Compressive Strength of Conventional Glass Ionomer Cement Modified with TiO2 Nano-Powder and Marine-Derived HAp Micro-Powder

Abstract

:1. Introduction

2. Materials and Methods

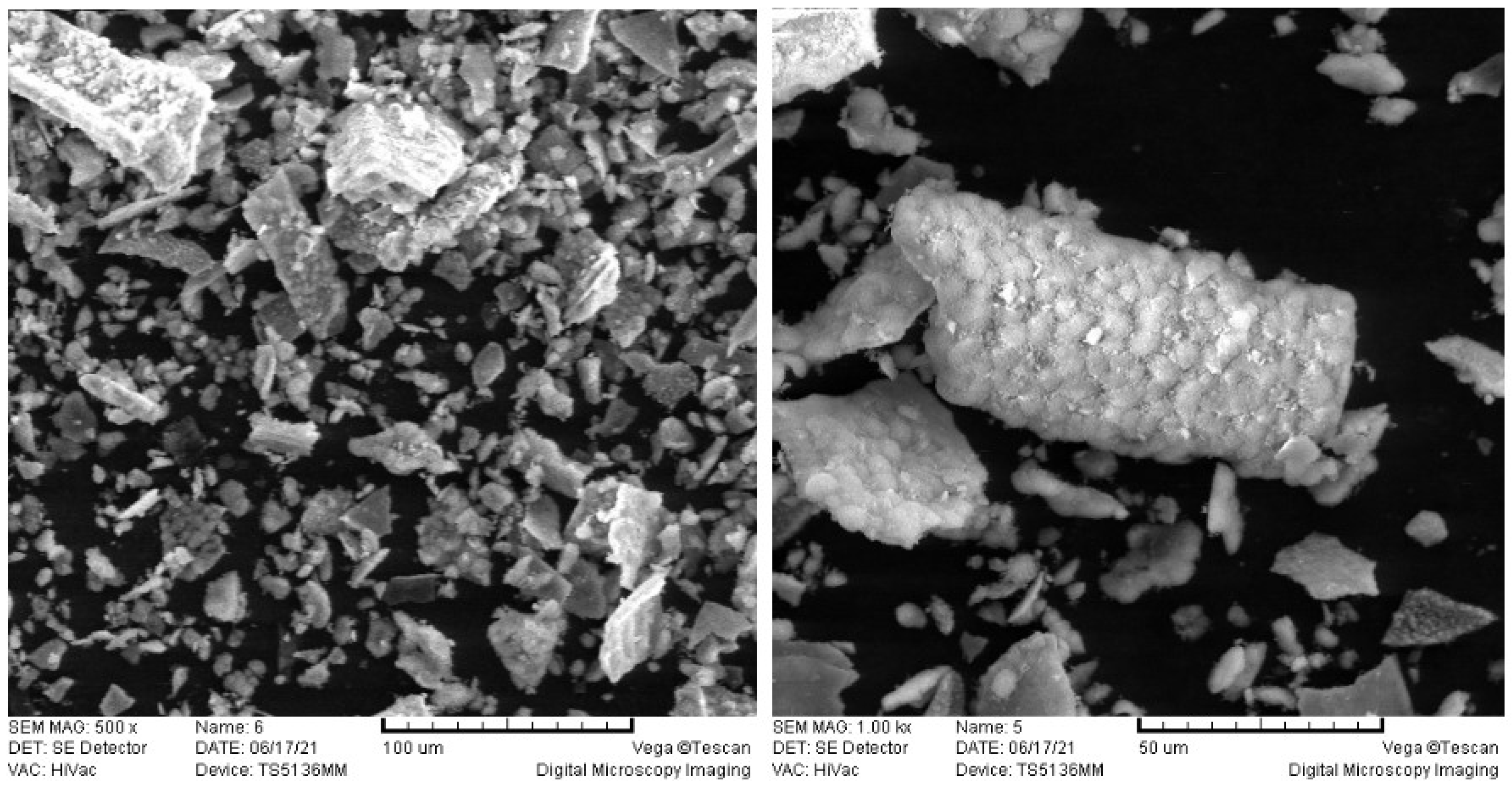

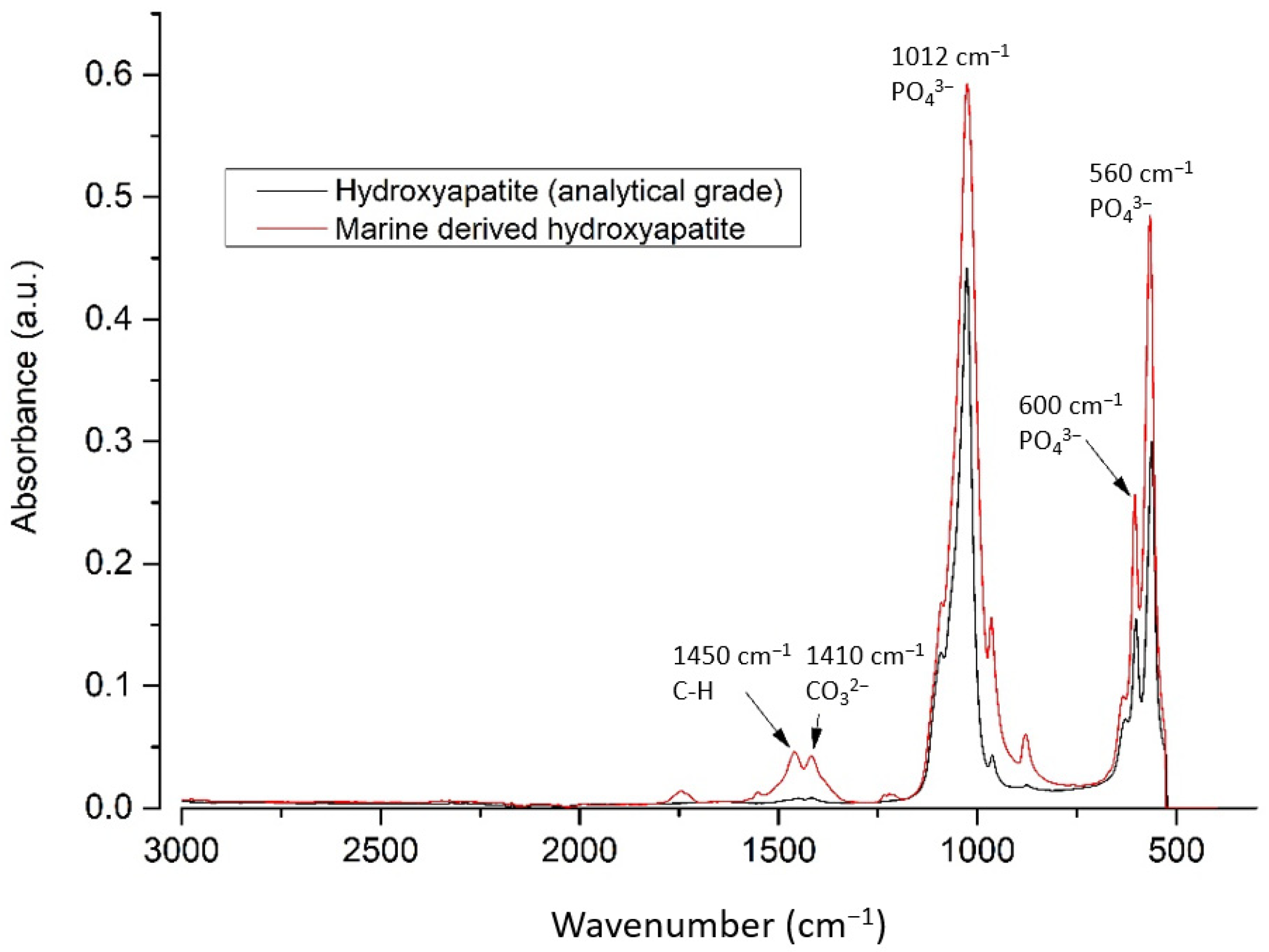

2.1. Characterization of md-HAp Using Fourier Transform Infrared (FTIR) Spectroscopy

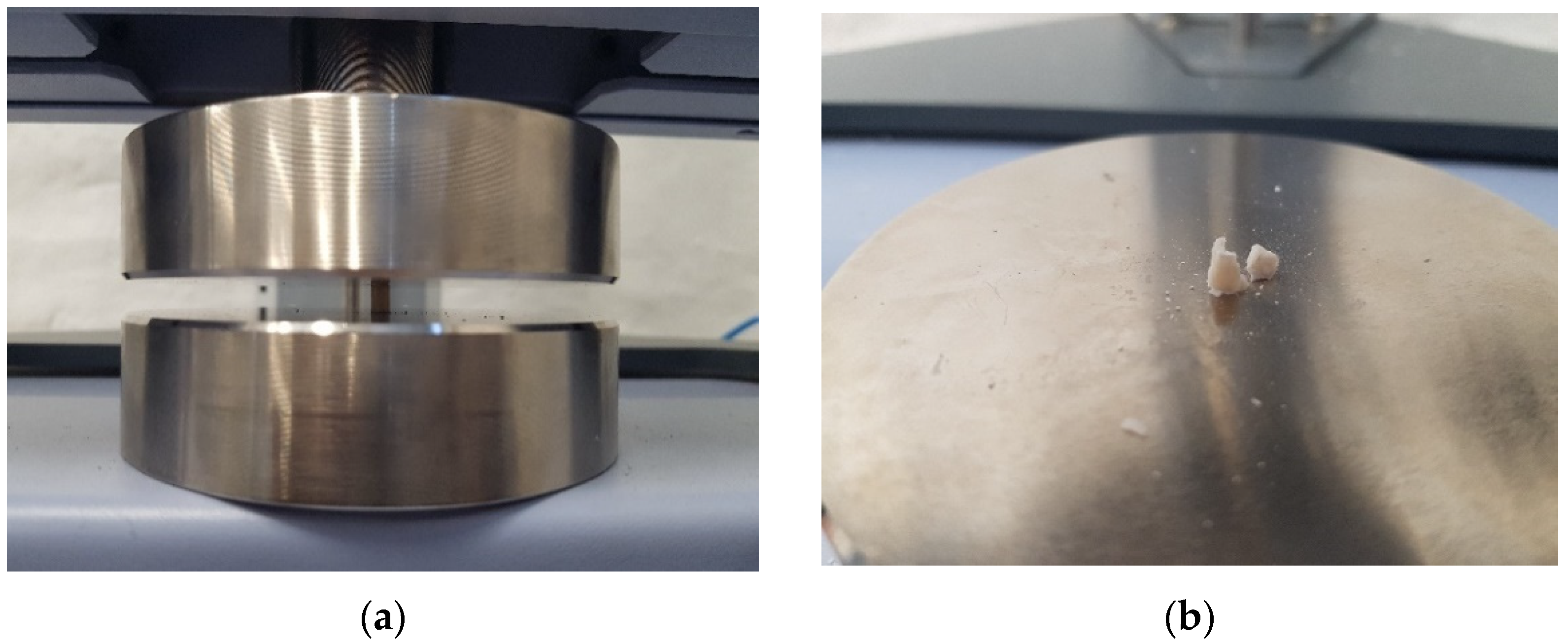

2.2. Preparation of Samples and Determining Mechanical Properties

3. Results

3.1. FTIR Analysis of md-HAp

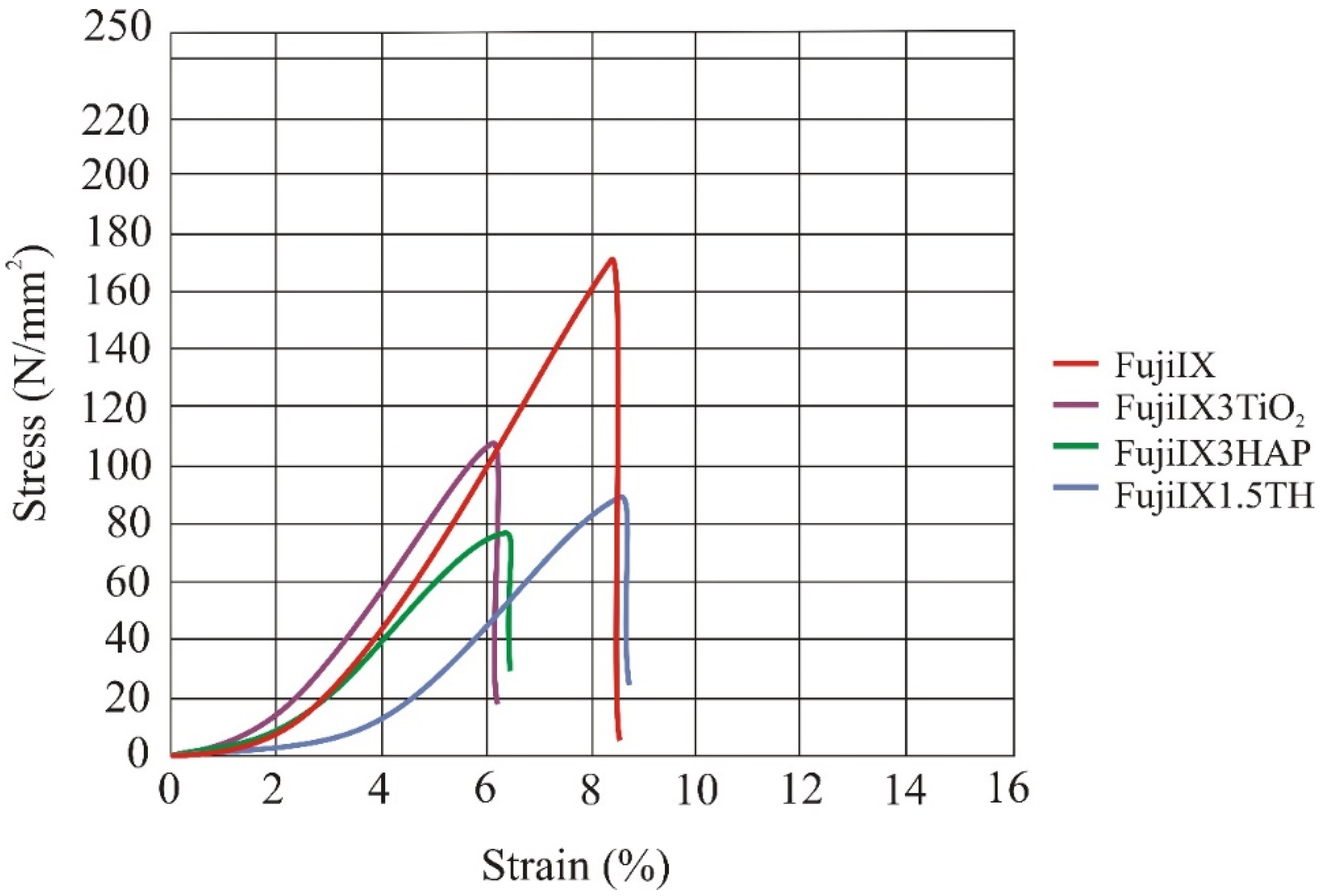

3.2. Mechanical Properties of the GIC Samples

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wilson, A.D.; Kent, B.E. A new translucent cement for dentistry. The glass ionomer cement. Br. Dent. J. 1972, 132, 133–135. [Google Scholar] [CrossRef] [PubMed]

- Nicholson, J.W. Chemistry of glass-ionomer cements: A review. Biomaterials 1998, 19, 485–494. [Google Scholar] [CrossRef]

- Fleming, G.J.P.; Farooq, A.A.; Barralet, J.E. Influence of powder/liquid mixing ratio on the performance of a restorative glassionomer dental cement. Biomaterials 2003, 24, 4173–4179. [Google Scholar] [CrossRef]

- Algera, T.J.; Kleverlaan, C.J.; Prahl-Andersen, B.; Feilzer, A.J. The Influence of Environmental Conditions on the Material Properties of Setting Glass-Ionomer Cements. Dent. Mat. 2006, 22, 852–856. [Google Scholar] [CrossRef] [PubMed]

- Andreeva, R. Usage of glass ionomer cements for reconstructions in the head region. Int. Bull. Otorhinolaryngol. 2020, 16, 38–41. [Google Scholar] [CrossRef]

- Geyer, G.; Städtgen, A.; Schwager, K.; Jonck, L. Ionomeric cement implants in the middle ear of the baboon (Papio ursinus) as a primate model. Eur. Arch. Otorhinolaryngol. 1998, 255, 402–409. [Google Scholar] [CrossRef] [PubMed]

- Brook, I.M.; Hatton, P.V. Glass-ionomers: Bioactive implant materials. Biomaterials 1998, 19, 565–571. [Google Scholar] [CrossRef]

- Espelid, I.; Tveit, A.B.; Tornes, K.H.; Alvheim, H. Clinical behaviour of glass ionomer restorations in primary teeth. J. Dent. 1999, 27, 437–442. [Google Scholar] [CrossRef]

- Šalinović, I.; Stunja, M.; Schauperl, Z.; Verzak, Ž.; Ivanišević Malčić, A.; Brzović Rajić, V. Mechanical Properties of High Viscosity Glass Ionomer and Glass Hybrid Restorative Materials. Acta Stomatol. Croat. 2019, 53, 125–131. [Google Scholar] [CrossRef] [PubMed]

- Mitra, S.B. Adhesion to dentin and physical properties of a light-cured glass-ionomer liner/base. J. Dent. Res. 1991, 70, 72–74. [Google Scholar] [CrossRef] [PubMed]

- Elsaka, S.E.; Hamouda, I.M.; Swain, M.V. Titanium dioxide nanoparticles addition to a conventional glass-ionomer restorative: Influence on physical and antibacterial properties. J. Dent. 2011, 39, 589–598. [Google Scholar] [CrossRef] [PubMed]

- Najeeb, S.; Khurshid, Z.; Zafar, M.S.; Khan, A.S.; Zohaib, S.; Martí, J.M.; Sauro, S.; Matinlinna, J.P.; Rehman, I.U. Modifications in Glass Ionomer Cements: Nano-Sized Fillers and Bioactive Nanoceramics. Int. J. Mol. Sci. 2016, 17, 1134. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bilić-Prcić, M.; Rajić, V.B.; Ivanišević, A.; Pilipović, A.; Gurgan, S.; Miletić, I. Mechanical Properties of Glass Ionomer Cements after Incorporation of Marine Derived Porous Cuttlefish Bone Hydroxyapatite. Materials 2020, 13, 3542. [Google Scholar] [CrossRef] [PubMed]

- Yap, A.U.J.; Pek, Y.S.; Kumar, R.A.; Cheang, P.; Khor, K.A. Experimental studies on a new bioactive material: HAIonomer cements. Biomaterials 2002, 23, 955–962. [Google Scholar] [CrossRef]

- Moshaverinia, A.; Ansari, S.; Moshaverinia, M.; Roohpour, N.; Darr, J.A.; Rehman, I. Effect of incorporation of hidroxyapatite and fluoroapatite nanobioceramics into conventional glass ionomer cements (GIC). Acta Biomater. 2008, 4, 432–440. [Google Scholar] [CrossRef] [PubMed]

- Cicciù, M.; Cervino, G.; Herford, A.S.; Famà, F.; Bramanti, E.; Fiorillo, L.; Lauritano, F.; Sambataro, S.; Troiano, G.; Laino, L. Facial Bone Reconstruction Using both Marine or Non-Marine Bone Substitutes: Evaluation of Current Outcomes in a Systematic Literature Review. Mar. Drugs 2018, 16, 27. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cibim, D.D.; Saito, M.T.; Giovani, P.A.; Borges, A.F.S.; Pecorari, V.G.A.; Gomes, O.P.; Lisboa-Filho, P.N.; Nociti-Junior, F.H.; Puppin-Rontani, R.M.; Kantovitz, K.R. Novel Nanotechnology of TiO2 Improves Physical-Chemical and Biological Properties of Glass Ionomer Cement. Int. J. Biomater. 2017, 2017, 7123919. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Garcia-Contreras, R.; Scougall-Vilchis, R.J.; Contreras-Bulnes, R.; Sakagami, H.; Morales-Luckie, R.A.; Nakajima, H. Mechanical, antibacterial and bond strength properties of nano-titanium-enriched glass ionomer cement. J. Appl. Oral. Sci. 2015, 23, 321–328. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Garcia-Contreras, R.; Scougall-Vilchis, R.J.; Contreras-Bulnes, R.; Kanda, Y.; Nakajima, H.; Sakagami, H. Induction of prostaglandin E2 production by TiO2 nanoparticles in human gingival fibroblast. In Vivo 2014, 28, 217–222. [Google Scholar]

- Ahn, T.K.; Lee, D.H.; Kim, T.S.; Jang, G.C.; Choi, S.; Oh, J.B.; Ye, G.; Lee, S. Modification of Titanium Implant and Titanium Dioxide for Bone Tissue Engineering. Adv. Exp. Med. Biol. 2018, 1077, 355–368. [Google Scholar] [CrossRef] [PubMed]

- Ivankovic, H.; Gallego Ferrer, G.; Tkalcec, E.; Orlic, S.; Ivankovic, M. Preparation of highly porous hydroxyapatite from cuttlefish bone. J. Mater. Sci. Mater. Med. 2009, 20, 1039–1046. [Google Scholar] [CrossRef]

- Figueiredo, M.M.; Gamelas, J.A.F.; Martins, A.G. Characterization of Bone and Bone-Based Graft Materials Using FTIR Spectroscopy, Infrared Spectroscopy—Life and Biomedical Sciences; Theophile, T., Ed.; InTech: Coimbra, Portugal, 2012; ISBN 978-953-51-0538-1. Available online: http://www.intechopen.com/books/infrared-spectroscopy-life-and-biomedical-sciences/characterization-ofbone-and-bone-based-graft-materials-using-ftir-spectroscopy (accessed on 10 June 2021).

- ISO 9917-1. Dentistry-Water-Based Cements—Part 1: Powder/Liquid Acid–Base Cements; International Organization for Standardization: Geneva, Switzerland, 2007. [Google Scholar]

- D´Alpino, P.H.; Lopes, L.G.; Pereira, J.C. Mechanical properties of dental restorative material: Relative contribution of laboratory test. J. Appl. Oral. Sci. 2003, 11, 162–167. [Google Scholar] [CrossRef] [Green Version]

- Williams, J.A.; Billington, R.W. Increase in compressive strength of glass ionomer restorative materials with respect to time: A guide to their suitability for use in posterior primary dentition. J. Oral. Rehab. 1989, 16, 475–479. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.W.; Yap, A.U.; Cheang, P.; Kumar, R. Spheroidization of glass powders for glass ionomer cements. Biomaterials 2004, 25, 4029–4035. [Google Scholar] [CrossRef] [PubMed]

- Liufu, S.; Xiao, H.; Li, Y. Adsorption of poly(acrylic acid) onto the surface of titanium dioxide and the colloidal stability of aqueous suspension. J. Colloid. Interface Sci. 2005, 281, 155–163. [Google Scholar] [CrossRef]

- Nicholson, J.W.; Sidhu, S.K.; Czarnecka, B. Enhancing the Mechanical Properties of Glass-Ionomer Dental Cements: A Review. Materials 2020, 13, 2510. [Google Scholar] [CrossRef] [PubMed]

- Imataki, R.; Shinonaga, Y.; Nishimura, T.; Yoko Abe, Y.; Arita, K. Mechanical and functional properties of a novel apatite-ionomer cement for prevention and remineralization of dental caries. Materials 2019, 12, 3998. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yoshida, Y.; Van Meerbeek, B.; Nakayama, Y.; Snauwaert, J.; Hellemans, L.; Lambrechts, P.; Vanherle, G.; Wakasa, K. Evidence of chemical bonding at biomaterial-hard tissue interfaces. J. Dent. Res. 2000, 79, 709–714. [Google Scholar] [CrossRef] [PubMed]

- Wilson, A.D.; Prosser, H.J.; Powis, D.R. Mechanism of adhesion of polyelectrolyte cements to hydroxyapatite. J. Dent. Res. 1983, 62, 590–592. [Google Scholar] [CrossRef] [PubMed]

- Arita, K.; Yamamoto, A.; Shinonaga, Y.; Harada, K.; Abe, Y.; Nakagawa, K.; Sugiyama, S. Hydroxyapatite particle characteristics influence the enhancement of the mechanical and chemical properties of conventional restorative glass ionomer cement. Dent. Mater. J. 2011, 30, 672–683. [Google Scholar] [CrossRef] [Green Version]

- Yap, A.U.; Pek, Y.S.; Cheang, P. Physico-mechanical properties of a fast-set highly viscous GIC restorative. J. Oral. Rehabil. 2003, 30, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Pereira, L.C.; Nunes, M.C.; Dibb, R.G.; Powers, J.M.; Roulet, J.F.; Navarro, M.F. Mechanical properties and bond strength of glass-ionomer cements. J. Adhes. Dent. 2002, 4, 73–80. [Google Scholar] [PubMed]

| Mechanical Property | 0% TiO2 0% HAp | 3% TiO2 | 3% HAp | 1.5% TiO2 1.5% HAp | ANOVA | ||||

|---|---|---|---|---|---|---|---|---|---|

| Mean | sd. | Mean | sd. | Mean | sd. | Mean | sd. | p | |

| Compressive strength (N/mm2) | 172.71 | (17.15) | 109.23 | (14.72) | 78.52 | (15.49) | 91.01 | (10.85) | <0.0001 a |

| Breaking strength (N/mm2) | 170.25 | (18.45) | 108.26 | (14.57) | 75.70 | (16.02) | 86.59 | (12.76) | <0.0001 a |

| Deformation at break (%) | 8.50 | (1.49) | 6.17 | (0.61) | 6.41 | (0.51) | 8.64 | (1.95) | 0.03 |

| Compressive modulus (N/mm2) | 2955.91 | (98.30) | 2343.39 | (195.60) | 1747.29 | (268.45) | 1886.06 | (267.68) | <0.0001 a |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ivanišević, A.; Rajić, V.B.; Pilipović, A.; Par, M.; Ivanković, H.; Baraba, A. Compressive Strength of Conventional Glass Ionomer Cement Modified with TiO2 Nano-Powder and Marine-Derived HAp Micro-Powder. Materials 2021, 14, 4964. https://doi.org/10.3390/ma14174964

Ivanišević A, Rajić VB, Pilipović A, Par M, Ivanković H, Baraba A. Compressive Strength of Conventional Glass Ionomer Cement Modified with TiO2 Nano-Powder and Marine-Derived HAp Micro-Powder. Materials. 2021; 14(17):4964. https://doi.org/10.3390/ma14174964

Chicago/Turabian StyleIvanišević, Ana, Valentina Brzović Rajić, Ana Pilipović, Matej Par, Hrvoje Ivanković, and Anja Baraba. 2021. "Compressive Strength of Conventional Glass Ionomer Cement Modified with TiO2 Nano-Powder and Marine-Derived HAp Micro-Powder" Materials 14, no. 17: 4964. https://doi.org/10.3390/ma14174964

APA StyleIvanišević, A., Rajić, V. B., Pilipović, A., Par, M., Ivanković, H., & Baraba, A. (2021). Compressive Strength of Conventional Glass Ionomer Cement Modified with TiO2 Nano-Powder and Marine-Derived HAp Micro-Powder. Materials, 14(17), 4964. https://doi.org/10.3390/ma14174964