Design and Durability Assessment of Restoring Mortar for Concrete Heritage

Abstract

:1. Introduction

2. Materials and Methods

2.1. Durability Tests

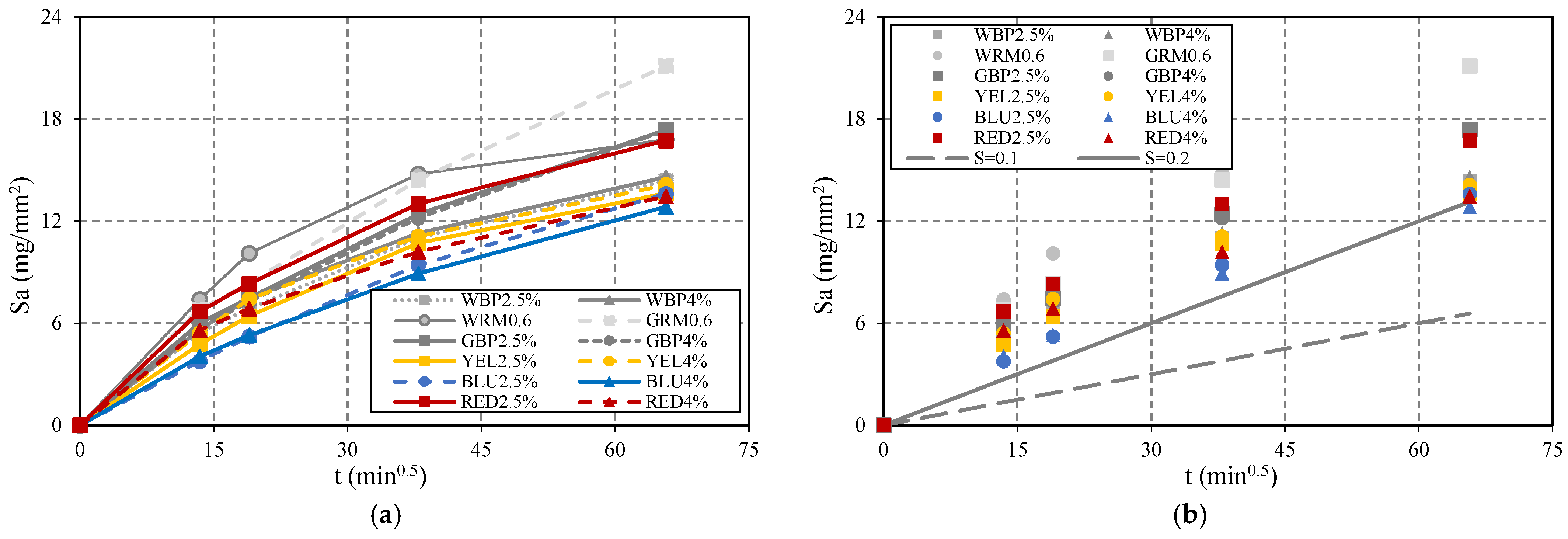

2.1.1. Capillary Water Absorption

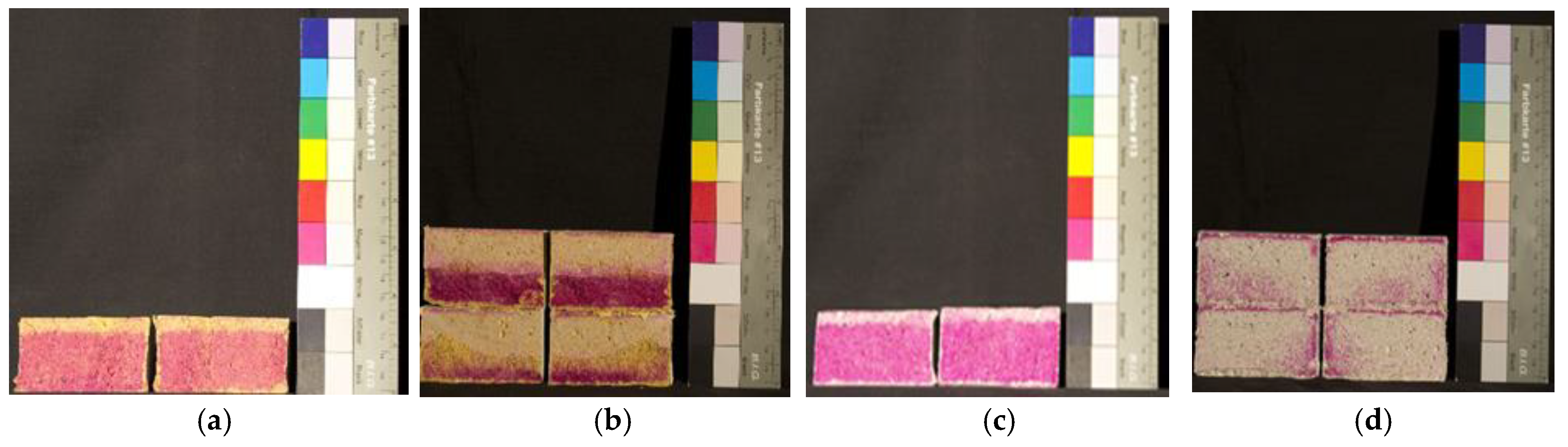

2.1.2. Accelerated Carbonation

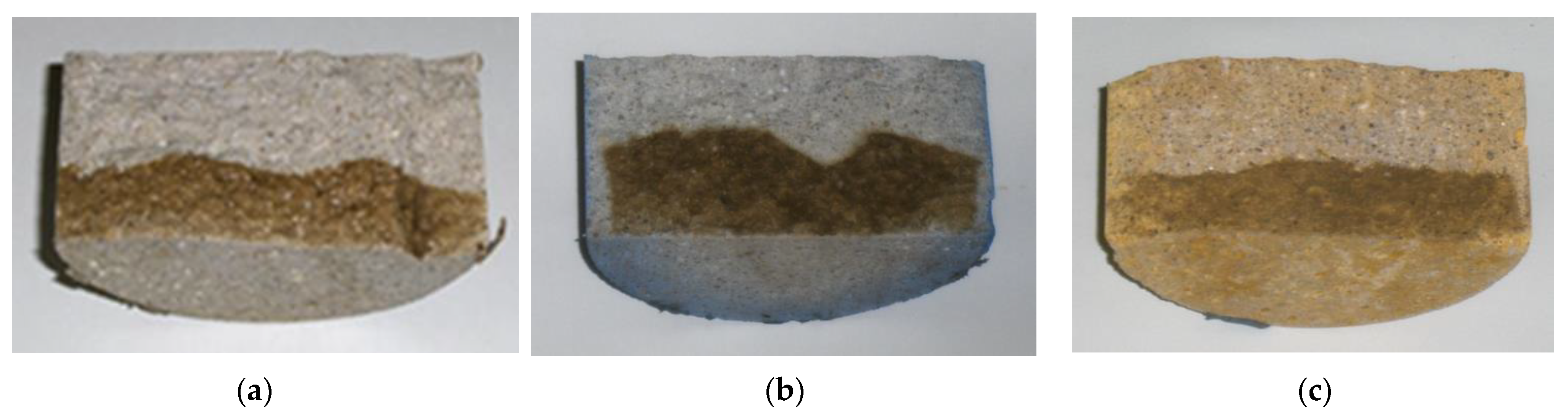

2.1.3. Diffusion Coefficient Chlorides

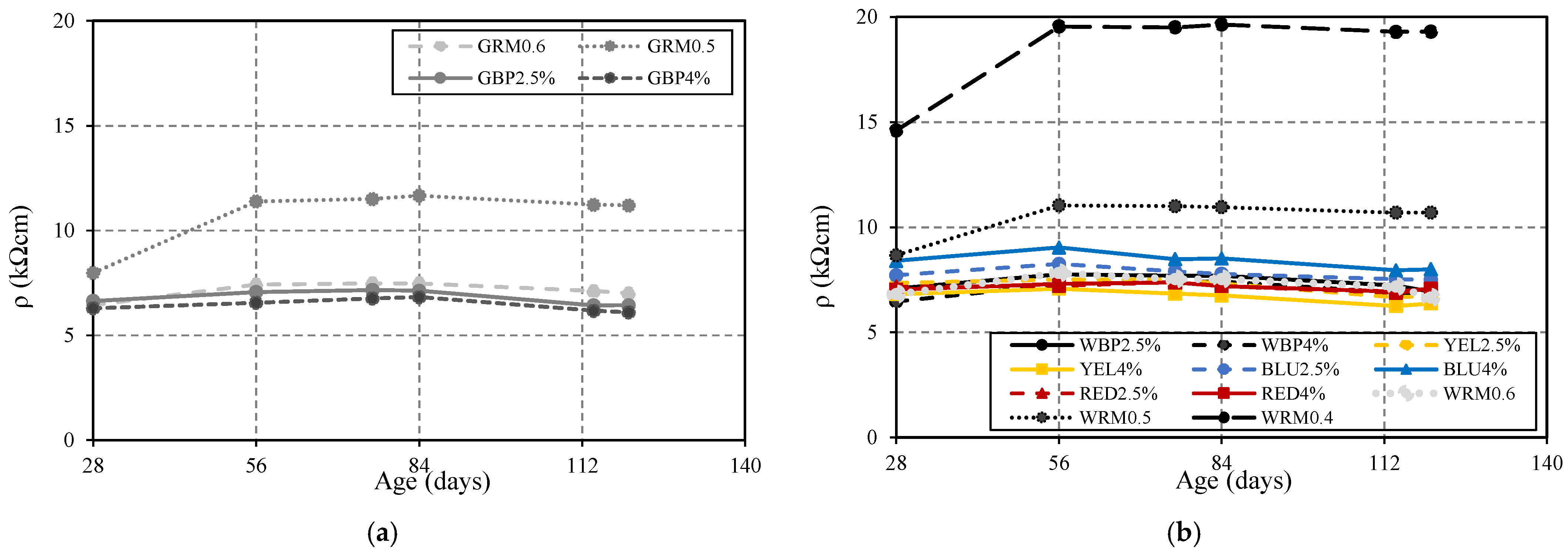

2.1.4. Electrical Resistivity

2.1.5. Shrinkage

2.2. Chromatic Evaluation Due to Carbonation

2.3. Service Life

2.3.1. Environmental Exposure XC (Carbonation-Induced Corrosion)

2.3.2. Environmental Exposure XS (Chloride-Induced Corrosion)

3. Restoration Mortar Evaluation

3.1. Durability Tests

3.1.1. Capillary Water Absorption Test

3.1.2. Accelerated Carbonation Test

3.1.3. Diffusion Coefficient Chlorides

3.1.4. Electrical Resistivity

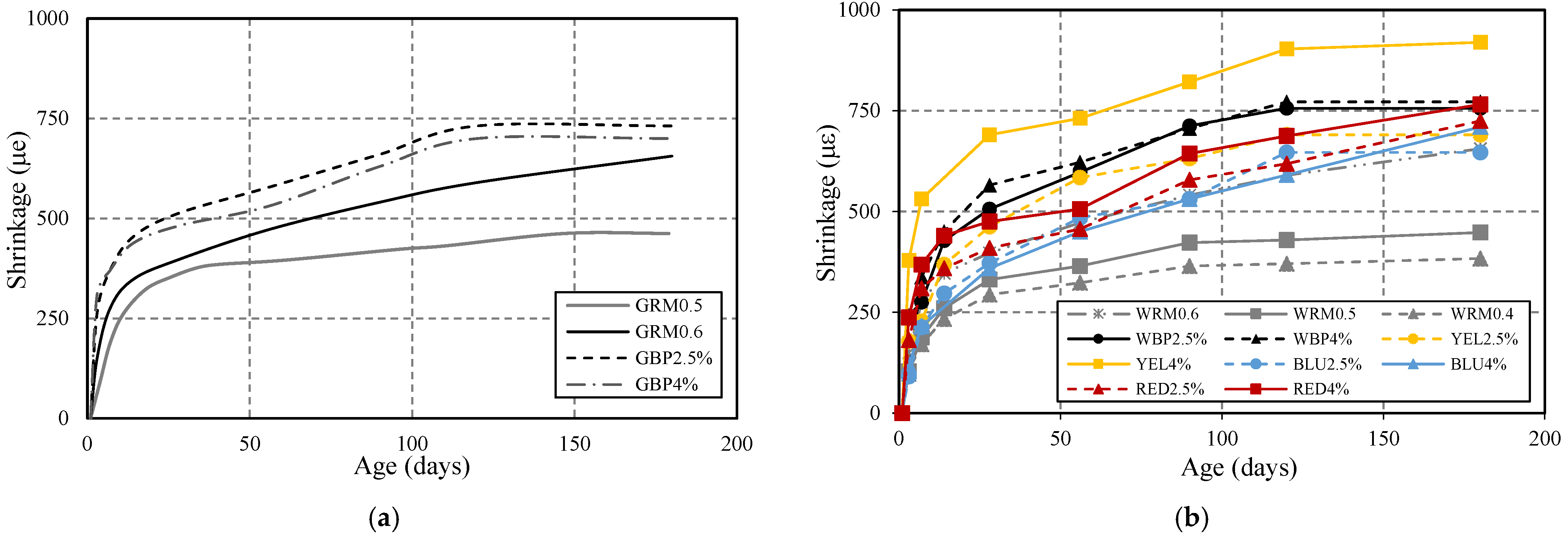

3.1.5. Shrinkage

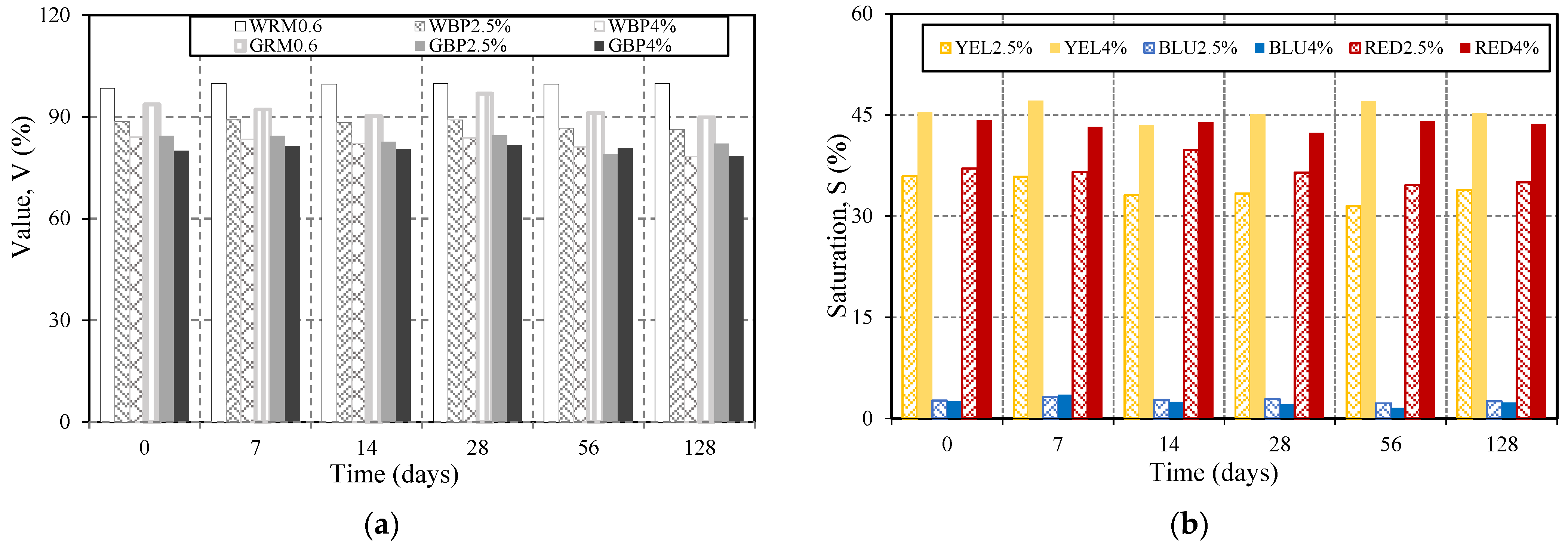

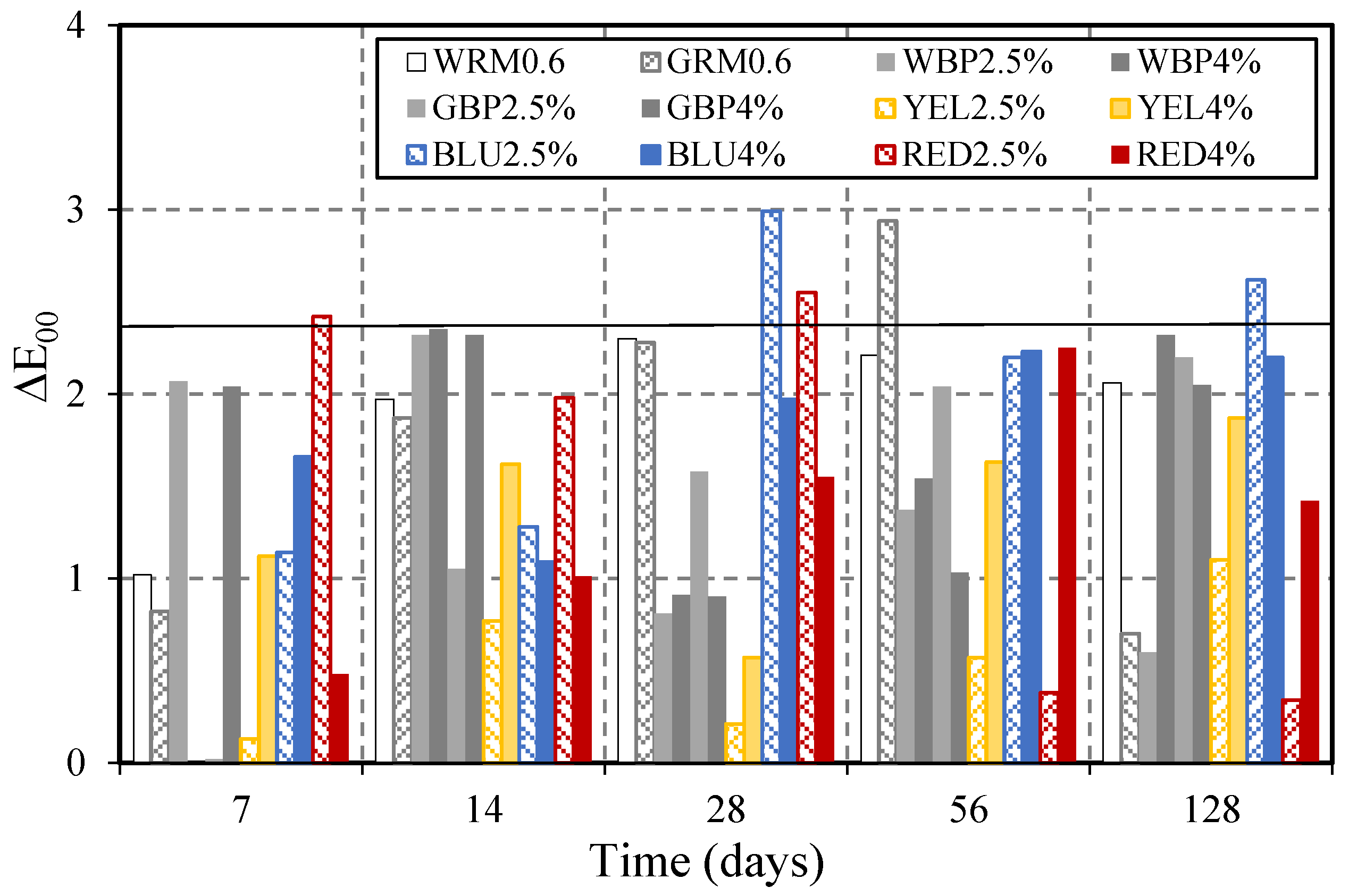

3.2. Chromatic Evaluation Due to Carbonation

3.3. Expected Service Life

3.3.1. Environmental Exposure XC (Corrosion Induced by Carbonation)

3.3.2. Environmental Exposure XS (Chloride-Induced Corrosion)

4. Conclusions

- (a)

- Indicators of durability performance

- (b)

- Colour change and shrinkage

- (c)

- Service life

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gaudette, P. Special Considerations in Repair of Historic Concrete. Concrete Repair Bulletin, International Concrete Repair Institute, Inc., St. Paul, Minnesota 55114 USA, January/February. 2000, pp. 12–13. Available online: https://www.icri.org/page/CRB_pastissues (accessed on 24 April 2019).

- McDonald, S.; Gonçalves, A. Conservation Principles for Concrete of Cultural Significance. Principles; Getty Co Servation Institute: Los Angeles, CA, USA, 2020; p. 27. ISBN 978-1-937433-80-2. [Google Scholar]

- Valença, J.; Almeida, C.; Miranda, J.; Júlio, E. Patch restoration method: A new concept for concrete heritage. Constr. Build. Mater. 2015, 101, 643–651. [Google Scholar] [CrossRef]

- Miranda, J.; Valença, J.; Costa, H.; Júlio, E. Chromatic design and application of restoration mortars on smooth surfaces of white and gray concrete. Structural Concrete. J. Fiber 2021, 22, 535–548. [Google Scholar] [CrossRef]

- Miranda, J.; Valença, J.; Júlio, E. Coloured concrete restoration method. For chromatic design and application of restoration mortars on smooth surfaces of coloured concrete. Structural Concrete. J. Fiber 2021, 20, 1391–1401. [Google Scholar] [CrossRef]

- Coutinho, A.S.; Gonçalves, A. Concrete Manufacturing and Properties; National Laboratory of Civil Engineering (LNEC): Lisboa, Portugal, 1994; Volume III, p. 368. (In Portuguese) [Google Scholar]

- Coutinho, J.S. Improving the Durability of Concrete by Treating Formwork, 1st ed.; FEUP: Porto, Portugal, 2005. (In Portuguese) [Google Scholar]

- EN 206-1. Concrete—Part 1: Specification, Performance, Production and Conformity; CEN: Brussels, Belgium, 2007. [Google Scholar]

- Miranda, J. Method for the Characterization and Application of Restoration Mortars on Smooth Concrete Surfaces. DEGRADA 2016. In Proceedings of the 2nd Luso-Brazilian Meeting on the Degradation of Concrete Structures; National Laboratory of Civil Engineering (LNEC): Lisboa, Portugal, 2016. (In Portuguese) [Google Scholar]

- Silva, A.S. Workshop. Expansive Reactions in Concrete; Context of Structures and Materials Subject to Internal Expansive Reactions. FCT EXREACT Project—Mitigation of Harmful Expansive Reactions in Concrete Structures (PTDC/CTM/65243/2006); National Civil Engineering Laboratory (LNEC): Lisboa, Portugal, 2010; pp. 7–39. (In Portuguese) [Google Scholar]

- EN 1015-18. Methods of Test for Mortar for Masonry—Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar; CEN: Brussels, Belgium, 2002. [Google Scholar]

- E393. Concrete. Determination of the Absorption of Water through Capillarity; National Laboratory of Civil Engineering (LNEC): Lisboa, Portugal, 1993. (In Portuguese) [Google Scholar]

- Ferreira, M.R. Evaluation of Concrete Durability Tests. Master’s Thesis, Civil Engineering—Materials and Construction Rehabilitation, Minho School of Engineering, University of Minho, Guimarães, Portugal, September 2020. (In Portuguese). [Google Scholar]

- E391. Concrete. Determination of Carbonation Resistance; National Laboratory of Civil Engineering (LNEC): Lisboa, Portugal, 1993. (In Portuguese) [Google Scholar]

- CPC-18. Measurement of Hardened Concrete Carbonatation Depth. In Materials and Structures; Springer: Berlin/Heidelberg, Germany, 1988; Volume 21, pp. 453–455. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Education: London, UK, 2012. [Google Scholar]

- Nordtest Ntbuild 492. Concrete Mortar and Cement-Based Repair Materials: Chloride Migration Coefficient from Non-Steady State Migration Experiments; Nordtest: Espoo, Finland, 1999. [Google Scholar]

- Cement Concrete & Aggregate Australia, Chloride Resistance of Concrete. CCAA Report, CCAA: Sydney, Australia. June 2009. Available online: https://www.ccaa.com.au (accessed on 5 May 2020).

- E463 Concrete. Determination of the Chloride Diffusion Coefficient by Migration Test in a Non-Stationary Regime; National Laboratory of Civil Engineering (LNEC): Lisboa, Portugal, 2004. (In Portuguese) [Google Scholar]

- Silva, P.C.F. Electrical Resisitivity and Concrete Quality Control Master’s Dissertation. Master’s Thesis, University of Minho, Guimarães, Portugal, 2011. [Google Scholar]

- Cascudo, O. Teaching Reseatch and Achievements; Ibracon: São Paulo, Brazil, 2005; Volume 1, pp. 713–751. [Google Scholar]

- AASHTO T 358. Standard Method of Test for Surface Resistivity Indication of Concrete’s Ability to Resist Chloride Ion Penetration; American Association of State Highway and Transportation Officials: Washington, WA, USA, 2015. [Google Scholar]

- EN 1015-13. Methods of Test for Mortar for Masonry—Part 13. Determination of Dimensional Stability of Hardened Mortars; CEN: Brussels, Belgium, 1995. [Google Scholar]

- Robertson, A.R. Historical development of CIE recommended color difference equations. Color Res. Appl. 2007, 15, 167–170. [Google Scholar] [CrossRef]

- Deutsches Institut fur Normung. DIN 6174: Colorimetric Evaluation of Colour Coordinates and Colour Differences According to the Approximately Uniform CIELAB Colour Space; DIN Edition: Berlin, Germany, 2007. [Google Scholar]

- E465. Methodology for Estimating the Concrete Performance Properties Allowing to Comply with the Design Working Life of the Reinforced or Prestressed Concrete Structures under the Environmental Exposures XC and XS; National Laboratory of Civil Engineering (LNEC): Lisboa, Portugal, 2007. (In Portuguese) [Google Scholar]

| Pigment | Phases | Density (kg/dm3) | Average Particle Diameter (nm) | Particle Shape |

|---|---|---|---|---|

| Yellow | FeHO2 | 4.25 | 48.73 | acicular |

| Red | Fe2O3 | 5.25 | 69.22 | spherical |

| Black | Fe3O4 | 5.18 | 67.02 | spherical |

| Blue | Co3O4 | 6.44 | 46.53 | prismatic |

| Mortar | Cement (kg/m3) | Filler (kg/m3) | Sand (kg/m3) | Water (kg/m3) | Superplast. (kg/m3) | W/C | |

|---|---|---|---|---|---|---|---|

| Colour | Reference | ||||||

| WRM0.6 | 400 | 180 | 1347 | 240 | 0.00 | 0.6 | |

| White | WRM0.5 | 400 | 180 | 1463 | 200 | 1.00 | 0.5 |

| WRM0.4 | 400 | 180 | 1564 | 160 | 2.80 | 0.4 | |

| Grey | GRM0.6 | 400 | 180 | 1355 | 240 | 0.00 | 0.6 |

| GRM0.5 | 400 | 180 | 1471 | 200 | 1.00 | 0.5 | |

| Mortar | Spread Diameter (cm) | Air Content (%) | Strength (MPa), at 28 Days | ||

|---|---|---|---|---|---|

| Colour | Reference | Flexural | Compressive | ||

| WRM0.6 | 11.5 | 5.0 | 7.8 | 59.0 | |

| White | WRM0.5 | 11.0 | 4.6 | 8.3 | 73.0 |

| WRM0.4 | 10.5 | 4.3 | 9.8 | 87.2 | |

| Grey | GRM0.6 | 12.0 | 4.8 | 7.7 | 51.6 |

| GRM0.5 | 11.5 | 4.5 | 7.3 | 66.8 | |

| Tests | Samples | Cure | Age |

|---|---|---|---|

| Capillary water absorption | 40 × 40 × 160 mm 3 samples | Water curing (20 °C ± 2 °C) | Test at 3, 6, 24, and 72 h |

| Accelerated carbonation test | 40 × 40 × 160 mm 3 samples per age | 14 days in water curing (T = 20 °C); 14 days in air dry (HR = 50% and T = 20 °C) | Test at 7, 14, 26, 56, and 128 days |

| Non-stationary migration test | Ø 100 × 50 mm 2 samples per age | 7 days of water curing (T = 20 °C); Cut; 21 days of air dry (HR = 50% and T = 20 °C) | Test at 28 and 56 days |

| Shrinkage | 40 × 40 × 160 mm 2 samples | Air dry curing (HR = 50% and T = 20 °C) | Measure at 1, 3, 7, 14, 28, 56, 90, 120, 180 days |

| Resistivity | Ø 100 × 200 mm 1 sample | Water curing (20 °C ± 2 °C) | Measure at 28, 56, 76, 84, 114, and 128 days |

| WRM0.6 | WRM0.5 | WRM0.4 | GRM0.6 | GRM0.5 | WBP 2.5% | WBP 4% | GBP 2.5% | GBP 4% | YEL 2.5% | YEL 4% | BLU 2.5% | BLU 4% | RED 2.5% | RED 4% |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 65 | >1000 | >1000 | 123 | >1000 | 115 | 47 | 149 | 127 | 66 | 73 | >1000 | 176 | 69 | 65 |

| WRM0.6 | WRM0.5 | WRM0.4 | GRM0.6 | GRM0.5 | WBP 2.5% | WBP 4% | GBP 2.5% | GBP 4% | YEL 2.5% | YEL 4% | BLU 2.5% | BLU 4% | RED 2.5% | RED 4% |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16.4 | 9.4 | 6.2 | 16.4 | 9.4 | 16.4 | 15.4 | 16.9 | 19.8 | 23.7 | 19.2 | 15.1 | 12.3 | 30.1 | 22.5 |

| Group of Mortar | Cover (mm) | Current Structures | |||

|---|---|---|---|---|---|

| XS1 2 | XS2 3 | XS3 4 | |||

| 1 m | 1.4–25 m | ||||

| {WBP4%, BLU2.5%, BLU_4%} | 20 | 1 | 40 | 40 | 0 |

| 30 | 5 | 41 | 41 | 0 | |

| 40 | 18 | 43 | 42 | 1 | |

| 50 | 48 | 48 | 46 | 1 | |

| 60 | >100 | 55 | 51 | 3 | |

| {WRM0.6, GRM0.6, WBP2.5% GBP2.5%} | 20 | 1 | 40 | 40 | 0 |

| 30 | 4 | 41 | 41 | 0 | |

| 40 | 14 | 43 | 42 | 0 | |

| 50 | 39 | 46 | 45 | 1 | |

| 60 | 88 | 52 | 49 | 3 | |

| {WRM0.5, WRM0.4, GRM0.5} | 20 | 4 | 41 | 41 | 0 |

| 30 | 22 | 44 | 43 | 1 | |

| 40 | 79 | 50 | 47 | 2 | |

| 50 | >100 | 63 | 56 | 6 | |

| 60 | >100 | 85 | 71 | 12 | |

| {YEL2.5%, YEL4%, GBP4%, RED4%} | 20 | 0 | 40 | 40 | 0 |

| 30 | 2 | 41 | 40 | 0 | |

| 40 | 7 | 42 | 41 | 0 | |

| 50 | 18 | 43 | 43 | 1 | |

| 60 | 41 | 47 | 45 | 1 | |

| 20 | 0 | 40 | 40 | 0 | |

| 30 | 1 | 40 | 40 | 0 | |

| {RED2.5%} | 40 | 4 | 41 | 41 | 0 |

| 50 | 11 | 42 | 42 | 0 | |

| 60 | 24 | 44 | 43 | 1 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miranda, J.; Costa, H.; Valença, J.; Carmo, R.d.; Júlio, E. Design and Durability Assessment of Restoring Mortar for Concrete Heritage. Materials 2021, 14, 4508. https://doi.org/10.3390/ma14164508

Miranda J, Costa H, Valença J, Carmo Rd, Júlio E. Design and Durability Assessment of Restoring Mortar for Concrete Heritage. Materials. 2021; 14(16):4508. https://doi.org/10.3390/ma14164508

Chicago/Turabian StyleMiranda, Judite, Hugo Costa, Jónatas Valença, Ricardo do Carmo, and Eduardo Júlio. 2021. "Design and Durability Assessment of Restoring Mortar for Concrete Heritage" Materials 14, no. 16: 4508. https://doi.org/10.3390/ma14164508

APA StyleMiranda, J., Costa, H., Valença, J., Carmo, R. d., & Júlio, E. (2021). Design and Durability Assessment of Restoring Mortar for Concrete Heritage. Materials, 14(16), 4508. https://doi.org/10.3390/ma14164508