Investigating the Feasibility of Preparing Metal–Ceramic Multi-Layered Composites Using Only the Aerosol-Deposition Technique

Abstract

:1. Introduction

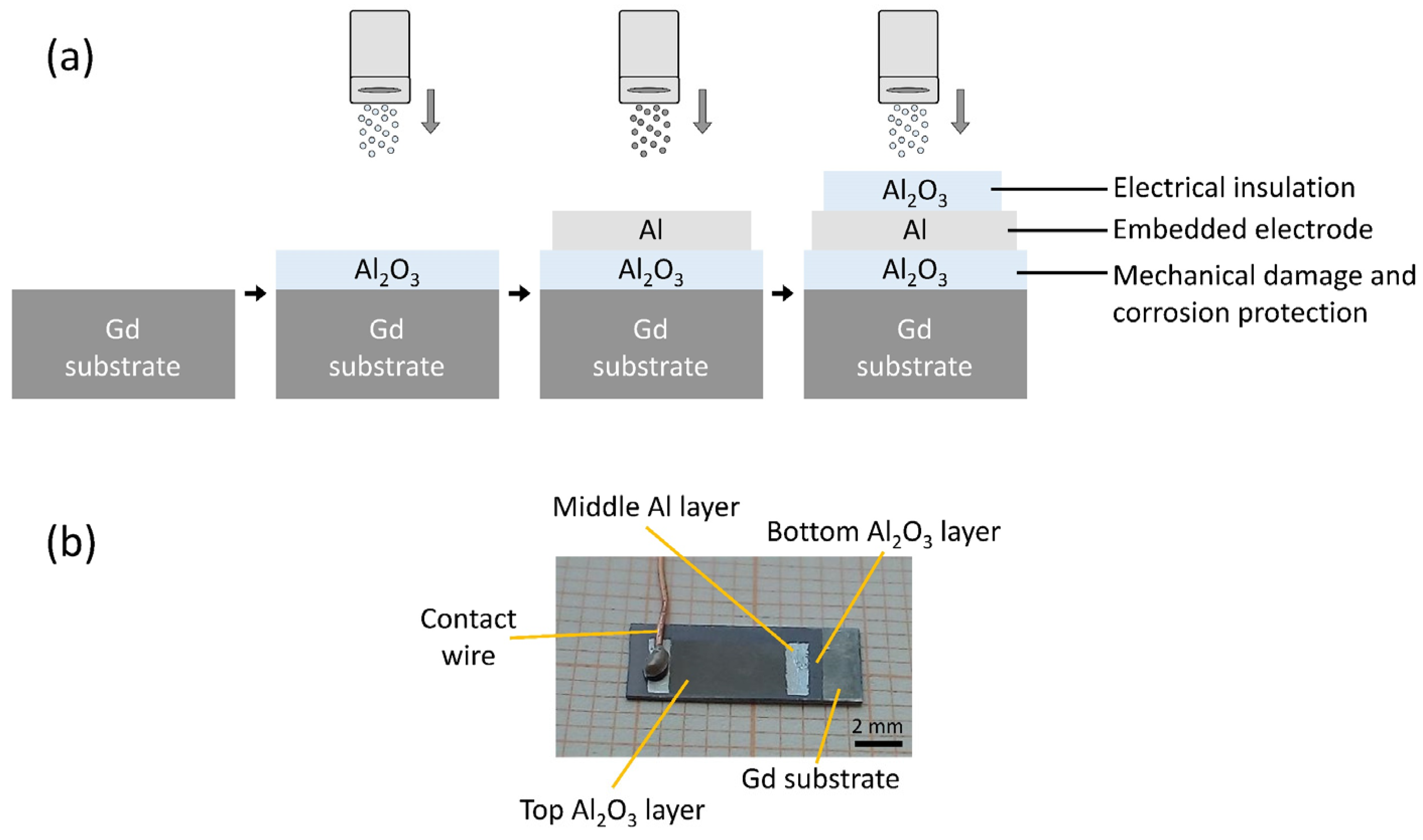

2. Materials and Methods

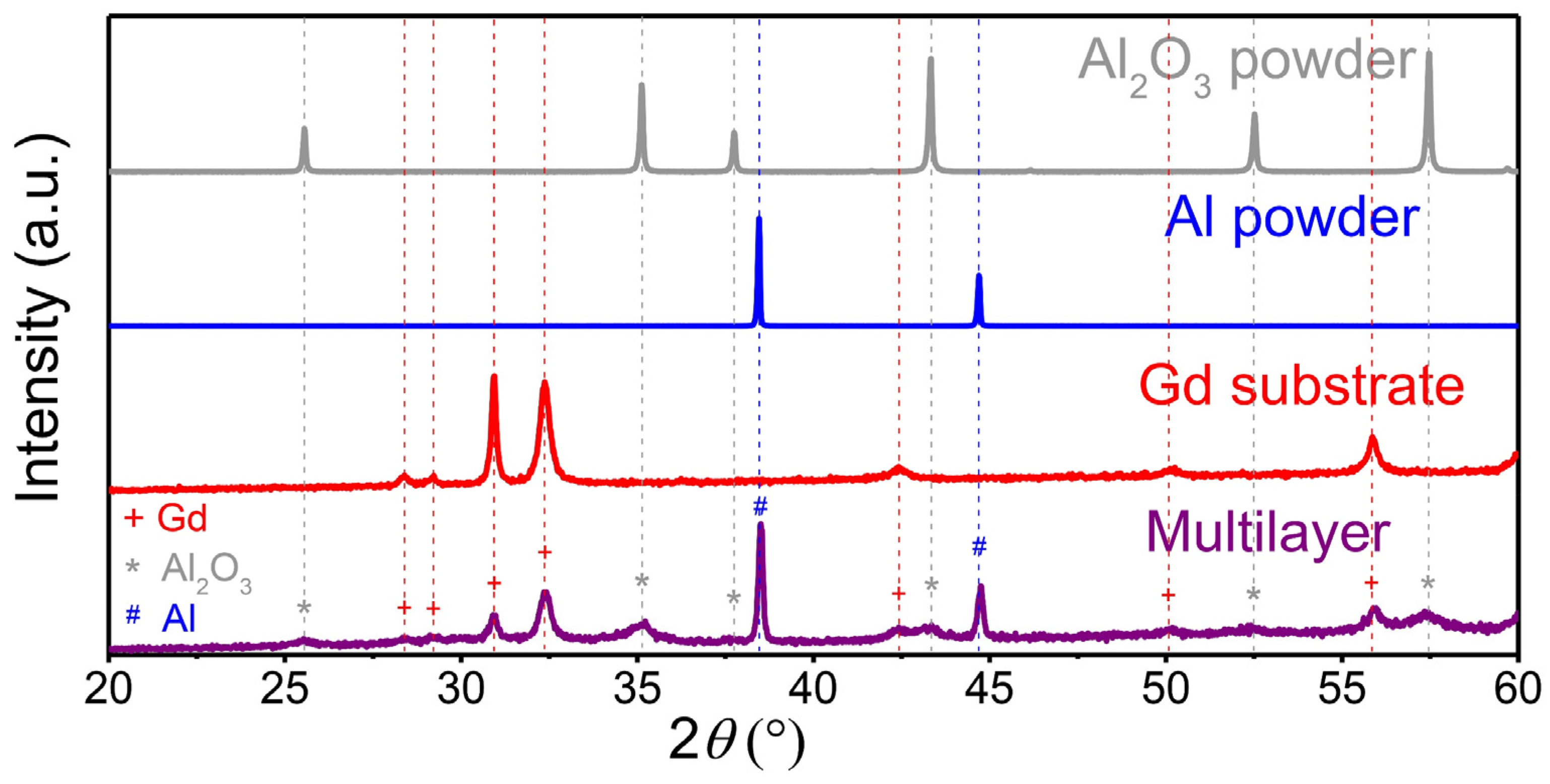

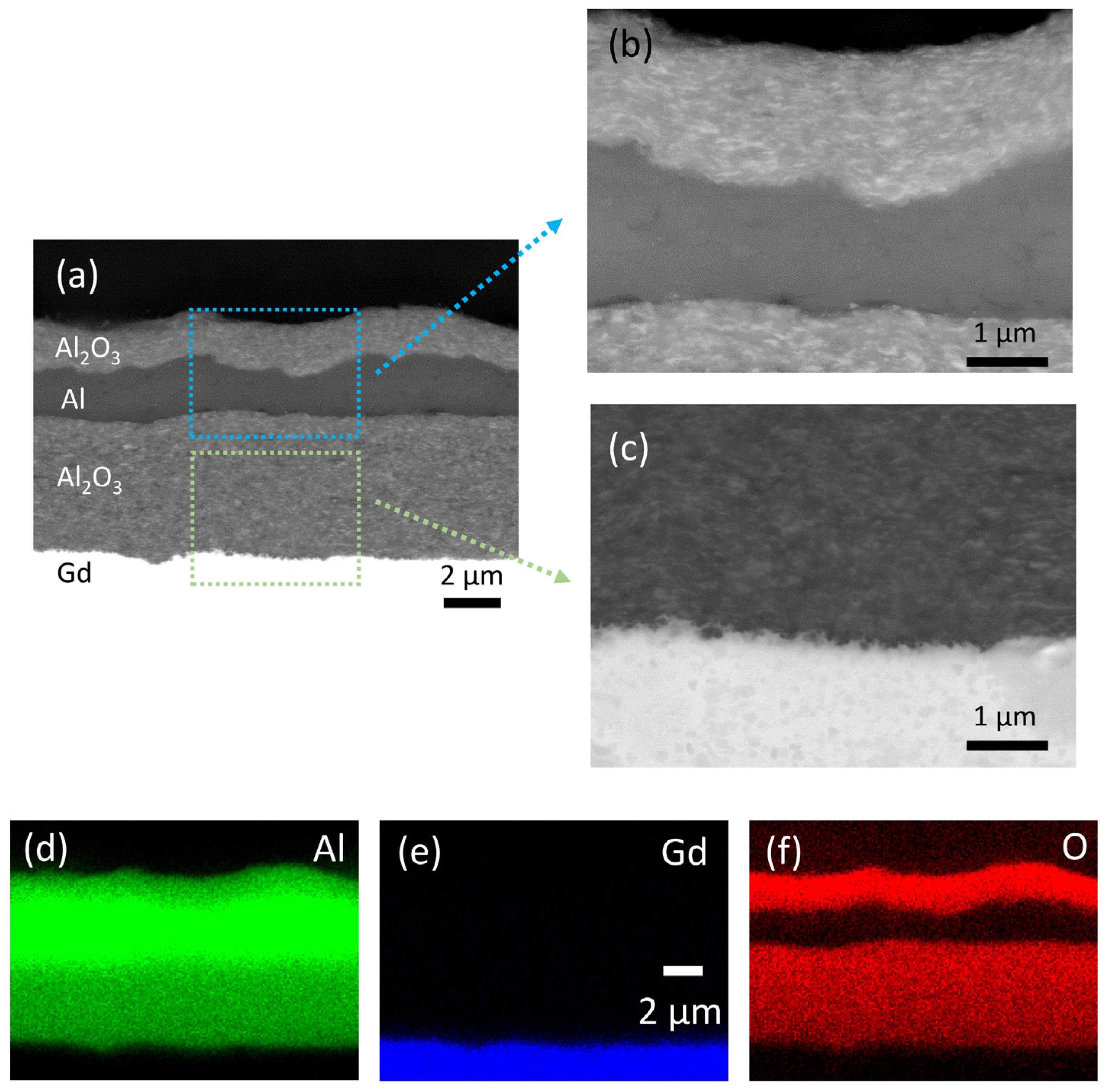

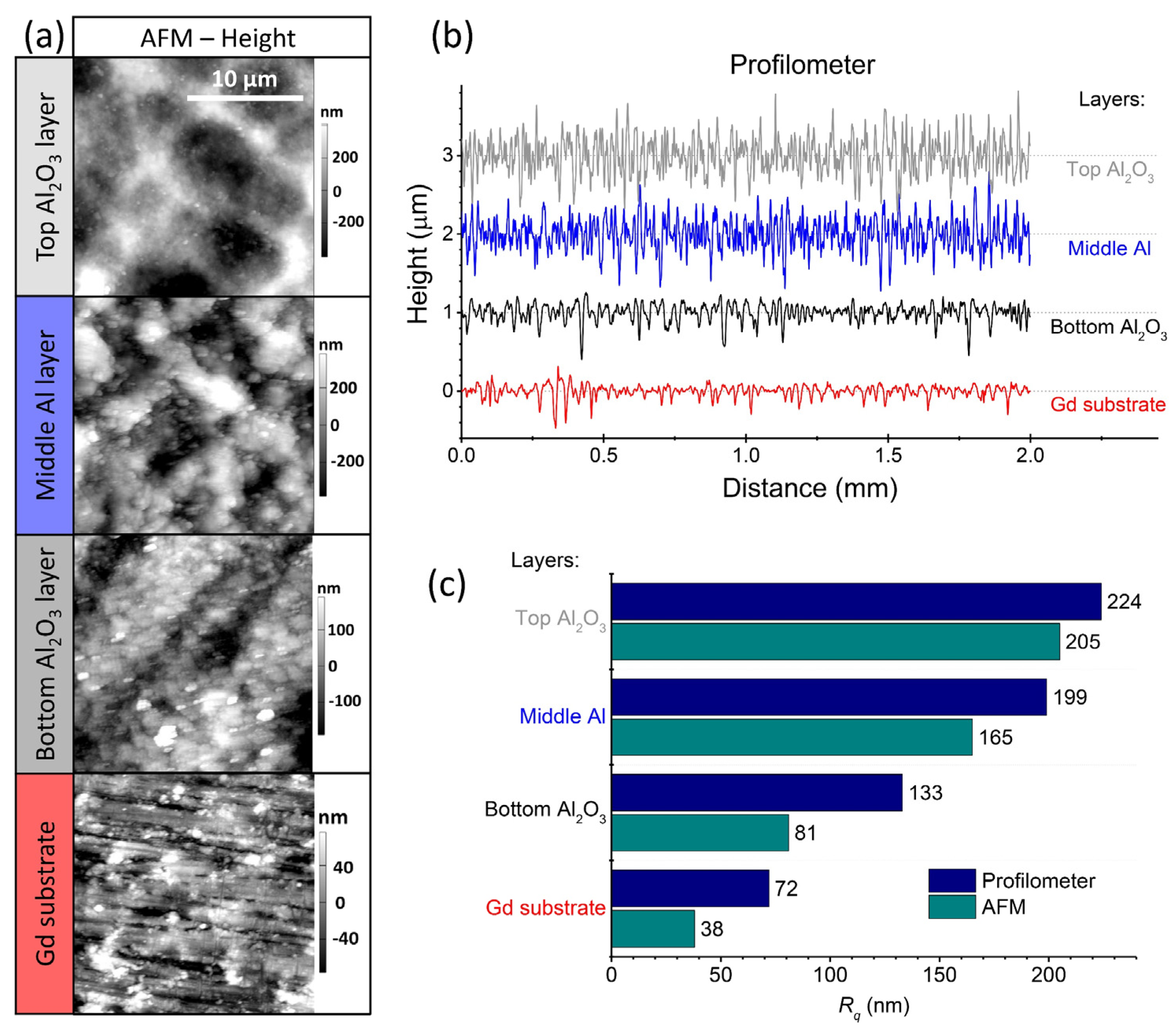

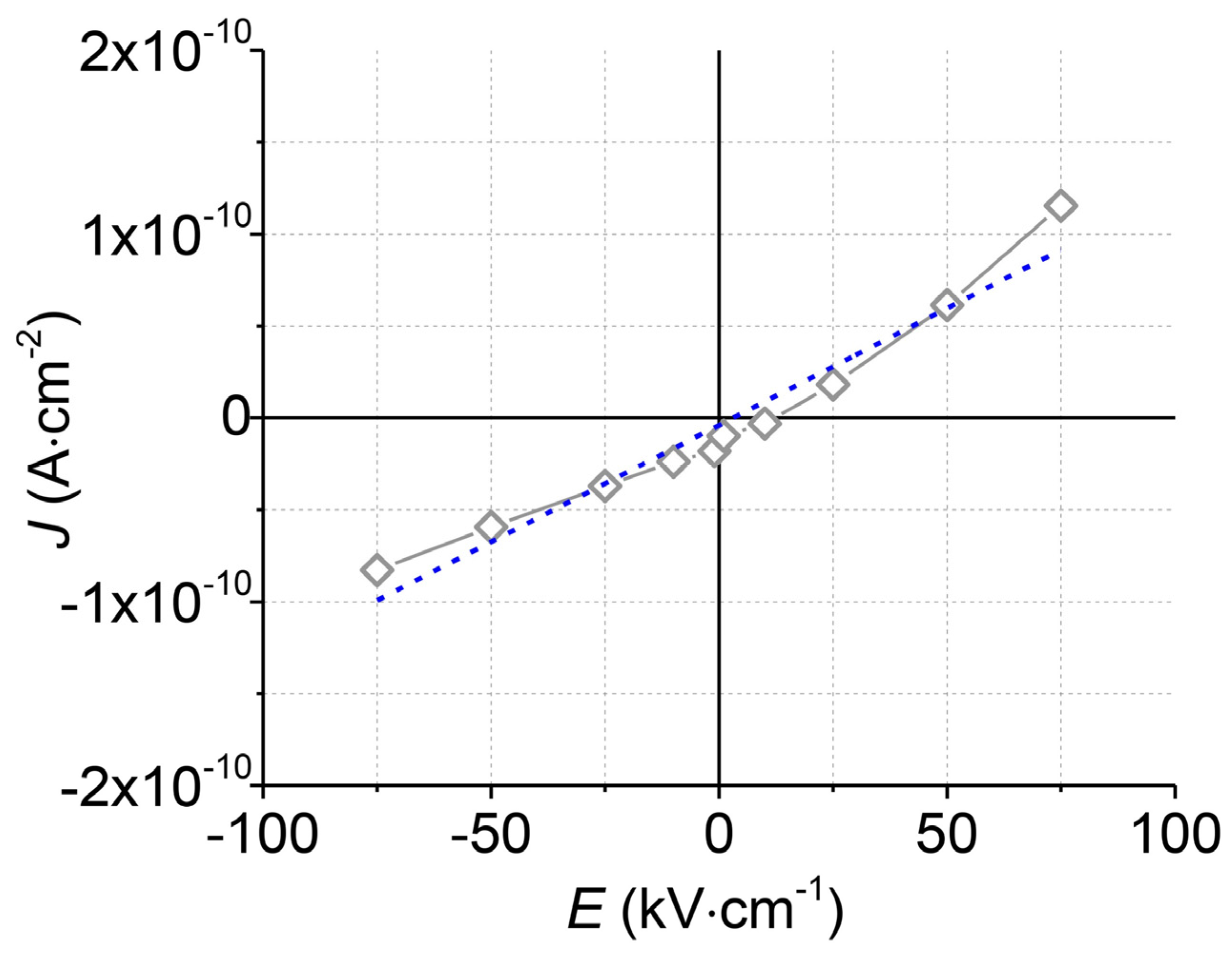

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kosec, M.; Kuscer, D.; Holc, J.; Pardo, L.; Ricote, J. Processing of Ferroelectric Ceramic Thick Films. In Multifunctional Polycrystalline Ferroelectric Materials; Springer: Dordrech, The Netherlands, 2011. [Google Scholar]

- Pan, M.-J.; Randall, C. A brief introduction to ceramic capacitors. IEEE Electr. Insul. Mag. 2010, 26, 44–50. [Google Scholar] [CrossRef]

- Schubert, M.; Hanft, D.; Nazarenus, T.; Exner, J.; Nieke, P.; Glosse, P.; Leupold, N.; Kita, J.; Moos, R. Powder aerosol deposition method—Novel applications in the field of sensing and energy technology. Funct. Mater. Lett. 2019, 12, 1930005. [Google Scholar] [CrossRef] [Green Version]

- Hanft, D.; Exner, J.; Schubert, M.; Stöcker, T.; Fuierer, P.; Moos, R. An overview of the Aerosol Deposition method: Process fundamentals and new trends in materials applications. J. Ceram. Sci. Technol. 2015, 6, 147–181. [Google Scholar] [CrossRef]

- Lee, D.-W.; Kim, H.-J.; Kim, Y.-H.; Yun, Y.-H.; Nam, S.-M. Growth Process of alpha-Al2O3 Ceramic Films on Metal Substrates Fabricated at Room Temperature by Aerosol Deposition. J. Am. Ceram. Soc. 2011, 94, 3131–3138. [Google Scholar] [CrossRef]

- Akedo, J. Room Temperature Impact Consolidation (RTIC) of Fine Ceramic Powder by Aerosol Deposition Method and Applications to Microdevices. J. Therm. Spray Technol. 2008, 17, 181–198. [Google Scholar] [CrossRef]

- Saunders, R.; Johnson, S.D.; Schwer, D.; Patterson, E.A.; Ryou, H.; Gorzkowski, E.P. A Self-Consistent Scheme for Understanding Particle Impact and Adhesion in the Aerosol Deposition Process. J. Therm. Spray Technol. 2021, 30, 523–541. [Google Scholar] [CrossRef]

- Ryu, J.; Park, D.-S.; Hahn, B.-D.; Choi, J.-J.; Yoon, W.-H.; Kim, K.-Y.; Yun, H.-S. Photocatalytic TiO2 thin films by aerosol-deposition: From micron-sized particles to nano-grained thin film at room temperature. Appl. Catal. B Environ. 2008, 83, 1–7. [Google Scholar] [CrossRef]

- Lee, B.-K.; Park, D.-S.; Yoon, W.-H.; Ryu, J.-H.; Hahn, B.-D.; Choi, J.-J. Microstructure and Properties of Yttria Film Prepared by Aerosol Deposition. J. Korean Ceram. Soc. 2009, 46, 441–446. [Google Scholar] [CrossRef] [Green Version]

- Baba, S.; Tsuda, H.; Akedo, J. Thickness dependence of electrical properties of PZT films deposited on metal substrates by laser-assisted aerosol deposition. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2008, 55, 1009–1016. [Google Scholar] [CrossRef]

- Khansur, N.H.; Eckstein, U.; Benker, L.; Deisinger, U.; Merle, B.; Webber, K.G. Room temperature deposition of functional ceramic films on low-cost metal substrate. Ceram. Int. 2018, 44, 16295–16301. [Google Scholar] [CrossRef]

- Heo, Y.J.; Kim, H.T.; Kim, K.J.; Nahm, S.; Yoon, Y.J.; Kim, J. Enhanced heat transfer by room temperature deposition of AlN film on aluminum for a light emitting diode package. Appl. Therm. Eng. 2013, 50, 799–804. [Google Scholar] [CrossRef]

- Park, D.-S.; Kim, I.-S.; Kim, H.; Chou, A.H.K.; Hahn, B.-D.; Li, L.-H.; Hwang, S.-J. Improved biocompatibility of hydroxyapatite thin film prepared by aerosol deposition. J. Biomed. Mater. Res. Part B Appl. Biomater. 2010, 94, 353–358. [Google Scholar] [CrossRef]

- Papyrin, A. Cold Spray Technology. Adv. Mater. Proc. 2001, 159, 49–51. [Google Scholar]

- Kim, Y.-H.; Lee, J.-W.; Kim, H.-J.; Yun, Y.-H.; Nam, S.-M. Silver metallization for microwave device using aerosol deposition. Ceram. Int. 2012, 38, S201–S204. [Google Scholar] [CrossRef]

- Lee, D.-W.; Kwon, O.-Y.; Cho, W.-J.; Song, J.-K.; Kim, Y.-N. Characteristics and Mechanism of Cu Films Fabricated at Room Temperature by Aerosol Deposition. Nanoscale Res. Lett. 2016, 11, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Khansur, N.H.; Eckstein, U.; Ursic, H.; Sadl, M.; Brehl, M.; Martin, A.; Riess, K.; de Ligny, D.; Webber, K.G. Enhanced Electromechanical Response and Thermal Stability of 0.93(Na1/2Bi1/2)TiO3-0.07BaTiO3 Through Aerosol Deposition of Base Metal Electrodes. Adv. Mater. Interfaces 2021, 8, 2100309. [Google Scholar] [CrossRef]

- Cho, M.-Y.; Lee, D.-W.; Kim, I.-S.; Lee, W.-H.; Yoo, J.-W.; Ko, P.-J.; Koo, S.-M.; Choi, Y.-K.; Oh, J.-M. Formation of silver films for advanced electrical properties by using aerosol deposition process. Jpn. J. Appl. Phys. 2018, 57, 11UF05. [Google Scholar] [CrossRef]

- Leupold, N.; Denneler, S.; Rieger, G.; Moos, R. Powder Treatment for Increased Thickness of Iron Coatings Produced by the Powder Aerosol Deposition Method and Formation of Iron–Alumina Multilayer Structures. J. Therm. Spray Technol. 2020, 30, 480–487. [Google Scholar] [CrossRef]

- Sugimoto, S.; Chan, V.; Noguchi, M.; Tezuka, N.; Inomata, K.; Akedo, J. Preparation of Fe/Ni–Zn–Cu ferrite stacked films by aerosol deposition method. J. Magn. Magn. Mater. 2007, 310, 2549–2551. [Google Scholar] [CrossRef]

- Kwon, J.; Park, H.; Lee, I.; Lee, C. Effect of gas flow rate on deposition behavior of Fe-based amorphous alloys in vacuum kinetic spray process. Surf. Coat. Technol. 2014, 259, 585–593. [Google Scholar] [CrossRef]

- Imanaka, Y.; Akedo, J. Embedded capacitor technology using aerosol deposition. Int. J. Appl. Ceram. Technol. 2010, 7, 23–32. [Google Scholar] [CrossRef]

- Miyoshi, T. Preparation of multilayer piezoelectric device by aerosol deposition using a novel detachment method. J. Ceram. Soc. Jpn. 2009, 117, 899–903. [Google Scholar] [CrossRef] [Green Version]

- Kambale, R.C.; Han, G.; Yoon, W.-H.; Kim, J.-W.; Choi, J.-J.; Hahn, B.-D.; Park, D.-S.; Ahn, C.-W.; Ryu, J. Reliability of ferroelectric multilayer PZT thick films fabricated by aerosol deposition. Ferroelectrics 2014, 470, 183–193. [Google Scholar] [CrossRef]

- Sadl, M.; Tomc, U.; Prah, U.; Ursic, H. Protective Alumina Coatings Prepared by Aerosol Deposition on Magnetocaloric Gadolinium Elements. Inf. MIDEM J. Microelectron. Electron. Compon. Mater. 2019, 49, 177–182. [Google Scholar] [CrossRef]

- Cha, G.; Kim, C.-J.; Ju, Y.S. Thermal conductance switching based on the actuation of liquid droplets through the electrowetting on dielectric (EWOD) phenomenon. Appl. Therm. Eng. 2016, 98, 189–195. [Google Scholar] [CrossRef] [Green Version]

- Klinar, K.; Kitanovski, A. Thermal control elements for caloric energy conversion. In Renewable and Sustainable Energy Reviews; Elsevier: Amsterdam, The Netherlands, 2020; Volume 118, p. 109571. [Google Scholar] [CrossRef]

- Swoboda, T.; Klinar, K.; Yalamarthy, A.S.; Kitanovski, A.; Rojo, M.M. Solid-State Thermal Control Devices. In Advanced Electronic Materials; Blackwell Publishing Ltd.: Hoboken, NJ, USA, 2021; Volume 7, p. 2000625. [Google Scholar] [CrossRef]

- Klinar, K.; Swoboda, T.; Rojo, M.M.; Kitanovski, A. Fluidic and Mechanical Thermal Control Devices. In Advanced Electronic Materials; Blackwell Publishing Ltd.: Hoboken, NJ, USA, 2021; Volume 7, p. 2000623. [Google Scholar] [CrossRef]

- Cheary, R.W.; Coelho, A. A fundamental parameters approach to X-ray line-profile fitting. J. Appl. Crystallogr. 1992, 25, 109–121. [Google Scholar] [CrossRef]

- Klug, H.P.; Alexander, L.E. X-Ray Diffraction Procedures: For Polycrystalline and Amorphous Materials, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1974. [Google Scholar]

- Akedo, J. Aerosol deposition of ceramic thick films at room temperature: Densification mechanism of ceramic layers. J. Am. Ceram. Soc. 2006, 89, 1834–1839. [Google Scholar] [CrossRef]

- Exner, J.; Schubert, M.; Hanft, D.; Kita, J.; Moos, R. How to treat powders for the room temperature aerosol deposition method to avoid porous, low strength ceramic films. J. Eur. Ceram. Soc. 2019, 39, 592–600. [Google Scholar] [CrossRef]

- Barsoum, M.W. Fundamentals of Ceramics; CRC Press: Boca Raton, FL, USA, 2019. [Google Scholar]

- Kingery, W.D.; Bowen, H.K.; Uhlmann, D.R. Introduction to Ceramics; Wiley: London, UK, 1976. [Google Scholar]

| Process Parameters | Al2O3 Powder | Al Powder |

|---|---|---|

| Carrier gas species | N2 | |

| Nozzle geometry (slit size) | (0.5 × 10) mm2 | |

| Distance between nozzle and substrate | 5 mm | |

| Sweep speed | 5 mm·s−1 | |

| Gas flow rate | 4 L·min−1 | 2 L·min−1 |

| Pressure in aerosol chamber | 180 mbar | 120 mbar |

| Pressure in deposition chamber | 2 mbar | 1 mbar |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadl, M.; Tomc, U.; Ursic, H. Investigating the Feasibility of Preparing Metal–Ceramic Multi-Layered Composites Using Only the Aerosol-Deposition Technique. Materials 2021, 14, 4548. https://doi.org/10.3390/ma14164548

Sadl M, Tomc U, Ursic H. Investigating the Feasibility of Preparing Metal–Ceramic Multi-Layered Composites Using Only the Aerosol-Deposition Technique. Materials. 2021; 14(16):4548. https://doi.org/10.3390/ma14164548

Chicago/Turabian StyleSadl, Matej, Urban Tomc, and Hana Ursic. 2021. "Investigating the Feasibility of Preparing Metal–Ceramic Multi-Layered Composites Using Only the Aerosol-Deposition Technique" Materials 14, no. 16: 4548. https://doi.org/10.3390/ma14164548

APA StyleSadl, M., Tomc, U., & Ursic, H. (2021). Investigating the Feasibility of Preparing Metal–Ceramic Multi-Layered Composites Using Only the Aerosol-Deposition Technique. Materials, 14(16), 4548. https://doi.org/10.3390/ma14164548