1. Introduction

In the last few years, one of the main problems has been the declining number of non-renewable resources and raw materials. However, these materials are closely linked to negative environmental impacts, including high primary energy consumption and CO

2 emissions. This issue is related to the global increase in waste [

1]. According to the latest data from the Czech Statistical Office (from 2019), up to 41% of this waste is generated by construction activities (construction, demolition, reconstruction, etc.). In recent years, there has been an effort to reduce the amount of concrete, which represents the larger volume of building materials used, or improve its impact on the environment.

About 10.9 thousand tons of this waste is glass, and about 39.7 tons of waste glass is from municipal waste [

1]. Recycling is a term generally connected to glass and already has very wide importance. Glass from municipal waste is reusable in the form of glass bottles. As a standard, up to 60% of every new glass bottle is made of recycled glass. This process is repeatable for a limited period, and, after that, due to impurities, the glass is usually landfilled [

2]. However, glass recycling does not necessarily mean only the reuse of, e.g., glass bottles for the same purpose repeatedly. Utilization in concrete is suitable because the purity demands are lower and the properties of glass are suitable for concrete composition. Czech Republic has a long tradition in jewelry, decoration, and accessory glass production. Accordingly, another used glass comes from brushing the jewelry, where impurities occur as well, and the landfill problem appears again. Due to the tested chemical properties, landfilling has been shown to be unsuitable due to the negative impacts on soil. There is an effort on so-called reuse of waste in other directions. Therefore, it is possible to use glass in a different way from how it was used before [

3]. This research deals with the glass component of the photovoltaic panels, which is the last investigated material. Photovoltaic panels are creating an established system for renewable energy utilization. The average lifetime of crystalline silicon photovoltaic module is 25–30 years [

4]. This means that the first generation of photovoltaic panel system is coming to the end of its lifetime. Due to the special chemical composition (i.e., high level of aluminum) and higher melting point, landfilling is an inappropriate approach; thus, it is necessary to develop the right way to recycle this technology [

5].

Within these intentions, it is appropriate to consider regular and high-quality concretes, which, with lower material consumption, may have the same (or better) properties than regular concrete. This study seeks to provide the possibility that the use of waste glass would bring. It is necessary to be aware of the risks associated with the use of waste materials and to verify, in particular, the impact on the environment and toxicity, given that efforts are being made to reduce the use of primary raw materials not only because their resources are depleted but also due to environmental threats.

Focused on the ingredients of concrete, and especially its effect on the environment, the attention of researchers is preferentially directed towards cement. Its properties when used in concrete are indispensable; however, the energy expended in its processing, in relation to carbon dioxide that is produced, is significant. In terms of CO

2 emissions, cement has the largest footprint and energy consumption. Therefore, the reduction in size of the cement industry is one of the global sustainability concerns of the 21st century [

6]. As a partial replacement for cement, various materials began to be used in our country it—primarily silica flour and microsilica. This paper deals with the mixtures in which silica flour is fully replaced by waste glass powder, and in which microsilica is completely omitted.

Silica flour is formed after the crushing and subsequent grinding of quartz sand to the required roughness. Quality and especially volume uniformity is ensured by modern equipment in production. The properties of silica flour have been investigated in several studies, usually compared with cement and limestone powder as well [

7,

8]. It has been verified that silica flour produces paste with different rheological properties when substituted at the same volume level [

9].

Microsilica (also silica fume) is known as a by-product of the smelting process of silicon metal and ferrosilicon manufacturing. After some research [

10,

11,

12], microsilica was verified as a possible partial replacement for cement in concrete. The knowledge gained about microsilica is partly summarized in a review by Siddique [

13]. The paper presents a summary of the physical and chemical properties of microsilica and the reaction mechanism and hardening properties of concrete.

While the use of microsilica in concrete was based on research [

10,

13,

14,

15] moving in the right direction, with the increasing consumption of this material, the amount produced as a by-product is not sufficient for use in concrete and microsilica began to be produced on purpose. However, this knowledge returns to the inequality and unecology of this solution and goes back to the core of the problem; it is necessary to look for a material that is purely waste material and has properties that are in some way unsuitable for landfilling and at the same time have similar properties to silica flour, silica fume, or cement, which are originally replaced. The chemical composition is one of the main problems when replacing cement in concrete. There are several types of fume whose chemical composition varies according to the type of produced metal. For example, the fume from a ferrosilicon furnace generally contains more iron and magnesium oxides than from a furnace producing silicon metal [

15].

After summarizing all these factors, a convenient raw material for the partial replacement of cement, silica flour, or fine sand in concrete, another perfect pozzolan—glass—was chosen. This choice was based mainly on chemical characterization, which was partly solved in previous research [

16]. Regarding the strict limitations and increasing demands of these materials, this research is focused on the problem, which was founded in the idea of replacing cement with silica powder.

The question is whether it is necessary to replace raw materials in concrete. Three types of waste glass powder are used as a full silica flour replacement in concrete. Although the chemical properties vary while using different types of waste glass powder, the properties verified for proper concrete utilization are tested, optimized, and verified [

16,

17]. Based on the chemical properties, microsilica was fully omitted from one of the mixtures.

To verify the suitability of the use of waste glass and concrete that contains waste glass, specific procedures were chosen according to the decrees of the Czech Republic. One of the main points of this work (apart from the high priority of chemical composition) is ecotoxicity. Ecotoxicology is a multidisciplinary field of modern attitude to deal with the verification of environmental and anthropogenic impacts on ecosystems (aquatic and terrestrial) [

18]. The experiments are provided under certain conditions, which are usually given by international organizations such as OECD, ISO, and ASTM in our research [

19,

20,

21,

22]. Most of the experiments are included in the European law system.

The ecological risk assessment is mostly expressed in EC50 (effective concentration causing 50% effect in comparison with control). The other possibilities are LC50 (lethal concentration causing 50% effect, in comparison with the control) or LOEC (lowest observed effect concentration) [

18]. The values indicate whether the tested samples are hazardous for the environment, and, based on the results, it is possible to evaluate the general ecological danger. The ecological point of view is becoming one of the main factors these days. In the near future, the quality of the environment is gradually becoming the most important thing that will need to be maintained.

The novelty of this study is in the performed ecotoxicology tests, with the focus on building materials such as concrete. It is common that concrete is tested to verify mechanical or physical properties (tensile bending strength, compressive strength, freeze–thaw resistance). However, equally important are the environmental issues and the caused impacts.

The aim of our research was to investigate whether a hazardous glass waste leaching and ecotoxic potential could significantly decrease after incorporation into concrete mix.

2. Methodology and Material Characterization

2.1. Methodology

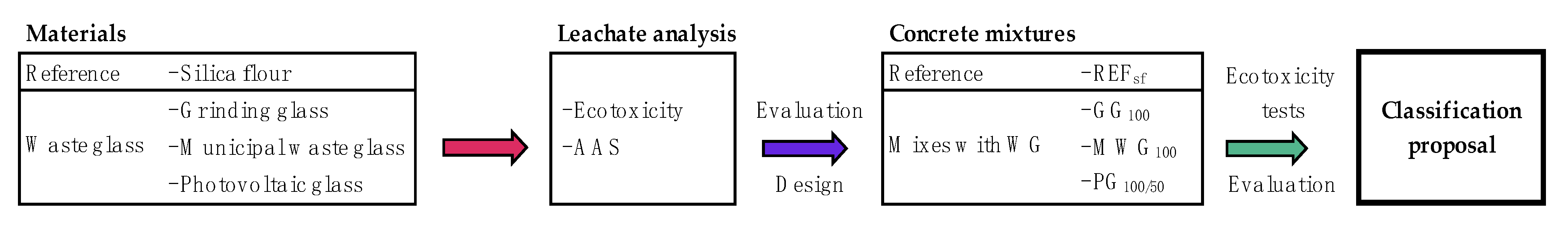

The work procedure is graphically explained below in

Figure 1.

Three samples of waste glass powders from different sources were chosen. Grinding glass, municipal waste glass, and photovoltaic glass in the form of powder were measured and analyzed to evaluate their impact on the environment. Silica flour (used as the reference sample) was exposed to the same experiments for comparison. AAS was made to collect the basic properties and evaluate the potential risks.

Given the results, the design of concrete mixtures was made. One reference mix as the sample (REFSF) and three concrete mixtures containing waste glass (GG100, MWG100, and PG100/50) and ecotoxicity experiments were made to verify the prediction of eliminating the ecotoxicity of waste glass when used in concrete.

After the evaluation of all collected results, our research team came with a methodology. Due to the lack of methodology in this field, the ecotoxicity classification proposal of waste materials and concrete was made.

2.2. Material Characterization

Glass is an amorphous pozzolanic material. The properties of different types of waste glass have been examined and tested in previous research [

3,

23]. Due to the examined properties, such as particle size distribution, chemical analyses, durability, and ecotoxicity experiments, the suitability of waste glass as an aggregate in concrete is explored. This statement is supported by numerous studies [

24,

25,

26,

27].

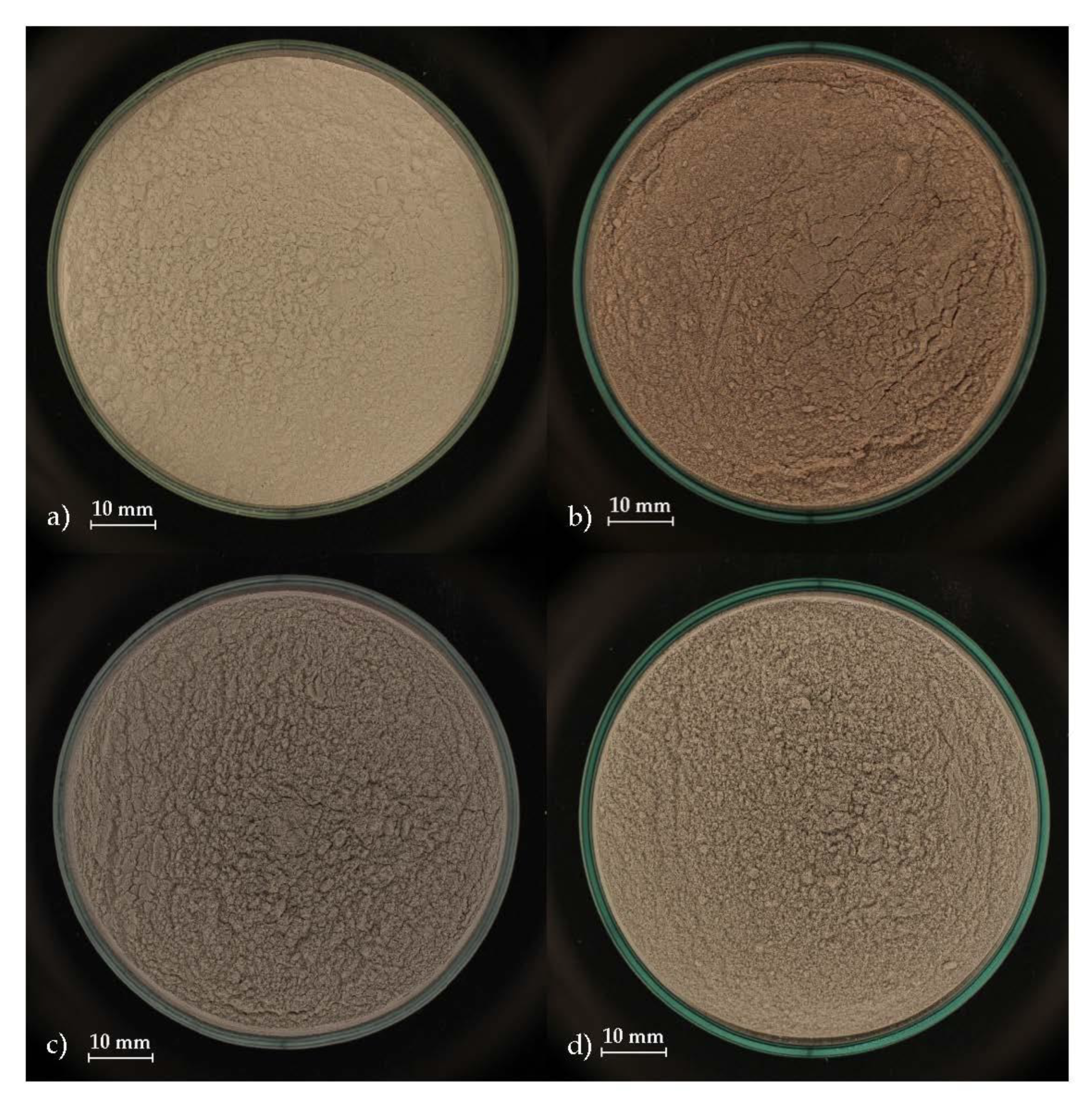

Three types of waste glass were used in this research and were selected based on the need to recycle them. All samples were tested in the form of powder. A summary of the tested samples is in

Table 1 and shown in

Figure 2a–d.

Glass from municipal waste is reusable in glass bottles, as mentioned before. This process can be repeated many times until the glass is filled with impurities, and another method of reuse is required. The utilization of glass in concrete is suitable because the purity demands are lower and the properties of glass are suitable for concrete composition.

Another source of used glass is in brushing jewelry. This type of glass powder also contains impurities, but there is a potential for use in concrete due to the pozzolanic properties. The finest fraction is used as a silica flour replacement to create high-performance concrete and verify the chemical properties and microscopic structures.

The last type of glass we explore in this research is glass from photovoltaic panels. Photovoltaic panels are a modern source of energy in the Czech Republic, and their use on a massive scale began approximately 15–20 years ago, which subsequently contributed to the reduction in panel prices in 2009–2010 [

28,

29]. As the aim of using energy from photovoltaic panels was to reduce CO

2 emissions, it is appropriate to consider their recycling so that their landfilling does not endanger the soil, for example. In the case of photovoltaic panels, recycling is ideal by disassembling the panels and using them individually. Glass from the photovoltaic panels was crushed into two fractions—fine sand and glass powder (flour). Subsequently, both fractions are used in this research in concrete as a substitute for fine sand and silica flour. The main aims are to save the number of primary resources and eliminate carbon dioxide production [

6].

2.3. Concrete Mixes

Based on the results of the chemical properties, the concrete mixes were designed. With regard to the results, one reference concrete mix and three concrete mixes containing different types of waste glass were tested.

The reference concrete mixture was made according to the recipe verified by the Department of Architectural Engineering at the Faculty at Civil Engineering, CTU Prague.

The mixture containing waste glass from grinding jewelry (grinding glass, GG) and crushing municipal waste glass (MWG) was added, as a full replacement for silica flour, to the concrete mixture. The replacement, in both cases, was realized in full weight ratio. The replacement ratio is 100% in both mixes (GG100 and MWG100).

Based on the chemical results and previous research [

3,

16,

23,

30], the concrete mixture containing photovoltaic glass was modified. Due to the specific chemical composition of the photovoltaic glass, which was verified in the recent experiments, the adaptation of the mixture was necessary to allow further testing of this mixture. The specification of the composition of this mixture omits microsilica from this type of concrete. This component caused premature cracking of the specimens during concrete hardening.

Full replacement of silica flour was provided by waste glass powder from photovoltaic panels. In addition, 50% of the natural sand (fraction 01/06) was replaced by photovoltaic glass with the requisite fraction (fine sand 01/06). The replacement ratio was 100% with silica flour and 50% with sand (PG100/50).

A more detailed description of the composition of the designed concrete mixes is given below in

Table 2.

The summary of basic information about the tested concrete mixes is in

Table 3, and the final samples are shown in

Figure 2a–d. All tested samples were cubes with dimensions 50 × 50 × 50 mm

3.

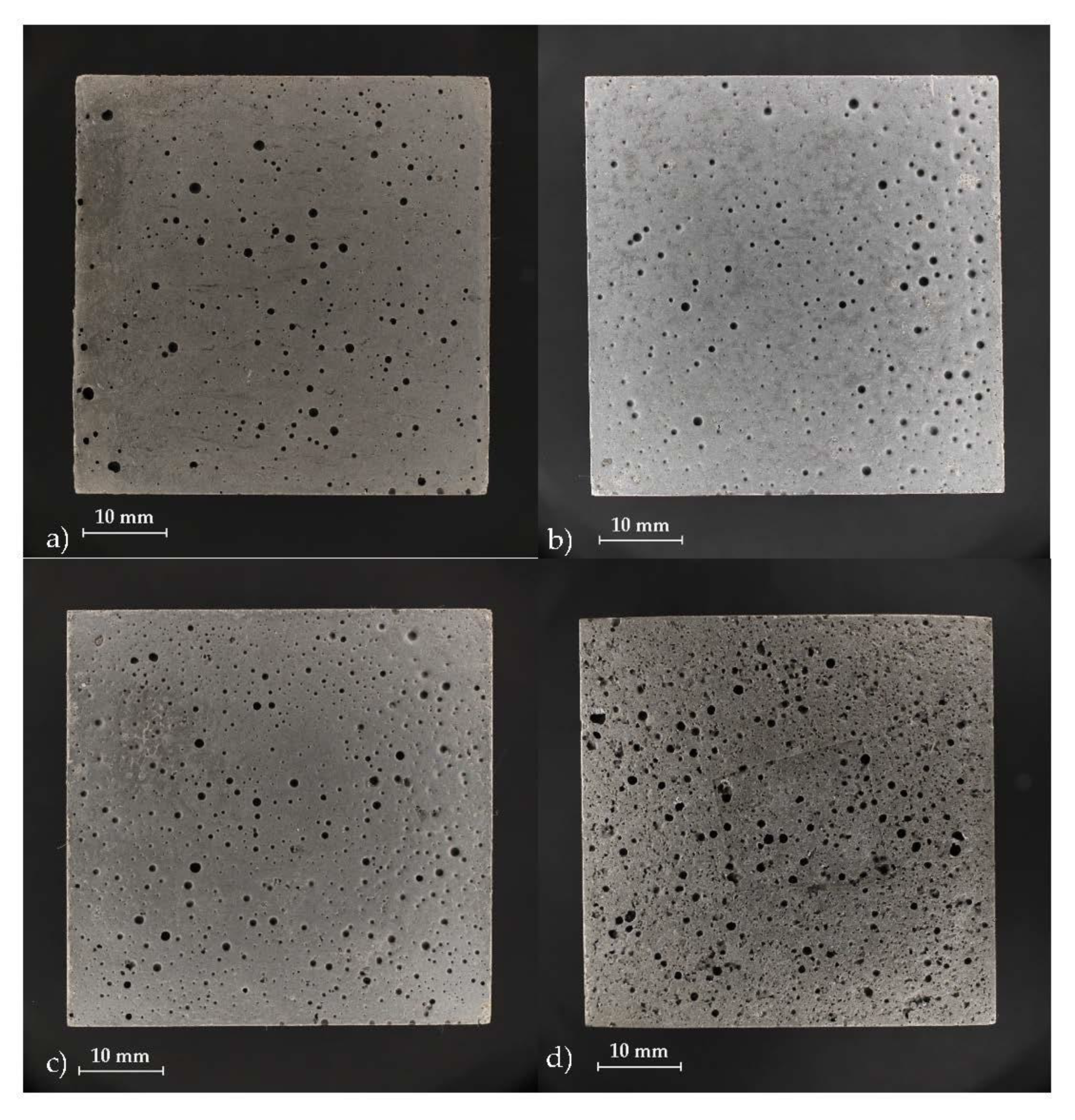

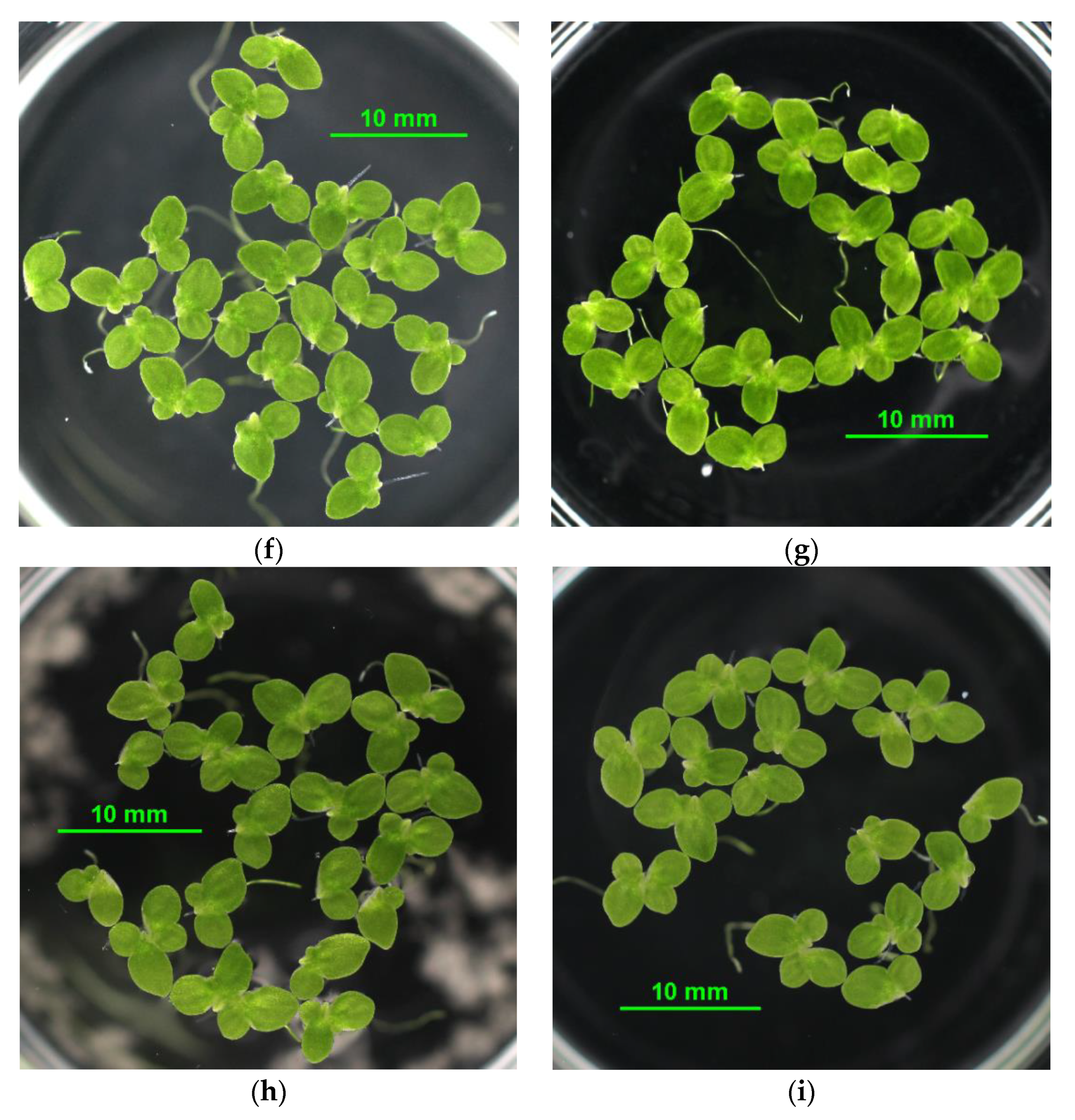

The concrete samples used for testing ecotoxicology properties are shown in

Figure 3. The testing methods of the experiments are described in detail below in

Section 2.6 and subsections. The surfaces of the concrete samples differ slightly; this is especially evident when comparing REF

SF with PG

100/50. A more porous structure is a sign of material with lower density, which predetermines different mechanical properties.

2.4. Testing Methods

All experiments were made following international standards. The used testing methods are summarized in

Table 4. The methodology is described in

Section 2.5 and

Section 2.6.

2.5. Leaching Experiments

For silica flour and glass, air-dried samples of 100 g were mixed with 1000 mL of H

2O and homogenized on an overhead shaker (7 rpm) for 24 h [

19]. Consequently, the solid particles in the leachates were settled for 10 min, and the liquid phase was centrifuged (2360

g, 10 min, 25 °C) and filtered through a membrane paper with pores of 5 μm. For the concrete samples, the leachate procedure was adjusted: concrete cubes (aged 28 days) were placed in 3.6 L bottles and covered with H

2O in the ratio 100 g/1000 mL. The bottles were covered, and the samples were left, without shaking, at room temperature. After 24 h, the concrete cubes were removed, and the leachates were filtrated without centrifugation step. pH and electrical conductivity were determined in the filtrated leachates at room temperature. All leachates were prepared in two replicates. Selected elements (B, Na, Mg, Al, Si, K, Ca, Cr, Fe, Ni, Cu, Zn, As, Se, Mo, Cd, Sb, Ba, Hg, and Pb) were determined using atomic absorption spectrometry with flame atomizer 280FS AA, developed by Agilent Technologies, Inc. (Santa Clara, CA, USA), in leachates after acidification by HCl to a pH of 2.0.

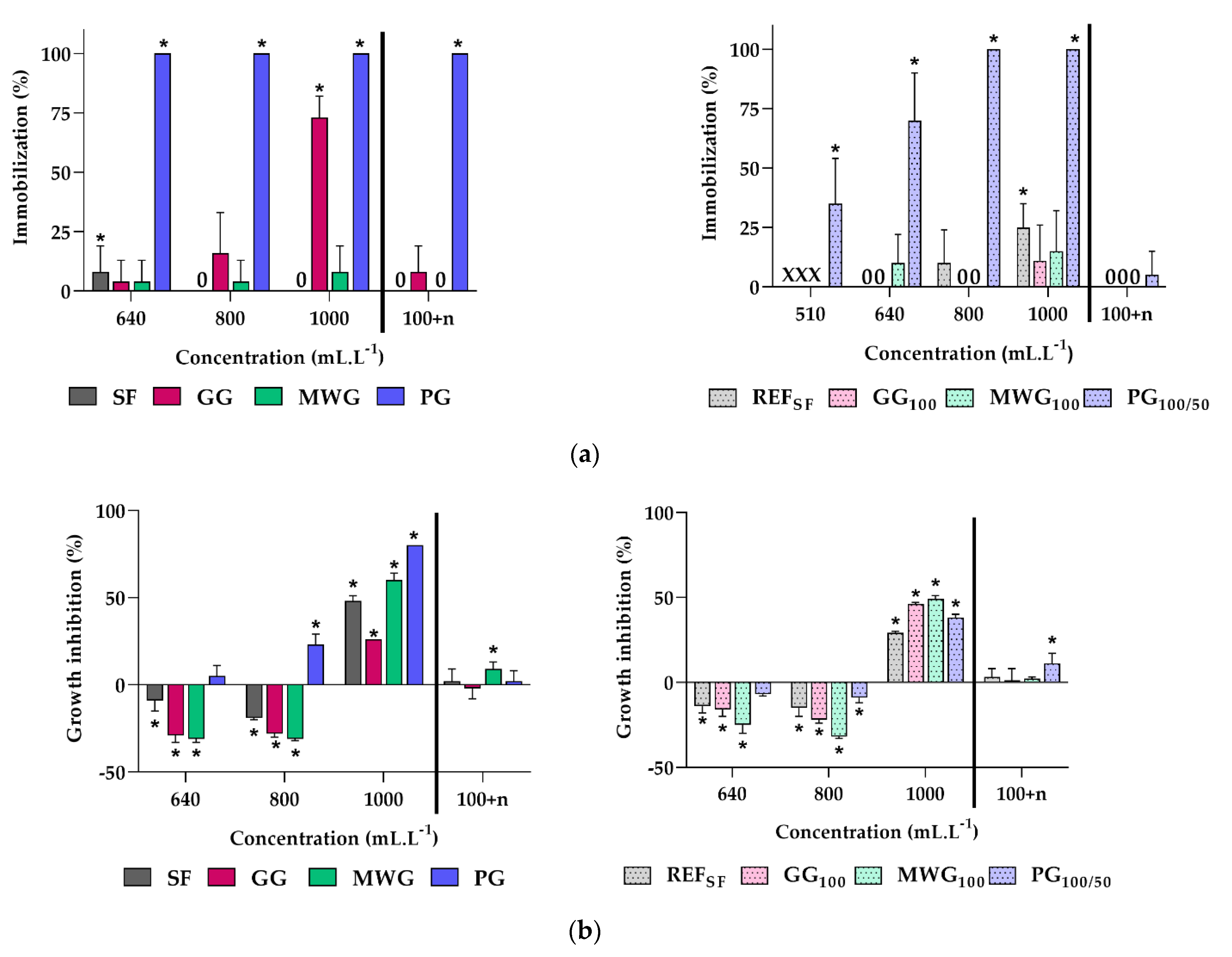

2.6. Ecotoxicity Experiments

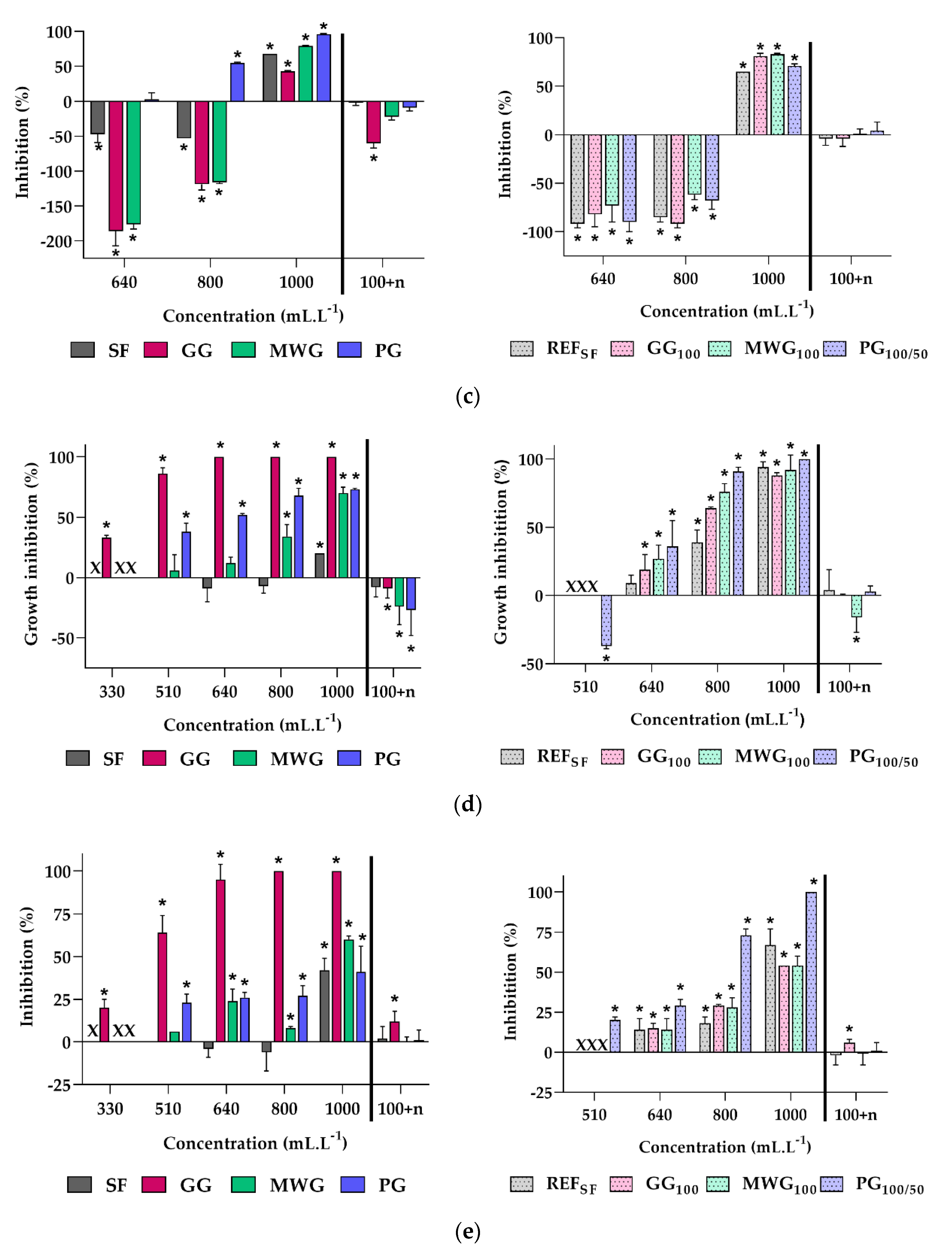

Ecotoxicological bioassays were performed with original untreated leachates, leachates diluted with nutrient media in a concentration range between 330–800 mL/L, and leachates diluted 10 times and amended with relevant inorganic nutrients according to the control media of the given test species (sample concentration 100 + n mL·L−1). pH adjustment was not included in the leachate’s treatment.

2.6.1. Daphnia Acute Toxicity Test

An acute toxicity assay was performed with

Daphnia magna juveniles aged up to 24 h, which were hatched from ephippia obtained from Microbiotests Inc. (Mariakerke (Gent), Belgium). The experiment was designed following ISO guideline 6341 [

21], with some adjustments. Freshly modified ADaM medium (pH ~ 7.3–7.6) prepared according to [

31] was used as the control sample.

Five juvenile individuals were transferred into 25 mL beakers with 20 mL of leachate or control sample, covered with transparent film, and put under stable temperature (20 ± 1 °C) and light cycle (fluorescent light, 1000–2000 lx; 16 h light/8 h dark). Each sample was represented by four replicates, whereas the control was represented by six replicates. The inhibition of daphnia mobility (viability) was observed after the 48 h exposition.

2.6.2. Freshwater Algae Toxicity Test

Algae growth inhibition test was performed with the freshwater green algae

Desmodesmus subspicatus, strain Brinkmann 1953/SAG 86.81, which was obtained from CCALA IBOT, AS CR (Trebon, Czech Republic) partly following the ISO guideline 8692 [

22]. Bold Basal Medium (BBM; pH 6.6 ± 0.2) according to [

32] was used as the control medium. For the test, 25 mL Erlenmeyer flasks were filled with 15 mL of leachate/control sample and inoculated with precultivated algae (80,000 cells per 1 mL). Samples and controls were represented by triplicates or quadruplicates, respectively. Flasks were covered with sterile cellulose caps and placed under a stable temperature (23 ± 1 °C) and light cycle (16 h of light period) with continuous shaking (130 rpm) for 72 h. An LED light with selected wavelengths (450–455 nm and 660–665 nm) and an illuminance of 3000–3500 lx was used as the light source. Algal cell density was determined via cell counting using a microscope and Bürker chamber (Hecht, Sondheim, Germany). Biomass was determined indirectly as optical density at 684 nm using spectrophotometer Shimadzu UV-1900 (Kyoto, Japan).

2.6.3. Duckweed Growth Inhibition Test

A duckweed assay was proposed by ISO guideline 20079 [

20] using

Lemna minor, strain Steinberg originated from Federal Environmental Agency (Berlin, Germany). Steinberg medium modified by Altenburg (pH 5.5 ± 0.2) [

20] served as the control. The test was carried out in 150 mL beakers, filled with 100 mL of sample/control medium. Samples and controls were represented by three and five replicates, respectively. Each vessel was inoculated with 10 fronds of duckweed of a similar total frond area and covered with transparent film. Test vessels were kept in a stable temperature (24 ± 2 °C) and exposed to a light cycle (fluorescent light, 5000–6000 lx; 16 h light/8 h dark).

The total frond area was determined by image analysis using NIS Elements (Version 5.20, Laboratory Imaging, Prague, Czech Republic). Growth rate (GR) was calculated from the values based on repeated measurements during the test exposure, i.e., 0th, 3rd, and 7th day. After the 7-day exposition, fronds were extracted by pure methanol (48 h; 4 °C, dark) and the total chlorophyll content was determined spectrophotometrically (Shimadzu UV-1900) according to [

33].

2.6.4. Evaluation of Ecotoxicity Data

In algae and duckweed, the growth rate (GR), based on cell number and frond area, respectively, was calculated using Equation (1):

where r is the growth rate per day,

Xt0 is the value of the parameter in

t0 (d), and

Xt1 is the value of the parameter in

t1 (d). [

20].

All ecotoxicological data (daphnia viability, algal and frond GR, algal biomass, and chlorophyll content) were consequently expressed as the values of inhibition/stimulation in percentage, where tested organisms in leachate were compared to control organisms using the following equation:

where

I is the inhibition/stimulation of growth (%),

Xc0 is the average value of control, and

Xci is the average value of sample

i. [

20].

EC50 values were calculated from the inhibition data for all ecotoxicity tests using non-linear regression. A one-way ANOVA and Dunnett’s post-hoc test was performed to compare samples with controls at the α level of 0.05. Based on the Dunnett test, the highest sample concentration, which was statistically not different from the control sample and had no stimulation effect at the same time, was chosen as the NOEC value. The statistical analyses were performed using GraphPad Prism software (Version 9.1, GraphPad Software, San Diego, CA, USA). The level of ecotoxicity was finally classified according to

Table 5.