Regulation of Hole Concentration and Mobility and First-Principle Analysis of Mg-Doping in InGaN Grown by MOCVD

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

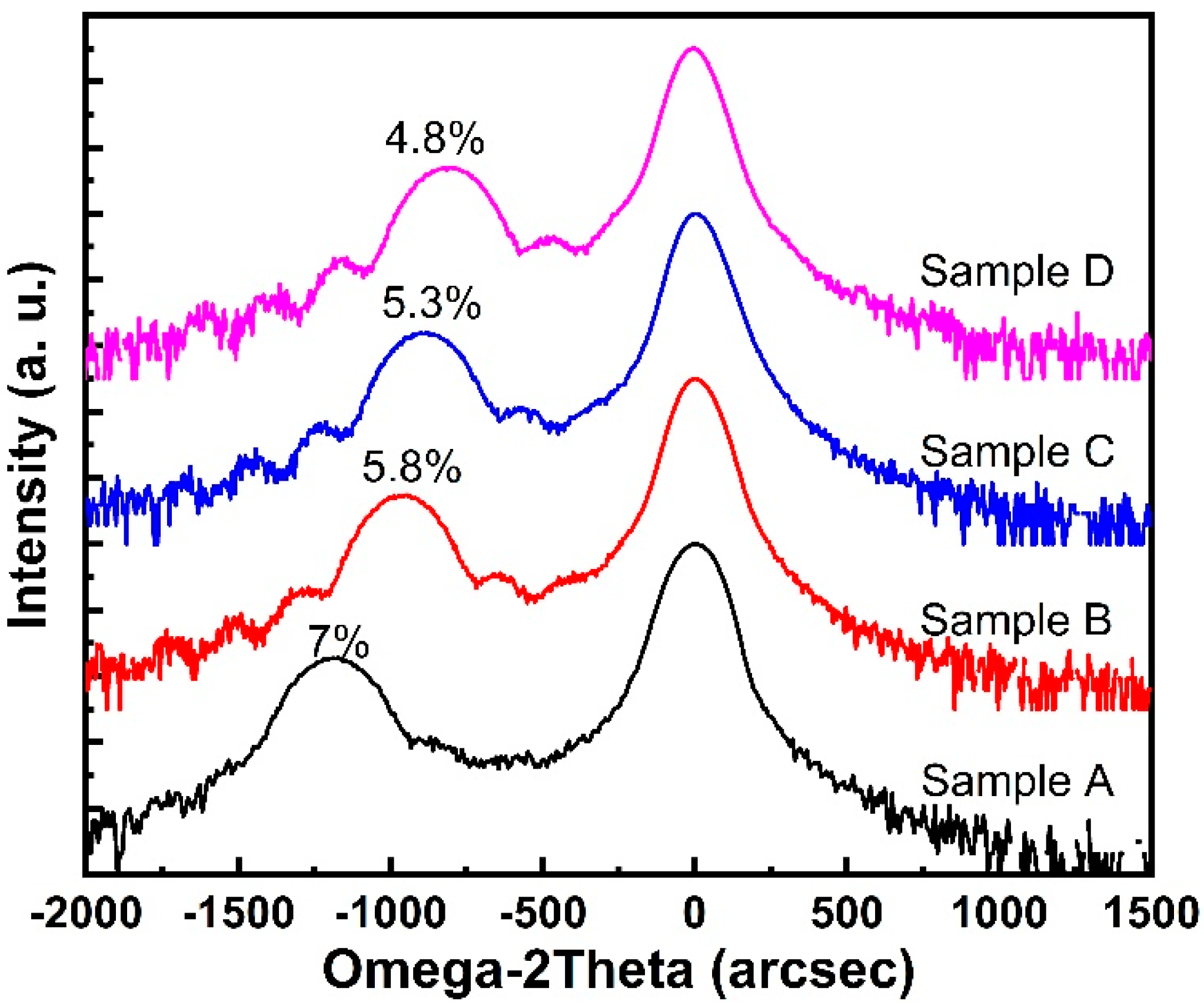

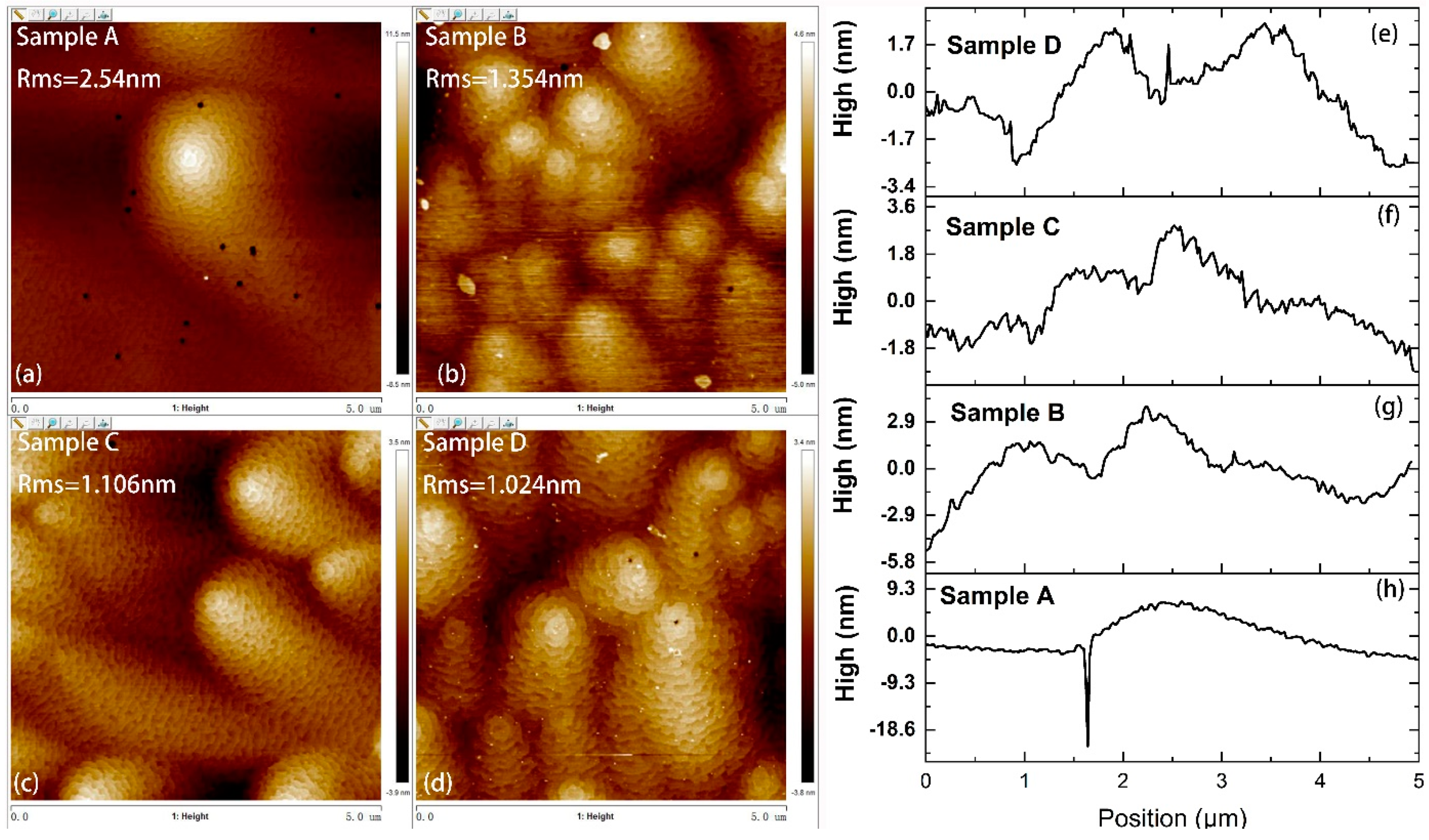

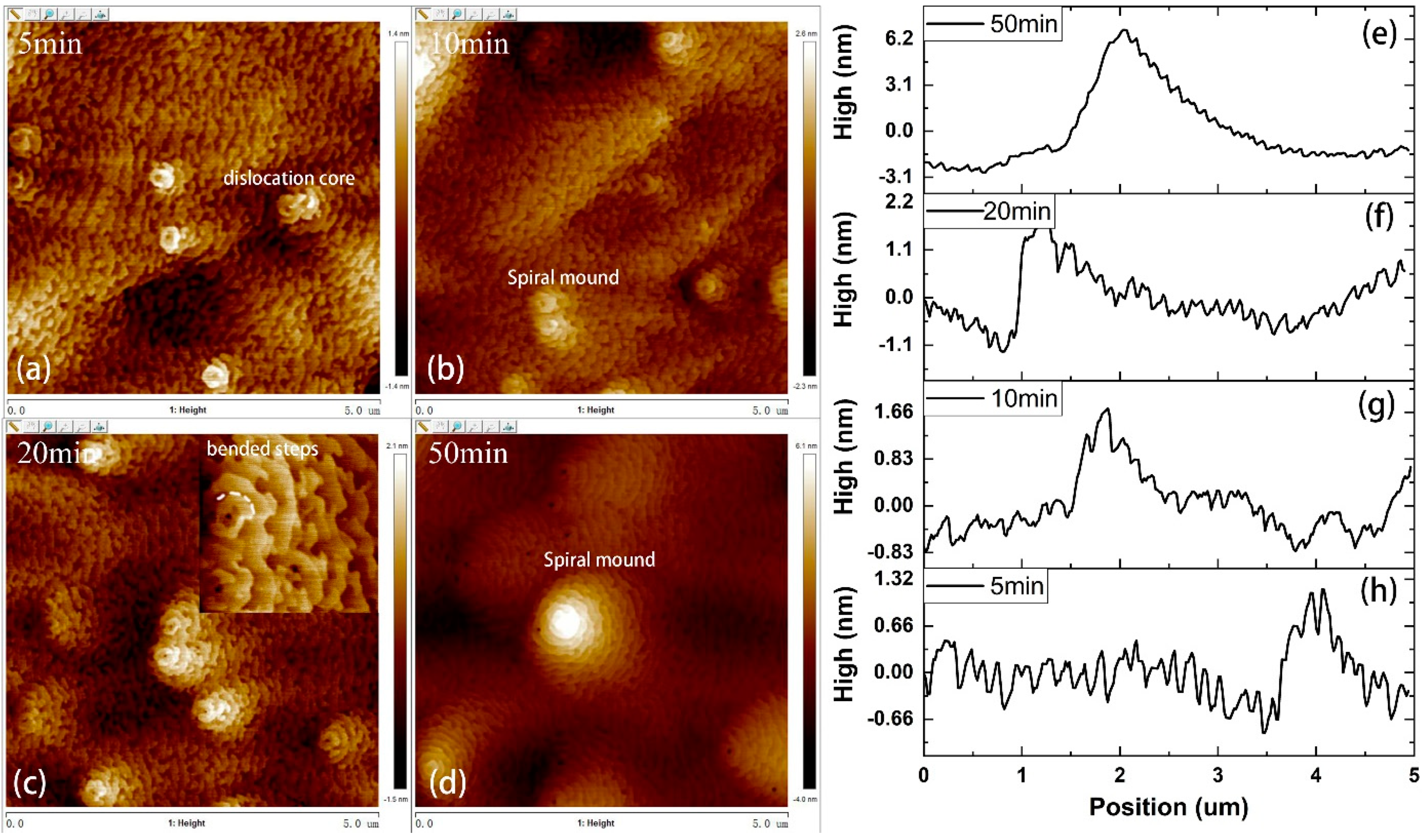

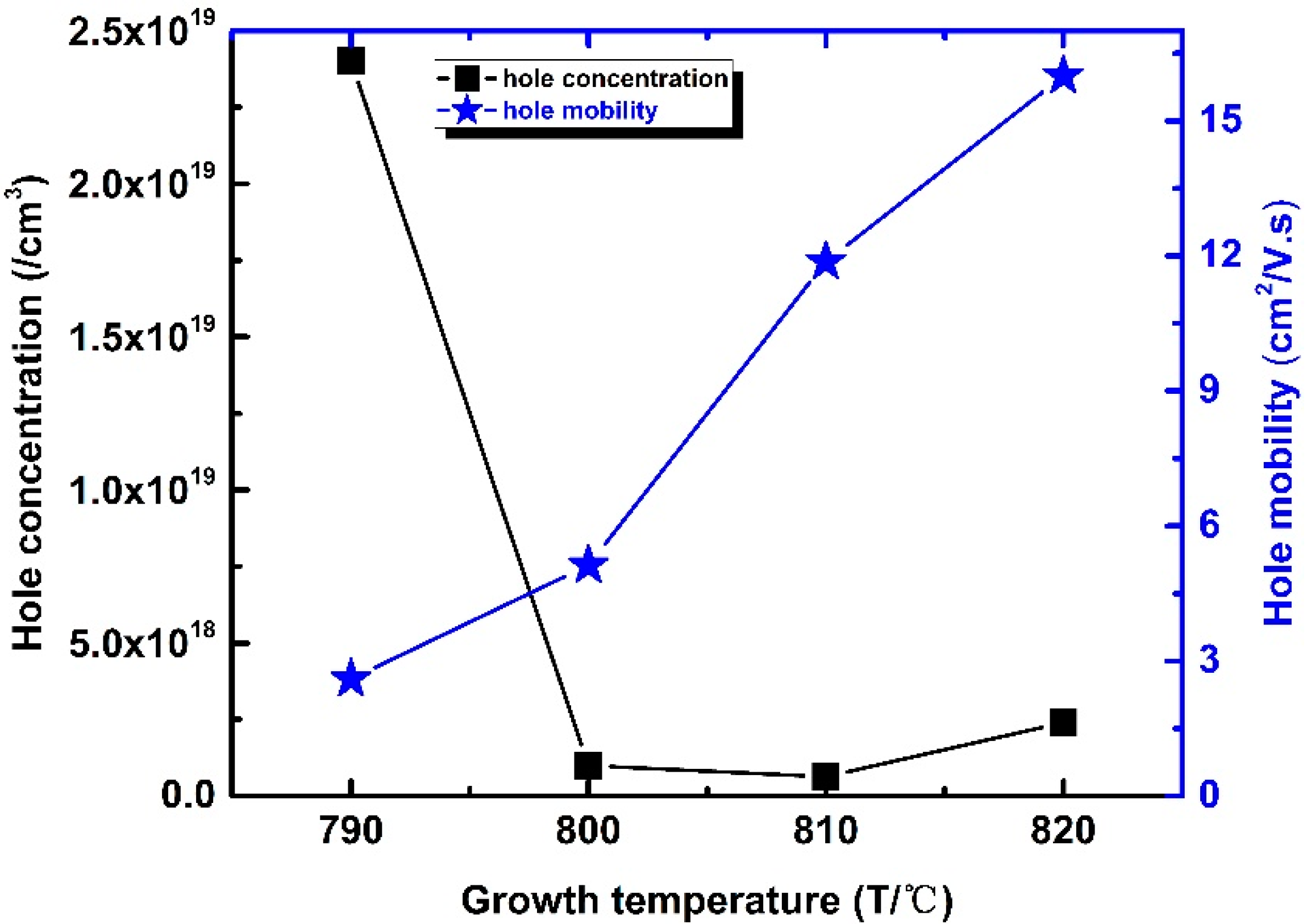

3.1. p-Type InGaN Growth

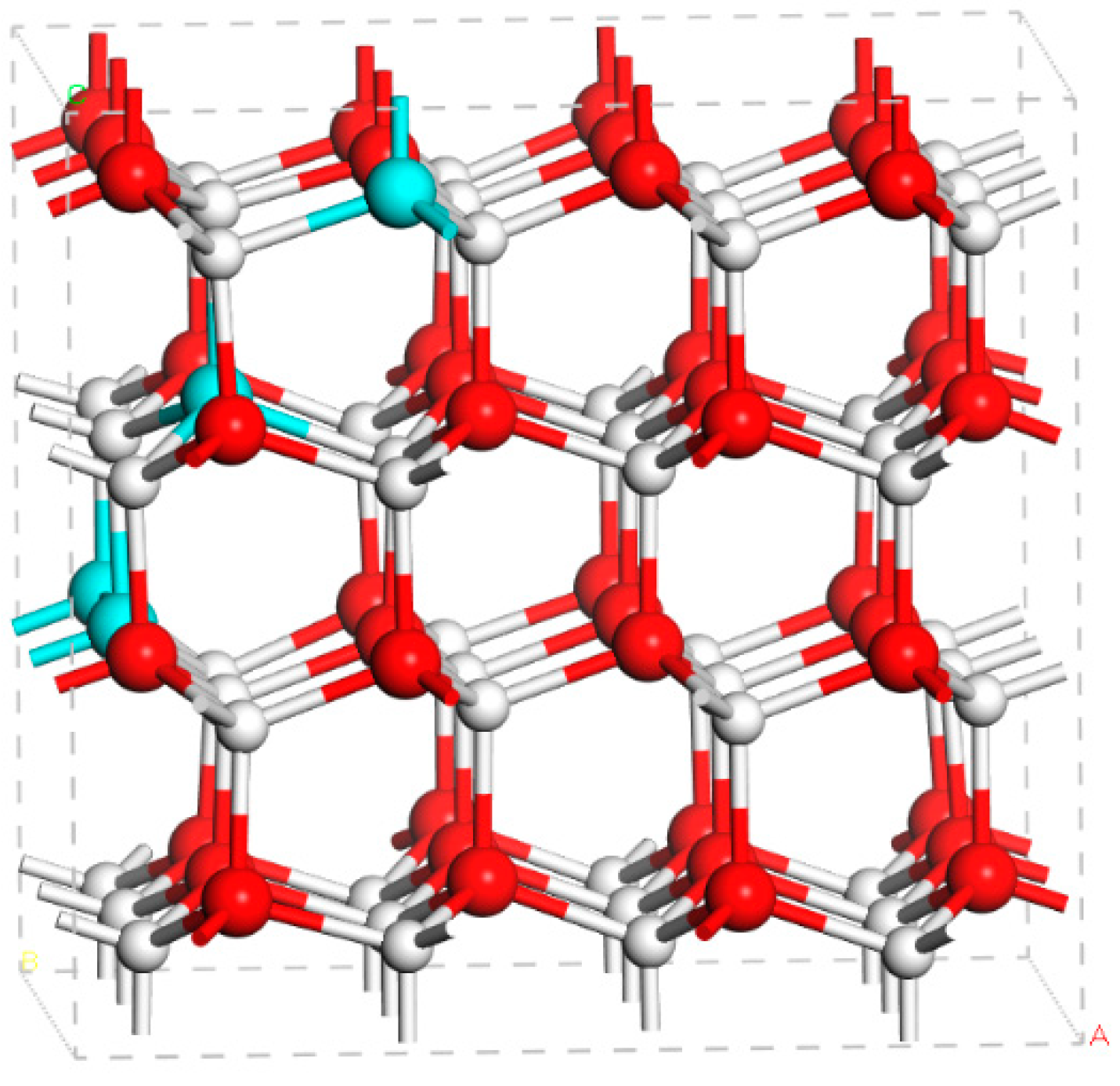

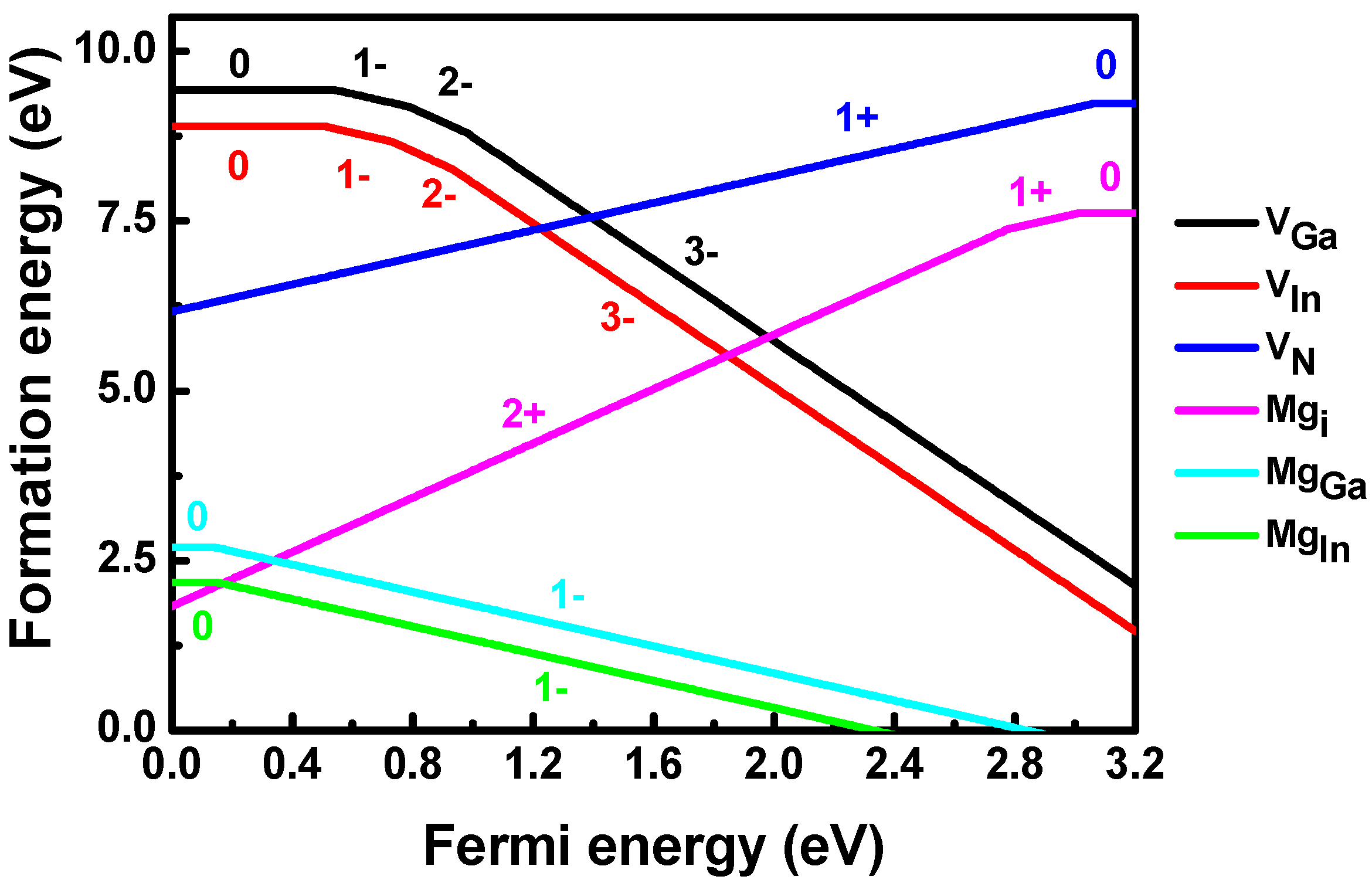

3.2. First-Principles Defect Calculations of p-Type InGaN

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- El-Mostafa, B.; Jeong, I.H. Electrical characterization and thermal admittance spectroscopy analysis of InGaN/GaN MQW blue LED structure. Electron. Mater. Lett. 2015, 11, 982–992. [Google Scholar]

- Lee, H.E.; Choi, J.H.; Lee, S.H.; Jeong, M.; Shin, J.H.; Joe, D.J.; Kim, D.; Kim, C.W.; Park, J.H.; Lee, J.H.; et al. Monolithic flexible vertical gan light-emitting diodes for a transparent wireless brain optical stimulator. Adv. Mater. 2018, 30, 1800649. [Google Scholar] [CrossRef]

- Lin, R.; Liu, X.; Zhou, G.; Qian, Z.; Cui, X.; Tian, P. InGaN Micro-LED Array Enabled Advanced Underwater Wireless Optical Communication and Underwater Charging. Adv. Opt. Mater. 2021, 9, 2002211. [Google Scholar] [CrossRef]

- Balakrishnam, R.J.; Andrew, G.M.; Muhammad, J.; Nikolai, N.F.; Robert, L.O.; Ian, T.F.; Christiana, B.H. Design and Realization of Wide-Band-Gap (∼2.67 eV) InGaN p-n Junction Solar Cell. IEEE Electron Device Lett. 2010, 31, 32–34. [Google Scholar]

- Omkar, J.; Ian, F.; Christiana, H.; Sarah, K. Design and characterization of GaN/InGaN solar cells. Appl. Phys. Lett. 2007, 91, 132117. [Google Scholar]

- Muzio, G.; Turski, H.; Siekacz, M.; Sawicka, M.; Skierbiszewski, C. Waveguide design for long wavelength ingan based laser diodes. Acta Phys. Pol. Ser. A 2012, 122, 1031–1033. [Google Scholar] [CrossRef]

- Mu-Tao, C.; Wen-Yih, L.; Ray-Hua, H.; Tsung-Yen, T.; Tsai-Bau, W.; Shu-Ping, L.; Ming-Hsien, W.; Ray-Ming, L. Growth and Characterization of p-InGaN/i-InGaN/n-GaN Double-Heterojunction Solar Cells on Patterned Sapphire Substrates. IEEE Electron Device Lett. 2011, 32, 922–924. [Google Scholar]

- Shen, S.C.; Dupuis, R.D.; Lochner, Z.; Lee, Y.C.; Kao, T.T.; Zhang, Y.; Kim, H.J.; Ryou, J.H. Working toward high-power GaN/InGaN heterojunction bipolar transistors. Semicond. Sci. Technol. 2013, 28, 074025. [Google Scholar] [CrossRef]

- Wang, X.; Che, S.B.; Ishitani, Y.; Yoshikawa, A. Systematic study on p-type doping control of InN with different Mg concentrations in both In and N polarities. Appl. Phys. Lett. 2007, 91, 242111. [Google Scholar] [CrossRef]

- Deng, Q.; Wang, X.; Xiao, H.; Wang, C.; Yin, H.; Chen, H.; Lin, D.; Jiang, L.; Feng, C.; Li, J.; et al. Comparison of as-grown and annealed GaN/InGaN:Mg samples. J. Phys. D-Appl. Phys. 2011, 44, 345101. [Google Scholar] [CrossRef]

- Chen, P.; Chen, C.H.; Chang, S.J.; Su, Y.K.; Chang, P.C.; Huang, B.R. High hole concentration of p-type InGaN epitaxial layers grown by MOCVD. Thin Solid Film. 2006, 498, 113–117. [Google Scholar] [CrossRef]

- Kuo, D.H.; Tuan, T.; Li, C.C.; Yen, W.C. Electrical and structural properties of Mg-doped InxGa1−xN (x ≤ 0.1) and p-InGaN/n-GaN junction diode made all by RF reactive sputtering. Mater. Sci. Eng. B 2015, 193, 13–19. [Google Scholar] [CrossRef]

- Chen, X.; Matthews, K.D.; Hao, D.; SchaFf, W.J.; Eastman, L.F.; Walukiewicz, W.; Ager, J.W.; Yu, K.M. Characterization of mg-doped ingan and inaln alloys grown by mbe for solar applications. In Proceedings of the 33rd IEEE Photovoltaic Specialists Conference, San Diego, CA, USA, 11–16 May 2008; p. 122. [Google Scholar]

- Pereiro, J.; Redondo-Cubero, A.; Fernandez-Garrido, S.; Rivera, C.; Navarro, A.; Muñoz, E.; Calleja, E.; Gago, R. Mg doping of InGaN layers grown by PA-MBE for the fabrication of Schottky barrier photodiodes. J. Phys. D-Appl. Phys. 2010, 43, 335101. [Google Scholar] [CrossRef]

- Pantha, B.N.; Sedhain, A.; Li, J.; Lin, J.Y.; Jiang, H.X. Electrical and optical properties of p-type InGaN. Appl. Phys. Lett. 2009, 95, 261904. [Google Scholar] [CrossRef] [Green Version]

- Van DenBroeck, D.M.; Bharrat, D.; Liu, Z.; Elmasry, N.A.; Bedair, S.M. Growth and Characterization of High-Quality, Relaxed InyGa1-yN Templates for Optoelectronic Applications. J. Electron. Mater. 2015, 44, 4161–4166. [Google Scholar] [CrossRef]

- Chichibu, S.F.; Uedono, A.; Onuma, T. Origin of defect-insensitive emission probability in In-containing (Al,In,Ga)N alloy semiconductors. Nat. Mater. 2006, 5, 810. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.N.; Sakong, T.; Lee, W.; Paek, H.; Son, J.; Yoon, E.; Nam, O.; Park, Y. Characterization of optical and electrical quality of Mg-doped I xGa1−xN grown by MOCVD. J. Cryst. Growth 2004, 261, 249–252. [Google Scholar] [CrossRef]

- Walle, V.D.; Chris, G. First-principles calculations for defects and impurities: Applications to III-nitrides. J. Appl. Phys. 2004, 96, 3851–3879. [Google Scholar] [CrossRef]

- Namkoong, G.; Trybus, E.; Lee, K.K.; Moseley, M.; Doolittie, W.A.; Look, D.C. Metal modulation epitaxy growth for extremely high hole concentrations above 1019 cm−3 in GaN. Appl. Phys. Lett. 2008, 93, 172112. [Google Scholar] [CrossRef] [Green Version]

- Ho, I.H.; Stringfellow, G.B. Solid phase immiscibility in gain. Appl. Phys. Lett. 1996, 69, 2701. [Google Scholar] [CrossRef]

- Oliver, R.A.; Kappers, M.J.; Humphreys, C.J.; Briggs, G. Growth modes in heteroepitaxy of InGaN on GaN. J. Appl. Phys. 2005, 97, 013707. [Google Scholar] [CrossRef]

- Cui, Y.; Li, L. Evolution of spirals during molecular beam epitaxy of GaN on 6H-SiC (0001). Phys. Rev. B. 2002, 66, 155330. [Google Scholar] [CrossRef]

- Sanchez, A.M.; Gass, M.; Papworth, A.J.; Goodhew, P.J.; Singh, P.; Ruterana, P.; Cho, H.K.; Choi, R.J.; Lee, H.J. V-defects and dislocations in InGaN/GaN heterostructures. Thin Solid Film. 2005, 479, 316–320. [Google Scholar] [CrossRef]

- Miraglia, P.Q.; Preble, E.A.; Roskowski, A.M.; Einfeldt, S.; Lim, S.H.; Weber, Z.L.; Davis, R.F. Helical-type surface defects in ingan thin films epitaxially grown on gan templates at reduced temperatures. Thin Solid Film. 2003, 437, 140–149. [Google Scholar] [CrossRef]

- Mnatsakanov, T.T.; Levinshtein, M.E.; Pomortseva, L.I.; Yurkov, S.N.; Khan, M.A. Carrier mobility model for GaN. Solid-State Electron. 2003, 47, 111–115. [Google Scholar] [CrossRef]

- Zunger, A.; Ferreira, L.G.; Bernard, J.E. Special quasirandom structures. Phys. Rev. Lett. 1990, 65, 353–356. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wei, S.H.; Ferreira, L.G.; Bernar, J.E.; Zunger, A. Electronic properties of random alloys: Special quasirandom structures. Phys. Rev. B 1990, 42, 9622–9649. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Blöchl, P.E. Projector augmented-wave method. Phys. Rev. B 1994, 50, 17953–17979. [Google Scholar] [CrossRef] [Green Version]

- Kresse, G.G.; Furthmüller, J.J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 1996, 54, 11169–11186. [Google Scholar] [CrossRef]

- Heyd, J.; Scuseria, G.E.; Ernzerhof, M. Hybrid functionals based on a screened coulomb potential. J. Chem. Phys. 2006, 124, 8207–8215. [Google Scholar] [CrossRef] [Green Version]

- Monkhorst, H.J.; Pack, J.D. Special points for Brillouin-zone integrations. Phys. Rev. B 1976, 13, 5188–5192. [Google Scholar] [CrossRef]

- Wei, S.H. Overcoming the doping bottleneck in semiconductors. Comput. Mater. Sci. 2004, 30, 337–348. [Google Scholar] [CrossRef]

- Yang, J.H.; Yin, W.J.; Park, J.S.; Ma, J.; Wei, S.H. Review on first-principles study of defect properties of CdTe as a solar cell absorber. Semicond. Sci. Technol. 2016, 31, 083002. [Google Scholar] [CrossRef]

- Cai, X.; Yang, J.; Zhang, P.; Wei, S.H. Origin of Deep Be Acceptor Levels in Nitride Semiconductors: The Roles of Chemical and Strain Effects. Phys. Rev. Appl. 2019, 11, 034019. [Google Scholar] [CrossRef]

- Lyons, J.L.; Janotti, A.; Walle, C. Shallow versus deep nature of Mg acceptors in nitride semiconductors. Phys. Rev. Lett. 2012, 108, 156403. [Google Scholar] [CrossRef] [Green Version]

- Wei, S.H.; Zunger, A. Valence band splittings and band offsets of AlN, GaN, and InN. Appl. Phys. Lett. 1996, 69, 2719–2721. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Wang, R.; Liu, Z.; Cheng, Z.; Tong, X.; Xu, J.; Zhang, S.; Zhang, Y.; Chen, F. Regulation of Hole Concentration and Mobility and First-Principle Analysis of Mg-Doping in InGaN Grown by MOCVD. Materials 2021, 14, 5339. https://doi.org/10.3390/ma14185339

Zhang L, Wang R, Liu Z, Cheng Z, Tong X, Xu J, Zhang S, Zhang Y, Chen F. Regulation of Hole Concentration and Mobility and First-Principle Analysis of Mg-Doping in InGaN Grown by MOCVD. Materials. 2021; 14(18):5339. https://doi.org/10.3390/ma14185339

Chicago/Turabian StyleZhang, Lian, Rong Wang, Zhe Liu, Zhe Cheng, Xiaodong Tong, Jianxing Xu, Shiyong Zhang, Yun Zhang, and Fengxiang Chen. 2021. "Regulation of Hole Concentration and Mobility and First-Principle Analysis of Mg-Doping in InGaN Grown by MOCVD" Materials 14, no. 18: 5339. https://doi.org/10.3390/ma14185339

APA StyleZhang, L., Wang, R., Liu, Z., Cheng, Z., Tong, X., Xu, J., Zhang, S., Zhang, Y., & Chen, F. (2021). Regulation of Hole Concentration and Mobility and First-Principle Analysis of Mg-Doping in InGaN Grown by MOCVD. Materials, 14(18), 5339. https://doi.org/10.3390/ma14185339