A Study on the Mechanical Characteristics of Glass and Nylon Fiber Reinforced Peach Shell Lightweight Concrete

Abstract

:1. Introduction

2. Material Properties

2.1. Cement and Silica Fume

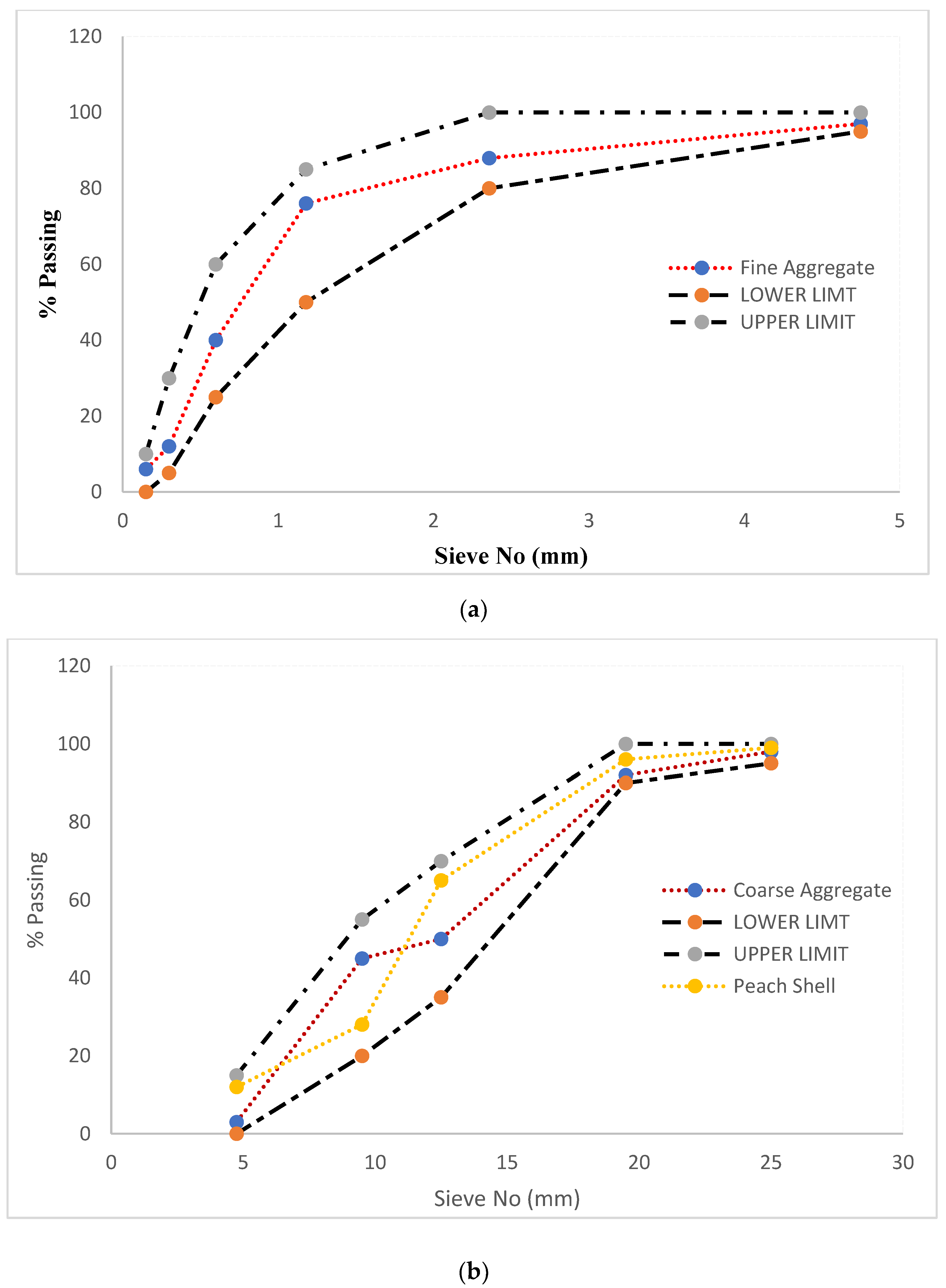

2.2. Coarse and Fine Aggregates

2.3. Water

2.4. Superplasticizer

2.5. Glass and Nylon Fibers

2.6. Mix Information

3. Sample Preparation and Testing Method

4. Results and Discussion

4.1. Workability

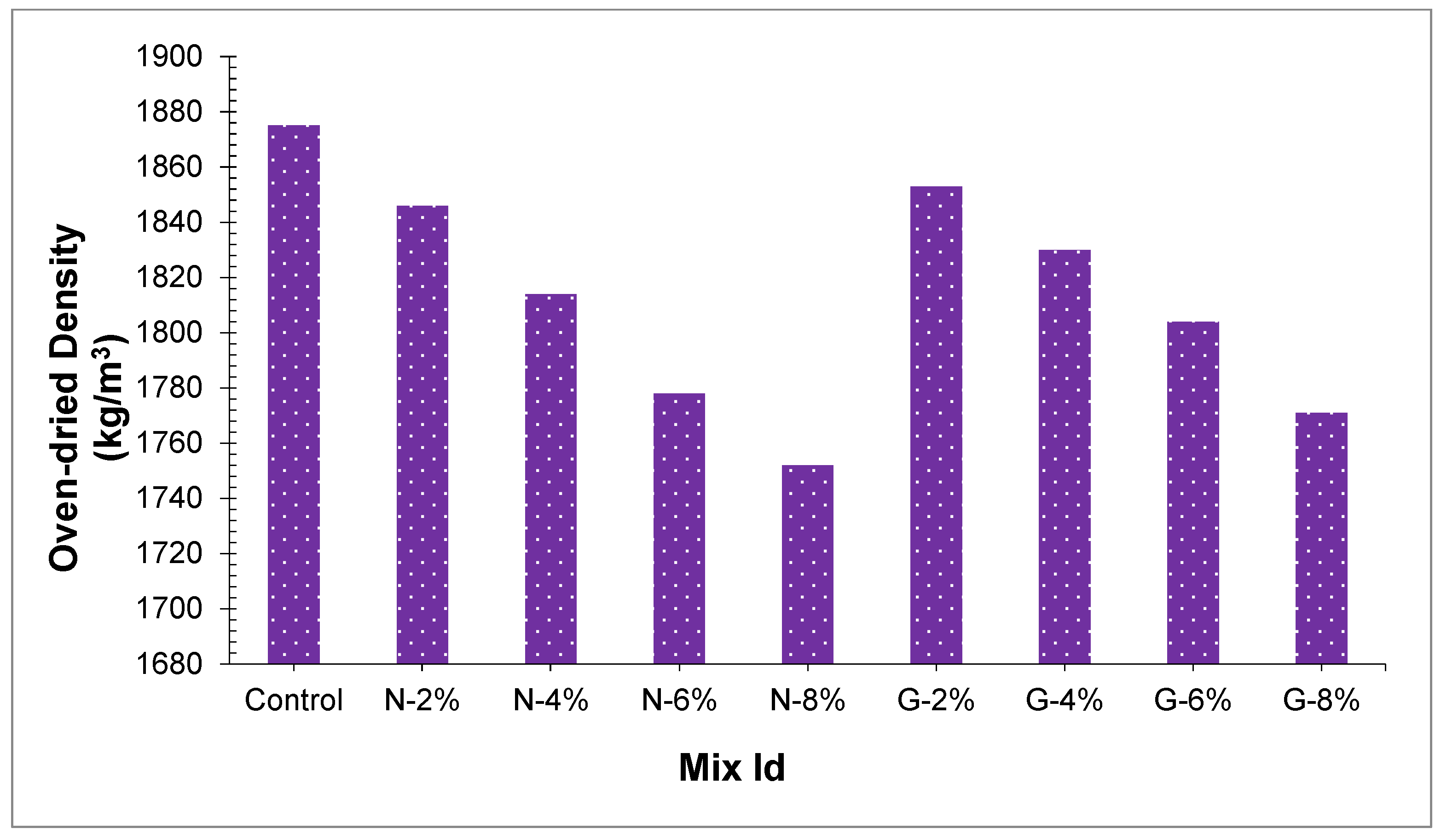

4.2. Density (Unit Weight)

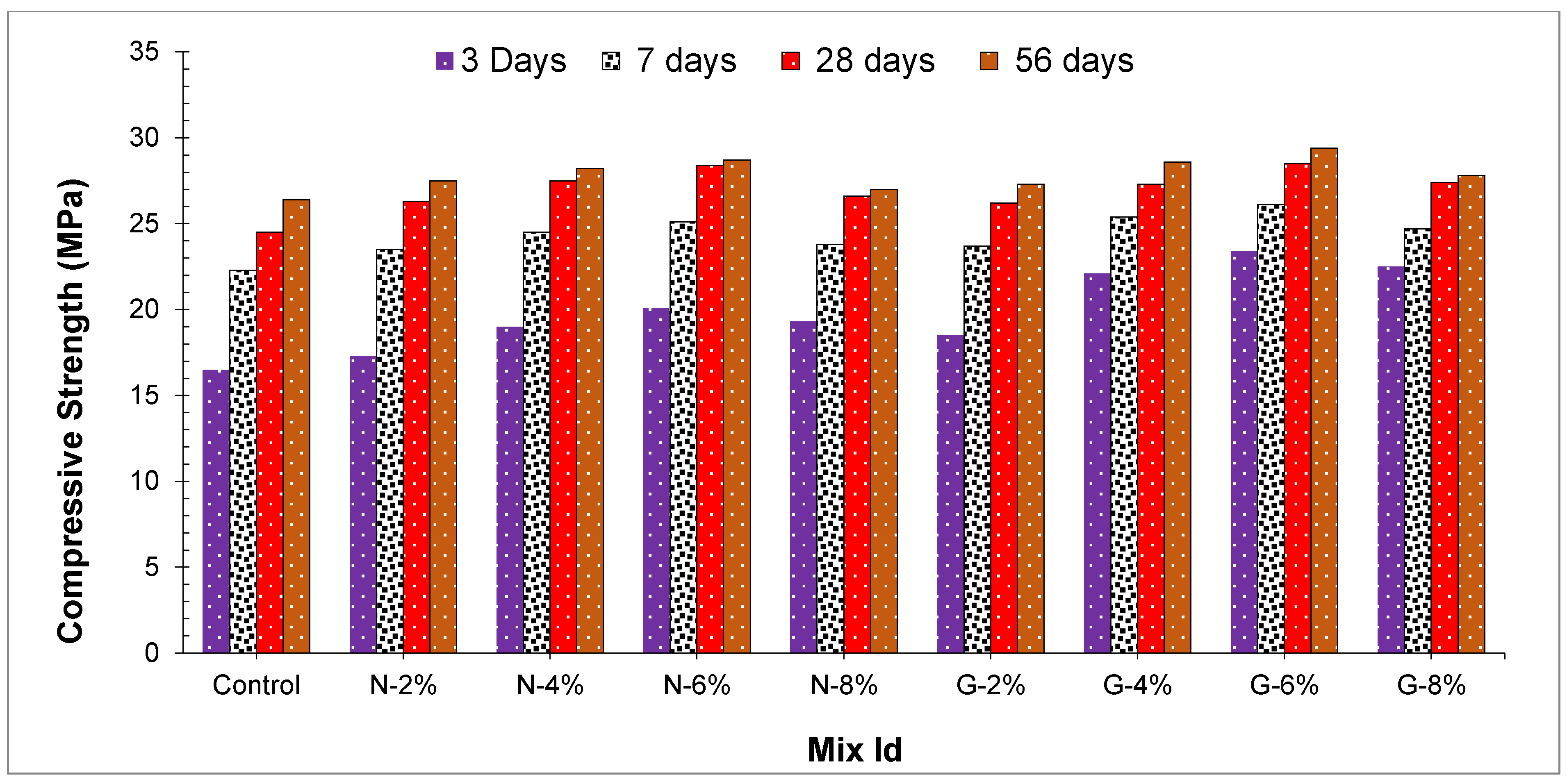

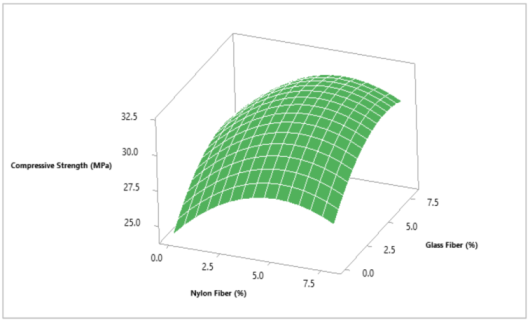

4.3. Compressive Strength

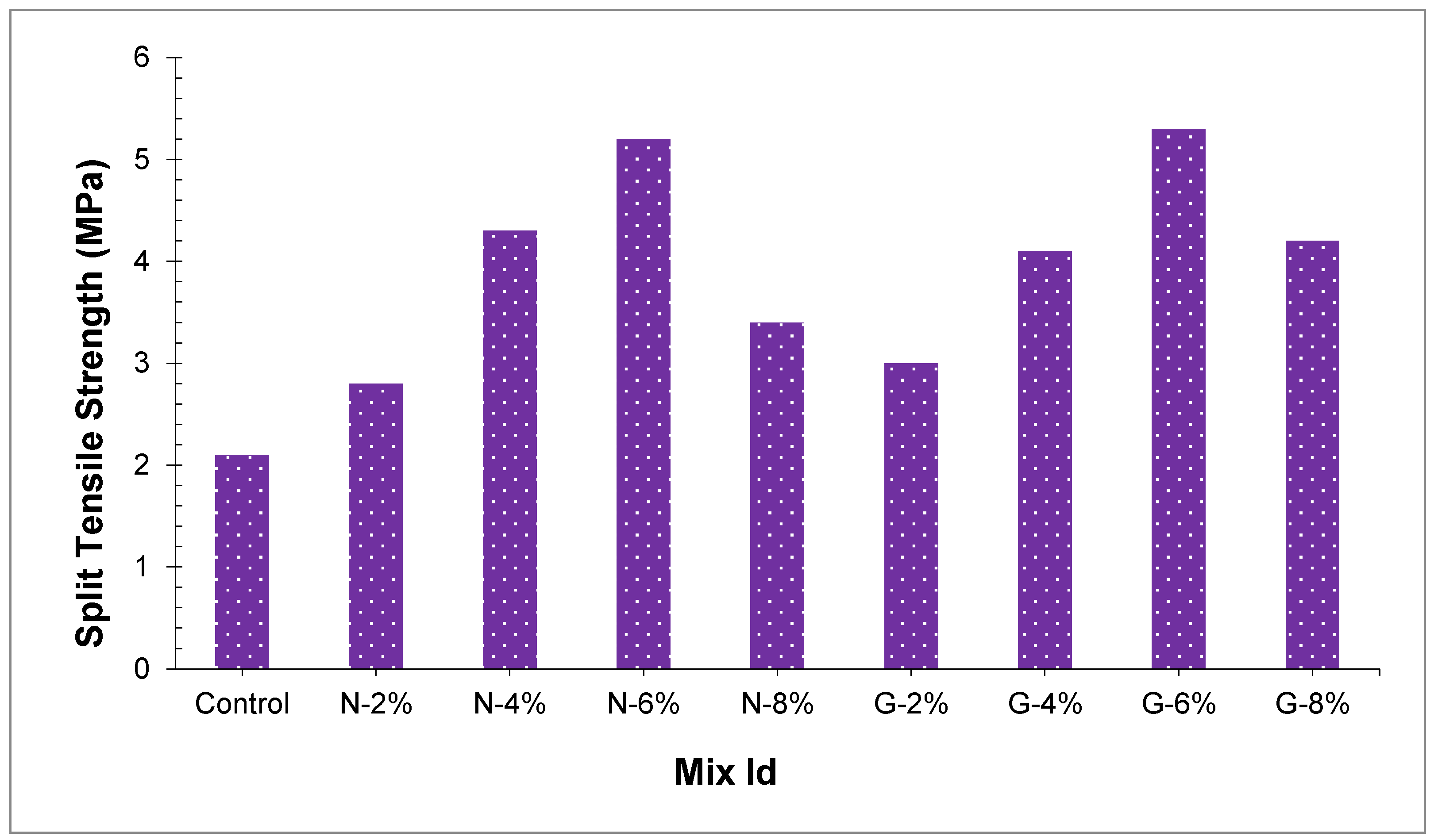

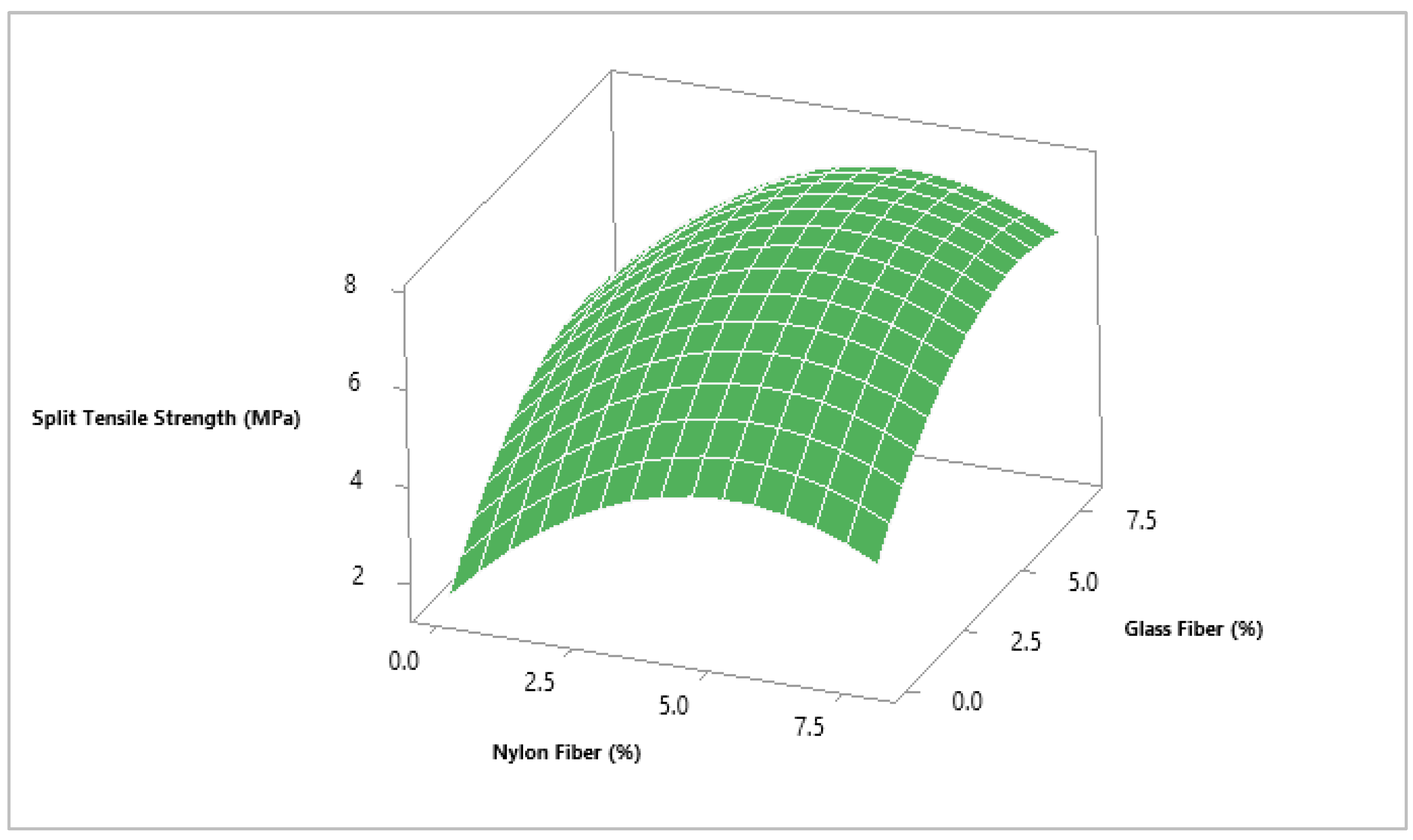

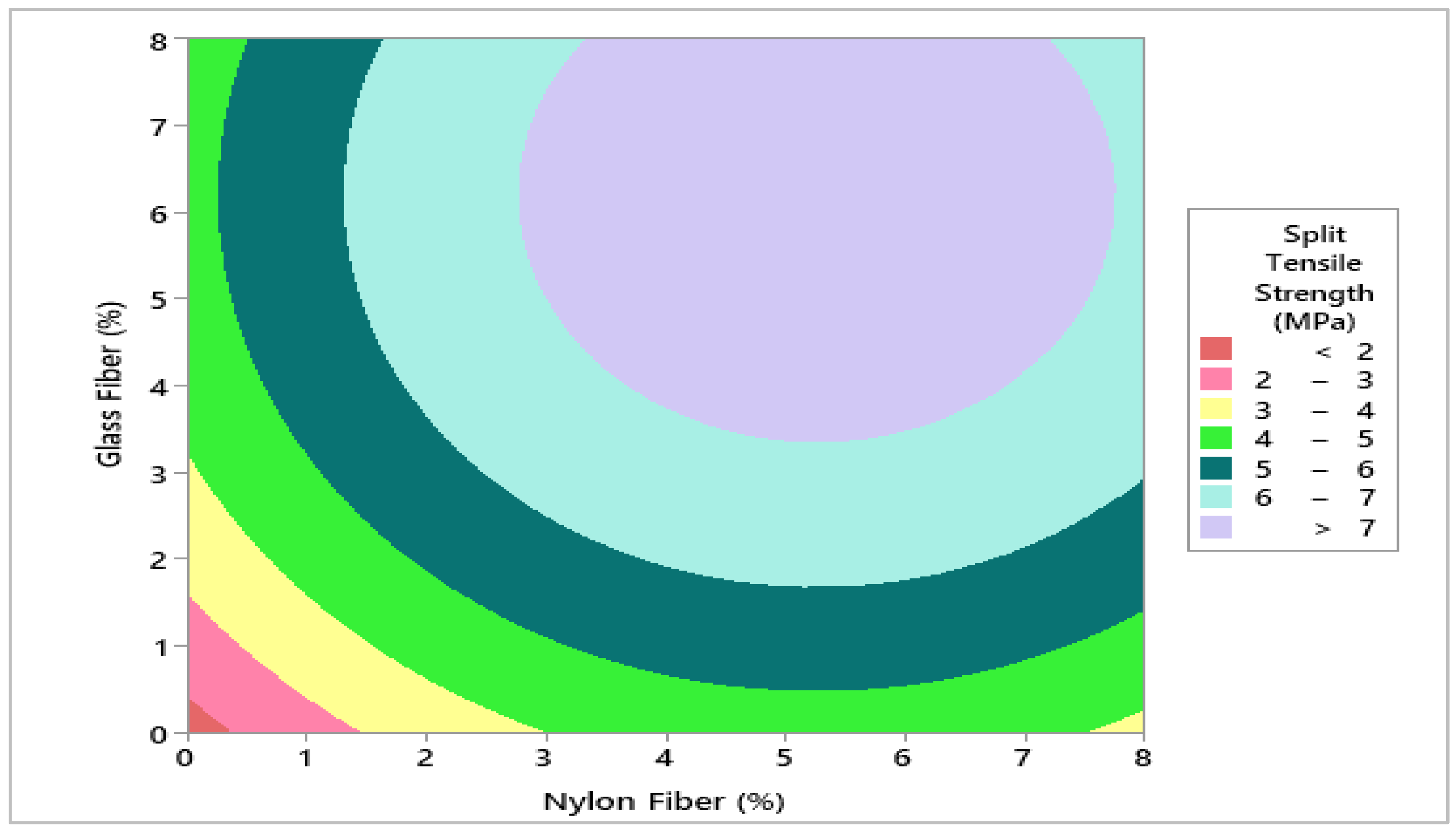

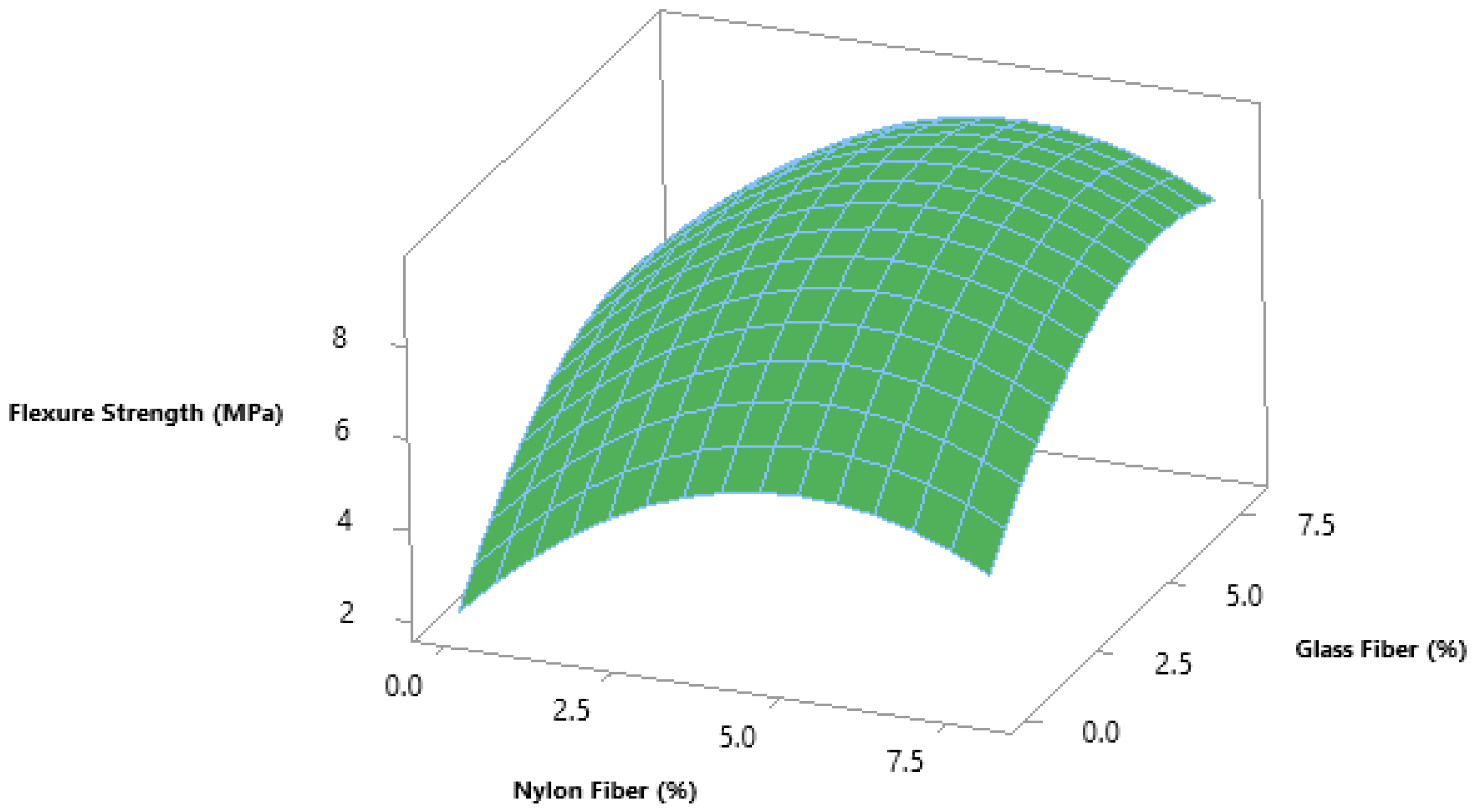

4.4. Split Tensile and Flexural Strength

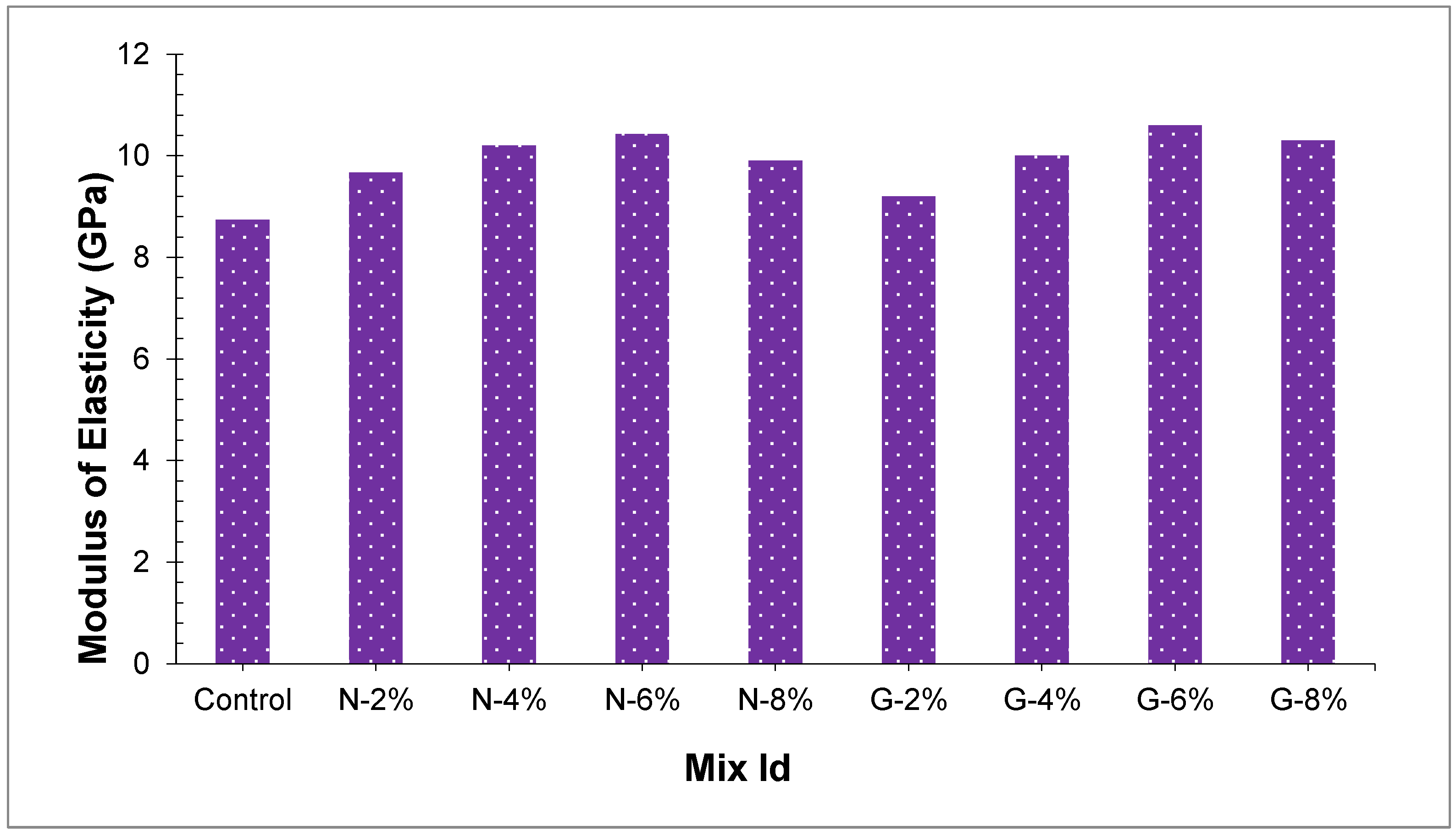

4.5. Modulus of Elasticity

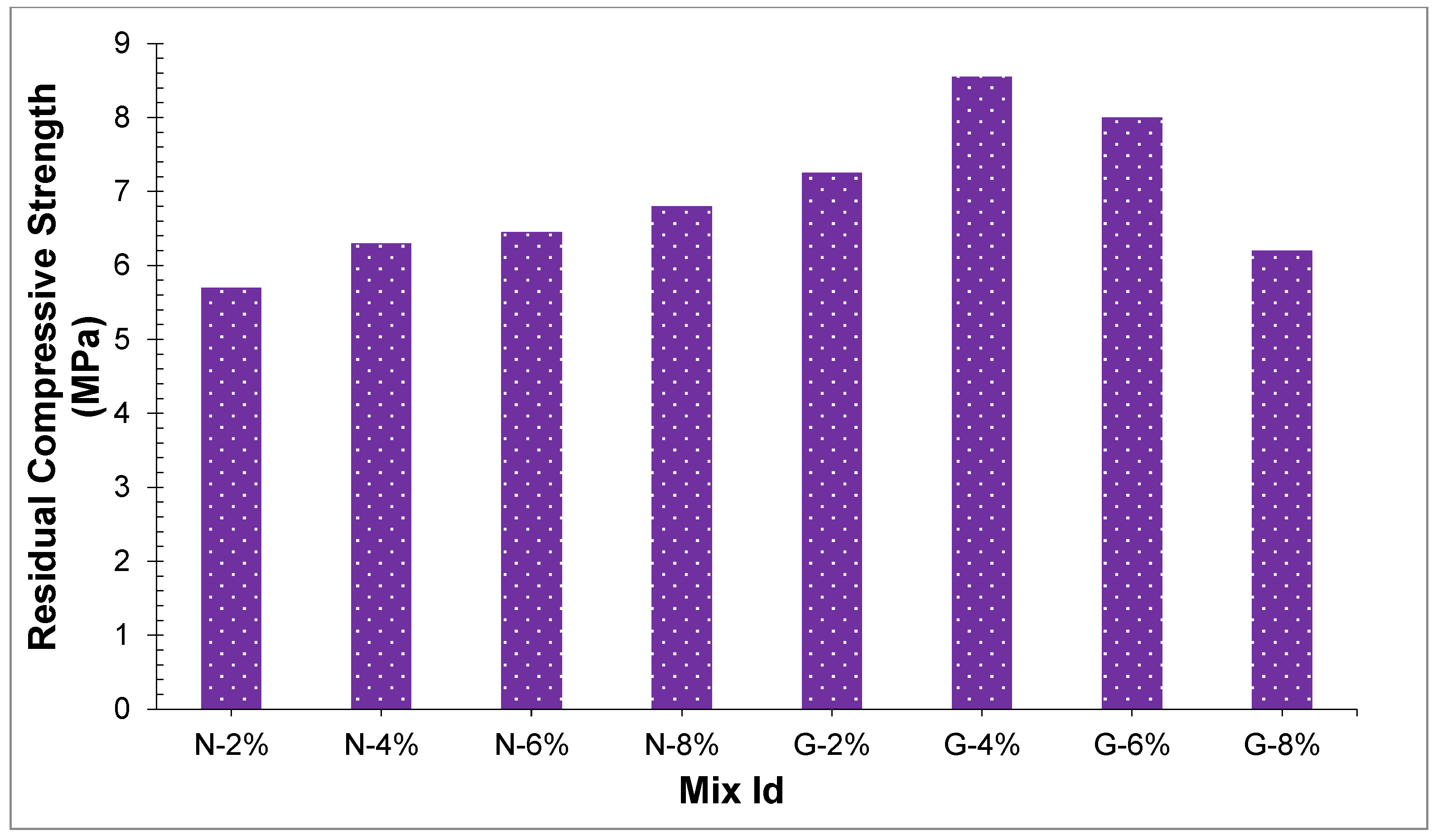

4.6. Residual Compressive Strength

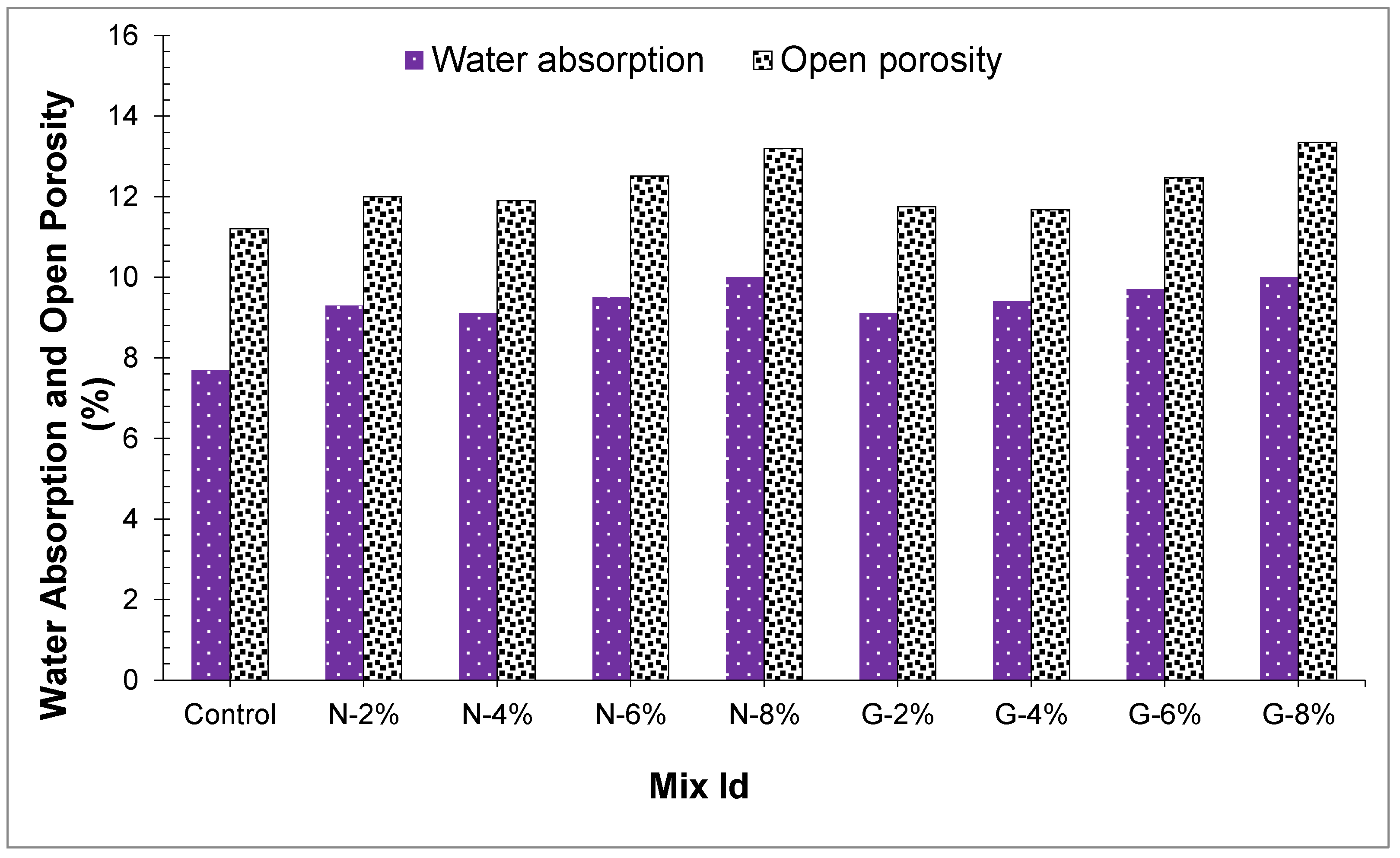

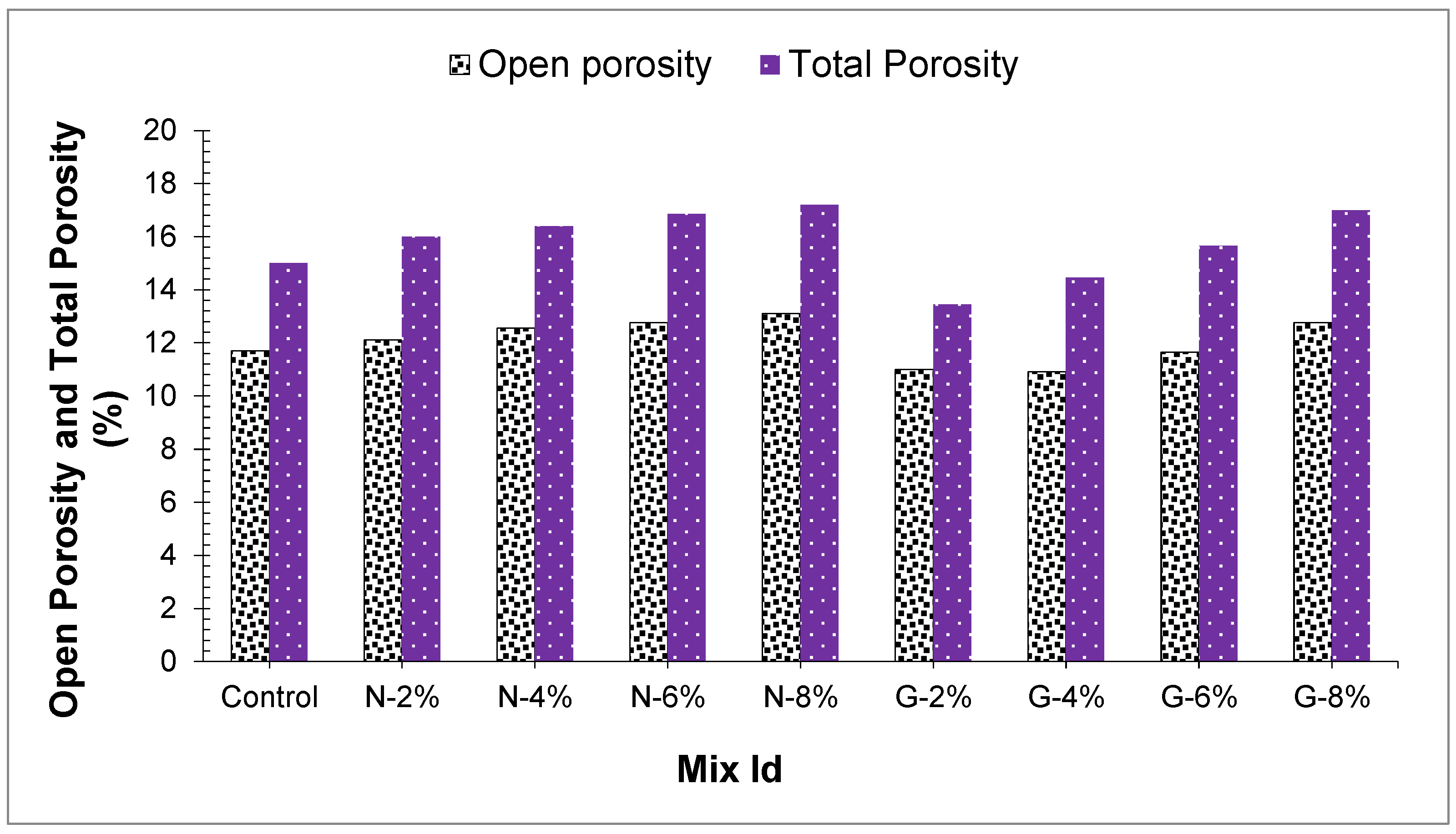

4.7. Porosity and Water Absorption

5. Conclusions

- Nylon and glass fibers reduce the PSC slump values. Fresh Peach shell concrete with nylon and glass fibers slump values are decreased to 60–70 mm. Concrete that has glass fibers had higher slump values as compared to nylon fibers.

- The oven-dried density of peach shell concrete is reduced by adding nylon and glass fibers. Concrete oven-dried density ranges from 1801 kg/m3 to 1914 kg/m3 and satisfies the lightweight aggregate concrete requirement.

- The early compressive strength of whole concrete samples was high. PSC compressive strength was increased with nylon fibers and glass fibers, and peach shell concrete compressive strength increments as we increase the fiber amount. Peach shell concrete compressive strength at 28 days was around 7–20%.

- Peach shell concrete split tensile strength is increased with adding of nylon fibers and glass fibers. Split tensile strength gets higher as the number of fibers is increased. Split tensile strength is increased by 9.8–57.2% and 8.0–60.3% by adding nylon and glass fibers from 2.0% to 8.0%.

- Peach shell concrete flexural strength improved as fiber content is increased. Flexural strength is increased by 6.2–39.4% and 7.1–63.4% by adding nylon and glass fibers from 2.0% to 8.0%.

- The flexural and split tensile strength of glass fiber-reinforced peach shell concrete is high. At the percentage of 6.0% and 8.0%, peach shell concrete containing glass fibers the split tensile and flexural strength are between 63.49% and 60.37% more as compared to nylon fibers.

- Statistical models (response surface methodology) confirmed the lab results, that glass and nylon could be utilized to improve the mechanical performance of peach shell concrete.

- Peach shell concrete modulus of elasticity is also improved with the addition of nylon fibers and glass fibers. All concrete samples’ modulus of elasticity ranges somewhere in the range of 10.2 GPa to 12.5 GPa. At percentages of 2.0%, 4.0%, 6.0%, and 8.0%, nylon and glass fiber-reinforced PSC modulus of elasticity enhanced by 11.2%, 13.1%, 14.6%, and 15.4 for nylon fibers and 22.6%, 23.9%, 26.5%, and 29.8% for glass fibers.

- No residual compressive strength was produced in a control sample. PSC residual compressive strength is increased by adding nylon and glass fibers. Furthermore, the higher the fiber amount, the higher the residual compressive strength. At a percentage of 8.0%, the residual compressive strength of nylon and glass fiber-reinforced PSC increases by 47% and 79%.

- Adding fibers marginally builds peach shell concrete porosity and water absorption. Despite that, the amount and type of fibers insignificantly affect water absorption and porosity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ahmad, J.; Aslam, F.; Zaid, O.; Alyousef, R.; Alabduljabbar, H. Mechanical and durability characteristics of sustainable concrete modified with partial substitution of waste foundry sand. Struct. Concr. 2021. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Góra, J.; Widomski, M.K. Durability of Hydrophobic/Icephobic Coatings in Protection of Lightweight Concrete with Waste Aggregate. Materials 2020, 14, 101. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Mahmud, H.; Jumaat, M.Z. Comparison of mechanical and bond properties of oil palm kernel shell concrete with normal weight concrete. Int. J. Phys. Sci. 2010, 5, 1231–1239. [Google Scholar]

- Ahmad, J.; Tufail, R.; Aslam, F.; Mosavi, A.; Alyousef, R.; Javed, M.F.; Zaid, O.; Niazi, M.K. A Step towards Sustainable Self-Compacting Concrete by Using Partial Substitution of Wheat Straw Ash and Bentonite Clay Instead of Cement. Sustainability 2021, 13, 824. [Google Scholar] [CrossRef]

- Prakash, R.; Thenmozhi, R.; Raman, S.N. Mechanical characterisation and flexural performance of eco-friendly concrete produced with fly ash as cement replacement and coconut shell coarse aggregate. Int. J. Environ. Sustain. Dev. 2019, 18, 131–148. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Al Muhit, B.A.; Jumaat, M.Z. Utilization of oil palm kernel shell as lightweight aggregate in concrete—A review. Constr. Build. Mater. 2013, 38, 161–172. [Google Scholar] [CrossRef]

- Atoyebi, O.D.; Odeyemi, S.O.; Bello, S.A.; Ogbeifun, C.O. Splitting tensile strength assessment of lightweight foamed concrete reinforced with waste tyre steel fibres. Int. J. Civ. Eng. Technol. 2018, 9, 1129–1137. [Google Scholar]

- Shafigh, P.; Jumaat, M.Z.; Mahmud, H. Mix design and mechanical properties of oil palm shell lightweight aggregate concrete: A review. Int. J. Phys. Sci. 2010, 5, 2127–2134. [Google Scholar]

- Assefa, S.; Dessalegn, M. Production of Lightweight Concrete Using Corncob Ash as Replacement of Cement in Concrete. Am. J. Civ. Eng. 2019, 7, 17–20. [Google Scholar] [CrossRef] [Green Version]

- Aguirre-Maldonado, E.; Hernández-Olivares, F. Study of Fine Mortar Powder from Different Waste Sources for Recycled Concrete Production. In Sustainable Development and Renovation in Architecture, Urbanism and Engineering; Springer: Berlin/Heidelberg, Germany, 2017; pp. 253–262. [Google Scholar]

- Wu, F.; Liu, C.; Zhang, L.; Lu, Y.; Ma, Y. Comparative study of carbonized peach shell and carbonized apricot shell to improve the performance of lightweight concrete. Constr. Build. Mater. 2018, 188, 758–771. [Google Scholar] [CrossRef]

- Li, L.G.; Ouyang, Y.; Zhuo, Z.-Y.; Kwan, A.K.H. Adding ceramic polishing waste as filler to reduce paste volume and improve carbonation and water resistances of mortar. Adv. Bridg. Eng. 2021, 2, 1–19. [Google Scholar] [CrossRef]

- Alengaram, U.J.; Mahmud, H.; Jumaat, M.Z.; Shirazi, S.M. Effect of aggregate size and proportion on strength properties of palm kernel shell concrete. Int. J. Phys. Sci. 2010, 5, 1848–1856. [Google Scholar]

- Khalou, A.R.; Sharifian, M. Experimental Investigation of Low to High Strength Steel Fiber Reinforced Lightweight Concrete under Pure Torsion. Asian J. Civ. Eng. 2005, 6, 533–547. [Google Scholar]

- Yew, M.K.; Bin Mahmud, H.; Ang, B.C. Influence of different types of polypropylene fibre on the mechanical properties of high-strength oil palm shell lightweight concrete. Constr. Build. Mater. 2015, 90, 36–43. [Google Scholar] [CrossRef]

- Li, C.; Zhao, M.; Zhang, X.; Li, J.; Li, X.; Zhao, M. Effect of Steel Fiber Content on Shear Behavior of Reinforced Expanded-Shale Lightweight Concrete Beams with Stirrups. Materials 2021, 14, 1107. [Google Scholar] [CrossRef]

- Yap, S.P.; Alengaram, U.J.; Jumaat, M.Z.; Khaw, K.R. Torsional behaviour of steel fibre-reinforced oil palm shell concrete beams. Mater. Des. 2015, 87, 854–862. [Google Scholar] [CrossRef]

- Prakash, R.; Thenmozhi, R.; Raman, S.N.; Subramanian, C. Fibre reinforced concrete containing waste coconut shell aggregate, fly ash and polypropylene fibre. Rev. Fac. Ing. Univ. Antioq. 2019, 94, 33–42. [Google Scholar] [CrossRef] [Green Version]

- Lo, T.Y.; Tang, W.; Cui, H. The effects of aggregate properties on lightweight concrete. Build. Environ. 2007, 42, 3025–3029. [Google Scholar] [CrossRef]

- Lo, T.; Cui, H. Effect of porous lightweight aggregate on strength of concrete. Mater. Lett. 2004, 58, 916–919. [Google Scholar] [CrossRef]

- Just, A.; Middendorf, B. Microstructure of high-strength foam concrete. Mater. Charact. 2009, 60, 741–748. [Google Scholar] [CrossRef]

- Wongkvanklom, A.; Posi, P.; Khotsopha, B.; Ketmala, C.; Pluemsud, N.; Lertnimoolchai, S.; Chindaprasirt, P. Structural Lightweight Concrete Containing Recycled Lightweight Concrete Aggregate. KSCE J. Civ. Eng. 2018, 22, 3077–3084. [Google Scholar] [CrossRef]

- Wongkvanklom, A.; Posi, P.; Homwuttiwong, S.; Sata, V.; Wongsa, A.; Tanangteerapong, D.; Chindaprasirt, P. Lightweight Geopolymer Concrete Containing Recycled Plastic Beads. Key Eng. Mater. 2019, 801, 377–384. [Google Scholar] [CrossRef]

- Hamoush, S.; Abu-Lebdeh, T.; Cummins, T. Deflection behavior of concrete beams reinforced with PVA micro-fibers. Constr. Build. Mater. 2010, 24, 2285–2293. [Google Scholar] [CrossRef]

- Yap, S.P.; Alengaram, U.J.; Jumaat, M.Z. Enhancement of mechanical properties in polypropylene–and nylon–fibre reinforced oil palm shell concrete. Mater. Des. 2013, 49, 1034–1041. [Google Scholar] [CrossRef]

- Shi, X.; Park, P.; Rew, Y.; Huang, K.; Sim, C. Constitutive behaviors of steel fiber reinforced concrete under uniaxial compression and tension. Constr. Build. Mater. 2020, 233, 117316. [Google Scholar] [CrossRef]

- Qian, C.; Stroeven, P. Development of hybrid polypropylene-steel fibre-reinforced concrete. Cem. Concr. Res. 2000, 30, 63–69. [Google Scholar] [CrossRef]

- Kikuchi, T.; Shintani, Y.; Hirashima, T.; Kohno, M. Mechanical properties of steel fiber reinforced concrete at high temperature. J. Struct. Constr. Eng. 2020, 85, 169–176. [Google Scholar] [CrossRef]

- Yap, S.P.; Bu, C.H.; Alengaram, U.J.; Mo, K.H.; Jumaat, M.Z. Flexural toughness characteristics of steel–polypropylene hybrid fibre-reinforced oil palm shell concrete. Mater. Des. 2014, 57, 652–659. [Google Scholar] [CrossRef]

- Ahmad, J.; Aslam, F.; Zaid, O.; Alyousef, R.; Alabduljabbar, H.; Manan, A. Self-Fibers Compacting Concrete Properties Reinforced with Propylene Fibers. Sci. Eng. Compos. Mater. 2021, 28, 64–72. [Google Scholar] [CrossRef]

- Ahmad, J.; Al-Dala’ien, R.N.S.; Manan, A.; Zaid, O.; Ahmad, M. Evaluating the effects of flexure cracking behaviour of beam reinforced with steel fibres from environment affect. J. Green Eng. 2020, 10, 4998–5016. [Google Scholar]

- Mastali, M.; Dalvand, A.; Sattarifard, A. The impact resistance and mechanical properties of reinforced self-compacting concrete with recycled glass fibre reinforced polymers. J. Clean. Prod. 2016, 124, 312–324. [Google Scholar] [CrossRef]

- Ahmad, J.; Manan, A.; Ali, A.; Khan, M.W.; Asim, M.; Zaid, O. A Study on Mechanical and Durability Aspects of Concrete Mo ified with Steel Fibers (SFs). Civ. Eng. Archit. 2020, 8, 814–823. [Google Scholar] [CrossRef]

- ASTM C150/C150M-20, Standard Specification for Portland Cement; ASTM International: West Conshohocken, PA, USA, 2020.

- Standard Test Method for Slump of Hydraulic-Cement Concrete, ASTM C143/C143M-03; ASTM International: West Conshohocken, PA, USA, 2003.

- Suksiripattanapong, C.; Horpibulsuk, S.; Boongrasan, S.; Udomchai, A.; Chinkulkijniwat, A.; Arulrajah, A. Unit weight, strength and microstructure of a water treatment sludge–fly ash lightweight cellular geopolymer. Constr. Build. Mater. 2015, 94, 807–816. [Google Scholar] [CrossRef]

- C496-71A. Standard TestMethod for Splitting Tensile Strength of Cylindrical Concrete Specimens; British Standard Institution: London, UK, 1976. [Google Scholar]

- Mehta, P.; Giaccio, G.; Malhotra, V. Concrete Incorporating High Volumes of ASTM Class F Fly Ash. Cem. Concr. Aggregates 1988, 10, 88–95. [Google Scholar] [CrossRef]

- ASTM. 1585-Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes; ASTM International: West Conshohocken, PA, USA, 2004. [Google Scholar]

- Bu, Y.; Spragg, R.; Weiss, W.J. Comparison of the Pore Volume in Concrete as Determined Using ASTM C642 and Vacuum Saturation. Adv. Civ. Eng. Mater. 2014, 3, 308–315. [Google Scholar] [CrossRef]

- Safiuddin; Hearn, N. Comparison of ASTM saturation techniques for measuring the permeable porosity of concrete. Cem. Concr. Res. 2005, 35, 1008–1013. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: New York, NY, USA, 2014. [Google Scholar]

- Song, P.; Hwang, S.; Sheu, B. Strength properties of nylon- and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Newman, J.; Choo, B.S. Advanced Concrete Technology 3: Processes; Elsevier: Amsterdam, The Netherlands, 2003. [Google Scholar]

- Kakooei, S.; Akil, H.M.; Jamshidi, M.; Rouhi, J. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Cominoli, L.; Failla, C.; Plizzari, G.A. Steel and synthetic fibres for enhancing concrete toughness and shrinkage behaviour. In Proceedings of the International Conference of Sustainable Construction Materials and Technologies, Coventry, UK, 11–13 June 2007; pp. 11–13. [Google Scholar]

- Banthia, N.; Gupta, R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Lo, T.Y.; Cui, H.; Tang, W.; Leung, W. The effect of aggregate absorption on pore area at interfacial zone of lightweight concrete. Constr. Build. Mater. 2008, 22, 623–628. [Google Scholar] [CrossRef]

- Neville, A.M.; Brooks, J.J. Concrete Technology; Malaysia; Pearson International: London, UK, 2008. [Google Scholar]

| Chemical Composition | Percentage (%) | Physical Properties | Results |

|---|---|---|---|

| CaO | 64.7 | Size | ≤75 microns |

| SiO2 | 23.9 | Fineness | 92% |

| Al2O3 | 5.4 | Normal Consistency | 31% |

| Fe2O3 | 3.7 | Initial Setting Time | 33 min |

| MgO | 3.5 | Final Setting Time | 410 min |

| SO3 | 2.9 | Specific surface | 322 m2/kg |

| K2O | 2.4 | Soundness | 1.70% |

| Na2O | 1.2 | 28-days compressive Strength | 42 MPa |

| Physical Property | Coarse Aggregate | Fine Aggregate | |

|---|---|---|---|

| Peach Shell (PS) | Natural Weight Aggregate (NWA) | Sand | |

| Fineness Modulus | 5 | 4.8 | 2.7 |

| Specific gravity (g/cm3) | 1.25 | 2.67 | 2.64 |

| Water absorption (%) | 27.64 | 0.7 | 1.4 |

| Bulk density (kg/m3) | 544 | 1552 | 1542 |

| LA abrasion value (%) | 5 | 26 | - |

| Aggregate Impact Value (%) | 1.89 | 17.21 | - |

| Elongation Index (%) | 62 | 33 | - |

| Flakiness Index (%) | 61 | 33 | - |

| Properties | Glass Fibers | Nylon Fibers |

|---|---|---|

| Color | White | White |

| Length (mm) | 23 | 20 |

| Diameter (um) | 28 | 24 |

| Aspect ratio | 821 | 833 |

| Density (g/cm3) | 2.32 | 1.21 |

| Tensile Strength (MPa) | 1200 | 921 |

| Elastic Modulus (GPa) | 7.0 | 5.4 |

| Mix Code | Cement (kg/m3) | Silica Fume (kg/m3) | Sand (kg/m3) | Water (kg/m3) | SP (kg/m3) | PS (kg/m3) | Nylon Fiber (%) | Glass Fiber (%) |

|---|---|---|---|---|---|---|---|---|

| Contol | 560 | 56 | 770 | 170 | 5.6 | 350 | - | - |

| N-2% | 560 | 56 | 770 | 170 | 5.6 | 350 | 2 | - |

| N-4% | 560 | 56 | 770 | 170 | 5.6 | 350 | 4 | - |

| N-6% | 560 | 56 | 770 | 170 | 5.6 | 350 | 6 | - |

| N-8% | 560 | 56 | 770 | 170 | 5.6 | 350 | 8 | - |

| G-2% | 560 | 56 | 770 | 170 | 5.6 | 350 | - | 2 |

| G-4% | 560 | 56 | 770 | 170 | 5.6 | 350 | - | 4 |

| G-6% | 560 | 56 | 770 | 170 | 5.6 | 350 | - | 6 |

| G-8% | 560 | 56 | 770 | 170 | 5.6 | 350 | - | 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ahmad, J.; Zaid, O.; Aslam, F.; Shahzaib, M.; Ullah, R.; Alabduljabbar, H.; Khedher, K.M. A Study on the Mechanical Characteristics of Glass and Nylon Fiber Reinforced Peach Shell Lightweight Concrete. Materials 2021, 14, 4488. https://doi.org/10.3390/ma14164488

Ahmad J, Zaid O, Aslam F, Shahzaib M, Ullah R, Alabduljabbar H, Khedher KM. A Study on the Mechanical Characteristics of Glass and Nylon Fiber Reinforced Peach Shell Lightweight Concrete. Materials. 2021; 14(16):4488. https://doi.org/10.3390/ma14164488

Chicago/Turabian StyleAhmad, Jawad, Osama Zaid, Fahid Aslam, Muhammad Shahzaib, Rahat Ullah, Hisham Alabduljabbar, and Khaled Mohamed Khedher. 2021. "A Study on the Mechanical Characteristics of Glass and Nylon Fiber Reinforced Peach Shell Lightweight Concrete" Materials 14, no. 16: 4488. https://doi.org/10.3390/ma14164488

APA StyleAhmad, J., Zaid, O., Aslam, F., Shahzaib, M., Ullah, R., Alabduljabbar, H., & Khedher, K. M. (2021). A Study on the Mechanical Characteristics of Glass and Nylon Fiber Reinforced Peach Shell Lightweight Concrete. Materials, 14(16), 4488. https://doi.org/10.3390/ma14164488