Study of ZnO-CNT Nanocomposites in High-Pressure Conditions

Abstract

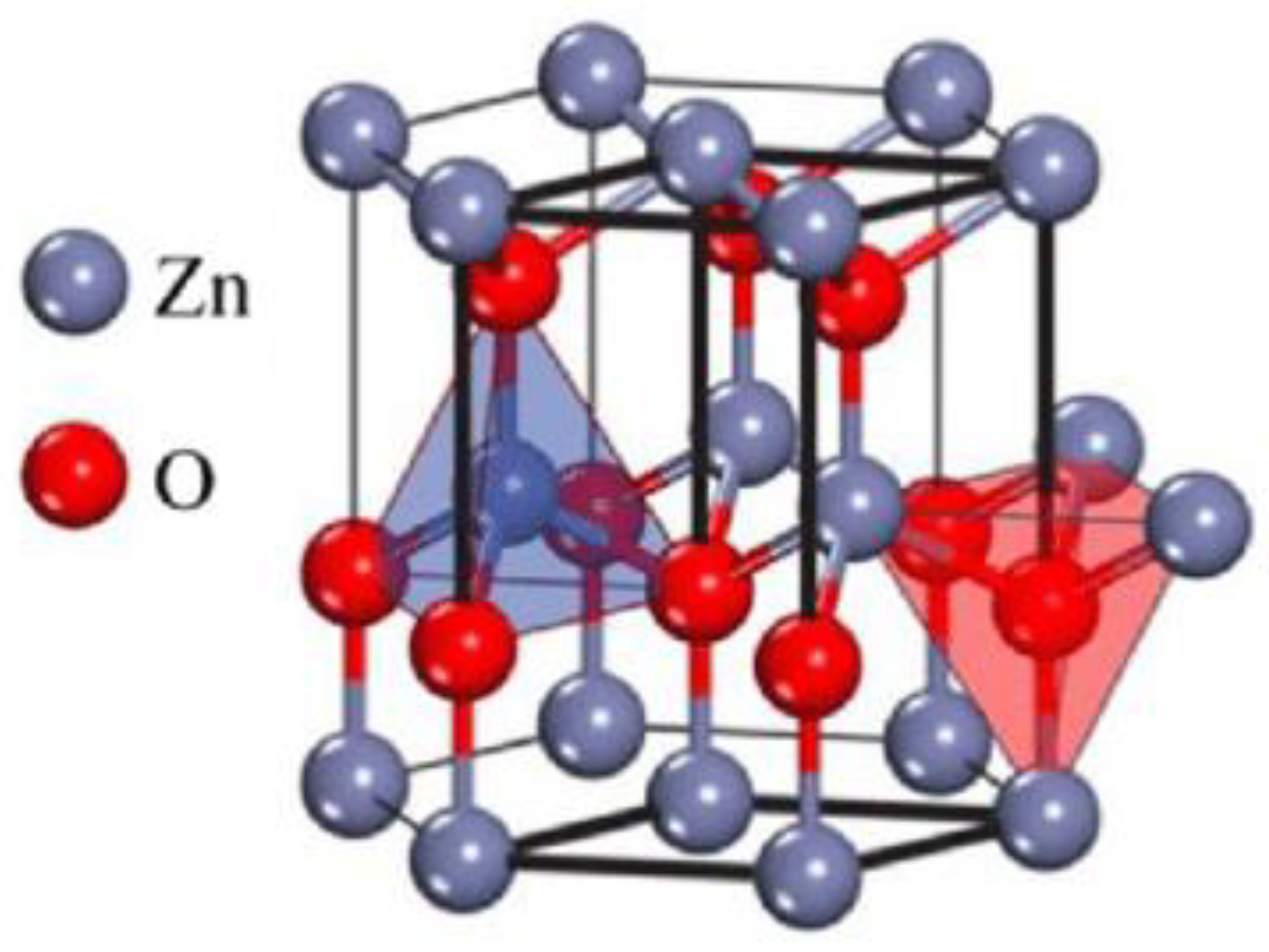

:1. Introduction

2. Materials and Methods

2.1. Functionalization of Multi-Walled Carbon Nanotubes (MWCNT)

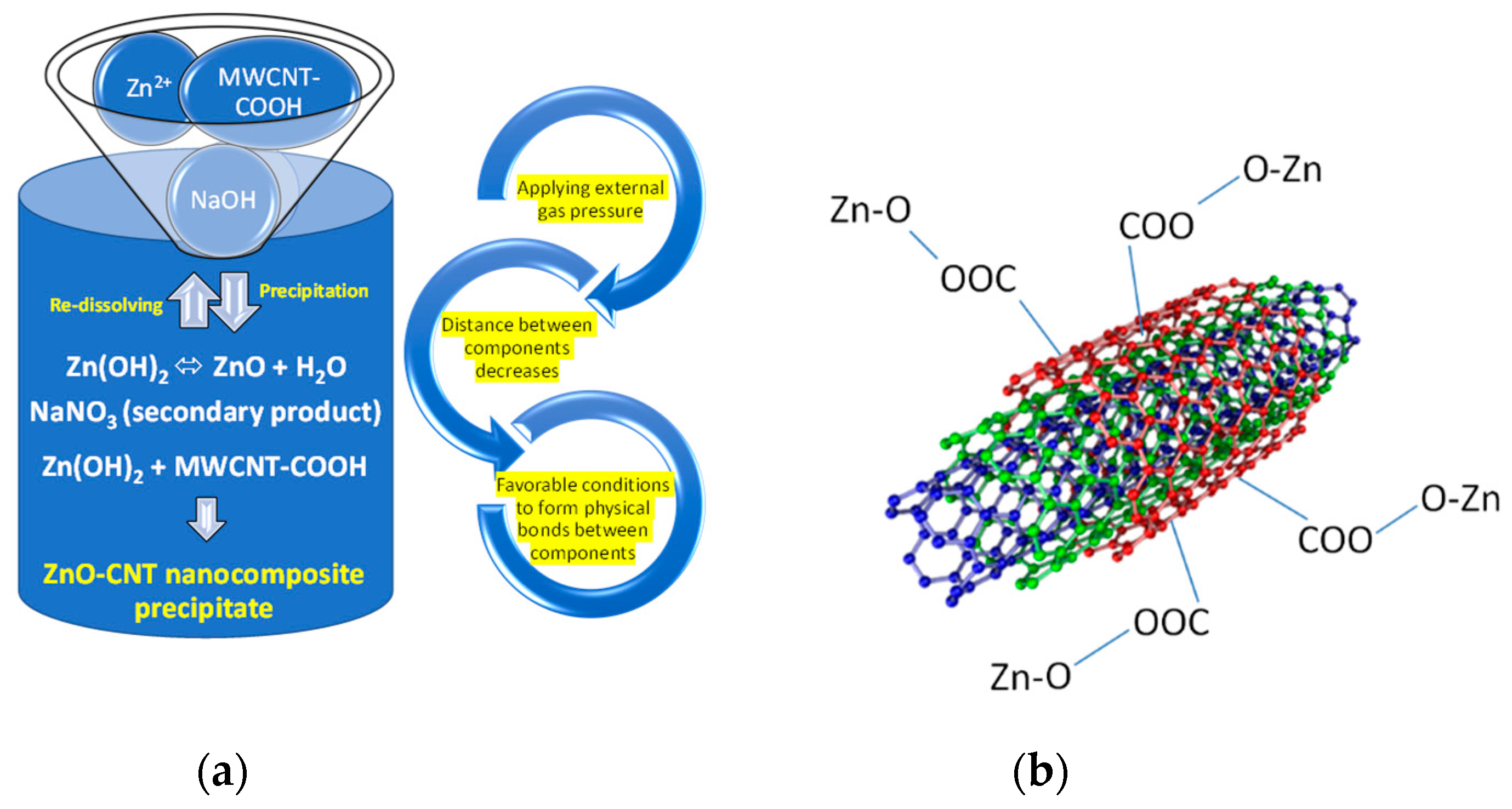

2.2. Hydrothermal Synthesis of ZnO-CNT Nanocomposites

2.3. Spectral, Thermal and Morpho-Structural Characterization of the Prepared Samples

2.4. Extrusion-Based 3D Printing of ZnO-CNT Nanocomposite Powders

3. Results and Discussion

3.1. Hydrothermal Synthesis of ZnO-CNT Nanocomposites

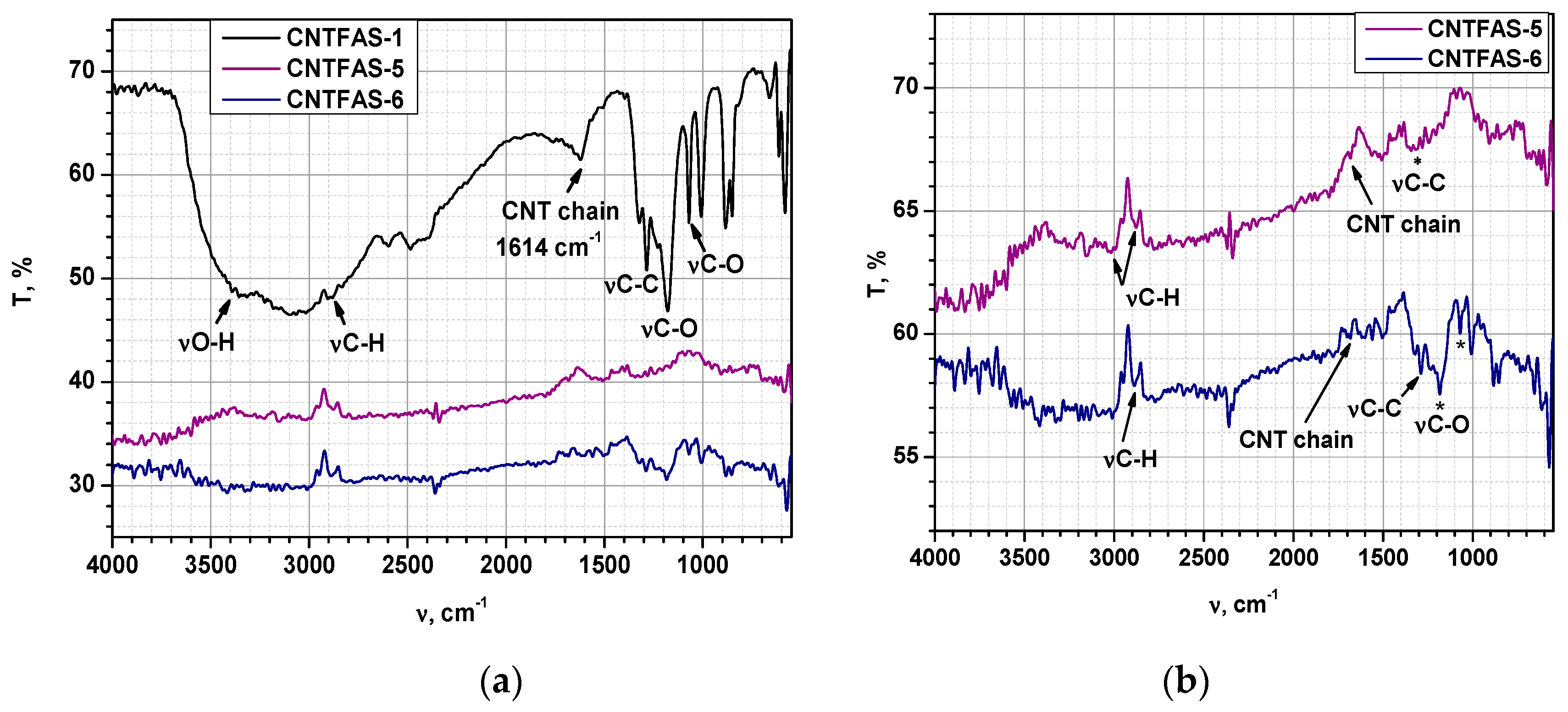

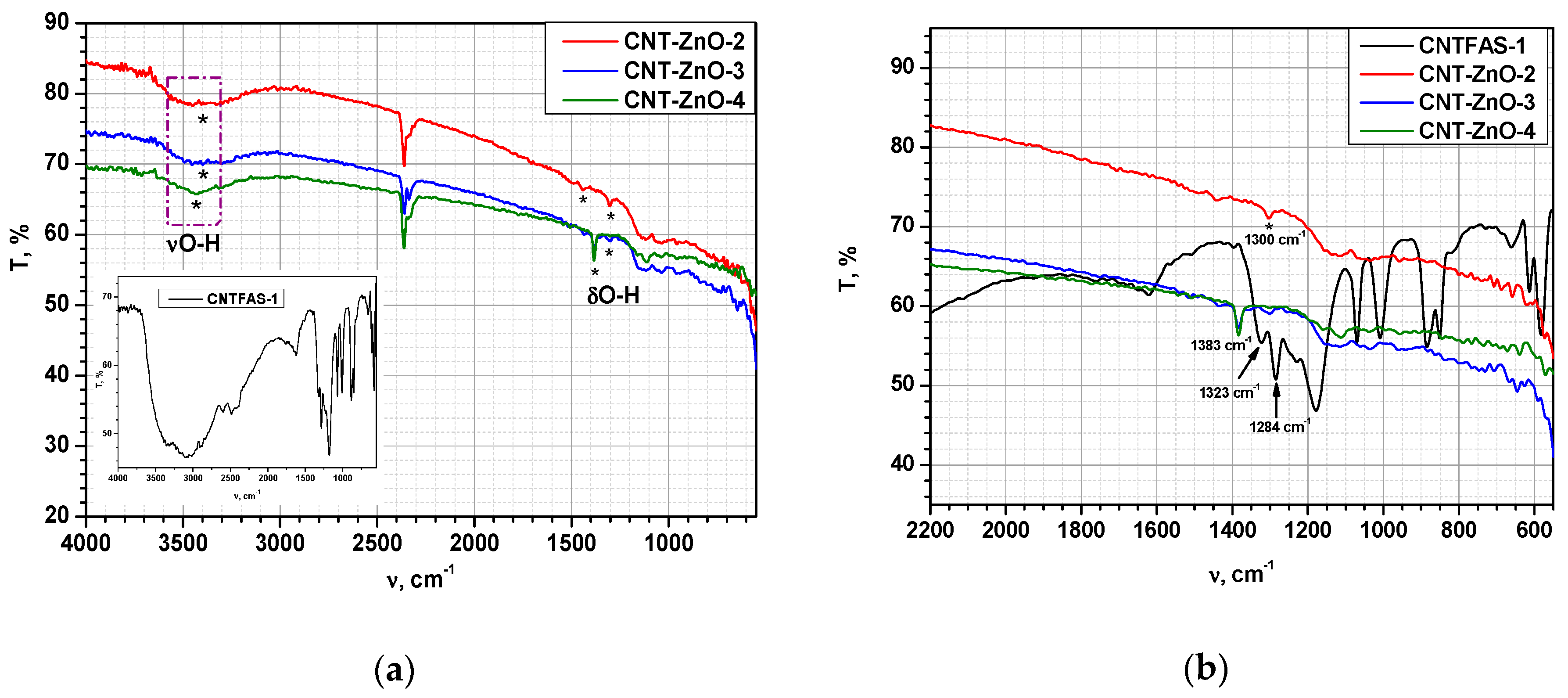

3.2. Spectral (FT-IR) Analysis of CNT and ZnO-CNT Samples, Respectively

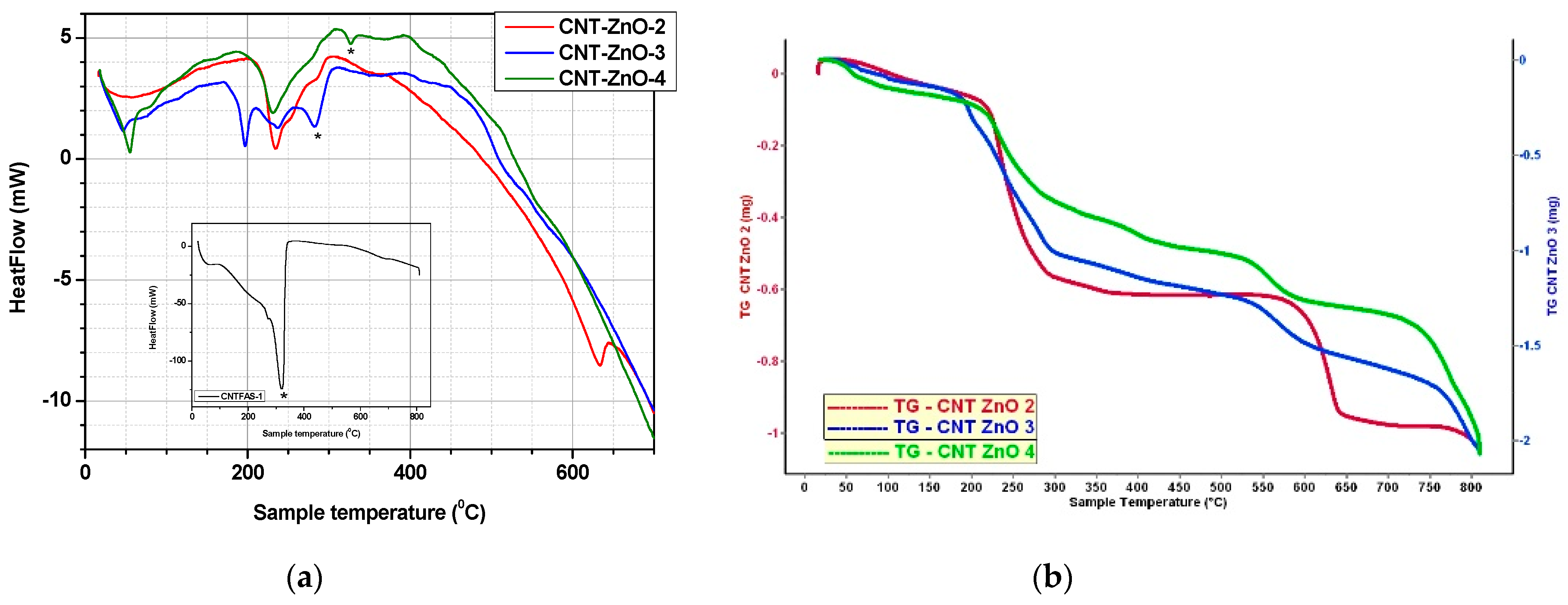

3.3. Thermal (DSC-TG) Analysis of CNT and ZnO-CNT Samples

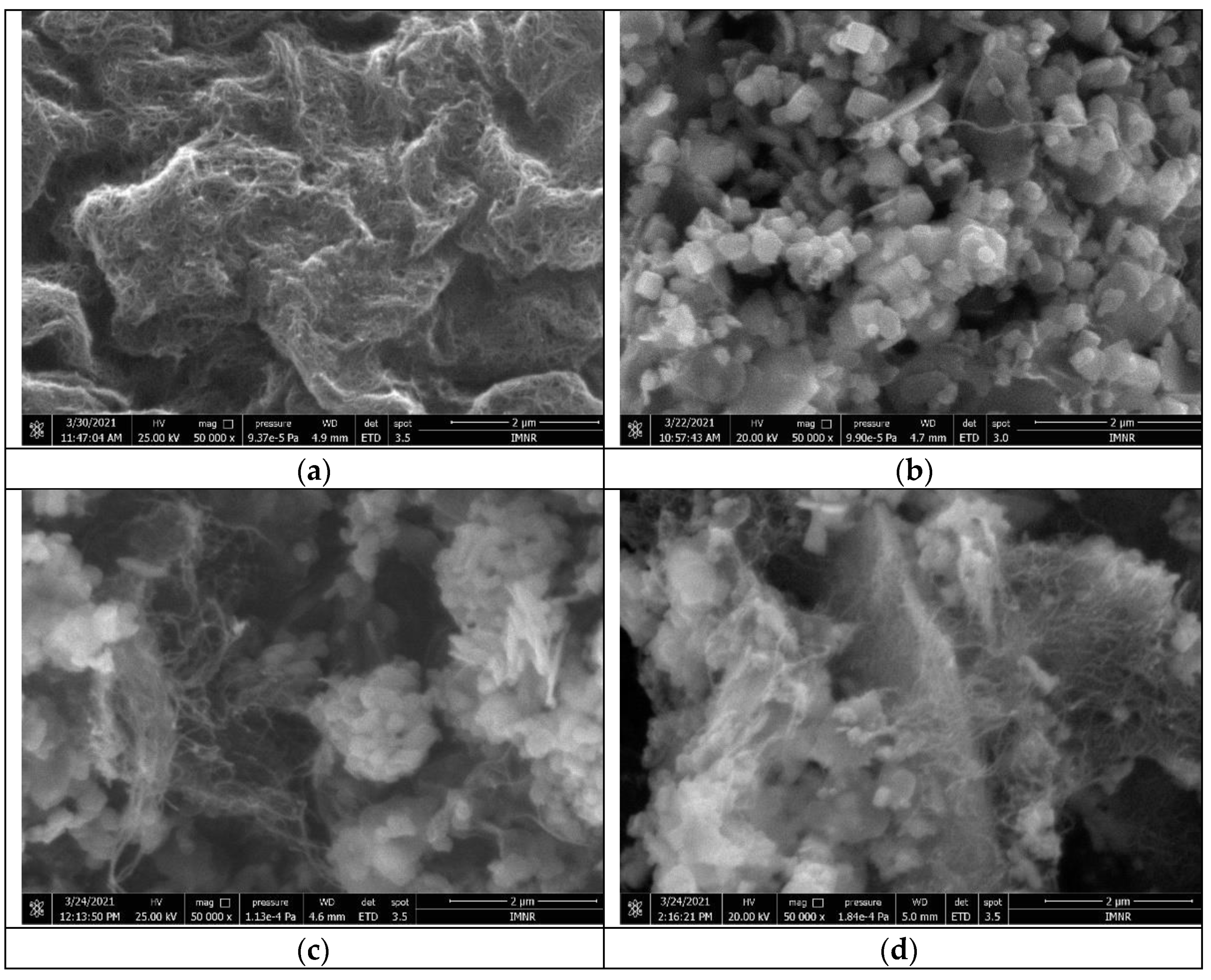

3.4. Morphological Characterization of Functionalised CNT Sample and ZnO-CNT Nanocomposites by Scanning Electron Microscopy (SEM)

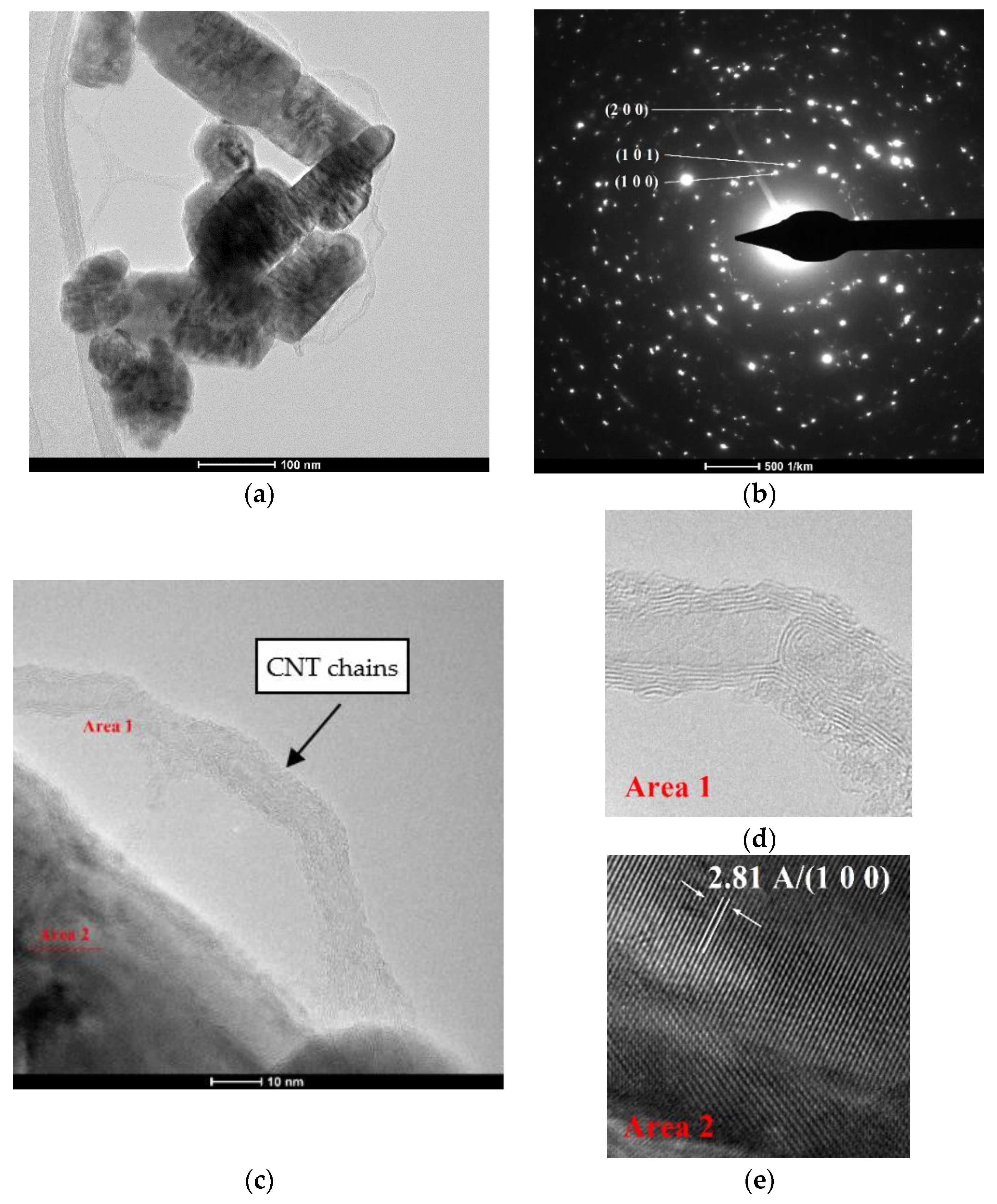

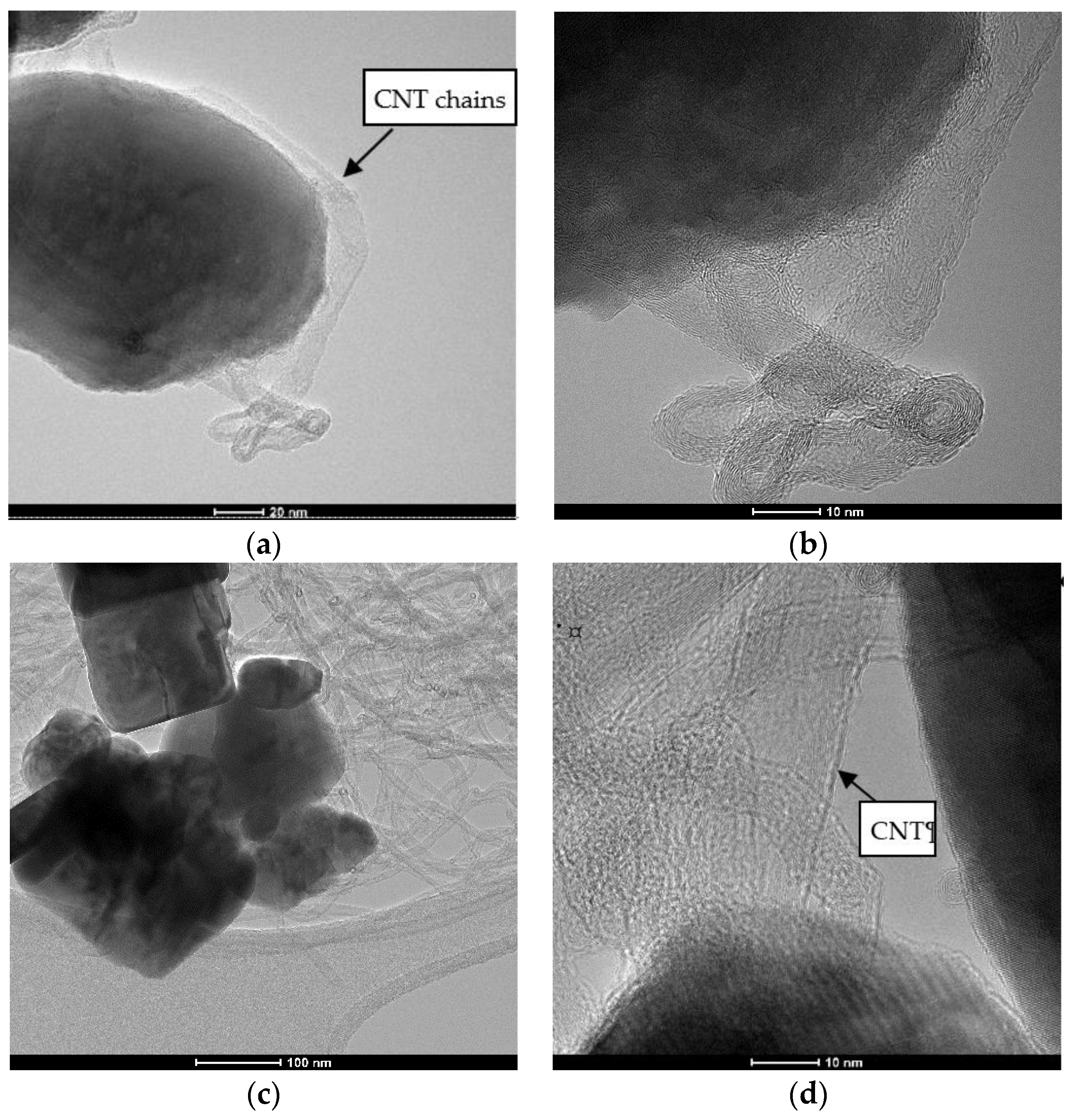

3.5. Transmission Electron Microscopy (TEM) Characterization of ZnO-CNT Nanocomposite Powder

3.6. XRD Characterization of ZnO-CNT Nanocomposites

- D—the average crystallite size, in nm

- β—the line broadening at half the maximum intensity, in radians,

- λ—the X-ray wavelength, in Å;

- κ = constant; κ = 0.9 according to Bragg or 0.70 < κ < 1.70 according to Klug and Alexander

- θ—diffraction (Bragg) angle.

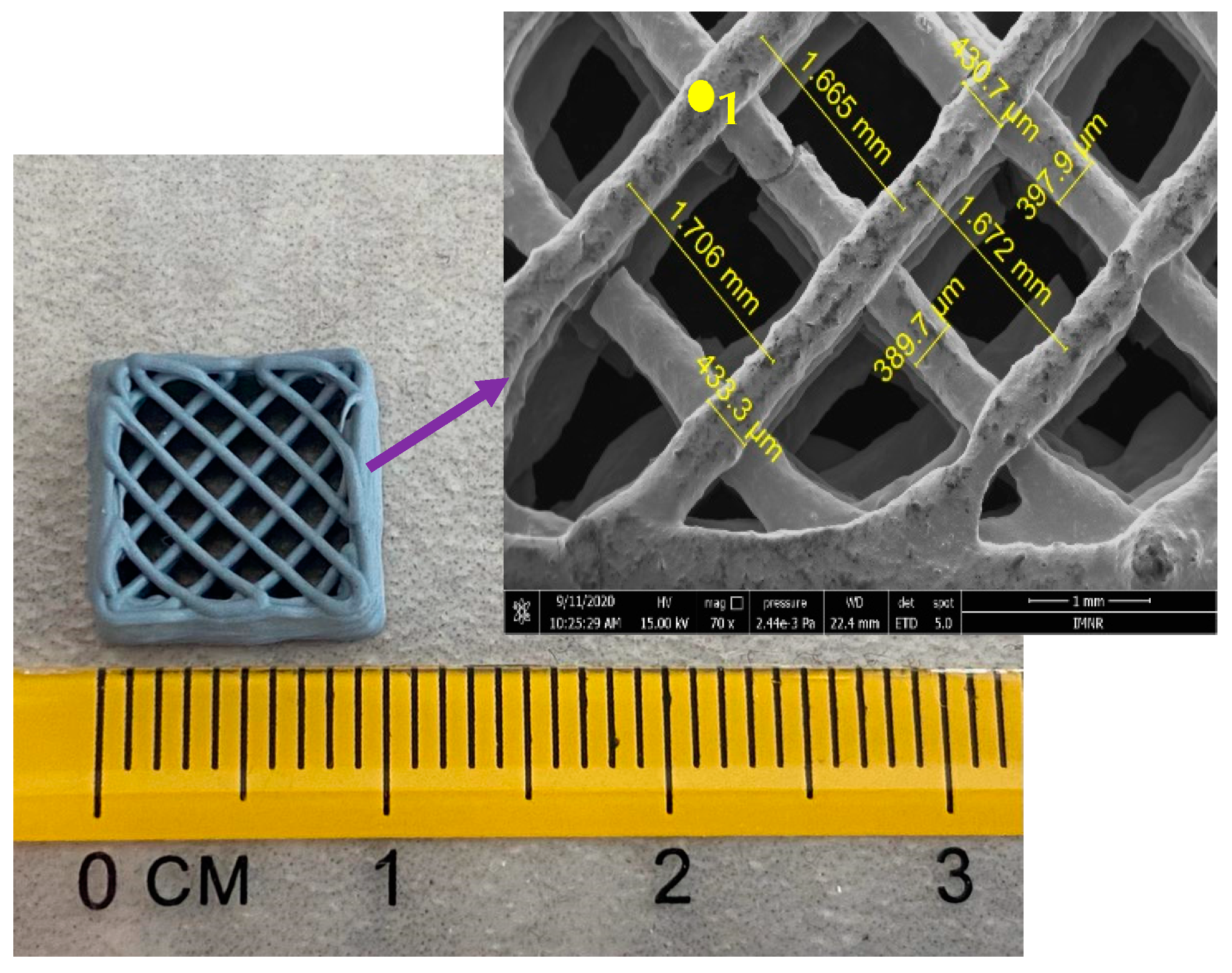

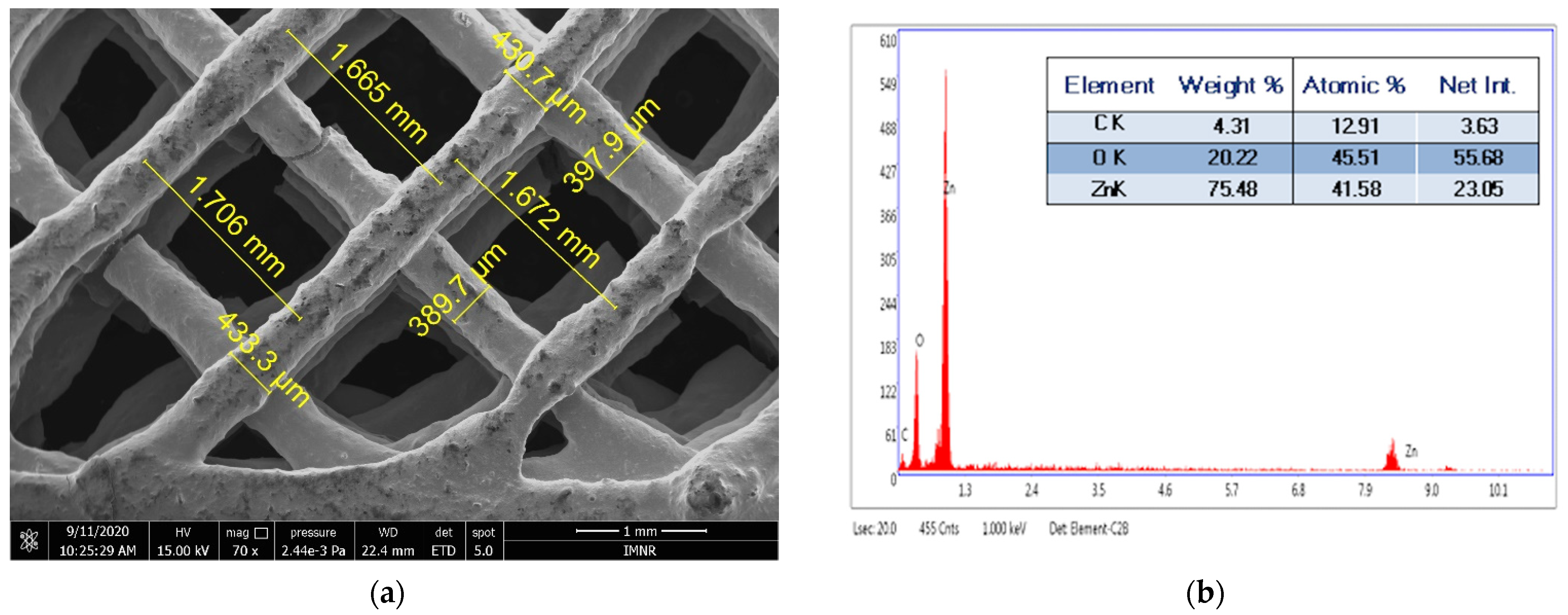

3.7. Extrusion-Based 3D Printing of ZnO-CNT Nanocomposite Powders

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ba-abbad, M.M.; Amir, A.; Kadhum, H.; Bakar, A.; Takriff, M.S. Visible light photocatalytic activity of Fe3+ doped ZnO nanoparticle prepared via sol-gel technique. Chemosphere 2013, 91, 1604–1611. [Google Scholar] [CrossRef] [PubMed]

- Zhong, J.; Li, J.; He, X.; Zeng, J.; Lu, Y.; Hu, W.; Lin, K. Improved photocatalytic performance of Pd-doped ZnO. Curr. Appl. Phys. 2012, 12, 998–1001. [Google Scholar] [CrossRef]

- Rabin, N.N.; Morshed, J.; Akhter, H.; Islam, M.S.; Hossain, M.A.; Elias, M.; Alam, M.M.; Karim, M.R.; Hasnat, M.A.; Nizam uddin, M.; et al. Surface modification of the ZnO nanoparticles with g-aminopropyltriethoxysilane and study of their photocatalytic activity, optical properties and antibacterial activities. Int. J. Chem. React. Eng. 2016, 14, 785–794. [Google Scholar] [CrossRef]

- Sakthivel, S.; Neppolian, B.; Shankar, M.V.; Arabindoo, B.; Palanichamy, M.; Murugesan, V. Solar photocatalytic degradation of azo dye: Comparison of photocatalytic efficiency of ZnO and TiO2. Sol. Energy Mater. Sol. Cells 2003, 77, 65–82. [Google Scholar] [CrossRef]

- Jongnavakit, P.; Amornpitoksuk, P.; Suwanboon, S.; Ndiege, N. Preparation and photocatalytic activity of Cu-doped ZnO thin films prepared by the sol-gel method. Appl. Surf. Sci. 2012, 258, 8192–8198. [Google Scholar] [CrossRef]

- Elias, M.; Nizam Uddin, M.; Hossain, M.A.; Saha, J.K.; Siddiquey, I.A.; Sarker, D.R.; Diba, Z.R.; Uddin, J.; Choudhury, M.H.R.; Firoz, S.H. An experimental and theoretical study of the effect of Ce doping in ZnO/CNT composite thin film with enhanced visible light photo-catalysis. Int. J. Hydrogen Energy 2019, 44, 20068–20078. [Google Scholar] [CrossRef]

- Gouvea, C.A.K.; Wypych, F.; Moraes, S.G.; Duran, N.; Nagata, N.; Peralta-Zamora, P. Semiconductor-assisted photocatalytic degradation of reactive dyes in aqueous solution. Chemosphere 2000, 40, 433–440. [Google Scholar] [CrossRef]

- Ren, X.L.; Han, D.; Chen, D.; Tang, F.Q. Large-scale synthesis of hexagonal cone-shaped ZnO nanoparticles with a simple route and their application to photocatalytic degradation. Mater. Res. Bull. 2007, 42, 807–813. [Google Scholar] [CrossRef]

- Yan, Y.; Chang, T.; Wei, P.; Kang, S.-Z.; Mu, J. Photocatalytic Activity of Nanocomposites of ZnO and Multi-Walled Carbon Nanotubes for Dye Degradation. J. Dispers. Sci. Technol. 2009, 30, 198–203. [Google Scholar] [CrossRef]

- Height, M.J.; Pratsinis, S.E.; Mekasuwandumrong, O.; Praserthdam, P. Ag-ZnO catalysts for UV-photodegradation of methylene blue. Appl. Catal. B 2006, 63, 305–312. [Google Scholar] [CrossRef]

- Matthews, R.W. Photooxidative degradation of coloured organics in water using supported catalysts TiO2 on sand. Water Res. 1991, 25, 1169–1176. [Google Scholar] [CrossRef]

- Li, S.; Zhang, M.; Gao, Y.; Bao, B.; Wang, S. ZnO–Zn/CNT hybrid film as light-free nanocatalyst for degradation reaction. Nano Energy 2013, 2, 1329–1336. [Google Scholar] [CrossRef]

- Chen, C.C.; Liu, P.; Lu, C.H. Synthesis and characterization of nano sized ZnO powders by direct precipitation method. Chem. Eng. J. 2008, 144, 509–513. [Google Scholar] [CrossRef]

- Samadi, M.; Zirak, M.; Naseri, A.; Kheirabadi, M.; Ebrahimi, M.; Moshfegh, A.Z. Design and tailoring of one-dimensional ZnO nanomaterials for photocatalytic degradation of organic dyes: A review. Res. Chem. Intermed. 2019, 45, 2197–2254. [Google Scholar] [CrossRef]

- Hilding, J.; Grulke, E.A.; Sinnott, S.B.; Qian, D.L.; Andrews, R.; Jagtoyen, M. Sorption of butane on carbon multiwall nanotubes at room temperature. Langmuir 2001, 17, 7540–7544. [Google Scholar] [CrossRef]

- Wang, X.; Chen, C.; Hu, W.; Ding, A.; Xu, D.; Zhou, X. Sorption of 243Am (III) to multiwall carbon nanotubes. Environ. Sci. Technol. 2005, 39, 2856–2860. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Wang, J.; Stoller, M.; Wang, T.; Bao, Y.; Hao, H. An Overview of Nanomaterials for Water and Wastewater Treatment. Adv. Mater. Sci. 2016, 2016, 4964828. [Google Scholar] [CrossRef] [Green Version]

- Abdelbasir, S.M.; Shalan, A.E. An overview of nanomaterials for industrial wastewater treatment. Korean J. Chem. Eng. 2019, 36, 1209–1225. [Google Scholar] [CrossRef]

- Aravinda, L.S.; Nagaraja, K.K.; Nagaraja, H.S.; Bhat, K.U.; Bhat, B.R. ZnO/carbon nanotube nanocomposite for high energy density supercapacitors. Electrochim. Acta 2013, 95, 119–124. [Google Scholar] [CrossRef]

- Anku, W.W.; Agorku, E.S.; Oppong, S.O.B.; Karikari, A.Y. MWCNTs attached neodymium doped-ZnO photocatalysts for efficient removal of dyes from wastewater. SN Appl. Sci. 2020, 2, 1–13. [Google Scholar] [CrossRef]

- Mazloumi, M.; Shadmehr, S.; Rangom, Y.; Nazar, L.F.; Tang, X. Fabrication of three-dimensional carbon nanotube and metal oxide hybrid mesoporous architectures. ACS Nano 2013, 7, 4281–4288. [Google Scholar] [CrossRef]

- Azqhandi, M.H.A.; Vasheghani, B.F.; Rajabi, F.H.; Keramati, M. Synthesis of Cd doped ZnO/CNT nanocomposite by using microwave method: Photocatalytic behavior, adsorption and kinetic study. Res. Phys. 2017, 7, 1106–1114. [Google Scholar] [CrossRef]

- Elahi, A.S.; Agah, K.M.; Ghoranneviss, M. A new perspective on structural and morphological properties of carbon nanotubes synthesized by Plasma Enhanced Chemical Vapor Deposition technique. Res. Phys. 2017, 7, 757–761. [Google Scholar]

- Elashmawi, I.S.; Gaabour, L.H. Raman, morphology and electrical behavior of nanocomposites based on PEO/PVDF with multi-walled carbon nanotubes. Res. Phys. 2015, 5, 105–110. [Google Scholar] [CrossRef] [Green Version]

- Nezhadheydari, H.; Tavabe, K.R.; Mirvaghefi, A.; Heydari, A.; Frinsko, M. Effects of different concentrations of Fe3O4-ZnO and Fe3O4-CNT. Environ. Technol. Innov. 2019, 15, 100414. [Google Scholar] [CrossRef]

- Khin, M.M.; Nair, A.S.; Babu, V.J.; Murugan, R.; Ramakrishna, S. A review on nanomaterials for environmental remediation. Energy Environ. Sci. 2012, 5, 8075–8109. [Google Scholar] [CrossRef]

- Anjum, M.; Miandad, R.; Waqas, M.; Gehany, F.; Barakat, M.A. Remediation of wastewater using various nano-materials. Arab. J. Chem. 2016, 12, 4897–4919. [Google Scholar] [CrossRef] [Green Version]

- Abdulgafour, H.I.; Alkhayat, Z.Q.; Nazal, Z.F. The temperatures effects on treatment of heavy metals with zinc oxide nano tubes from industrial wastewater. IOP Conf. Ser. Mater. Sci. Eng. 2018, 400, 7. [Google Scholar] [CrossRef]

- Arora, B.; Attri, P. Carbon Nanotubes (CNTs): A Potential Nanomaterial for Water Purification. J. Compos. Sci. 2020, 4, 135. [Google Scholar] [CrossRef]

- Mohd Adnan, M.A.; Julkapli, N.M.; Abd Hamid, S.B. Review on ZnO hybrid photocatalyst: Impact on photocatalytic activities of water pollutant degradation. Rev. Inorg. Chem. 2016, 36, 77–104. [Google Scholar] [CrossRef]

- Saleh, T.A.; Gondal, M.A.; Drmosh, Q.A. Preparation of a MWCNT/ZnO nanocomposite and its photocatalytic activity for the removal of cyanide from water using a laser. Nanotechnology 2010, 21, 495705. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, I.E.; Silva, R.M.; Girão, A.V.; Faria, J.L.; Silva, C.G.; Silva, R.F. Facile Preparation of ZnO/CNTs Nanocomposites via ALD for Photocatalysis Applications. Eur. J. Inorg. Chem. 2020, 2020, 1743–1750. [Google Scholar] [CrossRef]

- Byrappa, K.; Dayananda, A.S.; Sajan, C.P.; Basavalingu, B.; Shayan, M.B.; Soga, K.; Yoshimura, M. Hydrothermal preparation of ZnO:CNT and TiO2:CNT composites and their photocatalytic applications. J. Mater. Sci. 2008, 43, 2348–2355. [Google Scholar] [CrossRef]

- Sankapal, B.R.; Gajare, H.B.; Karade, S.S.; Salunkhe, R.R.; Dubal, D.P. Zinc Oxide Encapsulated Carbon Nanotube Thin Films for Energy Storage Applications. Electrochim. Acta 2016, 192, 377–384. [Google Scholar] [CrossRef]

- Saleh, T.A.; Gondal, M.; Drmosh, Q.; Yamani, Z.; Al-Yamani, A. Enhancement in photocatalytic activity for acetaldehyde removal by embedding ZnO nanoparticles on multiwall carbon nanotubes. Chem. Eng. J. 2011, 166, 407–412. [Google Scholar] [CrossRef]

- Liu, X.; Pan, L.; Lv, T.; Sun, Z.; Sun, C. Enhanced photocatalytic reduction of Cr (VI) by ZnO–TiO2–CNTs composites synthesized via microwave-assisted reaction. J. Mol. Catal. A Chem. 2012, 363, 417–422. [Google Scholar] [CrossRef]

- Wang, C.Y.; Adhikari, S. ZnO-CNT composite nanotubes as nanoresonators. Phys. Lett. A 2011, 375, 2171–2175. [Google Scholar] [CrossRef]

- Gupta, V.K.; Norouzi, P.; Ganjali, H.; Faridbod, F.; Ganjali, M.R. Flow injection analysis of cholesterol using FFT admittance voltammetric biosensor based on MWCNT–ZnO nanoparticles. Electrochim. Acta 2013, 100, 29–34. [Google Scholar] [CrossRef]

- Hu, F.; Chen, S.; Wang, C.; Yuan, R.; Chai, Y.; Xiang, Y.; Wang, C. ZnO nanoparticle and multiwalled carbon nanotubes for glucose oxidase direct electron transfer and electrocatalytic activity investigation. J. Mol. Catal. B Enzym. 2011, 72, 298. [Google Scholar] [CrossRef]

- Palanisamy, S.; Cheemalapati, S.; Chen, S.M. Highly sensitive and selective hydrogen peroxide biosensor based on hemoglobin immobilized at multiwalled carbon nanotubes-zinc oxide composite electrode. Anal. Biochem. 2012, 429, 108. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, T.; Huang, D.; Jiao, K.; Li, G. Synergistic effects of nano-ZnO/multi-walled carbon nanotubes/chitosan nanocomposite membrane for the sensitive detection of sequence-specific of PAT gene and PCR amplification of NOS gene. J. Membr. Sci. 2008, 325, 245. [Google Scholar] [CrossRef]

- Tak, M.; Gupta, V.; Tomar, M. Zinc oxide–multiwalled carbon nanotubes hybrid nanocomposite-based urea biosensor. J. Mater. Chem. B 2013, 1, 6392–6401. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, X.; Pan, L.; Li, H.; Sun, Z.; Sun, C.; Tay, B.K. Carbon nanotube–ZnO nanocomposite electrodes for supercapacitors. Solid State Ion. 2009, 180, 1525. [Google Scholar] [CrossRef]

- Barthwal, S.; Singh, B.; Barthwal, S.; Singh, N.B. ZnO-CNT Nanocomposite Based Gas Sensors—An Overview. Sens. Lett. 2017, 15, 955–969. [Google Scholar] [CrossRef]

- Subagio, A.; Darari, A.; Sulton Hakim, I.; Subhan, A. Preparation and Characterization of Carbon Nanotube/Graphite/Zinc Oxide Composite as Supercapacitor Electrode Material. MSF 2018, 929, 121–127. [Google Scholar] [CrossRef]

- Suroshe, J.S.; Garje, S.S. Capacitive behaviour of functionalized carbon nanotube/ZnO composites coated on a glassy carbon electrode. J. Mater. Chem. A 2015, 3, 15650–15660. [Google Scholar] [CrossRef]

- Zhu, G.; Wang, H.; Yang, G.; Chen, L.; Guo, P.; Zhang, L. A facile synthesis of ZnO/CNT hierarchical microsphere composites with enhanced photocatalytic degradation of methylene blue. RSC Adv. 2015, 5, 72476–72481. [Google Scholar] [CrossRef]

- Dai, K.; Dawson, G.; Yang, S.; Chen, Z.; Lu, L. Large scale preparing carbon nanotube/zinc oxide hybrid and its application for highly reusable photocatalyst. Chem. Eng. J. 2012, 191, 571–578. [Google Scholar] [CrossRef]

- Barthwal, S.; Singh, N.B. ZnO-CNT Nanocomposite: A Device as Electrochemical Sensor. Mater. Today-Proc. 2017, 4, 5552–5560. [Google Scholar] [CrossRef]

- Pahlavan, A.; Gupta, V.K.; Sanati, A.L.; Karimi, F.; Yoosefian, M.; Ghadami, M. ZnO/CNTs nanocomposite/ionic liquid carbon paste electrode for determination of noradrenaline in human samples. Electrochim. Acta 2014, 123, 456–462. [Google Scholar] [CrossRef]

- Wang, D.; Guo, J.; Cui, C.; Ma, J.; Cao, A. Controllable synthesis of CNT@ZnO composites with enhanced electrochemical properties for lithium-ion battery. Mater. Res. Bull. 2018, 101, 305–310. [Google Scholar] [CrossRef]

- Afsharmanesh, E.; Karimi-Maleh, H.; Pahlavan, A.; Vahedi, J. Electrochemical behavior of morphine at ZnO/CNT nanocomposite room temperature ionic liquid modified carbon paste electrode and its determination in real samples. J. Mol. Liq. 2013, 181, 8–13. [Google Scholar] [CrossRef]

- Ranjithkumar, R.; Arasi, S.E.; Sudhahar, S.; Nallamuthu, N.; Devendran, P.; Lakshmanan, P.; Kumar, M.K. Enhanced electrochemical studies of ZnO/CNT nanocomposite for supercapacitor devices. Phys. B Condens. Matter 2019, 568, 51–59. [Google Scholar] [CrossRef]

- Sun, Z.; Guo, Y.; Li, B.; Tan, T.; Zhao, Y. ZnO/carbon nanotube/reduced graphene oxide composite film as an effective interlayer for lithium/sulfur batteries. Solid State Sci. 2019, 95, 105924. [Google Scholar] [CrossRef]

- Zhang, W. De Growth of ZnO nanowires on modified well-aligned carbon nanotube arrays. Nanotechnology 2006, 17, 1036–1040. [Google Scholar] [CrossRef]

- Ramar, A.; Soundappan, T.; Chen, S.-M.; Rajkumar, M.; Ramiah, S. Incorporation of Multi-Walled Carbon Nanotubes in ZnO for Dye Sensitized Solar Cells. Int. J. Electrochem. Sci. 2012, 7, 11734–11744. [Google Scholar]

- Gogotsi, Y.; Libera, J.A.; Yoshimura, M. Hydrothermal synthesis of multiwall carbon nanotubes. J. Mater. Res. 2000, 15, 2591–2594. [Google Scholar] [CrossRef]

- Yoshimura, M.; Suchanek, W. In situ fabrication of morphology-controlled advanced ceramic materials by Soft Solution Processing. Solid State Ion. 1997, 98, 197–208. [Google Scholar] [CrossRef]

- Somiya, S.; Roy, R. Hydrothermal synthesis of fine oxide powders. Bull. Mater. Sci. 2000, 23, 453–460. [Google Scholar]

- Ding, M.; Sahebgharani, N.; Musharavati, F.; Jaber, F.; Zalnezhad, E.; Yoon, G.H. Synthesis and properties of HA/ZnO/CNT nanocomposite. Ceram. Int. 2018, 44, 7746–7753. [Google Scholar]

- Popescu, L.M.; Piticescu, R.M.; Petriceanu, M.; Ottaviani, M.F.; Cangiotti, M.; Vasile, E.; Dîrtu, M.M.; Wolff, M.; Garcia, Y.; Schinteie, G.; et al. Hydrothermal synthesis of nanostructured hybrids based on iron oxide and branched PEI polymers. Influence of high pressure on structure and morphology. Mater. Chem. Phys. 2015, 161, 84–95. [Google Scholar] [CrossRef]

- Demazeau, G. Impact of High Pressures in Solvothermal Processes. J. Phys. Conf. Ser. 2010, 215, 012124. [Google Scholar] [CrossRef]

- Ahmed, D.S.; Haider, A.J.; Mohammad, M.R. Comparesion of Functionalization of Multi-Walled Carbon Nanotubes Treated by Oil Olive and Nitric Acid and their Characterization. Energy Procedia 2013, 36, 1111–1118. [Google Scholar] [CrossRef] [Green Version]

- Girei, S.A.; Thomas, S.P.; Atieh, M.A.; Mezghani, K.; De, S.K.; Bandyopadhyay, S.; Al-Juhani, A. Effect of –COOH Functionalized Carbon Nanotubes on Mechanical, Dynamic Mechanical and Thermal Properties of Polypropylene Nanocomposites. J. Thermoplast. Compos. Mater. 2011, 25, 333–350. [Google Scholar] [CrossRef]

- Jayarambabu, N.; Siva Kumari, B.; Venkateswara Rao, K.; Prabhu, Y.T. Germination and Growth Characteristics of Mungbean Seeds (Vigna radiata L.) affected by Synthesized Zinc Oxide Nanoparticles. Int. J. Curr. Eng. Technol. 2014, 4, 3411–3416. [Google Scholar]

- Liang, S.; Li, G.; Tian, R. Multi-walled carbon nanotubes functionalized with an ultrahigh fraction of carboxyl and hydroxyl groups by ultrasound-assisted oxidation. J. Mater. Sci. 2015, 51, 3513–3524. [Google Scholar] [CrossRef]

- Lehman, J.H.; Terrones, M.; Mansfield, E.; Hurst, K.E.; Meunier, V. Evaluating the characteristics of multiwall carbon nanotubes. Carbon 2011, 49, 2581–2602. [Google Scholar] [CrossRef]

| Sample Name | Composition | Drying Method |

|---|---|---|

| CNTFAS-1 | HNO3 4 M:H2SO4 10 M = 1:3 | rotary evaporation |

| CNTFAS-5 | HNO3 2 M:H2SO4 10 M = 1:3 | freeze drying |

| CNTFAS-6 | HNO3 2 M:H2SO4 5 M = 1:3 | freeze drying |

| Nanocomposite Sample Code | Composition (Weight Ratio) |

|---|---|

| CNT-ZnO-2 | CNT:ZnO = 1:10 |

| CNT-ZnO-3 | CNT:ZnO = 1:5 |

| CNT-ZnO-4 | CNT:ZnO = 1:4 |

| Sample Name | Peak 1 (Endotherm) | Peak 2 (Endotherm) | Peak 3 (Endotherm) | Δm Total, % | |||

|---|---|---|---|---|---|---|---|

| T, °C | ΔH, J/g | T, °C | ΔH, J/g | T, °C | ΔH, J/g | ||

| CNTFAS-1 | 321.8 | 762.4 | −94.865 | ||||

| CNTFAS-5 | 46.6 | 19.9 | 78.1 | 46.0 | −44.211 | ||

| CNTFAS-6 | 47.5 | 10.9 | 204.3 | 2.9 | −17.416 | ||

| Sample Name | Peak 1 (Endotherm) | Peak 2 (Endotherm) | Peak 3 (Endotherm) | Peak4 (Endotherm) | Δm Total, % | % CNT (Theoretic) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| T, °C | ΔH, J/g | T, °C | ΔH, J/g | T, °C | ΔH, J/g | T, °C | ΔH, J/g | |||

| CNT-ZnO-2 | 63.2 | 20.4 | 233.7 | 75.4 | - | - | 631.7 | 26.3 | 9.7 | 9.1 |

| CNT-ZnO-3 | 46.5 | 15.6 | 196.5 231.6 | 91.0 5.1 | 290.9 | 29.4 | - | - | 17.6 | 16.7 |

| CNT-ZnO-4 | 55.2 | 18.6 | 231.5 | 65.3 | 326.3 | 2.1 | - | - | 18.4 | 20 |

| No. | 3D Object Name | Polymeric Additives | Printing Parameters | Observations |

|---|---|---|---|---|

| 1 | 3D-1 | Mowiflex 20% BAYMEDIX | - | Non-homogeneous paste. Non-printable paste. |

| 2 | 3D-2 | HPMC PAAS | - | The paste could not be extruded through the nozzle. Non-printable paste. |

| 3 | 3D-3 | HPMC PAAS | P = 5 bar, v = 3.5 mm/s nozzle φ = 0.4 mm | The paste is extruded in dots. The wire is not continuous. Non-printable paste. |

| 4 | 3D-4 | Tween 80 HPMC ethylene glycol | - | The paste is not homogeneous and is partially extrudable. Non-printable paste. |

| 5 | 3D-5 | HPMC PEI | P = 3.5 bar, v = 10 mm/s nozzle φ = 0.4 mm | Printable paste, a 3D object was obtained. |

| 6 | 3D-6 | HPMC PEI Tween 80 | P = 3.5 bar, v = 10 mm/s nozzle φ = 0.4 mm | Printable paste, a 3D object was obtained. |

| 7 | 3D-7 | HPMC PEI Tween 80 | P = 3.5 bar, v = 10 mm/s nozzle φ = 0.4 mm | Printable paste, a 3D object was obtained. |

| 8 | 3D-8 | HPMC PEI Tween 80 | P = 2 bar, v = 15 mm/s nozzle φ = 0.4 mm | Printable paste, a 3D object was obtained. |

| 9 | 3D-9 | PEI HPMC Tween 80 | P = 2 bar, v = 15 mm/s nozzle φ = 0.4 mm | Printable paste, a 3D object was obtained. |

| 10 | 3D-10 | PEI HPMC Tween 80 | P = 1.5- 2 bar, v = 12- 16 mm/s nozzle φ = 0.4 mm | Printable paste, a 3D object was obtained. |

| 11 | 3D-11 | PEI Tween 80 | P = 4.5 bar, v = 7 mm/s nozzle φ = 0.4 mm | Printable paste, a 3D object was obtained. |

| 12 | 3D-12 | PEI Tween 80 | P = 4.1 bar, v = 6 mm/s nozzle φ = 0.4 mm | Printable paste, a 3D object was obtained. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cursaru, L.-M.; Valsan, S.N.; Puscasu, M.-E.; Tudor, I.A.; Zarnescu-Ivan, N.; Vasile, B.S.; Piticescu, R.M. Study of ZnO-CNT Nanocomposites in High-Pressure Conditions. Materials 2021, 14, 5330. https://doi.org/10.3390/ma14185330

Cursaru L-M, Valsan SN, Puscasu M-E, Tudor IA, Zarnescu-Ivan N, Vasile BS, Piticescu RM. Study of ZnO-CNT Nanocomposites in High-Pressure Conditions. Materials. 2021; 14(18):5330. https://doi.org/10.3390/ma14185330

Chicago/Turabian StyleCursaru, Laura-Madalina, Sorina Nicoleta Valsan, Maria-Eliza Puscasu, Ioan Albert Tudor, Nicoleta Zarnescu-Ivan, Bogdan Stefan Vasile, and Roxana Mioara Piticescu. 2021. "Study of ZnO-CNT Nanocomposites in High-Pressure Conditions" Materials 14, no. 18: 5330. https://doi.org/10.3390/ma14185330

APA StyleCursaru, L.-M., Valsan, S. N., Puscasu, M.-E., Tudor, I. A., Zarnescu-Ivan, N., Vasile, B. S., & Piticescu, R. M. (2021). Study of ZnO-CNT Nanocomposites in High-Pressure Conditions. Materials, 14(18), 5330. https://doi.org/10.3390/ma14185330