An Investigation into the Effect of Electro-Contact Heating in the Machining of Low-Rigidity Thin-Walled Micro-Machine Parts

Abstract

1. Introduction

2. Materials and Methods

2.1. Characterization of the Machined Parts

2.2. Schematic of the Test Stand

2.3. Schematic of the Electro-Contact Heating Control System

3. Results and Discussion

3.1. Effect of Machining Type and Machining Parameters on the Cutting Operation

3.1.1. Effect of Cutting Forces

3.1.2. Effect of Cutting Parameters on Temperature Growth

3.1.3. Effect of Heating Current Density and Turning Parameters on Changes in Cutting Forces

3.2. Use of the Electro-Contact Heating Control System

4. Conclusions

- Cutting forces:

- -

- cutting forces generated during turning and boring increase from 2.6 to 3.7 times with considerable pulsation at the beginning of machining. This is caused by an increase in the depth of cut, and the pulsation of cutting forces in the initial stage of machining is a function of workpiece runout and the depth of cut; on the other hand, increasing the temperature improves the machinability of the materials as it leads to a reduction in their strength characteristics and a significant increase in the shape stability coefficient; increasing the temperature improves the machinability of Grade 2 and Ti-64, as their strength characteristics decrease, and significantly increases the shape stability coefficient;

- -

- the main cutting forces and the thrust cutting force generated during the machining of metal-ceramic titanium are from 25 to 27% and from 22 to 25% lower, respectively, than for uniform titanium;

- -

- the cutting forces during the boring of Ti-64 increase from 1.5 to 1.7 times, which leads to an increase in the intensity of the technological field of ultimate stresses, the relaxation of which leads to large deformations of the thin-walled sleeves.

- Effect of cutting parameters on temperature growth:

- -

- depth of cut at f = const has practically no effect on the machining temperature;

- -

- increasing feed rate f from 0.12 to 0.212 mm/rev leads to an increase in temperature by 35–420 °C;

- -

- changes in cutting speed (at f = const, ap = const) in the range from 1.3 to 3.0 m/s cause an increase in the average cutting zone temperature by 15–18 °C.

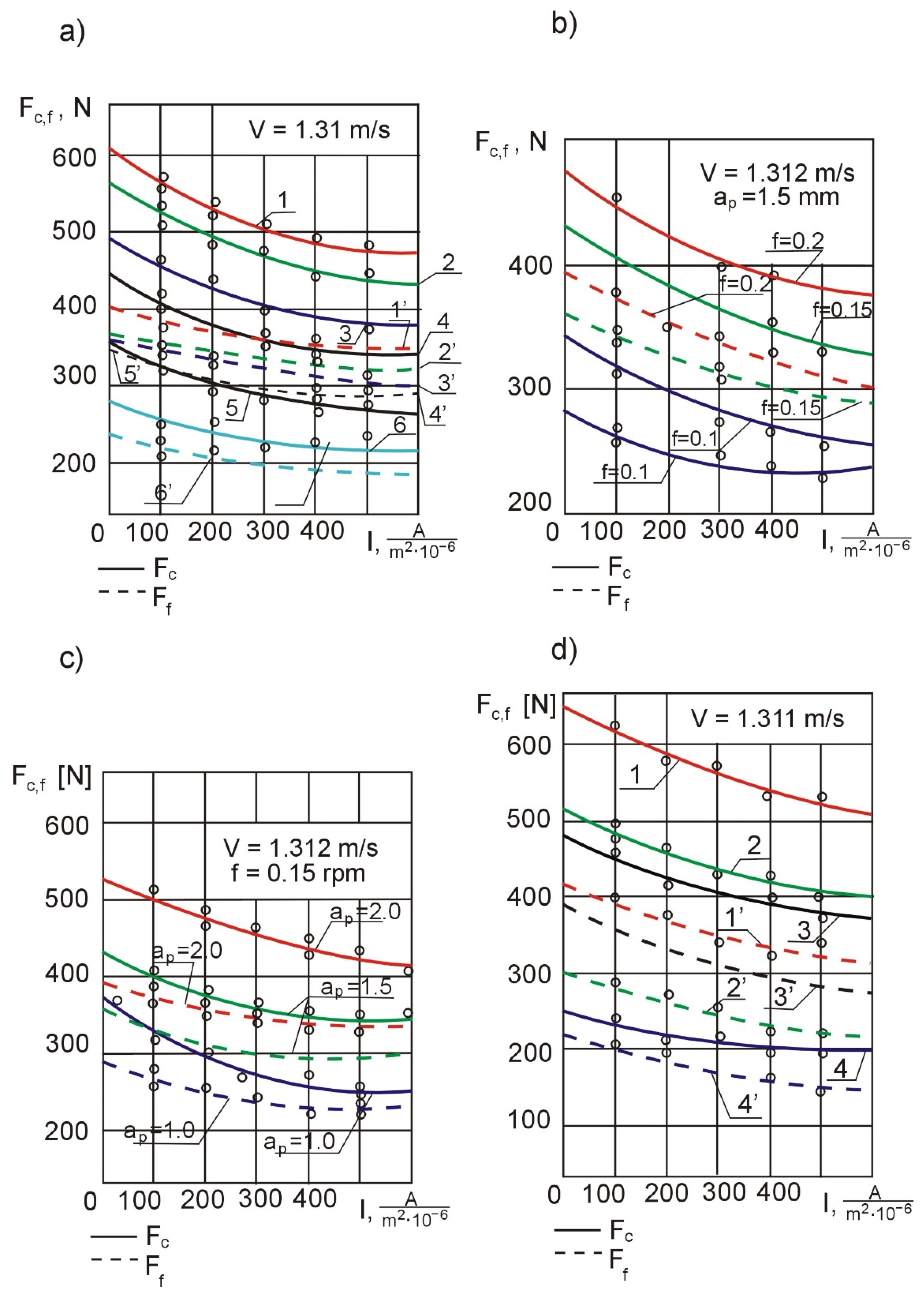

- Effect of current density on changes in cutting forces generated during the turning of Grade 2:

- -

- main cutting force Fc, at Ig.opt = 470 A/(m2·10−6) and θ°skr = 900 °C, declines by 18–22%;

- -

- feed component f decreases in the range from 13 to 15%;

- -

- a further increase in current density leads to an intensification of flank wear and an increase in the cutting forces and the temperature in the cutting zone.

- Effect of cutting parameters on changes in cutting forces in the operation of turning Ti-64:

- -

- increasing the feed rate leads to a change in the slope of the Ff = (f, Ig) curve, at vc = const, ap = const, causing practically no decrease in the Fc = (f, Ig) curve;

- -

- increasing the depth of cut ap causes practically no decrease in the Ff c = (f, Ig) curve, at vc = const, f = const, which is associated with the weak effect of ap on cutting temperature.

- The application of the electro-contact heating control system allows machining conical parts and semi-finished products at lower cutting forces. It also leads to an increase in the deformation of the thin-walled casings caused by the runout of the workpiece. Additionally, it was found that the dimensions of harder parts stabilize better (compared to parts with a lower hardness).

5. Patents

- Lathe tailstock [patent no. 212961]/Victor Taranenko, Antoni Świć, Dariusz Wołos, Georgiy Taranenko. Victor Taranenko, Antoni Świć, Dariusz Wołos, Georgiy Taranenko.-Patent no.; Patent application no.//Official Gazette of the Patent Office, 2012, No. 12, p. 2897.

- Lathe tailstock [patent no. 211537]/Victor Taranenko, Antoni Świć, Dariusz Wołos, Georgiy Taranenko; author: Victor Taranenko, Antoni Świć, Dariusz Wołos, Georgiy Taranenko.-Patent no.; Patent application no.//Official Gazette of the Patent Office, 2012, No. 5, p. 1073.

- Lathe tailstock [patent no. 213606]/Victor Taranenko, Antoni Świć, Dariusz Wołos, Georgiy Taranenko, Jakub Szabelski; author: Victor Taranenko, Antoni Świć, Dariusz Wołos, Georgiy Taranenko, Jakub Szabelski.-Patent no.; Patent application no.//Official Gazette of the Patent Office, 2013, No. 4, p. 851.

- Lathe tailstock [patent no. 214058]/Victor Taranenko, Antoni Świć, Dariusz Wołos, Georgiy Taranenko, Jakub Szabelski; author: Victor Taranenko, Antoni Świć, Dariusz Wołos, Gieorgij Taranenko, Jakub Szabelski.-Patent no.; Patent application no.//Official Gazette of the Patent Office, 2013, No. 6, p. 1426.1.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| H | external height of the machined cylindrical surface |

| h | internal height of the machined cylindrical surface |

| D | external diameter of the machined cylindrical surface |

| d | internal diameter of the machined cylindrical surface |

| HV | material hardness according to Vickers scale |

| σb | tensile strength [MPa] |

| vc | cutting speed |

| f | feed rate |

| ap | depth of cut |

| θ | temperature |

| F | cutting force |

| ρ | electrical resistance |

| γ | rake angle |

| α | clearance angle |

| κr | cutting edge angle |

| κp’ | end cutting edge angle |

| λs | side cutting edge inclination angle |

| rp | nose radius |

| Kk | shape stability coefficient |

| Fc | cutting force |

| Fp | thrust force |

| Ff | feed force |

| hp | flank wear |

| Fn | cross-sectional surface of the machined layer |

| Ig.op. | optimal current density |

References

- Świć, A.; Wołos, D.; Gola, A.; Kłosowski, G. The Use of Neural Networks and Genetic Algorithms to Control Low Rigidity Shafts Machining. Sensors 2020, 20, 4683. [Google Scholar] [CrossRef]

- Dziubińska, A.; Gontarz, A.; Dziedzic, K. Qualitative Research of AZ31 Magnesium Alloy Aircraft Brackets Produced by a New Forging Method. Arch. Met. Mater. 2016, 61, 1003–1008. [Google Scholar] [CrossRef][Green Version]

- Shao, Y.Z.; Cheng, K. Integrated modelling and analysis of micro-cutting mechanics with the precision surface genereation in abrasive flow machining. Int. J. Adv. Manuf. Technol. 2019, 105, 4571–4583. [Google Scholar] [CrossRef]

- Morozow, D.; Barlak, M.; Werner, Z.; Pisarek, M.; Konarski, P.; Zagórski, J.; Rucki, M.; Chałko, L.; Łagodziński, M.; Narojczyk, J.; et al. Wear Resistance Improvement of Cemented Tungsten Carbide Deep-Hole Drills after Ion Implanta-tion. Materials 2021, 14, 239. [Google Scholar] [CrossRef] [PubMed]

- Patalas-Maliszewska, J.; Topczak, M.; Klos, S. The Level of the Additive Manufacturing Technology Use in Polish Metal Au-tomotive Manufacturing Enterprises. Appl. Sci. 2020, 10, 735. [Google Scholar] [CrossRef]

- Świć, A.; Draczew, A.; Gola, A. METHOD OF ACHIEVING ACCURACY OF THERMO-MECHANICAL TREATMENT OF LOW-RIGIDITY SHAFTS. Adv. Sci. Technol. Res. J. 2016, 10, 62–70. [Google Scholar] [CrossRef]

- Dobrzynski, M.; Mietka, K. Surface Texture after Turning for Various Workpiece Rigidities. Mach. 2021, 9, 9. [Google Scholar] [CrossRef]

- Świć, A.; Gola, A.; Wołos, D.; Opielak, M. Microgeometry surface modelling in the process of lowrigidity elastic-deformable shafts turning. Iran. J. Sci. Technol. Trans. Mech. Eng. 2016, 41, 159–167. [Google Scholar]

- Krzyzak, A.; Kosicka, E.; Borowiec, M.; Szczepaniak, R. Selected Tribological Properties and Vibrations in the Base Resonance Zone of the Polymer Composite Used in the Aviation Industry. Materials 2020, 13, 1364. [Google Scholar] [CrossRef]

- Annoni, M.; Rebaioli, L.; Semeraro, Q. Thin wall geometrical quality improvement in micromilling. Int. J. Adv. Manuf. Technol. 2015, 79, 881–895. [Google Scholar] [CrossRef]

- Mehdi, K. Modal Analysis and Experimental Plan of Thin-Walled Workpieces in Turning Cutting Process. In Proceedings of the 2020 11th International Conference on Mechanical and Aerospace Engineering (ICMAE), Athens, Greece, 14–17 July 2020; pp. 155–161. [Google Scholar]

- Gorbatyuk, S.; Kondratenko, V.; Sedykh, L. Investigation of the Deep Hole Drill Stability When Using a Steady Rest. Mater. Today Proc. 2019, 11, 258–264. [Google Scholar] [CrossRef]

- Hayati, S.; Shahrokhi, M.; Hedayati, A. Development of a frictionally damped boring bar for chatter suppression in boring process. Int. J. Adv. Manuf. Technol. 2021, 113, 2761–2778. [Google Scholar] [CrossRef]

- Liu, J.; Ma, C.; Wang, S.; Wang, S.; Yang, B. Contact stiffness of spindle-tool holder based on fractal theory and multi-scale contact mechanics model. Mech. Syst. Signal Process. 2019, 119, 363–379. [Google Scholar] [CrossRef]

- Doluk, E.; Rudawska, A.; Kuczmaszewski, J.; Pieśko, P. Influence of Cutting Parameters on the Surface Quality of Two-Layer Sandwich Structures. Materials 2020, 13, 1664. [Google Scholar] [CrossRef]

- Struzikiewicz, G.; Zębala, W. Strain simulation in face turning of Ti6Al4V thin-walled parts. In Proceedings of the Photonics Applications in Astronomy, Communications, Industry, and High Energy Physics Experiments 2017, Wilga, Poland, 27 May–5 June 2017; Volume 104455. [Google Scholar]

- Świć, A.; Gola, A.; Sobaszek, L.; Šmidová, N. A thermo-mechanical machining method for improving the accuracy and stability of the geometric shape of long low-rigidity shafts. J. Intell. Manuf. 2021, in press. [Google Scholar] [CrossRef]

- Yang, Y.H.; Guo, J.Y.; Yu, C. Analysis to the Influences of Cutting Force to Machining Deformation of a Titanium Alloy Thin-Wall Tube. Adv. Mater. Res. 2011, 366, 510–513. [Google Scholar] [CrossRef]

- Slamani, M.; Chatelain, J.-F.; Il, A.; Balazinski, M. Statistical analysis and modeling of temperature distribution during various milling operations of thin walled aircraft parts. Phys. A Stat. Mech. its Appl. 2021, 570, 125842. [Google Scholar] [CrossRef]

- Zhou, J.M.; Yi, J.; Yi, F.Y.; Xiang, J.F.; Wang, Z.X.; Wang, J.B. Experimental study of micromilling deformation control of mi-cro-thin wall based on the optimal tool path. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 238. [Google Scholar] [CrossRef]

- Sahraoui, Z.; Mehdi, K.; Ben Jaber, M. Experimental Study of the Dynamic Behavior of Thin-Walled Tubular Workpieces in Turning Cutting Process. J. Adv. Manuf. Syst. 2020, 20, 1–19. [Google Scholar] [CrossRef]

- Swic, A.; Taranenko, W. Adaptive Control of Machining Accuracy of Axial-Symmetrical Low-Rigidity Parts in Elas-tic-Deformable State. Eksploat. i Niezawodn. 2012, 14, 215–221. [Google Scholar]

- Casanova, L.; Gruarin, M.; Pedeferri, M.; Ormellese, M. A comparison between corrosion performances of titanium grade 2 and 7 in strong reducing acids. Mater. Corros. 2021. [Google Scholar] [CrossRef]

- Vaché, N.; Cadoret, Y.; Dod, B.; Monceau, D. Modeling the oxidation kinetics of titanium alloys: Review, method and application to Ti-64 and Ti-6242s alloys. Corros. Sci. 2021, 178, 109041. [Google Scholar] [CrossRef]

- Dun, Y.C.; Zhus, L.D.; Yan, B.L.; Wang, S.H. A chatter detection method in milling of thin-walled TC4 alloy workpiece based on auto-enconding and hybrid clustering. Mech. Syst. Signal Pract. 2021, 158, 107755. [Google Scholar] [CrossRef]

- Jia, Z.; Lu, X.; Gu, H.; Ruan, F.; Liang, S.Y. Deflection prediction of micro-milling Inconel 718 thin-walled parts. J. Mater. Process. Technol. 2021, 291, 117003. [Google Scholar] [CrossRef]

- Peng, Z.; Zhang, D.; Zhang, X. Chatter stability and precision during high-speed ultrasonic vibration cutting of a thin-walled titanium cylinder. Chin. J. Aeronaut. 2020, 33, 3535–3549. [Google Scholar] [CrossRef]

- Gang, L. Study on deformation of titanium thin-walled part in milling process. J. Mater. Process. Technol. 2009, 209, 2788–2793. [Google Scholar] [CrossRef]

- Ma, J.; Ge, X.; Lei, S. Energy Efficiency in Thermally Assisted Machining of Titanium Alloy: A Numerical Study. J. Manuf. Sci. Eng. 2013, 135, 061001. [Google Scholar] [CrossRef]

| Cutting Forces F, [N] | Turning | Boring | ||

|---|---|---|---|---|

| Groove-Turning | Stabilization | Groove-Turning | Stabilization | |

| Ff | 145 | 380 | 145 | _ |

| Fp | _ | _ | _ | 480 |

| Fc | 150 | 490 | 150 | 600 |

| Material | Physicomechanical Properties of Materials at Q = 20–1000 °C | |||||||

|---|---|---|---|---|---|---|---|---|

| HV | σb | ρ · 10−8 Ω·m | Kk | |||||

| 20° | 1000° | 20° | 1000° | 20° | 1000° | 20° | 1000° | |

| H30 | 1450 | 380 | − | _ | 18.6 | 96 | 11 | 1 |

| Grade 2 | _ | _ | 56 | 3 | 150 | 220 | 6 | 43 |

| Ti-64 | _ | _ | 50 | 3 | _ | _ | 4 | 39 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Świć, A.; Gola, A.; Orynycz, O.; Tucki, K. An Investigation into the Effect of Electro-Contact Heating in the Machining of Low-Rigidity Thin-Walled Micro-Machine Parts. Materials 2021, 14, 4427. https://doi.org/10.3390/ma14164427

Świć A, Gola A, Orynycz O, Tucki K. An Investigation into the Effect of Electro-Contact Heating in the Machining of Low-Rigidity Thin-Walled Micro-Machine Parts. Materials. 2021; 14(16):4427. https://doi.org/10.3390/ma14164427

Chicago/Turabian StyleŚwić, Antoni, Arkadiusz Gola, Olga Orynycz, and Karol Tucki. 2021. "An Investigation into the Effect of Electro-Contact Heating in the Machining of Low-Rigidity Thin-Walled Micro-Machine Parts" Materials 14, no. 16: 4427. https://doi.org/10.3390/ma14164427

APA StyleŚwić, A., Gola, A., Orynycz, O., & Tucki, K. (2021). An Investigation into the Effect of Electro-Contact Heating in the Machining of Low-Rigidity Thin-Walled Micro-Machine Parts. Materials, 14(16), 4427. https://doi.org/10.3390/ma14164427