Compressive Creep and Shrinkage of High-Strength Concrete Based on Limestone Coarse Aggregate Applied to High-Rise Buildings

Abstract

:1. Introduction

2. Experiment

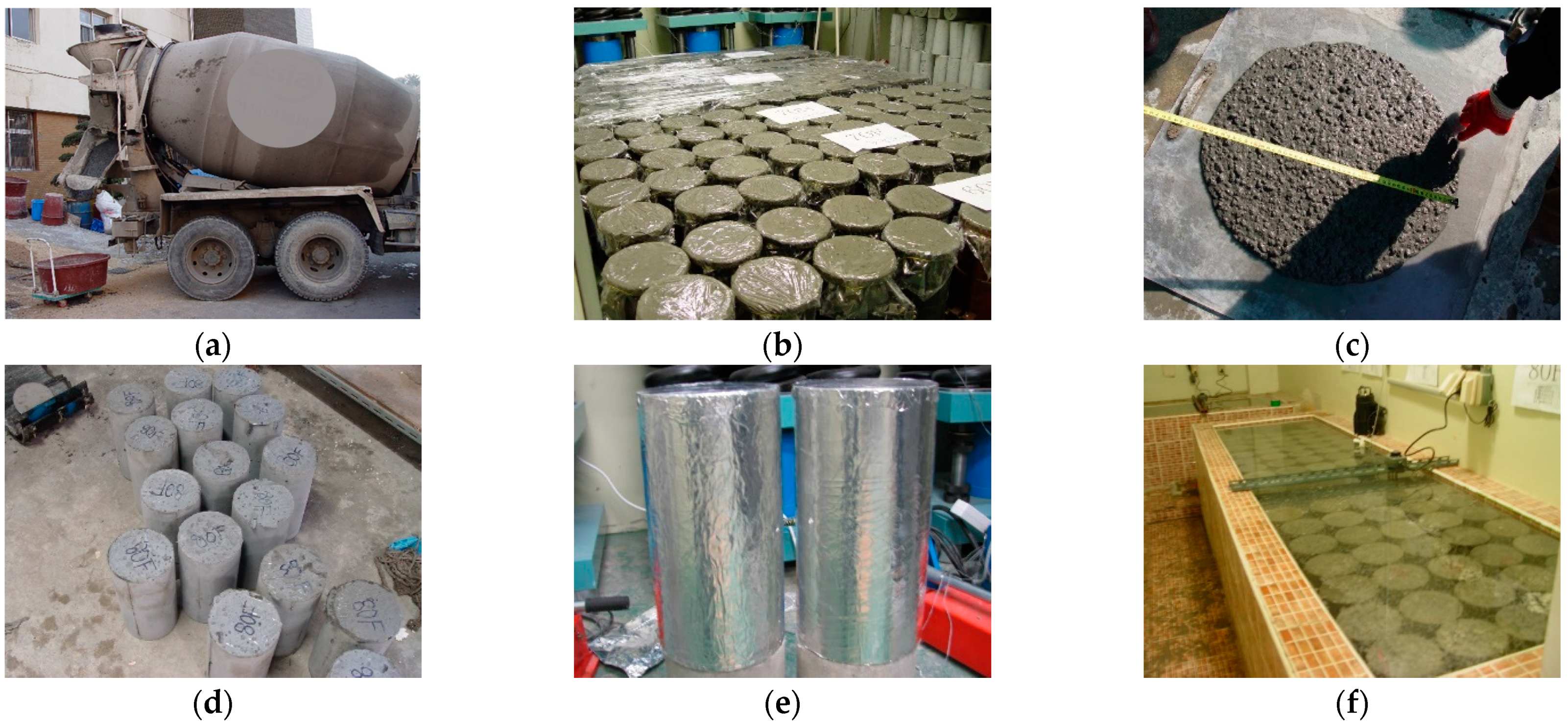

2.1. Experimental Procedure

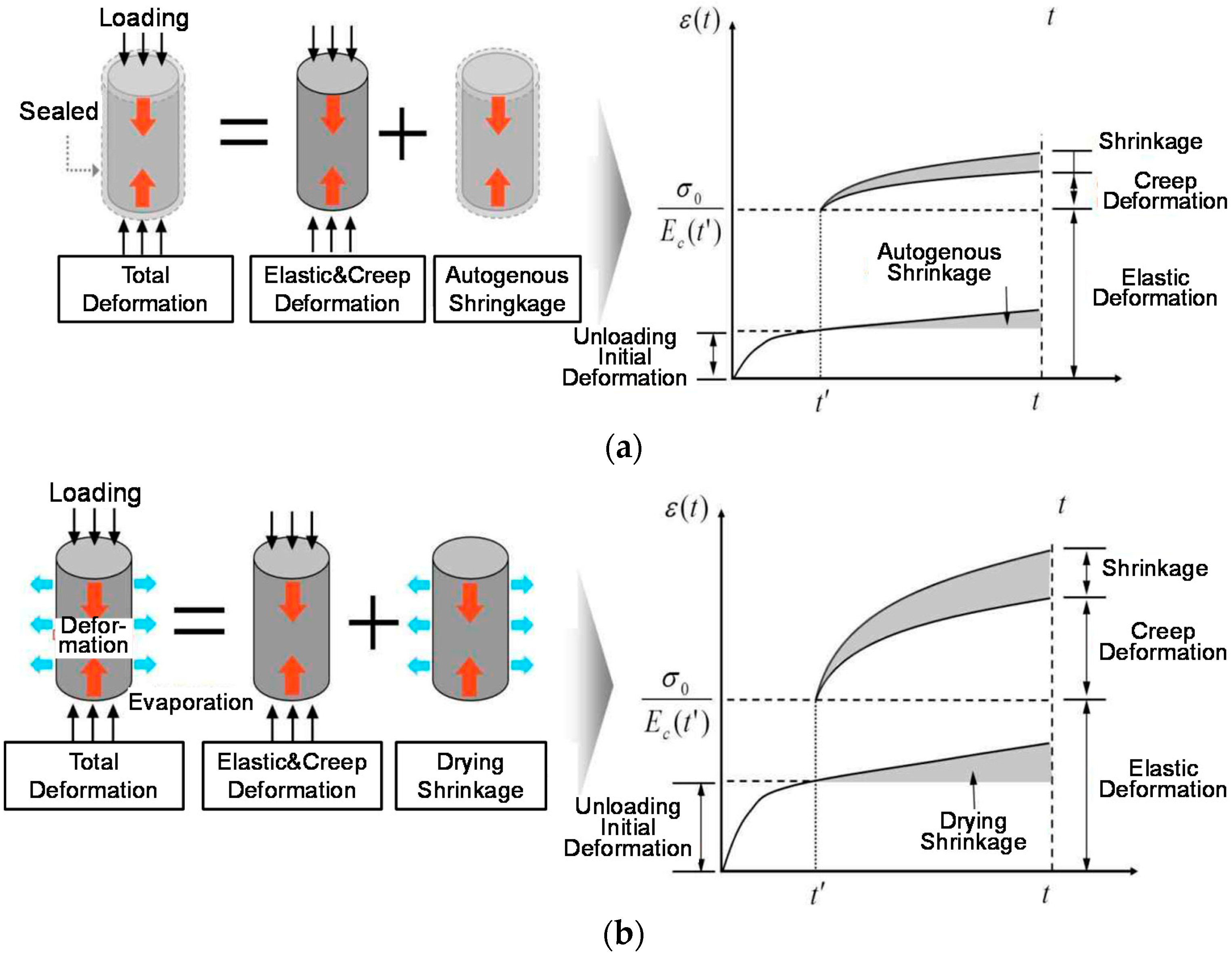

2.2. Concrete Specimen Production and Shrinkage Characteristics Evaluation Method

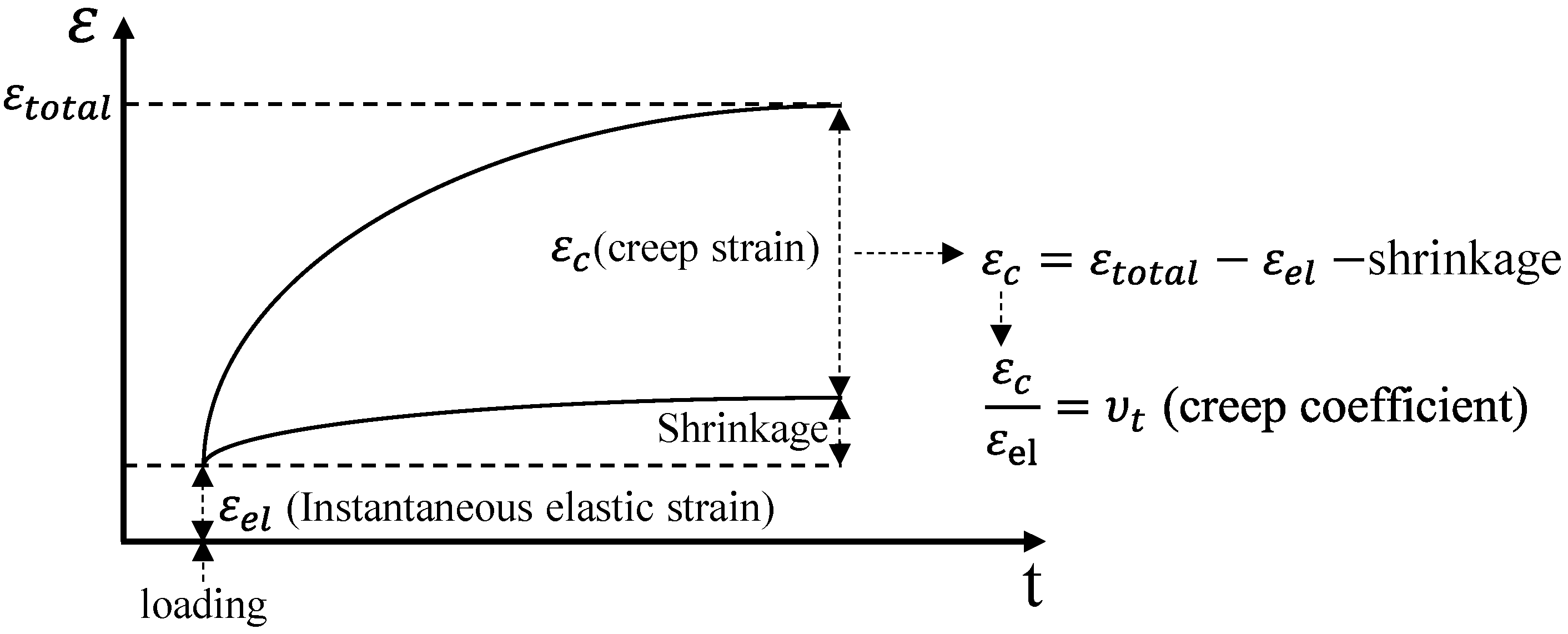

2.3. Shrinkage and Creep Models

- : creep coefficient;

- : creep strain;

- : instantaneous elastic strain.

- : creep coefficient;

- : days after loading;

- : ultimate creep coefficient;

- : applicable correction factors.

3. Experimental Results and Discussion

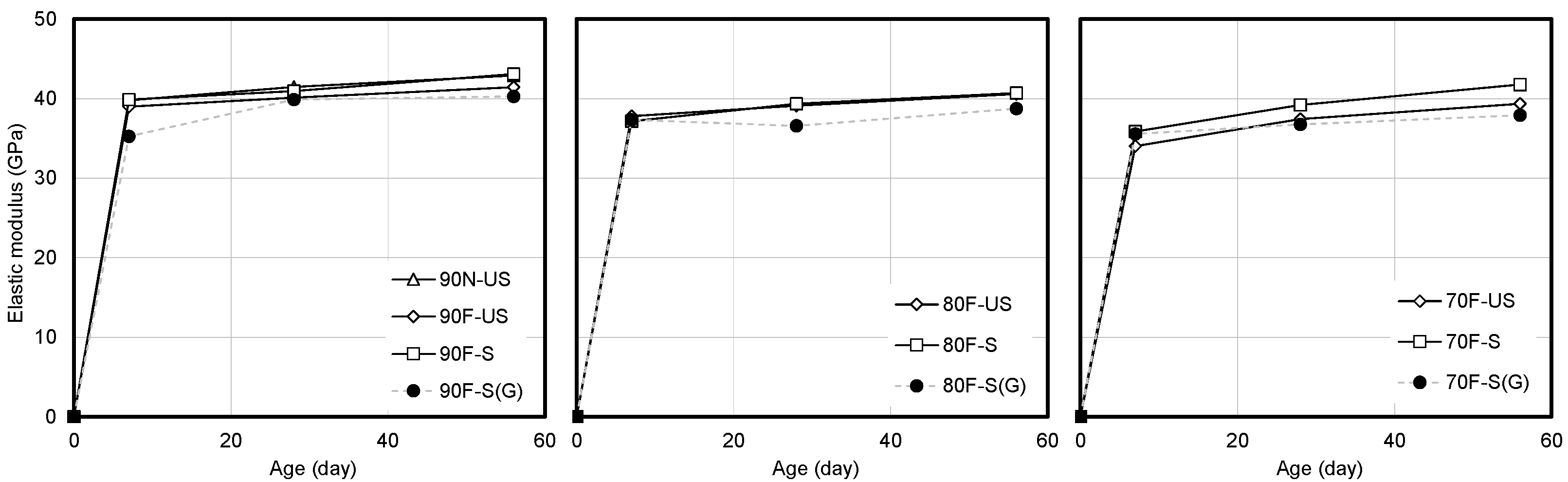

3.1. Compressive Strength and Elastic Modulus

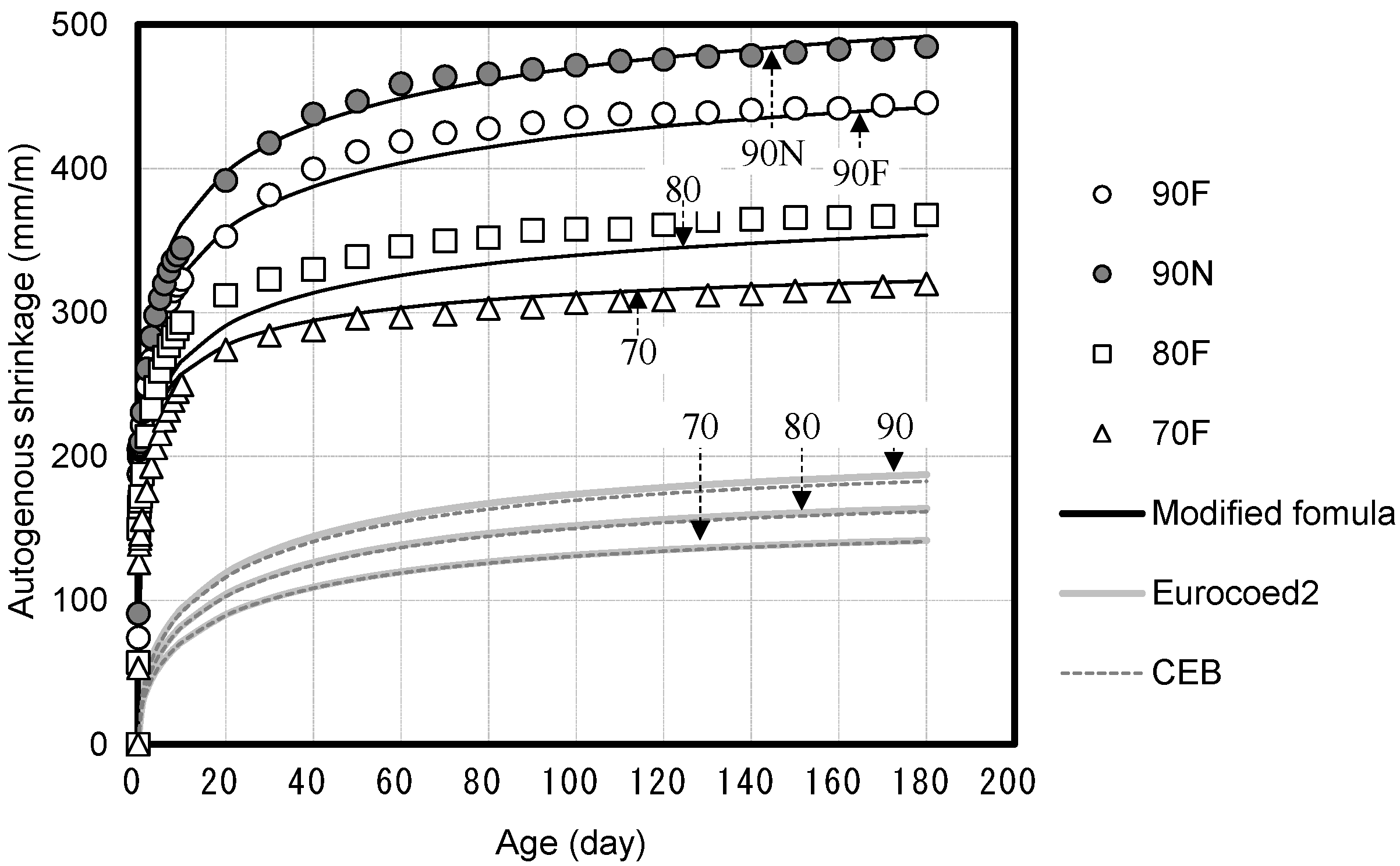

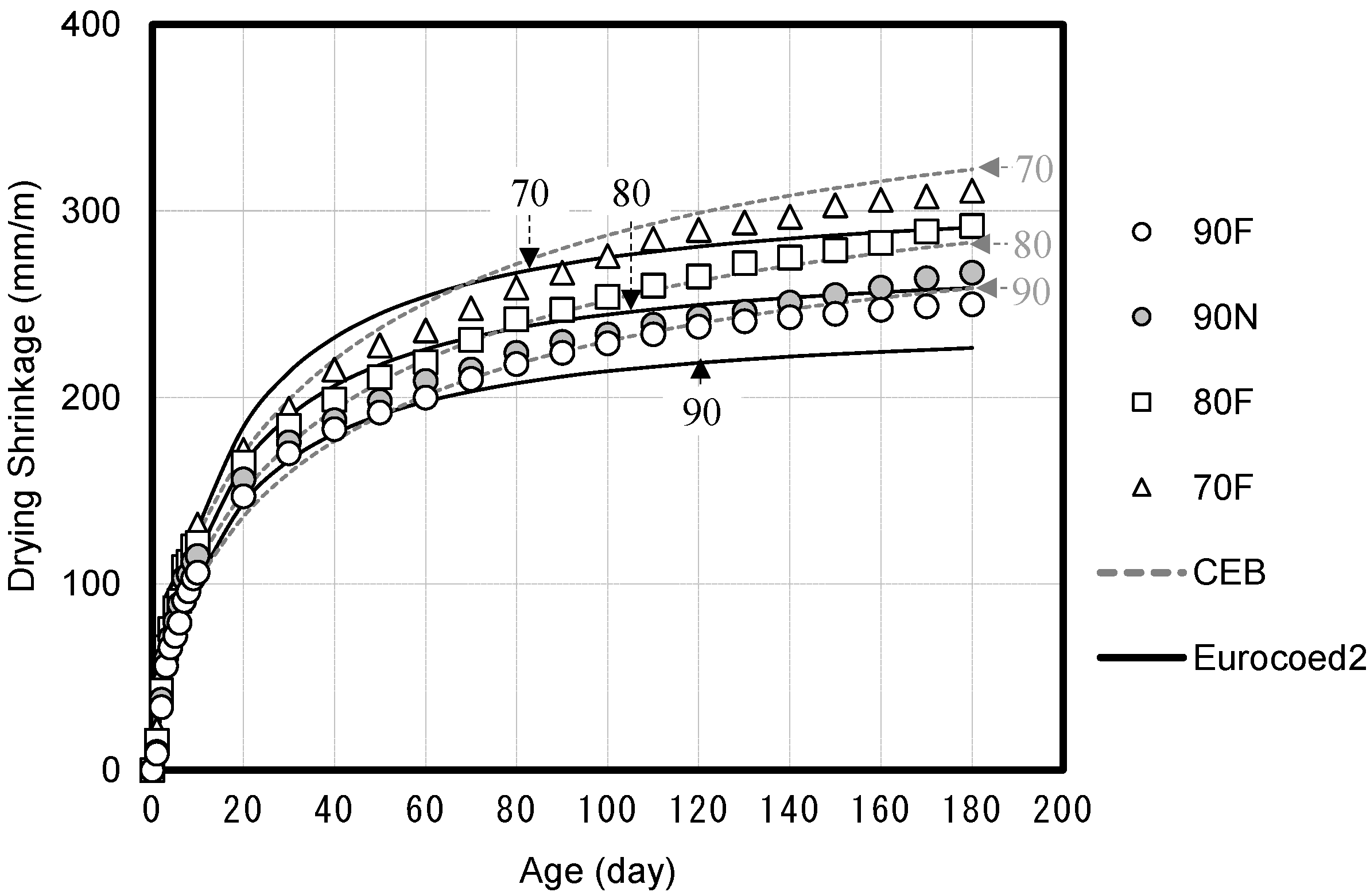

3.2. Autogenous and Drying Shrinkage

- : autogenous shrinkage with age (×10−6);

- : maximum amount of autogenous shrinkage with W/B (×10−6);

- : fiber mixing constant (range of this study: 0.9 when mixed, 1.0 without mixing);

- : aggregate constant (granite 1.0, limestone 1.087);

- : function that represents the progress of autogenous shrinkage;

- : experimental constants (Table 5);

- : age (days);

- : initial set time (days).

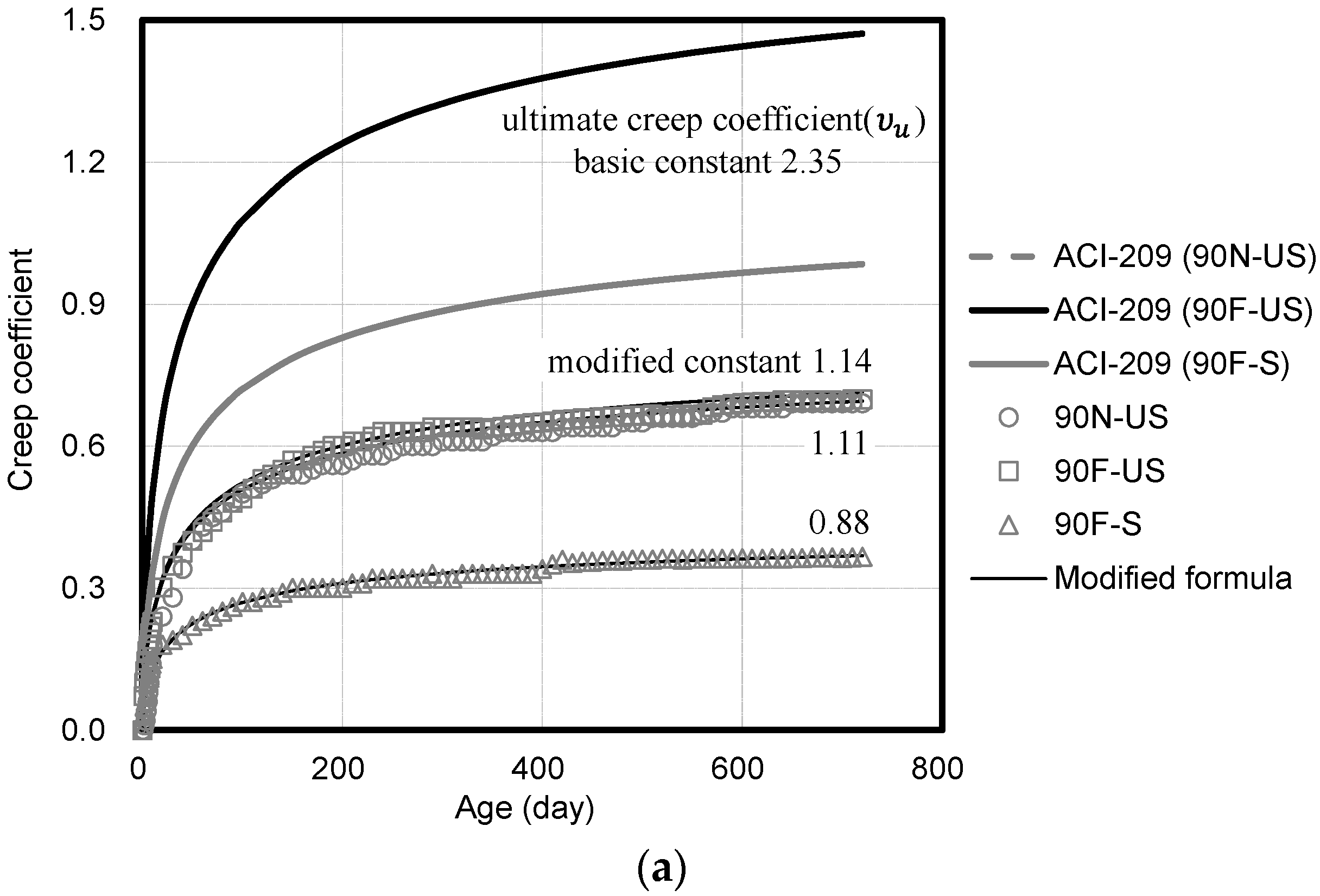

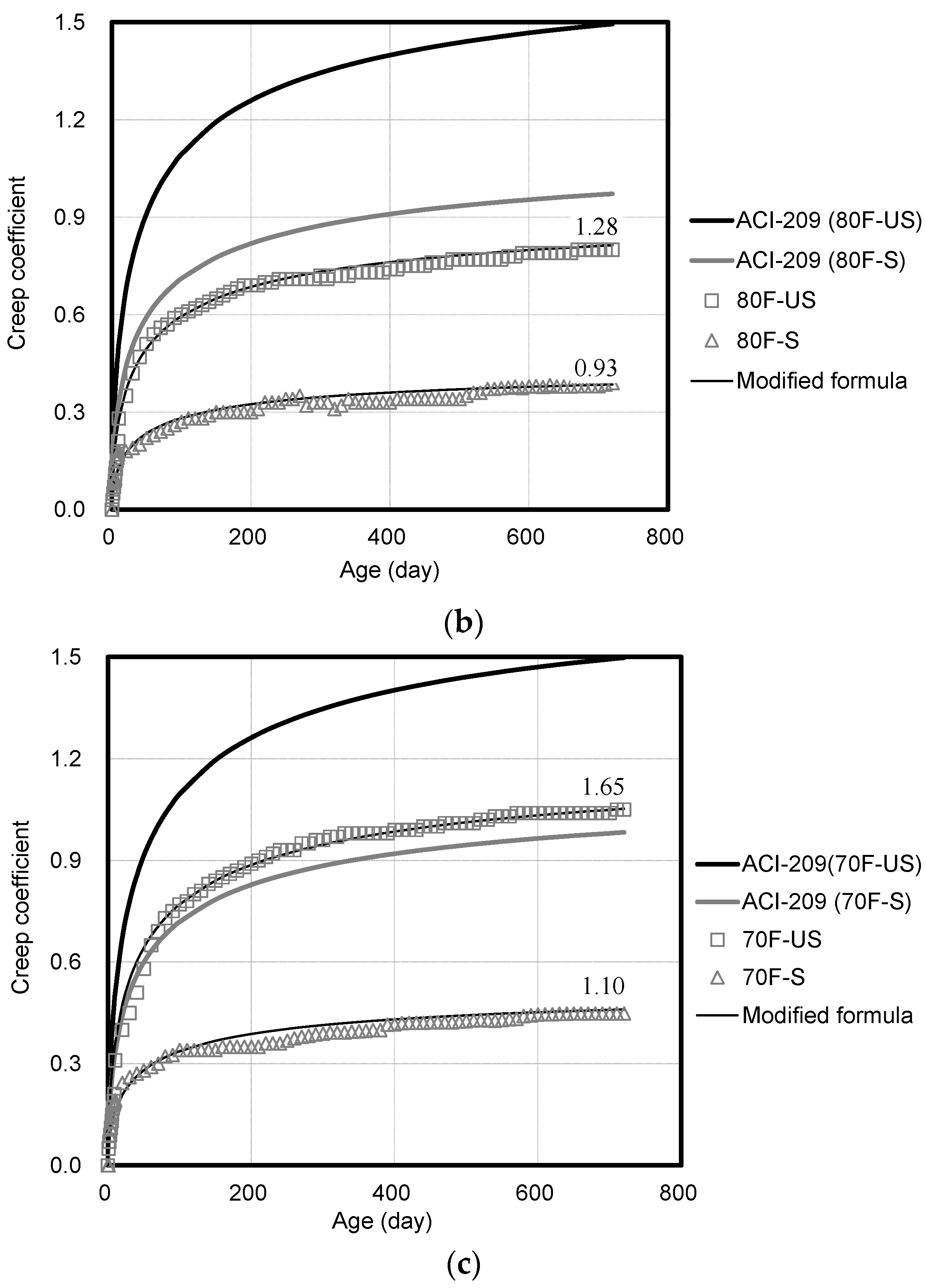

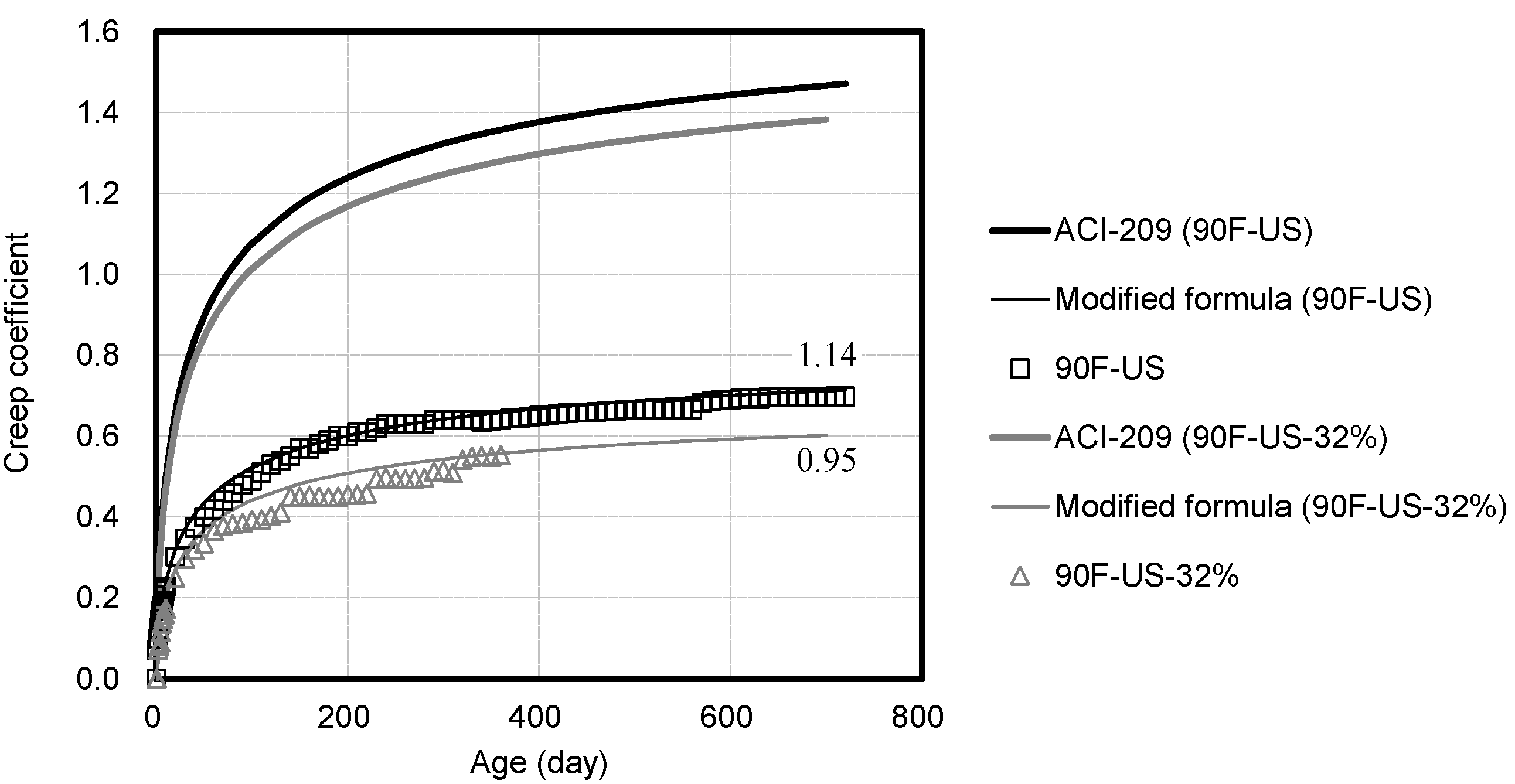

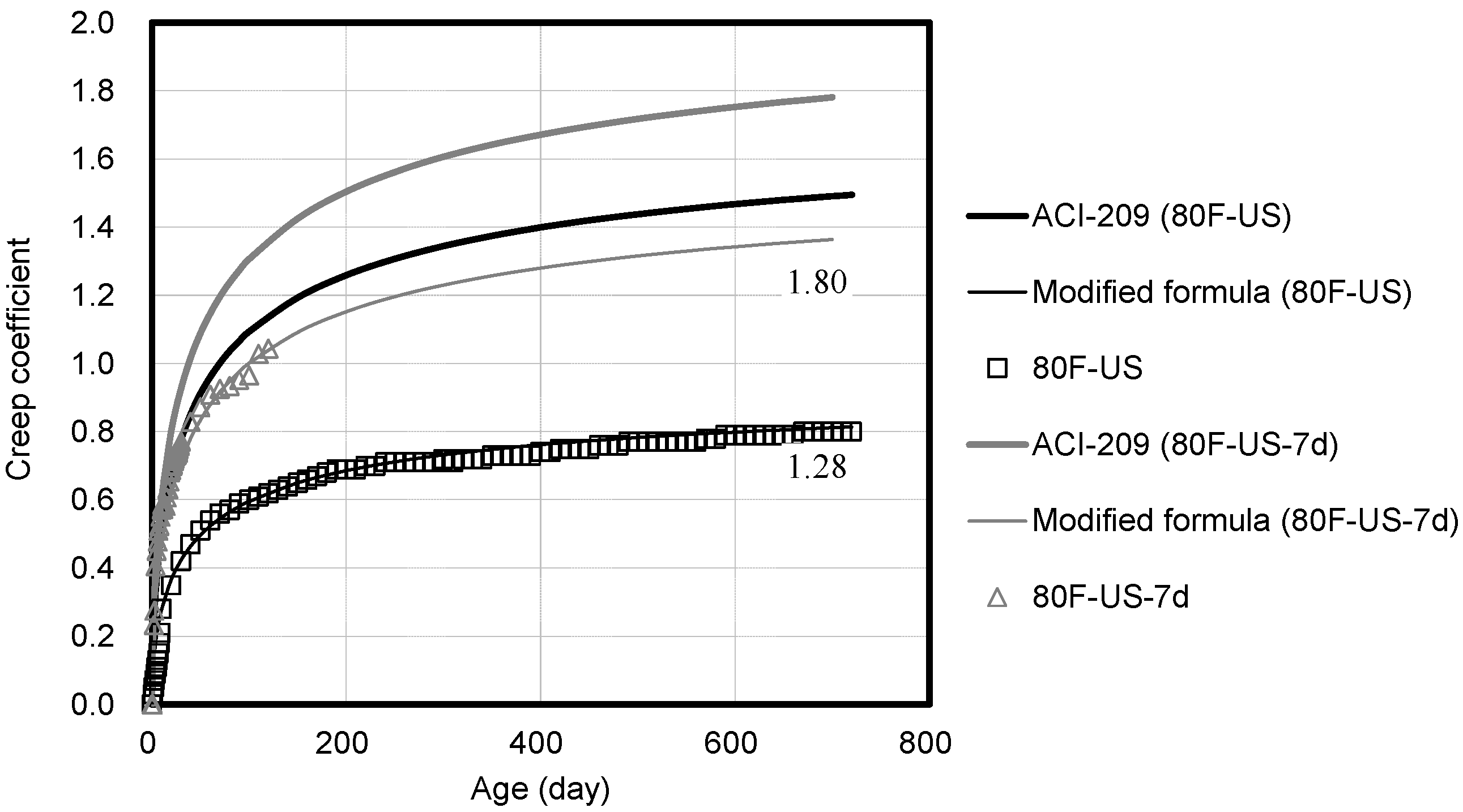

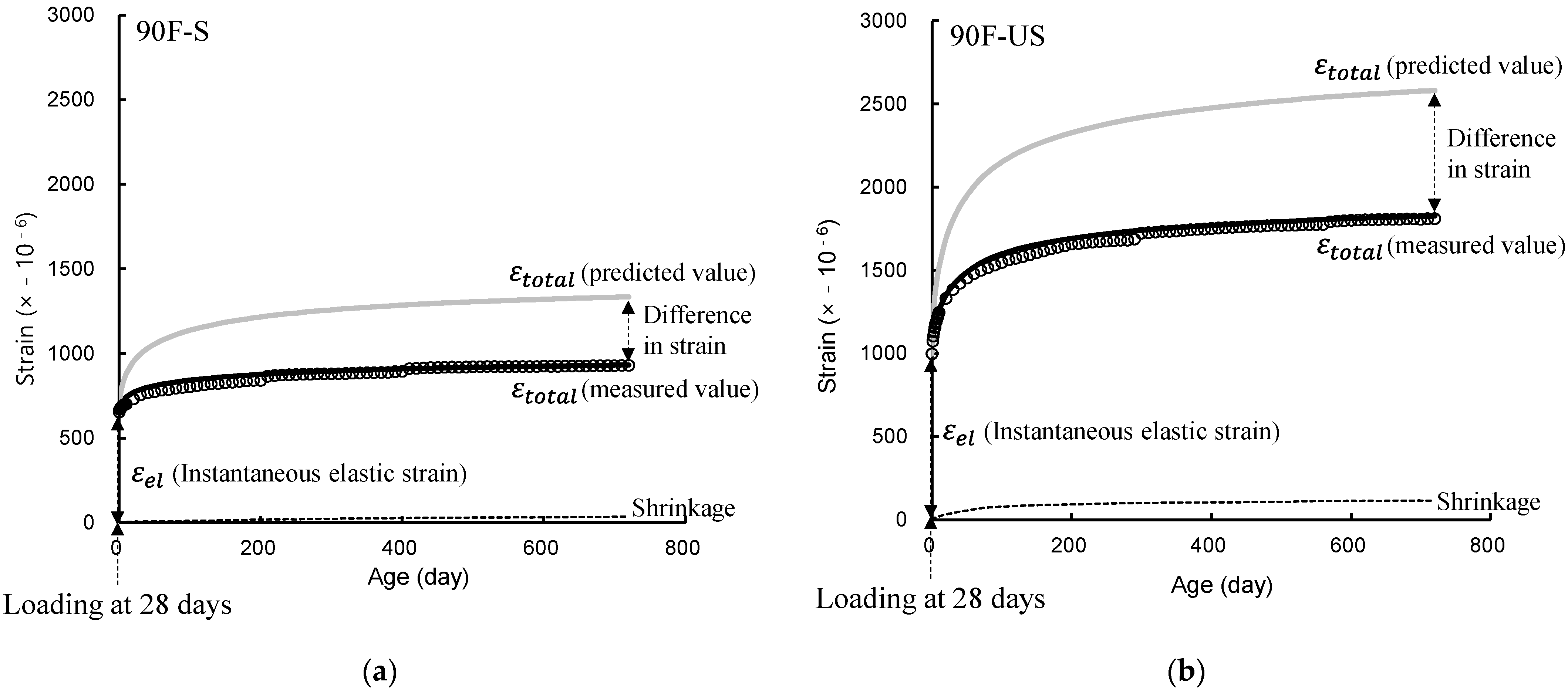

3.3. Compressive Creep Coefficient

- : modified ultimate creep coefficient;

- : modified constants;

4. Conclusions

- The compressive strength and elastic modulus of high-strength concrete were evaluated to be approximately 2% higher under the sealed condition than under the unsealed condition based on the curing conditions. This is attributed to the moisture conserved in the concrete under sealed conditions. Additionally, the compressive strength and elastic modulus of the high-strength concrete increased by approximately 4% when limestone coarse aggregate was used.

- The autogenous shrinkage increases, and the drying shrinkage decreases with the increase in the compressive strength of the concrete. Particularly, the autogenous shrinkage of high-strength concrete increases owing to the self-desiccation caused by the hydration of unhydrated cement, which cannot be implemented by the existing models. Autogenous shrinkage and drying shrinkage occur simultaneously under the unsealed conditions in actual structures. Therefore, both autogenous shrinkage and drying shrinkage must be considered to predict the overall shrinkage of high-strength concrete. Furthermore, modified formulas were derived using the autogenous shrinkage prediction model proposed by a previous study, which reflected the autogenous shrinkage development characteristics of high-strength concrete.

- The compressive creep coefficient of high-strength concrete was evaluated to be approximately 1.58 to 2.91 times higher under the unsealed condition than under the sealed condition based on the curing conditions and was also affected by the compressive strength, loading level, and loading age. Additionally, the coarse aggregates affect the elastic modulus and compressive creep of high-strength concrete, which varies depending on various conditions, which cannot be reflected by the existing models. The shrinkage and compressive creep characteristics must be reflected to improve the prediction accuracy for the deformation of high-strength concrete because actual structures are exposed to more conditions than in laboratory tests. Therefore, ACI-209 proposed modified formulas to derive the ultimate creep coefficient by reflecting the compressive creep characteristics of high-strength concrete based on the curing condition and compressive strength.

- High-strength concrete has different internal structures because it contains more binders than normal-strength concrete. Therefore, the shrinkage and compressive creep of the main structural members must be accurately predicted to ensure structural stability in high-rise buildings where high-strength concrete is used. The accurate prediction of the deformation characteristics of high-strength concrete requires the construction of databases considering conditions such as compressive strength, curing condition, and coarse aggregate. In addition, future studies should investigate the correspondence between the compressive deformation of concrete members of buildings and the predicted values of the compressive deformation of concrete based on material values.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Bažant, Z.P.; Baweja, S. Justification and refinements of model B3 for concrete creep and shrinkage 1. statistics and sensitivity. Mater. Struct. 1995, 28, 415–430. [Google Scholar] [CrossRef]

- Jonasson, J.E.; Persson, B. Creep. In Design Handbook; The Consortium for Research of HPC Structures; Technical University of Luleå: Luleå, Sweden, 1998; pp. 2–7. [Google Scholar]

- Persson, B. Hydration and strength of high performance concrete. Adv. Cem. Based Mater. 1996, 3, 107–123. [Google Scholar] [CrossRef]

- Persson, B. Self-desiccation and its importance in concrete technology. Mater. Struct. 1997, 30, 293–305. [Google Scholar] [CrossRef] [Green Version]

- Persson, B. Correlating laboratory and field tests of creep in high-performance concrete. Cem. Concr. Res. 2001, 31, 389–395. [Google Scholar] [CrossRef]

- Nguyen, D.B.; Lin, W.S.; Liao, W.C. Long-Term Creep and Shrinkage Behavior of Concrete-Filled Steel Tube. Materials 2021, 14, 295. [Google Scholar] [CrossRef]

- Beushausen, H.; Dittmer, T. The influence of aggregate type on the strength and elastic modulus of high strength concrete. Constr. Build. Mater. 2015, 74, 132–139. [Google Scholar] [CrossRef]

- Beshr, H.; Almusallam, A.A.; Maslehuddin, M. Effect of coarse aggregate quality on the mechanical properties of high strength concrete. Constr. Build. Mater. 2003, 17, 97–103. [Google Scholar] [CrossRef]

- Fanourakis, G.C. The Influence of Aggregate Stiffness on the Measured and Predicted Creep Behaviour of Concrete. Ph.D. Thesis, University of the Witwatersrand, Johannesburg, South Africa, 1998. [Google Scholar]

- Kim, S.W.; Koh, K.T.; Song, Y.C.; Park, H.S. Estimation method of drying shrinkage and creep in concrete structures. Korea Concr. Inst. 2005, 17, 25–33. [Google Scholar]

- ACI Committee 209. Prediction of Creep, Shrinkage, and Temperature Effects in Concrete Structures; ACI Manual of Concrete Practice; American Concrete Institute: Detroit, MI, USA, 1999. [Google Scholar]

- CEB-FIP, CEB-FIP Model Code 90, Final version; Thomas Telford Ltd.: London, UK, 1993.

- British Standards Institution. Eurocode 2: Design of Concrete Structures. General Rules; Structural Fire Design; BS EN 1992-1-2; BSI: London, UK, 2005. [Google Scholar]

- Moon, J.H. Evaluation of creep models with the consideration of concrete’s strength level. J. Korea Inst. Struct. Maint. Insp. 2010, 14, 154–159. [Google Scholar]

- Mazloom, M. Estimating long-term creep and shrinkage of high-strength concrete. Cem. Concr. Compos. 2008, 30, 316–326. [Google Scholar] [CrossRef]

- Neuner, M.; Cordes, T.; Drexel, M.; Hofstetter, G. Time-dependent material properties of shotcrete: Experimental and numerical study. Materials 2017, 10, 1067. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.H.; Choi, R.J.; Kwon, H.C.; Min, K.H. An Experimental Study on Creep Characteristics of High Strength Concrete of 100 MPa. J. Korean Soc. Hazard Mitig. 2018, 18, 13–18. [Google Scholar] [CrossRef] [Green Version]

- Haranki, B. Strength, Modulus of Elasticity, Creep and Shrinkage of Concrete Used in Florida. Ph.D. Thesis, University of Florida, Gainesville, FL, USA, 2009. [Google Scholar]

- Ojha, P.N.; Singh, B.; Singh, A.; Patel, V. Comparison of creep models and experimental verification of creep coefficients for normal and high strength concrete. J. Asian Concr. Fed. 2020, 6, 24–36. [Google Scholar] [CrossRef]

- Oh, B.H.; Lee, M.G.; Yoo, S.W.; Baik, S.H. A study on the strength and drying shrinkage crack control characteristics of polypropylene fiber reinforced concrete. Korea Concr. Inst. 1996, 8, 151–161. [Google Scholar]

- Kim, W.S.; Cho, H.W.; Oh, J.K.; Yom, K.S. Measured and predicted column shortening of a tall reinforced concrete building. Korea Concr. Inst. 1999, 11, 161–170. [Google Scholar]

- Kim, G.Y.; Kim, H.S.; Miyauchi, H.; Kim, J.J.; Koo, K.M.; Moon, H.J. Influence of Spalling Resistance Fiber and Surface Drying Condition on the Shrinkage Properties of High Strength Concrete. J. Archit. Inst. Korea Struct. Constr. 2012, 28, 81–88. [Google Scholar]

- Ko, J.H.; Yoo, S.Y.; Koo, J.S.; Moon, H.J.; Kim, J.J.; Park, S.J. An experimental study to apply for high-rise construction according to various technical properties of ultra high-strength concrete. J. Archit. Inst. Korea Struct. Constr. 2012, 28, 85–92. [Google Scholar]

- Aïtcin, P.C.; Mehta, P.K. Effect of coarse aggregate characteristics on mechanical properties of high-strength concrete. Materials 1990, 87, 103–107. [Google Scholar]

- Han, C.G.; Kim, K.H. Mechanical and Durability Properties of High Strength Concrete Using Limestone Coarse Aggregate. J. Archit. Inst. Korea Struct. Constr. 2015, 31, 35–42. [Google Scholar]

- Ezeldin, A.S.; Aitcin, P.C. Effect of coarse aggregate on the behavior of normal and high-strength concretes. Cem. Concr. Aggreg. 1991, 13, 121–124. [Google Scholar]

- Han, C.G.; Yang, S.H.; Han, M.C.; Pei, C.C. Spalling prevention of high strength concrete with 60–100 MPa of the compressive strength corresponding to addition of polypropylene fibre. Arch. Inst. Korea 2008, 24, 91–98. [Google Scholar]

- Raheem, A.A.; Soyingbe, A.A.; Emenike, A.J. Effect of curing methods on density and compressive strength of concrete. Int. J. Appl. Sci. Technol. 2013, 3, 55–64. [Google Scholar]

- Price, W.H. Factors Influencing Concrete Strength. ACI J. 1951, 47, 417–432. [Google Scholar]

- Tazawa, E.; Miyazawa, S. Autogenous shrinkage of concrete and its importance in concrete technology. In Proceedings of the Fifth International RILEM Symposium, Barcelona, Spain, 6–9 September 1993; pp. 159–168. [Google Scholar]

- Tazawa, E.; Miyazawa, S. Estimation of autogenous shrinkage of concrete. Doboku Gakkai Ronbunshu 1997, 571, 211–219. [Google Scholar] [CrossRef] [Green Version]

- Zhao, Q.; Yu, J.; Geng, G.; Jiang, J.; Liu, X. Effect of fiber types on creep behavior of concrete. Constr. Build. Mater. 2016, 105, 416–422. [Google Scholar] [CrossRef]

- Tošić, N.; Aidarov, S.; de la Fuente, A. Systematic Review on the Creep of Fiber-Reinforced Concrete. Materials 2020, 13, 5098. [Google Scholar] [CrossRef]

- Troxell, G.E.; Raphael, J.M.; Davis, R.E. Long-time creep and shrinkage tests of plain and reinforced concrete. In ASTM Proceeding 1958; ASTM: West Conshohocken, PA, USA, 1958; Volume 58, pp. 1101–1120. [Google Scholar]

| W/B | Specimen ID 1 | Curing Condition | Test Item |

|---|---|---|---|

| 0.24 | 90N-US 90F-US 90F-S 90F-S(G) 4 90F-US-32% 2 | Sealed Unsealed |

|

| 0.27 | 80F-US 80F-S 80F-S(G) 4 80F-US-7d 3 | ||

| 0.29 | 70F-US 70F-S 70F-S(G) 4 |

| fck | W/B | Slump Flow (mm) | Air (%) | S/a (%) | Unit Weight 1 (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| W | C | FA | SF | S | LG | GG | |||||

| 90 | 0.24 | 650 ± 20 | 1.6 | 47.5 | 155 | 481 | 130 | 39 | 745 | 835 | 829 |

| 80 | 0.27 | 650 ± 20 | 1.7 | 48.0 | 158 | 443 | 114 | 23 | 770 | 865 | 856 |

| 70 | 0.29 | 650 ± 20 | 1.8 | 49.0 | 163 | 418 | 110 | 22 | 815 | 875 | 868 |

| Material | Physical Properties |

|---|---|

| Cement | Ordinary Portland cement (OPC, density: 3.15 g/cm3, specific surface area: 3440 cm2/g) |

| Fly ash | Density: 2.30 g/cm3, specific surface area: 3228 cm2/g |

| Silica fume | Density: 2.22 g/cm3, specific surface area: 200,000 cm2/g |

| Fine aggregate | Sea sand (size: 5 mm, density: 2.56 g/cm3, absorption: 1.01%) |

| Coarse aggregate | Crushed limestone (size: 20 mm, density: 2.69 g/cm3, absorption: 0.32%, solid volume percentage: 60.80%) Crushed granite (size: 20 mm, density: 2.67 g/cm3, absorption: 0.35%, solid volume percentage: 55.42%) |

| Superplasticizer | Polycarboxylic-based superplasticizer (specific gravity: 1.05 ± 0.05, pH: 5.0 ± 1.5) |

| Fiber Type | Length (mm) | Diameter (mm) | Aspect Ratio | Density (g/cm3) | Tensile Strength (MPa) | Extension (%) | Elastic Modulus (GPa) | Melting Point (°C) |

|---|---|---|---|---|---|---|---|---|

| Nylon | 12.49 | 23.8 | 524.8 | 1.14 | 903.2 | 18.9 | 5.0 | 219.9 |

| Polypropylene | 19.17 | 37.0 | 518.1 | 0.91 | 611.4 | 21.7 | 5.8 | 167.7 |

| fck | Constant | |

|---|---|---|

| 90 | 0.6 | |

| 80 | 0.65 | 0.25 |

| 70 | 0.8 | |

| Condition | Basic | 90N | 90F | 90F (32%) | 80F | 80F (7d) | 70F |

|---|---|---|---|---|---|---|---|

| Sealed | 2.35 | - | 0.88 | - | 0.93 | - | 1.10 |

| Unsealed | 1.11 | 1.14 | 0.95 | 1.28 | 1.80 | 1.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, E.; Kim, G.; Koo, K.; Moon, H.; Choe, G.; Suh, D.; Nam, J. Compressive Creep and Shrinkage of High-Strength Concrete Based on Limestone Coarse Aggregate Applied to High-Rise Buildings. Materials 2021, 14, 5026. https://doi.org/10.3390/ma14175026

Hwang E, Kim G, Koo K, Moon H, Choe G, Suh D, Nam J. Compressive Creep and Shrinkage of High-Strength Concrete Based on Limestone Coarse Aggregate Applied to High-Rise Buildings. Materials. 2021; 14(17):5026. https://doi.org/10.3390/ma14175026

Chicago/Turabian StyleHwang, Euichul, Gyuyong Kim, Kyungmo Koo, Hyungjae Moon, Gyeongcheol Choe, Dongkyun Suh, and Jeongsoo Nam. 2021. "Compressive Creep and Shrinkage of High-Strength Concrete Based on Limestone Coarse Aggregate Applied to High-Rise Buildings" Materials 14, no. 17: 5026. https://doi.org/10.3390/ma14175026

APA StyleHwang, E., Kim, G., Koo, K., Moon, H., Choe, G., Suh, D., & Nam, J. (2021). Compressive Creep and Shrinkage of High-Strength Concrete Based on Limestone Coarse Aggregate Applied to High-Rise Buildings. Materials, 14(17), 5026. https://doi.org/10.3390/ma14175026