1. Introduction

In recent decades, the major incentive for the uptake and development of MOC (magnesium oxychloride cement) composites has been motivated from an environmental standpoint. In comparison to PC production, lower calcination temperature are required for MgO production; thus, energy savings associated with these reduced temperatures have led investigators to imagine MgO-based cement as being an eco-friendly binder in the future. Moreover, the ability of MgO to react with atmospheric CO

2 creating carbonates or hydroxycarbonates satisfies the image of so-called “carbon-neutral” cement, which is able to absorb nearly the same amount of CO

2 during its service life as was emitted during its manufacturing. Commercially produced MgO, as one of the raw materials important for the MOC synthesis, is not mined directly but is generally obtained using a dry route, which means the calcination of mined magnesite deposits (MgCO

3). Moreover, a wet route can be applied, in the form of the precipitations from magnesium-bearing brine or seawater, but it is more energy-consuming [

1]. Bilinski et al. observed [

2] that the setting time and strength of MOC can vary as a function of calcination conditions, which also strongly affects the reactivity of MgO; thus, it is the final phase formation in the MOC composite structure [

3,

4]. The ability of MOC cements to bind and incorporate large quantities of diverse filler materials ranging from granite to dust, with organic or inorganic origins and sizes from nanometer to centimeter, allows the creation of MOC composite materials with required properties [

5,

6,

7]. However, the popularity of MOC has sharply declined because of its poor water resistance and subsequent degradation during service life [

8]. The reason is that binding phases easily react with water molecules forming more voluminous hydroxides resulting in the loss of the strength of MOC in moist conditions. For that reason, it is important to create material with a defined porous structure and low open porosity. This can be achieved by the incorporation of microfillers into a composite mixture. As we confirmed in our previous works, the addition of fine particles results in structures with low porosity with improved mechanical strength, reduced water ingress and increased resistance against water damage [

9,

10,

11]. The positive effect of microfiller addition can be further strengthened by the application of reactive particles, which can form stable hydrated products. For that reason, it can be utilized. One example is diatomite containing amorphous SiO

2, and it is able to create M-S-H phases adequate to C-S-H phases in PC [

12]. Moreover, the incorporation of graphene nanoplatelets enables the production of materials with the decreased porosity and greatly improved mechanical resistance.

In this paper, we encapsulated our experience to develop novel ecofriendly MOC composite material with low porosity, reduced water ingress and enhanced mechanical properties. In order to decrease porosity and improve mechanical resistance, carbon nanotubes were incorporated in the amount of 0.2 wt.% of the whole composite mixture. In order to explore the most effective dosage of microfiller, we doped MOC with diatomite in the amount of 10, 20 and 30 wt.% of the excess mass of MgO, which served originally as fine filler. The raw materials and developed composites were characterized using a variety of methods, including X-ray powder diffraction (XRD), high-resolution transmission electron microscopy (HR-TEM), scanning electron microscopy (SEM), energy dispersive spectroscopy (EDS) and Fourier transform-infrared spectroscopy (FT-IR). The hardened composites concerned their thermal, structural, mechanical and hygric properties tested.

2. Materials and Methods

The mixture properties of the prepared samples are summarized in

Table 1. Let us note that MgO was added in excess; its unreacted part served as a filler. MOC-REF is a reference mixture without CNT (carbon nanotubes) and diatomite. In all samples marked CNT, the carbon nanotubes were used in the amount of 0.2 wt.% of the whole mixture. Samples termed MOC-CNT-D10, MOC-CNT-D20 and MOC-CNT-D30 contained diatomite as partial replacement of the over stoichiometric MgO in the amount of 10 wt.%, 20wt.% and 30 wt.%, respectively.

MgCl2·6H2O was dissolved in tap water. This solution was used for the dispersion of MWCNTs using Ultra Turrax T-18 (IKA, Staufen, Germany); the process took 5 min at 10,000 rpm. The obtained suspension/plain solution of MgCl2 was mixed with MgO/MgO-diatomite accordingly to the mixture prescription. The total mixing time in the planetary type mortar mixer (ELE) was 5 min. The fresh mixtures were then cast into steel molds with dimensions of 40 mm × 40 mm × 160 mm, unmolded after 24 h and cured in the air atmosphere at laboratory conditions (temperature of (23 ± 2) °C and relative humidity of (50 ± 5) %) for the next 27 days.

Diatomite and MgO used in this work were characterized by specific density, powder density, Blaine fineness and particle size distribution.

The prepared samples were analyzed by multiple analytical methods in order to determine their chemical, structural, mechanical, hygric and thermal properties. In order to analyze the fracture surface of the samples, optical microscopy (OM) was used. The phase composition was determined by using X-ray diffraction (XRD). For the study of the surface morphology, scanning electron microscopy (SEM) was used. In order to reach even higher magnification the high-resolution transmission, electron microscopy (HR-TEM) was used. The elemental compositions of the samples as well as the elemental maps were obtained by using energy dispersive spectroscopy (EDS). In order to study the mechanism of formation of the various composites based on the dosage of diatomite, the Fourier-transform infrared spectroscopy was used. The thermal behavior of the samples up to 800 °C was analyzed by using simultaneous thermal analysis in combination with mass spectrometry. The macrostructural and microstructural parameters were determined using helium pycnometry and mercury porosimetry. All the samples also underwent a series of mechanical tests to determine their flexural strength

ff (MPa), compressive strength

fc (MPa) and the dynamic modulus of elasticity

Ed (GPa). Moreover, the water transport parameters, which are crucial for the MOC-based composites, were studied. Finally, the thermal conductivity and the volumetric heat capacity were measured using a transient plane source technique. More detailed information about the analytical methods is provided in the

Supplementary Materials.

3. Results

The fundamental physical characteristics of diatomite and MgO are given in

Table 2. The specific and powder densities of diatomite were much lower compared to those of MgO. This provides evidence of the high porosity of the fossilized diatomite frustules. As MgO was found to be much finer than diatomite, its large specific surface can be attributed to its microporous nature.

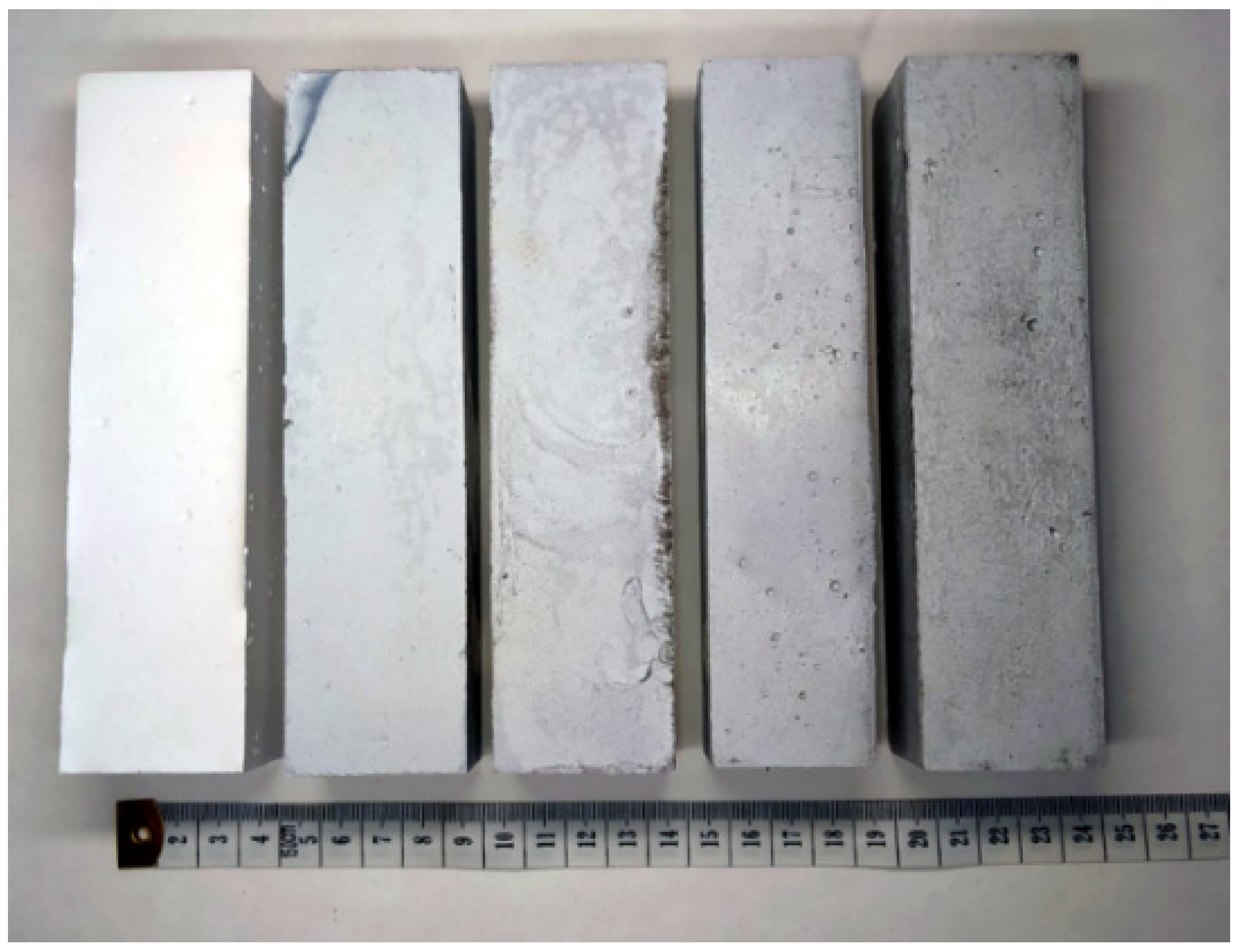

The photo of the hardened prismatic specimens is shown in

Figure 1. The use of CNTs and diatomite in composite mixtures did not negatively affect the original appearance of the cast prisms.

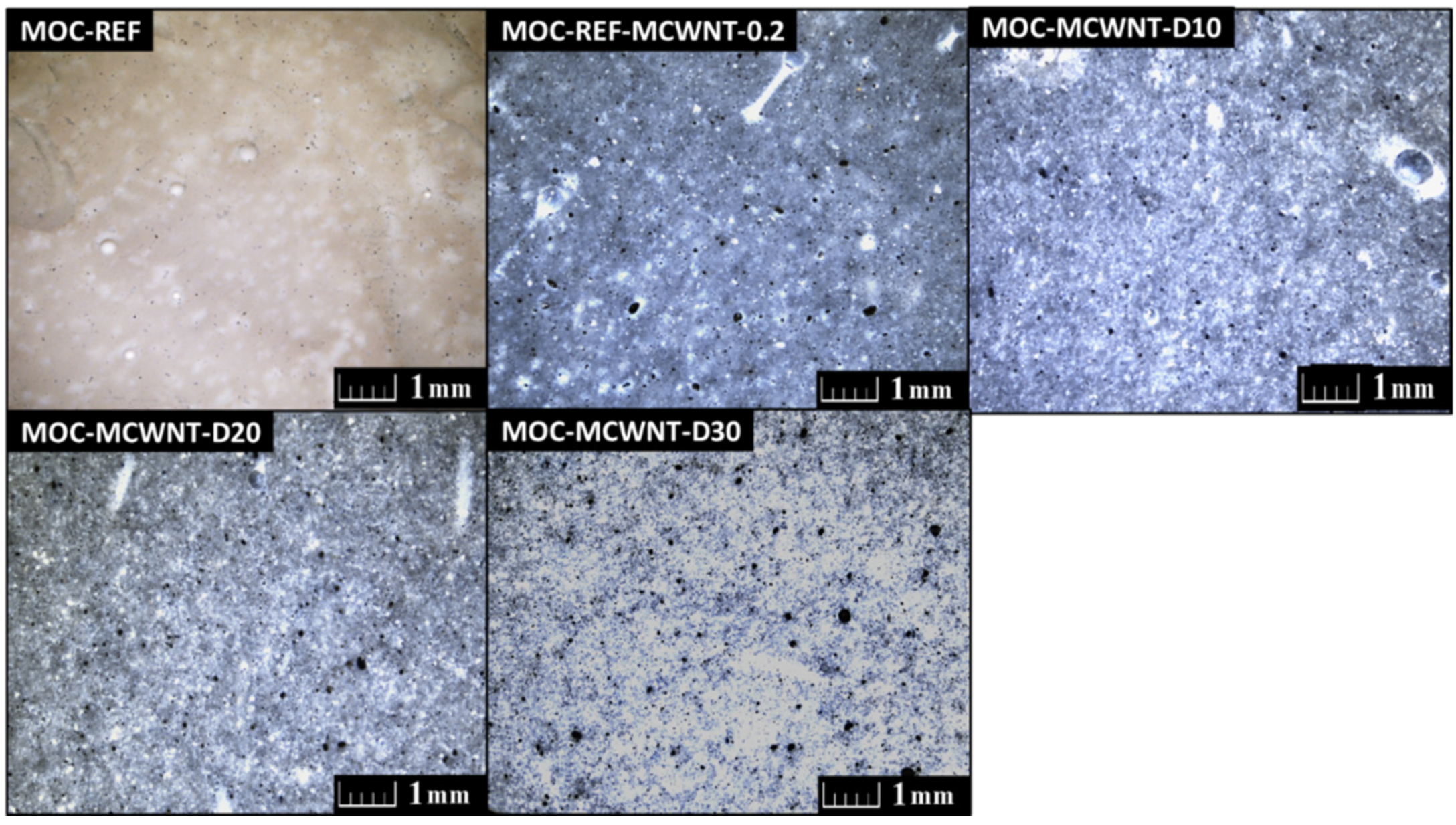

The fracture surface of the obtained samples was analyzed by using optical microscopy in order to detect the compactness and possible defects in the structure of the composites. The samples present as compact, with no visible defects and with homogenously dispersed additives. In all the samples, there is visible discoloration which is caused by the use of the MWCNTs. The obtained photographs are presented in

Figure 2.

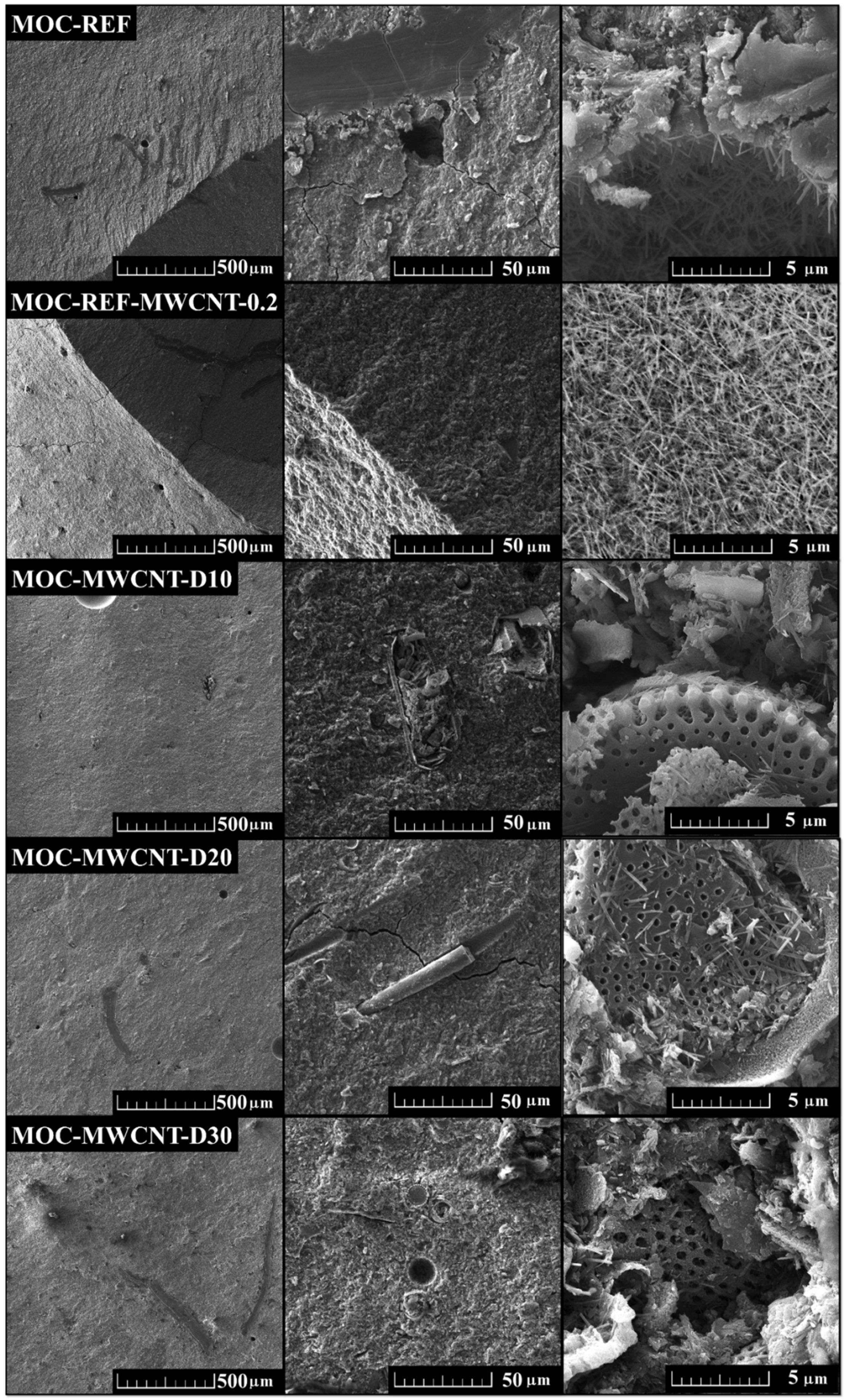

The SEM analysis was used to study the microstructure and morphology of the prepared composites. The micrographs with smaller magnification show the compact structure of the composites with some air bubbles. At higher magnifications, there are visible needle-shaped crystals which are typical of the MOC-type materials. These form in the bubbles and on the diatomite particles, which act as nucleation centers. The obtained micrographs are shown in

Figure 3.

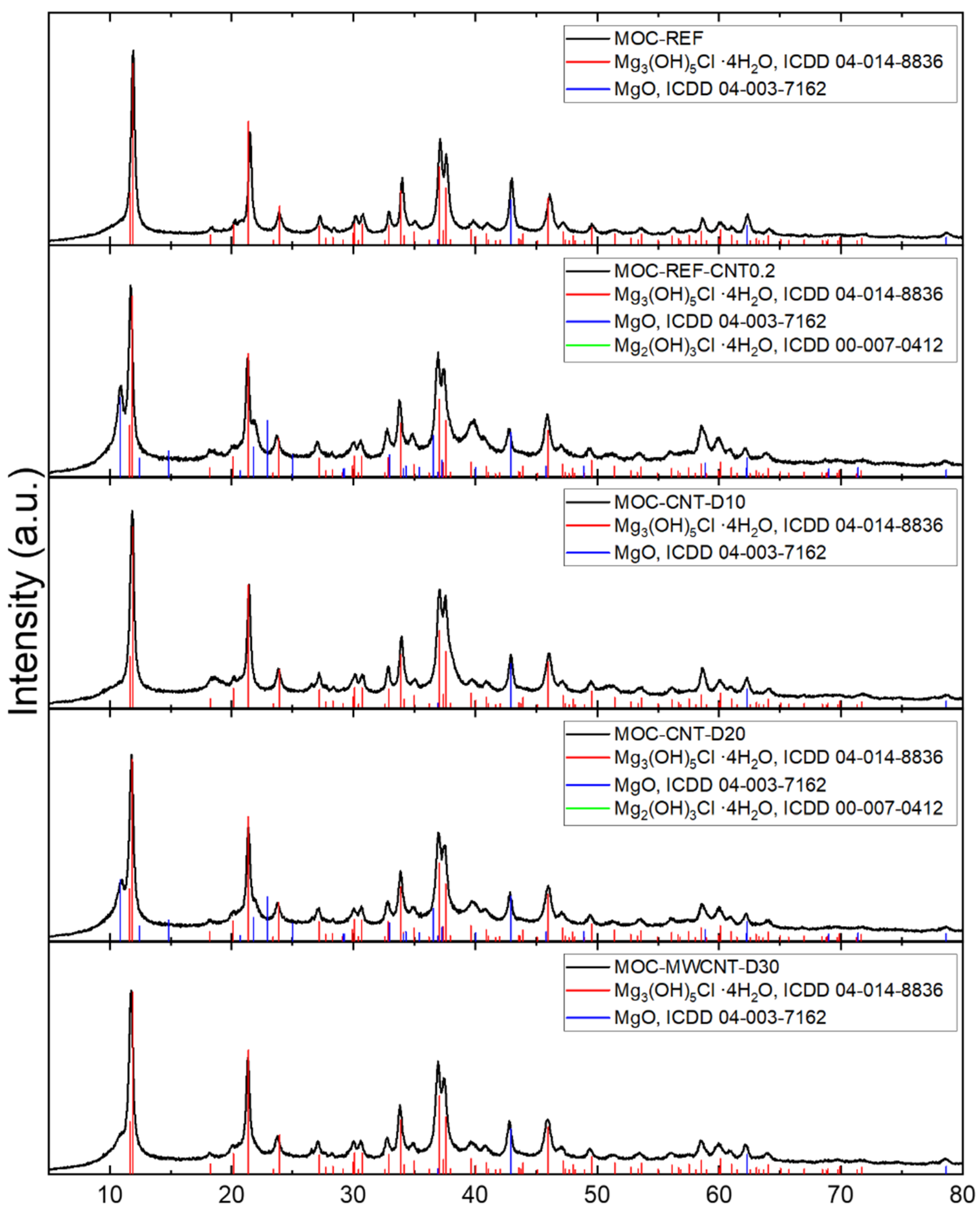

The phase composition of the samples was studied by X-ray diffraction. All diffractograms have shown the content of the MOC phase 5 (Mg

3(OH)

5Cl∙4H

2O, ICDD 04-014-8836) and MgO (ICDD 04-003-7162), which were used in excess as a part of the filler. The samples MOC-REF-CNT0.2 and MOC-CNT-D10 also showed that they also contain MOC phase 3 (Mg

2(OH)

3Cl∙4H

2O, ICDD 00-007-0412). Its formation was caused by the local lack of MgCl

2 due to its aggregation with the carbon nanotubes. The carbon nanotubes are not present in the diffractograms because of their low content and the diatomite is not visible due to its amorphous character. The diffraction patterns are shown in

Figure 4.

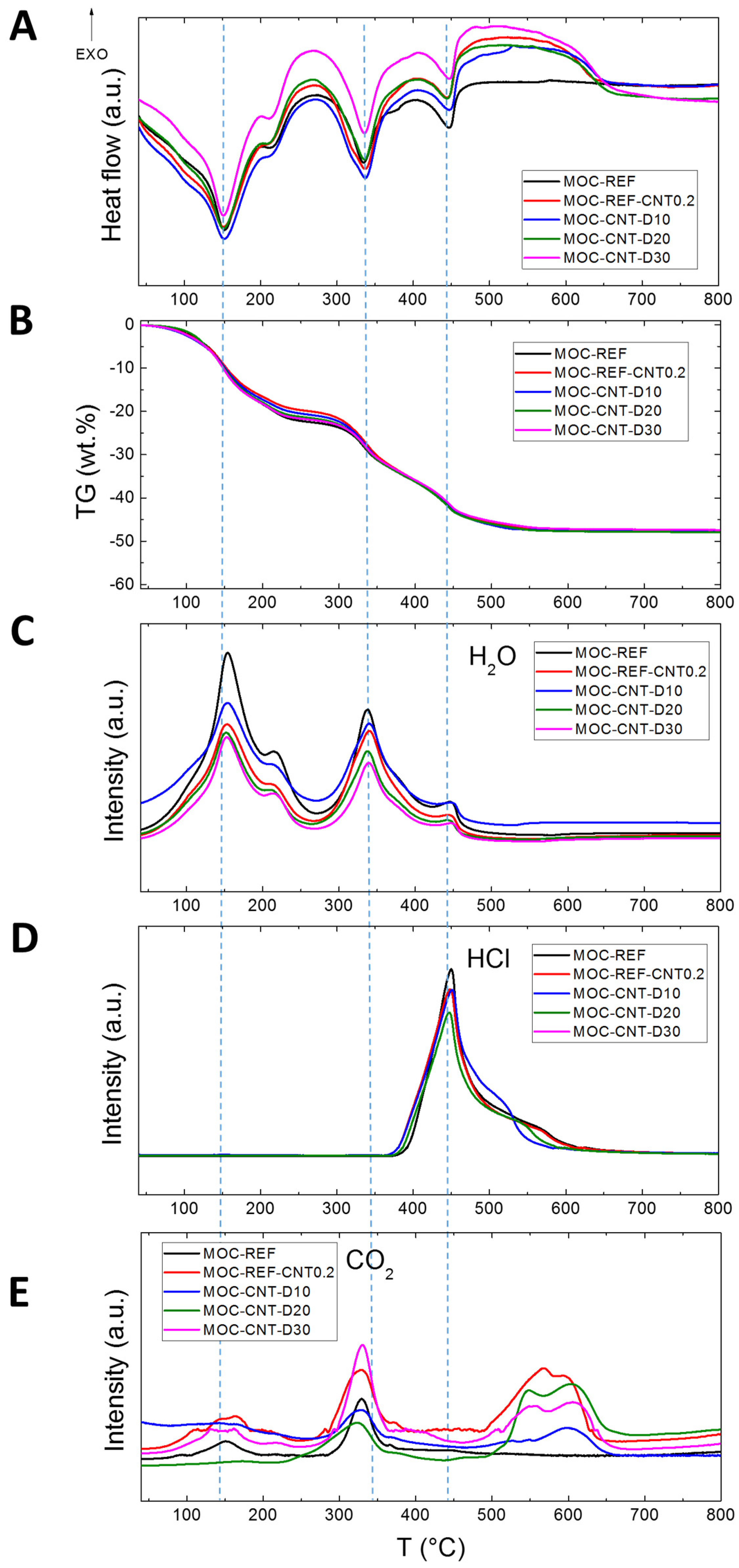

The STA-MS was used to study the thermal stability of the samples (see

Figure 5). All samples gradually decomposed, as can be observed from DTA and TG curves and also from MS signal for water, carbon dioxide and hydrochloric acid. After the heating, only magnesium oxide remained, while other products are gases. The DTA curve shows three major endothermic effects (marked by a blue dashed line). The first one at approximately 150 °C is associated with water release. Moreover, the second effect at approximately 340 °C is caused by water release, while the third effect at 445 °C is connected mainly due to the release of hydrochloric acid. The major difference between REF and other samples with MWCNT can be observed in the area between 450 and 650 °C, where a wide exothermic effect was detected. This is due to the oxidation of MWCNT, which was also confirmed by the MS spectrum for carbon dioxide (

Figure 5E). Let us note that carbon dioxide was also released between 300 and 350 °C. This was probably caused by the decomposition of chlorartinite Mg

2(CO

3)(OH)Cl·3H

2O, which usually forms on the surface of the samples due to CO

2 capture.

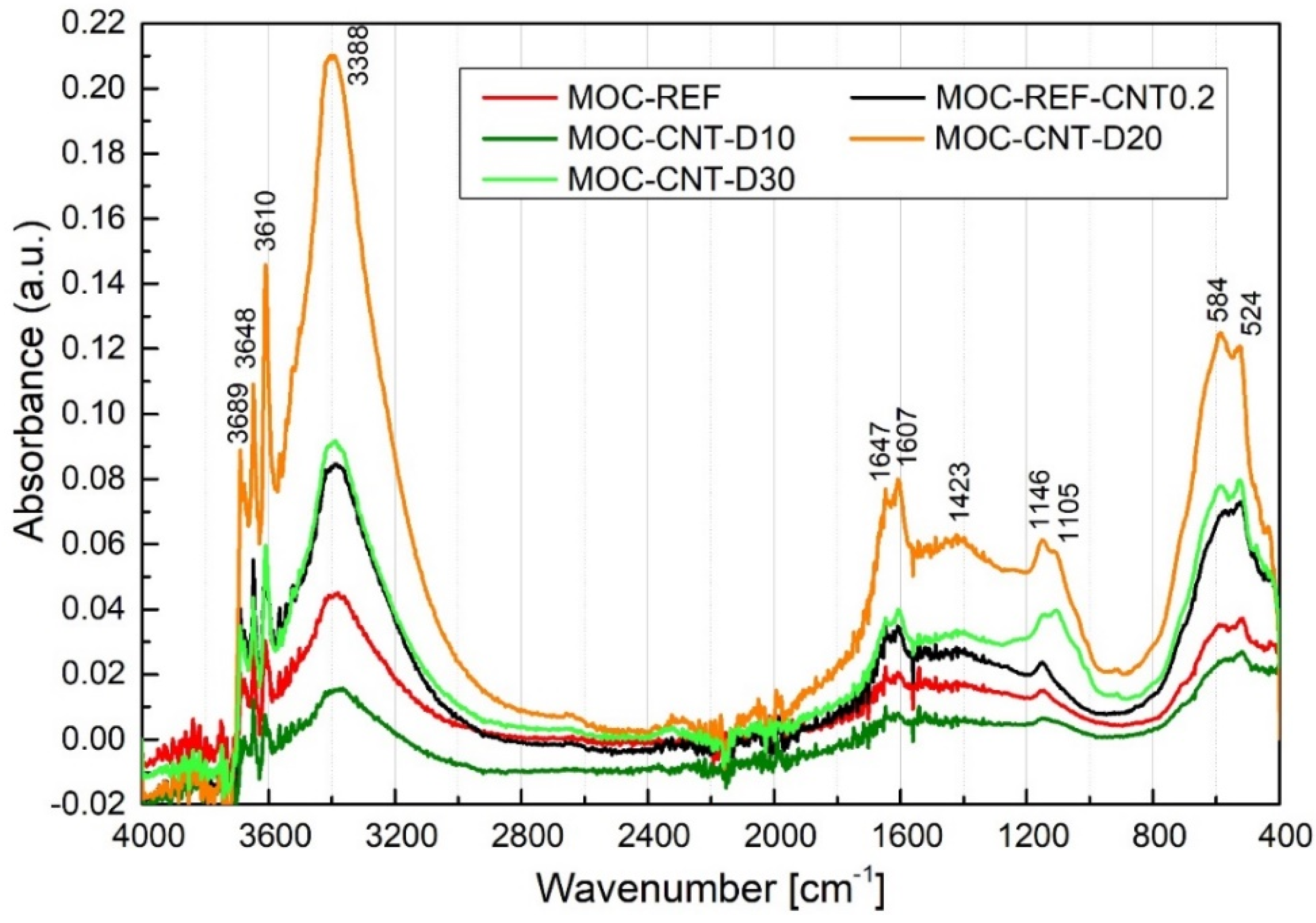

The collected MIR (medium infrared) spectra are presented in the form of spectral lines in

Figure 6. The major absorption bands are precisely assigned and summarised in the

Supplementary Materials. As we can observe, all lines are very similar and differ only in detail. The main differences can be observed in absorption bands around 1600 cm

−1. The stretching vibration of H–O–H in water in minerals around 1100 cm

−1, where the intensive band at 1050 cm

−1 coming from the in-plane vibration of Si–O–Si in quartz in MOC-REF and MOC-REF-CNT0.2, is broken into the bands between 1050 cm

−1 and 1105 cm

−1 in MOC-CNT-D composites [

13]. This can be assigned to the asymmetric in-plane stretching vibration of Si–O–Si in diatomite and Si–OH in calcium silicates and magnesium silicates. From the comparison of reference magnesium oxychloride cement sample and magnesium oxychloride cement with nanotubes, the presence of C=C bond is demonstrated at 1560 cm

−1. This vibration is moved to higher wavenumbers 1564 cm

−1 in the case of composites with diatomite. The reflection of Si–O, Si–O–Al or Si–O–Si bonds coming from diatomite can be observed as stretching vibration in the range below 800 cm

−1. In the range between 3300 and 3700 cm

−1, the symmetric and asymmetric stretching mode of O–H bonds can be observed. In order to explore material behaviour, the most important is the band at 3689 cm

−1, which can be attributed to the stretching vibration of OH group in brucite in H

2O and Mg(OH)

2 [

4]. The intensities decreased nearly half in the case of samples with 20 and 30 wt.% of diatomite, which means the poor formation of brucite that results in higher mechanical properties. Similarly, the formation of silicate hydrates influences the mechanical properties of prepared composites. The most intensive band can be observed in the case of the sample with 10 wt.% of diatomite, while the others show lower content of silicate hydrates.

The spectral range around 2000 cm

−1 was not analysed in detail, the low intensive bands were made up of bending and rocking vibrations of O–H in water and brucite and carbonates overtones. The band intensities between 1715 cm

−1 and 1150 cm

−1 are stretching and bending vibrations of Mg–O and O–H bonds in MgCl

2·8H

2O and C-S-H or M-S-H phases, respectively [

3,

4]. The presence of MgCO

3 in light burned magnesia and from the carbonation reaction can be observed as the stretching vibration of C=O in carbonates at 1488 cm

−1 [

11]. The series of modes below 1000 cm

−1 originated from the lattice translation and bond vibrations Mg–O/Mg–Cl and vibrations of Mg–O/Mg

2+, O/O–Mg–O/O–Mg

2+–O bonds, rocking motion of oxygen atoms bridging silicon and aluminium atoms in bonds Si–O–Si and Si–O–AlIV [

14].

The macrostructural parameters of the composites after 28 days are presented in

Table 3. The presented data represent mean values measured independently for five samples. The expanded combined uncertainty of the obtained parameters is also introduced. It is evident that the use of MWCNTs reduced the porosity of the prepared composites. The partial replacement of MgO, which was used as finer filler, by fine-grained diatomite also led to the reduction in total open porosity. However, in this case, the drop in porosity was much lower than the drop caused by MWCNTs solely.

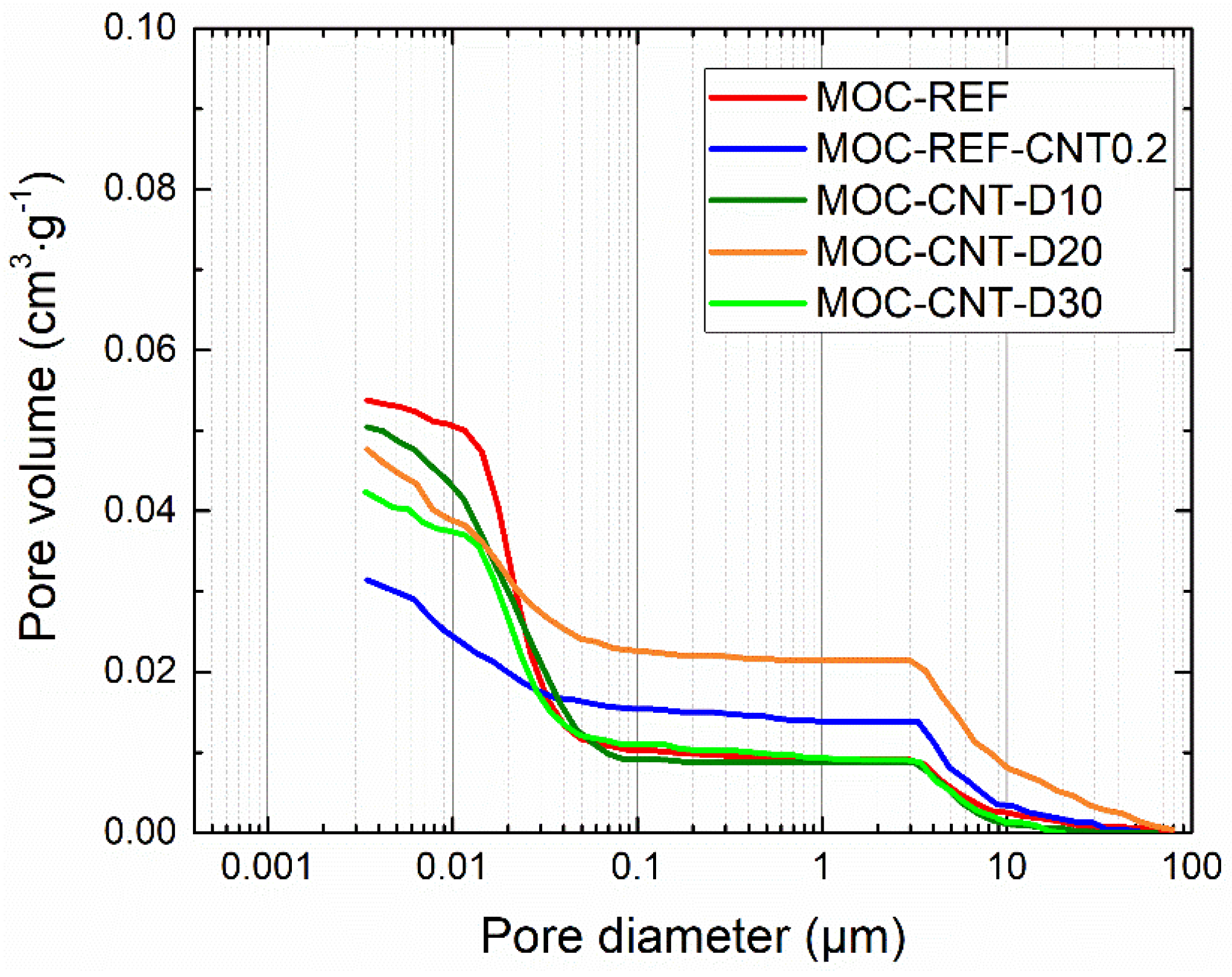

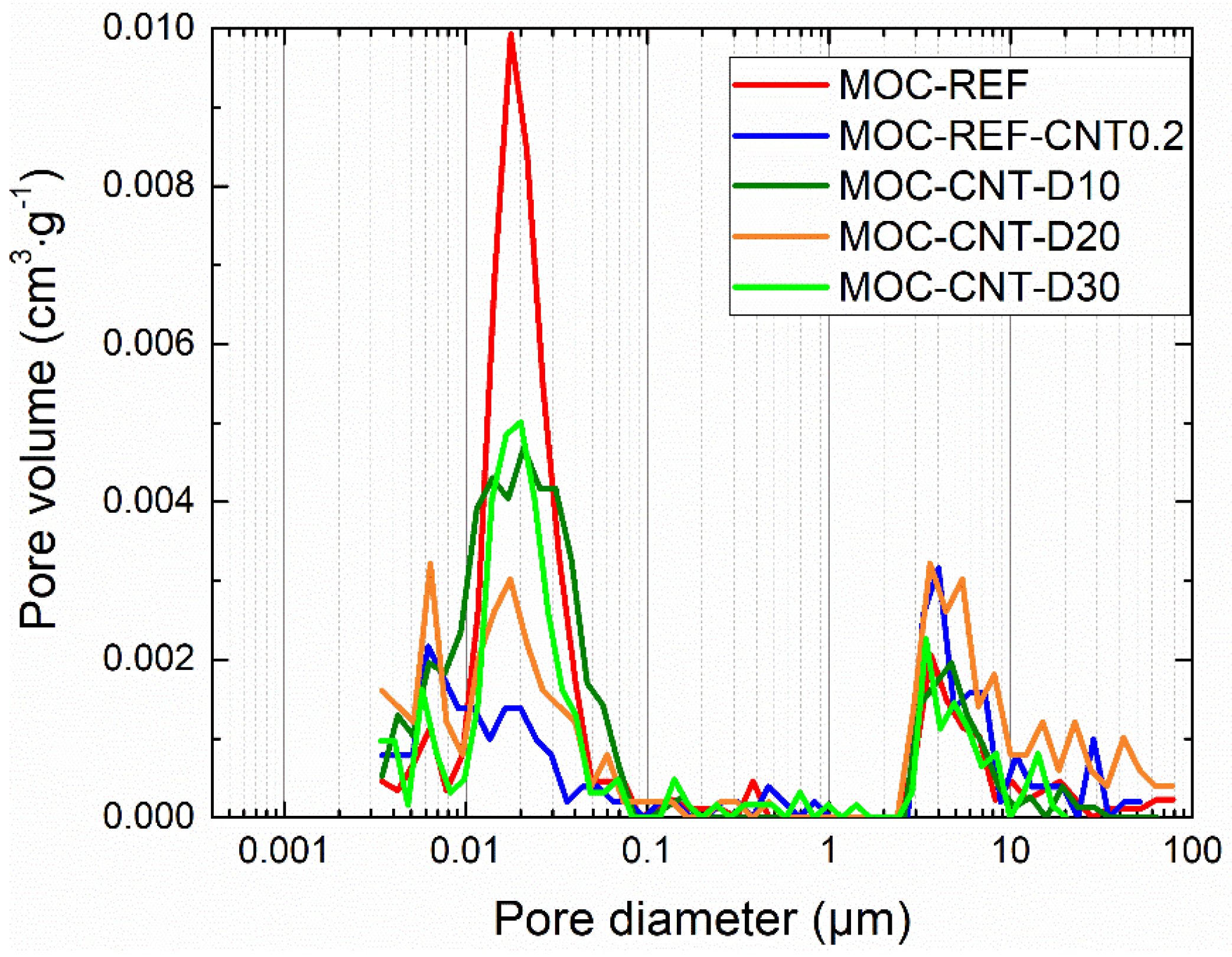

The cumulative and pore size distribution curves obtained by MIP (mercury intrusion porosimetry) are presented in

Figure 7 and

Figure 8. The microstructural data are presented in

Table 4. Classification of pores originally applied in Portland cement-based materials research was adopted in literature [

15]. In the analyzed composite, three classes of pores were identified: i) gel pores (<10 nm), which govern shrinkage and creep of the matrix components; ii) capillary pores (10–10,000 nm) driving the mechanical strength and transport processes; and iii) hollow shell pores (>0.1 mm) for which its presence negatively affects the mechanical resistance. The use of MWCNTs and diatomite resulted in a substantial decrease in pore volume in the 0.01–0.1 µm diameter range, which well corresponds with the results of the mechanical and hygric properties that were, thus, greatly improved by the reduction in capillary pores volume. The total porosity data measured by MIP analysis were almost similar to the data calculated from the bulk density and specific density values. Both the total cumulative volume and average pore diameter were reduced by the addition of MWCNTs and admixing of diatomite. This evinces the condensation and refinement of the MOC matrix, which was visible for all diatomite and MWCNTs doped composites.

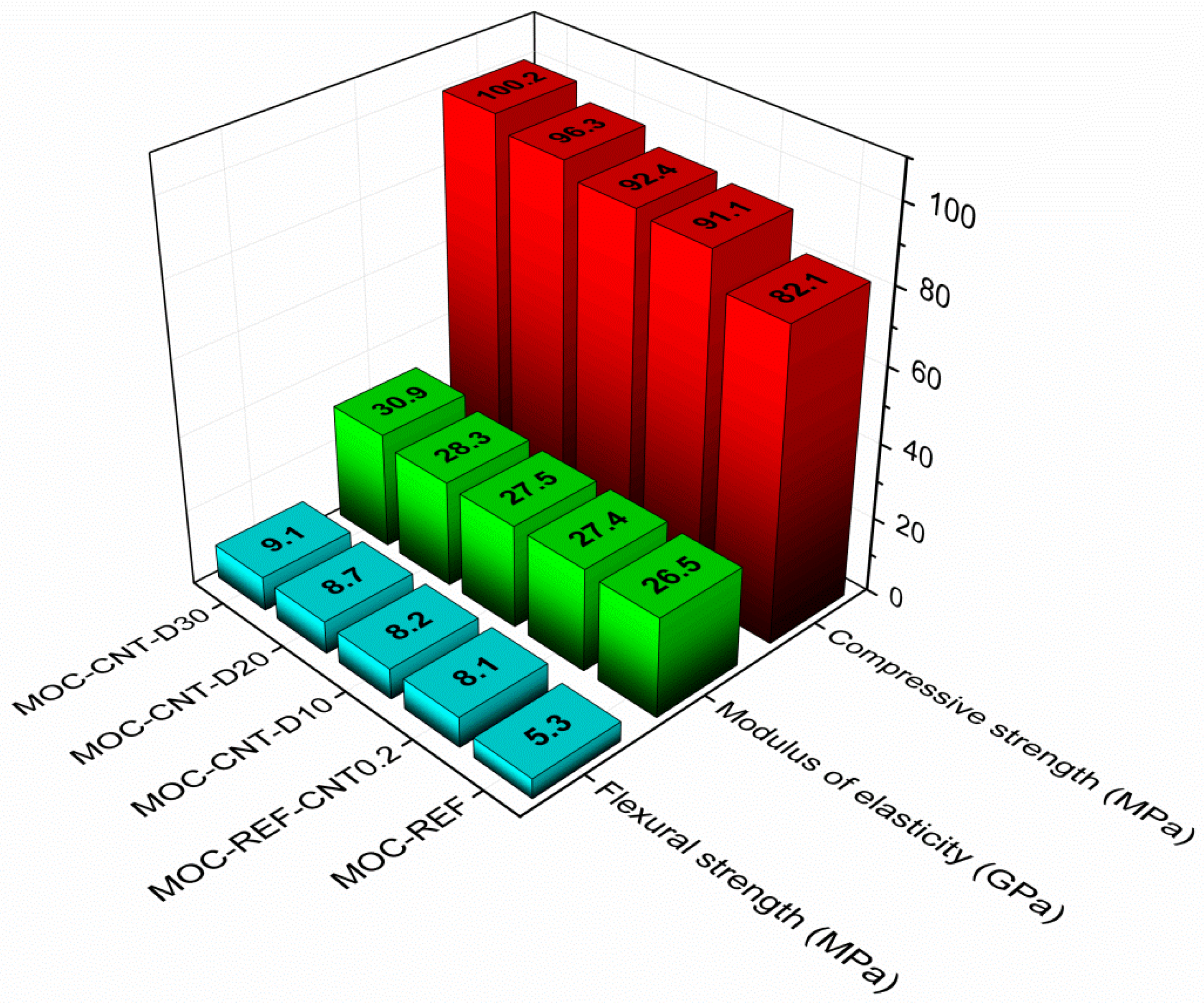

The mechanical parameters of the investigated composites measured for 28 days hardened samples are graphically presented in

Figure 9. Diatomite, as well as MWCNTs, greatly enhanced the mechanical strength and stiffness of the analyzed materials, and their synergic performance was, thus, well proven. Generally, all tested composites yielded excellent mechanical parameters, which were further improved by a coupled diatomite and MWCNTs effect. High compressive strengths together with high modulus of elasticity are typical properties of MOC-based materials and enable inmixing of different types of aggregates and fillers into the composite mixture without the immoderate loss of the mechanical parameters of the hardened composites. Moreover, with the higher replacement ratio of MgO with diatomite, the investigated mechanical parameters increased. This is a very promising result, especially due to the low carbon footprint of diatomite production compared to the expansive and polluting manufacturing of MgO. In this manner, high-strength composites can be obtained by more efficient and eco-friendly methods. Quantitatively, in the comparison with reference material MOC-REF, the increments in the compressive strength were 11.0%, 12.5%, 17.3% and 22.0 for composites MOC-REF-CNT0.2, MOC-CNT-D10, MOC-CNT-D20 and MOC-CNT-D30, respectively. A similar trend was also exhibited by the other two tested mechanical parameters, which were increased by 52.8%, 54.7%, 64.2% and 71.7% in the case of flexural strength and 3.4%, 3.8%, 6.8% and 16.6% for the modulus of elasticity values. The improvement in the stiffness of the composites was the lowest among the examined mechanical parameters, but still significant.

The mechanical parameters correspond well with the macrostructural and microstructural parameters data. The decrease in the volume of capillary pores is the reason for the improvement of mechanical resistance and stiffness of the composites with MWCNTs themselves or combined with diatomite of high Blaine fineness. The contribution of diatomite to the total mechanical resistance is due to two phenomena: (i) The filler effect of diatomite filling the gaps between the MgO particles and precipitated MOC-based compounds; (ii) the reactivity of diatomite and formation of magnesium silicate hydrate (M-S-H) phases. Thermal parameters of the studied samples are introduced in

Table 5. These are the results of the mutual combination of several effects: (i) porosity and, thus, bulk density, (ii) low thermal conductivity and specific heat of diatomite frustules [

16,

17] and (iii) high thermal conductivity and specific heat of CNTs [

18,

19]. In MOC-REF-CNT0.2, the effect of CNTs addition prevailed, whereas the use of CNTs increased both the thermal conductivity and specific heat. Similar enhancement of heat transport by the incorporation of CNTs was reported by Hassanzadeh-Aghdam et al. [

20] who introduced 1 vol.% of CNTs in concrete, and the thermal conductivity was observed to increase by 11.1%. In our case, due to the lower dosage of CNTs in the composite mixtures, the increase in the thermal conductivity was 3.6%. In MOC-CNT-D composites, the low thermal conductivity of diatomite produced reduced thermal conductivity values, and the drop in thermal conductivity was partially compensated by the decreased porosity of these materials in comparison to that of MOC-REF. On the contrary, the higher bulk density of MOC-CNT-D materials slightly enhanced the heat storage capability, which can find application, e.g.

, in passive moderation of indoor air climate. In case of the higher dosage of CNTs and their optimum disperison, good networking of CNTs can be anticipated and, thus, more significantly enhanced heat transport.

The parameters characterizing water ingress into the researched composites are presented in

Table 6. The addition of MWCNTs into the composites reduced the water transport, which is positive due to the partial elimination of the risk of moisture-induced damage. The partial MgO replacement with diatomite slightly devaluated the water transport retardation effect of CNTs due to the highly porous microstructure of diatomite skeletons, but MOC-CNT-D materials still yielded lower water transport parameters than the parameters obtained for MOC-REF. In this sense, the low porosity of magnesium silicate hydrates can partially reduce the total water ingress and rate of moisture transport. Quantitatively, the water absorption coefficient was low for all tested samples, which is favorable for the durability of the composites with respect to their deterioration in the presence of water and reactive MgO. Capillary active materials have the water absorption coefficient typically about one order of magnitude higher [

21,

22,

23] than measured for MOC-based derivatives examined in this work.