Abstract

The article presents the results of mechanical and tribological tests of Ni-P/Si3N4 nanocomposite coatings deposited on the AW-7075 aluminum alloy using the chemical reduction method. The influence of the chemical composition on the Vickers microhardness determined by the DSI method was examined. The nanocomposite layers were made of Si3N4 silicon nitride in a polydisperse powder with a particle size ranging from 20 to 25 nm. The influence of the content of the dispersion layer material on the adhesion to the substrate was analyzed. The abrasive wear was tested and determined in the reciprocating motion using the “ball-on-flat” method. The surface topography was examined by the contact method with the use of a profilometer. Based on the obtained test results, it was found that the Ni-P/Si3N4 layers produced in the bath with the Si3N4 nanoparticle content in the amount of 2 g/dm3 are more resistant to wear and show greater adhesion than the Ni-P/Si3N4 layers deposited in the bath with 5 g/dm3 of the dispersion phase. NiP/Si3N4 layers provide protection against abrasive wear under various loads and environmental conditions.

1. Introduction

AW-7075 aluminum alloy is an important construction material in any industry because of its lighter weight and better corrosion resistance compared to steel. Some aluminum alloys have similar mechanical properties to structural steels, such as C45 or C46. In this case, the AW-7075 alloy is often used in the shipbuilding, automotive, railway and especially aviation industries [1]. On the other hand, aluminum alloys are less resistant to abrasive wear than steel parts. Increasing the tribological properties can be achieved through an anti-wear layer; however, the appropriate matching of the coating and the substrate depends on their mutual synergism. It is an essential element that determines the proper cooperation of the deposited layer with the aluminum core in selected operating conditions. Aluminum alloys can be coated with various coatings for technical applications [2]. Regarding the mutual antagonism of the substrate and the layer, special attention should be paid to maintaining the basic tribological properties, due to the possibility of chipping, cracking, etc. Mohammadi et al. [3] fabricated Al2O3/Si3N4 nanocomposite coating on the surface of the commercial aluminum alloy. The results showed that the hardness of coatings increased from 380 ± 50 HV for the anodized layer to up to 712 ± 36 HV for the composite coating. Moreover, the mass loss decreased from 0.35 for the anodized coating to 0.20 for the coating with Si3N4 nanoparticles. Researches focused on the optical and mechanical properties of spinel/Si3N4 nanocomposite with different contents of Si3N4 were conducted by Nassajpour-Esfahani et al. [4]; in their conclusions, they noted that an increase in the Si3N4 content is associated with an increase in hardness. However, the highest fracture toughness is achieved in the sample with 1 wt% Si3N4 content. Further addition dramatically decreases the fracture toughness, caused by an increase in the volume fraction of porosities.

Currently, nanocomposite coatings are of great interest. The use of aluminum alloys significantly increases the abrasion resistance of the surface layer. Coatings are used to increase corrosion protection and tribological properties [5,6,7]. Sahoo and Suman [8] reviewed the tribological advancement of different electroless nickel coatings depending on the structure and testing parameters. Nanocomposite coatings consist of ceramic, polymer particles or nanoparticles (SiC, Si3N4, Al2O3, PTFE, diamond, etc.) in a metallic matrix made of a nickel–phosphorus alloy. Coatings with ceramic particles show a high hardness and abrasion resistance, which influences the mechanical and tribological properties of the coatings. However, too high a content of nanoparticles reduces the mechanical and tribological properties. It is essential to use an appropriate method of producing coatings. According to the results of the research conducted by Varshney et al. [9], the material underwent an increase in microhardness of 14% following the grain boundary relaxation heat treatment. Vijayanand and Elansezhian [10] found that it improved the wear resistance from ∼30 μm to ∼−70 μm and that the average coefficient of friction of the AHL samples decreased from 0.079 to 0.009. Similarly, the studies by Touri and Monirvaghefz [11] showed that heat treatment causes a significant increase in hardness in the section containing phosphorus, which radically increases its wear resistance. According to Kanamori et al. [12], owing to the post-heat treatment, it was found that the hardness of the coating, adhesion strength and durability were improved. Nanoparticles improve the properties of the coatings, but only the optimal selection of the dispersion phase, particle size and content in the coating will allow obtaining a layer with the required properties for applications in the expected operating conditions [13,14,15,16,17]. Szala and Kot [18] proved that repainting polyester powder coatings does not affect the microstructure and adhesion of the coating to the substrate, the results of the bending tests and the roughness of matt and silky coatings. Overcoating has been found to affect both the results of impact and stamping tests and the roughness of samples with a fine surface finish. Preliminary results of tribological tests performed with the three-ball-cone and roller-disc method showed that the Ni-P/Si3N4 layers of Si3N4 nanoparticles on the AW-7075 aluminum alloy increase the mechanical and tribological properties compared to the Ni-P layer [19,20]. Moreover, preliminary results of tribological tests of Ni-P/Si3N4 layers deposited by the chemical reduction method showed that the coating is characterized by better mechanical and tribological properties than the AW-7075 alloy [21].

Based on the literature analyses carried out in the area of Ni-P/Si3N4 nanocomposite coatings, it was found that the tests so far were carried out with the content of the Si3N4 dispersion phase within the range of precisely 0.5–10 g/dm3. While comparing the publications, it was noticed that the research methods, material conditions, test conditions, times and other factors had a clear impact on the final results obtained. It was also noted that the improvement of the tribological properties of Ni-P/Si3N4 nanocomposite coatings is achieved depending on the test conditions; e.g., according to [20], in specific time ranges (for the Ni-P/Si3N4 nanocomposite coating produced in a bath of a content of 10 g/dm3 Si3N4), or, according to [22], only as a result of the application of heat treatment (for the Ni-P/Si3N4 nanocomposite coating produced in a bath with 0.5 g/dm3 Si3N4 content). However, the mechanical and tribological properties improve due to the content of the dispersion phase. This article decided to include particles in the range of 0.5–10 g/dm3 Si3N4 in the chemical bath; more specifically, 2 g/dm3 and 5 g/dm3 are not extreme, but intermediate values. Extremely large or minimal values are not optimal values; therefore, from the point of view of the goal, i.e., searching for optimal values (i.e., improving both the mechanical and tribological properties of the amorphous nanocomposite Ni-P/Si3N4 coating), it was found that the selected values are appropriate at this stage when searching for optimal values. In addition, the preliminary research results [21] show an improvement in the properties of the Ni-P/Si3N4 coating material with an amorphous structure, which was deposited in the bath with Si3N4 particles at the level of 2 and 5 g/dm3, compared to the AW-7075 aluminum alloy, as well as the ordinary nickel Ni-P coating.

On this basis, it was found that nanocomposite layers are good materials for tribological applications in the case of AW-7075 aluminum alloys, which are now more widely used in mechanical engineering. Although some literature reports [20] that Ni-P/Si3N4 coatings remain in the phase of laboratory tests, the use of these coatings on an AW-7075 alloy is not yet recognized. The aim of this study was focused on identifying the basic mechanical properties of the coating. The conducted studies involved surface morphology and topography measurements, microhardness tests, adhesion analyses and friction coefficient determination. Moreover, the coating wear mechanism was identified based on tribological tests. Additionally, surface roughness tests were performed in order to determine the influence of Si3N4 nanoparticles on the friction coefficient parameter in tribological tests.

2. Materials and Methods

2.1. Plan of the Experiment

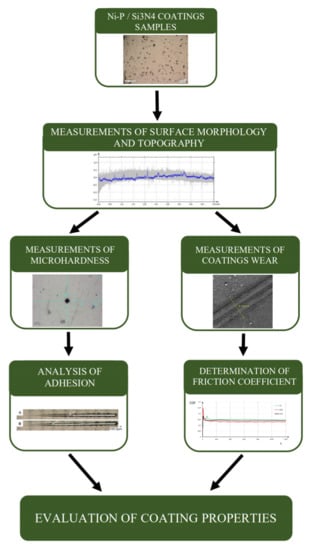

The basic mechanical parameters of Ni-P/Si3N4 nanocomposite coatings were evaluated as part of this study. Measurements of coating wear and evaluation of surface texture were performed during the experiments. Therefore, the microhardness and adhesion measurements have been applied. The tests were supplemented by the performance of complete tribological tests, including wear analysis and determination of the friction coefficient. Figure 1 presents the overall scheme of the conducted experiments.

Figure 1.

The scheme of a conducted experiment.

2.2. Materials

The laboratory tests included Ni-P/Si3N4 coatings with different disperse phases deposited on the AW-7075 alloy by chemical reduction. The chemical composition of the AW-7075 alloy is presented in Table 1.

Table 1.

Chemical composition of AW-7075 alloy, % by mass.

For the tests of hardness, morphology, roughness, adhesion and tribology, samples made of the AW-7075 alloy with dimensions D = 50 mm in diameter and g = 7 mm thick were used. Before depositing the Ni-P layers, the surfaces of the samples were degreased in an organic solvent, etched in an alkaline solution and galvanized in a multi-component solution. However, for the production of Ni-P layers by the chemical reduction method, a multi-component bath was prepared with the following composition: NiSO4, a reducer (NaH2PO2) and a buffer (C2H3NaO2), which stabilizes the pH at the level of 4.3–4.6. The bath temperature during the deposition process was 363 K. The nanocomposite layers were obtained by introducing the Si3N4 polydisperse powder in the form of a dispersion phase with a particle size of 20–25 nm. The thicknesses of the obtained coatings were the same and amounted to 10 ± 2 µm, while the Si3N4 phase content in the chemical bath was 2 g/dm3 and 5 g/dm3.

The Ni-P nickel and Ni-P/Si3N4 nanocomposite coatings were electroless deposited on the AW-7075 aluminium alloy, a disk-shaped substrate with a thickness of 7 mm and a diameter of 50 mm. The chemical composition of the alloy is given in Table 1. Silicon nitride Si3N4 was the dispersion phase in the nanocomposite coatings. Nickel sulfate, monosol phosphate (I) and hydroxy propionic acid were used in the bath.

The samples were degreased in acetone, etched in an alkaline solution (0.75% NaOH) (CHEMPUT, Piekary Śląskie, Poland) and galvanized in a multi-component solution; the composition and concentrations are given in Table 2.

Table 2.

Components concentrations of multi-constituent substance for galvanizing.

For electroless deposition of the layers (by chemical reduction), a bath with a chemical composition was used, as shown in Table 3. A stabilized pH was obtained (pH 4.3–4.6). The bath temperature during the deposition process was approximately 363 K. The nanocomposite layers were obtained by introducing the polydisperse Si3N4 powder as a dispersion phase with a particle size of 20–25 nm. The content of Si3N4 nanoparticles in the baths was 2 g/L and 5 g/L. Ultrasonic mixing was also used before the deposition process and during the deposition of the layers, and consisted in mechanical agitation using a stirrer in the form of a glass rod with paddles in order to ensure proper dispersion of particles and to prevent sedimentation, as well as to obtain a homogeneous suspension and efficient transfer of the reinforcing phase. The thicknesses of all coatings were 10 ± 2 μm based on the selected deposition time, which was 60 min.

Table 3.

Components concentrations of nickel deposition bath.

2.3. Surface Morphology and Topography Tests

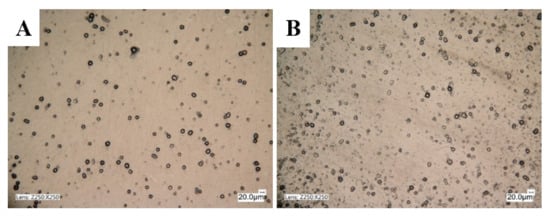

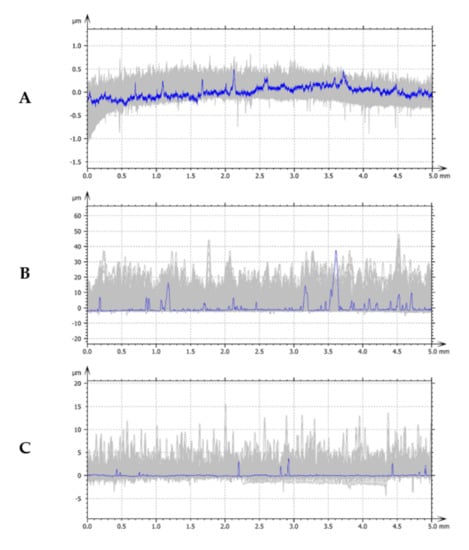

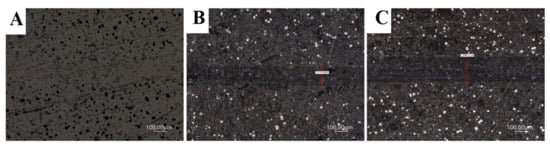

The surface morphology studies were carried out using the Keyence VHX 5000 optical microscope (Keyence Corporation of America, Itasca, IL, USA), while the surface topography was examined by scanning electron microscope Tescan Vega 5135 (Tescan Analytics, Fuveau, France) and profilometer Hommel ETAMIC T8000 (Jenoptik Industrial Metrology Germany GmbH, VS-Schwenningen, Germany) with the AltiMap Premium 7.1.7037 software (Jenoptik Industrial Metrology Germany GmbH, VS-Schwenningen, Germany). The topography tests were performed using the contact method in the middle parts of the samples. The measuring principle was to move the diamond measuring tip with a constant speed of 90° and a rounding radius from 2 µm over a precisely defined measuring section. The study of the surface topography revealed the parameters of the height of the peaks and roughness and the areas of depressions, elevations and bulges. Surface roughness tests were carried out individually, on each sample separately, and included a square of 5 mm × 5 mm surfaces in the central part of the sample. In turn, the morphology of each sample was repeatedly tested in several places. Figure 2 shows sample images, while the roughness test results are shown in Figure 3 and Table 2.

Figure 2.

The morphology of the layers: Ni-P/Si3N4; (A) Ni-P/Si3N4 (2 g/dm3); (B) Ni-P/Si3N4 (5 g/dm3).

Figure 3.

Topography of AW-7075 and Ni-P/Si3N4 coating surface: (A) AW-7075; (B) Ni-P/Si3N4 (2 g/dm3); (C) Ni-P/Si3N4 (5 g/dm3).

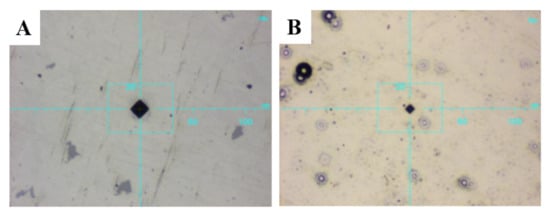

2.4. Microhardness and Adhesion Tests

The microhardness of the alloy system and the layered coating material was tested using the DSI (depth-sensing indentation) method on the PICODENTOR HM500 device (Helmut Fischer Gmbh, Sindelfingen, Germany). The measurements were made using the Vickers method with a load of 300 mN for 20 s and the holding of this force for 5 s. The microhardness test was carried out without piercing the material of the tested layers. The averaged measurement results (five measurements were made on each sample) are presented in Table 3. The tests of adhesion of coatings to the AW-7075 alloy were carried out using the scratch test method. The tests were carried out on the CSEM Revetest device (Anton Paar GmbH, Graz, Austria), using a Rockwell indenter and an increasing progressive load of 1 N to 100 N at a constant speed of 10 mm/min. The length of each scratch was 10 mm. Two scratches were made on each sample, and the acoustic emission signal, friction force, friction coefficient and normal force were recorded in parallel during the measurements.

2.5. Tribological Tests

The tribological properties of the layers deposited on the AW-7075 substrate were tested using the ball-on-flat method in reciprocating motion, in which the counter-sample was a bearing ball. The research was carried out with the use of the BRUKER UMT-2 Tribolab (Bruker Corporation, Billerica, MA, USA). The tribological tests were carried out in accordance with the applicable PN-EN 1071-12 standard. All measurements were carried out at various loads (5 N, 10 N, 15 N) using GL-4 75W/90 semi-synthetic gear oil. The samples were placed in a unique oil-filled tub, and then a counter-sample was mounted, which exerted appropriate pressure on the tested sample surface. Traces of wear were subjected to detailed microscopic analyses, which were made using the Keyence VHX 5000 optical microscope. The wear criterion was the width of the cracks formed according to the PN-EN 1071-12 standard. In addition, during the tests, changes in the friction coefficient were recorded, which, in combination with microscopic images, were used to determine the resistance of the layers to abrasive wear. The parameters are shown in Table 4.

Table 4.

Parameters of tribological tests.

After the measurements, the samples were again subjected to microscopic examination in order to thoroughly check the surface condition and width of the resulting scratches. Moreover, changes in the friction coefficient parameter recorded by the measuring machine were analyzed.

3. Results and Discussion

3.1. Evaluation of Coating Properties

The results of the morphological tests are shown in Figure 2. The matrix of the composite of layers produced was a solid solution of phosphorus in nickel Ni−P containing 6% P mass by the chemical reduction method. According to [5,13,23], the coating structure depends on the type of layer and composition. In a composite material, the structure is determined by constructing the matrix material, the type of dispersion ceramic phase, the degree of fragmentation and the material’s content. The content of the dispersion ceramic phase in the nanocomposite coating depends on the concentration of nanoparticles in the electroplating bath. As the Si3N4 content in the bath grows, the number of particles integrated into the deposited coating material increases, contributing to the formation of highly concentrated places.

The morphology results confirm that homogeneous and compact structures characterize all tested coatings. In the content of the dispersion phase, the nanocomposite layers are different from each other. The results of qualitative tests of the surface of Ni-P/Si3N4 layers deposited in the bath with 5 g/dm3 Si3N4 content showed an increased porosity and roughness compared to the layers deposited in the bath with 2 g/dm3 Si3N4 content. The reason is due to the more significant number of peaks, which was confirmed in later profilometric tests. The “dots” visible in Figure 2 are the peaks of the coating irregularities, the topography of which is shown in Figure 3. Increasing the concentration of Si3N4 causes an increase in the number of peaks.

The results presented in Table 5 and Figure 4 show two-dimensional images of the examined surfaces. In both cases, the surfaces are dull and devoid of gloss, and the peaks of the unevenness are even. Material defects, such as discontinuities, cavities or microcracks, were not observed.

Table 5.

Surface roughness test results.

Figure 4.

Images of traces on sample surfaces (magnification 20×; (A) AW-7075; (B) Ni-P/Si3N4).

3.2. Evaluation of Microhardness and Adhesion

The 10 µm thick Ni-P/Si3N4 coatings present a larger hardness than the AW-7075 aluminium alloy. The highest hardness characterizes coatings produced in a bath containing 2 g/dm3 of the dispersion phase. The content of Si3N4 nanoparticles in the coatings was different. Increasing the content of the dispersion phase to 5 g/dm3 reduces the hardness of the layer. This relationship was confirmed on all tested samples. The results are presented in Table 6 and Figure 4.

Table 6.

The coatings microhardness.

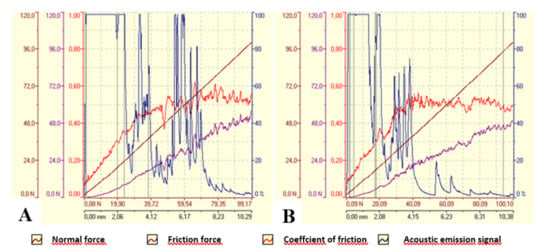

A scratch test was used to analyze the strength of the bond between the coating and the substrate. The diamond indenter moved along the surface of the test layer at a constant speed with a constantly increasing loading force. Changes in individual parameters recorded during the test, i.e., normal pressure, friction force, friction coefficient and acoustic emission along the crack, are shown in Figure 5. The images of the cracks are shown in Figure 6.

Figure 5.

Scratch tests results for Ni-P/Si3N4 coatings: (A) Ni-P/Si3N4 (2 g/dm3); (B) Ni-P/Si3N4 (5 g/dm3).

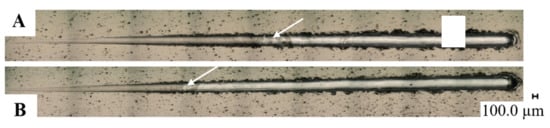

Figure 6.

Images of scratches on the surfaces of layers: Ni-P/Si3N4; (A) Ni-P/Si3N4 (2 g/dm3); (B) Ni-P/Si3N4 (5 g/dm3). The white arrows indicate the coating destruction point.

However, detailed analyses of the results are presented in Table 7 and Table 8. Changes in the topography are noticeable at low-pressure values (0.76 N and 1.73 N), propagating, according to the load, transversely to the head movement.

Table 7.

Description of the scratch test for Ni-P/Si3N4 (2 g/dm3) layer.

Table 8.

Description of the scratch test for Ni-P/Si3N4 (5 g/dm3) layer.

In Table 7 and Table 8, the damages of a cohesive and adhesive character are marked with colors. It was difficult to determine at what load the first cracks began. The focus was on cracks that were not single and random, as well as damage to the coatings that began to appear and grow and had a clear and indisputable cohesive or adhesive character. Detailed values of the critical loads are presented in Table 9. For both coatings, the lower limit loads are in a similar range of 19.73N and 17.91N. An evident change is noticeable in the critical load, during which the coating breaks; the values differ significantly. The moment of coating decohesion is marked with a white arrow in Figure 6.

Table 9.

Critical loads for the tested chemical coatings.

3.3. Evaluation of Tribological Parameters

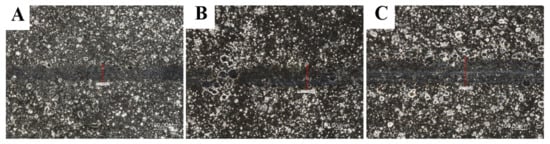

Figure 7, Figure 8 and Figure 9 show the results of tribological tests performed with the ball-on-flat method, which were carried out during 1200 s using GL-4 75W/90 semi-synthetic gear oil. All other parameters and wear diameters remained unchanged. Specialized computer software was used again, which is an integral part of the light microscope. The drawings show high-resolution microscopic images showing the width of the carved grooves to an accuracy of 0.1 µm.

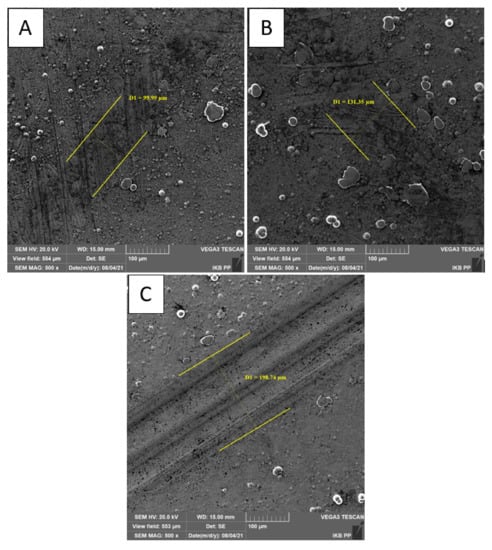

Figure 7.

Images of scratches for samples with NiP/Si3N4 coatings deposited in a bath with 2 g/dm3 Si3N4 (load: (A) 5 N; (B) 10 N; (C) 15 N; magnification: 500×).

Figure 8.

Images of cracks for samples with NiP/Si3N4 coatings deposited in a bath with 5 g/dm3 Si3N4 (load: (A) 5 N; (B) 10 N; (C) 15 N; magnification: 500×).

Figure 9.

SEM Images of cracks for samples with NiP/Si3N4 coatings deposited in a bath with 5 g/dm3 Si3N4 (load: (A) 5 N; (B) 10 N; (C) 15 N; magnification: 500×).

Based on the results of the second tribological tests stage, which were carried out on all samples, it was found that Ni-P/Si3N4 (2 g) coatings both contribute to the reduction of surface wear and are resistant to damage. The value of the loading force had the most significant impact on the size of the cracks. The content of the dispersion phase increases the abrasion resistance of the surface layer, but increasing its content from 2 to 5 g/dm3 in the chemical bath resulted in a slight increase in surface wear, as the crack width slightly raised to the range of 138.7 ÷ 152.5 µm. The lowest wear of the coating surface was recorded for the sample with the Ni-P/Si3N4 (2 g) layer, on which the crack widths were imperceptible and disappearing; therefore, their width cannot be precisely determined in this case. The exact results of the width of the resulting cracks are presented in Table 10.

Table 10.

Crack widths after tribological tests.

The microscopic images of the resulting cracks, shown in Figure 7 and Figure 8, clearly differ from each other. The crack widths characterizing the degree of surface wear depended on the pressure force of the counter-sample and the type of the tested surface, the use of lubricant and the duration of the tests at a given speed. Crack widths are not the only determinant of surface wear and its behavior under given operating conditions. The sample with the applied layer of Ni-P/Si3N4 (2 g) nanocomposite showed the highest resistance to any signs of wear because, during microscopic observations, it is difficult to see traces of the counter-sample for the 5 N force. In Figure 7a, no signs of wear have been noticed. The Ni-P/Si3N4 (5 g) layer showed higher wear than the previous sample because the scratches were distinct and larger than the Ni-P/Si3N4 (2 g) layer and its width was within the range of 114.0 ÷ 118.5 µm. It was noticed that these layers are characterized by a very high resistance to abrasion and puncturing of the coating.

Increasing the pressure of the counter-sample from 5 to 10 N, and then to 15 N, resulted in more expansive and distinct cracks; the edges and abrasion marks of the counter-sample passage are more visible. The SEM photos and the measurements of the width of the paths show that the 15 N force caused the most visible deformation of the surface of the samples (see Figure 9). The analysis of the cross-section profiles of the tracks using SEM did not show any significant differences between the samples. Similarly, no damage to the surface of the coatings in the form of cracks, delamination and material defects or nicks was found. In addition, the influence of the content of the disperse phase on the tribological properties is more noticeable at lower loads. The research confirmed that nanocomposite layers deposited on the AW-7075 alloy can be subjected to loads of various values and can be successfully operated in multiple environments using lubricants. It was confirmed that the tested layers contributed to the increase in the surface resistance to tribological wear to a different extent. Table 10 summarizes the crack widths for the individual samples in order to more accurately illustrate the degree of wear.

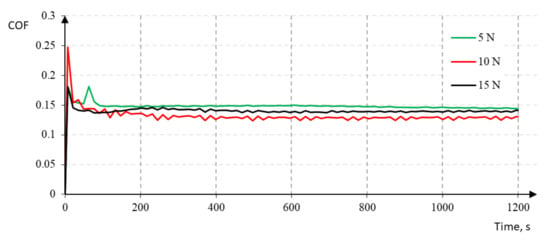

The example values of the measured friction coefficients were shown in Figure 10. The charts of changes in the friction coefficient were obtained automatically from tribological tests using the computer software attached to the BRUKER UMT TriboLab device. For all samples, the value of the friction coefficient was stabilized.

Figure 10.

The friction coefficient measurements for Ni-P/Si3N4 (2 g) sample with different basic loads.

The obtained diagrams show that the friction coefficients for the Ni-P/Si3N4 (2 g) layers with a thickness of 10 μm stabilize after 40 s at one level in the range 0.12–0.16 (see Figure 10). On the other hand, nanocomposite Ni-P/Si3N4 (5 g) layers with an increased content of the dispersion phase are characterized by a similar, slightly higher coefficient, which oscillated in the range of 0.14–0.15, which is reflected in the results of profilometric tests that confirmed a greater roughness. Moreover, the surfaces of the Ni-P/Si3N4 (2 g) nanocomposite layers showed significantly higher abrasive wear resistance—for the 5 N load, the crack was imperceptible, while for the 10 N and 15 N loads, the crack widths are much smaller compared to the Ni-P/Si3N4 layer (5 g), where the scratches are clearer and appear regardless of the load.

4. Discussion

The aim of this study was focused on identifying the basic mechanical properties of the coating. The obtained results provide the first instance in literature of essential information regarding the Ni-P/Si3N4 coatings’ mechanical properties, and enable the selection of a practical application of these coatings. These results are the basis for further research on using Al-Zn-Mg alloys with deposited nickel layers in the engineering industry. The development of the work is both to increase the durability of various materials used for machine parts and the possibility of improving the efficiency of subassemblies by reducing the weight of moving parts subject to loads.

Analyzing the literature, it can be easily seen that the problems related to Si3N4 and NI-P are very extensively analyzed. Mazurek et al. [24] showed that Ni-B/Si3N4 composite layers and Ni-B composite layers are characterized by compact structures and a good adhesion to the substrate material. The incorporation of Si3N4 particles into the Ni-B layers increases the degree of surface development of the layers. The Ni-B/Si3N4 composite layer material exhibits less microhardness and less abrasive wear compared to Ni-B layers. However, the extent of wear damage of the Ni-B/Si3N4 is relatively small when compared to the Ni-B layers. Liua et al. [25] studied the impact of Si3N4nws to CF-HA/resin composites. The tensile strength of the CF-Si3N4nws-HA/resin composites increased by 41.7% compared with CF-HA/resin composites. The wear rate decreased by 85.8% compared with CF-HA/resin composites. CF-Si3N4nws-HA/resin composites showed good in-vitro bioactivity and have the potential for applications in bone graft. Cao et al. [26] noticed that relatively porous Si3N4 ceramics with special three-dimensional cage structures have a high mechanical strength, good antioxidation properties and excellent dielectric properties. According to Khullar et al. [27], the electrochemical, mechanical and microscopic inspection data supported the hypothesis that the Si3N4/Ti-6Al-4Vcombination had a better fretting corrosion performance compared to CoCrMo/Ti-6Al-4V. Zhanga et al. [28] compared the the friction coefficient of the Si3N4/stainless and Si3N4/PEEK sliding pair with an increasing load of 10 N to 30 N. For the first pair, the friction coefficient increased from 0.48 to 0.72, whereas for the second pair, it decreased from 0.27 to 0.07. However, the wear rates of these two sliding pairs were consistent.

Trzaska et al. [29] proved in his research that the incorporation of the PTFE powder particles in the nickel–phosphorus matrix increases the degree of surface development and hardness of the coating material and increases the wear resistance. Li et al. [30] noticed that, compared to the as-deposited Ni-P coatings, the toughness of the annealed composite coatings improved significantly. The superelastic effect of NiTi particles was observed in the Hertzian indentation behavior of the annealed composite coatings. In the study, Mohsenifar and Ebrahimifar [31] studied properties of the Ni–P–Al2O3–TiO2 composite coating, which was made on AISI 316 steel using a direct current deposition technique. The microstructure of the coating and its corrosion resistance were studied by changing the amount of titanium oxide (1, 2, 3 and 4 g/L) in the bath. The results of these tests were also correlated with microscopic images and showed that the coatings in a bath containing 4 g/L titanium oxide have the highest corrosion resistance.

5. Conclusions

The tested Ni-P/Si3N4 nanocomposite coatings, with a thickness of 10 μm, were deposited on the AW-7075 aluminum alloy. The results show that nanocomposite coatings have better mechanical and tribological properties than the AW-7075 alloy. Moreover, the influence of the content of the dispersion phase on the tested properties is noticeable. Ni-P/Si3N4 nanocomposite layers produced in a 2 g/dm3 bath exhibit different mechanical and tribological properties than coatings produced in a 5 g/dm3 bath, especially hardness and wear resistance. The best results were obtained for coatings produced with a dispersion phase with a content of 2 g/dm3 in the bath during deposition. Based on the carried out test, the following conclusions were formulated.

- It is noteworthy that despite the largest observed values of the roughness parameters of Ni-P/Si3N4 nanocomposite layers (2 g/dm3), their surfaces also show the highest resistance to abrasive wear;

- Increasing the content of the dispersion phase to 5 g/dm3 resulted in a bit decrease in hardness and wear resistance;

- The results of the scratch adhesion test showed that adhesive cracks begin to appear at various loads and are dependent on the thickness of the chemical composition of the coatings, and, more precisely, on the content of the dispersion phase;

- Generally, the Ni-P/Si3N4 layers are characterized by good bonding to the base material, especially coatings deposited in a bath with a content of 2 g/dm3. In the case of this coating, both adhesive and cohesive cracks appear much later at higher loads compared to the Ni-P/Si3N4 coating produced in a bath with a content of 5 g/dm3;

- Both the results in the form of microscopic images and measured numerical values prove the advantage of the Ni-P/Si3N4 coating obtained in the bath with the content of 2 g/dm3 in terms of its adhesion to the aluminum substrate compared to the Ni-P/Si3N4 coating produced in a bath with a content of 5 g/dm3;

- The results obtained in the study prove that the Ni-P/Si3N4 nanocomposite coating–AW-7075 substrate system is a good areological system;

- The tests also confirmed that the tested nanocomposite layers are promising materials for further mechanical and tribological tests. The coatings were deposited on polished and smooth substrates; therefore, in order to improve the surface properties, the polishing process should be repeated after creating the layers.

Author Contributions

Formal analysis, P.Z. and R.T.; Investigation, K.C. and N.W.; Methodology, K.C.; Project administration, K.C.; Supervision, K.C.; Validation, P.Z. Writing—original draft, N.W.; Writing—review & editing, P.Z. and R.T. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Poznan University of technology (No. 0614/SBAD/1529).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to due to the large amount of data.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Matuszak, J.; Kłonica, M.; Zagórski, I. Measurements of Forces and Selected Surface Layer Properties of AW-7075 Aluminum Alloy Used in the Aviation Industry after Abrasive Machining. Materials 2019, 12, 3707. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Berlanga-Labari, C.; Biezma-Moraleda, M.V.; Rivero, P.J. Corrosion of Cast Aluminum Alloys: A Review. Metals 2020, 10, 1384. [Google Scholar] [CrossRef]

- Mohammadi, I.; Afshar, A.; Ahmadi, S. Al2O3/Si3N4 nanocomposite coating on aluminum alloy by the anodizing route: Fabrication, characterization, mechanical properties and electrochemical behavior. Ceram. Int. 2020, 42, 12105–12114. [Google Scholar] [CrossRef]

- Nassajpour-Esfahani, A.H.; Emadi, R.; Alhaji, A.; Bahrami, A.; Haftbaradaran-Esfahani, M.R. Towards high strength MgAl2O4/Si3N4 transparent nanocomposite, using spark plasma sintering. J. Alloys Compd. 2020, 830, 154588. [Google Scholar] [CrossRef]

- Hajiali Fini, M.; Amadeh, A. Improvement of wear and corrosion resistance of AZ91 magnesium alloy by applying Ni–SiC nanocomposite coating via pulse electrodeposition. Trans. Nonferrous Met. Soc. China 2013, 23, 10. [Google Scholar]

- Zhu, G.; Cui, X.; Zhang, Y.; Chen, S.; Dong, M.; Liu, H.; Shao, Q.; Ding, T.; Wu, S.; Guo, Z. Poly (vinyl butyral)/Graphene oxide/poly (methylhydrosiloxane) nanocomposite coating for improved aluminum alloy anticorrosion. Polymer 2020, 172, 415–422. [Google Scholar] [CrossRef]

- Sharifalhoseinia, Z.; Entezaria, M.H.; Davoodib, A.; Shahidi, M. Access to nanocrystalline, uniform, and fine-grained Ni-P coating with improved anticorrosive action through the growth of ZnO nanostructures before the plating process. Corros. Sci. 2020, 172, 108743. [Google Scholar] [CrossRef]

- Prasanta, S.; Suman, K.D. Tribology of electroless nickel coatings—A review. Mater. Des. 2011, 32, 1760–1775. [Google Scholar]

- Varshney, P.; Chhangani, S.; Prasad, M.J.N.V.; Pati, S.; Gollapudi, S. Effect of grain boundary relaxation on the corrosion behaviour of nanocrystalline Ni-P alloy. J. Alloys Compd. 2020, 830, 154616. [Google Scholar] [CrossRef]

- Vijayanand, M.; Elansezhian, R. Effect of different pretreatments and heat treatment on wear properties of electroless Ni-B coatings on 7075-T6 aluminum alloy. Procedia Eng. 2014, 97, 1707–1717. [Google Scholar] [CrossRef] [Green Version]

- Touri, S.; Monirvaghef, S.M. Fabrication and characterization of functionally graded Ni-P electroless coating with variable properties along the surface of the coating, Mater. Today Commun. 2020, 24, 101203. [Google Scholar]

- Kanamori, K.; Kimoto, Y.; Toriumi, S.; Yonezu, A. Evaluation of adhesion durability of Ni–P coating using repeated Laser Shock Adhesion Test. Surf. Coat. Technol. 2020, 396, 125953. [Google Scholar] [CrossRef]

- Wang, S.; Huang, X.; Gong, M.; Huang, W. Microstructure and mechanical properties of Ni-P-Si3N4 nanowire electroless composite coatings. Appl. Surf. Sci. 2015, 357, 328–332. [Google Scholar] [CrossRef]

- Farzeneh, A.; Mohammadi, M.; Ehteshamzadeh, M.; Mohammadi, F. Electrochemical and structural properties of electroless Ni-P-SiC nanocomposite coatings. Appl. Surf. Sci. 2013, 276, 697–704. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Ramamoorthy, B. Effect of reducing agent and nano Al2O3 particles on the properties of electroless Ni-P coating. Appl. Surf. Sci. 2014, 307, 654–660. [Google Scholar] [CrossRef]

- Franco, M.; Sha, W.; Aldic, G.; Malinov, S.; Cimenoglu, H. Effect of reinforcement and heat treatment on elevated temperature sliding of electroless Ni-P/SiC composite coatings. Tribol. Int. 2016, 97, 265–271. [Google Scholar] [CrossRef] [Green Version]

- Soleimani, R.; Mahboubi, F.; Arman, S.Y.; Kazemi, M.; Maniee, A. Development of mathematical model to evaluate microstructure and corrosion behavior of electroless Ni–P/nano-SiC coating deposited on 6061 aluminum alloy. J. Ind. Eng. Chem. 2015, 23, 328–337. [Google Scholar] [CrossRef]

- Szala, M.; Kot, E.A. Influence of repainting on the mechanical properties, surface topography and microstructure of polyester powder coatings, Adv. Sci. Technol. Res. J. 2017, 11, 159–165. [Google Scholar] [CrossRef]

- Matik, U. Structural and wear properties of heat-treated electroless Ni-P alloy and Ni-P-Si3N4 composite coatings on iron based compacts. Surf. Coat. Technol. 2016, 302, 528–534. [Google Scholar] [CrossRef]

- Trzaska, M. Studies of the structure and properties of Ni-P and Ni-P/Si3N4 surface layers deposited on aluminum by the electroless method. J. Achiev. Mater. Manuf. Eng. 2010, 43, 269–275. [Google Scholar]

- Czapczyk, K. Tribological Properties of Ni-P/Si3N4 Nanocomposite Layers Deposited by Chemical Reduction Method on Aluminum Alloy AW-7075. Materials 2020, 13, 5797. [Google Scholar]

- Dhani, R.D.; Kshetri, Y.K.; Gyawali, G.; Kim, T.H.; Choi, J.H.; Lee, S.W. Understanding the effect of Si3N4 nanoparticles on wear resistance behavior of electroless Nickel-Phosphorus coating through structural investigation. Appl. Surf. Sci. 2021, 542, 148403. [Google Scholar]

- Balaraju, J.N.; Ezhil Selvi, V.; Rajam, K.S. Electrochemical behavior of low phosphorus electroless Ni-P-Si3N4 composite coatings. Mater. Chem. Phys. 2010, 120, 546–551. [Google Scholar] [CrossRef]

- Mazurek, A.; Cieślak, G.; Bartoszek, W.; Trzaska, M. Abrasion resistance of Ni-B/Si3N4 composite layers produced by electroless method. Arch. Mater. Sci. Eng. 2017, 87, 21–26. [Google Scholar] [CrossRef]

- Liua, Y.; Zhanga, L.; Zhaob, W.; Shengc, H.; Lia, H. Fabrication and properties of carbon fiber-Si3N4 nanowires-hydroxyapatite/phenolic resin composites for biological applications. Ceram. Int. 2020, 46, 16397–16404. [Google Scholar] [CrossRef]

- Cao, S.; Zhang, D.; Wang, J.; Zhang, J.; Zhou, J.; Zhang, Y. Synthesis of self-toughness porous Si3N4 ceramics with three-dimensional cage structures. Mater. Lett. 2020, 270, 127651. [Google Scholar] [CrossRef]

- Khullar, P.; Zhu, D.; Gilbert, J.L. Fretting corrosion of Si3N4 vs CoCrMo femoral heads on Ti-6Al-V trunnions. J. Orthop. Res. 2020, 38, 1617–1626. [Google Scholar] [CrossRef]

- Zhanga, J.; Liub, J.; Wangc, Z.; Chenc, W.; Hud, B.; Zhangd, Y.; Liaoa, H.; Ma, S. Tribological behavior and lubricating mechanism of Si3N4 in artificial seawater. Ceram. Int. 2020, 46, 14361–14368. [Google Scholar] [CrossRef]

- Trzaska, M.; Cieślak, G.; Mazurek, A. Structure and properties of Ni-P/PTFE composite coatings produced by chemical reduction method. Compos. Theory Pract. 2016, 16, 174–179. [Google Scholar]

- Li, Z.; Farhat, Z. Hertzian Indentation Behavior of Electroless Ni-P-Ti Composite Coatings. Metall. Mater. Trans. 2020, 51, 3674–3691. [Google Scholar] [CrossRef]

- Mohsenifar, F.; Ebrahimifar, H. Effect of titanium oxide ceramic particles concentration on microstructure and corrosion behaviour of Ni–P–Al2O3–TiO2 composite coating. Bull. Mater. Sci. 2020, 43, 99. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).