Study on the Frost Resistance of Concrete Modified with Steel Balls Containing Phase Change Material (PCM)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Encapsulation and Preparation of Phase Change Steel Balls and Grouting Steel Balls

2.3. Preparation of Concrete Mixed with Phase Change Steel Balls

2.4. Preparation of Concrete Mixed with Grouting Steel Balls

2.5. Test Design

2.5.1. Mechanical Performance Test

2.5.2. Rapid Freeze–Thaw Test

2.5.3. Industrial CT Inspection

3. Results and Discussion

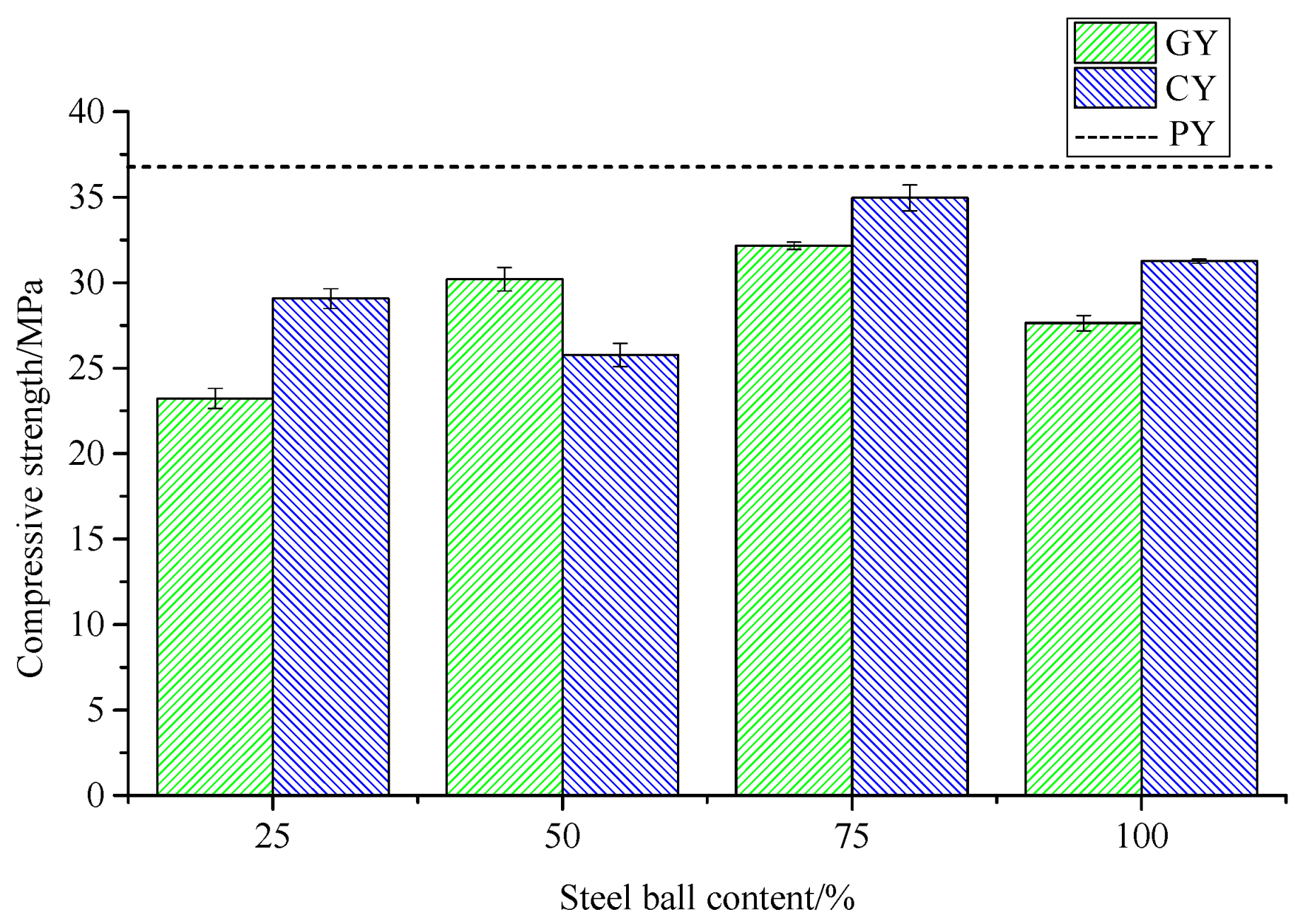

3.1. Compressive Strength of Concrete Mixed with Grouting Steel Balls

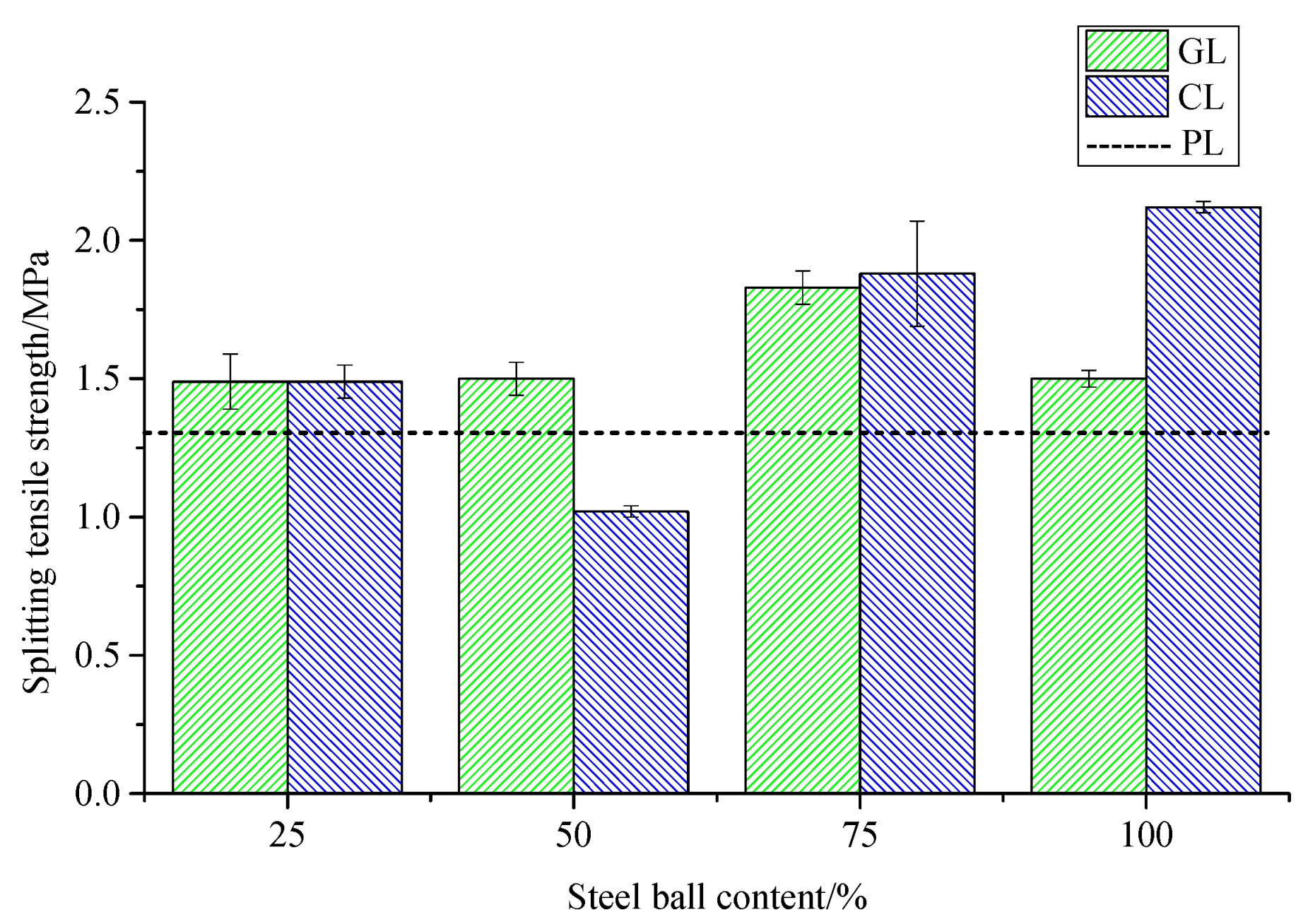

3.2. Splitting Tensile Strength of Concrete Mixed with Grouting Steel Balls

3.3. Frost Resistance of Concrete Mixed with Phase Change Steel Balls

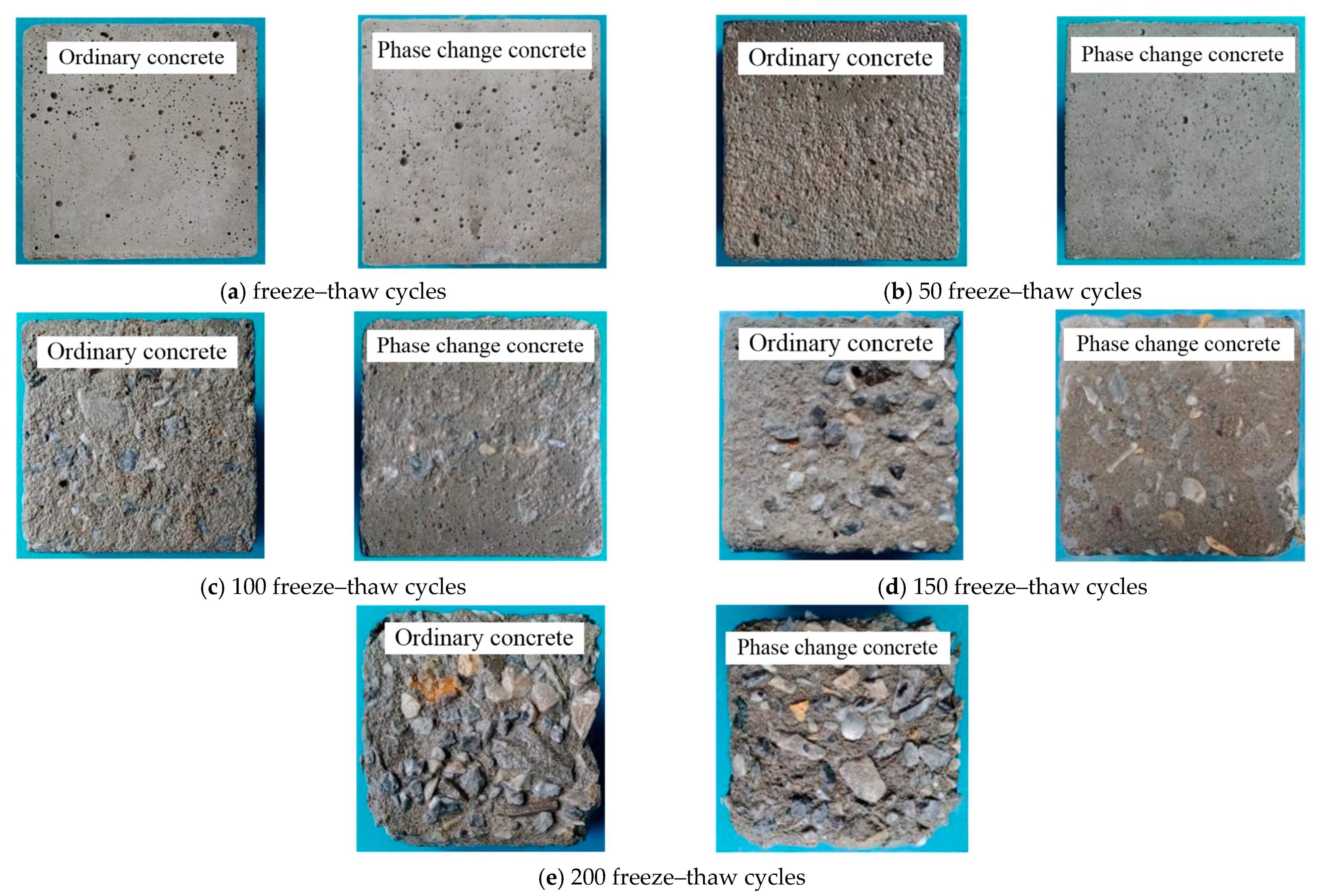

3.3.1. Surface Spalling

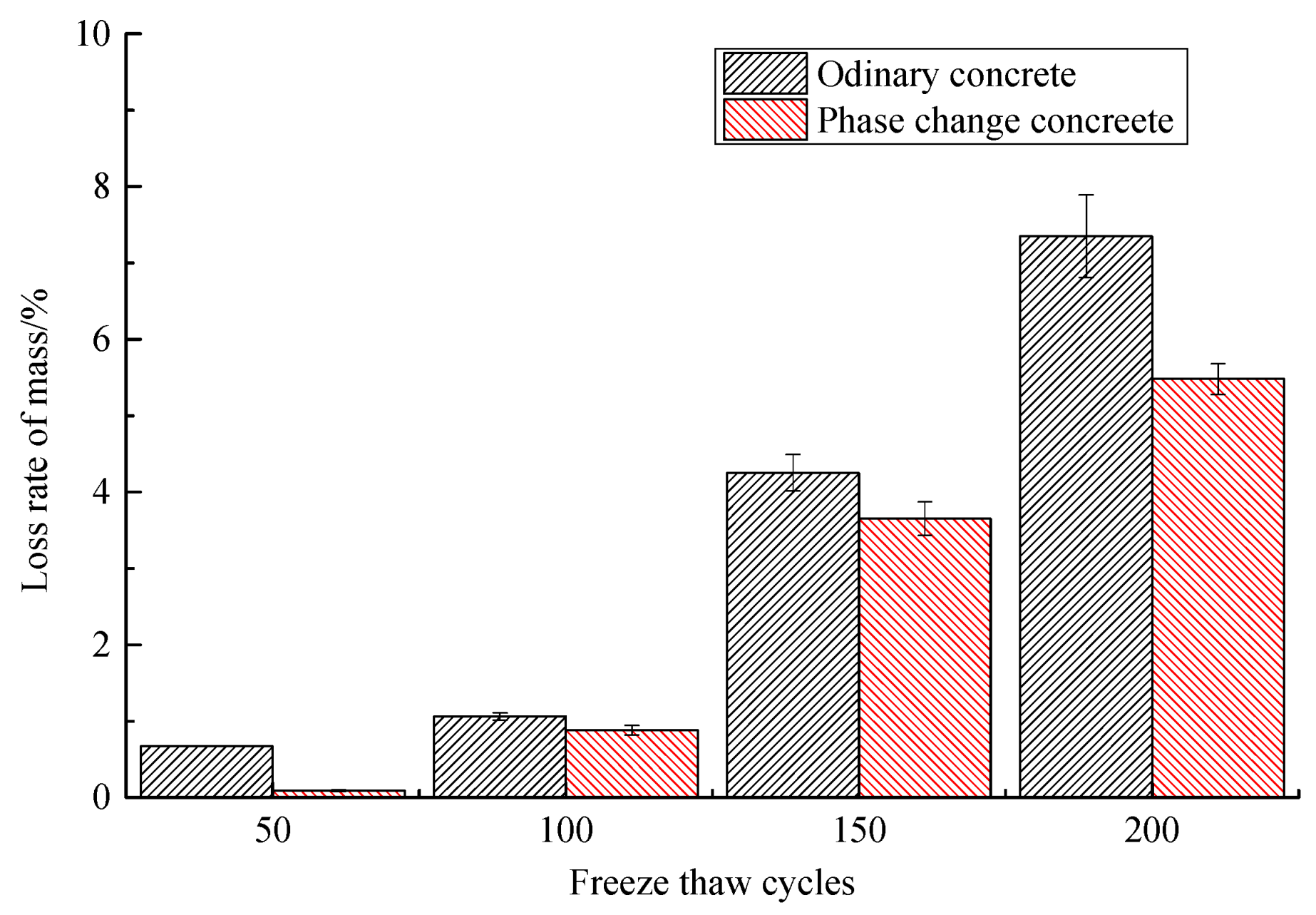

3.3.2. Mass Loss and Relative Dynamic Modulus of Elasticity

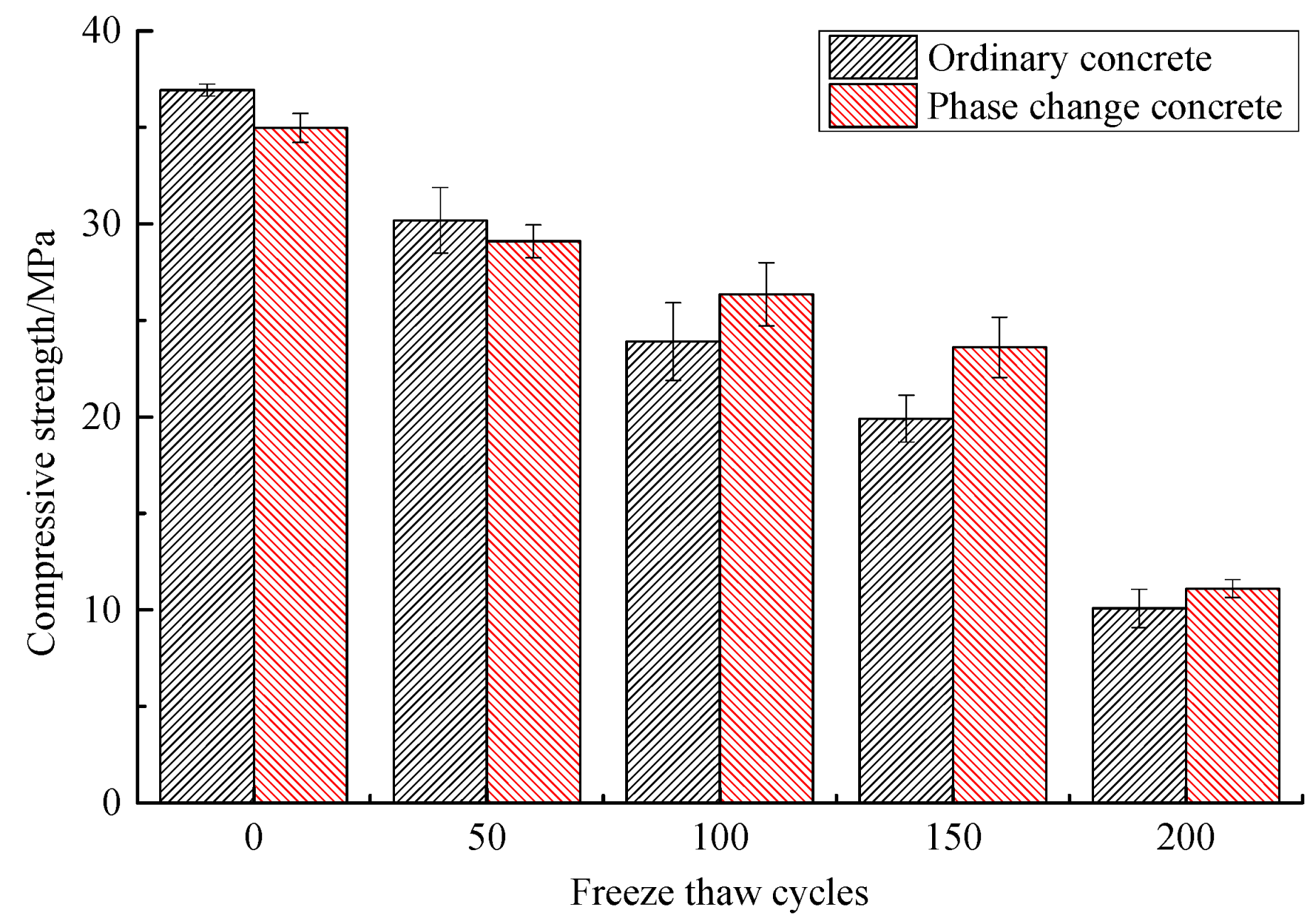

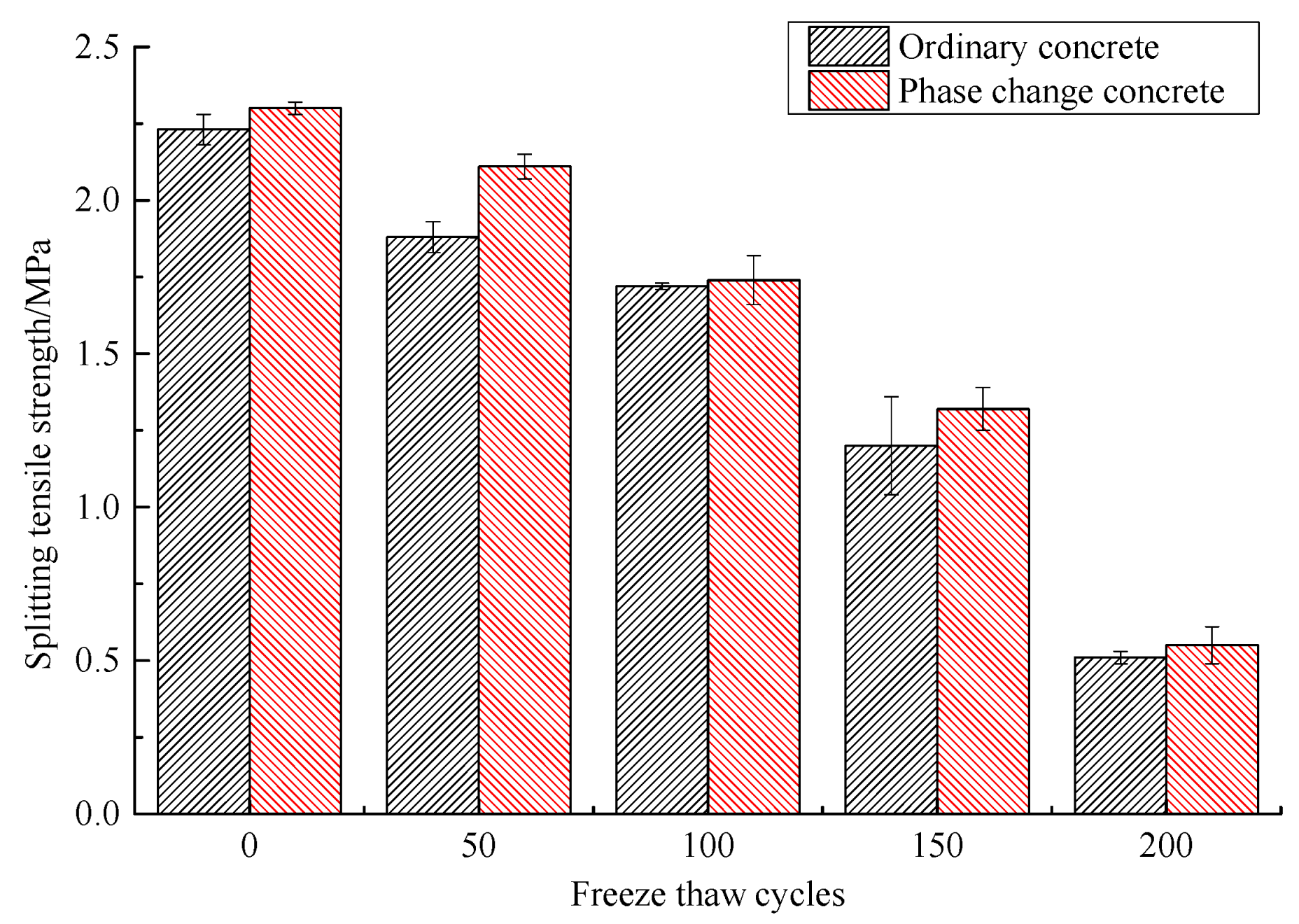

3.3.3. Mechanical Properties

3.4. Analysis of the Pore Structure in Concrete

3.4.1. Porosity

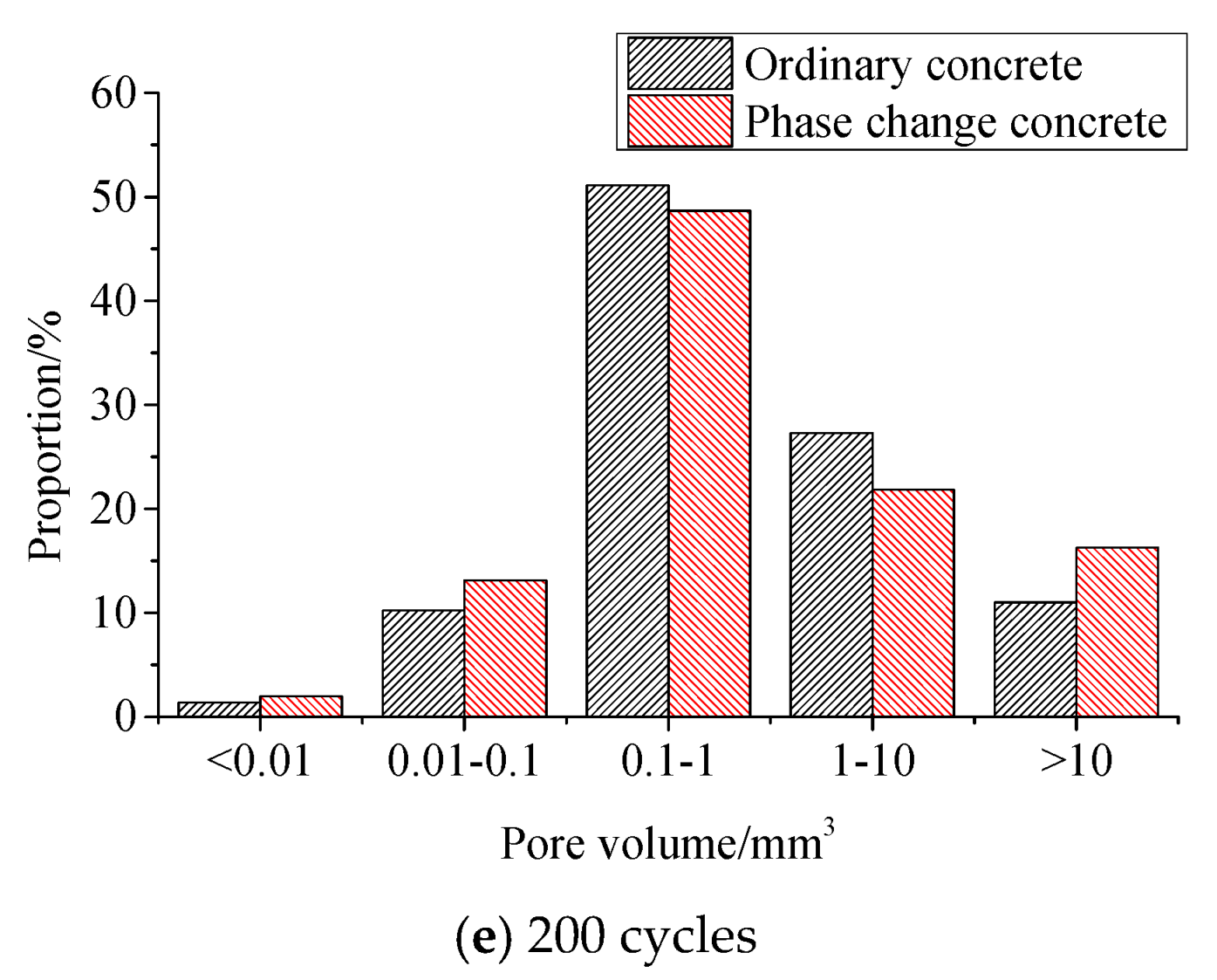

3.4.2. Pore Distribution

4. Conclusions

- (1)

- The incorporation of grouting steel balls can reduce compressive strength and increase the splitting tensile strength of concrete to varying degrees, and the balls with the rough surface have a better effect on the modification of concrete; combining the results of compressive strength and splitting tensile strength, the optimum dosing of grouting steel balls can be initially determined to be 75%.

- (2)

- During the freeze–thaw process, all the freeze-resistance indexes of phase change concrete are better than those of ordinary concrete. In the early freeze–thaw period (50 cycles), the difference in compressive strength loss between ordinary concrete and phase change concrete is not significant, while the improvement in splitting tensile strength of phase change concrete is more obvious at this time. In the middle freeze–thaw period (100–150 freeze–thaw cycles), the difference between them increases greatly and the advantage of phase change materials in improving the reduction of compressive strength is significant. In the late freeze–thaw period (200 freeze–thaw cycles), the difference in strength loss between the two types of concrete is not obvious.

- (3)

- Throughout the whole freeze–thaw process, the change in porosity of phase change concrete is significantly lower than that of ordinary concrete, and its internal deterioration is lesser. The addition of phase change materials optimises the pore structure distribution in concrete and improves the internal pore structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kürklü, A. Energy storage applications in greenhouses by means of phase change materials (PCMs): A review. Renew. Energy 1998, 13, 89–103. [Google Scholar] [CrossRef]

- Lecompte, T.; Bideau, P.L.; Glouannec, P.; Nortershauser, D.; Masson, S.L. Mechanical and thermo-physical behaviour of concretes and mortars containing phase change material. Energy Build. 2015, 94, 52–60. [Google Scholar] [CrossRef]

- Yan, Q.; He, W.; Yue, L. Experimental study on preparation of phase change energy storage building materials by direct immersion method. New Build. Mater. 2015, 42, 78–80. (In Chinese) [Google Scholar]

- Tie, S.; Liu, X.; Tie, J. Research progress of corrosivity of phase change material and relevant packaging materials. Mater. Rep. 2015, 29, 138–143. (In Chinese) [Google Scholar]

- Jessica, G.P.; Refat, A.S.; Fernández, A.; Mohammed, F. Preparation and Characterization of Microencapsulated Phase Change Materials for Use in Building Applications. Materials 2015, 9, 11–23. [Google Scholar]

- Šavija, B.; Zhang, H.; Schlangen, E. Influence of Microencapsulated Phase Change Material (PCM) Addition on (Micro) Mechanical Properties of Cement Paste. Materials 2017, 10, 863. [Google Scholar] [CrossRef] [Green Version]

- Sakulich, A.R.; Bentz, D.P. Incorporation of phase change materials in cementitious systems via fine lightweight aggregate. Constr. Build. Mater. 2012, 35, 483–490. [Google Scholar] [CrossRef]

- Lin, Z.; Zhuo, Y.; Ji, Z.; Cui, H. Review of PCM in Macro Encapsulated Form and Improving Conductivity. Build. Energy Effic. 2016, 44, 105–111. (In Chinese) [Google Scholar]

- Liu, Y.; Xie, M.; Gao, X.; Yang, Y.; Sang, Y. Experimental exploration of incorporating form-stable hydrate salt phase change materials into cement mortar for thermal energy storage. Appl. Therm. Eng. 2018, 140, 112–119. [Google Scholar] [CrossRef]

- Kheradmand, M.; Castro-Gomes, J.; Azenha, M.; Silva, P.D.; de Aguiar, J.L.B.; Zoorob, S.E. Assessing the feasibility of impregnating phase change materials in lightweight aggregate for development of thermal energy storage systems. Constr. Build. Mater. 2015, 89, 48–59. [Google Scholar] [CrossRef] [Green Version]

- Lee, T.; Hawes, D.W.; Banu, D.; Feldman, D. Control aspects of latent heat storage and recovery in concrete. Sol. Energy Mater. Sol. Cells 2000, 62, 217–237. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Castellón, C.; Nogués, M.; Medrano, M.; Leppers, R.; Zubillaga, O. Use of microencapsulated PCM in concrete walls for energy savings. Energy Build. 2006, 39, 113–119. [Google Scholar] [CrossRef]

- Chai, M. Research on the Effect of Integrating Energy Saving and Structure Performance in Concrete with Phase Change Steel Ball. Master′s Thesis, Shenzhen University, Shenzhen, China, 2015. (In Chinese). [Google Scholar]

- Hadjieva, M.; Stoykov, R.T.Z. Composite salt-hydrate concrete system for building energy storage. Renew. Energy 2000, 19, 111–115. [Google Scholar] [CrossRef]

- Koschenz, M.; Lehmann, B. Development of a thermally activated ceiling panel with PCM for application in lightweight and retrofitted buildings. Energy Build. 2004, 36, 567–578. [Google Scholar] [CrossRef]

- Karim, L.; Barbeon, F.; Gegout, P.; Bontemps, A.; Royon, L. New phase-change material components for thermal management of the light weight envelope of buildings. Energy Build. 2014, 68, 703–706. [Google Scholar] [CrossRef]

- Ryms, M.; Klugmann-Radziemska, E. Possibilities and benefits of a new method of modifying conventional building materials with phase-change materials (PCMs). Constr. Build. Mater. 2019, 211, 1013–1024. [Google Scholar] [CrossRef]

- Ryms, M.; Januszewicz, K.; Kazimierski, P.; Łuczak, J.; Klugmann-Radziemska, E.; Lewandowski, W.M. Post-Pyrolytic Carbon as a Phase Change Materials (PCMs) Carrier for Application in Building Materials. Materials 2020, 13, 1268. [Google Scholar] [CrossRef] [Green Version]

- Mazzucco, G.; Xotta, G.; Salomoni, V.A.; Giannuzzi, M.; Maiorana, C.E. Solid Thermal Storage with PCM Materials. Numerical Investigations. Appl. Therm. Eng. 2017, 124, 545–559. [Google Scholar] [CrossRef]

- Luo, T.; Ma, J.; Liu, F.; Zhang, M.; Sun, C.; Ji, Y.; Yuan, X. Direct incorporation of Paraffin wax as Phase Change Material into mass concrete for temperature control: Mechanical and thermal properties. Sci. Cold Arid. Reg. 2021, 13, 30–42. [Google Scholar]

- Kim, Y.R.; Khil, B.S.; Jang, S.J.; Choi, W.C.; Yun, H.D. Effect of barium-based phase change material (PCM) to control the heat of hydration on the mechanical properties of mass concrete. Thermochim. Acta 2015, 613, 100–107. [Google Scholar] [CrossRef]

- Qian, C.; Gao, G. Reduction of interior temperature of mass concrete using suspension of phase change materials as cooling fluid. Constr. Build. Mater. 2012, 26, 527–531. [Google Scholar] [CrossRef]

- Nayak, S.; Krishnan, N.M.A.; Das, S. Microstructure-guided numerical simulation to evaluate the influence of phase change materials (PCMs) on the freeze-thaw response of concrete pavements. Constr. Build. Mater. 2019, 201, 246–256. [Google Scholar] [CrossRef] [Green Version]

- Bentz, D.P.; Turpin, R. Potential applications of phase change materials in concrete technology. Cem. Concr. Comp. 2007, 29, 527–532. [Google Scholar] [CrossRef] [Green Version]

| Type | CaO | SiO2 | Al2O3 | Fe2O3 | TiO2 | MgO | SO3 | Na2O | Ignition Loss |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 8.93 | 48.50 | 25.36 | 5.12 | 0.57 | 1.15 | 1.15 | 0.52 | 0.79 |

| Fly ash | 4.88 | 49.02 | 31.56 | 6.97 | - | 0.83 | 1.2 | - | 3.65 |

| Normal Consistency (%) | Setting Time (h) | Stability | Compressive Strength (MPa) | Flexural Strength (MPa) | Density (g/cm3) | |||

|---|---|---|---|---|---|---|---|---|

| Initial | Final | 3 Days | 28 Days | 3 Days | 28 Days | |||

| 25.3 | 1:38 | 2:33 | Qualified | 18.3 | 39.3 | 2.6 | 6.2 | 3.11 |

| Specific Surface Area (m2/kg) | Apparent Density (g/cm3) | Fineness (45 μm) | Water Content | Water Demand Ratio |

|---|---|---|---|---|

| 0.994 | 2.56 | 18.0% | 0.4% | 88.0% |

| Type | C | FA | S | W | SBPCM | Coarse Aggregate | WRA | AEA | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Small | Medium | Large | ||||||||

| Ordinary concrete | 202 | 87 | 688 | 130 | 0 | 389 | 505 | 355 | 1.1918 | 0.0202 |

| Phase change concrete | 202 | 87 | 688 | 130 | 214.5 | 389 | 505 | 88.75 | 1.1918 | 0.0202 |

| Type | C | FA | S | W | GSB | CA | WRA | AEA | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Small | Medium | Large | ||||||||

| Ordinary Concrete | 202 | 87 | 688 | 130 | 0 | 389 | 505 | 355 | 1.1918 | 0.0202 |

| Grouted steel ball concrete | 202 | 87 | 688 | 130 | 100 | 389 | 505 | 266.25 | 1.1918 | 0.0202 |

| 202 | 87 | 688 | 130 | 200 | 389 | 505 | 177.5 | 1.1918 | 0.0202 | |

| 202 | 87 | 688 | 130 | 300 | 389 | 505 | 88.75 | 1.1918 | 0.0202 | |

| 202 | 87 | 688 | 130 | 400 | 389 | 505 | 0 | 1.1918 | 0.0202 | |

| No. | Compressive Strength (MPa) | No. | Compressive Strength (MPa) |

|---|---|---|---|

| PY | 36.93 ± 0.31 | ||

| GY25 | 23.23 ± 0.59 | CY25 | 29.07 ± 0.58 |

| GY50 | 30.20 ± 0.69 | CY50 | 25.77 ± 0.68 |

| GY75 | 32.17 ± 0.21 | CY75 | 34.97 ± 0.75 |

| GY100 | 27.63 ± 0.45 | CY100 | 31.27 ± 0.12 |

| No. | Loss Rate (%) | ||

|---|---|---|---|

| PY | 0 | ||

| GY25 | 37.10 | CY25 | 21.28 |

| GY50 | 18.22 | CY50 | 30.22 |

| GY75 | 12.89 | CY75 | 5.31 |

| GY100 | 25.18 | CY100 | 15.33 |

| No. | Splitting Tensile Strength (MPa) | No. | Splitting Tensile Strength (MPa) |

|---|---|---|---|

| PL | 1.31 ± 0.05 | ||

| GL25 | 1.49 ± 0.10 | CL25 | 1.49 ± 0.06 |

| GL50 | 1.50 ± 0.06 | CL50 | 1.02 ± 0.02 |

| GL75 | 1.83 ± 0.06 | CL75 | 1.88 ± 0.19 |

| GL100 | 1.58 ± 0.03 | CL100 | 2.12 ± 0.02 |

| No. | Improvement (%) | ||

|---|---|---|---|

| PL | 0 | ||

| GL25 | 13.74 | CL25 | 13.74 |

| GL50 | 14.50 | CL50 | −22.14 |

| GL75 | 39.69 | CL75 | 43.51 |

| GL100 | 20.61 | CL100 | 61.83 |

| Freeze–Thaw Cycles | Ordinary Concrete | Phase Change Concrete |

|---|---|---|

| 50 | 0.67 ± 0 | 0.09 ± 0.01 |

| 100 | 1.06 ± 0.047 | 0.88 ± 0.06 |

| 150 | 4.25 ± 0.24 | 3.65 ± 0.22 |

| 200 | 7.35 ± 0.54 | 5.48 ± 0.20 |

| Freeze–Thaw Cycles | Ordinary Concrete | Phase Change Concrete |

|---|---|---|

| 0 | 100 | 100 |

| 50 | 97.21 ± 0.85 | 98.38 ± 0.46 |

| 100 | 82.12 ± 0.54 | 88.69 ± 0.56 |

| 150 | 74.90 ± 0.96 | 78.24 ± 0.37 |

| 200 | 52.53 ± 0.49 | 57.55 ± 0.16 |

| Freeze–Thaw Cycles | Ordinary Concrete | Phase Change Concrete |

|---|---|---|

| 0 | 36.93 ± 0.31 | 34.97 ± 0.75 |

| 50 | 30.17 ± 1.70 | 29.10 ± 0.85 |

| 100 | 23.90 ± 2.01 | 26.35 ± 1.63 |

| 150 | 19.9 ± 1.21 | 23.60 ± 1.56 |

| 200 | 10.07 ± 1.00 | 11.10 ± 0.46 |

| Freeze–Thaw Cycles | Ordinary Concrete | Phase Change Concrete |

|---|---|---|

| 0 | 2.23 ± 0.05 | 2.30 ± 0.02 |

| 50 | 1.88 ± 0.05 | 2.11 ± 0.04 |

| 100 | 1.72 ± 0.01 | 1.74 ± 0.08 |

| 150 | 1.20 ± 0.16 | 1.32 ± 0.07 |

| 200 | 0.51 ± 0.02 | 0.55 ± 0.06 |

| 0 Cycles | 50 Cycles | 100 Cycles | 150 Cycles | 200 Cycles | ||

|---|---|---|---|---|---|---|

| Ordinary concrete | Porosity (%) | 2.41 | 2.91 | 3.47 | 3.97 | 4.61 |

| Increment (%) | - | 20.75 | 43.98 | 64.73 | 91.29 | |

| Phase change concrete | Porosity (%) | 1.64 | 1.90 | 2.14 | 2.44 | 2.87 |

| Increment (%) | - | 15.85 | 60.49 | 40.78 | 75.00 | |

| Type | Cycles | Pores of Different Sizes | ||||

|---|---|---|---|---|---|---|

| <0.01 mm3 | 0.01~0.1 mm3 | 0.1~1 mm3 | 1~10 mm3 | >10 mm3 | ||

| Ordinary concrete | 0 | 1.20 | 15.84 | 53.59 | 15.29 | 14.07 |

| 50 | 1.24 | 14.34 | 53.85 | 17.93 | 12.64 | |

| 100 | 1.38 | 12.57 | 51.17 | 24.09 | 10.78 | |

| 150 | 1.41 | 11.39 | 50.38 | 26.66 | 10.15 | |

| 200 | 1.35 | 10.24 | 51.11 | 27.28 | 11.02 | |

| Phase change concrete | 0 | 2.29 | 15.53 | 46.69 | 17.21 | 17.65 |

| 50 | 2.07 | 12.88 | 49.03 | 20.57 | 15.45 | |

| 100 | 2.30 | 13.99 | 48.66 | 19.35 | 15.70 | |

| 150 | 2.00 | 12.25 | 47.50 | 19.87 | 18.37 | |

| 200 | 1.98 | 13.12 | 46.80 | 21.85 | 16.25 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, X.; Wang, B.; Chen, P.; Luo, T. Study on the Frost Resistance of Concrete Modified with Steel Balls Containing Phase Change Material (PCM). Materials 2021, 14, 4497. https://doi.org/10.3390/ma14164497

Yuan X, Wang B, Chen P, Luo T. Study on the Frost Resistance of Concrete Modified with Steel Balls Containing Phase Change Material (PCM). Materials. 2021; 14(16):4497. https://doi.org/10.3390/ma14164497

Chicago/Turabian StyleYuan, Xiaosa, Baomin Wang, Peng Chen, and Tao Luo. 2021. "Study on the Frost Resistance of Concrete Modified with Steel Balls Containing Phase Change Material (PCM)" Materials 14, no. 16: 4497. https://doi.org/10.3390/ma14164497

APA StyleYuan, X., Wang, B., Chen, P., & Luo, T. (2021). Study on the Frost Resistance of Concrete Modified with Steel Balls Containing Phase Change Material (PCM). Materials, 14(16), 4497. https://doi.org/10.3390/ma14164497