Analytical Solution for Chloride Diffusivity of Concrete with Aggregate Shape Effect

Abstract

:1. Introduction

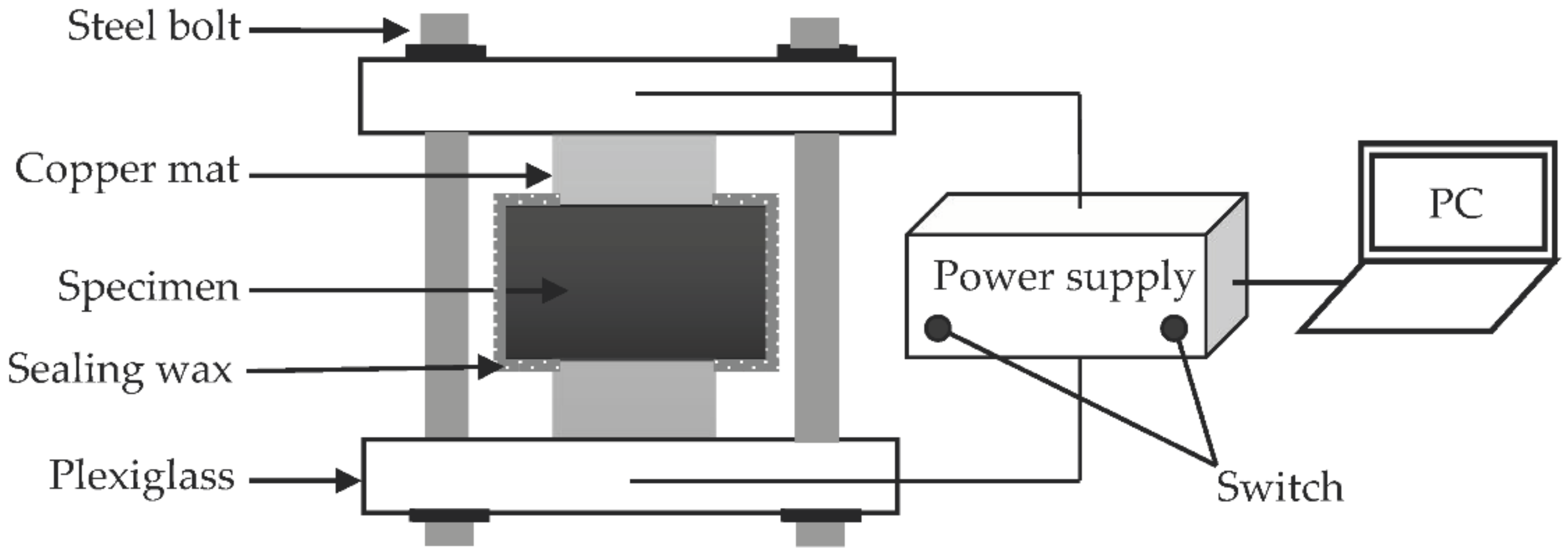

2. Chloride Diffusion Test

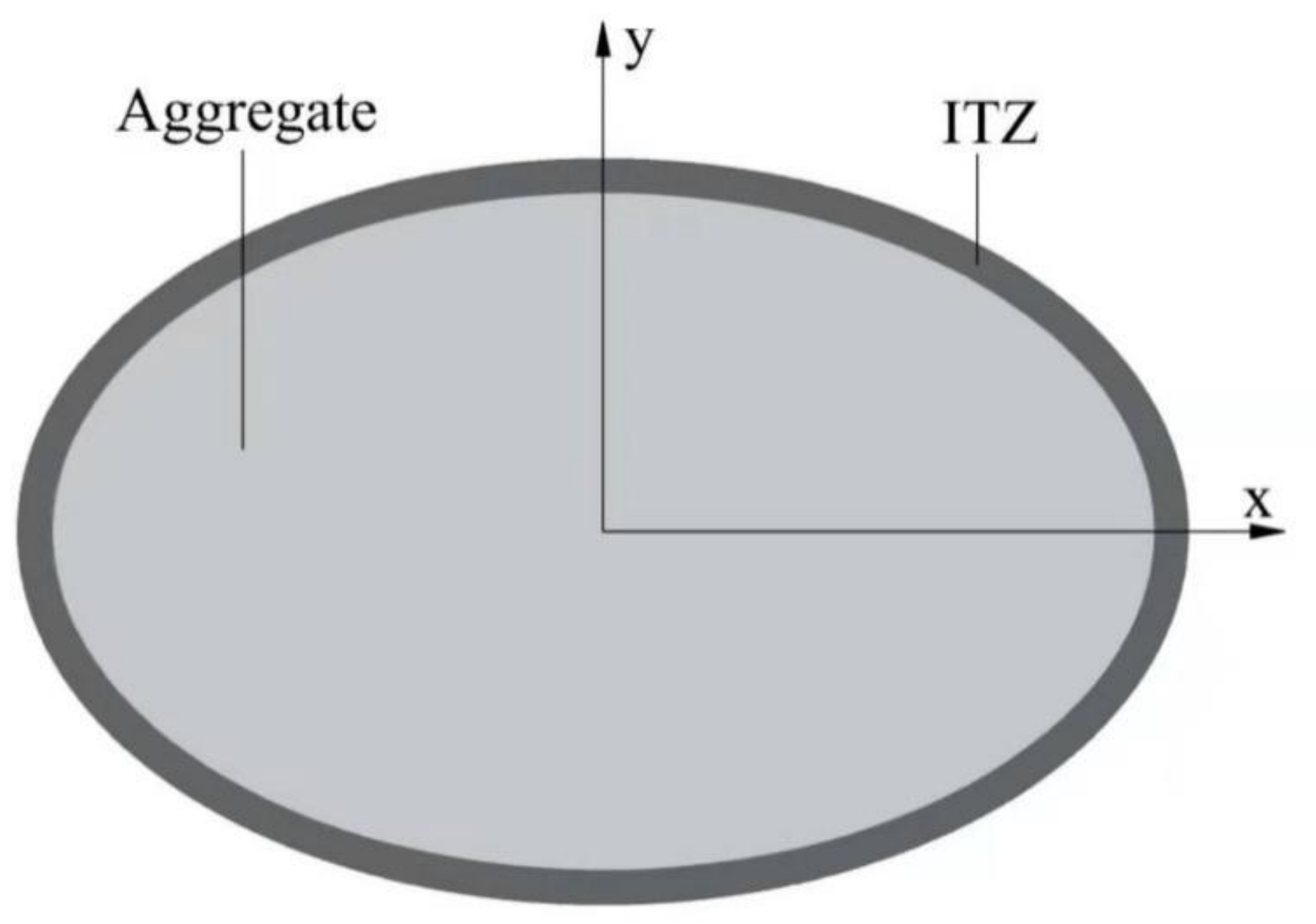

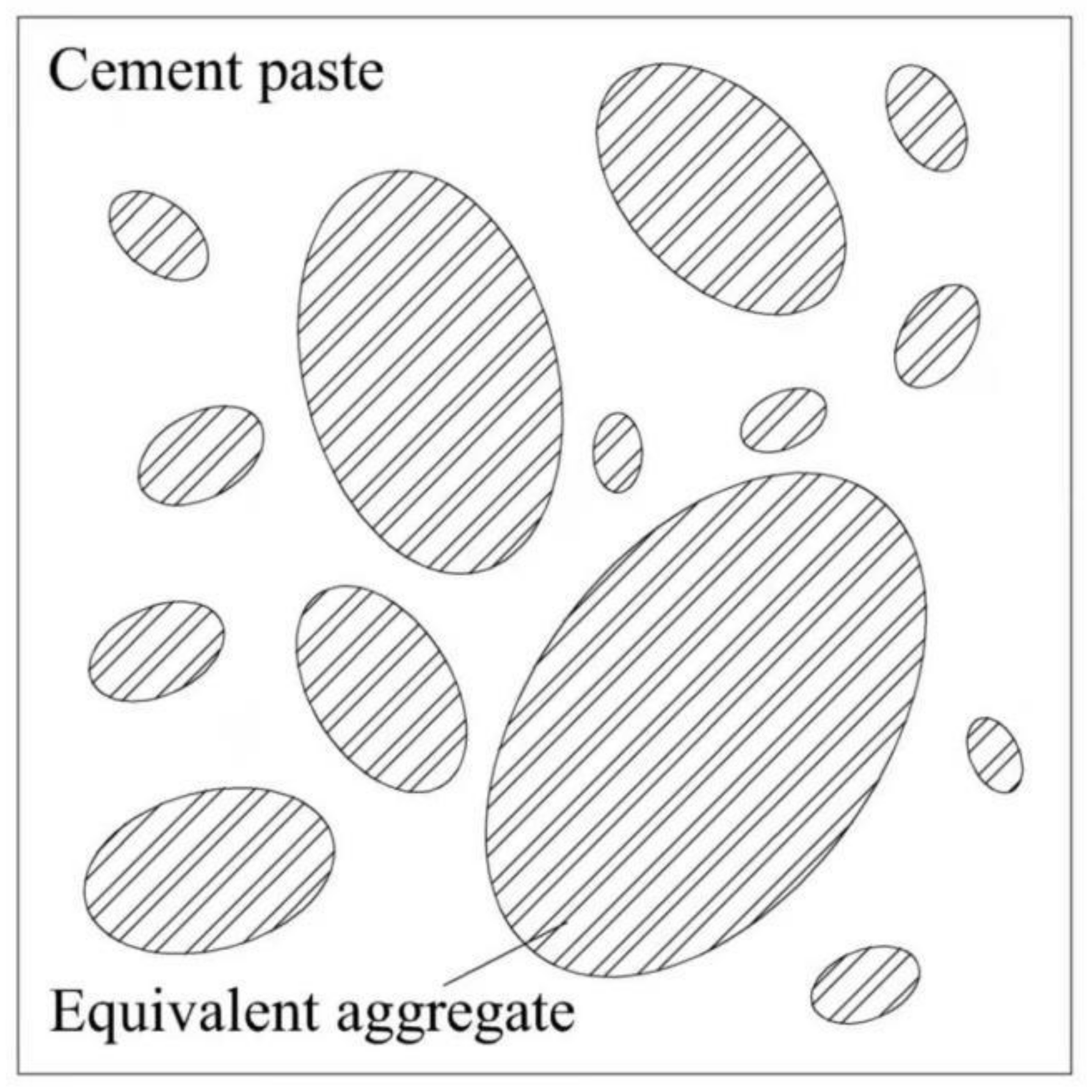

3. Chloride Diffusivity of Concrete

4. Experimental Verification and Discussions

5. Conclusions

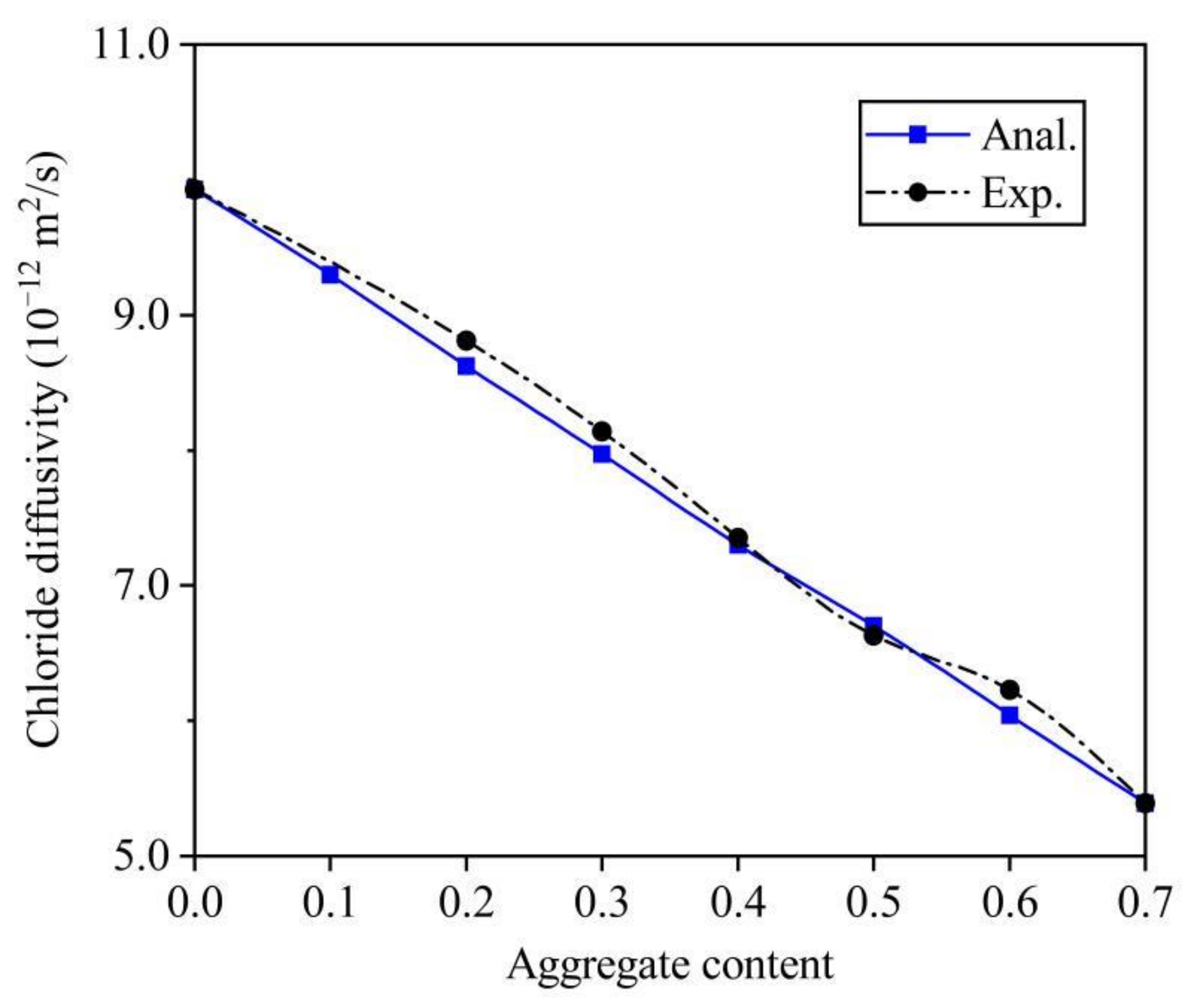

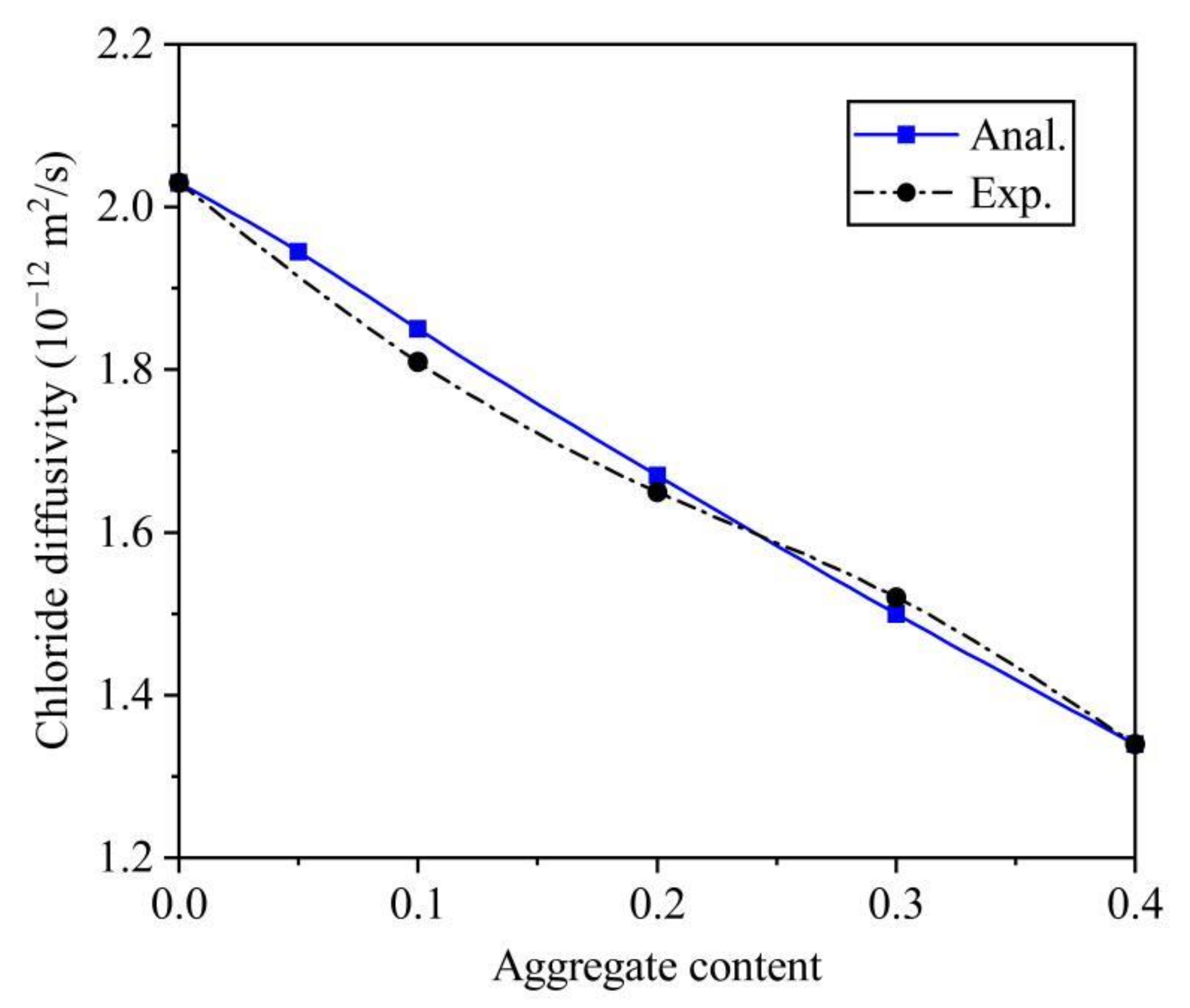

- By comparison of the data from the self-conducted experiment and the literature, the average relative error is only 1.64% and 1.57%, respectively. Thus, the accuracy of the analytical solution was fully verified.

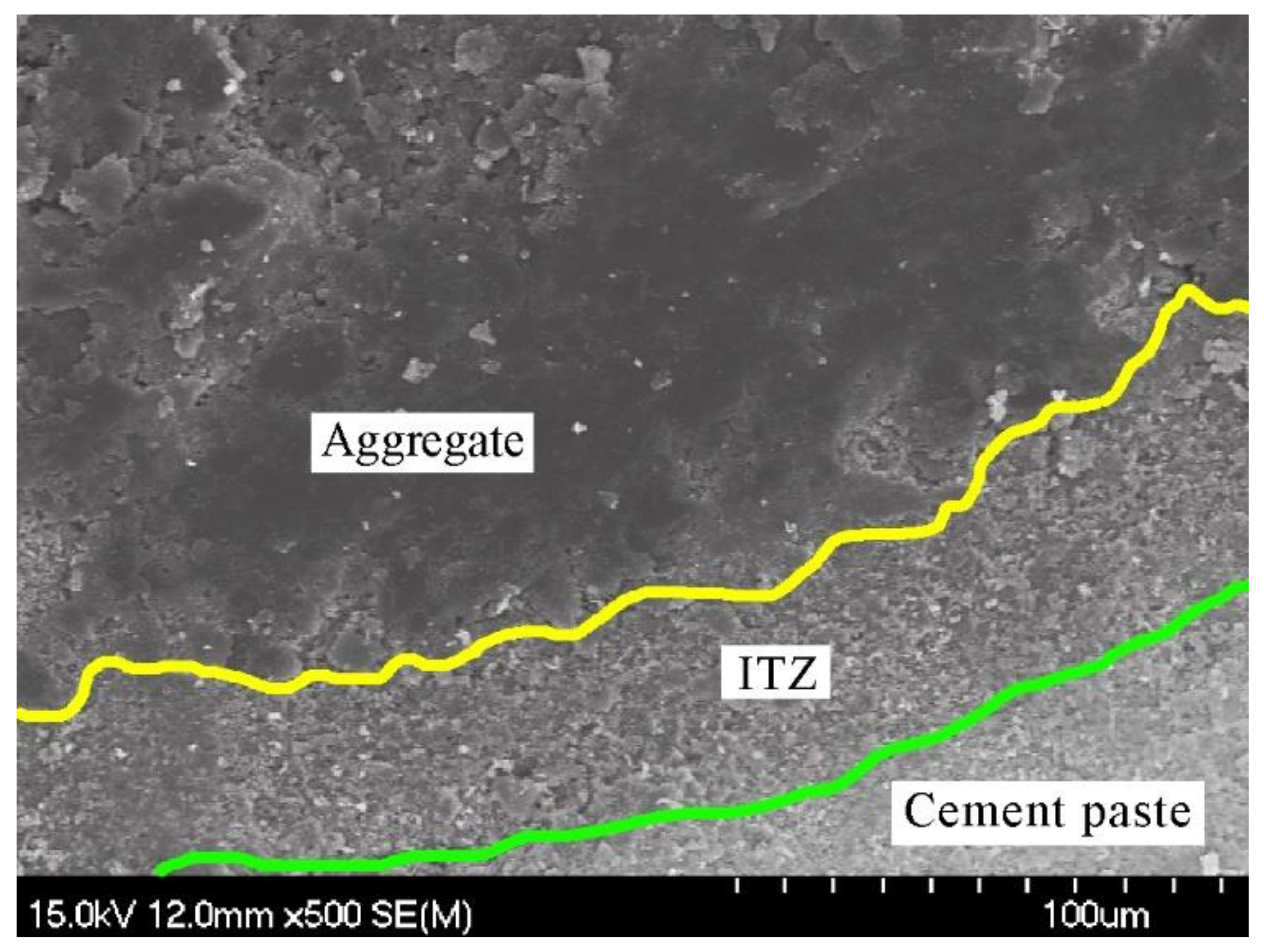

- With resort to the SEM observation, the thickness of ITZ was reasonably determined as 0.04 mm. In addition, based on the conductivity method, the chloride diffusivities with various aggregate contents were measured. It can be found that Dc approximately changed linearly with Ca, which was mainly due to the coupled effects from the acceleration effect of ITZs and the dilution and zigzag effects caused by aggregates. When the aggregate content increased from 0 to 0.7, the chloride diffusivity had a reduction of 45.7%.

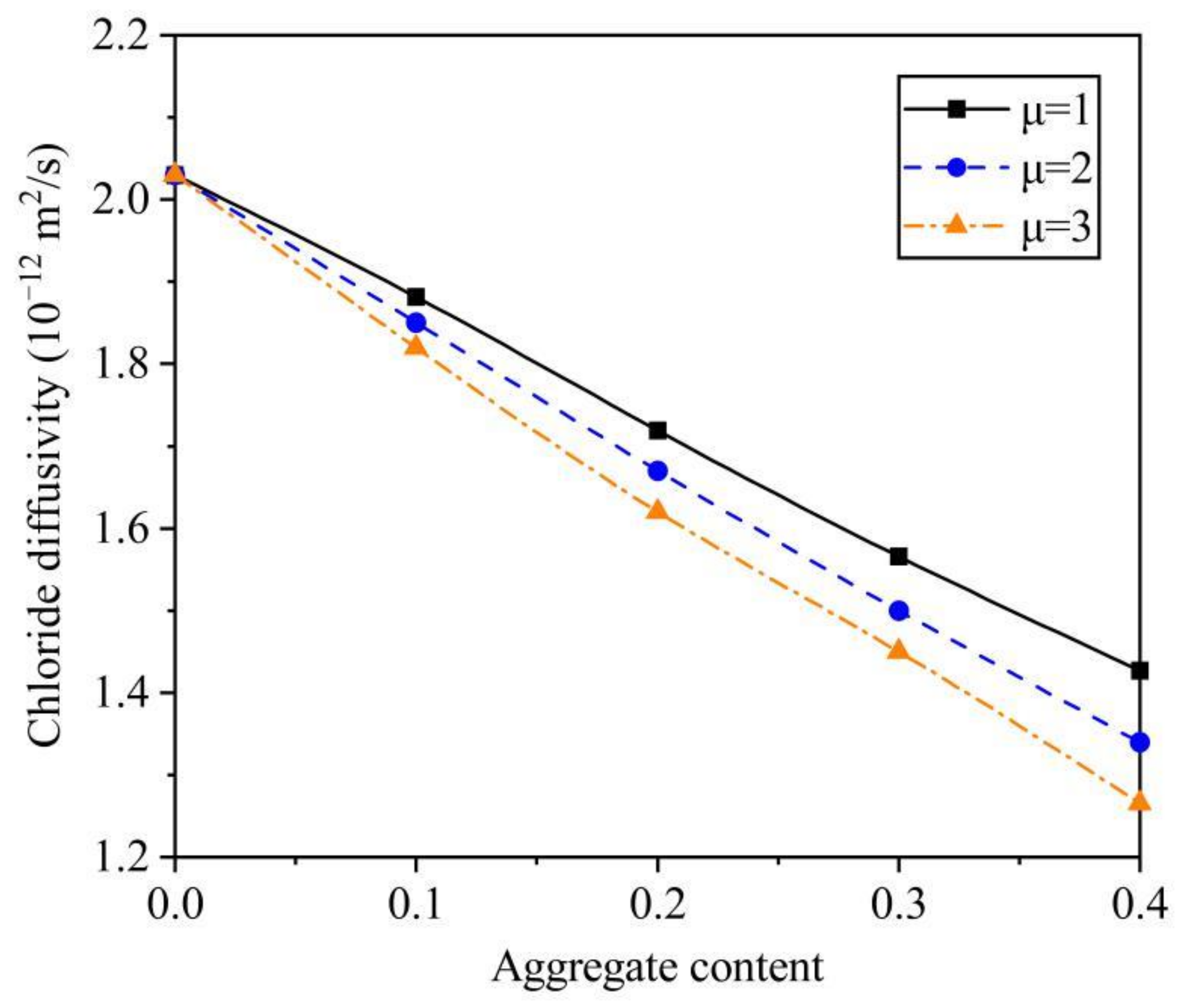

- According to the sensitivity analysis based on the analytical solution, the impact of aggregate shape on Dc was significant. For Ca = 0.1, 0.2, 0.3, and 0.4, when μ decreased from 3 to 1, Dc was increased by 3.4%, 6.1%, 8.0%, and 12.8%, respectively. The main reason can be analyzed as the increase of μ leading to the decrease of ITZ content and the increase of the tortuosity of aggregate.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Petcherdchoo, A. Pseudo-coating model for predicting chloride diffusion into surface-coated concrete in tidal zone: Time- dependent approach. Cem. Concr. Compos. 2016, 74, 88–99. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, X.Z.; Zheng, J.J.; Ye, H.L.; Yang, J. Experimental investigation and analytical modeling of chloride diffusivity of fly ash concrete. Materials 2020, 13, 862. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Q.F.; Hu, Z.; Lu, X.Y.; Yang, J.; Azim, I.; Sun, W.Z. Prediction of chloride distribution for offshore concrete based on statistical analysis. Materials 2020, 13, 174. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, Q.F.; Easterbrook, D.; Yang, J.; Li, L.Y. A three-phase, multi-component ionic transport model for simulation of chloride penetration in concrete. Eng. Struct. 2015, 86, 122–133. [Google Scholar]

- Liu, Q.F.; Feng, G.L.; Xia, J.; Yang, J.; Li, L.Y. Ionic transport features in concrete composites containing various shaped aggregates: A numerical study. Compos. Struct. 2018, 183, 371–380. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.L.; Chen, Z.W.; Sun, X.Y.; Zhang, J.; Zheng, J.J. New numerical method for predicting chloride diffusivity of concrete considering the profiles of practical aggregates. Constr. Build. Mater. 2021, 290, 123245. [Google Scholar] [CrossRef]

- Liu, Y.; Presuel-Moreno, F.J.; Paredes, M.A. Determination of chloride diffusion coefficients in concrete by electrical resistivity method. ACI Mater. J. 2015, 112, 631–640. [Google Scholar] [CrossRef]

- Delagrave, A.; Bigas, J.P.; Ollivier, J.P.; Marchand, J.; Pigeon, M. Influence of the interfacial zone on the chloride diffusivity of mortars. Adv. Cem. Based Mater. 1997, 7, 86–92. [Google Scholar] [CrossRef]

- Yang, C.C.; Su, J.K. Approximate migration coefficient of interfacial transition zone and the effect of the aggregate content on the migration coefficient of mortar. Cem. Concr. Res. 2002, 32, 1559–1565. [Google Scholar] [CrossRef]

- Caré, S. Influence of aggregates on chloride diffusion coefficient into mortar. Cem. Concr. Res. 2003, 33, 1021–1028. [Google Scholar] [CrossRef]

- Zheng, J.J.; Zhou, X.Z.; Huang, X.F.; Fu, C.Q. Experiment and modeling of the effect of aggregate shape on the chloride diffusivity of concrete. J. Mater. Civ. Eng. 2014, 26, 04014048. [Google Scholar] [CrossRef]

- Caré, S.; Hervé, H. Application of a n-phase model to the diffusion coefficient of chloride in mortar. Transp. Porous Media 2004, 56, 119–135. [Google Scholar] [CrossRef] [Green Version]

- Milton, G.W. Concerning bounds on the transport and mechanical properties of multicomponent composite materials. Appl. Phys. A Mater. 1981, 26, 125–130. [Google Scholar] [CrossRef]

- Garboczi, E.J.; Bentz, D.P. Analytical formulas for interfacial transition zone properties. Adv. Cem. Based Mater. 1997, 6, 99–108. [Google Scholar] [CrossRef]

- Zheng, J.J.; Zhou, X.Z. Prediction of the chloride diffusion coefficient of concrete. Mater. Struct. 2007, 40, 693–701. [Google Scholar] [CrossRef]

- Zheng, J.J.; Zhou, X.Z. Three-phase composite sphere model for the prediction of chloride diffusivity of concrete. J. Mater. Civ. Eng. 2008, 20, 205–211. [Google Scholar] [CrossRef]

- Crumbie, A.K. Characterisation of the Microstructure of Concrete. Ph.D. Thesis, Imperial College, London, UK, 1994. [Google Scholar]

- Zheng, J.J.; Hong, S.W.; Buenfeld, N.R. Assessing the influence of ITZ on the steady-state chloride diffusivity of concrete using a numerical model. Cem. Concr. Res. 2009, 39, 805–813. [Google Scholar] [CrossRef] [Green Version]

- Zheng, J.J.; Zhou, X.Z.; Xing, H.Y.; Jin, X.Y. Differential effective medium theory for the chloride diffusivity of concrete. ACI Mater. J. 2015, 112, 3–10. [Google Scholar] [CrossRef]

- Choi, Y.C.; Park, B.; Pang, G.S.; Lee, K.M.; Choi, S.C. Modelling of chloride diffusivity in concrete considering effect of aggregates. Constr. Build. Mater. 2017, 136, 81–87. [Google Scholar] [CrossRef]

- Ma, H.Y.; Hou, D.S.; Li, Z.J. Two-scale modeling of transport properties of cement paste: Formation factor, electrical conductivity and chloride diffusivity. Comp. Mater. Sci. 2015, 110, 270–280. [Google Scholar] [CrossRef]

- Du, X.L.; Jin, L.; Ma, G.W. A meso-scale numerical method for the simulation of chloride diffusivity in concrete. Finite Elem. Anal. Des. 2014, 85, 87–100. [Google Scholar] [CrossRef]

- Ukrainczyk, N.; Koenders, E. Representative elementary volumes for 3D modeling of mass transport in cementitious materials. Model. Simul. Mater. Sci. Eng. 2014, 22, 035001. [Google Scholar] [CrossRef]

- Zhang, M.Z.; Ye, G.; Breugel, K.V. Multiscale lattice Boltzmann-finite element modelling of chloridediffusivity in cementitious materials. Part I: Algorithms and implementation. Mech. Res. Commun. 2014, 58, 53–63. [Google Scholar] [CrossRef]

- Kim, I.C.; Torquato, S. Determination of the effective conductivity of heterogeneous media by Brownian motion simulation. J. Appl. Phys. 1990, 68, 3892–3903. [Google Scholar] [CrossRef]

- Kim, I.C.; Torquato, S. Effective conductivity of suspensions of hard spheres by Brownian motion simulation. J. Appl. Phys. 1991, 69, 2280–2289. [Google Scholar]

- Zheng, J.J.; Zhang, C.Y.; Sun, L.Z.; Zhou, X.Z. A Brownian motion simulation for the chloride diffusivity of concrete. Constr. Build. Mater. 2016, 122, 478–487. [Google Scholar] [CrossRef]

- Wang, L.B.; Wang, X.R.; Mohammad, L.; Abadie, C. Unified method to quantify aggregate shape angularity and texture using Fourier analysis. J. Mater. Civ. Eng. 2005, 17, 498–504. [Google Scholar] [CrossRef]

- Li, L.Y.; Xia, J.; Lin, S.S. A multi-phase model for predicting the effective diffusion coefficient of chlorides in concrete. Constr. Build. Mater. 2012, 26, 295–301. [Google Scholar] [CrossRef]

- Jie, W.; Dassekpo, J.B.M.; Wan, C.Y.; Zha, X.X. Experimental and numerical modeling of chloride diffusivity in hardened cement concrete considering the aggregate shapes and exposure-duration effects. Results Phys. 2017, 7, 1427–1432. [Google Scholar] [CrossRef]

- Liu, Q.F.; Iqbal, M.F.; Yang, J.; Lu, X.Y.; Zhang, P.; Rauf, M. Prediction of chloride diffusivity in concrete using artificial neural network: Modelling and performance evaluation. Constr. Build. Mater. 2021, 268, 121082. [Google Scholar] [CrossRef]

- Liu, Q.F.; Yang, J.; Xia, J.; Easterbrook, D.; Li, L.Y.; Lu, X.Y. A numerical study on chloride migration in cracked concrete using multi-component ionic transport models. Comp. Mater. Sci. 2015, 99, 396–416. [Google Scholar] [CrossRef]

- Zheng, J.J. Mesostructure of Concrete-Stereological Analysis and Some Mechanical Implications; Delft University: Delft, The Netherlands, 2000. [Google Scholar]

- Lu, X.Y. Application of the Nernst-Einstein equation to concrete. Cem. Concr. Res. 1997, 27, 293–302. [Google Scholar] [CrossRef]

- Fu, C.Q.; Ling, Y.F.; Wang, K.J. An innovation study on chloride and oxygen diffusions in simulated interfacial transition zone of cementitious material. Cem. Concr. Compos. 2020, 110, 103585. [Google Scholar] [CrossRef]

- Zhang, H.R.; Ji, T.; Liu, H. Performance evolution of the interfacial transition zone (ITZ) in recycled aggregate concrete under external sulfate attacks and dry-wet cycling. Constr. Build. Mater. 2019, 229, 116938. [Google Scholar] [CrossRef]

- Sun, G.W.; Zhang, Y.S.; Sun, W.; Liu, Z.Y.; Wang, C.H. Multi-scale prediction of the effective chloride diffusion coefficient of concrete. Constr. Build. Mater. 2011, 25, 3820–3831. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Nemati, K.M. The percolation of pore space in the cement paste/aggregate interfacial zone of concrete. Cem. Concr. Res. 1996, 26, 35–40. [Google Scholar] [CrossRef]

- Zheng, J.J.; Li, C.Q.; Zhao, L.Y. Simulation of two-dimensional aggregate distribution with wall effect. J. Mater. Civ. Eng. 2003, 15, 506–510. [Google Scholar] [CrossRef]

- Zheng, J.J.; Zhang, J.; Zhou, X.Z.; Song, W.B. A numerical algorithm for evaluating the chloride diffusion coefficient of concrete with crushed aggregates. Constr. Build. Mater. 2018, 171, 977–983. [Google Scholar] [CrossRef]

- Duan, H.L.; Karihaloo, B.L.; Wang, J.Q.; Yi, X. Effective conductivities of heterogeneous media containing multiple inclusions with various spatial distributions. Phys. Rev. B 2006, 73, 174203. [Google Scholar] [CrossRef] [Green Version]

- Torquato, S. Random Heterogenerous Materials: Microstructure and Macroscopic Properties; Springer: New York, NY, USA, 2001. [Google Scholar]

- Zheng, J.J.; Zhang, J.; Zhou, X.Z.; Wang, J.W.; Ding, Y.W. Random walk algorithm for chloride diffusivity of concrete. ACI Mater. J. 2020, 117, 1–8. [Google Scholar] [CrossRef]

| Material | CaO (%) | SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | MgO (%) | SO3 (%) | K2O (%) | Na2O (%) |

|---|---|---|---|---|---|---|---|---|

| Cement | 65.31 | 21.21 | 3.88 | 3.25 | 1.12 | 0.98 | 0.57 | 0.12 |

| Aggregate Size (mm) | 0.3–0.6 | 0.6–1.18 | 1.18–2.36 | 2.36–4.75 | 4.75–9.5 |

| Proportion | 9.0% | 12.2% | 17.8% | 25.4% | 35.6% |

| Ca | Dosage of Material (kg/m3) | ||

|---|---|---|---|

| Cement | Water | Aggregate | |

| 0 | 1223.3 | 611.7 | 0 |

| 0.2 | 978.6 | 489.3 | 536 |

| 0.3 | 856.3 | 428.2 | 804 |

| 0.4 | 734.0 | 367 | 1072 |

| 0.5 | 611.7 | 305.8 | 1340 |

| 0.6 | 489.3 | 244.7 | 1608 |

| 0.7 | 367.0 | 183.5 | 1876 |

| Ca | Specimen 1# (10−12 m2/s) | Specimen 2# (10−12 m2/s) | Specimen 3# (10−12 m2/s) | Average Value (10−12 m2/s) |

|---|---|---|---|---|

| 0 | 10.13 | 9.97 | 9.69 | 9.93 |

| 0.2 | 8.72 | 8.96 | 9.07 | 8.92 |

| 0.3 | 8.17 | 8.05 | 8.2 | 8.14 |

| 0.4 | 7.28 | 7.36 | 7.41 | 7.35 |

| 0.5 | 6.62 | 6.71 | 6.56 | 6.63 |

| 0.6 | 6.23 | 6.12 | 6.33 | 6.23 |

| 0.7 | 5.35 | 5.38 | 5.43 | 5.39 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Ying, Z.-X.; Chen, Z.-W.; Wang, H.-L.; Li, J.-H.; Yue, H.; Zheng, J.-J. Analytical Solution for Chloride Diffusivity of Concrete with Aggregate Shape Effect. Materials 2021, 14, 3957. https://doi.org/10.3390/ma14143957

Zhang J, Ying Z-X, Chen Z-W, Wang H-L, Li J-H, Yue H, Zheng J-J. Analytical Solution for Chloride Diffusivity of Concrete with Aggregate Shape Effect. Materials. 2021; 14(14):3957. https://doi.org/10.3390/ma14143957

Chicago/Turabian StyleZhang, Jian, Zhuo-Xuan Ying, Zhi-Wei Chen, Hai-Long Wang, Jian-Hua Li, Hui Yue, and Jian-Jun Zheng. 2021. "Analytical Solution for Chloride Diffusivity of Concrete with Aggregate Shape Effect" Materials 14, no. 14: 3957. https://doi.org/10.3390/ma14143957

APA StyleZhang, J., Ying, Z.-X., Chen, Z.-W., Wang, H.-L., Li, J.-H., Yue, H., & Zheng, J.-J. (2021). Analytical Solution for Chloride Diffusivity of Concrete with Aggregate Shape Effect. Materials, 14(14), 3957. https://doi.org/10.3390/ma14143957