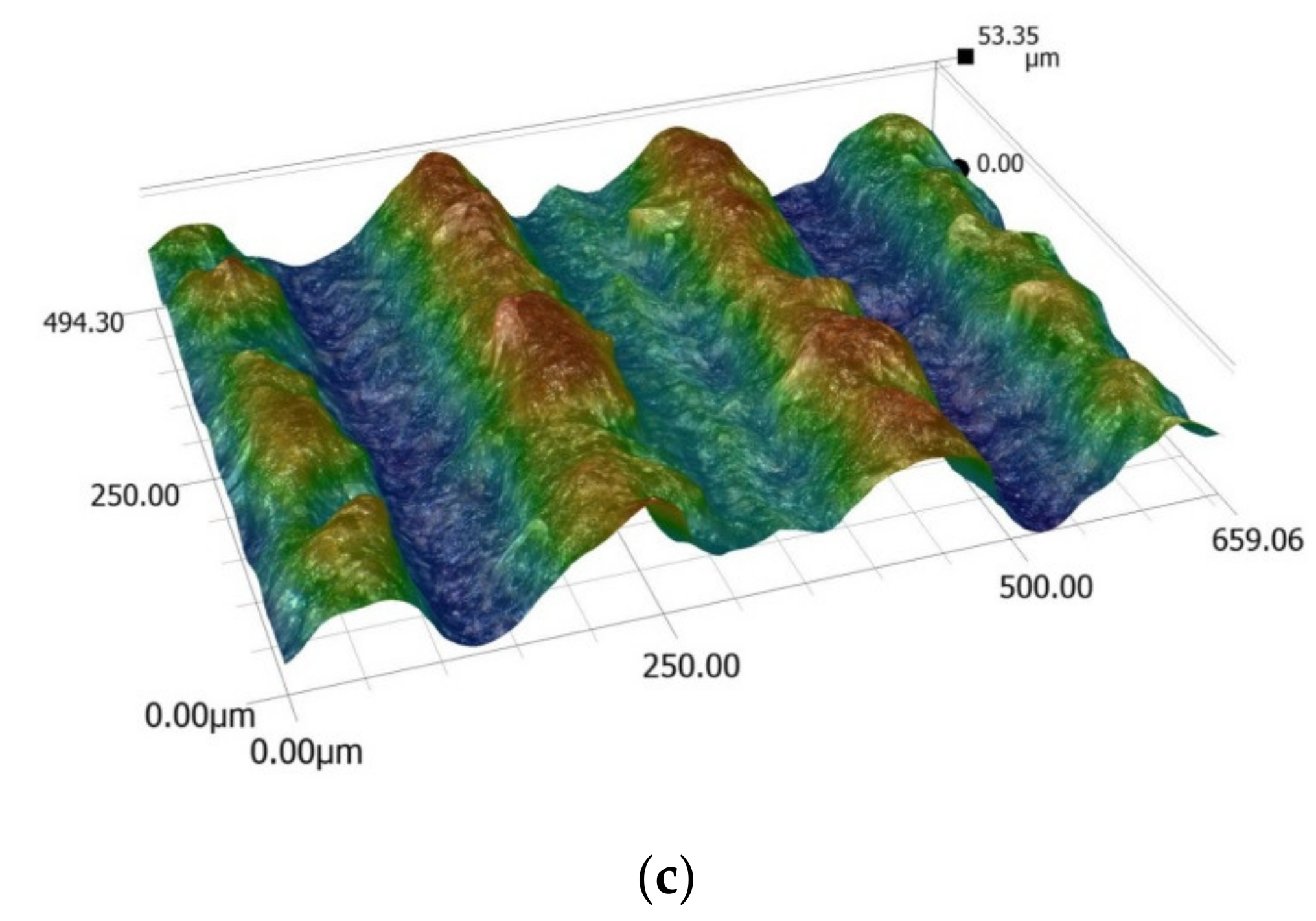

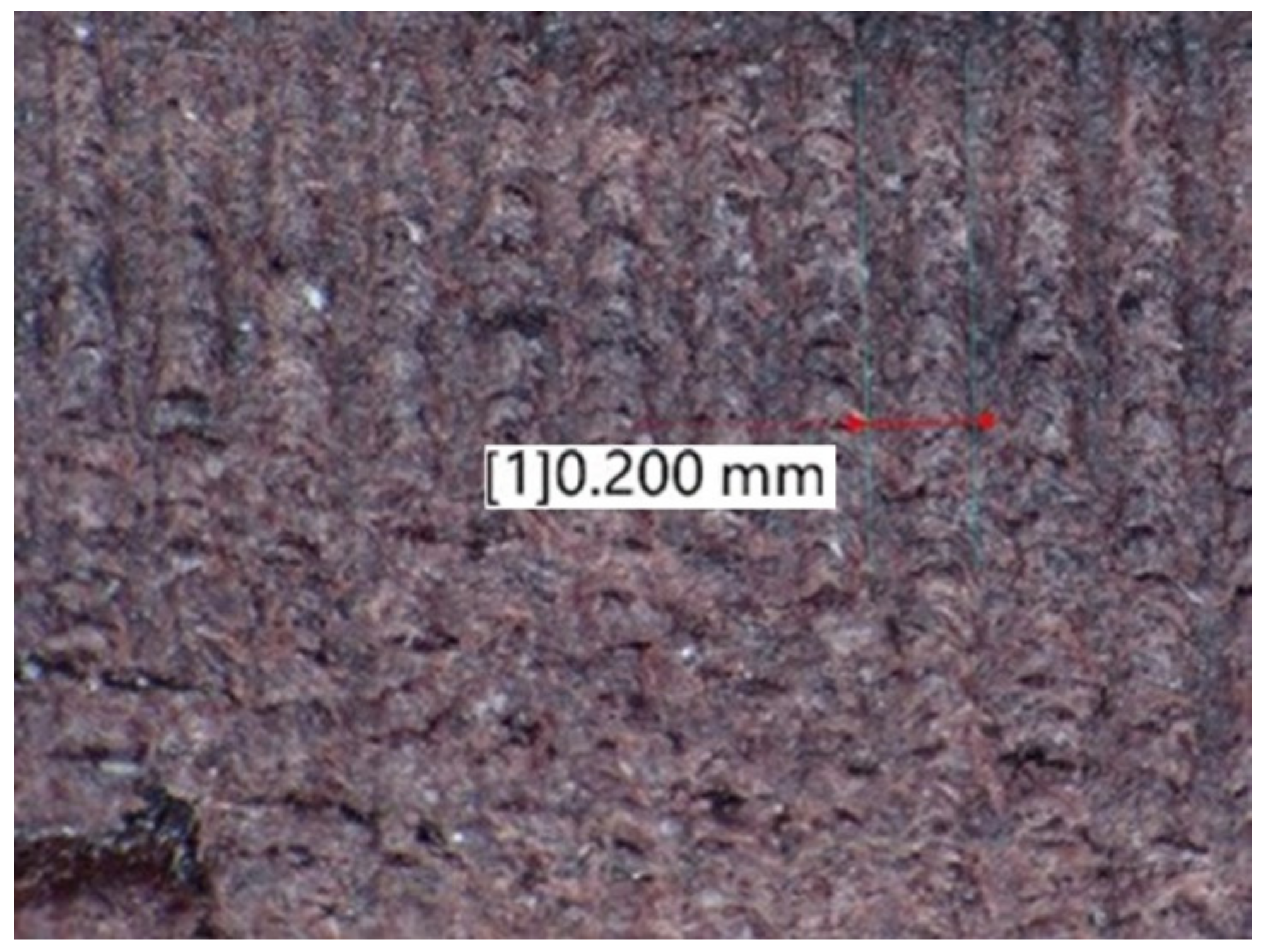

2. Materials and Methods

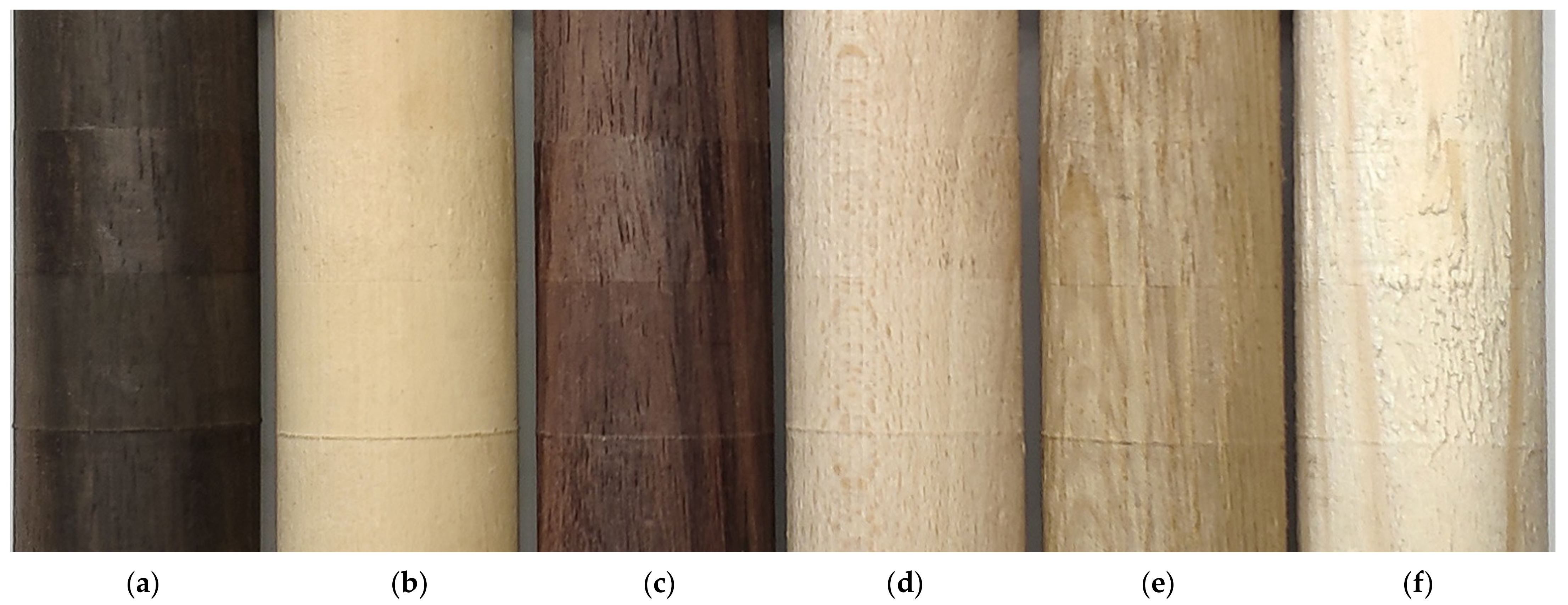

- West African Ebony, Diospyros crassiflora (EB);

- San Domingo Boxwood, Phyllostylon brasiliense (BoW);

- Rio Rosewood, Dalbergia nigra (RW);

- Beechwood, Fagus sylvatica (BeW);

- Oakwood, Quercus robur (OW);

- Pinewood, Pinus silvestris (PW).

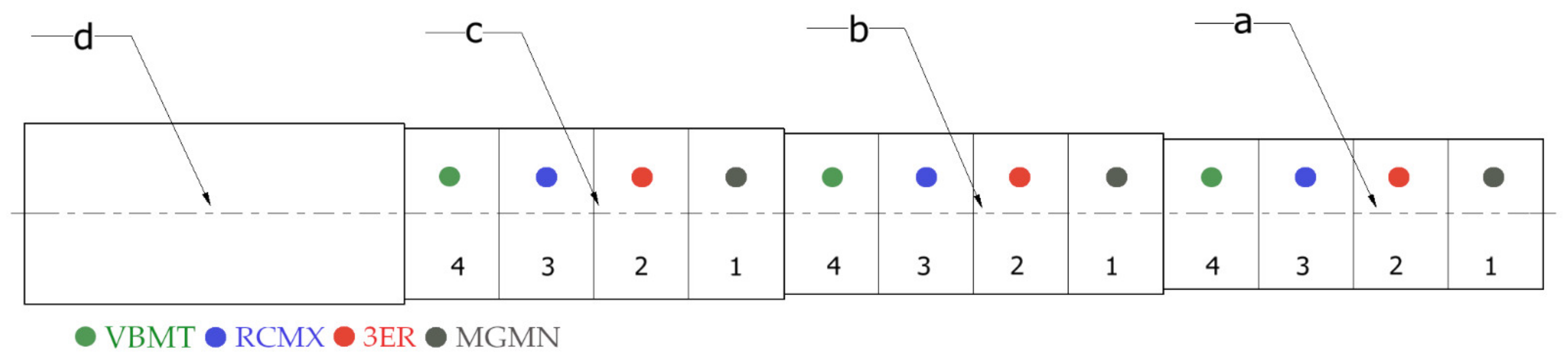

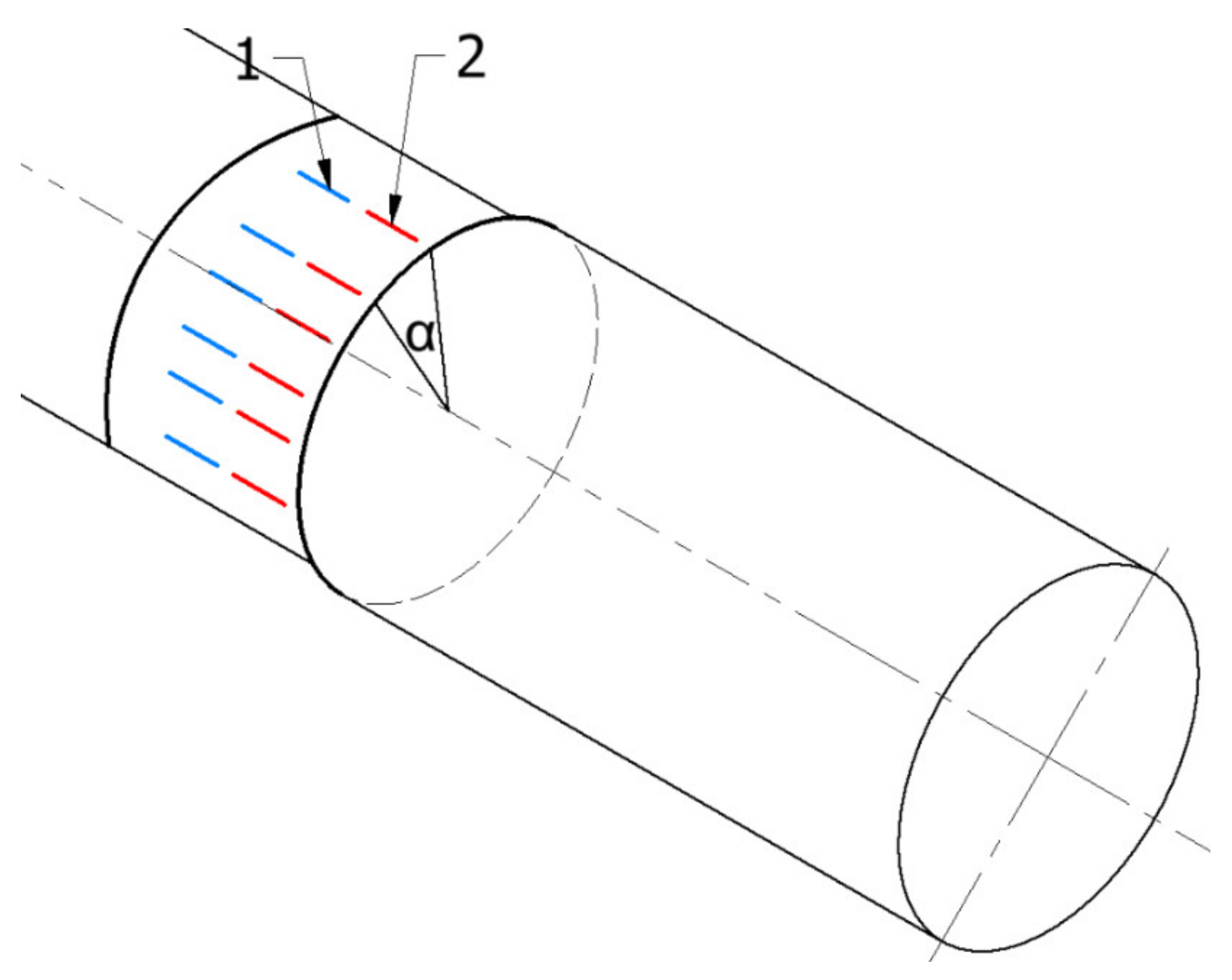

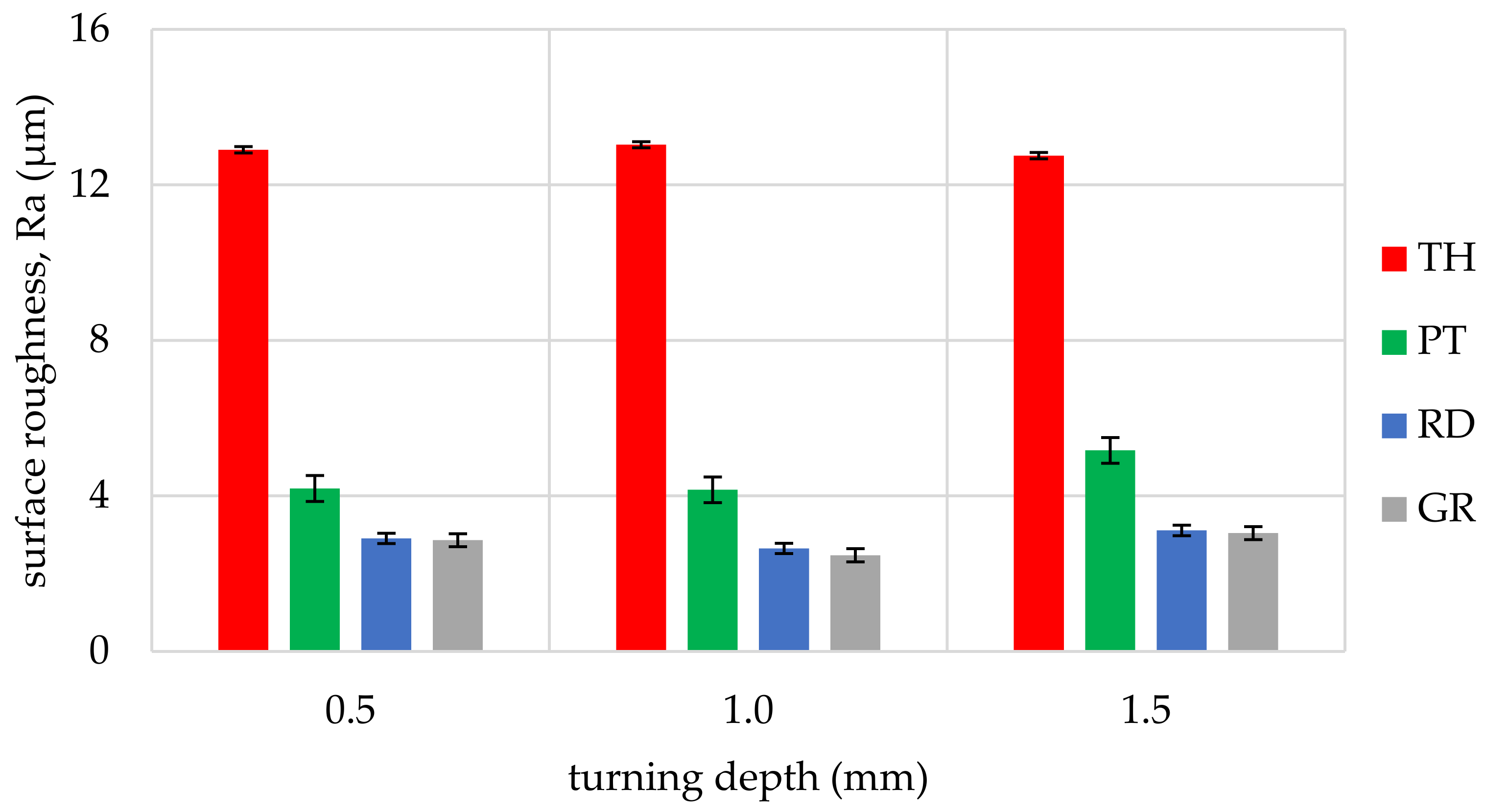

- 3ER threadcutting insert (TH);

- VBMT pointed straight insert (PT);

- RCMX round insert (RD);

- MGMN grooving insert (GR).

- West African Ebony 13,700 N;

- San Domingo Boxwood 8050 N;

- Rio Rosewood 12,410 N;

- Beechwood 6460 N;

- Oakwood 4980 N;

- Pinewood 2420 N.

3. Results

- West African Ebony 4.2%;

- San Domingo Boxwood 6.0%;

- Rio Rosewood 4.9%;

- Beechwood 3.5%;

- Oakwood 6.1%;

- Pinewood 6.2%.

4. Discussion

- Ra—surface roughness, µm;

- JH—Janka hardness, N;

- ICR—insert corner radius, mm.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shimelmitz, R. The Chalcolithic Lithic Assemblage. Salvage Excav. Rep. 2007, 4, 77–87. [Google Scholar]

- Davis, V.; Edmonds, M. Stone Axe Studies III; Oxbow Books: Oxford, UK, 2011; ISBN 978-1-84217-596-5. [Google Scholar]

- Bailey, J.A.; Bayoumi, A.-M.; Stewart, J.S. Wear of Some Cemented Tungsten Carbide Tools in Machining Oak. Wear 1983, 85, 69–79. [Google Scholar] [CrossRef]

- Cristóvão, L.; Lhate, I.; Grönlund, A.; Ekevad, M.; Sitoe, R. Tool Wear for Lesser Known Tropical Wood Species. Wood Mater. Sci. Eng. 2011, 6, 155–161. [Google Scholar] [CrossRef]

- Kazlauskas, D.; Jankauskas, V.; Tučkutė, S. Research on Tribological Characteristics of Hard Metal WC-Co Tools with TiAlN and CrN PVD Coatings for Processing Solid Oak Wood. Coatings 2020, 10, 632. [Google Scholar] [CrossRef]

- Pangestu, K.T.P.; Darmawan, W.; Nandika, D.; Usuki, H. Cutting Performance of Multilayer Coated Tungsten Carbide in Milling of Wood Composites. Int. Wood Prod. J. 2019, 10, 78–85. [Google Scholar] [CrossRef]

- Winkelmann, H.; Badisch, E.; Roy, M.; Danninger, H. Corrosion Mechanisms in the Wood Industry, Especially Caused by Tannins. Mater. Corros. 2009, 60, 40–48. [Google Scholar] [CrossRef]

- Zelinka, S.L.; Stone, D.S. The Effect of Tannins and PH on the Corrosion of Steel in Wood Extracts: The Effect of Tannins and PH on the Corrosion of Steel in Wood Extracts. Mater. Corros. 2011, 62, 739–744. [Google Scholar] [CrossRef]

- Igaz, R.; Kminiak, R.; Krišťák, Ľ.; Němec, M.; Gergeľ, T. Methodology of Temperature Monitoring in the Process of CNC Machining of Solid Wood. Sustainability 2018, 11, 95. [Google Scholar] [CrossRef]

- Wang, Z. An Investigation on Water Jet Machining for Hardwood Floors. Eur. J. Wood Wood Prod. 2012, 70, 55–59. [Google Scholar] [CrossRef]

- Denaud, L.E.; Bléron, L.; Eyma, F.; Marchal, R. Wood Peeling Process Monitoring: A Comparison of Signal Processing Methods to Estimate Veneer Average Lathe Check Frequency. Eur. J. Wood Wood Prod. 2012, 70, 253–261. [Google Scholar] [CrossRef][Green Version]

- Öhman, M.; Grubîi, V.; Sandberg, D.; Ekevad, M. Moistening of the Wood Surface before Planing for Improved Surface Quality. Wood Mater. Sci. Eng. 2016, 11, 156–163. [Google Scholar] [CrossRef]

- Kilic, M.; Hiziroglu, S.; Burdurlu, E. Effect of Machining on Surface Roughness of Wood. Build. Environ. 2006, 41, 1074–1078. [Google Scholar] [CrossRef]

- Ribeiro, J.E.; César, M.B.; Lopes, H. Optimization of Machining Parameters to Improve the Surface Quality. Procedia Struct. Integr. 2017, 5, 355–362. [Google Scholar] [CrossRef]

- Qehaja, N.; Jakupi, K.; Bunjaku, A.; Bruçi, M.; Osmani, H. Effect of Machining Parameters and Machining Time on Surface Roughness in Dry Turning Process. Procedia Eng. 2015, 100, 135–140. [Google Scholar] [CrossRef]

- Hendarto, B.; Shayan, E.; Ozarska, B.; Carr, R. Analysis of Roughness of a Sanded Wood Surface. Int. J. Adv. Manuf. Technol. 2006, 28, 775–780. [Google Scholar] [CrossRef]

- Bergmann Tiest, W.M.; Kappers, A.M.L. Haptic and Visual Perception of Roughness. Acta Psychol. 2007, 124, 177–189. [Google Scholar] [CrossRef]

- Liu, M.; Peng, L.; Lyu, S.; Lyu, J. Properties of Common Tropical Hardwoods for Fretboard of String Instruments. J. Wood Sci. 2020, 66, 14. [Google Scholar] [CrossRef]

- Sproßmann, R.; Zauer, M.; Wagenführ, A. Characterization of Acoustic and Mechanical Properties of Common Tropical Woods Used in Classical Guitars. Results Phys. 2017, 7, 1737–1742. [Google Scholar] [CrossRef]

- Hendarto, B.; Shayan, D.E.; Ozarska, D.B. Characterisation of Surface Finishing Processes in Wood Furniture Manufacturing. Available online: https://pdfs.semanticscholar.org/6a6d/de2c2c28aaa20fb1376365071e58883be873.pdf (accessed on 6 April 2021).

- Zhong, Z.W.; Hiziroglu, S.; Chan, C.T.M. Measurement of the Surface Roughness of Wood Based Materials Used in Furniture Manufacture. Measurement 2013, 46, 1482–1487. [Google Scholar] [CrossRef]

- Marchal, R.; Mothe, F.; Denaud, L.-E.; Thibaut, B.; Bleron, L. Cutting Forces in Wood Machining—Basics and Applications in Industrial Processes. A Review COST Action E35 2004–2008: Wood Machining—Micromechanics and Fracture. Holzforschung 2009, 63. [Google Scholar] [CrossRef]

- Francis, W.O.; Felix, B.; Godwin, Z. Timber Species from Afram Arm of the Volta Lake in Ghana: Planing and Sanding Properties. J. Hortic. For. 2015, 7, 84–93. [Google Scholar] [CrossRef][Green Version]

- Hiziroglu, S.; Zhong, Z.W.; Ong, W.K. Evaluating of Bonding Strength of Pine, Oak and Nyatoh Wood Species Related to Their Surface Roughness. Measurement 2014, 49, 397–400. [Google Scholar] [CrossRef]

- Morala-Argüello, P.; Barreiro, J.; Alegre, E. A Evaluation of Surface Roughness Classes by Computer Vision Using Wavelet Transform in the Frequency Domain. Int. J. Adv. Manuf. Technol. 2012, 59, 213–220. [Google Scholar] [CrossRef]

- Thoma, H.; Peri, L.; Lato, E. Evaluation of Wood Surface Roughness Depending on Species Characteristics. Maderas Cienc. Tecnol. 2015, 17, 285–292. [Google Scholar] [CrossRef]

- Gurau, L.; Irle, M. Surface Roughness Evaluation Methods for Wood Products: A Review. Curr. For. Rep. 2017, 3, 119–131. [Google Scholar] [CrossRef]

- Thibaut, B.; Denaud, L.; Collet, R.; Marchal, R.; Beauchêne, J.; Mothe, F.; Méausoone, P.-J.; Martin, P.; Larricq, P.; Eyma, F. Wood Machining with a Focus on French Research in the Last 50 Years. Ann. For. Sci. 2016, 73, 163–184. [Google Scholar] [CrossRef]

- Sofuoglu, S.D. Determination of Optimal Machining Parameters of Massive Wooden Edge Glued Panels Which Is Made of Scots Pine (Pinus sylvestris L.) Using Taguchi Design Method. Eur. J. Wood Wood Prod. 2017, 75, 33–42. [Google Scholar] [CrossRef]

- Hazir, E.; Koc, K.H. Optimization of Wood Machining Parameters in CNC Routers: Taguchi Orthogonal Array Based Simulated Angling Algorithm. Maderas Cienc. Tecnol. 2019, 21, 493–510. [Google Scholar] [CrossRef]

- Ayanleye, S.; Nasir, V.; Avramidis, S.; Cool, J. Effect of Wood Surface Roughness on Prediction of Structural Timber Properties by Infrared Spectroscopy Using ANFIS, ANN and PLS Regression. Eur. J. Wood Wood Prod. 2021, 79, 101–115. [Google Scholar] [CrossRef]

- Rawangwong, S.; Chatthong, J.; Rodjananugoon, J.; Boonchouytan, W. An Investigation of the Optimal Cutting Conditions in Coconut Wood and Palmyra Palm Wood Turning Process Using Design of Experiment. Walailak J. Sci. Technol. WJST 2013, 10, 267–276. [Google Scholar]

- Rawangwong, S.; Chatthong, J.; Boonchouytan, W. The Influence of Cutting Parameters of Turning Process on the Oil Palm Wood Using Carbide Tool. Appl. Mech. Mater. 2013, 415, 666–671. [Google Scholar] [CrossRef]

- Dündar Sofuoğlu, S.; Kurtoğlu, A. Effects of Machining Conditions on Surface Roughness in Planing and Sanding of Solid Wood. Drv. Ind. 2015, 66, 265–272. [Google Scholar] [CrossRef]

- Meyer, E. Wood! Identifying and Using Hundreds of Woods Worldwide. The Wood Database. 2015. Available online: https://www.wood-database.com/ (accessed on 6 April 2021).

- Hass, P.; Wittel, F.K.; McDonald, S.A.; Marone, F.; Stampanoni, M.; Herrmann, H.J.; Niemz, P. Pore Space Analysis of Beech Wood: The Vessel Network. Holzforschung 2010, 64. [Google Scholar] [CrossRef]

| Insert Type | Color | Symbol | Corner Radius, mm | Tool Orthogonal Wedge Angle, ° | Clearance Angle, ° |

|---|---|---|---|---|---|

| 3ER threadcutting insert (TH) | red | 3 ER AG60 VTX | 0.08 | 60 | 7 |

| VBMT pointed straight (PT) | green | VBMT160404-MF2CP500 | 0.4 | 35 | 5 |

| RCMX round insert (RD) | blue | RCMX 12 04 00 4225 | 6.0 | 15 | - |

| MGMN grooving insert (GR) | grey | N123G2-0300-0002-CM-1125 | 0.2 1 | - | - |

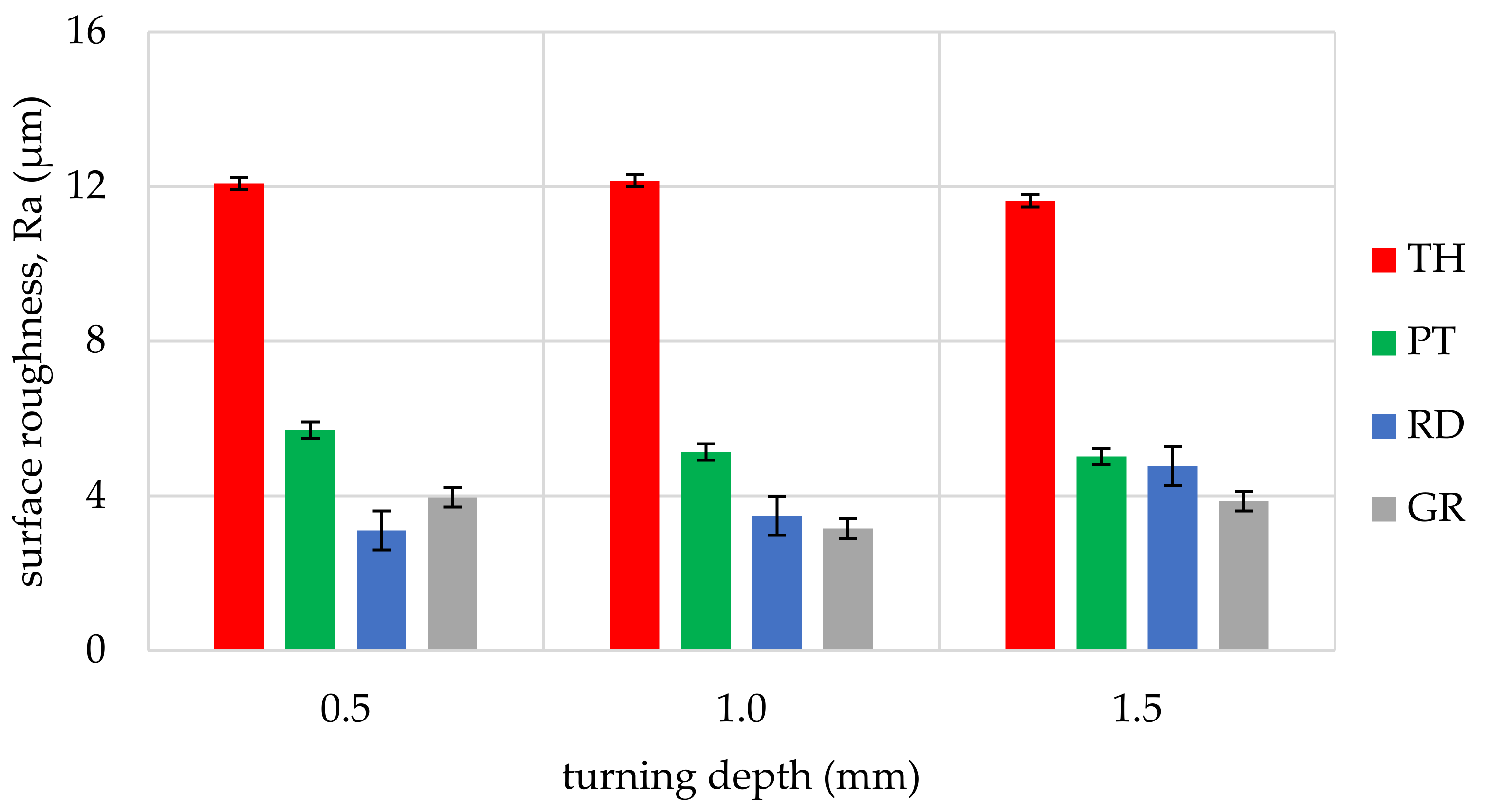

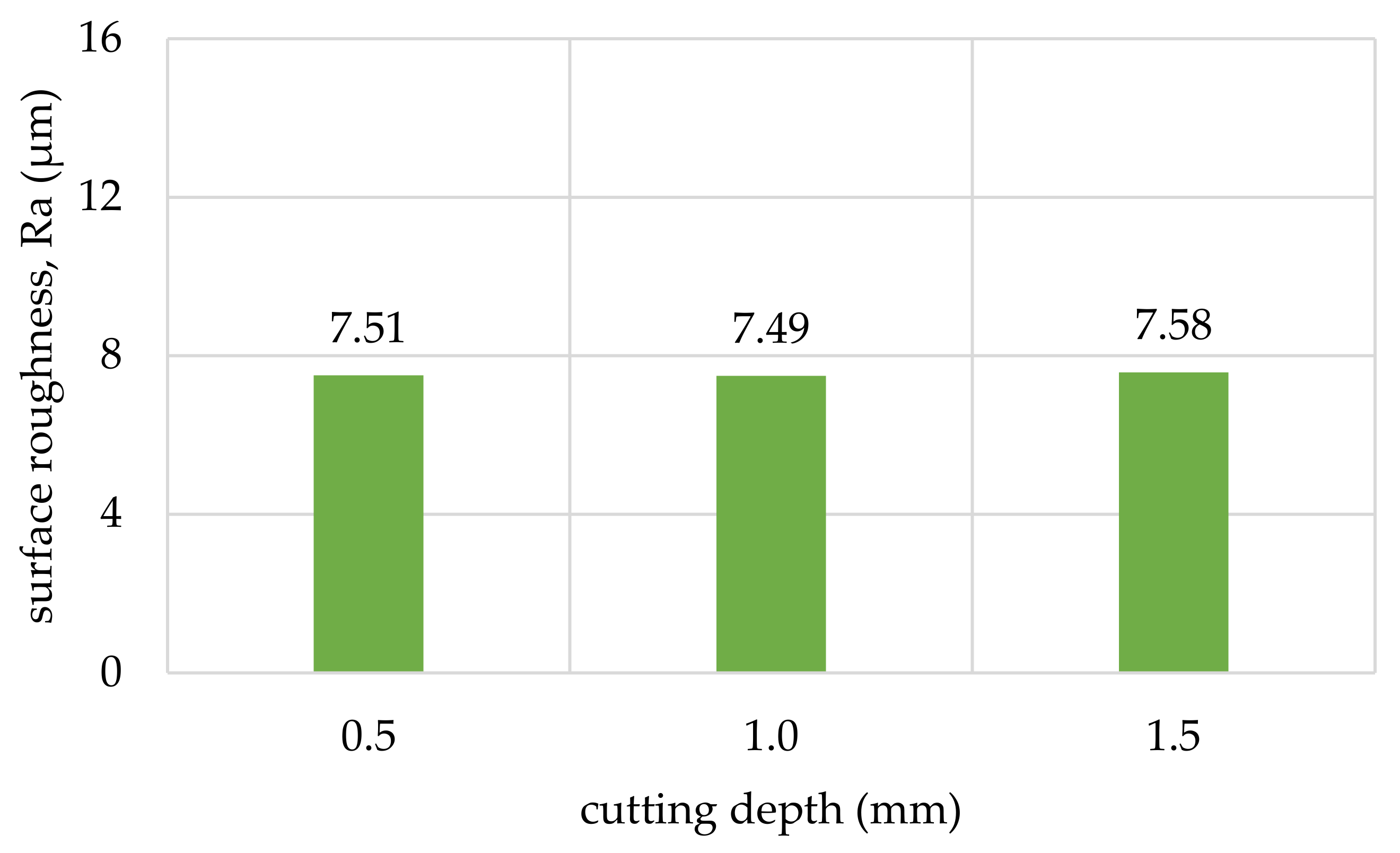

| Species of Wood | Turning Depth, mm | Type of Insert/Surface Roughness Ra, µm | |||

|---|---|---|---|---|---|

| 3ER (TH) | VBMT (PT) | RCMX (RD) | MGMN (GR) | ||

| West African Ebony Diospyros crassiflora (EB) | 0.5 | 12.90 (±0.33%) | 4.19 (±0.25%) | 2.91 (±0.33%) | 2.86 (±0.41%) |

| 1.0 | 13.03 (±0.39%) | 4.16 (±0.24%) | 2.65 (±0.17%) | 2.47 (±0.28%) | |

| 1.5 | 12.75 (±0.27%) | 5.17 (±0.39%) | 3.11 (±0.33%) | 3.04 (±0.22%) | |

| San Domingo Boxwood Phyllostylon brasiliense (BoW) | 0.5 | 12.94 (±0.44%) | 6.17 (±0.37%) | 4.96 (±0.38%) | 4.61 (±0.26%) |

| 1.0 | 12.50 (±0.31%) | 6.11 (±0.23%) | 5.62 (±0.27%) | 3.72 (±0.27%) | |

| 1.5 | 12.46 (±0.34%) | 6.19 (±0.39%) | 5.66 (±0.39%) | 4.36 (±0.22%) | |

| Rio Rosewood Dalbergia nigra (RW) | 0.5 | 12.08 (±0.32%) | 5.70 (±0.38%) | 3.11 (±0.42%) | 3.96 (±0.51%) |

| 1.0 | 12.15 (±0.40%) | 5.13 (±0.36%) | 3.48 (±0.50%) | 3.16 (±0.47%) | |

| 1.5 | 11.63 (±0.28%) | 5.02 (±0.37%) | 4.77 (±0.59%) | 3.86 (±0.86%) | |

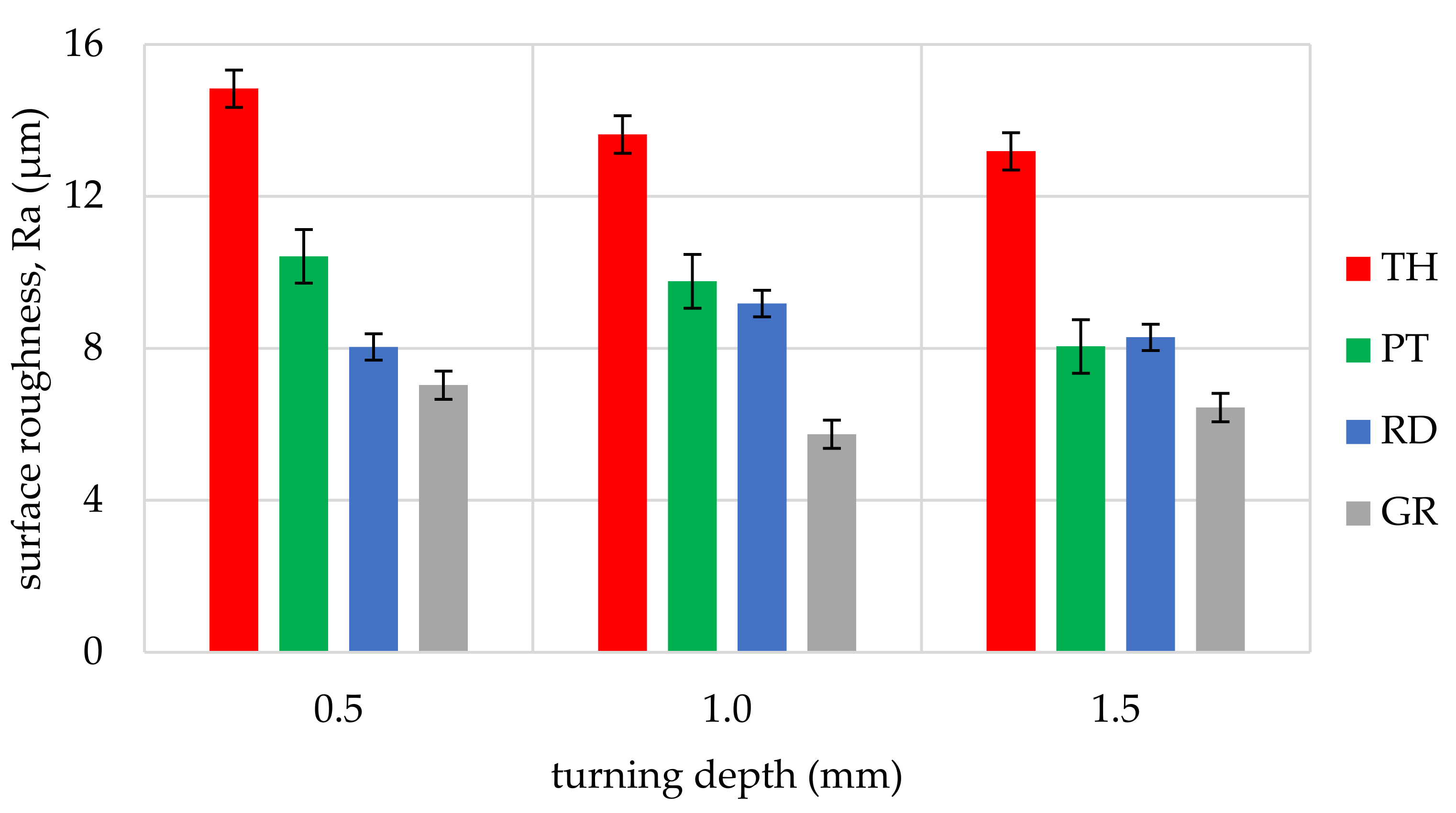

| Beechwood Fagus sylvatica (BeW) | 0.5 | 14.84 (±0.52%) | 10.42 (±0.92%) | 8.04 (±0.86%) | 7.03 (±0.64%) |

| 1.0 | 13.63 (±0.43%) | 9.77 (±0.99%) | 9.18 (±1.06%) | 5.74 (±0.66%) | |

| 1.5 | 13.19 (±0.43%) | 8.05 (±0.53%) | 8.29 (±0.93%) | 6.44 (±0.62%) | |

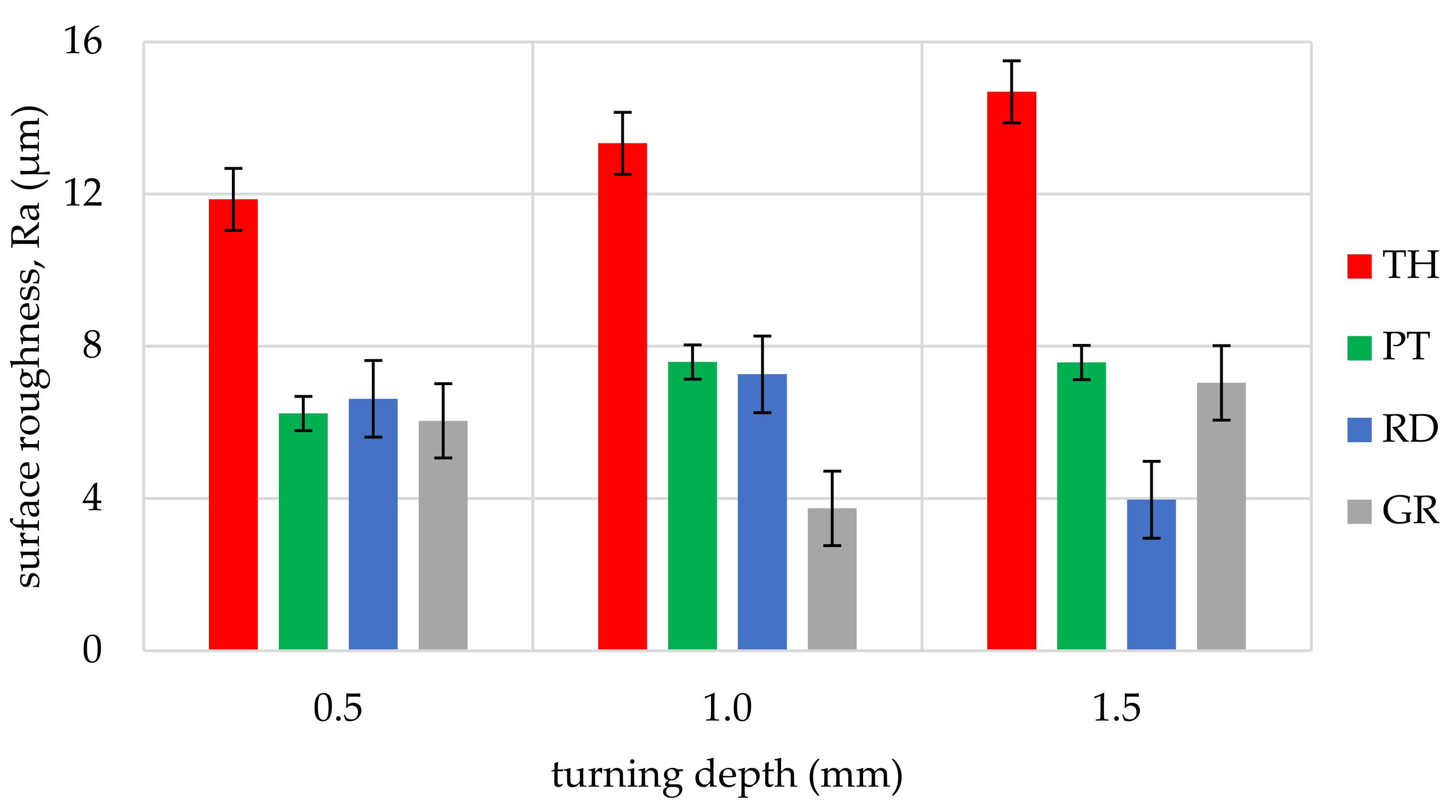

| Oakwood Quercus robur (OW) | 0.5 | 11.86 (±0.84%) | 6.23 (±0.60%) | 6.62 (±1.38%) | 6.04 (±1.38%) |

| 1.0 | 13.34 (±0.86%) | 7.59 (±0.91%) | 7.26 (±1.19%) | 3.74 (±0.55%) | |

| 1.5 | 14.68 (±0.89%) | 7.57 (±0.92%) | 3.97 (±0.43%) | 7.04 (±1.20%) | |

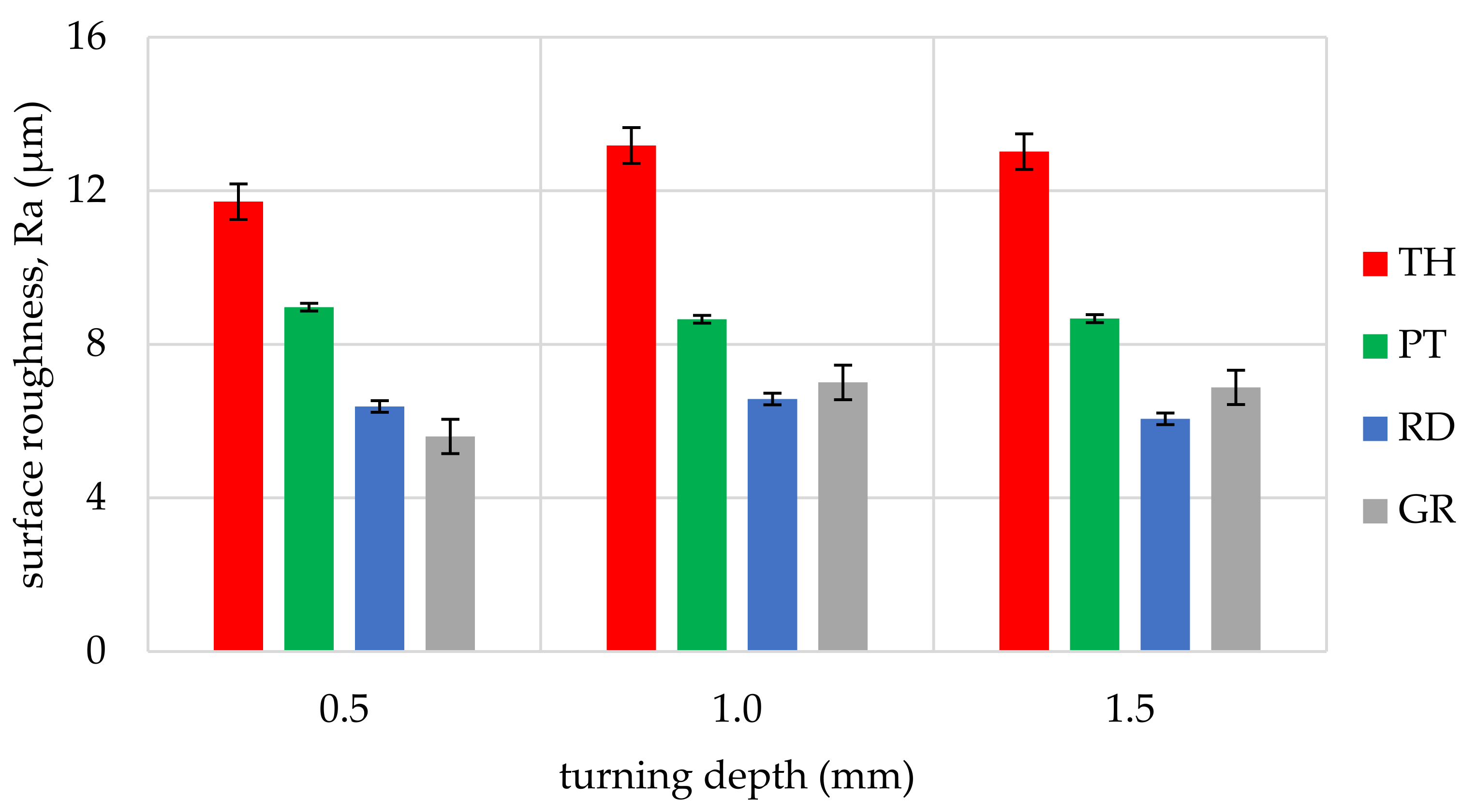

| Pinewood Pinus silvestris (PW) | 0.5 | 11.72 (±0.47%) | 8.97 (±0.96%) | 6.38 (±0.57%) | 5.60 (±0.66%) |

| 1.0 | 13.18 (±0.68%) | 8.66 (±1.06%) | 6.58 (±0.81%) | 7.01 (±0.82%) | |

| 1.5 | 13.02 (±0.73%) | 8.67 (±0.84%) | 6.06 (±0.85%) | 6.88 (±0.49%) | |

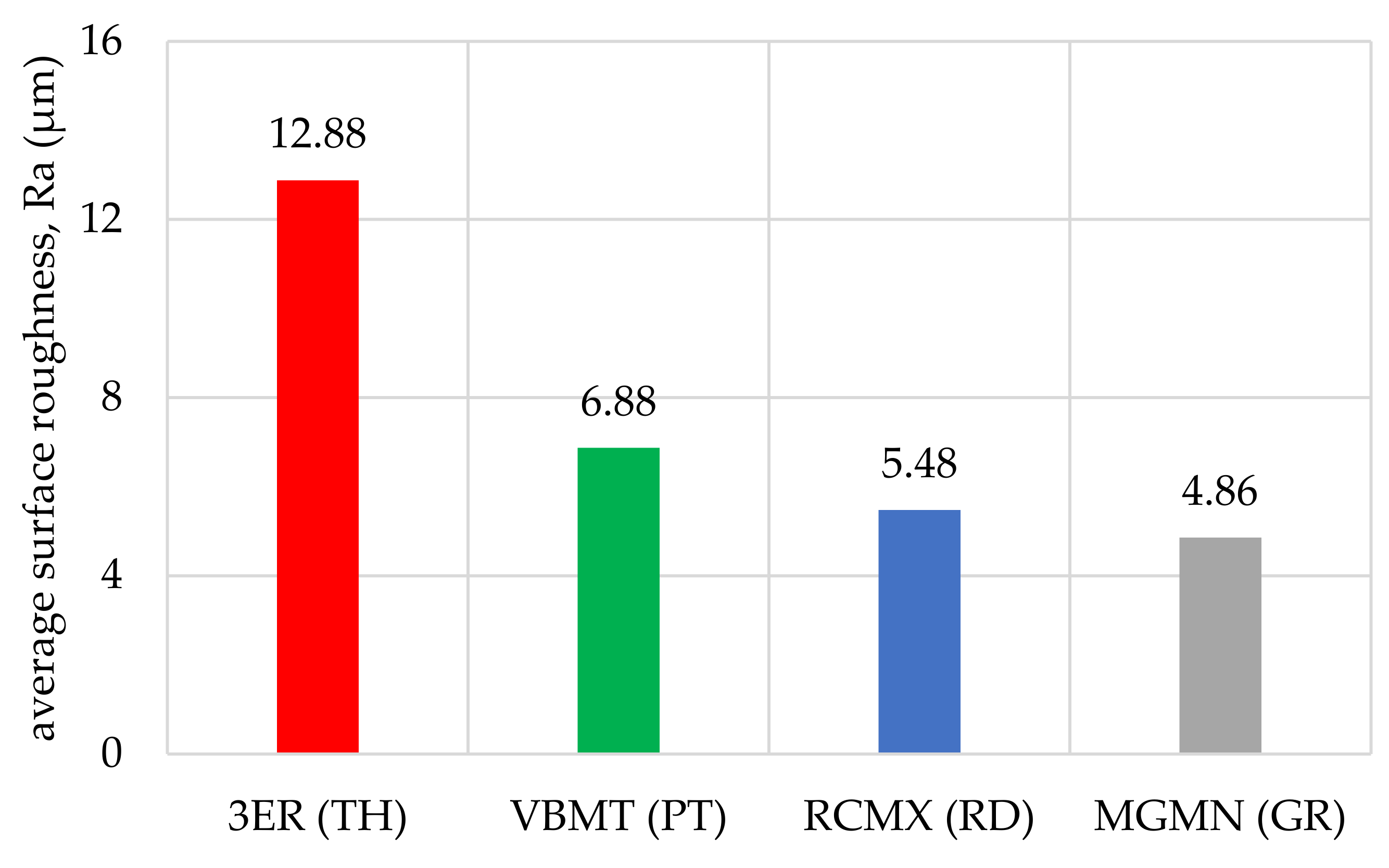

| All average | 0.5–1.5 | 12.88 | 6.88 | 5.48 | 4.86 |

| Species of Wood | Turning Depth, mm | Type of Insert/Surface Roughness Rz, µm | |||

|---|---|---|---|---|---|

| 3ER (TH) | VBMT (PT) | RCMX (RD) | MGMN (GR) | ||

| West African Ebony Diospyros crassiflora (EB) | 0.5 | 56.32 (±1.67%) | 23.54 (±1.41%) | 16.62 (±1.72%) | 16.38 (±2.26%) |

| 1.0 | 55.68 (±1.24%) | 23.80 (±1.22%) | 15.47 (±0.92%) | 14.29 (±1.43%) | |

| 1.5 | 54.74 (±1.07%) | 29.37 (±2.43%) | 17.03 (±1.58%) | 17.47 (±1.25%) | |

| San Domingo Boxwood Phyllostylon brasiliense (BoW) | 0.5 | 56.18 (±2.04%) | 33.52 (±1.63%) | 27.01 (±2.18%) | 25.90 (±1.51%) |

| 1.0 | 57.13 (±1.71%) | 32.64 (±1.21%) | 29.58 (±1.59%) | 20.79 (±1.27%) | |

| 1.5 | 55.52 (±1.94%) | 33.28 (±1.79%) | 31.77 (±2.34%) | 24.10 (±0.99%) | |

| Rio Rosewood Dalbergia nigra (RW) | 0.5 | 54.99 (±1.55%) | 30.56 (±1.81%) | 17.64 (±2.39%) | 21.05 (±2.31%) |

| 1.0 | 56.62 (±1.75%) | 28.91 (±1.79%) | 19.67 (±2.51%) | 18.40 (±2.56%) | |

| 1.5 | 51.91 (±1.26%) | 28.85 (±2.13%) | 26.05 (±3.22%) | 21.07 (±3.49%) | |

| Beechwood Fagus sylvatica (BeW) | 0.5 | 69.09 (±2.00%) | 54.48 (±5.39%) | 42.56 (±3.86%) | 37.53 (±2.88%) |

| 1.0 | 65.08 (±2.60%) | 52.79 (±4.62%) | 47.12 (±4.22%) | 31.10 (±3.34%) | |

| 1.5 | 62.75 (±2.57%) | 44.88 (±2.85%) | 41.39 (±4.11%) | 32.26 (±2.80%) | |

| Oakwood Quercus robur (OW) | 0.5 | 55.15 (±3.61%) | 34.00 (±2.81%) | 34.46 (±5.89%) | 33.13 (±7.03%) |

| 1.0 | 63.42 (±4.05%) | 39.15 (±3.66%) | 39.47 (±6.18%) | 20.88 (±2.76%) | |

| 1.5 | 70.09 (±4.72%) | 40.14 (±4.22%) | 21.92 (±2.22%) | 37.30 (±5.16%) | |

| Pinewood Pinus silvestris (PW) | 0.5 | 56.53 (±1.93%) | 45.90 (±4.86%) | 32.84 (±3.02%) | 27.98 (±2.99%) |

| 1.0 | 62.78 (±4.12%) | 43.95 (±4.59%) | 34.54 (±4.08%) | 35.57 (±3.55%) | |

| 1.5 | 65.39 (±4.33%) | 43.03 (±3.87%) | 31.77 (±4.32%) | 34.53 (±2.30%) | |

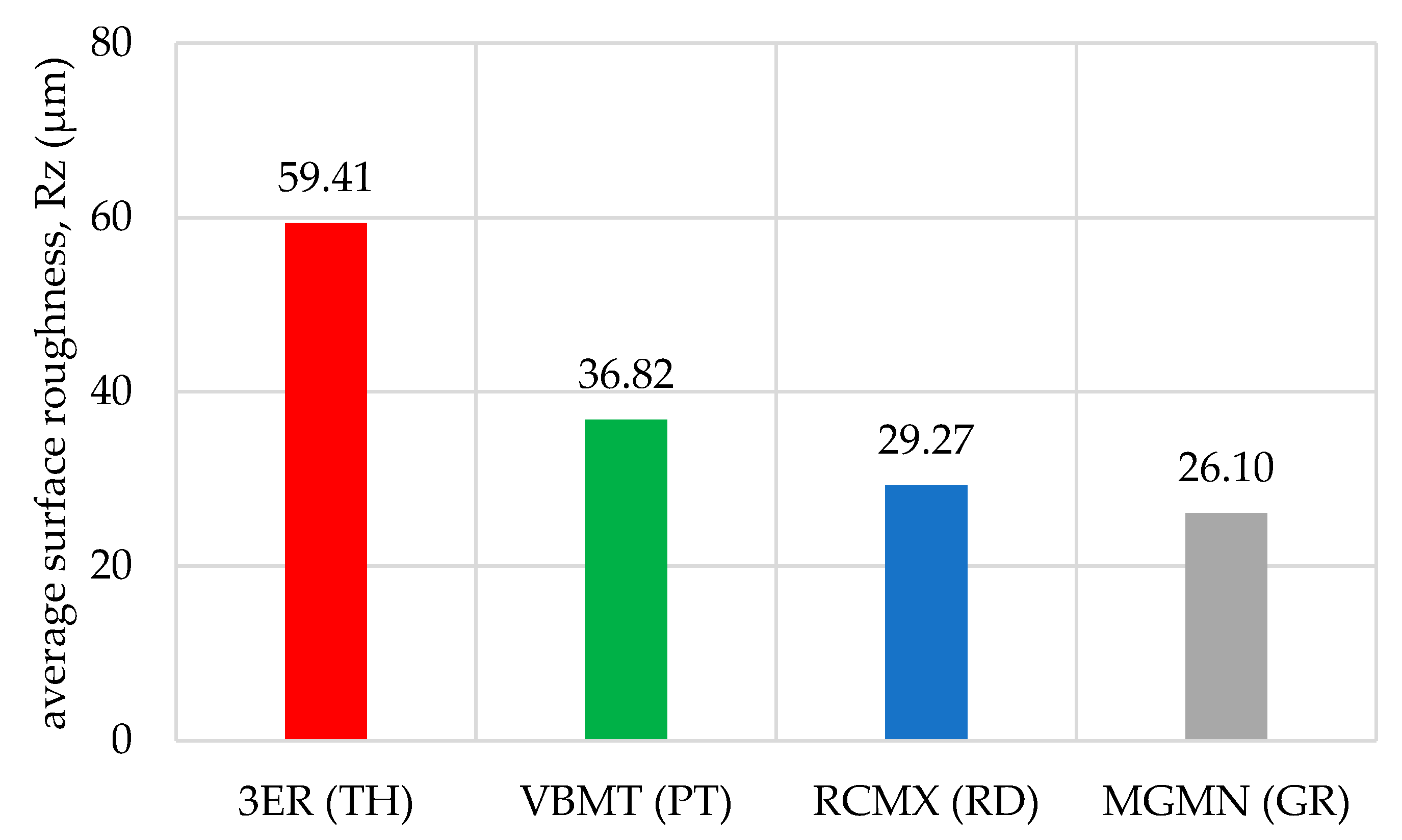

| All average | 0.5–1.5 | 59.41 | 36.82 | 29.27 | 26.10 |

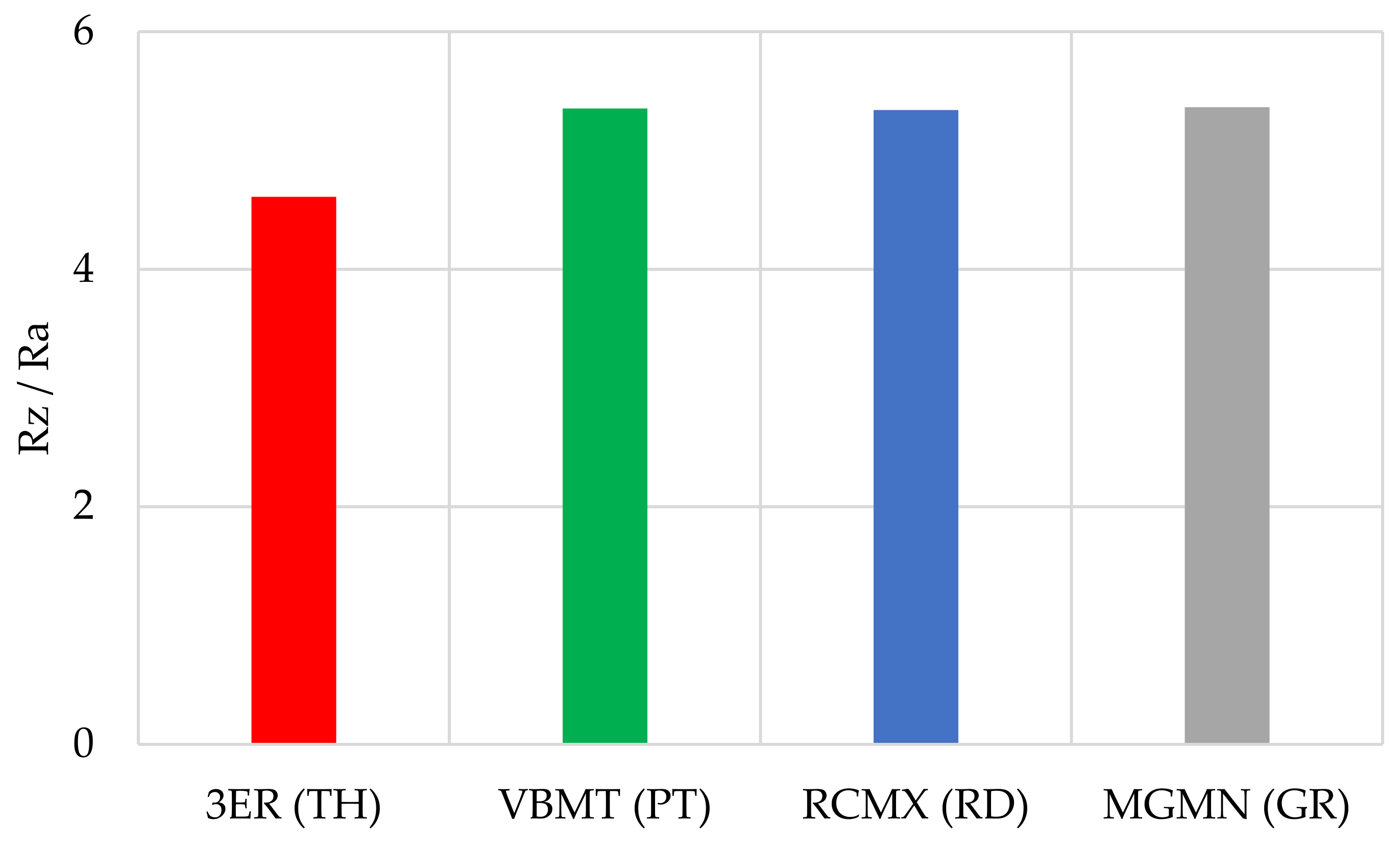

| Species of Wood | Turning Depth, mm | Type of Insert/Rz to Ra | |||

|---|---|---|---|---|---|

| 3ER (TH) | VBMT (PT) | RCMX (RD) | MGMN (GR) | ||

| West African Ebony Diospyros crassiflora (EB) | 0.5 | 4.37 | 5.62 | 5.71 | 5.73 |

| 1.0 | 4.27 | 5.72 | 5.84 | 5.79 | |

| 1.5 | 4.29 | 5.68 | 5.48 | 5.75 | |

| San Domingo Boxwood Phyllostylon brasiliense (BoW) | 0.5 | 4.34 | 5.43 | 5.45 | 5.62 |

| 1.0 | 4.57 | 5.34 | 5.26 | 5.59 | |

| 1.5 | 4.46 | 5.38 | 5.61 | 5.53 | |

| Rio Rosewood Dalbergia nigra (RW) | 0.5 | 4.55 | 5.36 | 5.67 | 5.32 |

| 1.0 | 4.66 | 5.64 | 5.65 | 5.82 | |

| 1.5 | 4.46 | 5.75 | 5.46 | 5.46 | |

| Beechwood Fagus sylvatica (BeW) | 0.5 | 4.66 | 5.23 | 5.29 | 5.34 |

| 1.0 | 4.77 | 5.40 | 5.13 | 5.42 | |

| 1.5 | 4.76 | 5.58 | 4.99 | 5.01 | |

| Oakwood Quercus robur (OW) | 0.5 | 4.65 | 5.46 | 5.21 | 5.49 |

| 1.0 | 4.75 | 5.16 | 5.44 | 5.58 | |

| 1.5 | 4.77 | 5.30 | 5.52 | 5.30 | |

| Pinewood Pinus silvestris (PW) | 0.5 | 4.82 | 5.12 | 5.15 | 5.00 |

| 1.0 | 4.76 | 5.08 | 5.25 | 5.07 | |

| 1.5 | 5.02 | 4.96 | 5.24 | 5.02 | |

| All average | 0.5–1.5 | 4.61 | 5.35 | 5.34 | 5.37 |

| Coefficients Value | Standard Error | t-Statistic | p-Value | Upper 95% | Lower 95% | |

|---|---|---|---|---|---|---|

| Constant | 11.41135 | 0.783334 | 14.56766 | 9.74 × 10−23 | 9.848638 | 12.97406 |

| insert corner radius (ICR) | −0.25046 | 0.040501 | −6.18413 | 3.86 × 10−8 | −0.33126 | −0.16967 |

| Janka hardness (JH) | −0.00028 | 8.24 × 10−5 | −3.3778 | 0.001204 | −0.00044 | −0.00011 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bembenek, M.; Kudelski, R.; Pawlik, J.; Kowalski, Ł. The Influence of CNC Turning with VBMT, RCMX, 3ER, and MGMN Type Indexable Inserts on West African Ebony/Diospyros crassiflora, San Domingo Boxwood/Phyllostylon brasiliense, Rio Rosewood/Dalbergia nigra, Beechwood/Fagus sylvatica, Oakwood/Quercus robur, and Pinewood/Pinus silvestris Surface Roughness. Materials 2021, 14, 5625. https://doi.org/10.3390/ma14195625

Bembenek M, Kudelski R, Pawlik J, Kowalski Ł. The Influence of CNC Turning with VBMT, RCMX, 3ER, and MGMN Type Indexable Inserts on West African Ebony/Diospyros crassiflora, San Domingo Boxwood/Phyllostylon brasiliense, Rio Rosewood/Dalbergia nigra, Beechwood/Fagus sylvatica, Oakwood/Quercus robur, and Pinewood/Pinus silvestris Surface Roughness. Materials. 2021; 14(19):5625. https://doi.org/10.3390/ma14195625

Chicago/Turabian StyleBembenek, Michał, Rafał Kudelski, Jan Pawlik, and Łukasz Kowalski. 2021. "The Influence of CNC Turning with VBMT, RCMX, 3ER, and MGMN Type Indexable Inserts on West African Ebony/Diospyros crassiflora, San Domingo Boxwood/Phyllostylon brasiliense, Rio Rosewood/Dalbergia nigra, Beechwood/Fagus sylvatica, Oakwood/Quercus robur, and Pinewood/Pinus silvestris Surface Roughness" Materials 14, no. 19: 5625. https://doi.org/10.3390/ma14195625

APA StyleBembenek, M., Kudelski, R., Pawlik, J., & Kowalski, Ł. (2021). The Influence of CNC Turning with VBMT, RCMX, 3ER, and MGMN Type Indexable Inserts on West African Ebony/Diospyros crassiflora, San Domingo Boxwood/Phyllostylon brasiliense, Rio Rosewood/Dalbergia nigra, Beechwood/Fagus sylvatica, Oakwood/Quercus robur, and Pinewood/Pinus silvestris Surface Roughness. Materials, 14(19), 5625. https://doi.org/10.3390/ma14195625