Assessment of the Technological Quality of X5CRNI18-10 Steel Parts after Laser and Abrasive Water Jet Cutting Using Synthetic Index of Technological Quality

Abstract

:1. Introduction

- Easy automation of the process and its high flexibility,

- Wide range of materials that can be cut (from very soft and brittle to very hard),

- High speed of the process,

- Narrow cutting gap and heat affected zone,

- The possibility of obtaining semi-products on dimension and contactless process resulting in the lack of tool wear,

- High degree of process automation,

- The possibility of obtaining high precision cutting,

- Control of energy supply to the material to be cut,

- High process flexibility when changing the production profile, as there is no need to change cutting tools.

2. Materials and Methods

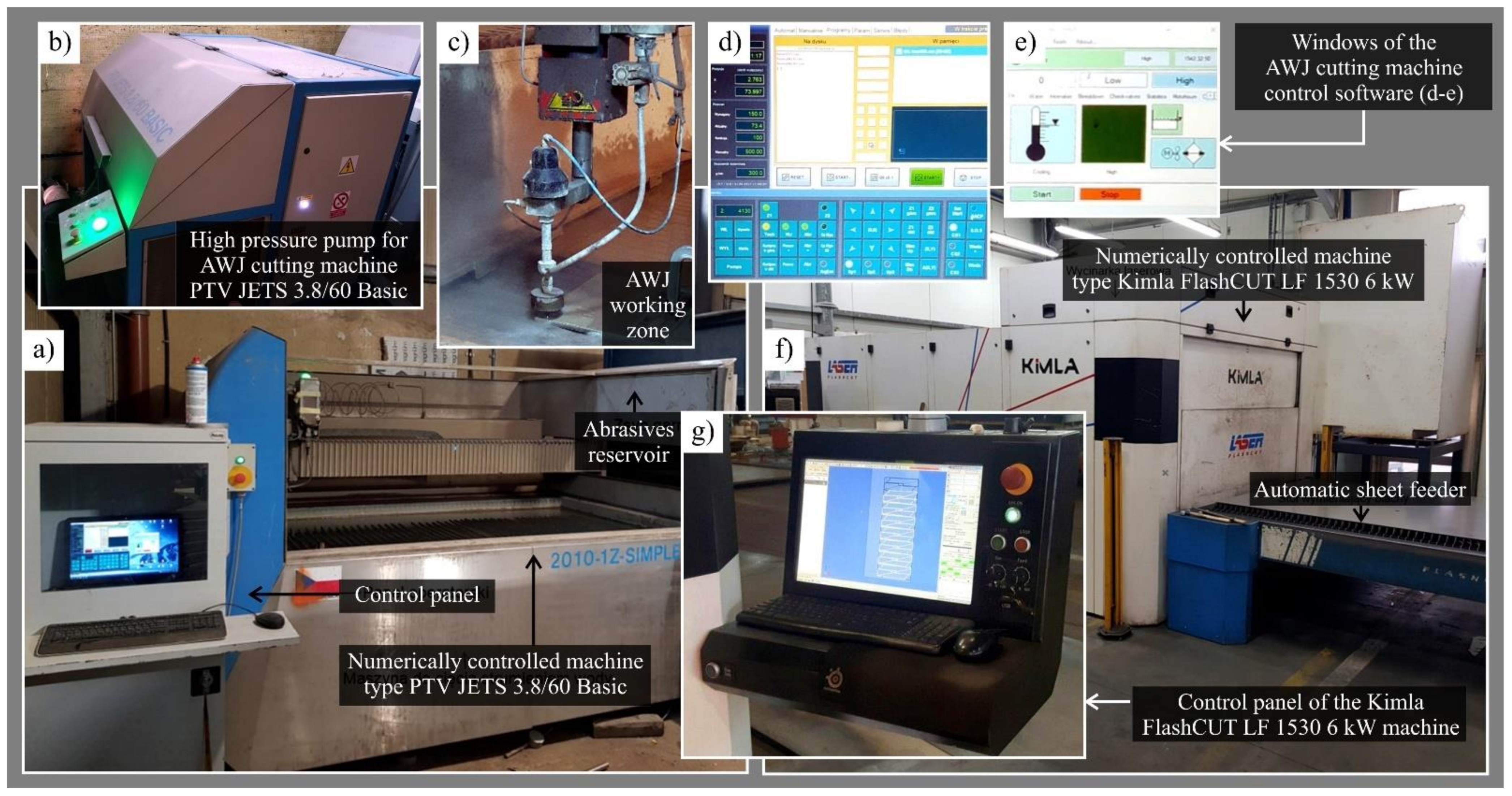

2.1. Experimental Positions and Workpiece

2.2. Measurement of Process Results

2.3. Process Parameters

2.4. Synthetic Index of Cutting Technological Quality CTQ

3. Results and Discussion

3.1. Surface Texture Analysis

- Sa–arithmetic mean deviation of the surface (μm),

- St–total height of the surface (μm).

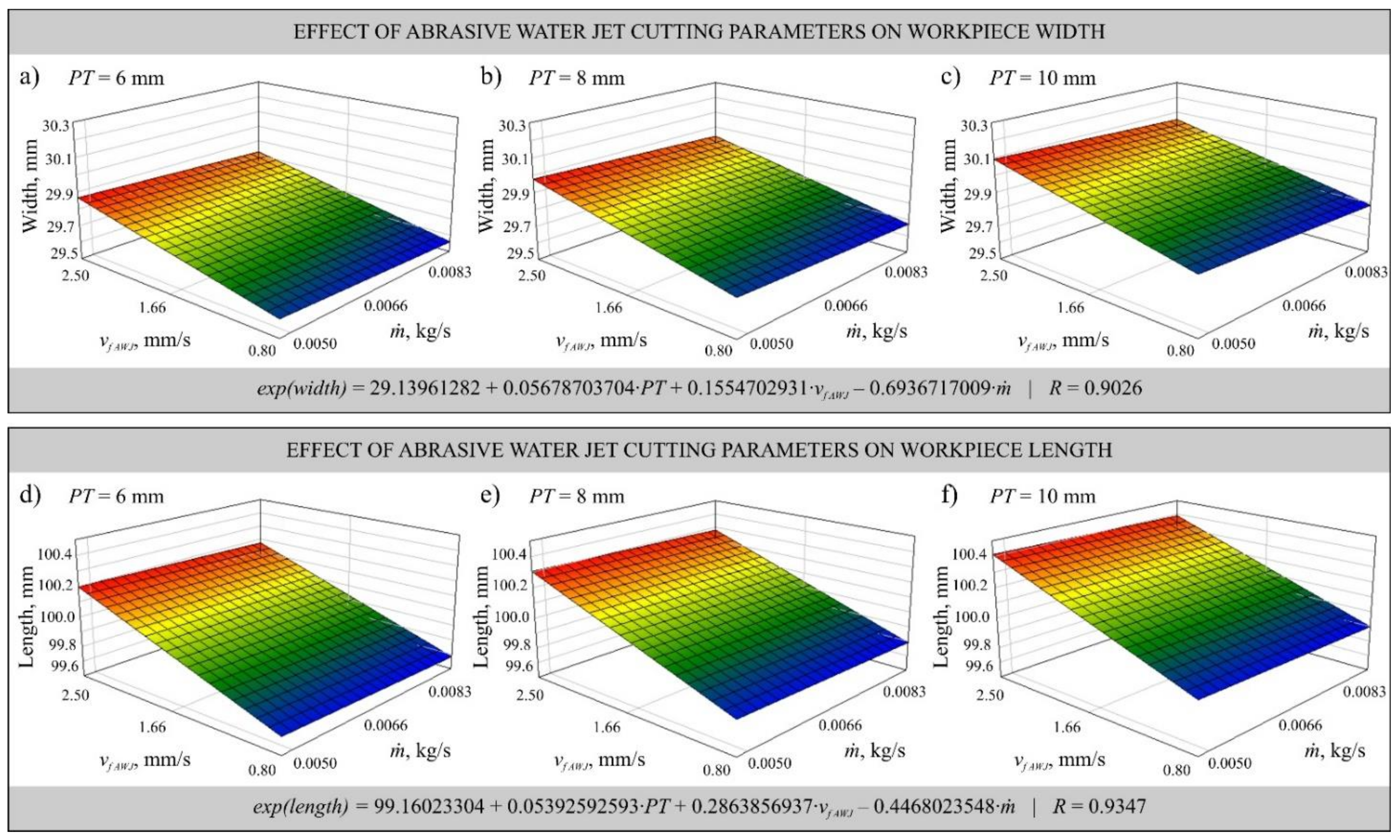

3.2. Dimensional Accuracy Analysis

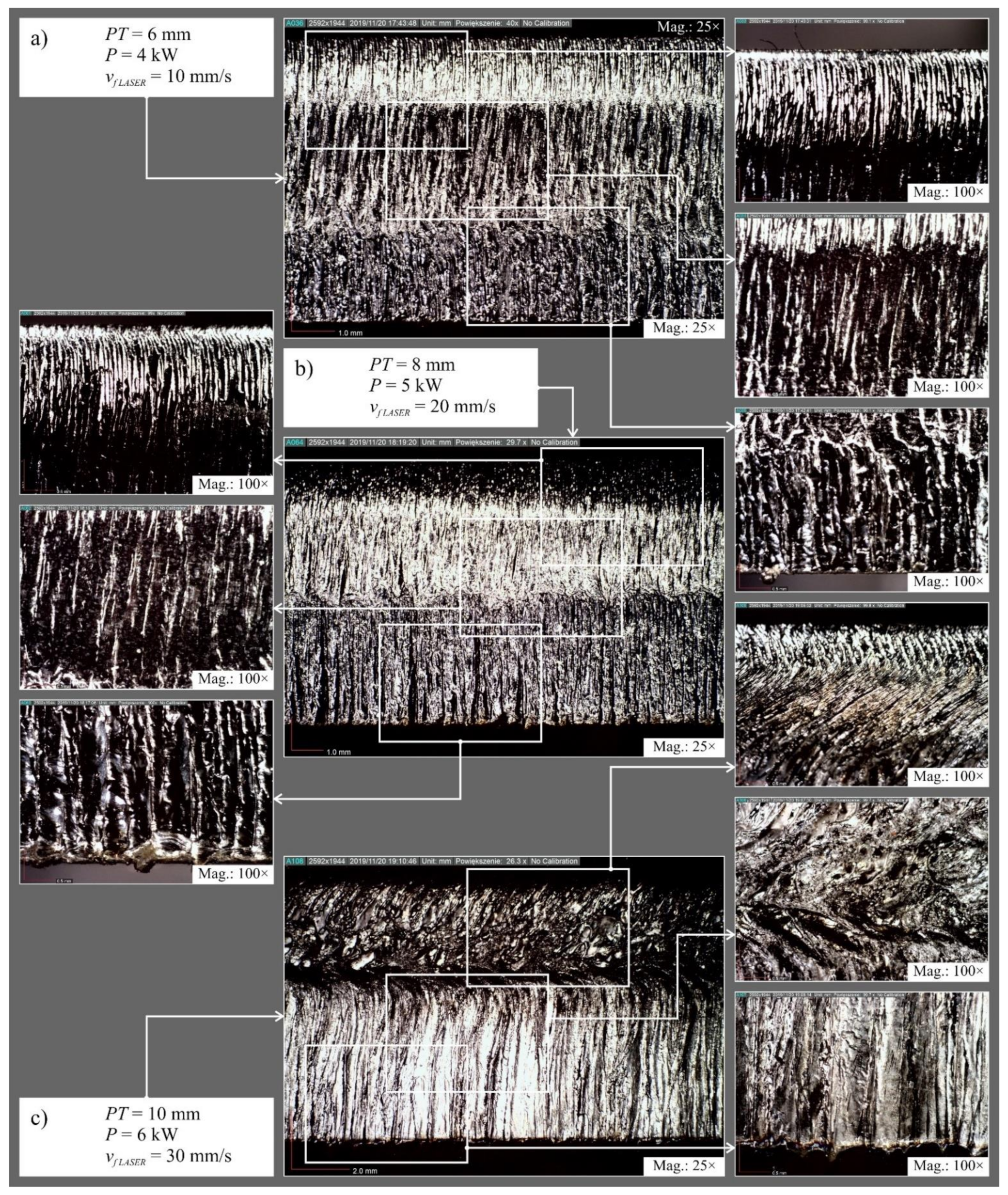

3.3. Microscopic Image Analysis

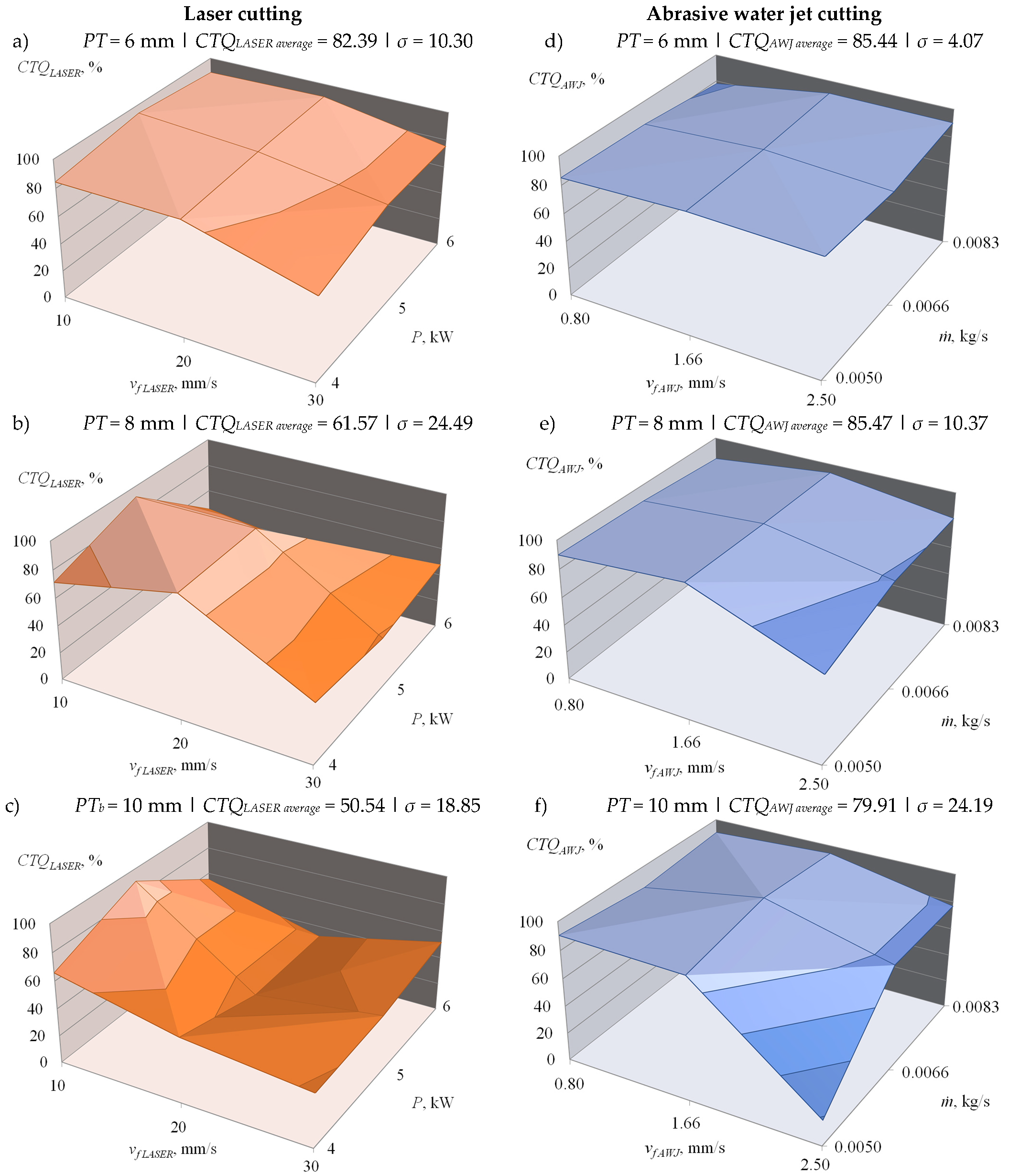

3.4. Technological Quality Analysis

- For sheet thickness PT = 6 mm: laser power P = 5 kW and working head feed rate vf LASER = 10 mm/s (CTQLASER = 93.85%),

- For sheet thickness PT = 8 mm: laser power P = 5 kW and working head feed rate vf LASER = 10 mm/s (CTQLASER = 92.31%),

- For sheet thickness PT = 10 mm: laser power P = 5 kW and working head feed rate vf LASER = 10 mm/s (CTQLASER = 90.90%).

- For sheet thickness PT = 6 mm: abrasive flow rate ṁ = 0.0083 kg/s and working head feed rate vf AWJ = 1.66 mm/s (CTQAWJ = 90.68%),

- For sheet thickness PT = 8 mm: abrasive flow rate ṁ = 0.0050 kg/s and working head feed rate vf AWJ = 1.66 mm/s (CTQAWJ = 96.30%),

- For sheet thickness PT = 10 mm: abrasive flow rate ṁ = 0.0066 kg/s and working head feed rate vf AWJ = 1.66 mm/s (CTQAWJ = 99.41%).

4. Conclusions

- The obtained results of surface texture measurements of surfaces cut by the water-abrasive jet prove that the decrease in roughness amplitude parameter values (Sa and St) is affected by decreasing the value of abrasive flow rate ṁ and increasing the cutting head feed speed vf AWJ.

- In the laser cutting process an increase in the cutting head feed rate vf LASER affects increase of parameters Sa and St of the cut surface, at the same time the effect of laser cutting power P was inconclusive in this study.

- For both analyzed cutting methods plate thickness PT significantly affects the quality of the surface after cutting–at the smallest plate thickness PT = 6 mm in the examined range, no significant traces of the effect of concentrated energy flux were observed, which became apparent when cutting plate thickness PT = 8 and 10 mm.

- In the laser cutting process the dimensional accuracy of the cut workpieces affects mostly the head feed rate vf LASER (high feed rate causes deviations of up to 0.2 mm) and plate thickness (the thicker the plate, the larger the positive deviation).

- In abrasive water jet cutting trends are similar, however, the dimensional deviation occurring is larger and amounts even to 0.3 mm. Additionally it was noted that increasing the head feed rate vf AWJ causes deviation from perpendicularity of the surface formed. No significant effect of abrasive flow rate ṁ on the dimensional deviation was observed.

- Observation of microscopic images showed that increasing the plate thickness from PT = 6 to 8 mm and then to 10 mm resulted in an increase in the number of surface deformations in both cutting methods.

- The surface after laser cutting was characterized by significantly higher deformation intensity (with visible division into three zones of the cut surface) compared to the surface after abrasive water jet cutting.

- The analysis showed that the most favorable (highest) CTQ value of the entire set of analyzed results (CTQAWJ = 99.41%) was obtained for the abrasive water jet cutting process with sheet thickness PT = 10 mm, abrasive flow rate ṁ = 0.0066 kg/s and working head feed rate vf AWJ = 1.66 mm/s.

- The most favorable value of CTQ index for laser cutting process (CTQLASER = 93.85%) was obtained for sheet thickness PT = 6 mm, laser power P = 5 kW and working head feed rate vf LASER = 10 mm/s.

- The relative (percentage) form of the CTQ index means that it can be used to compare the results of a cutting process conducted using different methods and under different conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Nomenclature

| AWJ | Abrasive water jet |

| CTQ | Cutting technological quality, – |

| CTQLASER | Laser cutting technological quality, – |

| CTQAWJ | Abrasive water jet cutting technological quality, – |

| DI | Deformation intensity, – |

| DIn | Normalized deformation intensity, – |

| ICZ | Identification of cutting zones, – |

| ICZn | Normalized identification of cutting zones, – |

| l | Workpiece length, mm |

| LD | Length deviation, mm |

| LDn | Normalized length deviation, mm |

| ṁ | Abrasive flow rate, kg/s |

| P | Laser power, kW |

| PT | Plate thickness, mm |

| R | Multivariate correlation coefficient of mathematical model, – |

| Sa | Arithmetic mean deviation of the surface, μm |

| San | Normalized arithmetic mean deviation of the surface, μm |

| St | Total height of the surface, μm |

| Stn | Normalized total height of the surface, μm |

| vf LASER | Laser head feed rate, mm/s |

| vf AWJ | Abrasive water jet head feed rate, mm/s |

| w | Workpiece width, mm |

| WD | Width deviation, mm |

| WDn | Normalized width deviation, mm |

References

- Rao, P.N. Manufacturing Technology: Metal Cutting and Machine Tools; Tata McGraw-Hill Education: Kala Nilayam, India, 2013. [Google Scholar]

- Khan, M.A.; Soni, H.; Mashinini, P.M.; Uthayakumar, U. Abrasive water jet cutting process form machining metals and composites for engineering applications: A review. Eng. Res. Express 2021, 3, 022004. [Google Scholar] [CrossRef]

- Llanto, J.; Tolouei-Rad, M.; Vafadar, A.; Aamir, M. Recent Progress Trend on Abrasive Waterjet Cutting of Metallic Materials: A Review. Appl. Sci. 2021, 11, 3344. [Google Scholar] [CrossRef]

- Kuttan, A.A.; Rajesh, R.; Anand, M.D. Abrasive water jet machining techniques and parameters: A state of the art, open issue challenges and research directions. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 1–14. [Google Scholar] [CrossRef]

- Klichová, D. Advances in Water Jetting: Selected Papers from the International Conference on Water Jet 2019—Research, Development, Applications; Springer Nature: Basingstoke, UK, 2020. [Google Scholar]

- Zhang, S.; Ji, L.; Wu, Y.; Chen, M.; Zhou, W. Exploring a new method to obtain the 3D abrasive water jet profile. Int. J. Adv. Manuf. Technol. 2020, 107, 4797–4809. [Google Scholar] [CrossRef]

- Radu, M.C.; Schnakovszky, C.; Herghelegiu, E.; Tampu, N.C.; Zichil, V. Comparative analysis of the processing accuracy of high strength metal sheets by AWJ, laser and plasma. IOP Conf. Ser. Mater. Sci. Eng. 2016, 145, 022034. [Google Scholar] [CrossRef] [Green Version]

- Radu, C.; Herghelegiu, E.; Schnakovszky, C. Comparative study on the effects of three unconventional cutting technologies on cut surface quality. Indian J. Eng. Mater. Sci. 2015, 22, 127–132. [Google Scholar]

- Tezuka, M.; Nakamura, Y.; Iwai, H.; Sano, K.; Fukui, Y. The development of thermal and mechanical cutting technology for the dismantlement of the internal core of Fukushima Daiichi NPS. J. Nucl. Sci. Technol. 2014, 51, 1054–1058. [Google Scholar] [CrossRef] [Green Version]

- Dahil, L.; Dahil, I.; Karabulut, A. Comparison of advanced cutting techniques on hardox 500 steel material and the effect of structural properties of the material. Metalurgija 2014, 53, 291–294. [Google Scholar]

- Akkurt, A. Experimental investigation of the surface properties obtained by cutting brass-353 (α + β) with an abrasive water jet and other cutting methods. Mater. Tehnol. 2014, 48, 725–734. [Google Scholar]

- Peržel, V.; Hloch, S.; Tozan, H.; Yagimli, M.; Hreha, P. Comparative analysis of abrasive waterjet (AWJ) technology with selected unconventional manufacturing processes. Int. J. Phys. Sci. 2011, 6, 5587–5593. [Google Scholar]

- Kechagias, J.; Petropoulos, G.; Vaxevanidis, N. Application of Taguchi design for quality characterization of abrasive water jet machining of TRIP sheet steels. Int. J. Adv. Manuf. Technol. 2011, 62, 635–643. [Google Scholar] [CrossRef]

- Momber, A.W.; Kovacevic, R. Principles of Abrasive Water Jet Machining; Springer Science and Business Media LLC: Berlin, Germany, 1998. [Google Scholar]

- Sutowska, M.; Kapłonek, W.; Pimenov, D.Y.; Gupta, M.K.; Mia, M.; Sharma, S. Influence of Variable Radius of Cutting Head Trajectory on Quality of Cutting Kerf in the Abrasive Water Jet Process for Soda–Lime Glass. Materials 2020, 13, 4277. [Google Scholar] [CrossRef]

- Zheng, H.Y.; Han, Z.Z.; Chen, Z.D.; Chen, W.L.; Yeo, S. Quality and Cost Comparisons between Laser and Waterjet Cutting. J. Mater. Process. Technol. 1996, 62, 294–298. [Google Scholar] [CrossRef]

- Ninikas, K.; Kechagias, J.; Salonitis, K. The Impact of Process Parameters on Surface Roughness and Dimensional Accuracy during CO2 Laser Cutting of PMMA Thin Sheets. J. Manuf. Mater. Process. 2021, 5, 74. [Google Scholar] [CrossRef]

- Kudelski, R.; Zagórski, K.; Cieślik, J. Dependency of the technological quality of elements made from multi layered materials on their shape in the water jet machining method. In Proceedings of the 3rd National Conference on Current and Emerging Process Technologies—Concept 2020; AIP Publishing: Melville, NY, USA, 2020; Volume 2239, p. 020024. [Google Scholar]

- Vartanov, M.V.; Vlasov, A.S. Technological quality maintenance of finishing robotic machining in mechanical engineering. IOP Conf. Series: Mater. Sci. Eng. 2020, 971, 042084. [Google Scholar] [CrossRef]

- Kmec, J.; Gombár, M.; Harničárová, M.; Valíček, J.; Kušnerová, M.; Kříž, J.; Kadnár, M.; Karková, M.; Vagaská, A. The Predictive Model of Surface Texture Generated by Abrasive Water Jet for Austenitic Steels. Appl. Sci. 2020, 10, 3159. [Google Scholar] [CrossRef]

- Bringas, J.E. Handbook of Comparative World Steel Standards; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- Kazantseva, N.V.; Stepanova, N.N.; Rigmant, M.B. Superalloys: Analysis and Control of Failure Process; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Romanowski, M.; Nadolny, K. Surface texture analysis of the X5CrNi18-10 steel after cutting with abrasive water jet and photon beam (laser). J. Mech. Energy Eng. 2021, 4, 365–374. [Google Scholar] [CrossRef]

- Product Website. Available online: https://kimla.pl/en/machines/laser-fiber-cutter (accessed on 21 July 2021).

- Product Website. Available online: https://ptv.com.pl/produkty/wysokocisnieniowe-pompy/ptv-jets-38-60-cbasic/ (accessed on 21 July 2021).

- Kapłonek, W.; Nadolny, K.; Valíček, J.; Zeleňák, M. A non-contact laser method based on the imaging and analysis of scattered light used for assessment of the surface imperfections. Meas. Autom. Monit. 2012, 58, 554–558. [Google Scholar]

- Product Website. Available online: https://www.dino-lite.eu/index.php/en/component/k2/item/3088-am7915mzt (accessed on 21 July 2021).

| Cutting Process | Variable Input Quantities | Constant Input Quantities | Output Quantities |

|---|---|---|---|

| Laser cutting | Plate thickness PT in mm–is described as the thickness of a flat or coiled metallurgical product, much smaller than its length and width, the range used in testing is: 6, 8, 10 mm. Laser power P in kW–described as output power, normalized; it is a scalar physical quantity that reports the work done over time, the range used in the study is 4.0, 5.0, 6.0 kW. Cutting head feed rate vf LASER in mm/s–this is the feed rate of the cutting head relative to the workpiece per unit time, the range used in the study is 10, 20, 30 mm/s. | Cut material: X5CrNi18-10 steel. Constant distance of the laser lens from the plate to be cut of 1.5 mm. Lens diameter: 19.05 mm. The lens was positioned at the same consistent right angle to the cut plate throughout the cutting process. | Measurement results of overall dimensions (length l and width w) of machined workpieces. Results of surface texture parameter measurements after cutting using the following parameters:

|

| Abrasive water jet cutting | Plate thickness PT in mm–the range used in testing is: 6, 8, 10 mm. Cutting head feed rate vf AWJ in mm/min–the range used in testing is: 0.80, 1.66, 2.50 mm/s. The process was controlled by adjusting the abrasive flow rate ṁ in kg/s–the range used in testing is: 0.005, 0.0066, 0.0083 kg/s. | Cut material: X5CrNi18-10 steel. Abrasive material: amaldine garnet mesh 80 with a nominal abrasive grit size of 0.18 mm in the range (106–300 µm). Fixed nozzle distance of 2 mm from the plate to be cut. Nozzle diameter: 0.25 mm. The nozzle was set at the same constant right angle to the plate throughout the cutting process. Water was supplied directly from the water supply system with a constant pressure of 0.3 MPa. |

| Laser Cutting | Abrasive Water Jet Cutting | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Laser Power P, kW | Laser Head Feed Rate vf LASER, mm/s | Sa for PT = 6 mm, µm | Sa for PT = 8 mm, µm | Sa for PT = 10 mm, µm | AWJ Head Feed Rate vf AWJ, mm/s | Abrasive Flow Rate ṁ, kg/s | Sa for PT = 6 mm, µm | Sa for PT = 8 mm, µm | Sa for PT = 10 mm, µm |

| 4.0 | 10 | 13.9 | 31.1 | 49.8 | 0.80 | 0.0050 | 9.22 | 10.0 | 7.49 |

| 4.0 | 20 | 14.7 | 25.5 | 51.0 | 0.80 | 0.0066 | 10.6 | 6.9 | 5.62 |

| 4.0 | 30 | 59.5 | 50.5 | 109.0 | 0.80 | 0.0083 | 7.9 | 6.33 | 5.56 |

| 5.0 | 10 | 14.1 | 25.4 | 19.7 | 1.66 | 0.0050 | 23.7 | 11.6 | 13.8 |

| 5.0 | 20 | 15.3 | 19.8 | 95.5 | 1.66 | 0.0066 | 13.0 | 8.86 | 7.15 |

| 5.0 | 30 | 16.7 | 88.1 | 88.5 | 1.66 | 0.0083 | 14.0 | 12.2 | 12.0 |

| 6.0 | 10 | 16.8 | 82.3 | 20.9 | 2.50 | 0.0050 | 28.7 | 25.7 | 46.3 |

| 6.0 | 20 | 14.6 | 88.2 | 84.5 | 2.50 | 0.0066 | 26.2 | 19.9 | 17.3 |

| 6.0 | 30 | 14.7 | 85.4 | 101.0 | 2.50 | 0.0083 | 16.5 | 14.6 | 15.4 |

| Laser Cutting | Abrasive Water Jet Cutting | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Laser Power P, kW | Laser Head Feed Rate vf AWJ, mm/s | St for PT = 6 mm, µm | St for PT = 8 mm, µm | St for PT = 10 mm, µm | AWJ Head Feed Rate vf AWJ, mm/s | Abrasive Flow Rate ṁ, kg/s | St for PT = 6 mm, µm | St for PT = 8 mm, µm | St for PT = 10 mm, µm |

| 4.0 | 10 | 106 | 151 | 453 | 0.80 | 0.0050 | 90.9 | 63.6 | 80.9 |

| 4.0 | 20 | 113 | 157 | 578 | 0.80 | 0.0066 | 84.1 | 46.7 | 39.6 |

| 4.0 | 30 | 619 | 568 | 680 | 0.80 | 0.0083 | 51.4 | 53.1 | 36.9 |

| 5.0 | 10 | 96 | 139 | 139 | 1.66 | 0.0050 | 110.0 | 87.7 | 79.2 |

| 5.0 | 20 | 108 | 126 | 767 | 1.66 | 0.0066 | 93.2 | 61.7 | 54.5 |

| 5.0 | 30 | 106 | 524 | 625 | 1.66 | 0.0083 | 79.2 | 79.2 | 91.2 |

| 6.0 | 10 | 138 | 639 | 151 | 2.50 | 0.0050 | 174.0 | 211.0 | 255.0 |

| 6.0 | 20 | 95 | 501 | 682 | 2.50 | 0.0066 | 151.0 | 143.0 | 120.0 |

| 6.0 | 30 | 126 | 523 | 643 | 2.50 | 0.0083 | 104.0 | 99.0 | 99.0 |

| Plate Thickness PT, mm | Laser Head Feed Rate vf LASER, mm/s | Laser Power P, kW | Sa, µm | San | St, µm | Stn | Average Dimensional Deviation | DI | DIn | ICZ | ICZn | CTQLASER, % | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LD, mm | LDn | WD, mm | WDn | ||||||||||||

| 6 | 10 | 4.0 | 13.90 | 0.128 | 106.00 | 0.138 | −0.005 | −0.012 | −0.086 | −0.239 | ++ | 0.67 | ++ | 0.67 | 84.35 |

| 5.0 | 14.10 | 0.129 | 96.00 | 0.125 | −0.181 | −0.437 | −0.049 | −0.136 | + | 0.33 | + | 0.33 | 93.85 | ||

| 6.0 | 16.80 | 0.154 | 138.00 | 0.180 | −0.138 | −0.333 | −0.210 | −0.583 | + | 0.33 | + | 0.33 | 88.97 | ||

| 20 | 4.0 | 14.70 | 0.135 | 113.0 | 0.147 | −0.187 | −0.452 | −0.004 | −0.011 | ++ | 0.67 | ++ | 0.67 | 84.21 | |

| 5.0 | 15.30 | 0.140 | 108.0 | 0.141 | −0.031 | −0.075 | −0.018 | −0.050 | +++ | 1.00 | + | 0.33 | 88.22 | ||

| 6.0 | 14.60 | 0.134 | 95.0 | 0.124 | −0.166 | −0.401 | −0.041 | −0.114 | + | 0.33 | ++ | 0.67 | 90.55 | ||

| 30 | 4.0 | 59.50 | 0.546 | 619.0 | 0.807 | 0.173 | 0.418 | 0.348 | 0.967 | +++ | 1.00 | + | 0.33 | 60.84 | |

| 5.0 | 16.70 | 0.153 | 106.0 | 0.138 | −0.116 | −0.280 | −0.069 | −0.192 | ++ | 0.67 | +++ | 1.00 | 75.17 | ||

| 6.0 | 14.70 | 0.135 | 126.0 | 0.164 | −0.077 | −0.186 | −0.093 | −0.258 | ++ | 0.67 | +++ | 1.00 | 75.33 | ||

| 8 | 10 | 4.0 | 31.10 | 0.285 | 151.0 | 0.197 | −0.144 | −0.348 | −0.141 | −0.392 | +++ | 1.00 | ++ | 0.67 | 71.25 |

| 5.0 | 25.40 | 0.233 | 139.0 | 0.181 | −0.114 | −0.275 | −0.104 | −0.289 | + | 0.33 | + | 0.33 | 92.31 | ||

| 6.0 | 82.30 | 0.755 | 639.0 | 0.833 | 0.056 | 0.135 | 0.040 | 0.111 | +++ | 1.00 | +++ | 1.00 | 45.20 | ||

| 20 | 4.0 | 25.50 | 0.234 | 157.0 | 0.205 | −0.182 | −0.440 | −0.128 | −0.356 | + | 0.33 | + | 0.33 | 89.55 | |

| 5.0 | 19.80 | 0.182 | 126.0 | 0.164 | −0.146 | −0.353 | −0.113 | −0.314 | + | 0.33 | + | 0.33 | 91.68 | ||

| 6.0 | 88.20 | 0.809 | 501.0 | 0.653 | 0.235 | 0.568 | 0.288 | 0.800 | +++ | 1.00 | +++ | 1.00 | 33.90 | ||

| 30 | 4.0 | 50.50 | 0.463 | 568.0 | 0.741 | 0.414 | 1.000 | 0.239 | 0.664 | +++ | 1.00 | ++ | 0.67 | 44.10 | |

| 5.0 | 88.10 | 0.808 | 524.0 | 0.683 | 0.279 | 0.674 | 0.336 | 0.933 | +++ | 1.00 | ++ | 0.67 | 38.30 | ||

| 6.0 | 85.40 | 0.783 | 523.0 | 0.682 | 0.248 | 0.599 | 0.217 | 0.603 | +++ | 1.00 | ++ | 0.67 | 47.82 | ||

| 10 | 10 | 4.0 | 49.80 | 0.457 | 453.0 | 0.591 | 0.176 | 0.425 | 0.360 | 1.000 | + | 0.33 | +++ | 1.00 | 65.84 |

| 5.0 | 19.70 | 0.181 | 139.0 | 0.181 | 0.069 | 0.167 | 0.041 | 0.114 | ++ | 0.67 | + | 0.33 | 90.90 | ||

| 6.0 | 20.90 | 0.192 | 151.0 | 0.197 | −0.210 | −0.507 | −0.219 | −0.608 | +++ | 1.00 | +++ | 1.00 | 55.13 | ||

| 20 | 4.0 | 51.00 | 0.468 | 578.0 | 0.754 | 0.120 | 0.290 | 0.273 | 0.758 | +++ | 1.00 | +++ | 1.00 | 47.59 | |

| 5.0 | 95.50 | 0.876 | 767.0 | 1.000 | 0.113 | 0.273 | 0.278 | 0.772 | +++ | 1.00 | +++ | 1.00 | 30.44 | ||

| 6.0 | 84.50 | 0.775 | 682.0 | 0.889 | 0.175 | 0.423 | 0.296 | 0.822 | +++ | 1.00 | +++ | 1.00 | 32.10 | ||

| 30 | 4.0 | 109.00 | 1.000 | 680.0 | 0.887 | 0.167 | 0.403 | 0.244 | 0.678 | +++ | 1.00 | ++ | 0.67 | 39.01 | |

| 5.0 | 88.50 | 0.812 | 625.0 | 0.815 | 0.205 | 0.495 | 0.293 | 0.814 | +++ | 1.00 | ++ | 0.67 | 42.18 | ||

| 6.0 | 101.00 | 0.927 | 643.0 | 0.838 | 0.025 | 0.060 | 0.022 | 0.061 | +++ | 1.00 | ++ | 0.67 | 51.65 | ||

| Plate Thickness PT, mm | AWJ Head Feed Rate vf AWJ, mm/s | Abrasive Flow Rate ṁ, kg/s | Sa, µm | San | St, µm | Stn | Average Dimensional Deviation | DI | DIn | ICZ | ICZn | CTQAWJ, % | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LD, mm | LDn | WD, mm | WDn | ||||||||||||

| 6 | 0.8 | 0.0050 | 9.22 | 0.199 | 90.9 | 0.356 | −0.191 | −0.380 | −0.294 | −0.698 | + | 0.33 | + | 0.33 | 85.16 |

| 0.0066 | 10.60 | 0.229 | 84.1 | 0.330 | −0.207 | −0.412 | −0.321 | −0.762 | + | 0.33 | + | 0.33 | 83.39 | ||

| 0.0083 | 7.90 | 0.171 | 51.4 | 0.202 | −0.298 | −0.592 | −0.372 | −0.884 | + | 0.33 | + | 0.33 | 77.78 | ||

| 1.66 | 0.0050 | 23.70 | 0.512 | 110.0 | 0.431 | −0.027 | −0.054 | −0.374 | −0.888 | + | 0.33 | + | 0.33 | 87.41 | |

| 0.0066 | 13.00 | 0.281 | 93.2 | 0.365 | −0.081 | −0.161 | −0.421 | −1.000 | + | 0.33 | + | 0.33 | 87.58 | ||

| 0.0083 | 14.00 | 0.302 | 79.2 | 0.311 | −0.045 | −0.089 | −0.363 | −0.862 | + | 0.33 | + | 0.33 | 90.68 | ||

| 2.5 | 0.0050 | 28.70 | 0.620 | 174.0 | 0.682 | 0.145 | 0.288 | −0.106 | −0.252 | + | 0.33 | + | 0.33 | 84.69 | |

| 0.0066 | 26.20 | 0.566 | 151.0 | 0.592 | 0.020 | 0.040 | −0.216 | −0.513 | ++ | 0.67 | + | 0.33 | 82.14 | ||

| 0.0083 | 16.50 | 0.356 | 104.0 | 0.408 | 0.077 | 0.153 | −0.193 | −0.458 | ++ | 0.67 | + | 0.33 | 90.12 | ||

| 8 | 0.8 | 0.0050 | 10.00 | 0.216 | 63.6 | 0.249 | −0.103 | −0.205 | −0.291 | −0.691 | + | 0.33 | + | 0.33 | 89.85 |

| 0.0066 | 6.90 | 0.149 | 46.7 | 0.183 | −0.177 | −0.352 | −0.257 | −0.610 | + | 0.33 | + | 0.33 | 88.30 | ||

| 0.0083 | 6.33 | 0.137 | 53.1 | 0.208 | −0.219 | −0.435 | −0.331 | −0.786 | + | 0.33 | + | 0.33 | 84.02 | ||

| 1.66 | 0.0050 | 11.60 | 0.251 | 87.7 | 0.344 | 0.170 | 0.338 | −0.105 | −0.249 | + | 0.33 | + | 0.33 | 96.30 | |

| 0.0066 | 8.86 | 0.191 | 61.7 | 0.242 | −0.021 | −0.042 | −0.153 | −0.363 | + | 0.33 | + | 0.33 | 94.32 | ||

| 0.0083 | 12.20 | 0.263 | 79.2 | 0.311 | −0.004 | −0.008 | −0.157 | −0.373 | + | 0.33 | + | 0.33 | 93.54 | ||

| 2.5 | 0.005 | 25.70 | 0.555 | 211.0 | 0.827 | 0.491 | 0.976 | 0.087 | 0.207 | ++ | 0.67 | ++ | 0.67 | 62.99 | |

| 0.0066 | 19.90 | 0.430 | 143.0 | 0.561 | 0.339 | 0.674 | −0.028 | −0.067 | ++ | 0.67 | ++ | 0.67 | 78.51 | ||

| 0.0083 | 14.60 | 0.315 | 99.0 | 0.388 | 0.234 | 0.465 | −0.012 | −0.029 | ++ | 0.67 | ++ | 0.67 | 81.41 | ||

| 10 | 0.8 | 0.0050 | 7.49 | 0.162 | 80.9 | 0.317 | −0.116 | −0.231 | −0.228 | −0.542 | + | 0.33 | + | 0.33 | 90.49 |

| 0.0066 | 5.62 | 0.121 | 39.6 | 0.155 | −0.208 | −0.414 | −0.228 | −0.542 | ++ | 0.67 | + | 0.33 | 84.52 | ||

| 0.0083 | 5.56 | 0.120 | 36.9 | 0.145 | −0.161 | −0.320 | −0.227 | −0.539 | + | 0.33 | + | 0.33 | 90.04 | ||

| 1.66 | 0.0050 | 13.80 | 0.298 | 79.2 | 0.311 | 0.195 | 0.388 | 0.031 | 0.074 | ++ | 0.67 | + | 0.33 | 88.59 | |

| 0.0066 | 7.15 | 0.154 | 54.5 | 0.214 | 0.179 | 0.356 | −0.147 | −0.349 | + | 0.33 | + | 0.33 | 99.41 | ||

| 0.0083 | 12.00 | 0.259 | 91.2 | 0.358 | 0.050 | 0.099 | −0.118 | −0.280 | + | 0.33 | + | 0.33 | 94.20 | ||

| 2.5 | 0.0050 | 46.30 | 1.000 | 255.0 | 1.000 | 0.442 | 0.879 | 0.212 | 0.504 | +++ | 1.00 | +++ | 1.00 | 18.57 | |

| 0.0066 | 17.30 | 0.374 | 120.0 | 0.471 | 0.503 | 1.000 | 0.033 | 0.078 | ++ | 0.67 | ++ | 0.67 | 76.58 | ||

| 0.0083 | 15.40 | 0.333 | 99.0 | 0.388 | 0.451 | 0.897 | 0.056 | 0.133 | ++ | 0.67 | ++ | 0.67 | 76.76 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Romanowski, M.; Łukianowicz, C.; Sutowska, M.; Zawadka, W.; Pimenov, D.Y.; Nadolny, K. Assessment of the Technological Quality of X5CRNI18-10 Steel Parts after Laser and Abrasive Water Jet Cutting Using Synthetic Index of Technological Quality. Materials 2021, 14, 4801. https://doi.org/10.3390/ma14174801

Romanowski M, Łukianowicz C, Sutowska M, Zawadka W, Pimenov DY, Nadolny K. Assessment of the Technological Quality of X5CRNI18-10 Steel Parts after Laser and Abrasive Water Jet Cutting Using Synthetic Index of Technological Quality. Materials. 2021; 14(17):4801. https://doi.org/10.3390/ma14174801

Chicago/Turabian StyleRomanowski, Marcin, Czesław Łukianowicz, Marzena Sutowska, Wojciech Zawadka, Danil Yurievich Pimenov, and Krzysztof Nadolny. 2021. "Assessment of the Technological Quality of X5CRNI18-10 Steel Parts after Laser and Abrasive Water Jet Cutting Using Synthetic Index of Technological Quality" Materials 14, no. 17: 4801. https://doi.org/10.3390/ma14174801

APA StyleRomanowski, M., Łukianowicz, C., Sutowska, M., Zawadka, W., Pimenov, D. Y., & Nadolny, K. (2021). Assessment of the Technological Quality of X5CRNI18-10 Steel Parts after Laser and Abrasive Water Jet Cutting Using Synthetic Index of Technological Quality. Materials, 14(17), 4801. https://doi.org/10.3390/ma14174801