An In Situ Synchrotron Dilatometry and Atomistic Study of Martensite and Carbide Formation during Partitioning and Tempering

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation Details for the STEM Imaging

2.2. TEM Technique and Image Analysis

2.3. In Situ Synchrotron Experiments

2.4. DFT Calculation Method

2.5. DFT Microstructure Setup

3. Results and Discussion

4. Summary and Conclusions

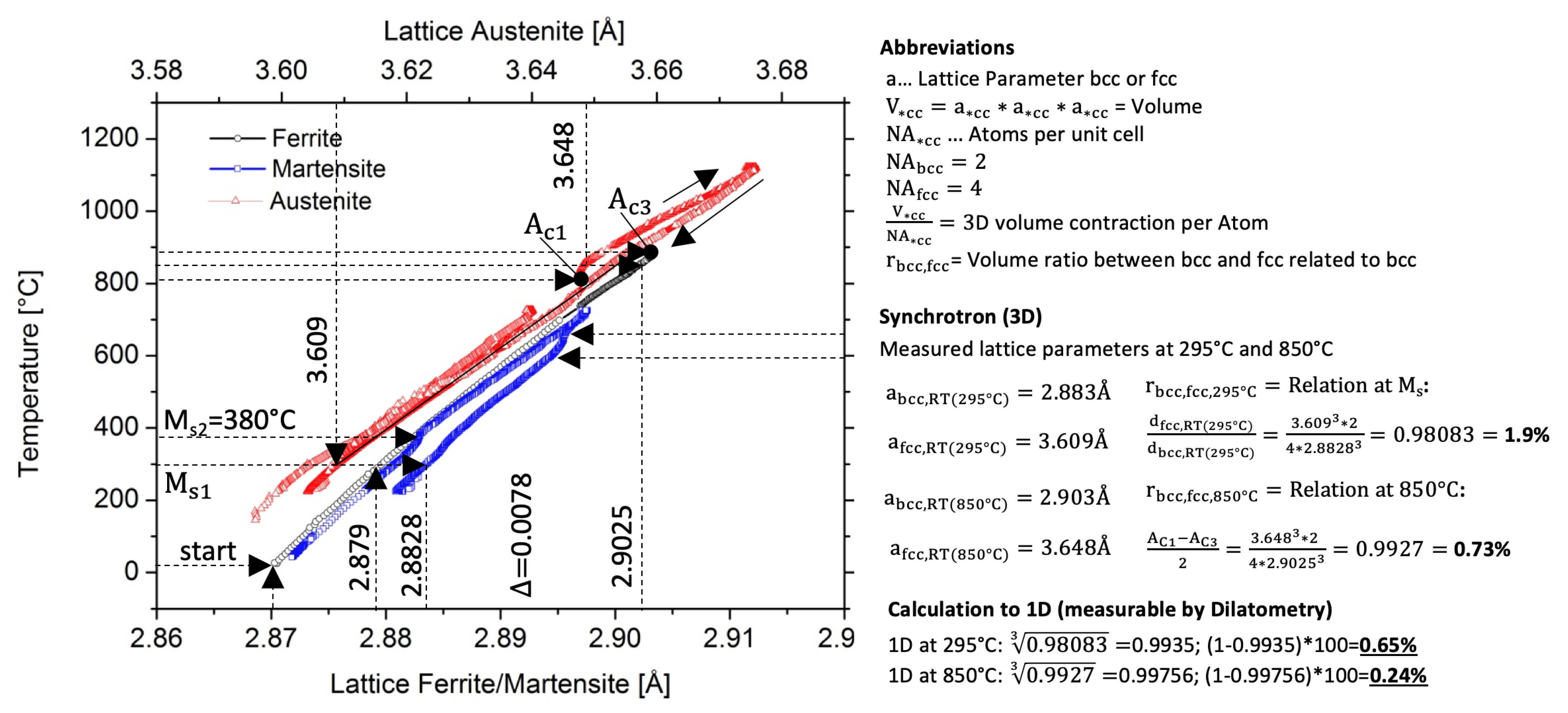

- When cooling from the austenitizing temperature, the substitutional dissolved portion of Cr in the matrix coupled with the high affinity of Cr for the element C retains C in the matrix and prevents the rapid precipitation of stable carbide. The lattice parameter of the parent phase (austenite) shrinks faster than the thermodynamically stable phase (ferrite). Their measurable difference plus the compressive strain on the local yield stress is represented by the martensitic expansion at M temperature.

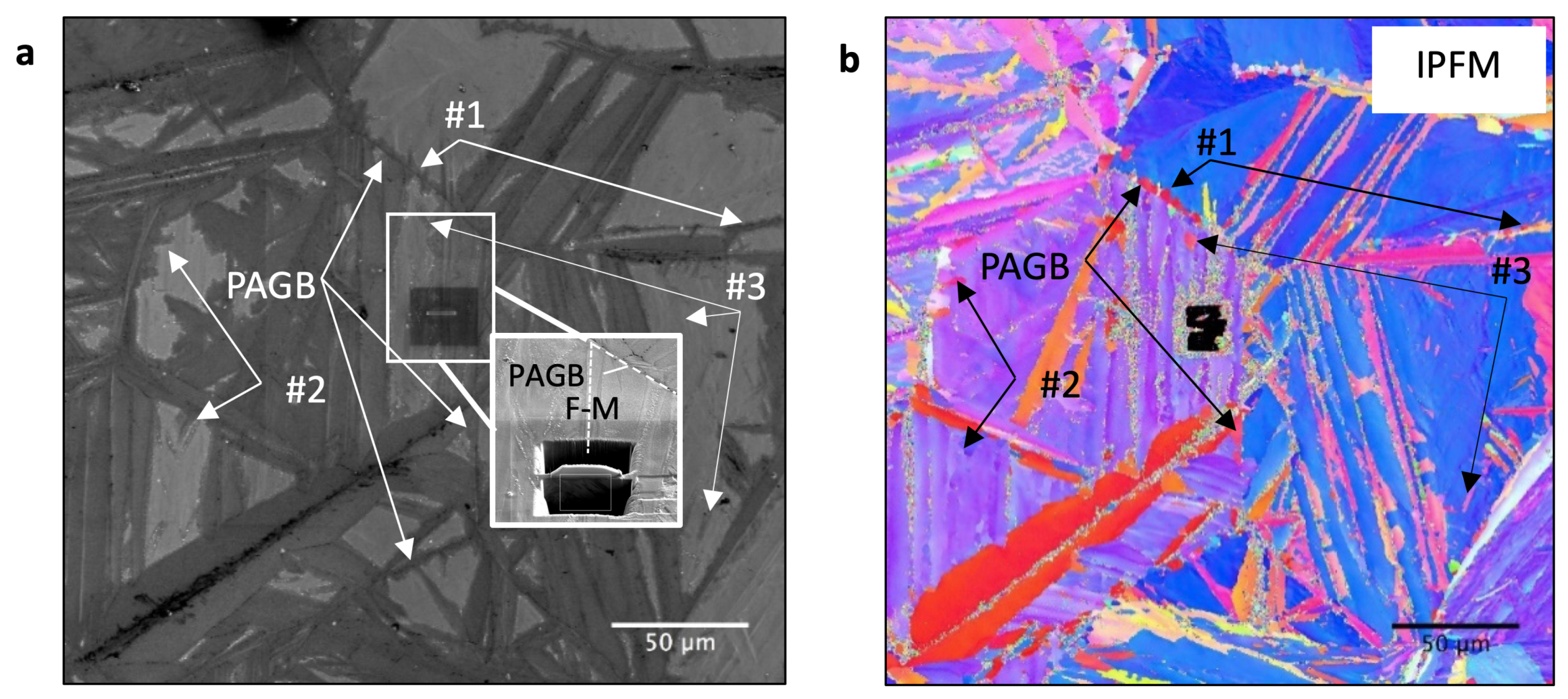

- The martensitic expansion dissipates heat and separates the austenitic parent matrix into deformed retained austenite and martensite. Heterogeneous nucleation sites (voids, dislocations, and interfaces) are created during partitioning for the subsequent tempering step.

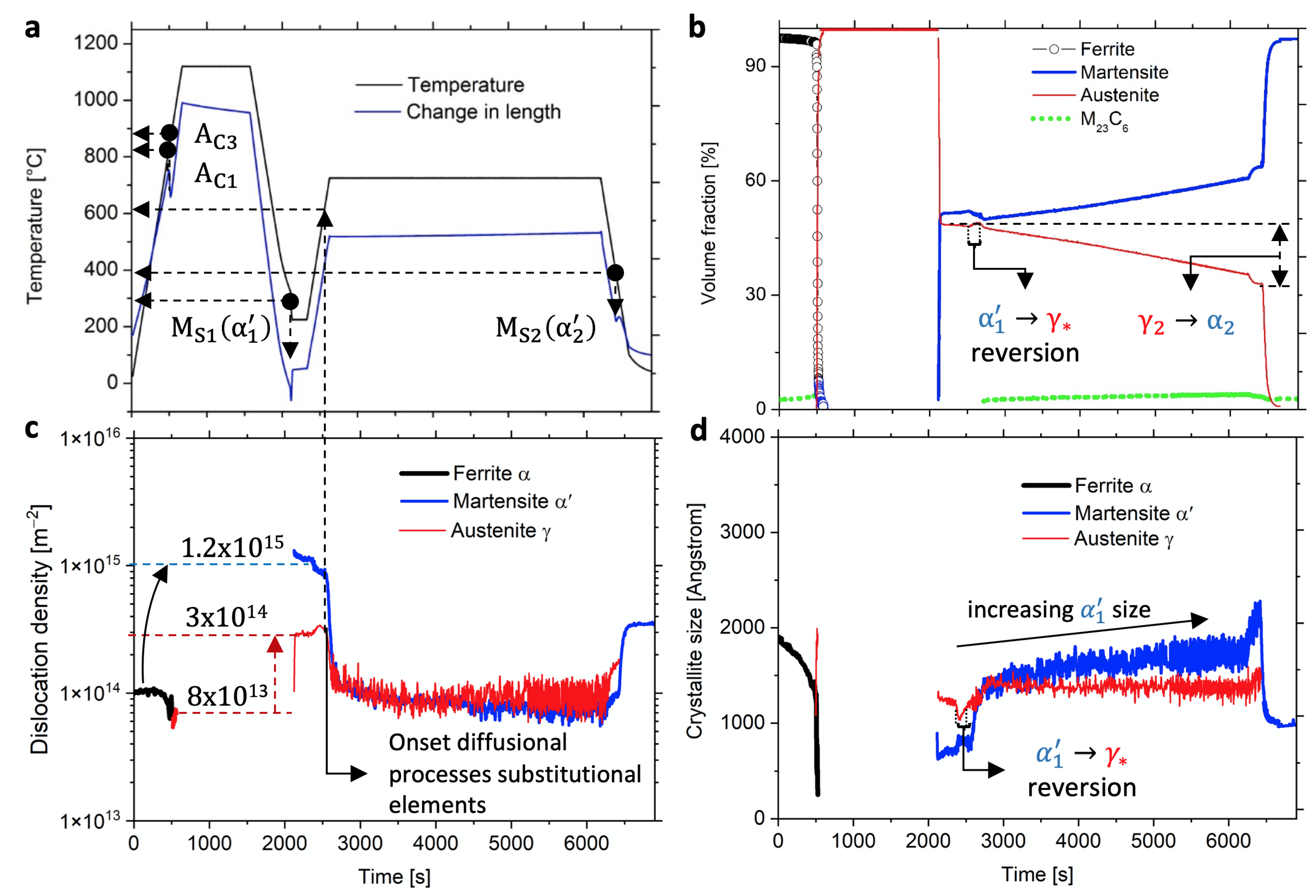

- Tempering above 600 C leads to immediate recovery, thermally activated coarsening of martensite crystal laths (150 nm to 190 nm), carbide precipitation, and subsequent ferrite formation. The ferrite morphologies formed depend on the amount of locally forcibly dissolved C in the austenite and occur spontanously after local depletion by, for example, precipitation.

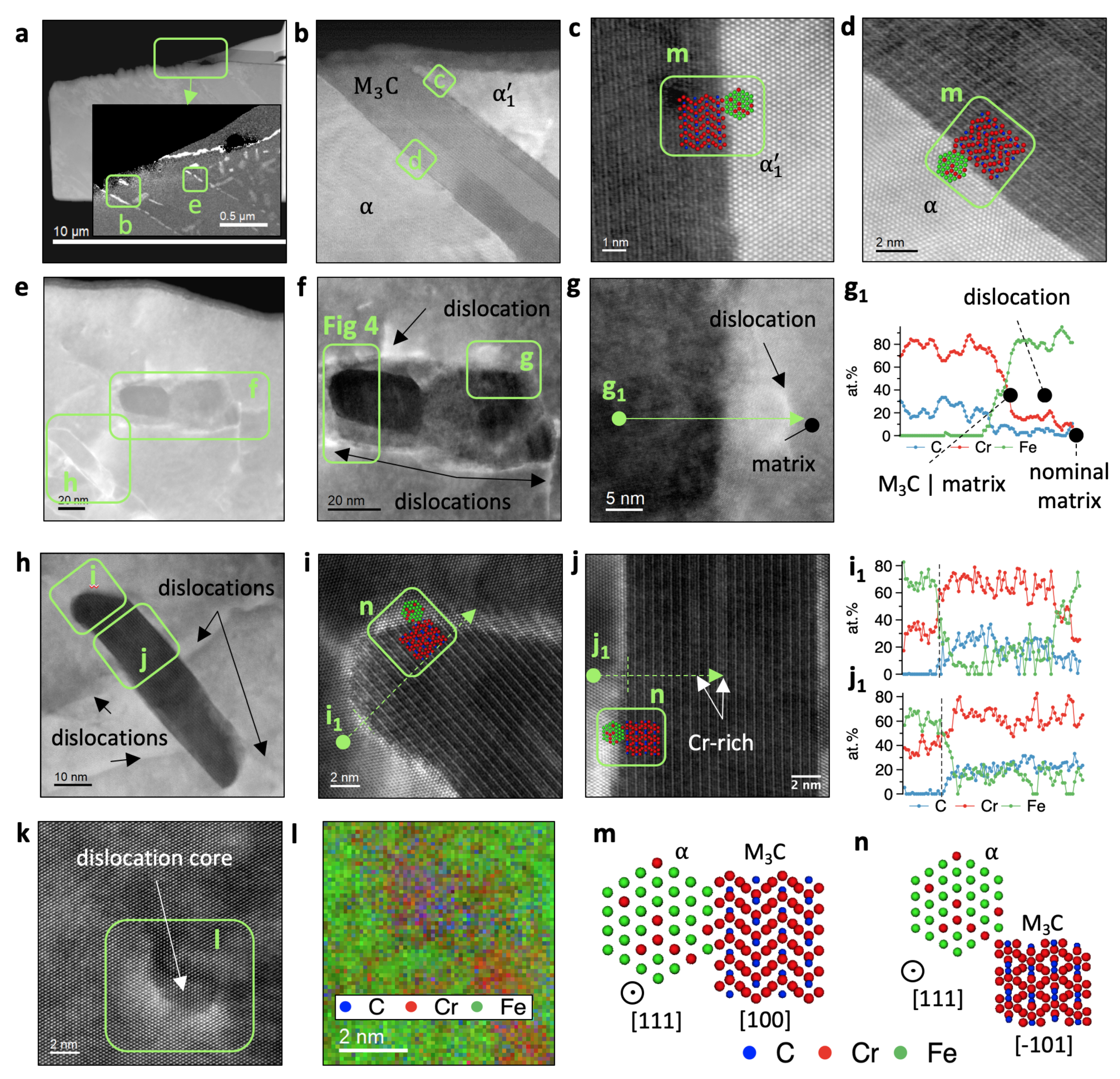

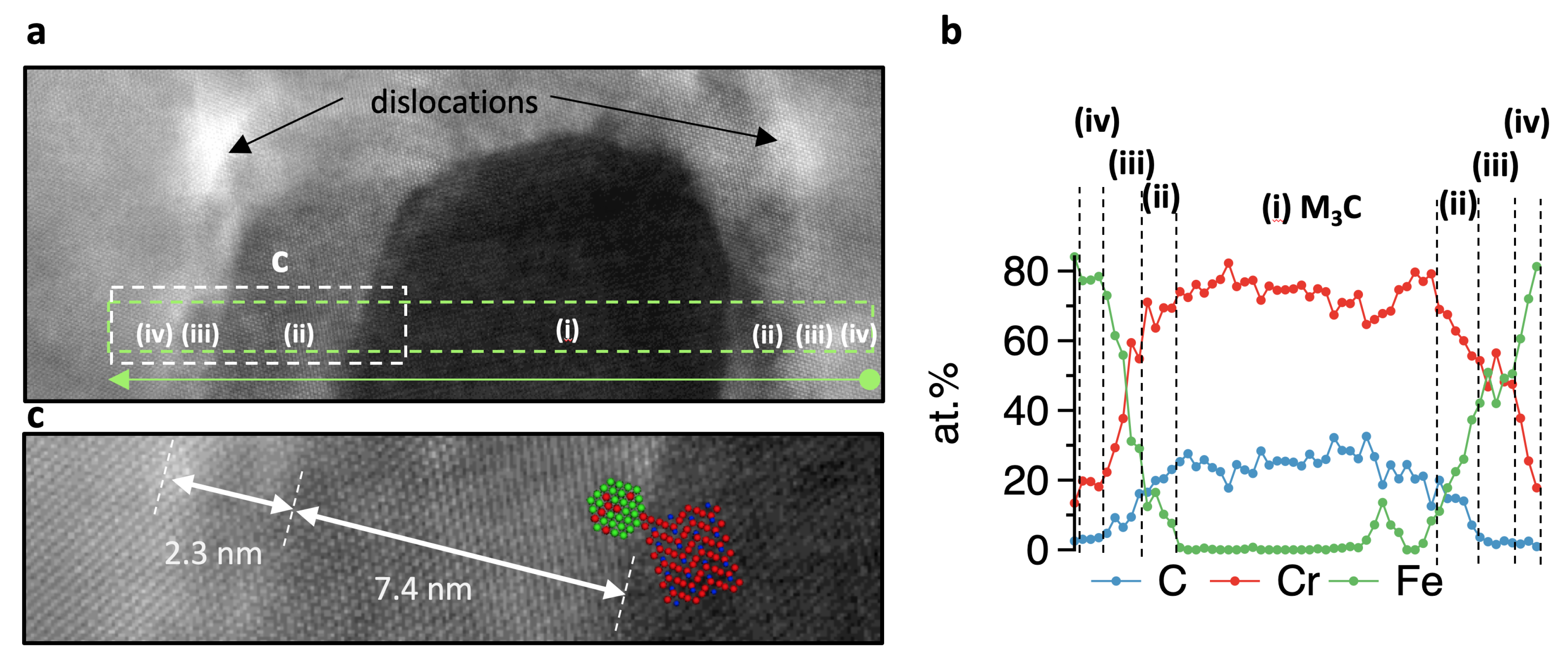

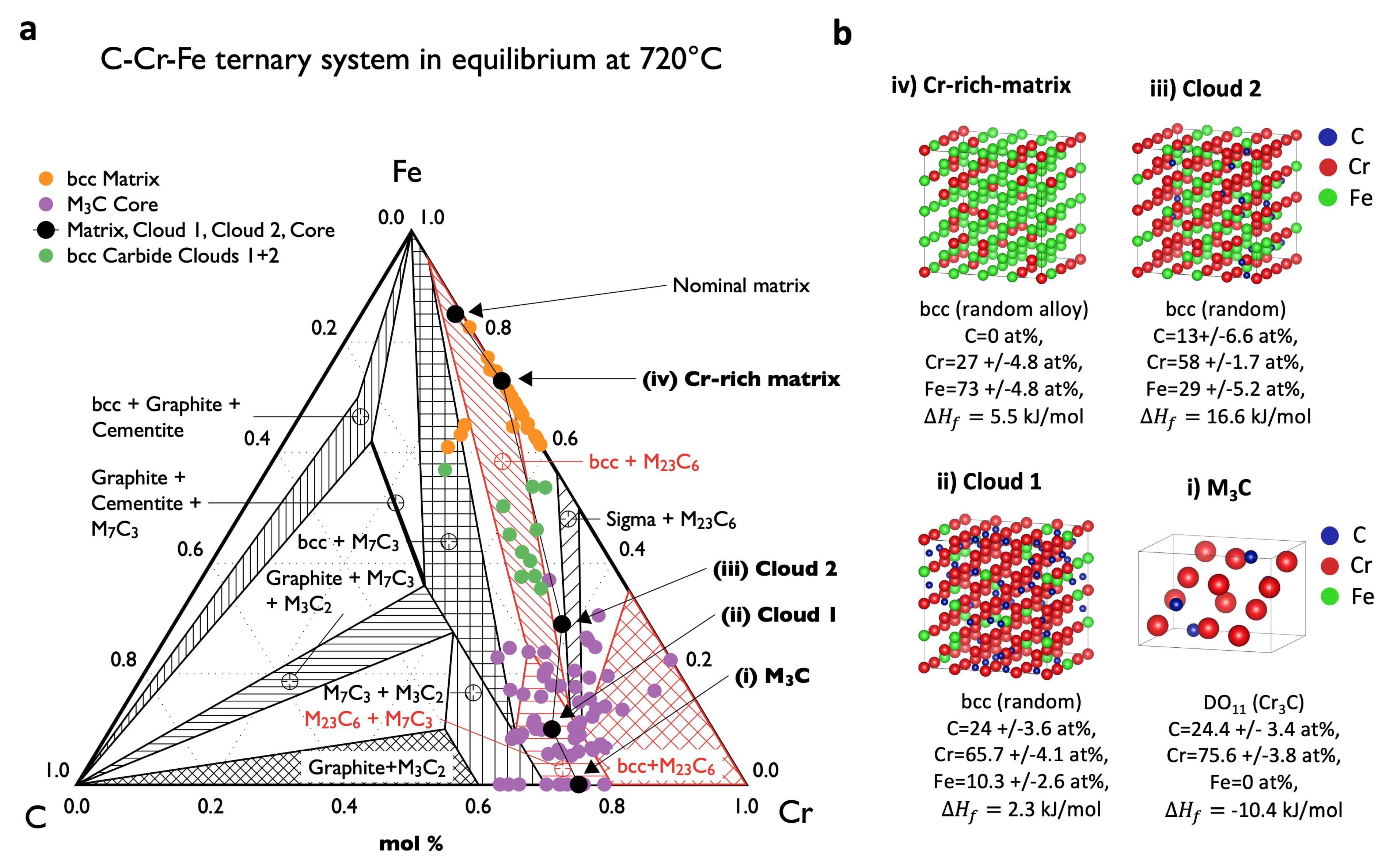

- Formation of metastable MC carbide: Carbon segregates into dislocations and interfaces after partitioning. Cottrell atmospheres form in dislocations, and discrete enrichment with the element Cr occurs. The step-wise enrichment through the diffusion of Cr to discrete bcc random solid solutions such as FeCrC, here referred to as clouds, takes time and is necessary for the nearly Fe-free CrC carbide to form.

- The determination of the driving force with density functional theory confirms that the energy state of the supersaturated bcc solid solution (cloud) is energetically favorable ( = 3.2 kJ·mol) compared with the ground state of the matrix, leading to its formation. Thus, the coherent carbide (perhaps some other carbides too) is formed from the driving forces between the cloud and the carbide.

- Interphase and intraphase MC carbides utilize nucleation and growth or spinodal decomposition for precipitation. Carbide also precipitates in deformed retained austenite during tempering, which explains the higher measured M temperature on cooling from the tempering temperature of retained austenite.

- Cr-depleted zones are present prior to the existence of precipitates and may affect the corrosion resistance of the alloy by sensitization.

- In situ synchrotron studies provide an immediate estimate of the maximum operating temperature from the decrease in dislocation density between 580 and 600 C. While this temperature increases for more heat-resistant steels, this experiment could save valuable time and expensive preliminary tests such as creep tests for new alloy developments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| # | Time/ | Micro- | Temperature | Lattice | |

|---|---|---|---|---|---|

| Gradient | Structure | [C] | [m] | Parameter [Å] | |

| Nominal | 84 | 14 | 1 | - | - |

| A | 1.66 C/s | 825 | 0.8 | 2.895, 3.650 | |

| A | 1.66 C/s | 875 | 50, 0.7 | 2.905, 3.660 | |

| T | 200 s | 290 | 18, 0.7 | 2.885, 3.605 | |

| 1.66 C/s | 265 | 12, 3.0 | (2.877) 2.885, 3.606 | ||

| 1.66 C/s | 265–400 | 11.5–9.5, 3.0–3.2 | |||

| 1.66 C/s | 400–550 | 9.5–9.0, 3.2 | |||

| 1.66 C/s | 550–610 | 9.0–8.0, 3.2–2.8 | |||

| 1.66 C/s | 610–725 | 8.0–1.6, 2.8–1.2 | |||

| 1 h | 725 | 1.6–0.75, 1.2–0.7 | 2.898 | ||

| 1.66 C/s | 725–400 | 0.75–1.0, 0.7–2.0 | |||

| 1.66 C/s | 400–220 | 1.0–3.0, 2.0–1.0 | |||

| 1.66 C/s | 220–50 | 3.0–3.25, 10–200 |

| FeCrC (Matrix) | <ss> | Alpha | |||

|---|---|---|---|---|---|

| Alloy Components: Fe Cr | |||||

| <ss> | 1 | (−0.5000 −0.5000 −0.5000) | = | −0.203125 | −0.002765 |

| <ss> | 2 | (−1.0000 −0.0000 −0.0000) | = | −0.208333 | −0.003789 |

| <ss> | 3 | (−1.0000 −1.0000 −0.0000) | = | −0.203125 | −0.002765 |

| <ss> | 4 | (−1.5000 −0.5000 −0.5000) | = | −0.205729 | 0.000512 |

| <ss> | 5 | (−1.0000 −1.0000 −1.0000) | = | −0.203125 | −0.002765 |

| <ss> | 6 | (−2.0000 0.0000 0.0000) | = | −0.21875 | 0.016897 |

| <ss> | 7 | (−1.5000 −1.5000 −0.5000) | = | −0.203125 | −0.002765 |

| <ss> | 8 | (−2.0000 −1.0000 0.0000) | = | −0.166667 | −0.048643 |

| FeCrC (Cloud 1) | <ss> | Alpha | |||

|---|---|---|---|---|---|

| Alloy Components: Fe Cr | |||||

| <ss> | 1 | (−0.5000 −0.5000 −0.5000) | = | −0.296875 | −0.003135 |

| <ss> | 2 | (−1.0000 −0.0000 −0.0000) | = | −0.302083 | 0.004296 |

| <ss> | 3 | (−1.0000 −1.0000 −0.0000) | = | −0.296875 | −0.003135 |

| <ss> | 4 | (−1.5000 −0.5000 −0.5000) | = | −0.299479 | 0.000581 |

| <ss> | 5 | (−1.0000 −1.0000 −1.0000) | = | −0.296875 | −0.003135 |

| <ss> | 6 | (−2.0000 0.0000 0.0000) | = | −0.302083 | 0.004296 |

| <ss> | 7 | (−1.5000 −1.5000 −0.5000) | = | −0.302083 | 0.004296 |

| <ss> | 8 | (−2.0000 −1.0000 0.0000) | = | −0.276042 | −0.032857 |

| Alloy Components: C Em (empty) | <ss> | Alpha | |||

| <ss> | 1 | (−0.5000 −0.5000 −0.5000) | = | −0.15625 | −0.000515 |

| <ss> | 2 | (−1.0000 −0.0000 −0.0000) | = | −0.159722 | 0.003603 |

| <ss> | 3 | (−1.0000 −1.0000 −0.0000) | = | −0.15625 | −0.000515 |

| <ss> | 4 | (−1.5000 −0.5000 −0.5000) | = | −0.15625 | −0.000515 |

| <ss> | 5 | (−1.0000 −1.0000 −1.0000) | = | −0.15625 | −0.000515 |

| <ss> | 6 | (−2.0000 0.0000 0.0000) | = | −0.161458 | 0.005661 |

| <ss> | 7 | (−1.5000 −1.5000 −0.5000) | = | −0.165365 | 0.010293 |

| <ss> | 8 | (−2.0000 −1.0000 0.0000) | = | −0.166667 | 0.011837 |

| FeCrC (Cloud 2) | <ss> | Alpha | |||

|---|---|---|---|---|---|

| Alloy Components: Fe Cr [B] | |||||

| <ss> | 1 | (−0.5000 −0.5000 −0.5000) | = | −0.085938 | −0.00241 |

| <ss> | 2 | (−1.0000 −0.0000 −0.0000) | = | −0.083333 | −0.005266 |

| <ss> | 3 | (−1.0000 −1.0000 −0.0000) | = | −0.088542 | 0.000446 |

| <ss> | 4 | (−1.5000 −0.5000 −0.5000) | = | −0.085938 | −0.00241 |

| <ss> | 5 | (−1.0000 −1.0000 −1.0000) | = | −0.085938 | −0.00241 |

| <ss> | 6 | (−2.0000 0.0000 0.0000) | = | −0.09375 | 0.006158 |

| <ss> | 7 | (−1.5000 −1.5000 −0.5000) | = | −0.078125 | −0.010977 |

| <ss> | 8 | (−2.0000 −1.0000 0.0000) | = | −0.083333 | −0.005266 |

| Alloy Components: C Em (empty) | <ss> | Alpha | |||

| <ss> | 1 | (−0.5000 −0.5000 −0.5000) | = | −0.713542 | 0.00565 |

| <ss> | 2 | (−1.0000 −0.0000 −0.0000) | = | −0.715278 | 0.011676 |

| <ss> | 3 | (−1.0000 −1.0000 −0.0000) | = | −0.710938 | −0.00339 |

| <ss> | 4 | (−1.5000 −0.5000 −0.5000) | = | −0.711806 | −0.000377 |

| <ss> | 5 | (−1.0000 −1.0000 −1.0000) | = | −0.710938 | −0.00339 |

| <ss> | 6 | (−2.0000 0.0000 0.0000) | = | −0.713542 | 0.00565 |

| <ss> | 7 | (−1.5000 −1.5000 −0.5000) | = | −0.708333 | −0.012429 |

| <ss> | 8 | (−2.0000 −1.0000 0.0000) | = | −0.715278 | 0.011676 |

References

- Li, S.; Xie, Y.; Wu, X. Hardness and toughness investigations of deep cryogenic treated cold work die steel. Cryogenics 2010, 50, 89–92. [Google Scholar] [CrossRef]

- Yuan, L.; Ponge, D.; Wittig, J.; Choi, P.; Jiménez, J.; Raabe, D. Nanoscale austenite reversion through partitioning, segregation and kinetic freezing: Example of a ductile 2 GPa Fe–Cr–C steel. Acta Mater. 2012, 60, 2790–2804. [Google Scholar] [CrossRef] [Green Version]

- Seo, E.; Cooman, B.C.D. Quenching and Partitioning (Q&P) Processing of AISI 420 Stainless Steel. In Proceedings of the 8th Pacific Rim International Congress on Advanced Materials and Processing; Springer International Publishing: Cham, Switzerland, 2013; Volume 1. [Google Scholar] [CrossRef]

- Tobata, J.; Ngo-Huynh, K.L.; Nakada, N.; Tsuchiyama, T.; Takaki, S. Role of silicon in quenching and partitioning treatment of lowcarbon martensitic stainless steel. ISIJ Int. 2012, 52, 1377–1382. [Google Scholar] [CrossRef] [Green Version]

- Tamura, M.; Kumagai, T.; Sakai, K.; Shinozuka, K.; Esaka, H. A new approach to improve creep resistance of high Cr martensitic steel. J. Nucl. Mater. 2011, 417, 29–32. [Google Scholar] [CrossRef]

- Plesiutschnig, E.; Beal, C.; Sommitsch, C.; Paul, S.; Zeiler, G. Ferritic phase transformation to improve creep properties of martensitic high Cr steels. Scr. Mater. 2016, 122, 98–101. [Google Scholar] [CrossRef]

- Robson, J.D.; Bhadeshia, H.K.D.H. Modelling precipitation sequences in power plant steels Part 1—Kinetic theory. Mater. Sci. Technol. 1997, 13, 631–639. [Google Scholar] [CrossRef]

- Robson, J.D.; Bhadeshia, H.K.D.H. Modelling precipitation sequences in powerplant steels Part 2—Application of kinetic theory. Mater. Sci. Technol. 1997, 13, 640–644. [Google Scholar] [CrossRef]

- Schneider, A.; Inden, G. Simulation of the kinetics of precipitation reactions in ferritic steels. Acta Mater. 2005, 53, 519–531. [Google Scholar] [CrossRef]

- Hou, Z.; Babu, R.P.; Hedström, P.; Odqvist, J. Early stages of cementite precipitation during tempering of 1C–1Cr martensitic steel. J. Mater. Sci. 2019, 54, 9222–9234. [Google Scholar] [CrossRef] [Green Version]

- Kurdjumow, G.; Sachs, G. Über den Mechanismus der Stahlhärtung. Z. Phys. 1930, 64, 325–343. [Google Scholar] [CrossRef]

- Easterling, K.; Thölén, A. The nucleation of martensite in steel. Acta Metall. 1976, 24, 333–341. [Google Scholar] [CrossRef]

- Kitahara, H.; Ueji, R.; Tsuji, N.; Minamino, Y. Crystallographic features of lath martensite in low-carbon steel. Acta Mater. 2006, 54, 1279–1288. [Google Scholar] [CrossRef]

- Strangwood, M. Fundamentals of ferrite formation in steels. In Phase Transformations in Steels; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar] [CrossRef]

- Kral, M.V. Proeutectoid Ferrite and Cementite Transformations in Steels; Woodhead Publishing Limited: Sawston, UK, 2012; Volume 1. [Google Scholar] [CrossRef]

- García de Andrés, C.; Caruana, G.; Alvarez, L. Control of M23C6 carbides in 0.45C–13Cr martensitic stainless steel by means of three representative heat treatment parameters. Mater. Sci. Eng. A 1998, 241, 211–215. [Google Scholar] [CrossRef]

- Barlow, L.D.; Du Toit, M. Effect of Austenitizing Heat Treatment on the Microstructure and Hardness of Martensitic Stainless Steel AISI 420. J. Mater. Eng. Perform. 2012, 21, 1327–1336. [Google Scholar] [CrossRef]

- Schmidtseifer, N.; Weber, S. Microstructural Changes During Short-Term Heat Treatment of Martensitic Stainless Steel—Simulation and Experimental Verification. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2021, 52, 2885–2895. [Google Scholar] [CrossRef]

- Olson, G.; Bhadeshia, H.; Cohen, M. Coupled diffusional/displacive transformations. Acta Metall. 1989, 37, 381–390. [Google Scholar] [CrossRef]

- Plesiutschnig, E.; Paul, S.; Schider, S.; Gamsjäger, E. Martensitic/Ferritic Phase Transformation of Modern Power Plant Steels. 2014. Available online: https://youtu.be/aKM_EsZBLl8 (accessed on 29 December 2015).

- Speer, J.; Matlock, D.K.; De Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Edmonds, D.; He, K.; Rizzo, F.; De Cooman, B.; Matlock, D.; Speer, J. Quenching and partitioning martensite—A novel steel heat treatment. Mater. Sci. Eng. A 2006, 438–440, 25–34. [Google Scholar] [CrossRef]

- Bouville, M.; Ahluwalia, R. Interplay between Diffusive and Displacive Phase Transformations: Time-Temperature-Transformation Diagrams and Microstructures. Phys. Rev. Lett. 2006, 97, 055701. [Google Scholar] [CrossRef] [Green Version]

- Bhadeshia, H.K. Cementite. Int. Mater. Rev. 2020, 65, 1–27. [Google Scholar] [CrossRef] [Green Version]

- Razumovskiy, V.; Ghosh, G. A first-principles study of cementite (Fe3C) and its alloyed counterparts: Structural properties, stability, and electronic structure. Comput. Mater. Sci. 2015, 110, 169–181. [Google Scholar] [CrossRef] [Green Version]

- Korzhavyi, P.A.; Ruban, A.V.; Odqvist, J.; Nilsson, J.O.; Johansson, B. Electronic structure and effective chemical and magnetic exchange interactions in bcc Fe-Cr alloys. Phys. Rev. B 2009, 79, 054202. [Google Scholar] [CrossRef]

- Ruban, A.V.; Razumovskiy, V.I. First-principles based thermodynamic model of phase equilibria in bcc Fe-Cr alloys. Phys. Rev. B 2012, 86, 174111. [Google Scholar] [CrossRef]

- Thermo Fisher Scientific Inc. EDS Elemental Analysis. 2014. Available online: https://www.thermofisher.com/at/en/home/materials-science/elemental-analysis.html (accessed on 30 June 2021).

- Gatan Inc. GIF Continuuum and Continuum S. 2014. Available online: https://www.gatan.com/products/tem-imaging-spectroscopy/gif-continuum-and-continuum-s (accessed on 30 June 2021).

- Schell, N.; King, A.; Beckmann, F.; Fischer, T.; Müller, M.; Schreyer, A. The High Energy Materials Science Beamline (HEMS) at PETRA III. Mater. Sci. Forum 2013, 772, 57–61. [Google Scholar] [CrossRef] [Green Version]

- Canelo-Yubero, D.; Requena, G.; Sket, F.; Poletti, C.; Warchomicka, F.; Daniels, J.; Schell, N.; Stark, A. Load partition and microstructural evolution during in situ hot deformation of Ti–6Al–6V–2Sn alloys. Mater. Sci. Eng. A 2016, 657, 244–258. [Google Scholar] [CrossRef] [Green Version]

- TAInstruments. DIL 805A/D Dilatometer. 2016. Available online: http://www.tainstruments.com/dil-805adt-quenching-dilatomers/ (accessed on 30 June 2021).

- Raue, L. Input4MAUD: An efficient program for automatic two-dimensional diffraction image series input and/or batch refinement with MAUD. J. Appl. Crystallogr. 2014, 47, 2081–2085. [Google Scholar] [CrossRef]

- Lutterotti, L.; Matthies, S.; Wenk, H.R.; Schultz, A.S.; Richardson, J.W. Combined texture and structure analysis of deformed limestone from time-of-flight neutron diffraction spectra. J. Appl. Phys. 1997, 81, 594–600. [Google Scholar] [CrossRef]

- Williamson, G.K.; Smallman, R.E., III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos. Mag. 1956, 1, 34–46. [Google Scholar] [CrossRef]

- Blöchl, P.E. Projector augmented-wave method. Phys. Rev. B 1994, 50, 17953–17979. [Google Scholar] [CrossRef] [Green Version]

- Kresse, G.; Joubert, D. From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 1999, 59, 1758–1775. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 1996, 6, 15–50. [Google Scholar] [CrossRef]

- Kresse, G.; Furthmüller, J. Efficient Iterative Schemes for Ab Initio Total-Energy Calculations Using a Plane-Wave Basis Set. Phys. Rev. B 1996, 54, 11169. [Google Scholar] [CrossRef] [PubMed]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1997, 78, 1396. [Google Scholar] [CrossRef] [Green Version]

- Monkhorst, H.J.; Pack, J.D. Special points for Brillouin-zone integrations. Phys. Rev. B 1976, 13, 5188. [Google Scholar] [CrossRef]

- Moruzzi, V.L.; Janak, J.F.; Schwarz, K. Calculated thermal properties of metals. Phys. Rev. B 1988, 37, 790–799. [Google Scholar] [CrossRef]

- Momma, K.; Izumi, F. VESTA 3 for three-dimensional visualization of crystal, volumetric and morphology data. J. Appl. Crystallogr. 2011, 44, 1272–1276. [Google Scholar] [CrossRef]

- Bhadeshia, H.; Wayman, C. Phase Transformations. In Physical Metallurgy; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar] [CrossRef]

- Bhadeshia, H.; Honeycombe, R. Steels: Microstructure and Properties, 3rd ed.; Elsevier Ltd.: Oxford, UK, 2006. [Google Scholar] [CrossRef]

- Rosemann, P.; Kauss, N.; Müller, C.; Halle, T. Influence of solution annealing temperature and cooling medium on microstructure, hardness and corrosion resistance of martensitic stainless steel X46Cr13. Mater. Corros. 2015, 66, 1068–1076. [Google Scholar] [CrossRef]

- Candelária, A.F.; Pinedo, C.E. Influence of the heat treatment on the corrosion resistance of the martensitic stainless steel type AISI 420. J. Mater. Sci. Lett. 2003, 22, 1151–1153. [Google Scholar] [CrossRef]

- Aghajani, A.; Somsen, C.; Eggeler, G. On the effect of long-term creep on the microstructure of a 12% chromium tempered martensite ferritic steel. Acta Mater. 2009, 57, 5093–5106. [Google Scholar] [CrossRef]

- Bale, C.; Bélisle, E.; Chartrand, P.; Decterov, S.; Eriksson, G.; Gheribi, A.; Hack, K.; Jung, I.H.; Kang, Y.B.; Melançon, J.; et al. FactSage thermochemical software and databases, 2010–2016. Calphad 2016, 54, 35–53. [Google Scholar] [CrossRef] [Green Version]

| Composition | Lattice | |||||||

|---|---|---|---|---|---|---|---|---|

| [at%] | Parameters | [kJmol] | [kJmol] | |||||

| # | Fe | Cr | C | a | b | c | ||

| Nominal | 84 | 14 | 1 | - | - | - | - | - |

| Matrix | 0 | 2.87 | 2.87 | 2.87 | 5.5 | −2 | ||

| Cloud 2 | 2.87 | 2.87 | 2.87 | 16.6 | 0.8 | |||

| Cloud 1 | 2.87 | 2.87 | 2.87 | 2.3 | −6.2 | |||

| MC core | 0 | 5.09 | 6.74 | 4.52 | −10.4 | - | ||

| MC core | 0 | 5.19 | 6.74 | 4.52 | −10.4 | - | ||

| (theory) | −7.3 [25] | |||||||

| Matrix | - | - | - | 2.84 [26] | 2.84 | 2.84 | −10.4 | - |

| (theory) | - | - | - | 2.83 [25] | 2.83 | 2.83 | 395.6 [27] | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Plesiutschnig, E.; Albu, M.; Canelo-Yubero, D.; Razumovskiy, V.I.; Stark, A.; Schell, N.; Kothleitner, G.; Beal, C.; Sommitsch, C.; Hofer, F. An In Situ Synchrotron Dilatometry and Atomistic Study of Martensite and Carbide Formation during Partitioning and Tempering. Materials 2021, 14, 3849. https://doi.org/10.3390/ma14143849

Plesiutschnig E, Albu M, Canelo-Yubero D, Razumovskiy VI, Stark A, Schell N, Kothleitner G, Beal C, Sommitsch C, Hofer F. An In Situ Synchrotron Dilatometry and Atomistic Study of Martensite and Carbide Formation during Partitioning and Tempering. Materials. 2021; 14(14):3849. https://doi.org/10.3390/ma14143849

Chicago/Turabian StylePlesiutschnig, Ernst, Mihaela Albu, David Canelo-Yubero, Vsevolod I. Razumovskiy, Andreas Stark, Norbert Schell, Gerald Kothleitner, Coline Beal, Christof Sommitsch, and Ferdinand Hofer. 2021. "An In Situ Synchrotron Dilatometry and Atomistic Study of Martensite and Carbide Formation during Partitioning and Tempering" Materials 14, no. 14: 3849. https://doi.org/10.3390/ma14143849

APA StylePlesiutschnig, E., Albu, M., Canelo-Yubero, D., Razumovskiy, V. I., Stark, A., Schell, N., Kothleitner, G., Beal, C., Sommitsch, C., & Hofer, F. (2021). An In Situ Synchrotron Dilatometry and Atomistic Study of Martensite and Carbide Formation during Partitioning and Tempering. Materials, 14(14), 3849. https://doi.org/10.3390/ma14143849