Numerical Analysis of the Bond Strength between Two Methacrylic Polymers by Surface Modification

Abstract

1. Introduction

- ethylene glycol dimethacrylate (EGDMA) [10],

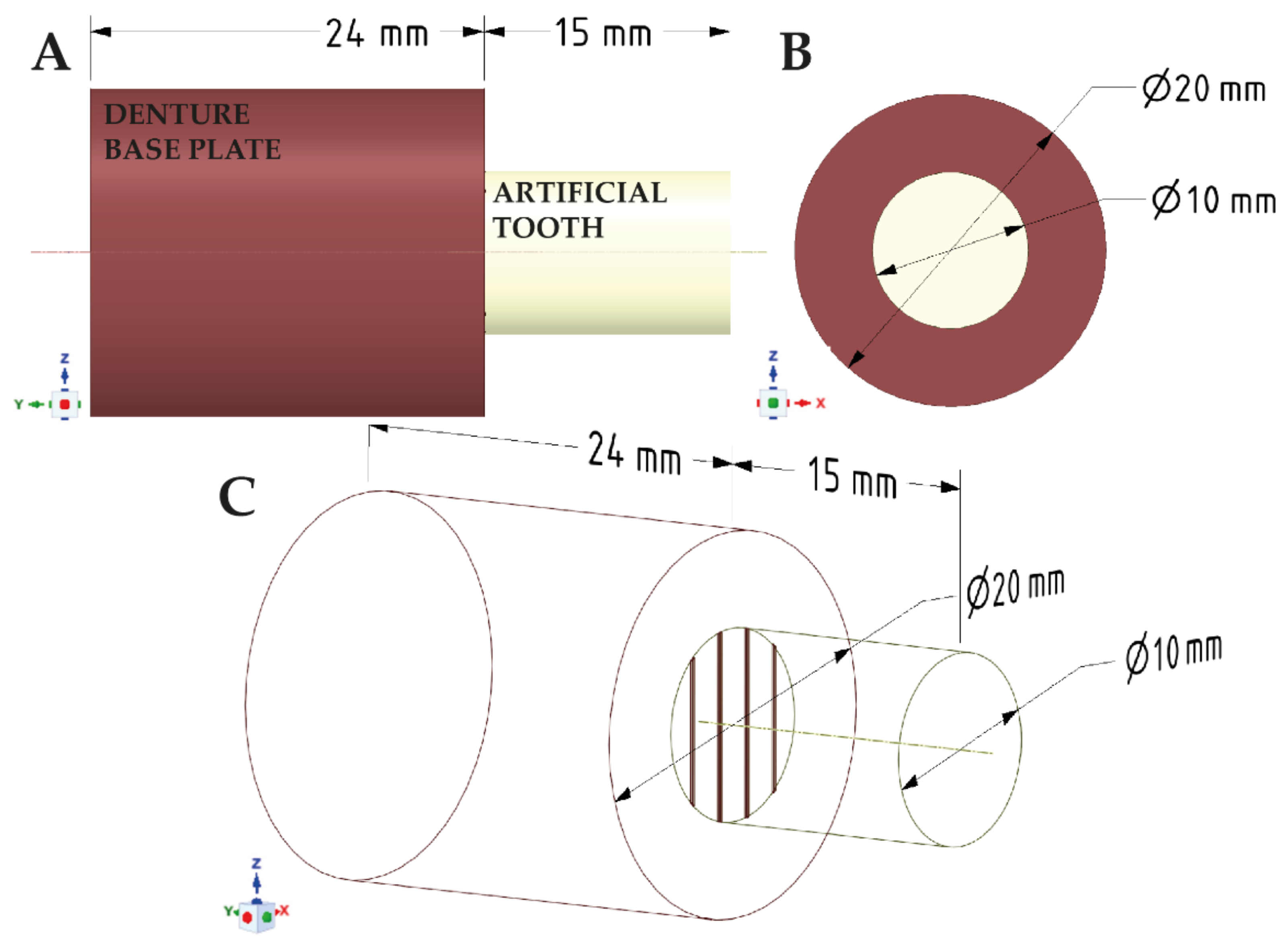

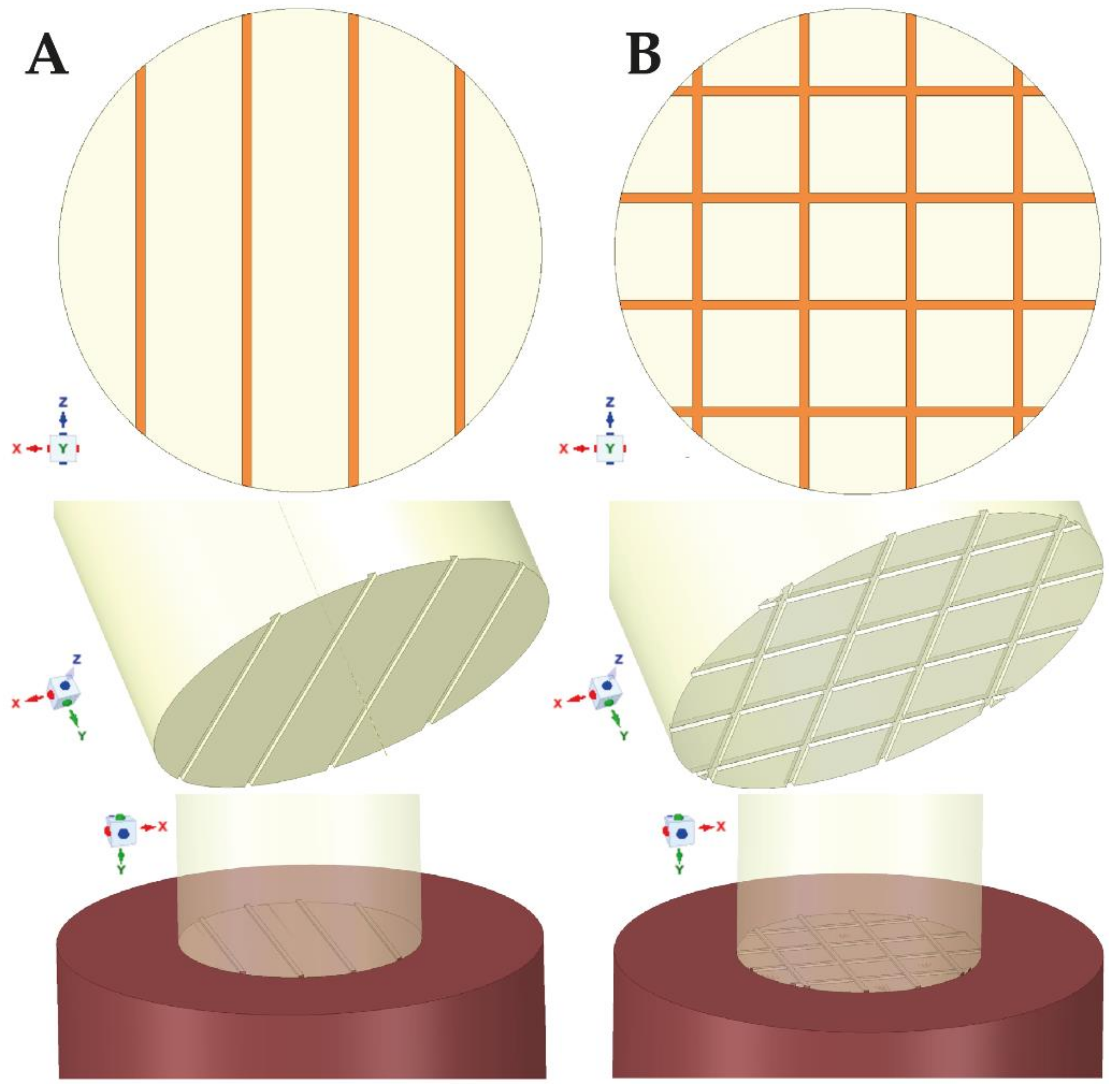

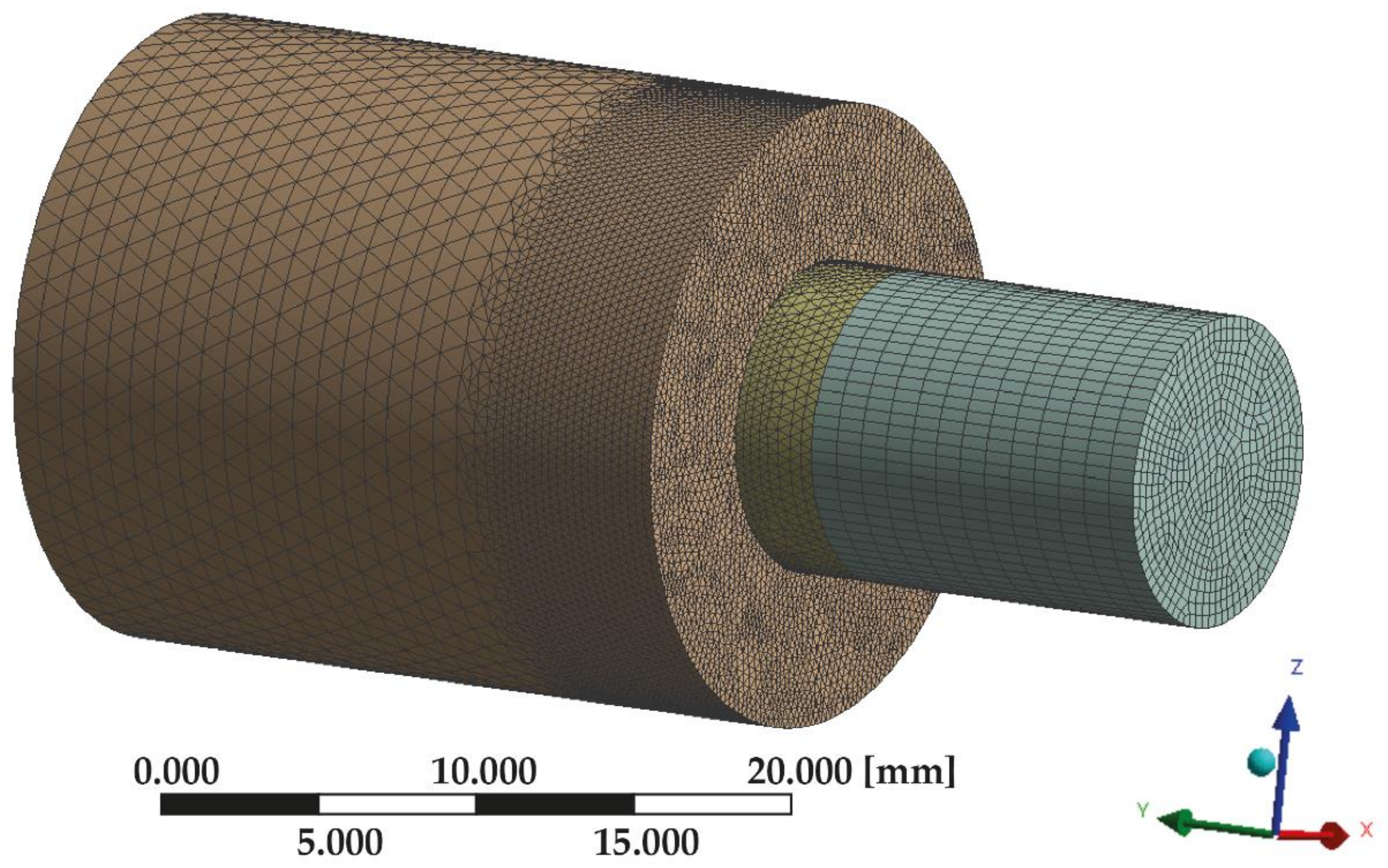

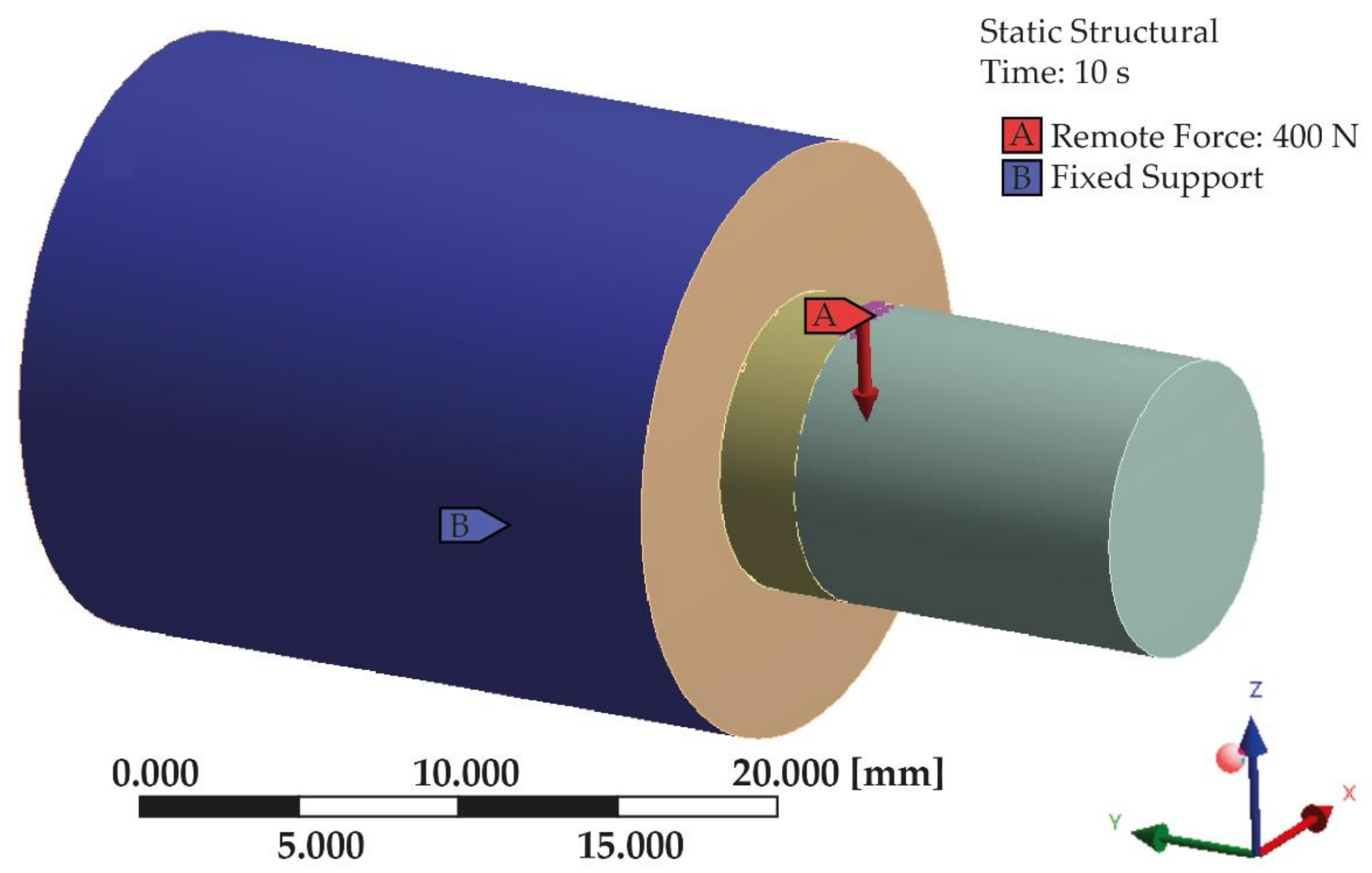

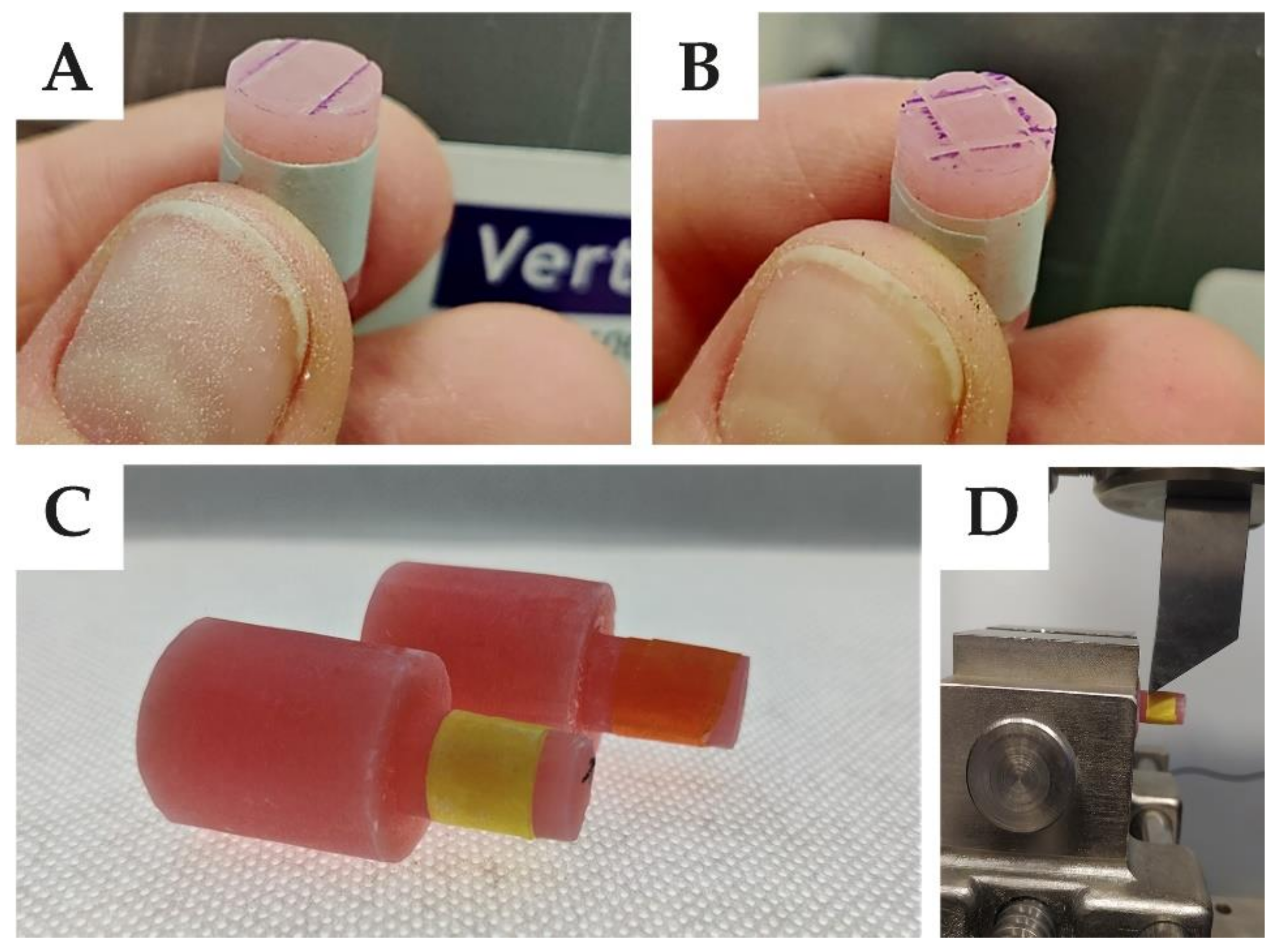

2. Materials and Methods

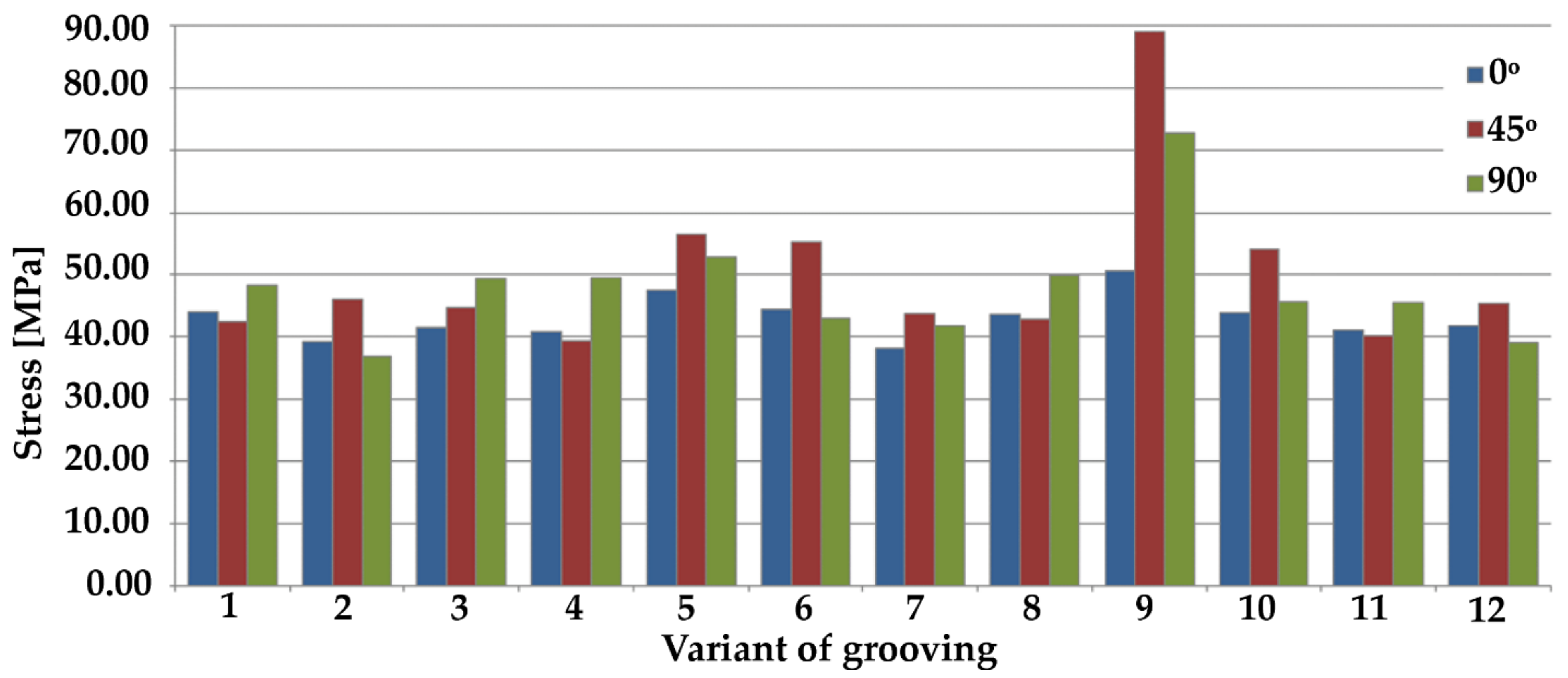

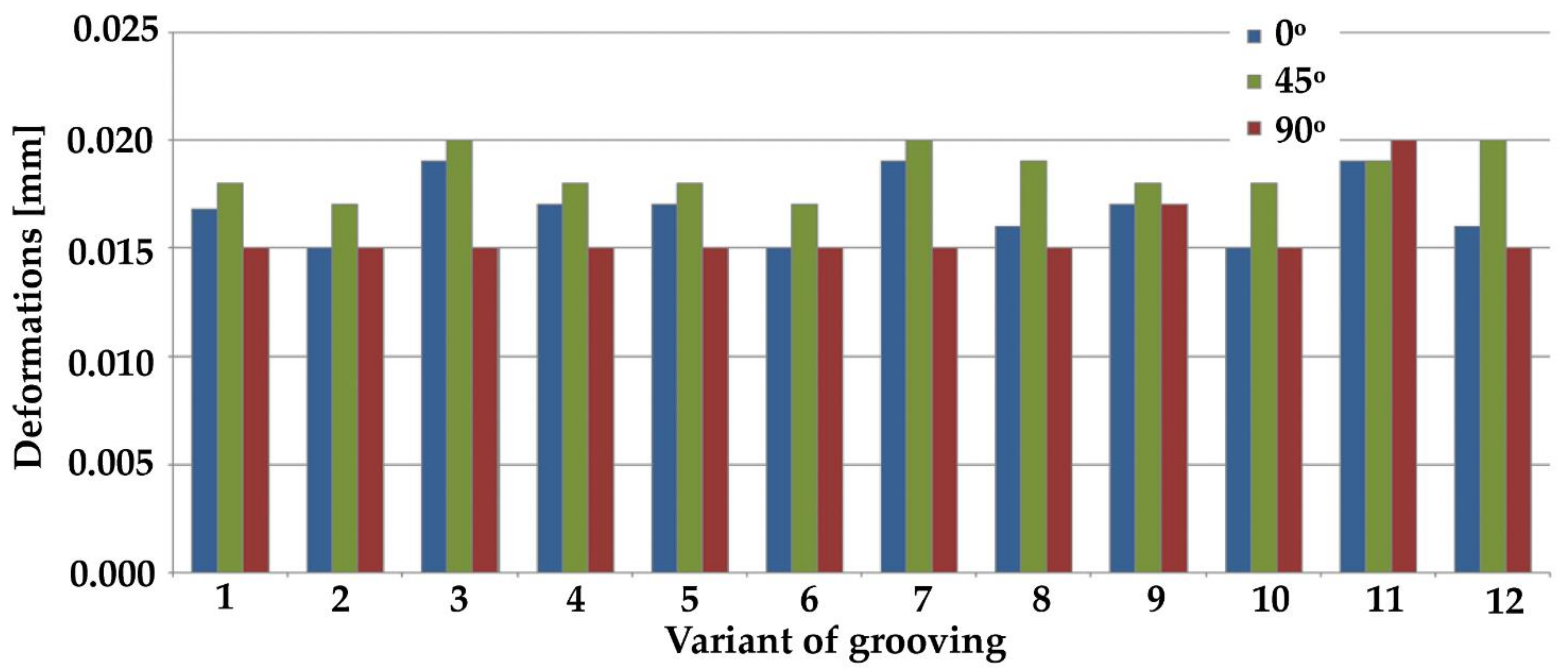

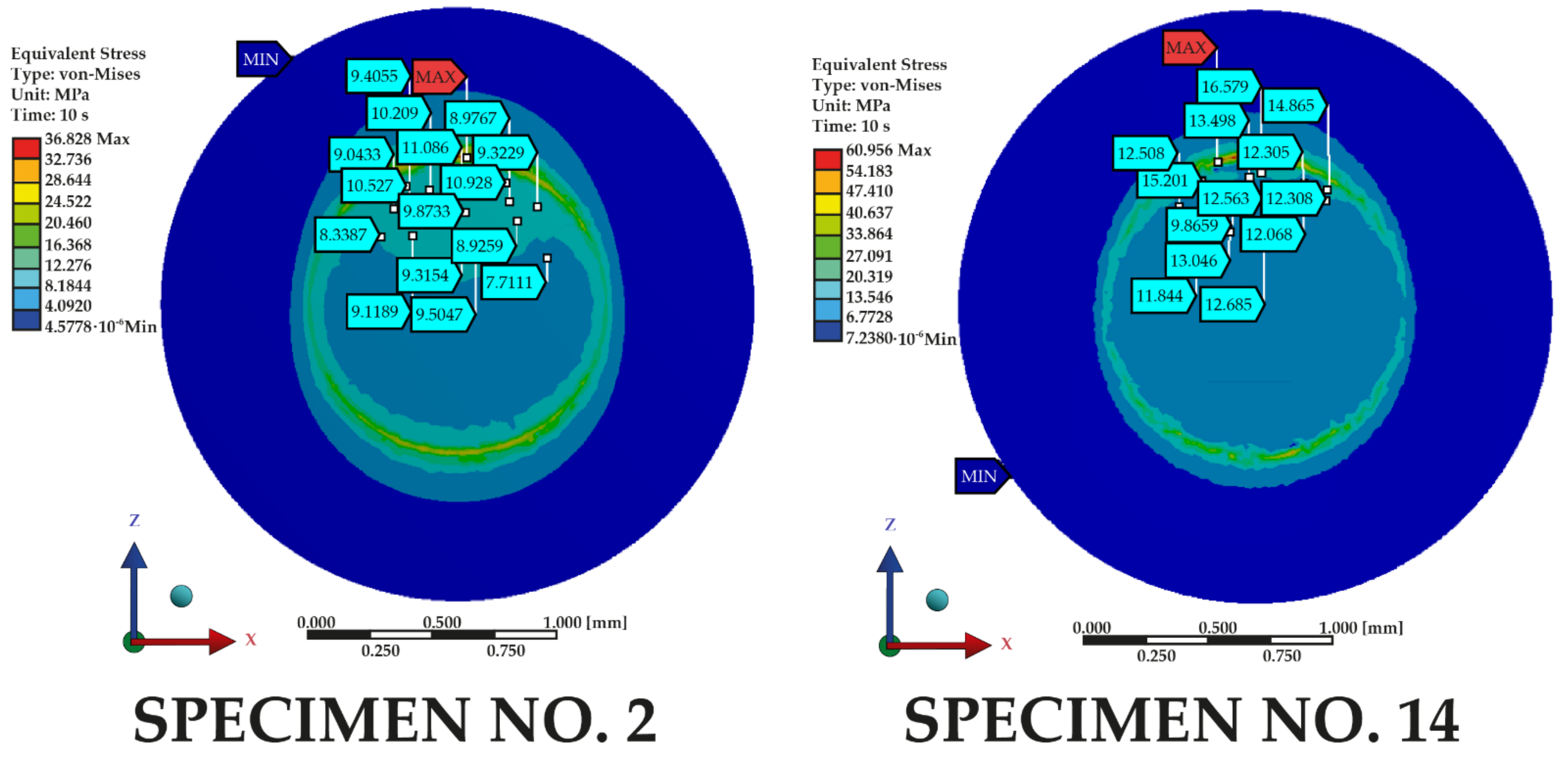

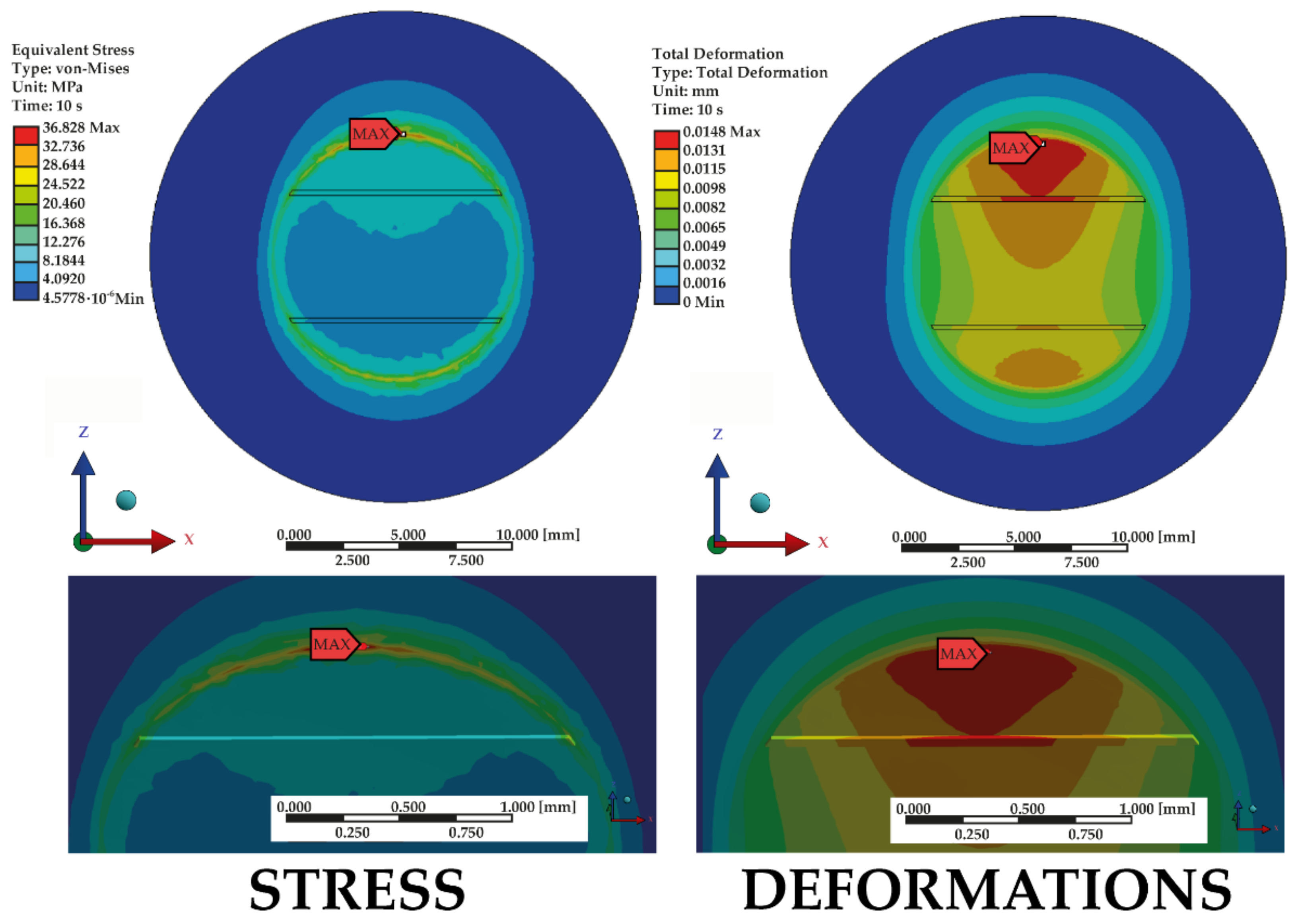

3. Results

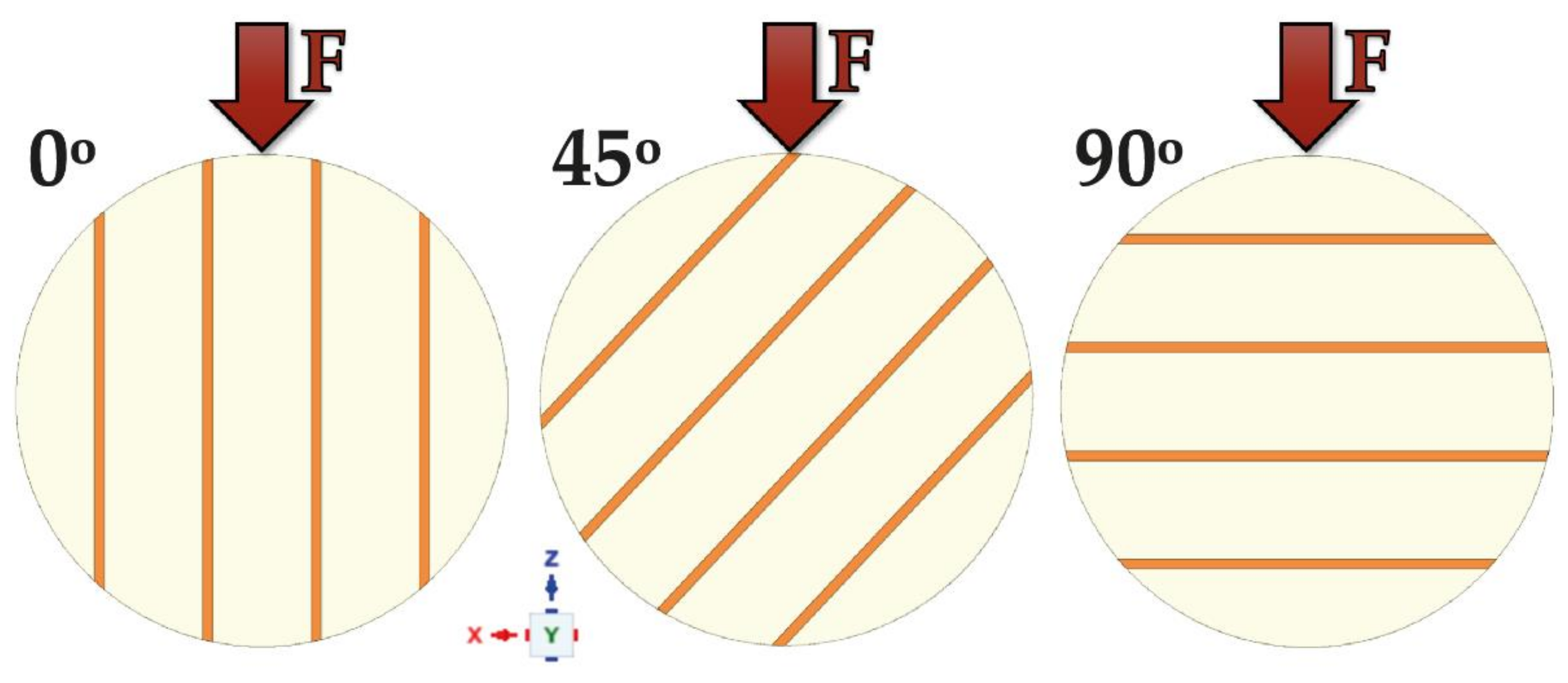

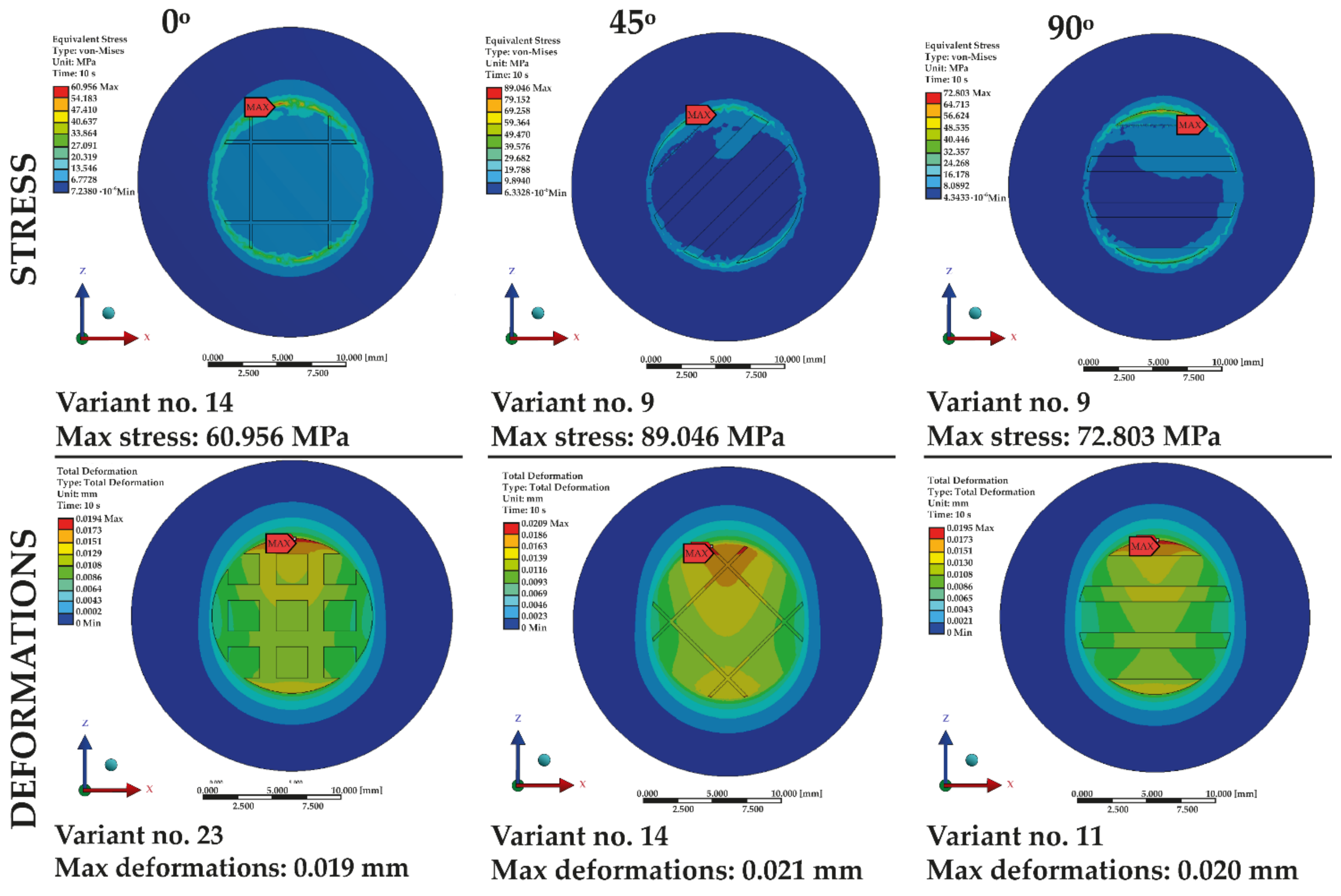

- no. 2, with grooves positioned at an angle of 90°,

- no. 4, with grooves positioned at an angle of 45°,

- no. 7 and no. 15, with grooves positioned at an angle of 0°.

4. Discussion

5. Conclusions

- The angle of 0° produces the lowest stresses in most samples, irrespective of groove dimensions.

- The lowest deformations were observed in samples with parallel grooving at an angle of 90°.

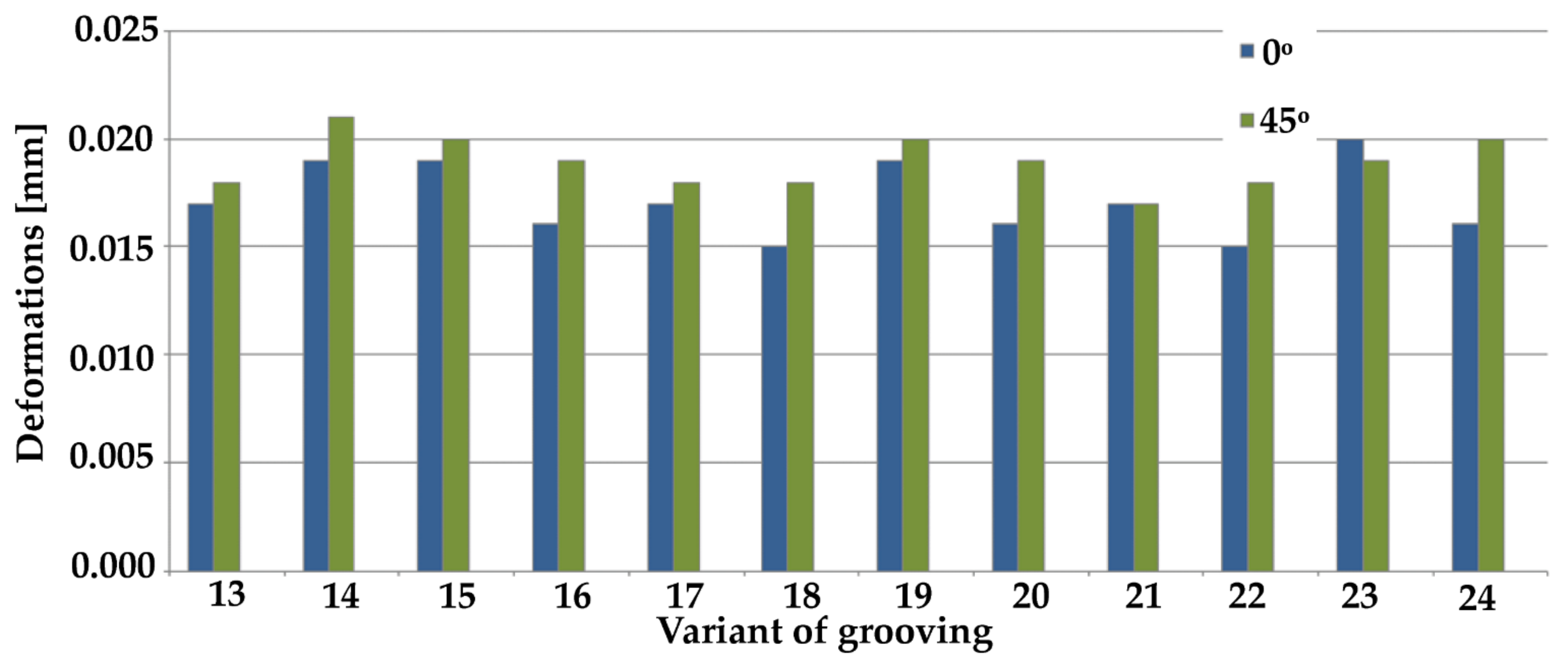

- The highest stresses were recorded when the grooving angle was 45° and the depth was 0.10 mm, indicating that increasing grooving depth reduces stresses but increases deformation.

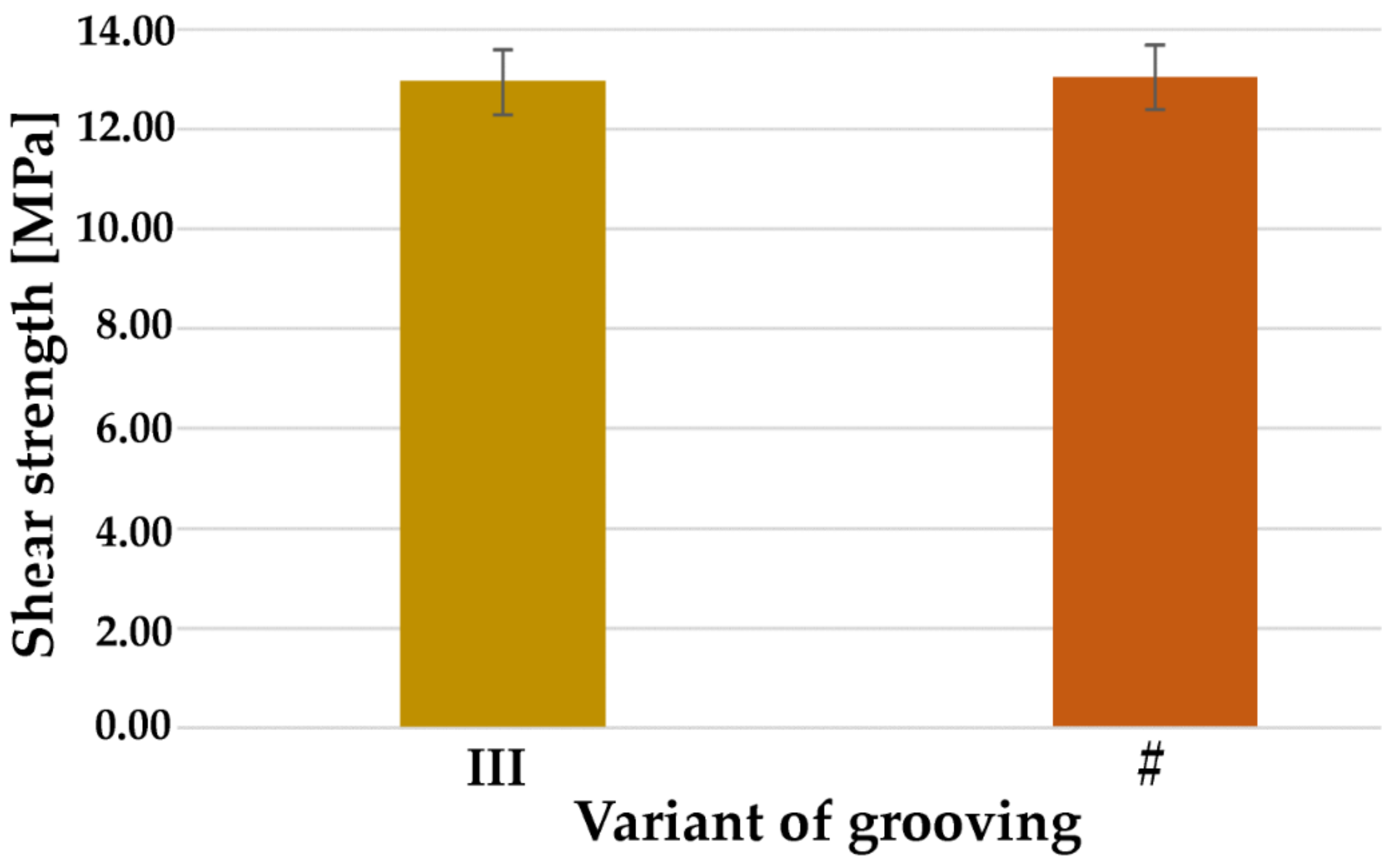

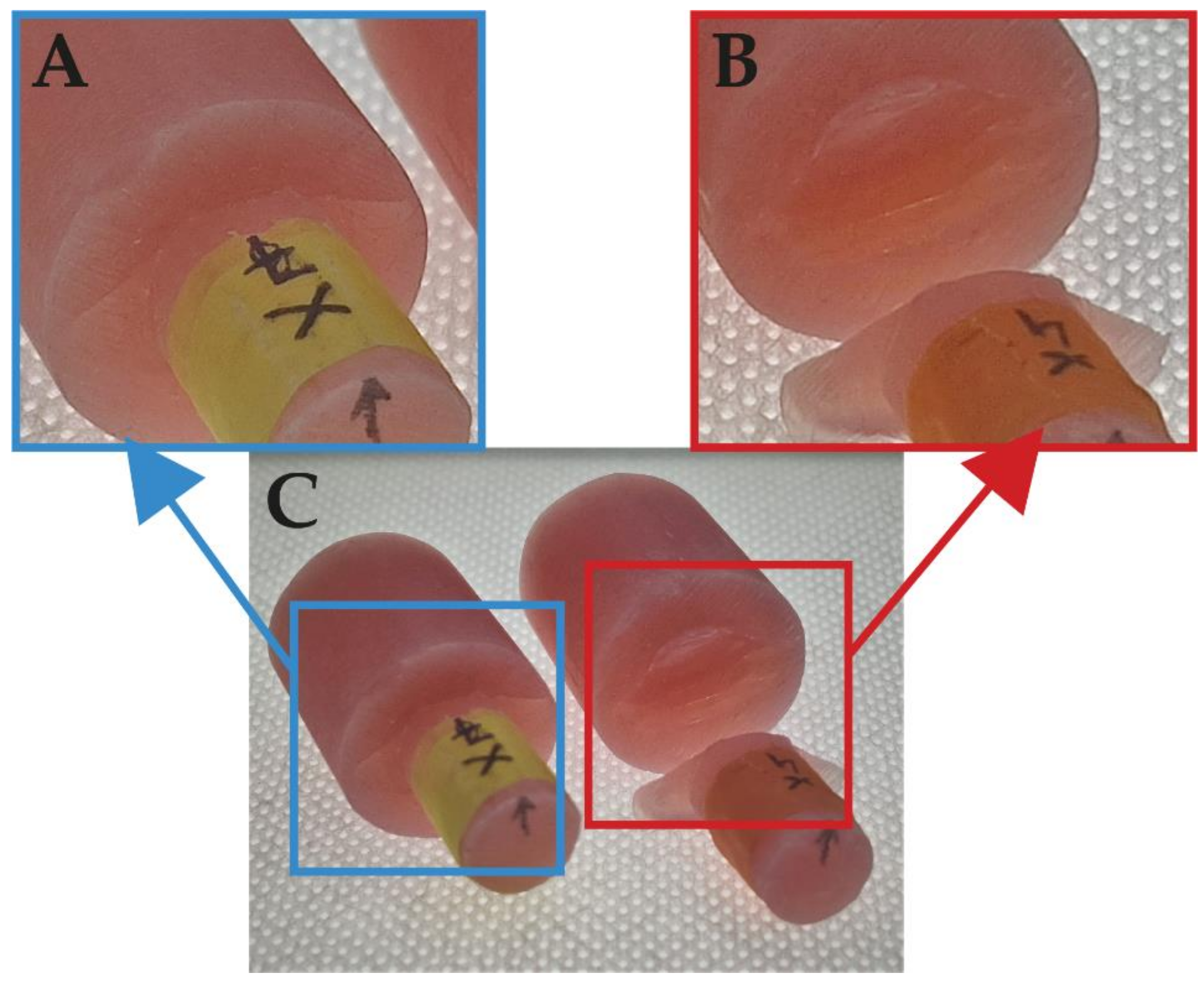

- In samples with parallel (III) grooves, increasing the groove depth in most cases increased the deformations but reduced stresses.

- In cross-grooved (#) variants, increased depth resulted in higher deformations but lower stresses.

- Increasing the width of III grooves had no clear impact on results.

- The greater the distance of the grooves in the # shape, the lower the deformations and stresses.

- Increasing the width results in a slight increase in deformations and stresses (III shape).

- Increasing the width has no clear impact (# shape).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Announcement of the Minister of Health of 30 May 2019 on the publication of the uniform text of the Regulation of the Minister of Health on guaranteed benefits in the field of dental treatment. J. Laws Repub. Poland 2019, 1199, 1–82. Available online: http://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20190001199 (accessed on 13 July 2021).

- McGivney, G.P.; Carr, A.B. Removable Partial Dentures According to McCracken, 1st ed.; Czelej: Lublin, Poland, 2003. [Google Scholar]

- Taczała, J. Influence of the groove on stress distribution and deformations in the case of a single incisor in removable partial denture metal framework. In The Book of Articles National Scientific Conference “Zrozumieć Naukę”; Promovendi Foundation Publishing: Łódź, Poland, 2018; pp. 238–248. [Google Scholar]

- Taczała, J. 3D geometry optimization of the fragment of removable partial denture metal framework with single incisor in numerical analysis. In The Book of Articles National Scientific Conference “Knowledge–Key to Success 2019”; Promovendi Foundation: Toruń, Poland, 19 January 2019; pp. 128–133. [Google Scholar]

- Taczała, J.; Krupanek, K.; Sawicki, J. Numerical analysis of the influence of surface modification on the bond strength between a single incisal tooth with a removable partial denture metal framework. AIP Conf. Proc. 2019, 2078, 020057. [Google Scholar]

- Spiechowicz, E. Dental Prosthetics. Textbook for Students, 6th ed.; PZWL: Warszawa, Poland, 2013. [Google Scholar]

- Budkiewicz, A. Skeletal Dentures, 4th ed.; PZWL: Warszawa, Poland, 2004. [Google Scholar]

- Dejak, B. Compendium of Making Prosthetic Restorations; Med Tour Press International: Otwock, Poland, 2014. [Google Scholar]

- Grosfeldowa, O.; Budkiewicz, A. Chewing Organ. Physiology; PZWL: Warszawa, Poland, 1981. [Google Scholar]

- Taczała, J.; Sawicki, J. Bond between single artificial teeth and the base plate in removable denture metal framework. J. Achiev Mater. Manuf. Eng. 2018, 90, 11–21. [Google Scholar] [CrossRef]

- Darbar, U.R.; Huggett, R.; Harrison, A. Denture fracture: A survey. Br. Dent. J. 1994, 176, 342–345. [Google Scholar] [CrossRef] [PubMed]

- Patil, S.B.; Naveen, B.H.; Patil, N.P. Bonding acrylic teeth to acrylic resin denture bases: A review. Gerodontology 2006, 23, 131–139. [Google Scholar] [CrossRef] [PubMed]

- Akin, H.; Kirmali, O.; Tugut, F.; Coskun, M.E. Effects of different surface treatments on the bond strength of acrylic denture teeth to polymethylmethacrylate denture base material. Photomed Laser Surg. 2014, 32, 512–516. [Google Scholar] [CrossRef] [PubMed]

- Muñoz, M.; Reales, E.; Prates, L.; Volpato, C. Bond strength assessment between acrylic teeth and acrylic resin repairs: Effect of different surface treatments. Odovtos Int. J. Dent. Sci. 2016, 18, 109. [Google Scholar] [CrossRef][Green Version]

- Kurt, M.; Saraç, Y.Ş.; Ural, Ç.; Saraç, D. Effect of pre-processing methods on bond strength between acrylic resin teeth and acrylic denture base resin. Gerodontology 2012, 29, e357–e362. [Google Scholar] [CrossRef]

- Ivoclar Vivaden. ProBase Cold. Available online: https://www.ivoclarvivadent.com/en_US/Products/Removable-Prosthetics/ProBase-Cold (accessed on 22 March 2021).

- Schütz Dental GmbH. FuturAcryl 2000. Available online: https://www.schuetz-dental.de/media/pdf/8a/6a/5a/FuturAcryl_2000-Anleitung_07_2019.pdf (accessed on 8 April 2021).

- Meloto, C.; Silva-Concílio, L.; Rodrigues-Garciai, R.; Canales, G.; Rizzatti-Barbosa, C. Effect of surface treatments on the bond strength of different resin teeth to complete denture base material. Acta Odontol. Lat. 1984, 26, 37–42. [Google Scholar]

- Choi, J.J.E.; Uy, C.E.; Plaksina, P.; Ramani, R.S.; Ganjigatti, R.; Waddell, J.N. Bond strength of denture teeth to heat-cured, CAD/CAM and 3D printed denture acrylics. J. Prosthodont. 2019, 29, 1–19. [Google Scholar] [CrossRef]

- Akin, H.; Tugut, F.; Guney, U.; Akar, T. Shear bond strength of denture teeth to two chemically different denture base resins after various surface treatments. J. Prosthodont. 2014, 23, 152–156. [Google Scholar] [CrossRef]

- Jayakrishnakumar, S.; Ramakrishnan, H.; Divagar, C.; Mahadevan, V.; Azhagarasan, N. Comparative evaluation of the effect of surface treatments on the shearbond strength between acrylic denture teeth and denture base resin—Three dimensional study. IOSR J. Dent. Med. Sci. 2019, 18, 29–45. [Google Scholar]

- Raszewski, Z. A New View at Acrylic Materials; Elamed: Łódź, Poland, 2009. [Google Scholar]

- Taczala, J.; Fu, C.; Sawicki, J.; Pietrasik, J. Influence different amount of cellulose on the mechanical strength of dental acrylic resin. IOP Conf. Ser. Mater. Sci. Eng. 2020, 743, 012044. [Google Scholar] [CrossRef]

- Taczała, J.; Sawicki, J.; Pietrasik, J. Chemical modification of cellulose microfibres to reinforce poly(methyl methacrylate) used for dental application. Materials 2020, 13, 17. [Google Scholar] [CrossRef]

- Smielak, B.; Klimek, L. Effect of hydrofluoric acid concentration and etching duration on select surface roughness parameters for zirconia. J. Prosthet Dent. 2015, 113, 596–602. [Google Scholar] [CrossRef]

- Parchańska-Kowalik, M.; Wołowiec-Korecka, E.; Klimek, L. Effect of chemical surface treatment of titanium on its bond with dental ceramics. J. Prosthet Dent. 2018, 120, 470–475. [Google Scholar] [CrossRef]

- Colebeck, A.C.; Monaco, E.A.; Pusateri, C.R.; Davis, E.L. Microtensile bond strength of different acrylic teeth to high-impact denture base resins. J. Prosthodont. 2015, 24, 43–51. [Google Scholar] [CrossRef]

- Śmielak, B.; Klimek, L.; Wojciechowski, R.; Bąkała, M. Effect of zirconia surface treatment on its wettability by liquid ceramics. J. Prosthet Dent. 2019, 122, e1–e410. [Google Scholar] [CrossRef]

- Chung, K.-H.; Chung, C.Y.; Chung, C.Y.; Chan, D.C.N. Effect of pre-processing surface treatments of acrylic teeth on bonding to the denture base. J. Oral Rehabil. 2008, 35, 268–275. [Google Scholar] [CrossRef]

- Consani, R.; Naoe, H.; Mesquita, M.; Sinhoreti, M.; Mendes, W. Effect of ridge-lap surface treatments on the bond of resin teeth to denture base. J. Adhes Dent. 2011, 13, 287–293. [Google Scholar]

- Saavedra, G.; Neisser, M.P.; Sinhoreti, M.A.C.; Machado, C. Evaluation of bond strength of denture teeth bonded to heat polymerized acrylic resin denture bases. Braz. J. Oral Sci. 2004, 3, 458–464. [Google Scholar]

- Golebiowski, M.; Wolowiec, E.; Klimek, L. Airborne-particle abrasion parameters on the quality of titanium-ceramic bonds. J. Prosthet. Dent. 2015, 113, 453–459. [Google Scholar] [CrossRef]

- Pietnicki, K.; Wołowiec, E.; Klimek, L. The effect of abrasive blasting on the strength of a joint between dental porcelain and metal base. Acta Bioeng. Biomech. 2014, 16, 63–68. [Google Scholar]

- Śmielak, B.; Klimek, L. Effect of air abrasion on the number of particles embedded in zironia. Materials 2018, 11, 259. [Google Scholar] [CrossRef]

- Śmielak, B.; Klimek, L.; Świniarski, J. The use of the finite elements method (FEM) to determine the optimal angle of force application in relation to grooves notched into a zirconia coping with the aim of reducing load on a connection with veneering ceramic. Biomed. Res. Int. 2019. [Google Scholar] [CrossRef]

- Śmielak, B.; Klimek, L.; Świniarski, J. The use of the FEM to identify the optimal groove dimensions ensuring the least stressed connection between a zirconia. Materials 2018, 11, 2360. [Google Scholar] [CrossRef]

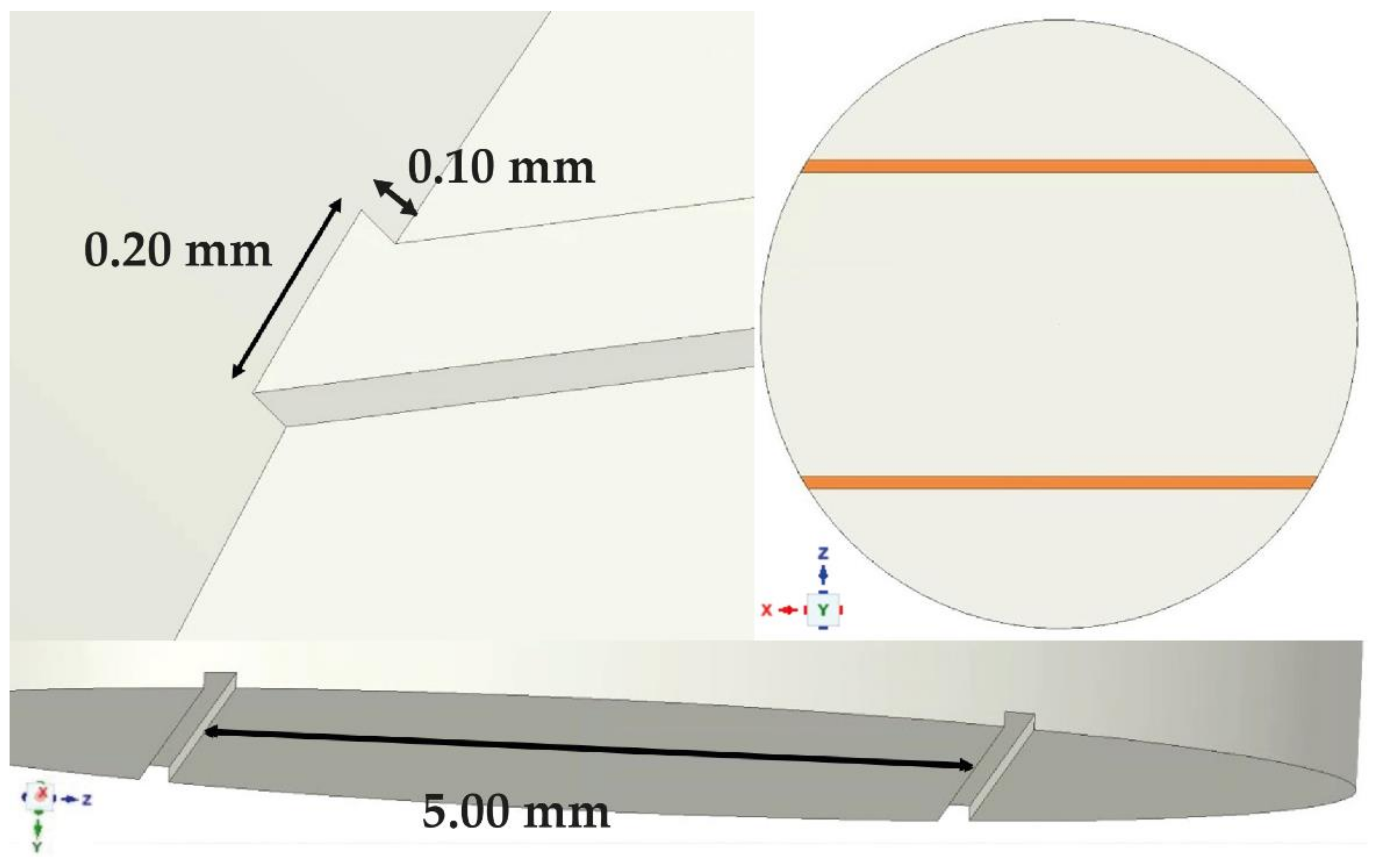

| Parallel Grooving (Marked as ‘III’) | ||||||||

| N° | Dimensions (mm) | N° | Dimensions (mm) | N° | Dimensions (mm) | |||

| 1 | width | 0.20 | 5 | width | 0.50 | 9 | width | 1.00 |

| distance | 2.00 | distance | 2.00 | distance | 2.00 | |||

| depth | 0.10 | depth | 0.10 | depth | 0.10 | |||

| 2 | width | 0.20 | 6 | width | 0.50 | 10 | width | 1.00 |

| distance | 5.00 | distance | 5.00 | distance | 5.00 | |||

| depth | 0.10 | depth | 0.10 | depth | 0.10 | |||

| 3 | width | 0.20 | 7 | width | 0.50 | 11 | width | 1.00 |

| distance | 2.00 | distance | 2.00 | distance | 2.00 | |||

| depth | 0.20 | depth | 0.20 | depth | 0.20 | |||

| 4 | width | 0.20 | 8 | width | 0.50 | 12 | width | 1.00 |

| distance | 5.00 | distance | 5.00 | distance | 5.00 | |||

| depth | 0.20 | depth | 0.20 | depth | 0.20 | |||

| Cross Grooving (Marked as ‘#’) | ||||||||

| N° | Dimensions (mm) | N° | Dimensions (mm) | N° | Dimensions (mm) | |||

| 13 | width | 0.20 | 17 | width | 0.50 | 21 | width | 1.00 |

| distance | 2.00 | distance | 2.00 | distance | 2.00 | |||

| depth | 0.10 | depth | 0.10 | depth | 0.10 | |||

| 14 | width | 0.20 | 18 | width | 0.50 | 22 | width | 1.00 |

| distance | 5.00 | distance | 5.00 | distance | 5.00 | |||

| depth | 0.10 | depth | 0.10 | depth | 0.10 | |||

| 15 | width | 0.20 | 19 | width | 0.50 | 23 | width | 1.00 |

| distance | 2.00 | distance | 2.00 | distance | 2.00 | |||

| depth | 0.20 | depth | 0.20 | depth | 0.20 | |||

| 16 | width | 0.20 | 20 | width | 0.50 | 24 | width | 1.00 |

| distance | 5.00 | distance | 5.00 | distance | 5.00 | |||

| depth | 0.20 | depth | 0.20 | depth | 0.20 | |||

| Property | Value |

|---|---|

| Density | 1.9 g/cm3 |

| Poisson’s Ratio | 0.44 |

| Young’s Modulus | 2 940 MPa |

| Yield Strength | 51.7 MPa |

| Tensile Strength | 58.5 MPa |

| Compressive Yield Strength | 81.4 MPa |

| Grooving | Analyzed Dimensions | The Best Values Were Obtained with | ||

|---|---|---|---|---|

| Width (mm) | Distance (mm) | Angle (°) | Depth (mm) | |

| Parallel | 0.20 | 2.00 | 0 | 0.20 |

| 0.20 | 5.00 | 90 | 0.10 | |

| 0.50 | 2.00 | 90 | 0.20 | |

| 0.50 | 5.00 | 90 | 0.10 | |

| 1.00 | 2.00 | 45 | 0.20 | |

| 1.00 | 5.00 | 90 | 0.20 | |

| Cross | 0.20 | 2.00 | 0 | 0.20 |

| 0.20 | 5.00 | 0 | 0.20 | |

| 0.50 | 2.00 | 0 | 0.20 | |

| 0.50 | 5.00 | 45 | 0.20 | |

| 1.00 | 2.00 | 45 | 0.20 | |

| 1.00 | 5.00 | 0 | 0.20 | |

| Grooving | Analyzed Dimensions | The Best Values Were Obtained with | ||

|---|---|---|---|---|

| Width (mm) | Depth (mm) | Angle (°) | Distance (mm) | |

| Parallel | 0.20 | 0.10 | 90 | 5.00 |

| 0.20 | 0.20 | 45 | 5.00 | |

| 0.50 | 0.10 | 90 | 5.00 | |

| 0.50 | 0.20 | 90 | 2.00 | |

| 1.00 | 0.10 | 0 | 5.00 | |

| 1.00 | 0.20 | 90 | 5.00 | |

| Cross | 0.20 | 0.10 | 0 | 2.00 |

| 0.20 | 0.20 | 0 | 5.00 | |

| 0.50 | 0.10 | 0 | 5.00 | |

| 0.50 | 0.20 | 0 | 5.00 | |

| 1.00 | 0.10 | 0 | 5.00 | |

| 1.00 | 0.20 | 0 | 5.00 | |

| Grooving | Analyzed Dimensions | The Best Values Were Obtained with | ||

|---|---|---|---|---|

| Distance (mm) | Depth (mm) | Angle (°) | Width (mm) | |

| Parallel | 2.00 | 0.10 | 45 | 0.20 |

| 5.00 | 0.10 | 90 | 0.20 | |

| 2.00 | 0.20 | 90 | 0.20 | |

| 5.00 | 0.20 | 90 | 1.00 | |

| Cross | 2.00 | 0.10 | 0 | 0.20 |

| 5.00 | 0.10 | 0 | 0.50 | |

| 5.00 | 0.20 | 0 | 0.20 | |

| 5.00 | 0.20 | 0 | 0.20 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taczała, J.; Rak, K.; Sawicki, J.; Krasowski, M. Numerical Analysis of the Bond Strength between Two Methacrylic Polymers by Surface Modification. Materials 2021, 14, 3927. https://doi.org/10.3390/ma14143927

Taczała J, Rak K, Sawicki J, Krasowski M. Numerical Analysis of the Bond Strength between Two Methacrylic Polymers by Surface Modification. Materials. 2021; 14(14):3927. https://doi.org/10.3390/ma14143927

Chicago/Turabian StyleTaczała, Joanna, Katarzyna Rak, Jacek Sawicki, and Michał Krasowski. 2021. "Numerical Analysis of the Bond Strength between Two Methacrylic Polymers by Surface Modification" Materials 14, no. 14: 3927. https://doi.org/10.3390/ma14143927

APA StyleTaczała, J., Rak, K., Sawicki, J., & Krasowski, M. (2021). Numerical Analysis of the Bond Strength between Two Methacrylic Polymers by Surface Modification. Materials, 14(14), 3927. https://doi.org/10.3390/ma14143927