Dual-Laser PBF-LB Processing of a High-Performance Maraging Tool Steel FeNiCoMoVTiAl

Abstract

:1. Introduction

1.1. High-Performance Tool Steels for PBF-LB

1.2. Multi-Laser PBF-LB Processing

2. Experimental Setup

2.1. Material

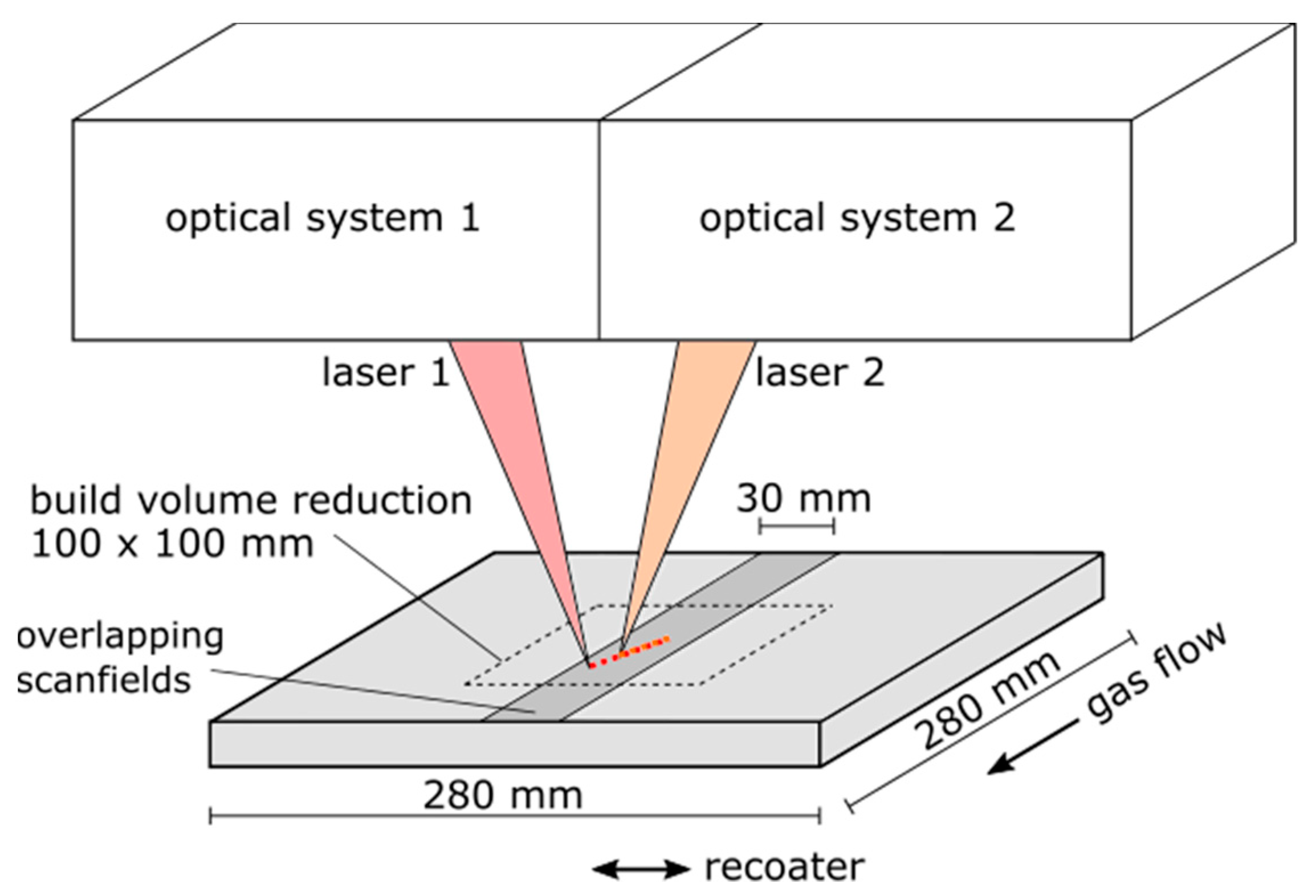

2.2. Machine

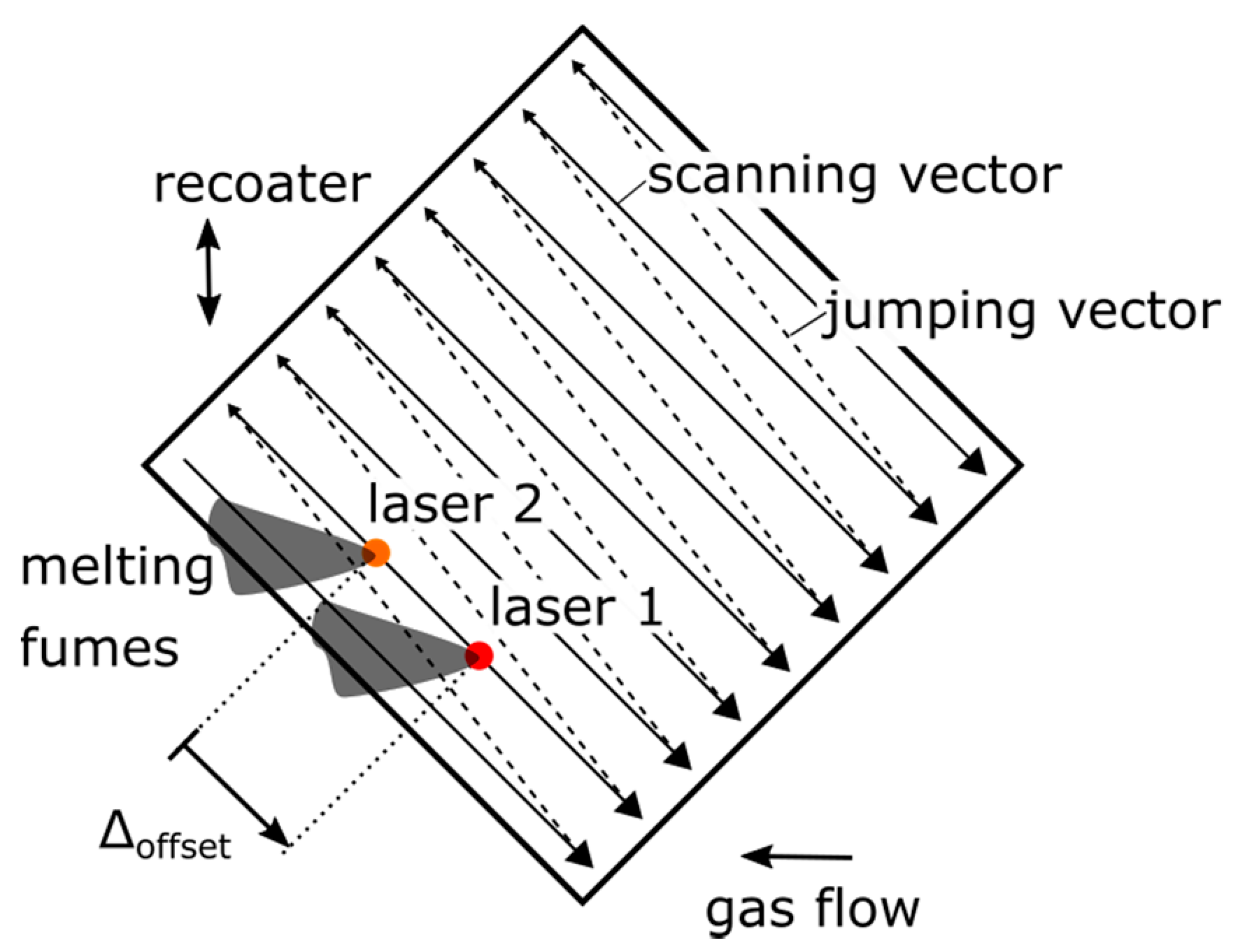

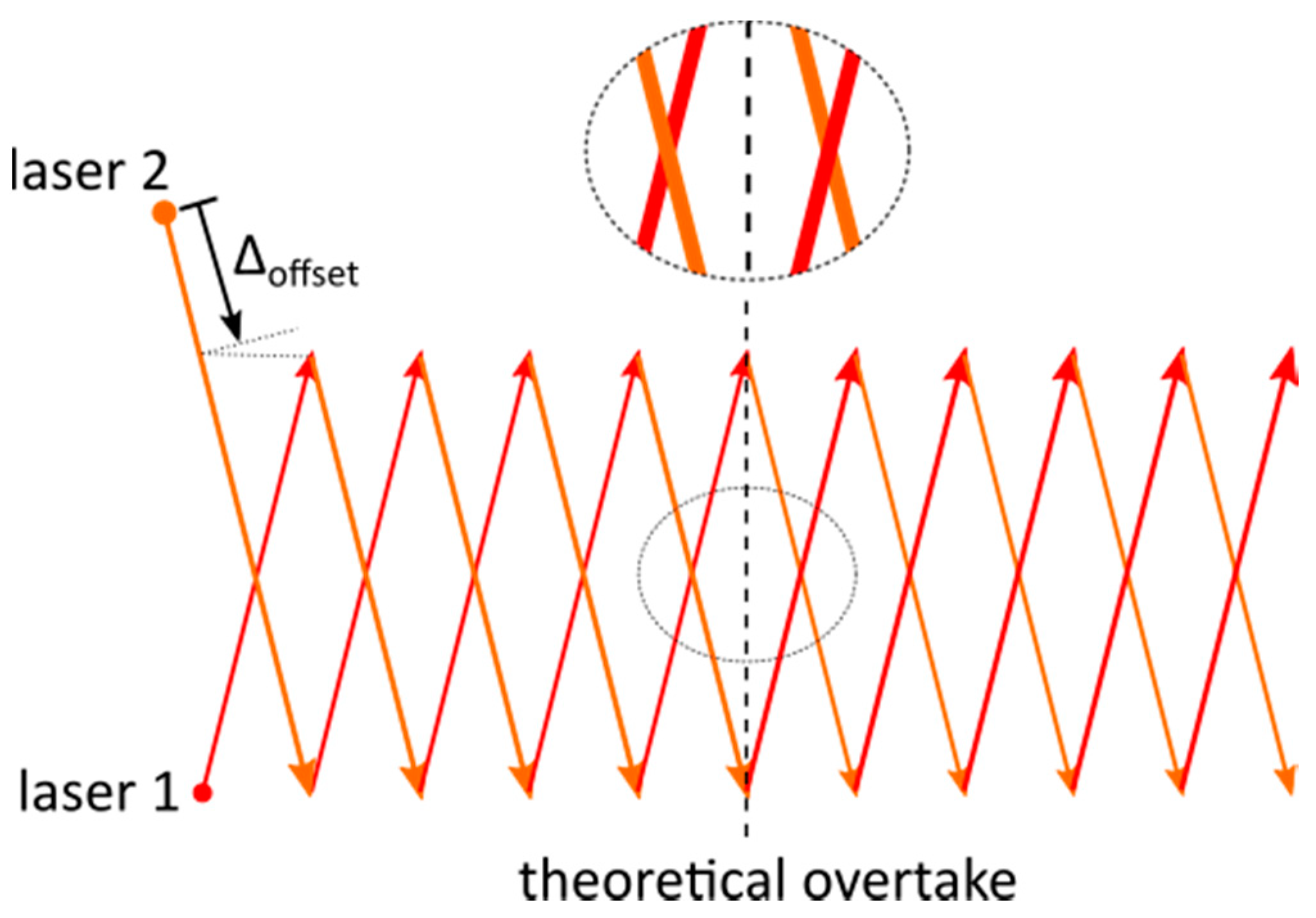

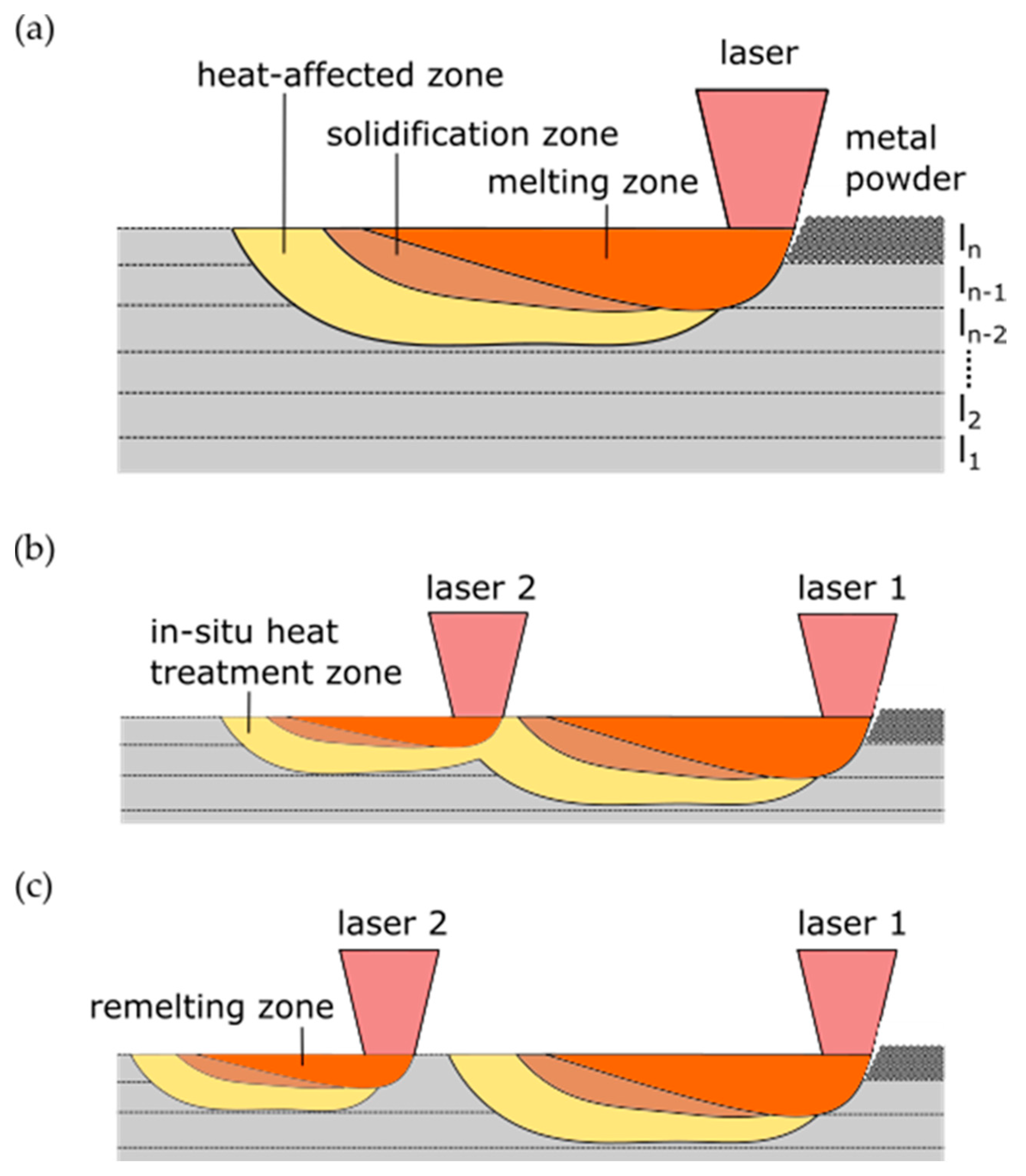

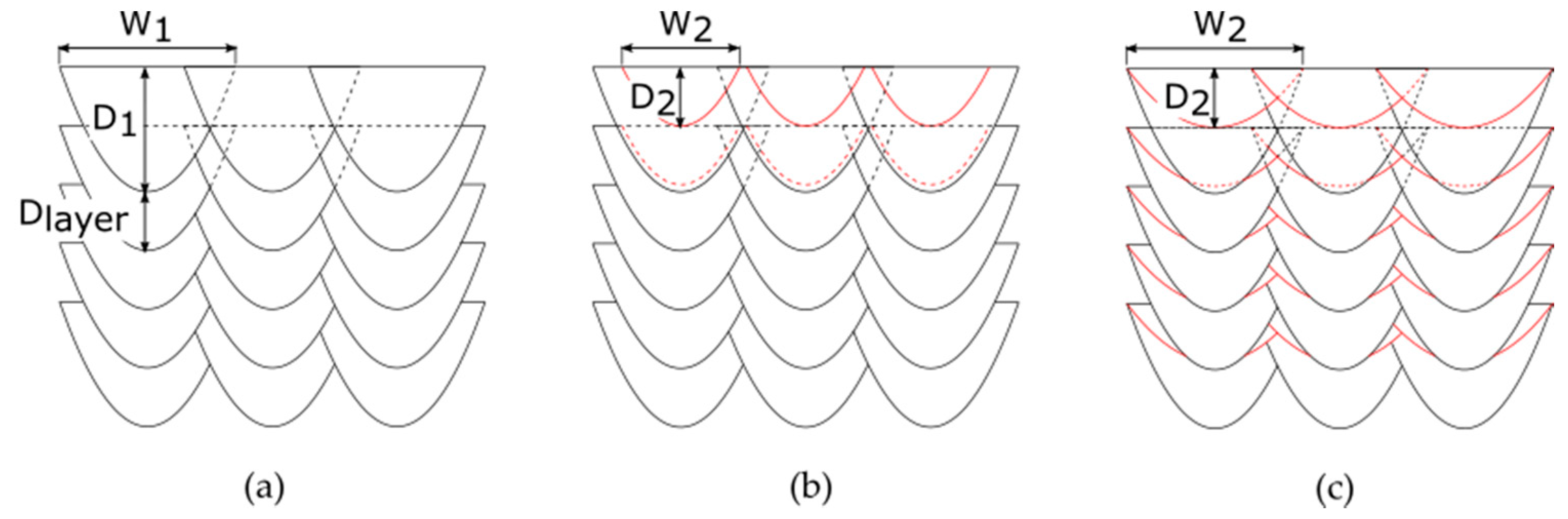

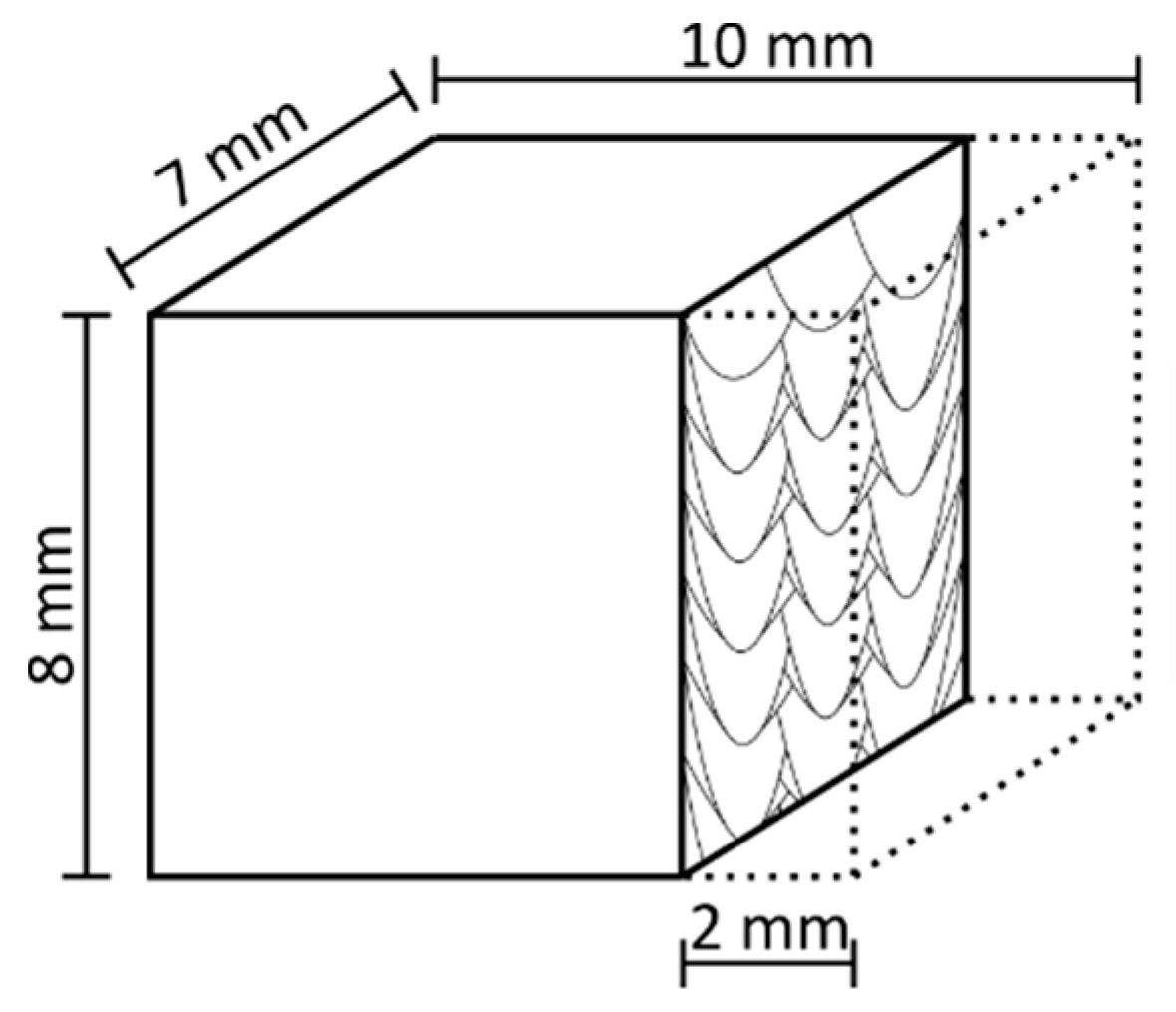

2.3. Double-Laser Exposure Strategy

2.4. Calibration Procedure

2.5. Experimental Design

2.6. Evaluation Method

3. Results and Discussion

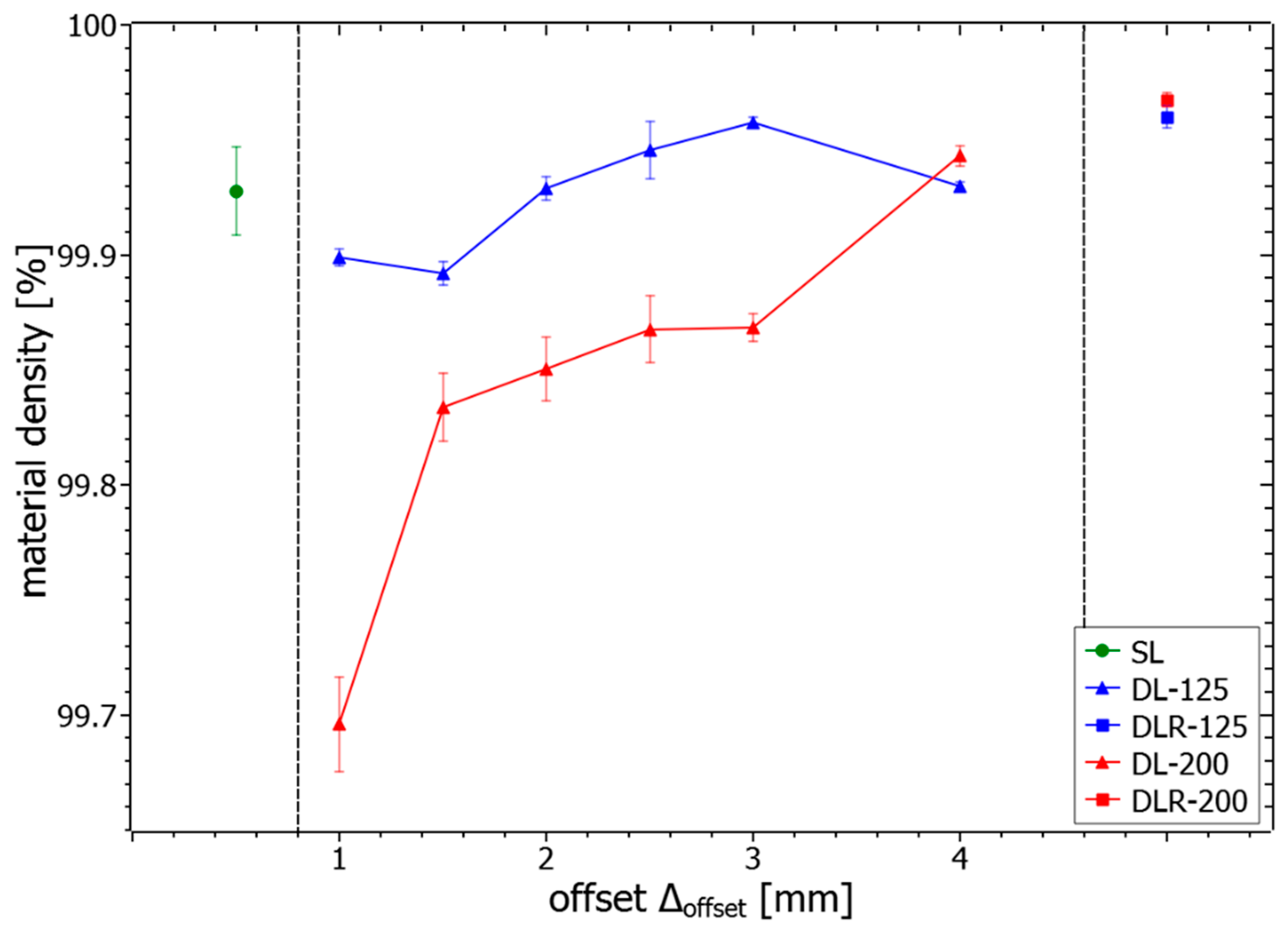

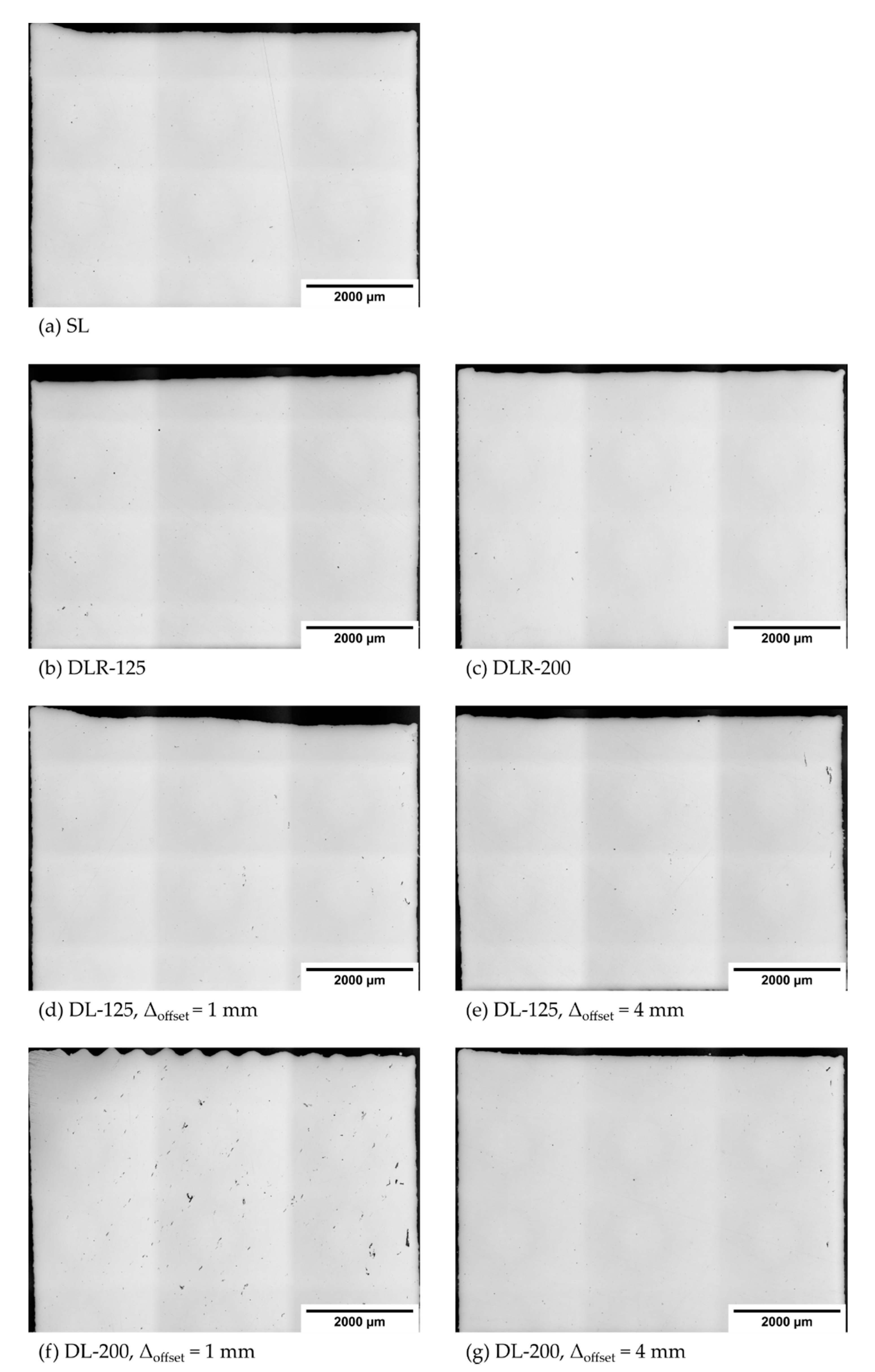

3.1. Effect on Material Density

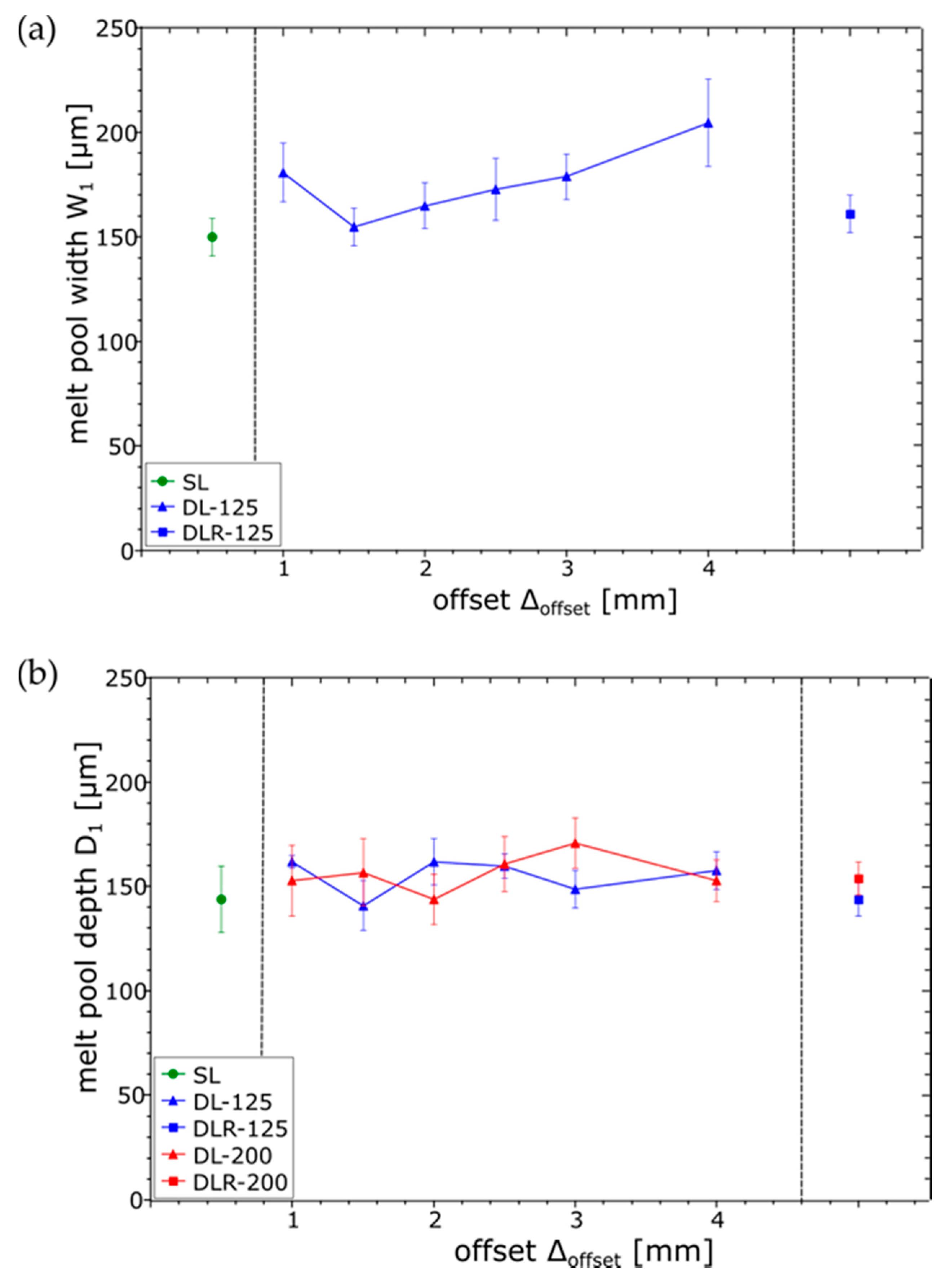

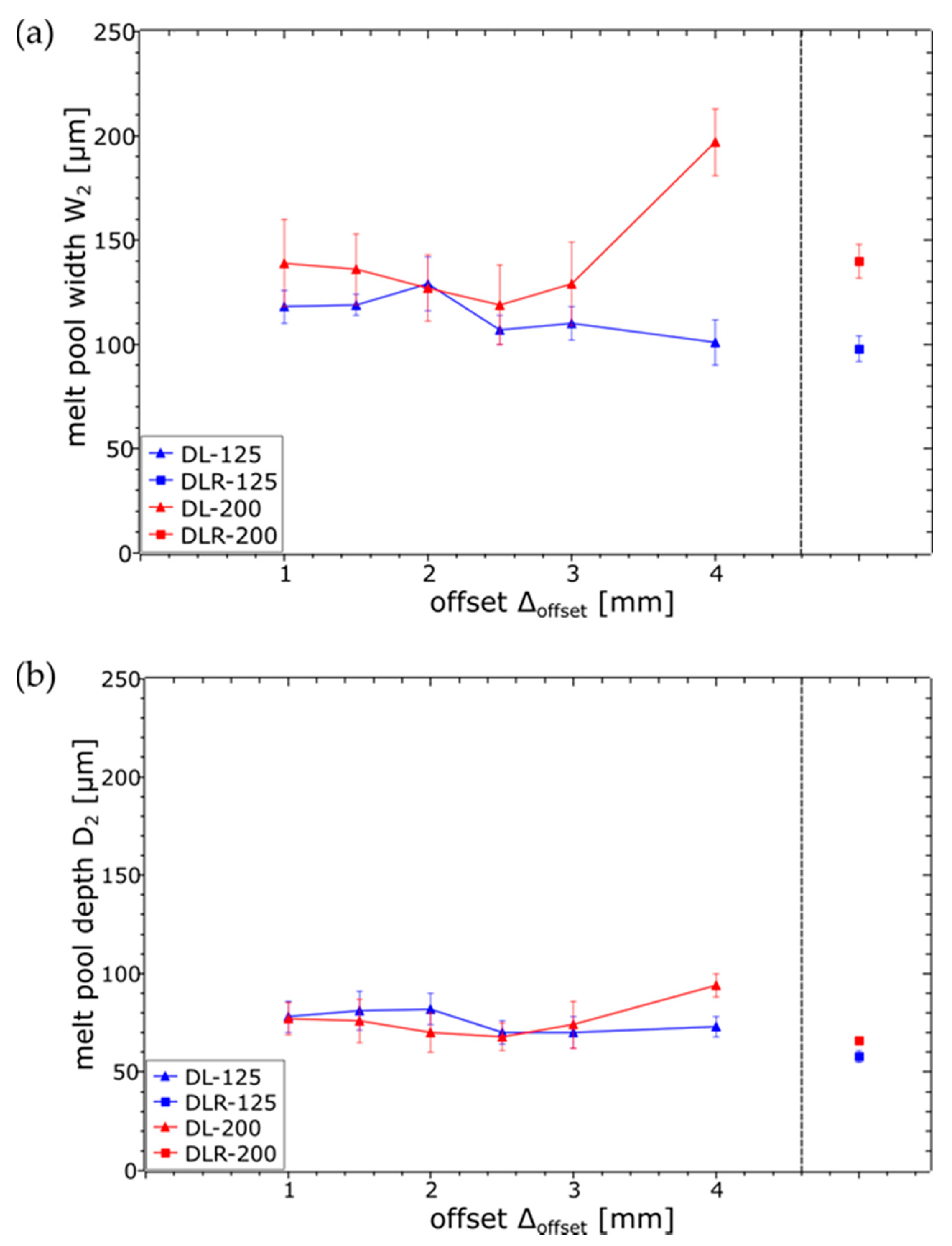

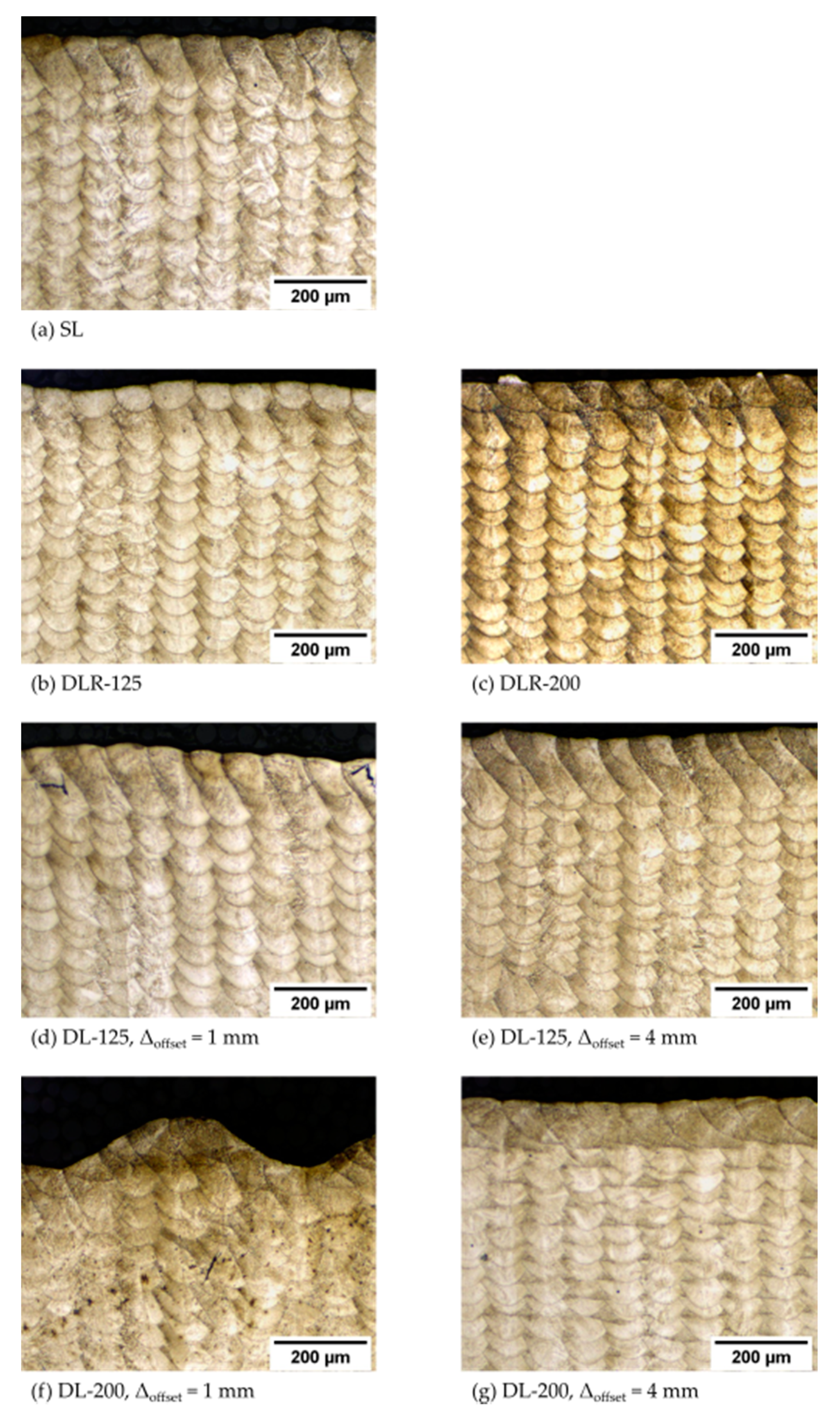

3.2. Effect on Melt Pool Dimensions

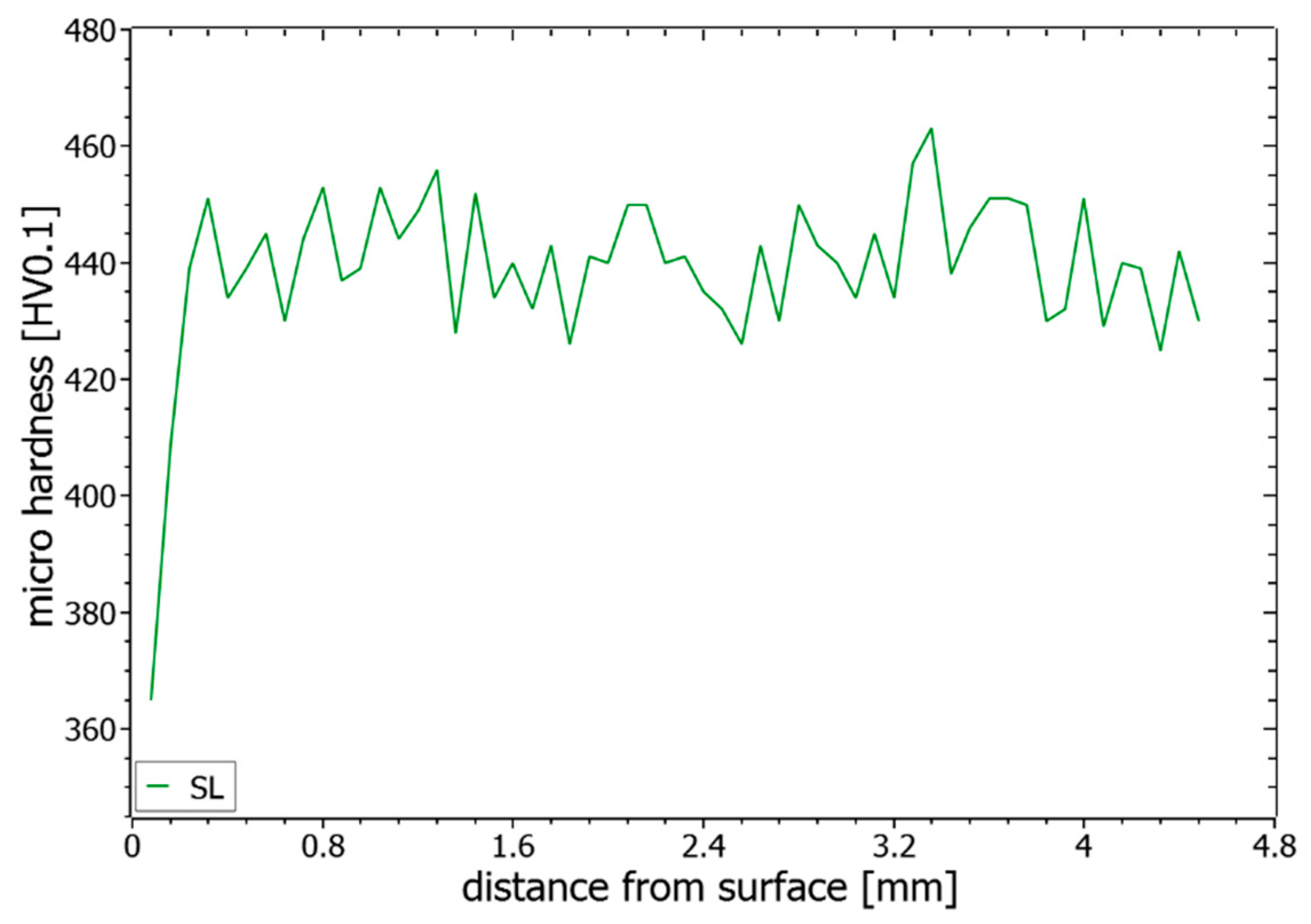

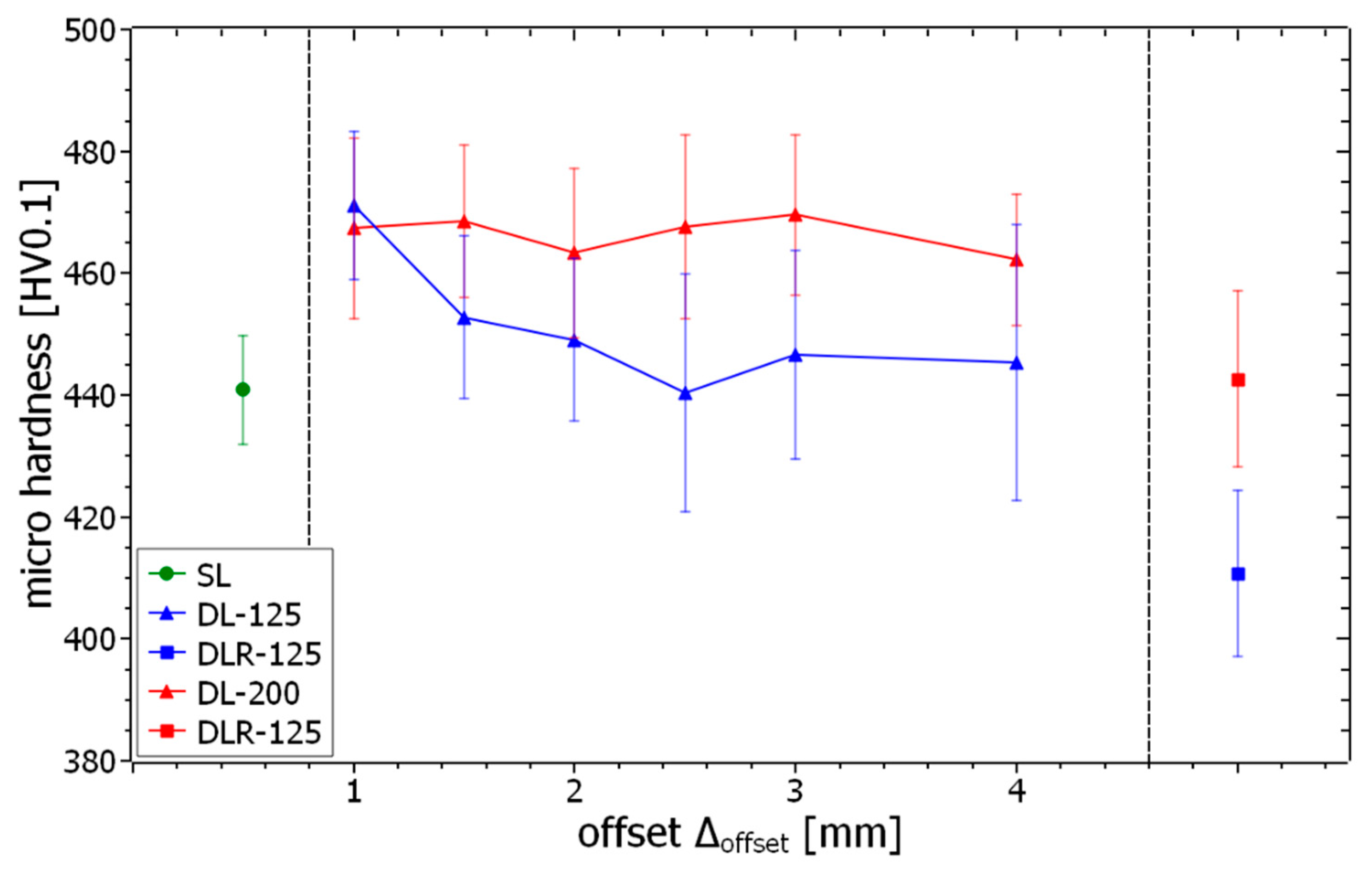

3.3. Effect on Micro Hardness

3.4. Observed Potential for Functionally Graded Materials by Double-Laser PBF-LB Processing

4. Conclusions

- A material density of more than 99.69% was obtained for all tested parameter sets. The best density results were determined for single-laser and remelting parameters with more than 99.92%. The dual-laser parameters with the subsequent 125 W laser beam resulted in a material density of more than 99.89% due to the more stable processing conditions in comparison to the dual-laser parameters with 200 W.

- Significant changes in the resulting melt pool dimensions regarding the parameter variations of the subsequent laser beam were measured on the surface layer. As a result of the elaborated exposure strategies, a consistent melt pool structure was still obtainable for all tested parameter sets.

- The modified dual-laser process parameter sets led to a significant hardness change compared to single-laser PBF-LB processing with around 441 HV0.1. An increase by around 30 HV0.1 was obtained by using the dual-laser exposure strategies. A higher laser power as well as a shorter offset distance of the subsequent laser beam appear to have hardness-increasing effects on the resulting material structure. Possibly, short-time aging effects of the in-situ heat treatment zone could be the reason for the hardness increase. A hardness decrease by around 30 HV0.1 compared to the single laser parameter was determined by a remelting strategy with 125 W laser power. Solution annealing effects within the heat-affected zone could be a possible explanation for this.

- The adjustable hardness levels for the different dual-laser parameter sets in combination with no significant changes in the resulting melt pool structure open new possibilities to produce functionally graded material structures by dual-laser PBF-LB processing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Santhoshsarang, D.M.; Divya, K.; Telasang, G.; Soundarapandian, S.; Bathe, R.; Padmanabham, G. Additively manufactured high-performance conformally cooled H13 tool steel die insert for pressure die casting. Trans. Indian Natl. Acad. Eng. 2021, 1–12. [Google Scholar] [CrossRef]

- Chantzis, D.; Liu, X.; Politis, D.J.; El Fakir, O.; Chua, T.Y.; Shi, Z.; Wang, L. Review on additive manufacturing of tooling for hot stamping. Int. J. Adv. Manuf. Technol. 2020, 109, 87–107. [Google Scholar] [CrossRef]

- Shinde, M.S.; Ashtankar, K.M. Additive manufacturing–assisted conformal cooling channels in mold manufacturing processes. Adv. Mech. Eng. 2017, 9, 1687814017699764. [Google Scholar] [CrossRef]

- Munsch, M.; Schmidt-Lehr, M.; Wycisk, E. AMPOWER Report: Metal Additive Manufacturing. 2020. Available online: https://additive-manufacturing-report.com/ (accessed on 25 June 2021).

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Meier, C.; Penny, R.W.; Zou, Y.; Gibbs, J.S.; Hart, A.J. Thermophysical phenomena in metal additive manufacturing by selective laser melting: Fundamentals, modeling, simulation and experimentation. Annu. Rev. Heat Transfer. 2017, 20, 241–316. [Google Scholar] [CrossRef]

- Wu, L.; Das, S.; Gridin, W.; Leuders, S.; Kahlert, M.; Vollmer, M.; Niendorf, T. Hot work tool steel processed by laser powder bed fusion: A review on most relevant influencing factors. Adv. Eng. Mater. 2021, 23, 2100049. [Google Scholar] [CrossRef]

- Saewe, J.; Carstensen, N.; Kürnsteiner, P.; Jägle, E.A.; Schleifenbaum, J.H. Influence of increased carbon content on the processability of high-speed steel HS6-5-3-8 by laser powder bed fusion. Addit. Manuf. 2021, 46, 102125. [Google Scholar] [CrossRef]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Casati, R.; Lemke, J.N.; Tuissi, A.; Vedani, M. Aging behaviour and mechanical performance of 18-Ni 300 steel processed by selective laser melting. Metals 2016, 6, 218. [Google Scholar] [CrossRef]

- Casati, R.; Coduri, M.; Lecis, N.; Andrianopoli, C.; Vedani, M. Microstructure and mechanical behavior of hot-work tool steels processed by selective laser melting. Mater. Charact. 2018, 137, 50–57. [Google Scholar] [CrossRef]

- Turk, C.; Zunko, H.; Aumayr, C.; Leitner, H.; Kapp, M. Advances in maraging steels for additive manufacturing. Berg. Huettenmaenn Mon. 2019, 164, 112–116. [Google Scholar] [CrossRef] [Green Version]

- Song, J.; Tang, Q.; Feng, Q.; Ma, S.; Setchi, R.; Liu, Y.; Han, Q.; Fan, X.; Zhang, M. Effect of heat treatment on microstructure and mechanical behaviours of 18Ni-300 maraging steel manufactured by selective laser melting. Opt. Laser Technol. 2019, 120, 105725. [Google Scholar] [CrossRef]

- Jägle, E.A.; Choi, P.-P.; Van Humbeeck, J.; Raabe, D. Precipitation and austenite reversion behavior of a maraging steel produced by selective laser melting. J. Mater. Res. 2014, 29, 2072–2079. [Google Scholar] [CrossRef] [Green Version]

- Marcisz, J.; Stępień, J. Short-time ageing of MS350 maraging steel with and without plastic deformation. Arch. Metall. Mater. 2014, 59, 513–520. [Google Scholar] [CrossRef]

- Bai, Y.; Wang, D.; Yang, Y.; Wang, H. Effect of heat treatment on the microstructure and mechanical properties of maraging steel by selective laser melting. Mater. Sci. Eng. A 2019, 760, 105–117. [Google Scholar] [CrossRef]

- Kučerová, L.; Zetková, I.; Jandová, A.; Bystrianský, M. Microstructural characterisation and in-situ straining of additive-manufactured X3NiCoMoTi 18-9-5 maraging steel. Mater. Sci. Eng. A 2019, 750, 70–80. [Google Scholar] [CrossRef]

- Graf, G.; Neuenfeldt, M.; Müller, T.; Fischer-Bühner, J.; Beckers, D.; Donisi, S.; Zanger, F.; Schulze, V. Efficient qualification strategy of new steel alloys for laser powder bed fusion. Adv. Mater. Res. 2021, 1161, 27–36. [Google Scholar] [CrossRef]

- SLM Solutions Group, A.G. Eigenkapitalforum. 2019. Available online: https://www.slm-solutions.com/fileadmin/Content/Investor_Relations/29_SLM__Eigenkapitalforum_20191126.pdf (accessed on 25 June 2021).

- Masoomi, M.; Thompson, S.M.; Shamsaei, N. Quality part production via multi-laser additive manufacturing. Manuf. Lett. 2017, 13, 15–20. [Google Scholar] [CrossRef]

- Abe, F.; Osakada, K.; Shiomi, M.; Uematsu, K.; Matsumoto, M. The manufacturing of hard tools from metallic powders by selective laser melting. J. Mater. Process. Technol. 2001, 111, 210–213. [Google Scholar] [CrossRef]

- Heeling, T.; Gerstgrasser, M.; Wegener, K. Investigation of Selective Laser Melting Spatter Characteristics for Single- and Multi-Beam Strategies Using High Speed Imaging. 2017. Available online: https://www.wlt.de/lim/Proceedings2017/Data/PDF/Contribution10_final.pdf (accessed on 25 June 2021).

- Heeling, T.; Wegener, K. The effect of multi-beam strategies on selective laser melting of stainless steel 316L. Addit. Manuf. 2018, 22, 334–342. [Google Scholar] [CrossRef]

- Heeling, T.; Wegener, K. Computational investigation of synchronized multibeam strategies for the selective laser melting process. Phys. Procedia 2016, 83, 899–908. [Google Scholar] [CrossRef] [Green Version]

- Zavala-Arredondo, M.; Boone, N.; Willmott, J.; Childs, D.T.; Ivanov, P.; Groom, K.; Mumtaz, K. Laser diode area melting for high speed additive manufacturing of metallic components. Mater. Des. 2017, 117, 305–315. [Google Scholar] [CrossRef]

- Tsai, C.-Y.; Cheng, C.-W.; Lee, A.-C.; Tsai, M.-C. Synchronized multi-spot scanning strategies for the laser powder bed fusion process. Addit. Manuf. 2019, 27, 1–7. [Google Scholar] [CrossRef]

- Kürnsteiner, P.; Wilms, M.B.; Weisheit, A.; Gault, B.; Jägle, E.A.; Raabe, D. High-strength damascus steel by additive manufacturing. Nature 2020, 582, 515–519. [Google Scholar] [CrossRef] [PubMed]

- Schwenck, D.; Ellendt, N.; Fischer-Bühner, J.; Hofmann, P.; Uhlenwinkel, V. A novel convergent–divergent annular nozzle design for close-coupled atomisation. Powder Metall. 2017, 60, 198–207. [Google Scholar] [CrossRef]

- Schwenck, D.; Ellendt, N.; Mädler, L.; Fischer-Bühner, J.; Hofmann, P.; Uhlenwinkel, V. Generation of small batch high quality metal powder. Powder Metall. 2014, 57, 171–175. [Google Scholar] [CrossRef]

- DIN EN ISO 4490:2018-08. Metallpulver—Bestimmung der Durchflussrate mit Hilfe eines kalibrierten Trichters (Hall Flowmeter) (ISO_4490:2018); Deutsche Fassung EN_ISO_4490: Berlin, Germany, 2018. [Google Scholar]

- SCANLAB, Installation und Inbetriebnahme RTC®5 PCI-Karte, RTC®5 PCI-Express-Karte, RTC®5 PC/104-Plus-Karte und RTC®5 PCIe/104-Karte für die Scan-Kopf- und Lasersteuerung in Echtzeit. 2015. Available online: https://www.manualslib.de/manual/351204/Scanlab-Rtc-5.html (accessed on 25 June 2021).

- DIN EN ISO 6507-1:2018-07. Metallische Werkstoffe—Härteprüfung nach Vickers—Teil_1: Prüfverfahren (ISO_6507-1:2018); Deutsche Fassung EN_ISO_6507-1: Berlin, Germany, 2018. [Google Scholar]

| Element | Fe | C | Ni | Co | Mo | Ti | V | Al |

|---|---|---|---|---|---|---|---|---|

| wt% | Bal. | 0.02 | 18.33 | 11.39 | 4.44 | <2 | <2 | <0.5 |

| Powder Parameter | Values | Measurement Method | |

|---|---|---|---|

| Particle size distribution | d10,3 (µm) | 19.32 | Dynamic particle imaging with Camsizer X2 by Retsch GmbH (Haan, Germany) |

| d50,3 (µm) | 32.30 | ||

| d90,3 (µm) | 54.91 | ||

| Particle sphericity | SPHT3 | 0.85 | |

| Flowability | (s/50 g) | 14.86 | Hall flowmeter according to DIN EN ISO 4490:2018 [30] |

| Residual moisture | (%) | <5 | humimeter RH2 by Schaller Messtechnik GmbH (St. Ruprecht an der Raab, Austria) |

| Parameter Set | Acronym | Plaser2 (W) | dlaser2 (µm) | ∆offset (mm) |

|---|---|---|---|---|

| Reference single-laser | SL | 0 | - | - |

| Double-laser 125 W | DL-125 | 125 | 85 | 1, 1.5, 2, 2.5, 3, 4 |

| Reference remelting 125 W | DLR-125 | 125 | 85 | 2400 |

| Double-laser 200 W | DL-200 | 200 | 170 | 1, 1.5, 2, 2.5, 3, 4 |

| Reference remelting 200 W | DLR-200 | 200 | 170 | 2400 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Graf, G.; Nouri, N.; Dietrich, S.; Zanger, F.; Schulze, V. Dual-Laser PBF-LB Processing of a High-Performance Maraging Tool Steel FeNiCoMoVTiAl. Materials 2021, 14, 4251. https://doi.org/10.3390/ma14154251

Graf G, Nouri N, Dietrich S, Zanger F, Schulze V. Dual-Laser PBF-LB Processing of a High-Performance Maraging Tool Steel FeNiCoMoVTiAl. Materials. 2021; 14(15):4251. https://doi.org/10.3390/ma14154251

Chicago/Turabian StyleGraf, Gregor, Niki Nouri, Stefan Dietrich, Frederik Zanger, and Volker Schulze. 2021. "Dual-Laser PBF-LB Processing of a High-Performance Maraging Tool Steel FeNiCoMoVTiAl" Materials 14, no. 15: 4251. https://doi.org/10.3390/ma14154251

APA StyleGraf, G., Nouri, N., Dietrich, S., Zanger, F., & Schulze, V. (2021). Dual-Laser PBF-LB Processing of a High-Performance Maraging Tool Steel FeNiCoMoVTiAl. Materials, 14(15), 4251. https://doi.org/10.3390/ma14154251