Study on the Time-Dependent Mechanical Behavior and Springback of Magnesium Alloy Sheet (AZ31B) in Warm Conditions

Abstract

1. Introduction

2. Materials and Methods

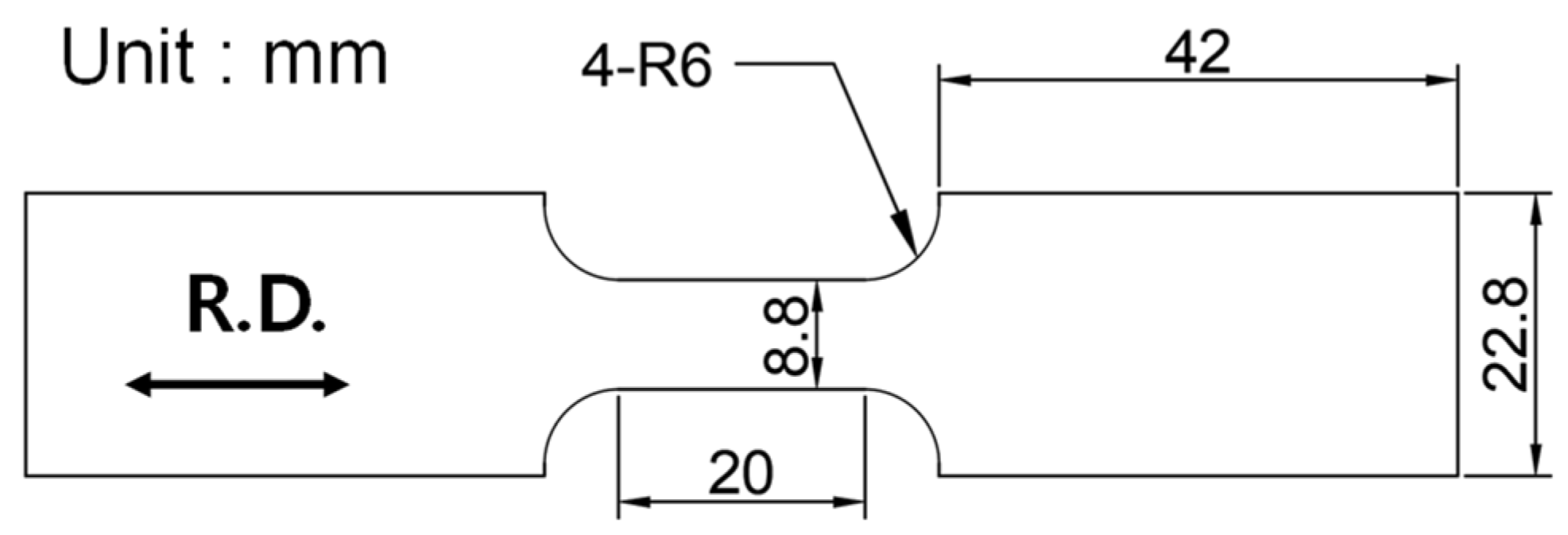

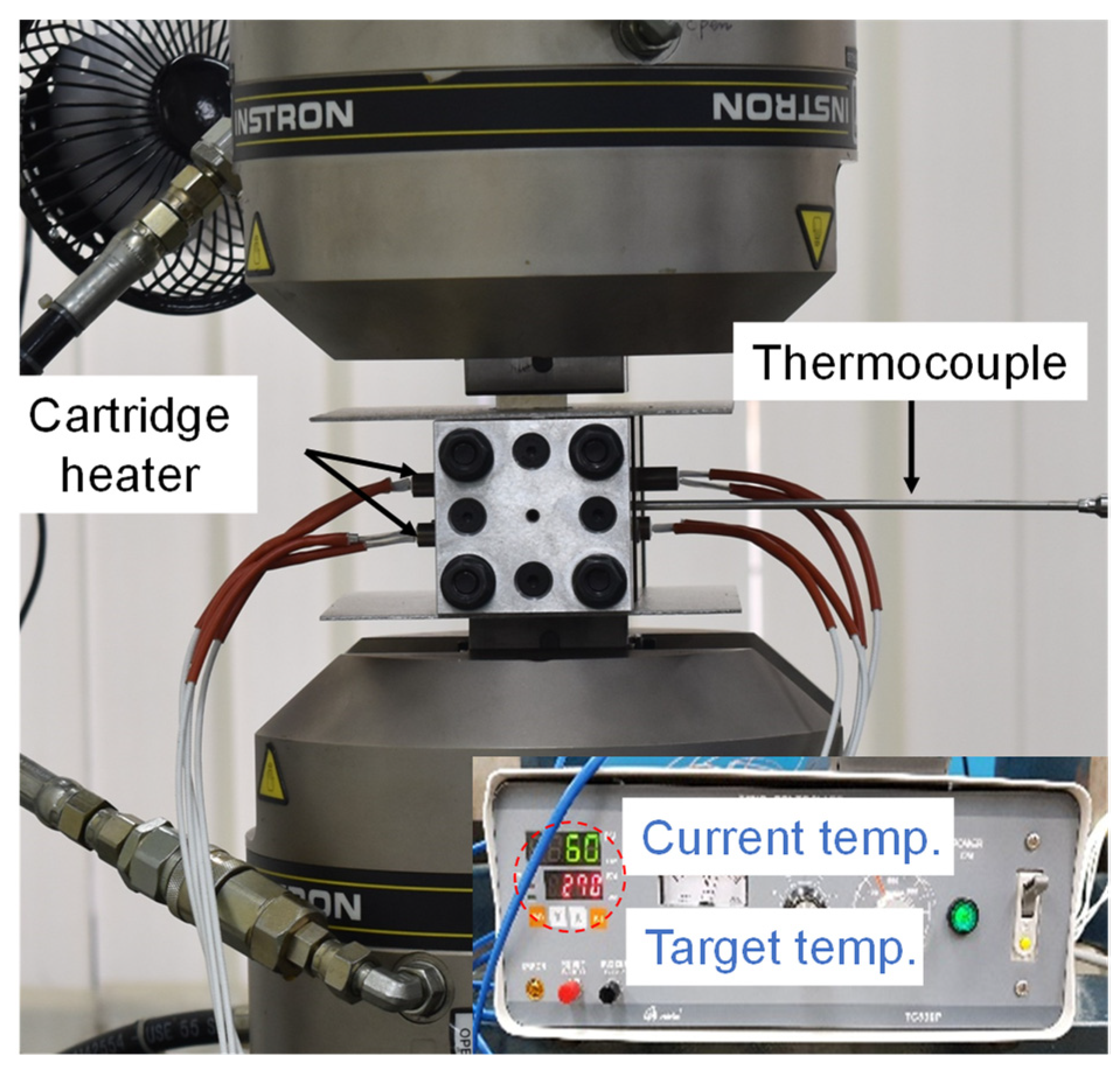

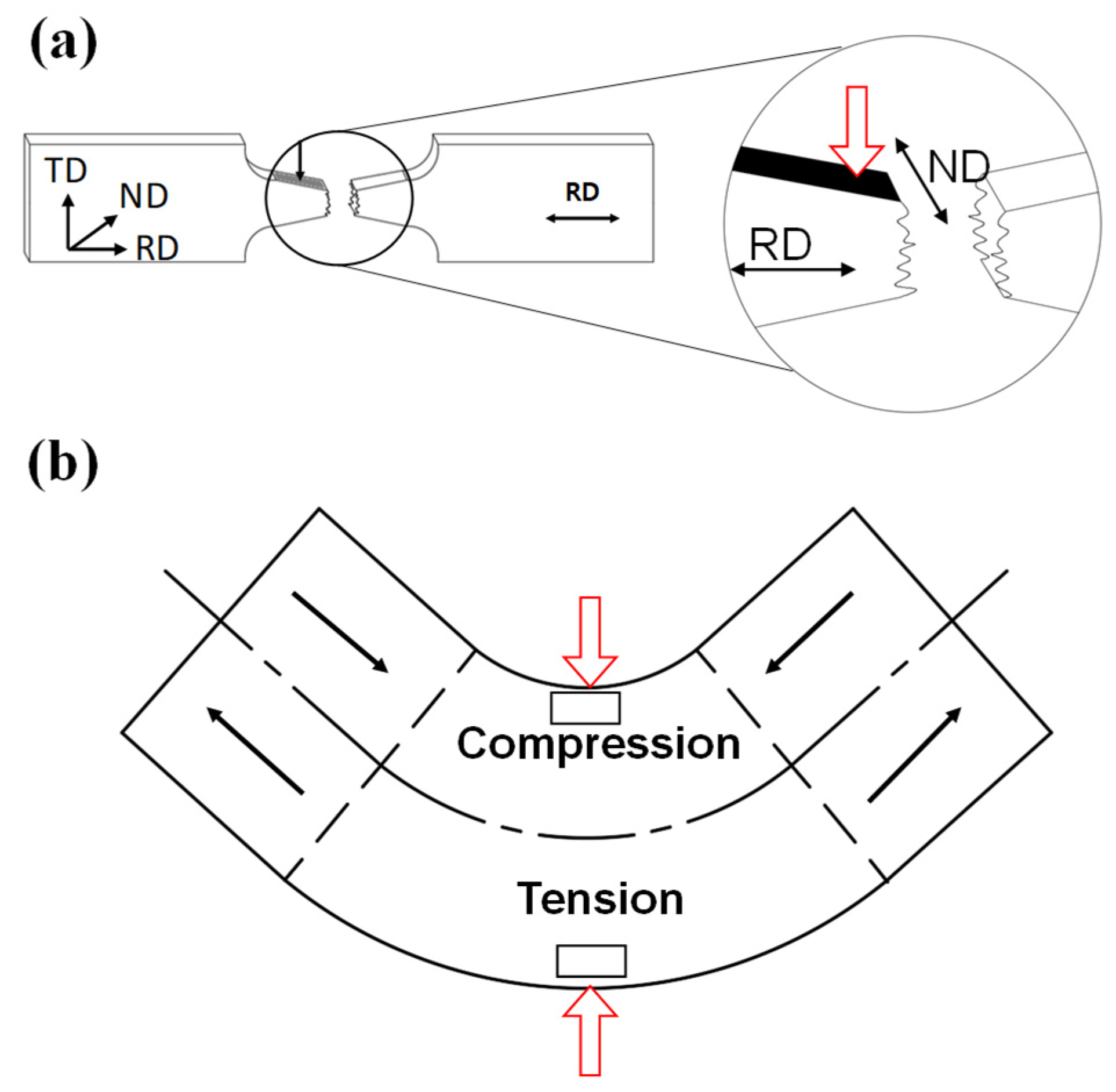

2.1. Uniaxial Tensile Test

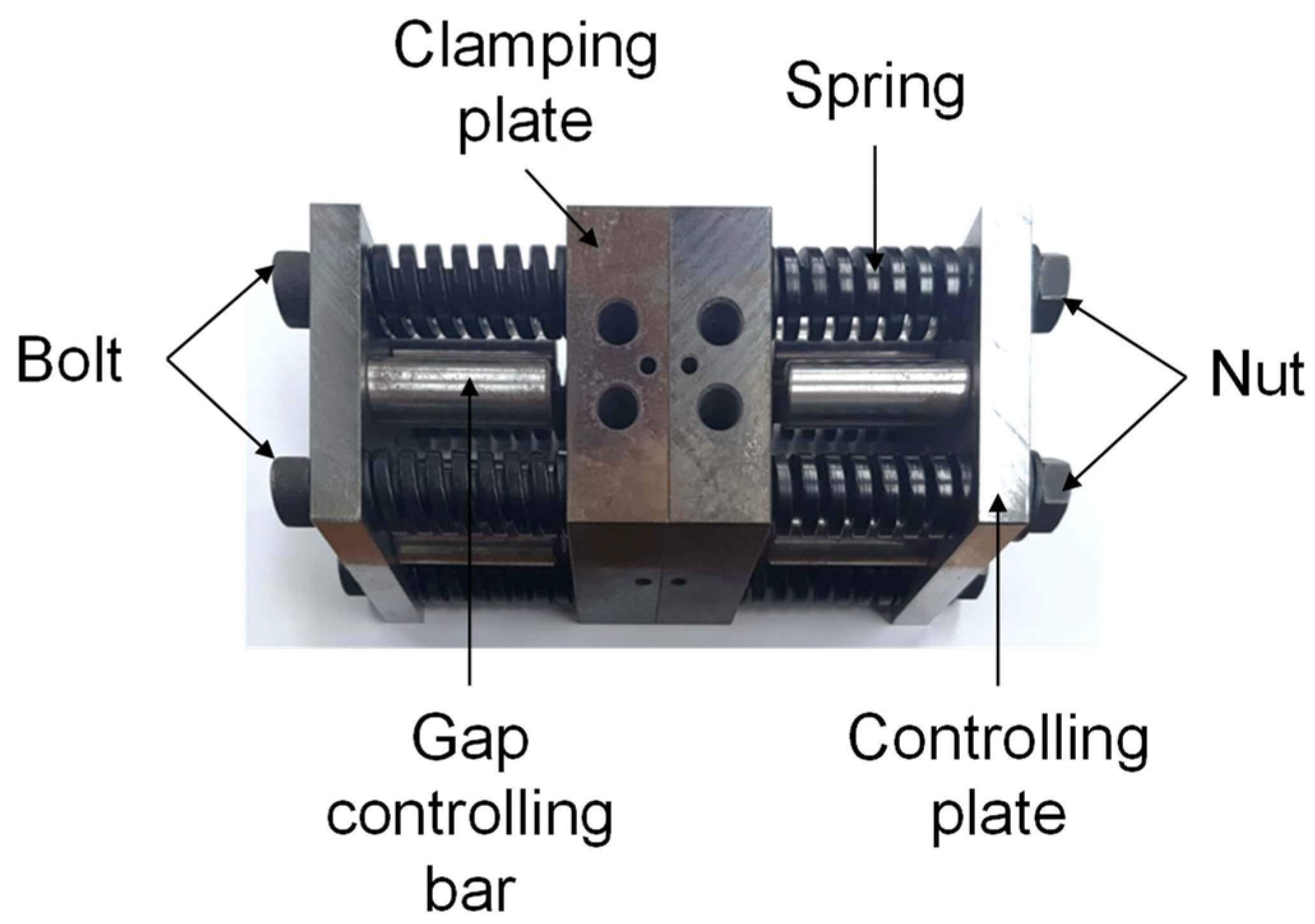

2.2. Creep and Stress Relaxation Experiment

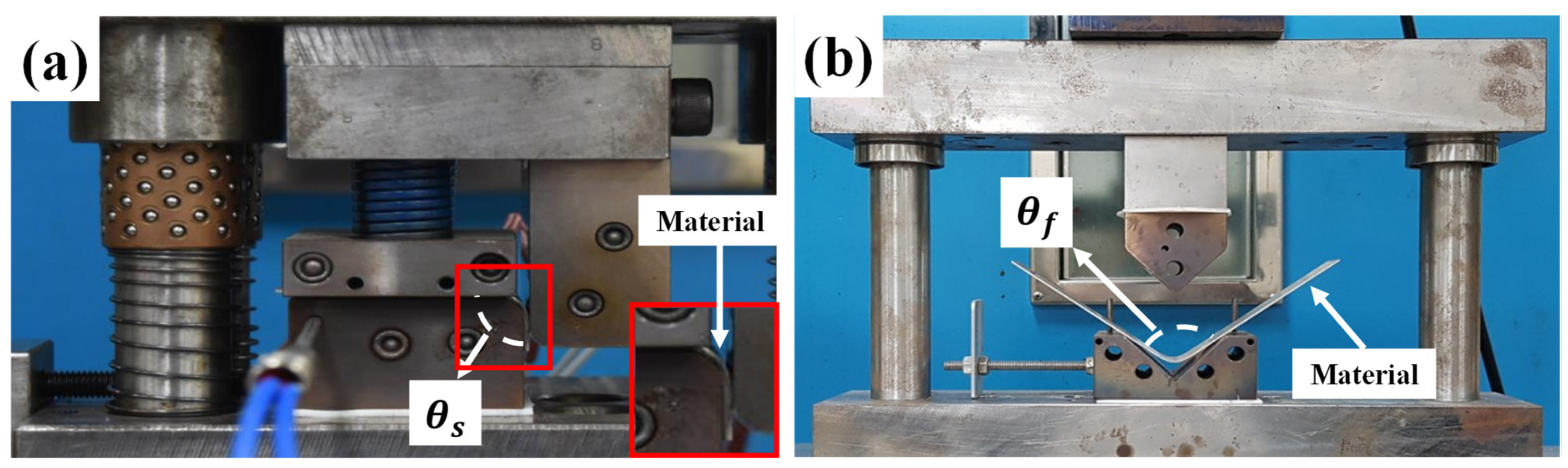

2.3. L-Bending and V-Bending Experiments

2.4. Microstructure Observation

3. Results and Discussion

3.1. Tensile and Creep Experiment

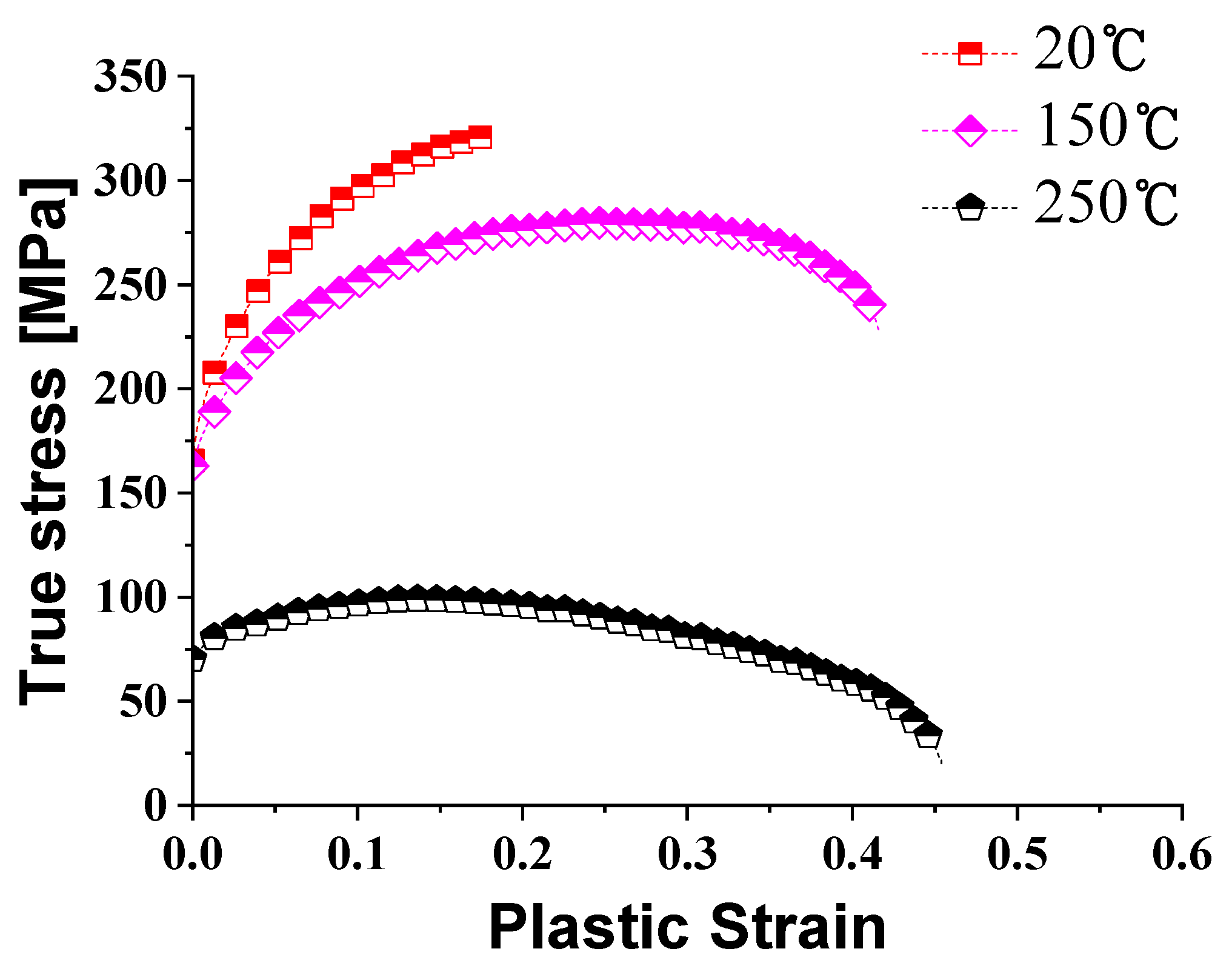

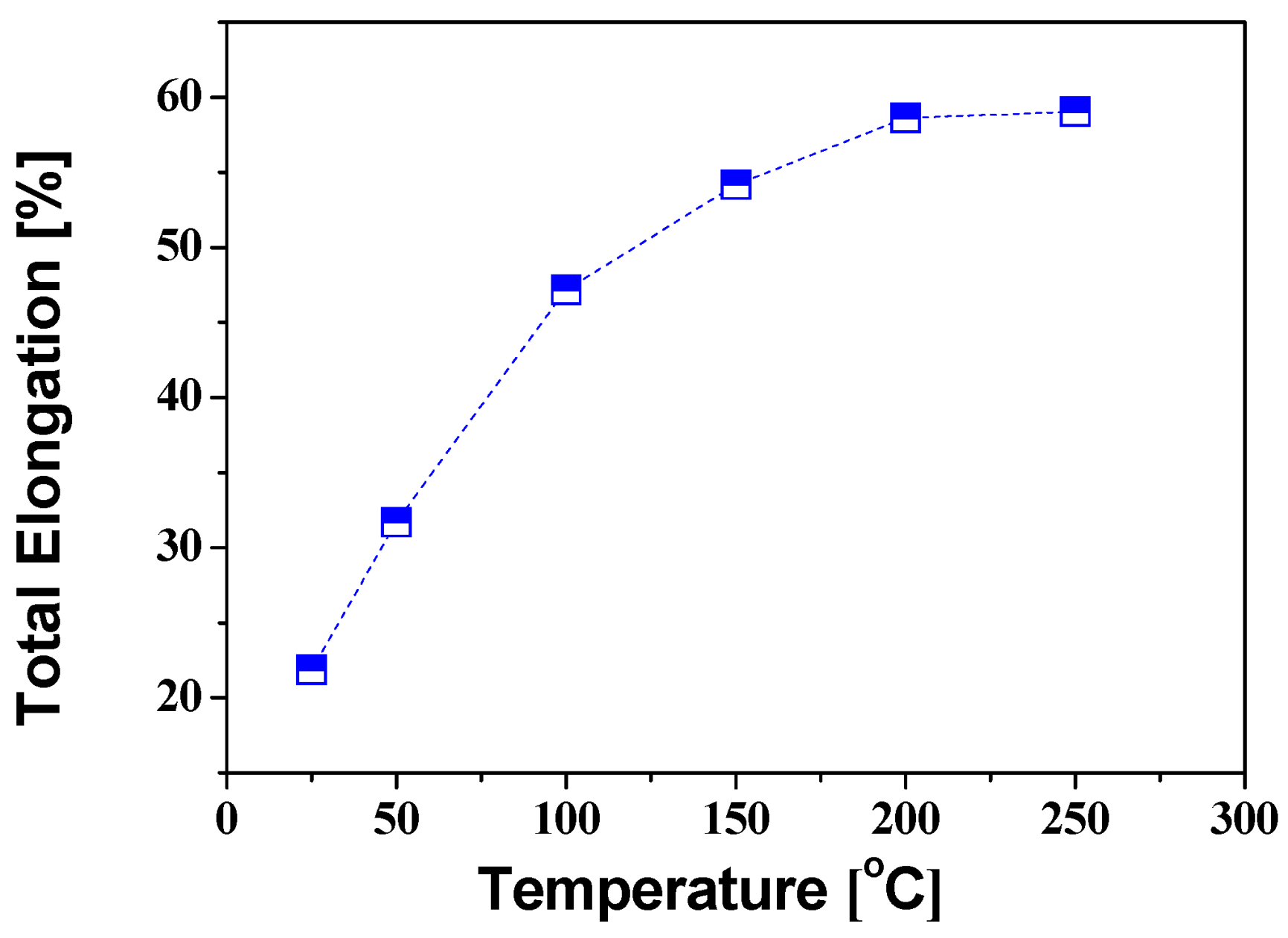

3.1.1. Uniaxial Tensile Test Results with Respect to Forming Temperature

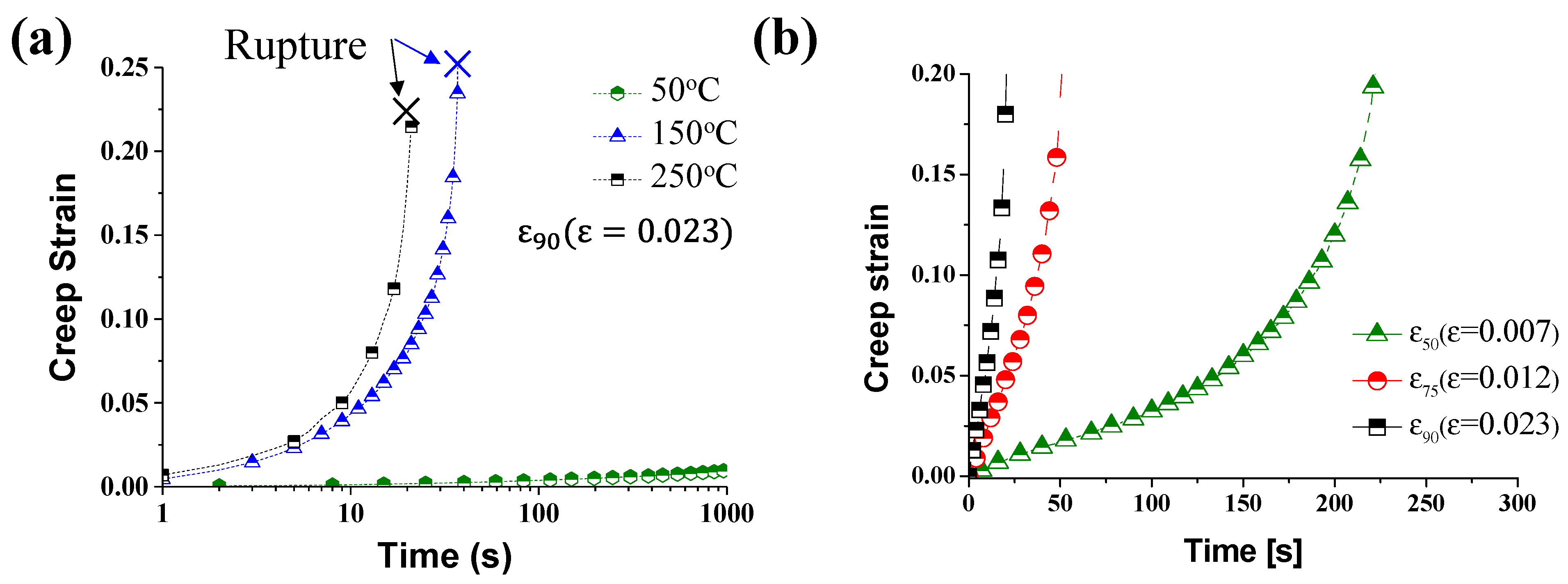

3.1.2. The Creep Behavior with Various Pre-Strain and Forming Temperature

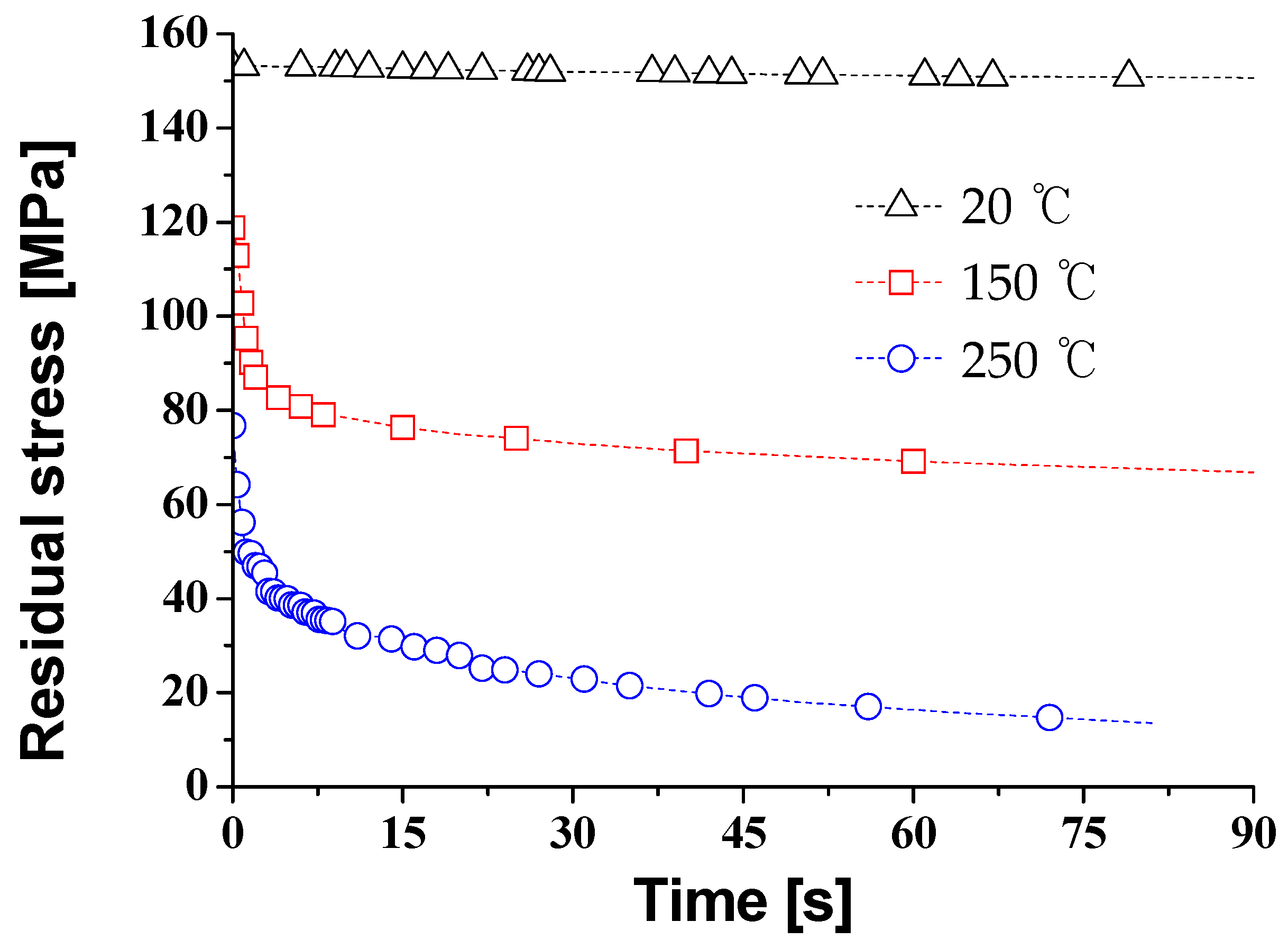

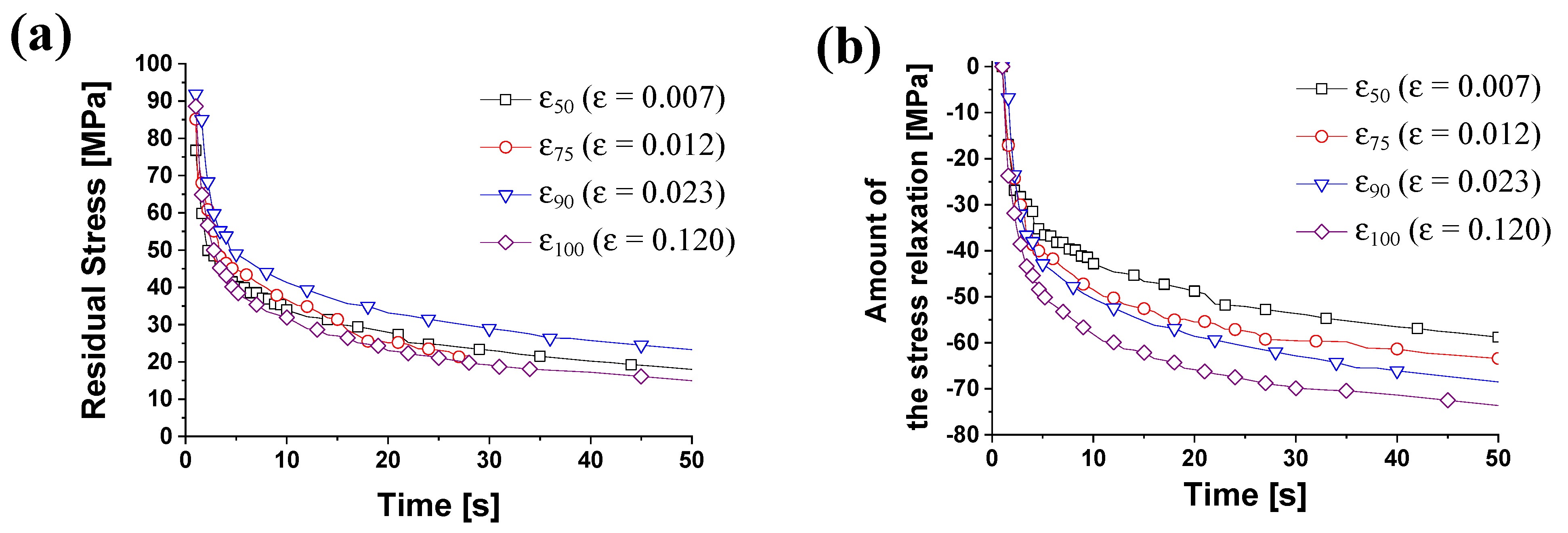

3.1.3. The Stress Relaxation Behavior with Various Pre-Strains and Forming Temperatures

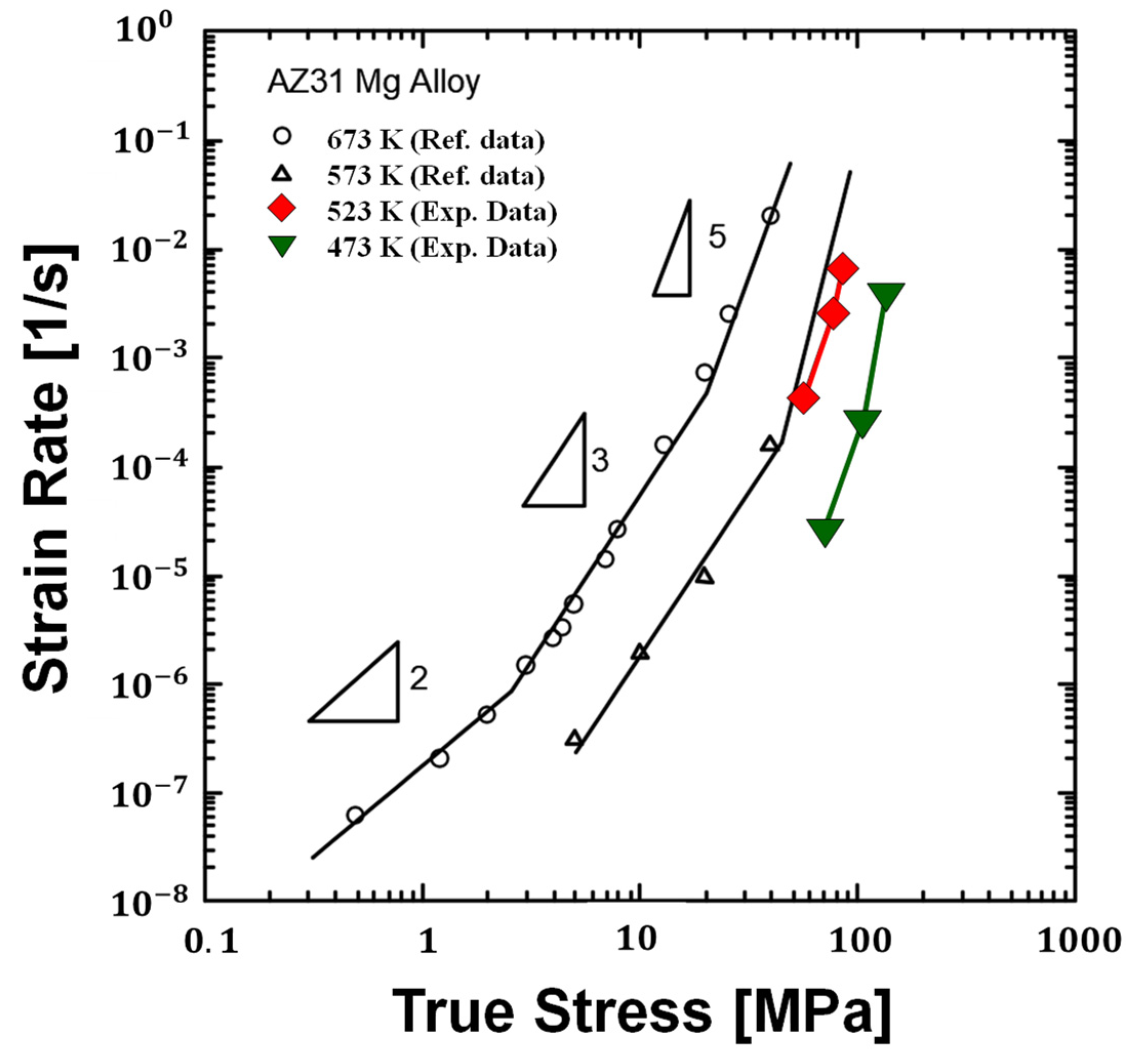

3.1.4. Stress Exponent of Creep Strain

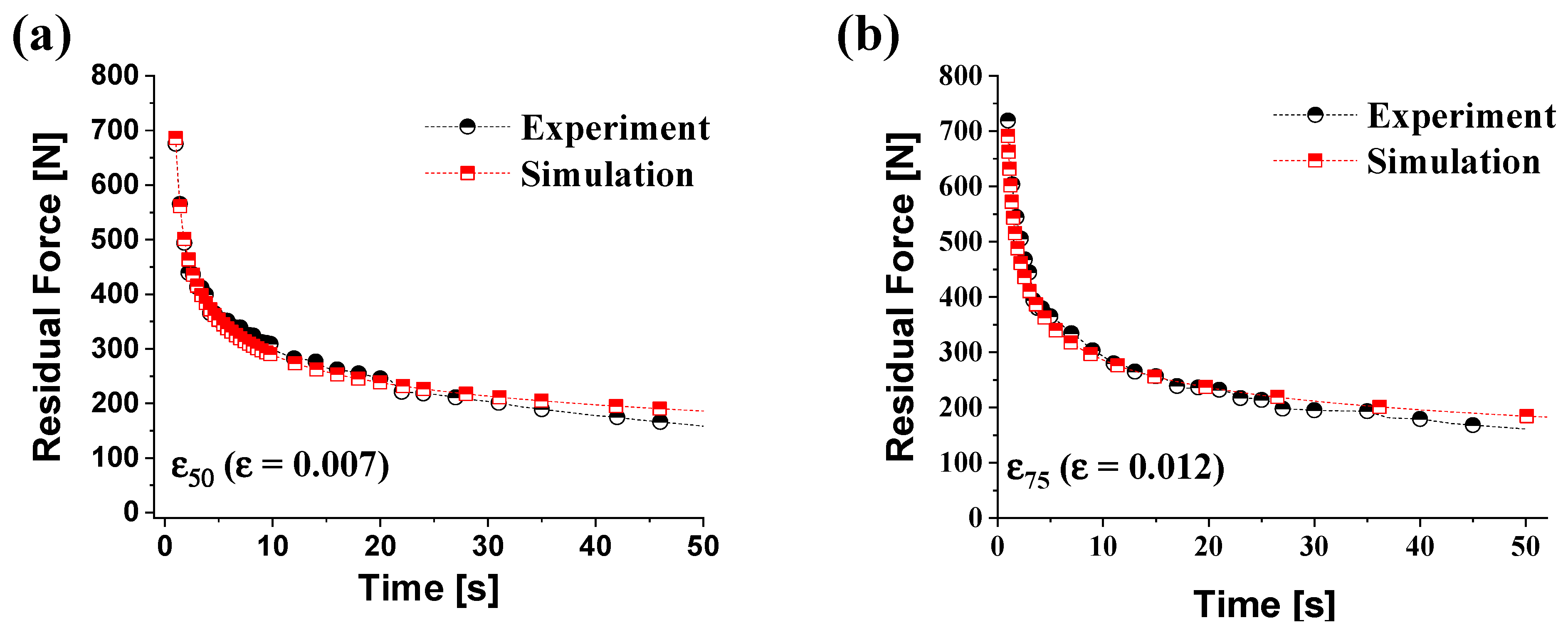

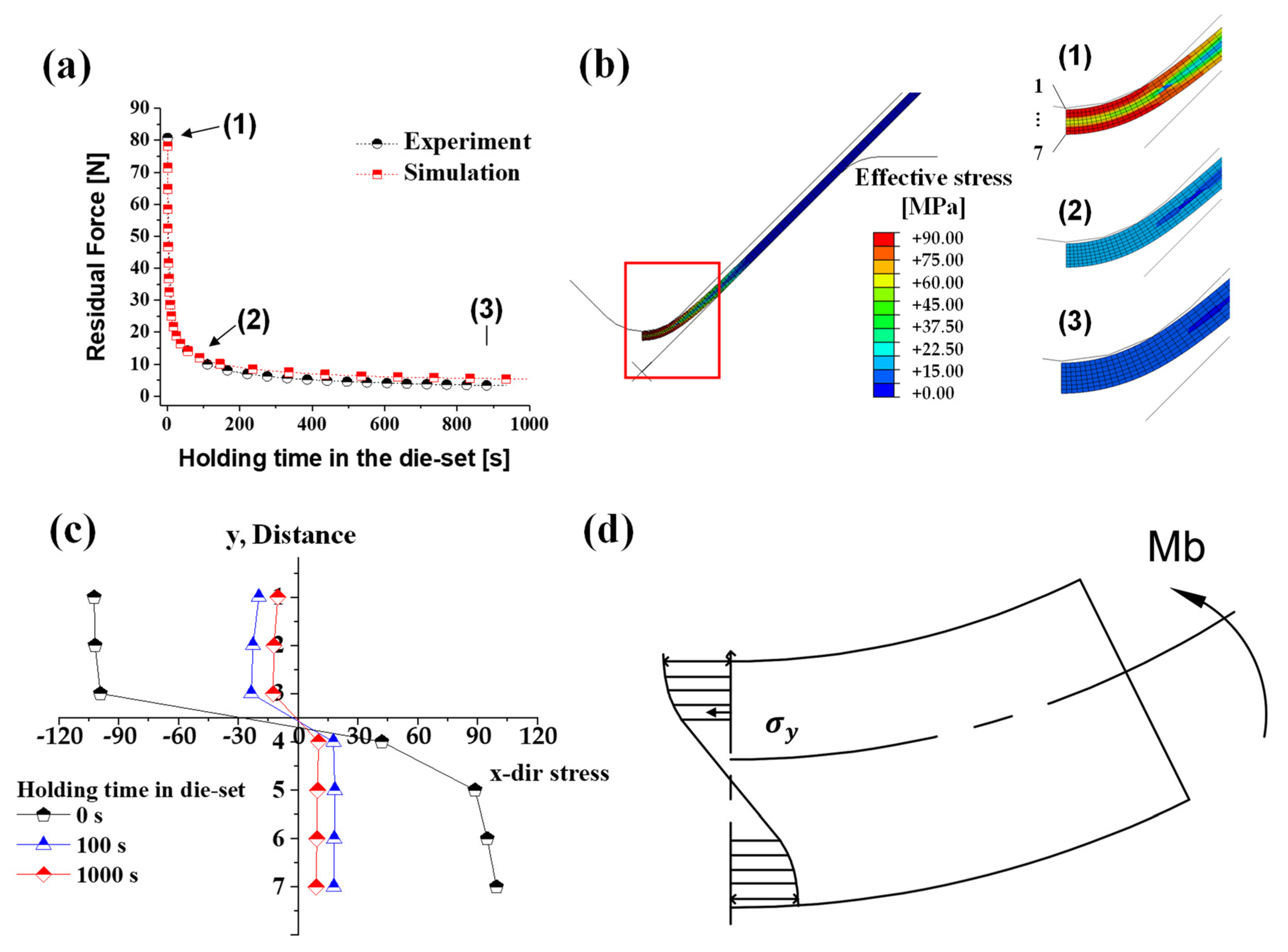

3.1.5. Validation of Creep Parameters Using Finite Element Simulation

3.2. Time-Dependent Springback in Bending Deformation

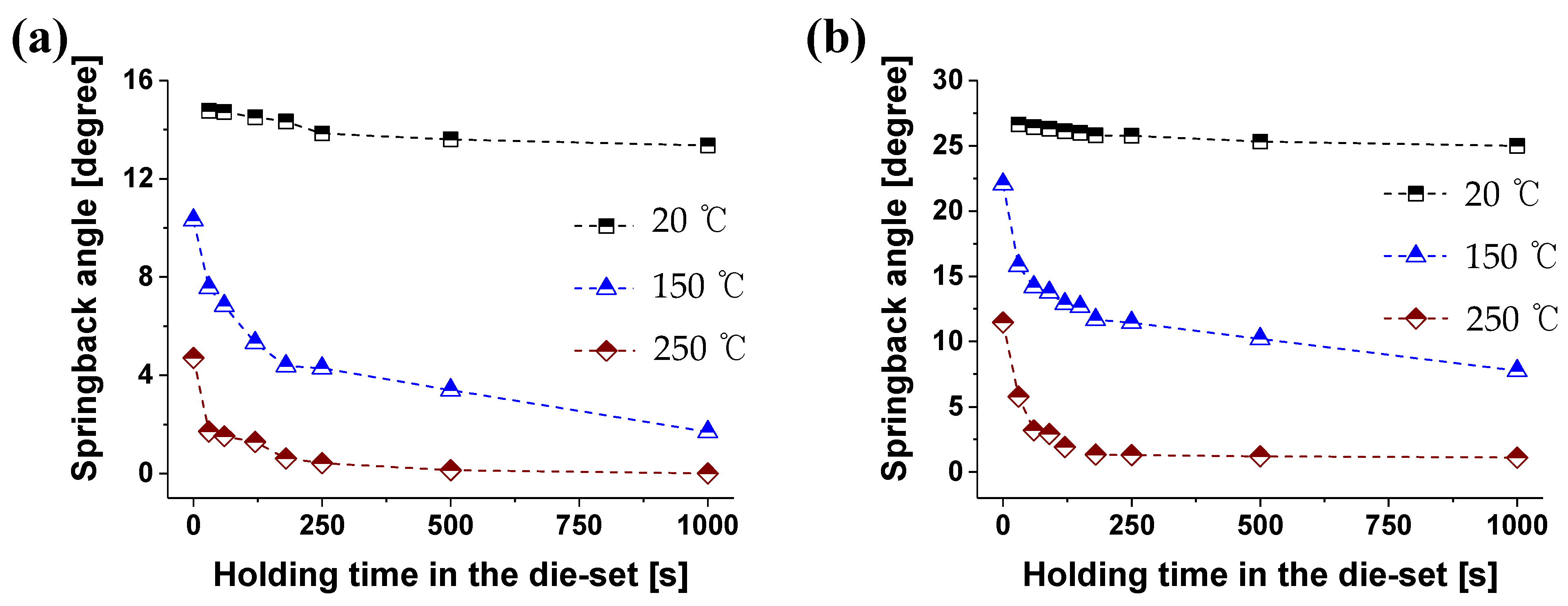

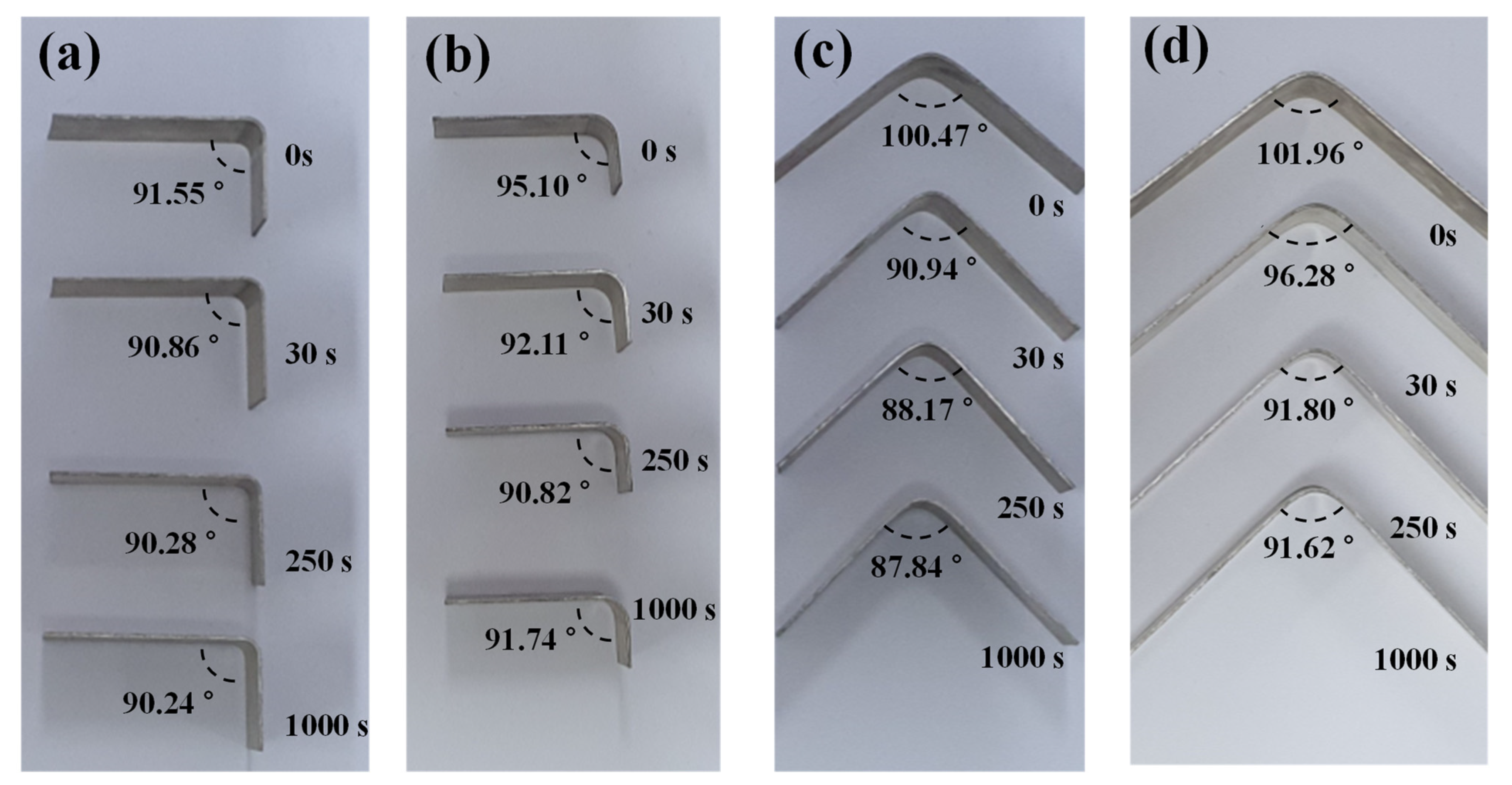

3.2.1. Time-Dependent Springback with Different Temperature

3.2.2. Time-Dependent Springback with Different Stress Levels

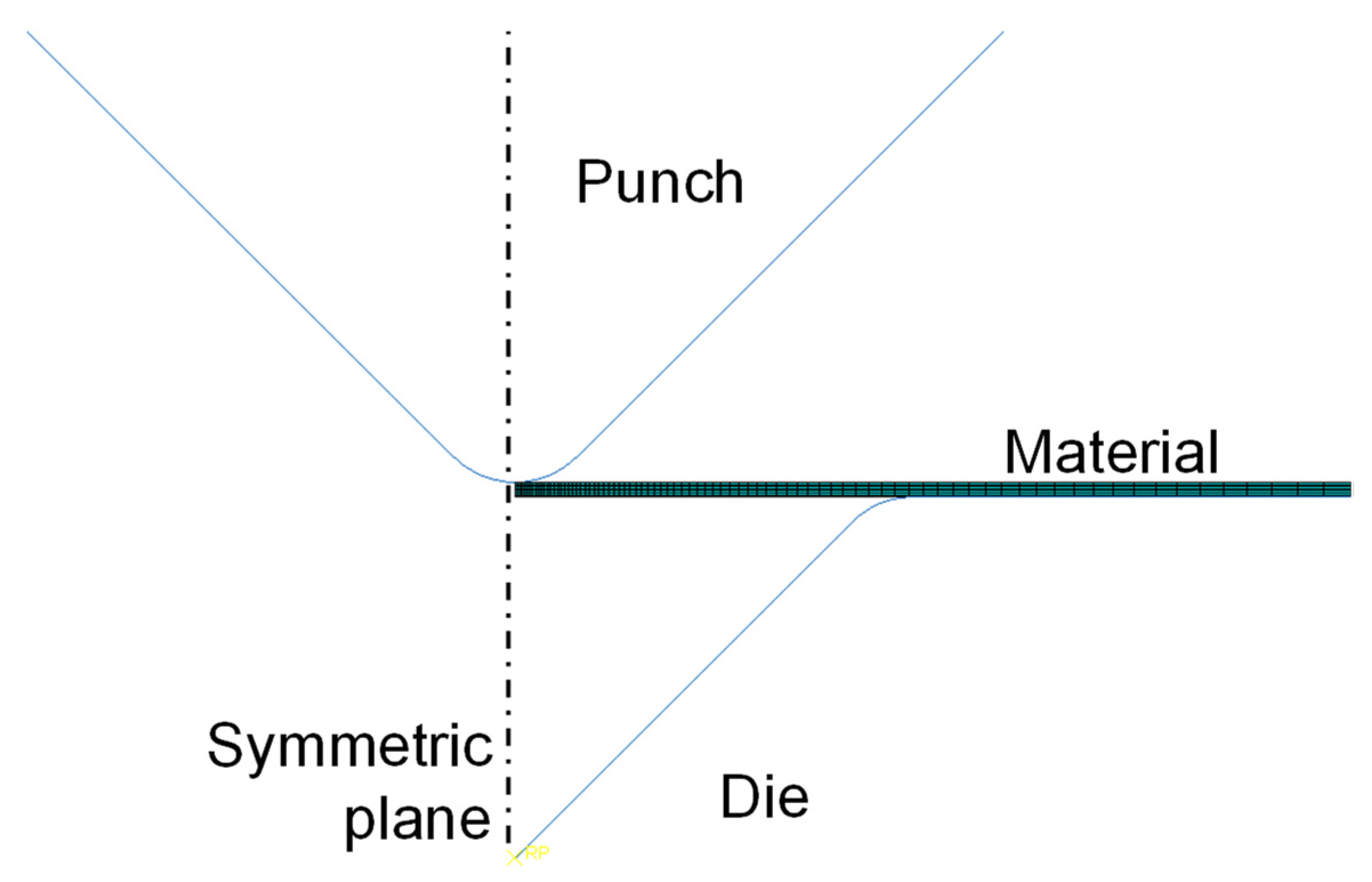

3.2.3. FE Modeling

3.2.4. Simulation Results of the Bending Process

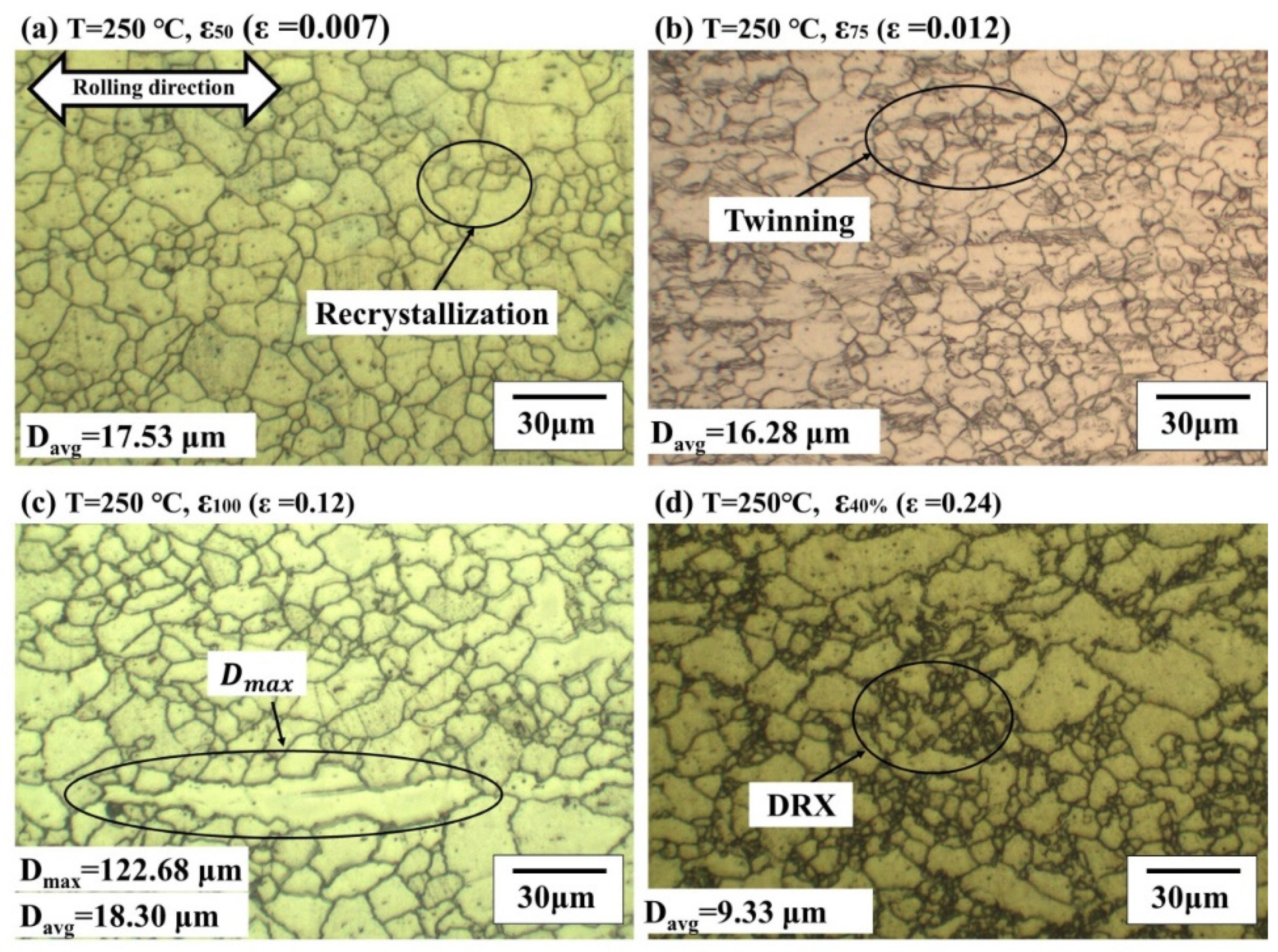

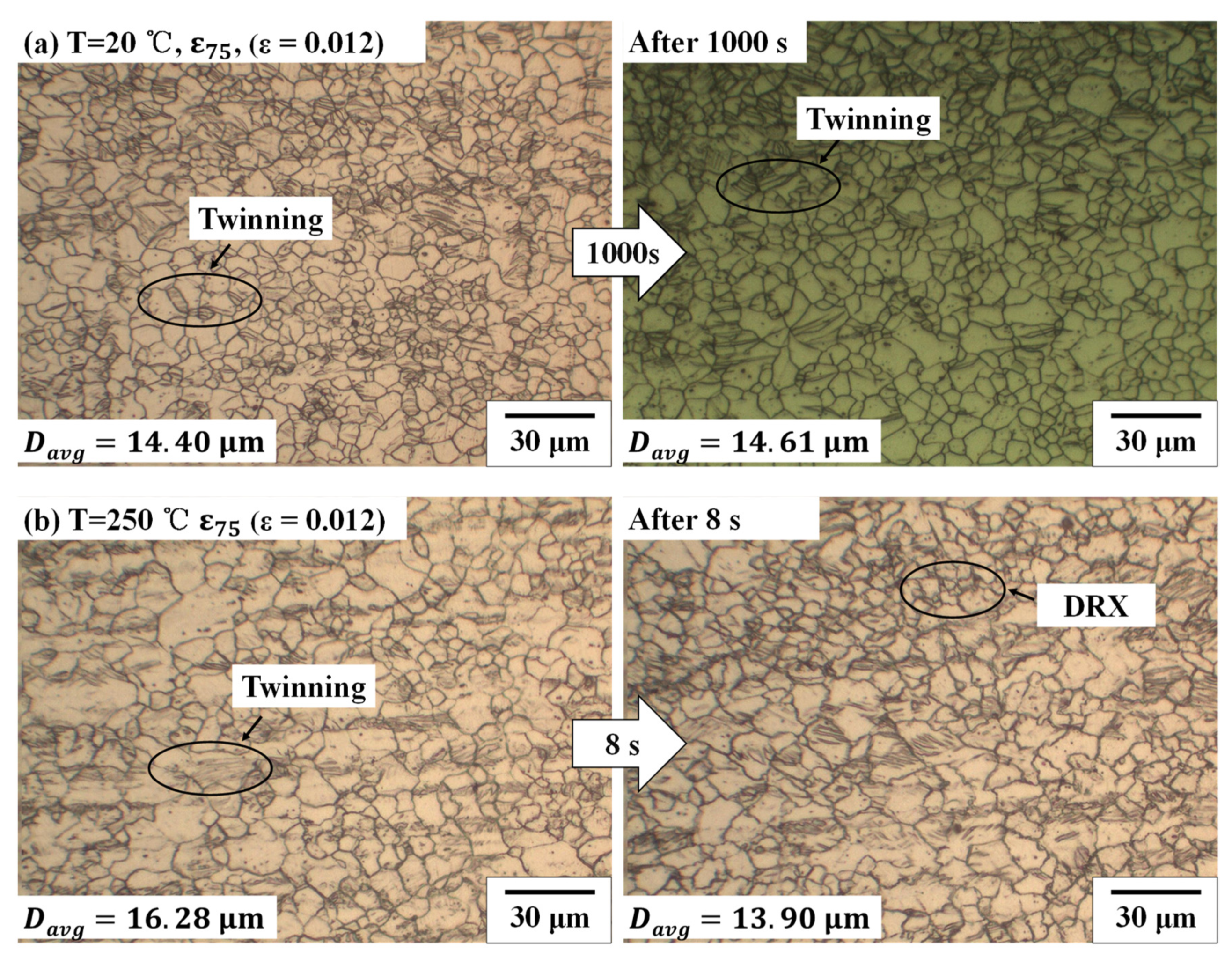

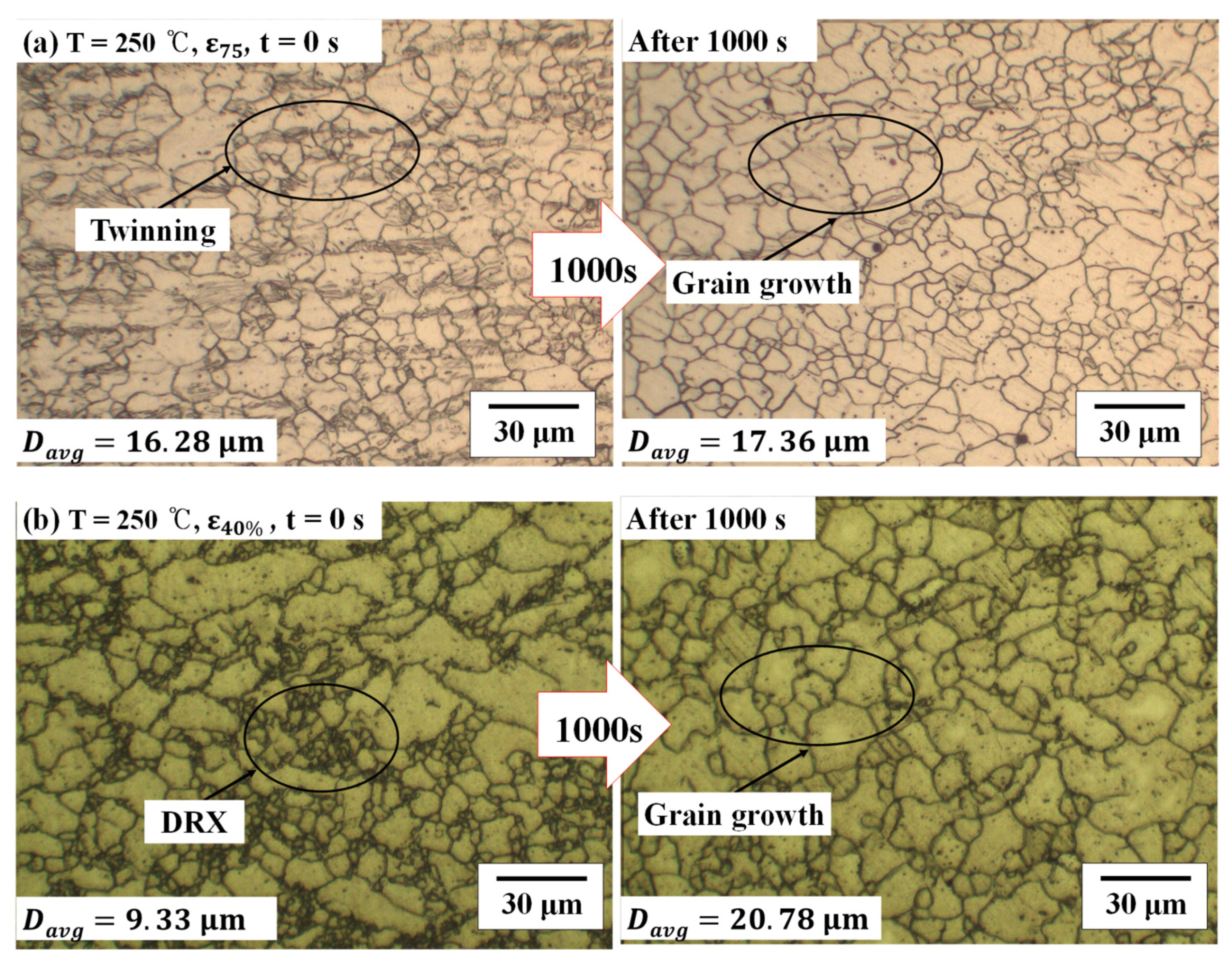

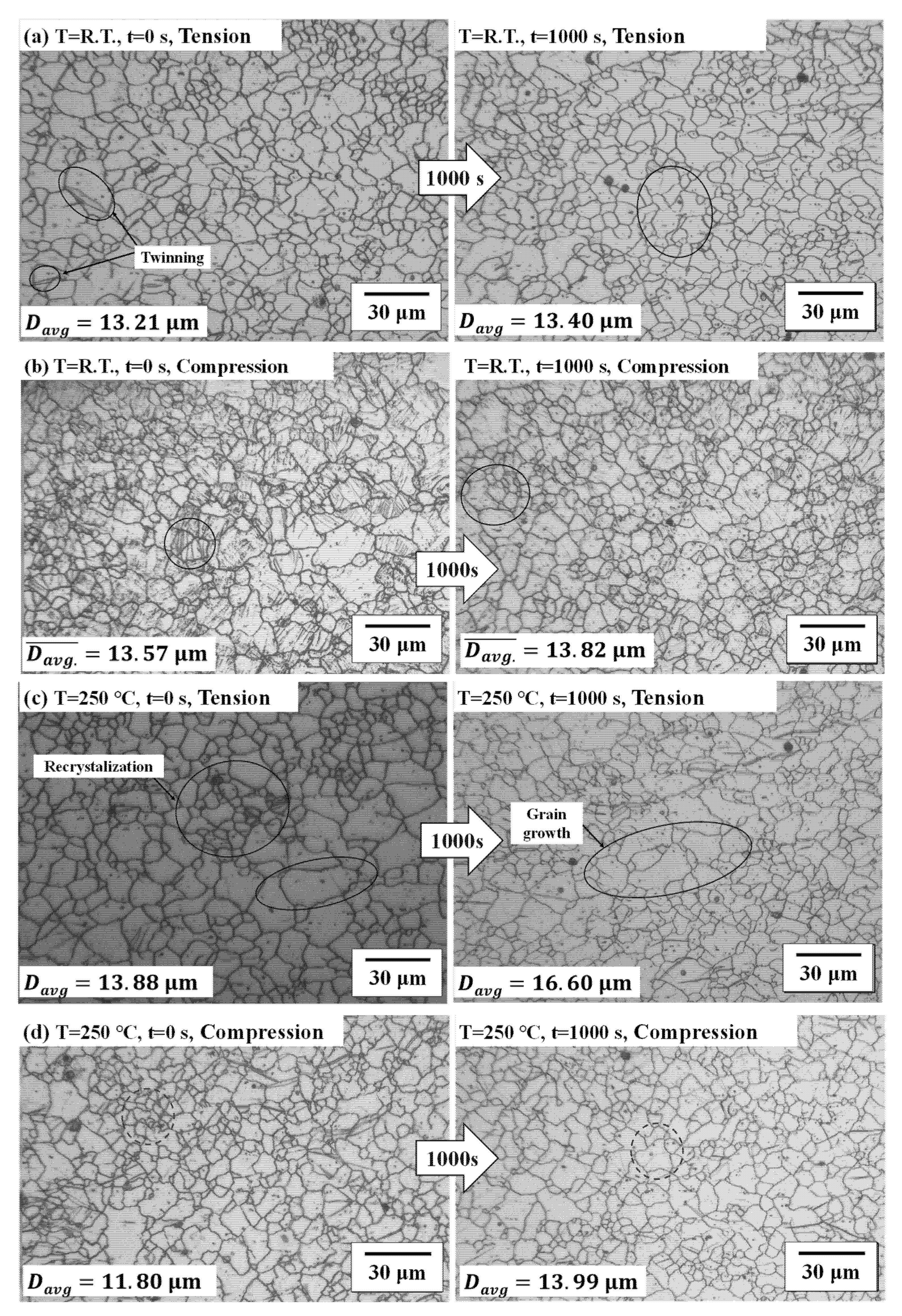

3.2.5. Microstructure Change in the Bending Deformation with Respect to Time

4. Conclusions

- The magnesium alloy sheet has a lower resistance to creep and stress relaxation as the forming temperature increases. It is confirmed that the resistance is lowered due to static and dynamic recrystallization due to temperature and deformation.

- In the creep test, the time to rupture was shortened to 339 s at 100 °C and 21 s at 250 °C at pre-strain of ε90. At the same forming temperature of 250 °C, the time to rupture was shortened to 226 s at ε50 and 21 s at ε90.

- In the stress relaxation test, at the same pre-strain ε75, the load reduction was 5% at room temperature and 73% at 250 °C. In addition, the load relaxation time was 900 s at 150 °C and 19 s at 250 °C. The higher the forming temperature, the shorter the load relaxation time. It can be seen that as the forming temperature increases, the internal stress decreases due to recrystallization and the rate of stress released is also fast.

- In the stress relaxation test at the same pre-strain (ε75), the residual force at constant holding time 0 s and 250 °C is 76.7 MPa and the residual force is 20.7 MPa after a holding time 1000 s at 250 °C. It was reduced by 73% based on the initial load. On the other hand, at the same pre-strain and at room temperature, the residual force at a constant holding time of 0 s is 152.3 MPa and the residual force is 144.9 MPa after a holding time of 1000 s at room temperature. It was reduced by 5% based on the initial load. In addition, under the same forming temperature (250 °C) condition, the initial load was reduced by 69% and 74% at pre-strain ε50 and ε90, respectively. As the pre-strain increases, the rate of stress relaxation is faster.

- In the warm V-bending, the springback reduction according to the forming temperature was reduced by 59% from 28.11° at room temperature to 11.46° at 250 °C. Springback reduction according to the holding time of the material in the die at 250 °C was 11.46° at 0 s, 1.12° at 1000 s, with a 90% reduction compared to the initial angle. This shows that the amount of springback decrease due to the increase in the holding time of the material in the die is greater than the amount of springback decrease due to the temperature of the material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fernández, A.; Pérez Prado, M.T.; Wei, Y.; Jérusalem, A. Continuum modeling of the response of a Mg alloy AZ31 rolled sheet during uniaxial deformation. Int. J. Plast. 2011, 27, 1739–1757. [Google Scholar] [CrossRef]

- Neugebauer, R.; Altan, T.; Geiger, M.; Kleiner, M.; Sterzing, A. Sheet metal forming at elevated temperatures. CIRP Ann. 2006, 55, 793–816. [Google Scholar] [CrossRef]

- Wang, L.; Huang, G.; Zhang, H.; Wang, Y.; Yin, L. Evolution of springback and neutral layer of AZ31B magnesium alloy V-bending under warm forming conditions. J. Mater. Process. Technol. 2013, 213, 844–850. [Google Scholar] [CrossRef]

- Reddy, A.; Rajesham, S.; Reddy, P. Experimental and simulation study on the warm deep drawing of AZ31 alloy. Adv. Prod. Eng. Manag. 2015, 10, 153. [Google Scholar] [CrossRef]

- Kim, H.-K.; Kim, W.-J. Creep behavior of AZ31 magnesium alloy in low temperature range between 423 K and 473 K. J. Mater. Sci. 2007, 42, 6171–6176. [Google Scholar] [CrossRef]

- Kang, D.M.; An, J.O.; Jeon, S.H.; Koo, Y.; Sim, S.B. Prediction of Creep Deformation and Short Time Rupture Life of AZ31 Magnesium Alloy below 0.5 T m. Trans. Mater. Process. 2008, 17, 558–563. [Google Scholar]

- Li, B.; McClelland, Z.; Horstemeyer, S.J.; Aslam, I.; Wang, P.T.; Horstemeyer, M.F. Time dependent springback of a magnesium alloy. Mater. Des. 2015, 66, 575–580. [Google Scholar] [CrossRef]

- Yu, J.; Lee, C.-W. Analysis of Springback Characteristics of Magnesium Alloy Sheet (AZ31B) Considering Time-Dependence in Warm Bending. J. Korean Soc. Precis. Eng. 2020, 37, 201–207. [Google Scholar] [CrossRef]

- Sun, S.; Daxin, E. The investigation of time-dependent springback for AC170PX aluminum alloy at room temperature. Mater. Des. 2016, 93, 118–127. [Google Scholar] [CrossRef]

- Lim, H.; Lee, M.G.; Sung, J.H.; Kim, J.H.; Wagoner, R.H. Time-dependent springback of advanced high strength steels. Int. J. Plast. 2012, 29, 42–59. [Google Scholar] [CrossRef]

- Lim, H.; Lee, M.G.; Sung, J.H.; Wagoner, R.H. Time-dependent springback. Int. J. Mater. Form. 2008, 1, 157–160. [Google Scholar] [CrossRef]

- Xie, H.; Wang, Q.; Liu, K.; Peng, F.; Dong, X.; Wang, J. Investigation of influence of direct-current pulses on springback during V-bending of AZ31B magnesium alloy sheet. J. Mater. Process. Technol. 2015, 219, 321–327. [Google Scholar] [CrossRef]

- Xie, H.; Dong, X.; Peng, F.; Wang, Q.; Liu, K.; Wang, X.; Chen, F. Investigation on the electrically-assisted stress relaxation of AZ31B magnesium alloy sheet. J. Mater. Process. Technol. 2016, 227, 88–95. [Google Scholar] [CrossRef]

- Bae, G.H. A Study on the Tension/Compression Hardening Behavior of Auto-Body Steel Sheets Considering the Pre-Strain and the Strain Rate. Ph.D. Thesis, Korea Advanced Institute of Science and Technology, Daejeon, Korea, 2011. [Google Scholar]

- Kim, H.W.; Yu, J.H.; Lee, C.W. Study on the Deformation Characteristics of AZ31B Sheets in V-bending and Effect of Bottoming Process. Trans. Mater. Process. 2018, 27, 139–144. [Google Scholar]

- Atwell, D.L.; Barnett, M.R.; Hutchinson, W.B. The effect of initial grain size and temperature on the tensile properties of magnesium alloy AZ31 sheet. J. Mater. Sci. Eng. A 2012, 549, 1–6. [Google Scholar] [CrossRef]

- Bruni, C.; Forcellese, A.; Gabrielli, F.; Simoncini, M. Effect of temperature, strain rate and fibre orientation on the plastic flow behaviour and formability of AZ31 magnesium alloy. J. Mater. Process. Technol. 2010, 210, 1354–1363. [Google Scholar] [CrossRef]

- Jäger, A.; Lukáč, P.; Gärtnerová, V.; Bohlen, J.; Kainer, K.U. Tensile properties of hot rolled AZ31 Mg alloy sheets at elevated temperatures. J. Alloy. Compd. 2004, 378, 184–187. [Google Scholar] [CrossRef]

- Jabbari, A.; Sedighi, M.; Jahed, H.; Sommitsch, C. Low cycle fatigue behavior of AZ31B extrusion at elevated temperatures. Int. J. Fatigue 2020, 139, 105803. [Google Scholar] [CrossRef]

- Ulacia, I.; Salisbury, C.P.; Hurtado, I.; Worswick, M.J. Tensile characterization and constitutive modeling of AZ31B magnesium alloy sheet over wide range of strain rates and temperatures. J. Mater. Process. Technol. 2011, 211, 830–839. [Google Scholar] [CrossRef]

- McQueen, H.J. Development of dynamic recrystallization theory. J. Mater. Sci. Eng. A 2004, 387–389, 203–208. [Google Scholar] [CrossRef]

- Choi, S.H.; Shin, E.J.; Seong, B.S. Simulation of deformation twins and deformation texture in an AZ31 Mg alloy under uniaxial compression. Acta Mater. 2007, 55, 4181–4192. [Google Scholar] [CrossRef]

- Tian, S.; Wang, L.; Sohn, K.Y.; Kim, K.H.; Xu, Y.; Hu, Z. Microstructure evolution and deformation features of AZ31 Mg-alloy during creep. Mater. Sci. Eng. A 2006, 415, 309–316. [Google Scholar] [CrossRef]

- Yoon, J.; Cazacu, O.; Lee, J. Construction of Yield Criterion for AZ31 Sheet Alloy by Considering Tension-Compression Asymmetry. Trans. Mater. Process. 2011, 20, 527–533. [Google Scholar] [CrossRef][Green Version]

- Pekguleryuz, M.; Celikin, M. Creep resistance in magnesium alloys. Int. Mater. Rev. 2010, 55, 197–217. [Google Scholar] [CrossRef]

- Chung, C.-S.; Kim, H.-K. Creep Properties of AZ31 Magnesium Alloy at Elevated Temperature. J. Korean Soc. Saf. 2009, 24, 20–26. [Google Scholar]

- Ishikawa, K.; Watanabe, H.; Mukai, T. High temperature compressive properties over a wide range of strain rates in an AZ31 magnesium alloy. J. Mater. Sci. 2005, 40, 1577–1582. [Google Scholar] [CrossRef]

- Khan, A.S.; Pandey, A.; Gnäupel-Herold, T.; Mishra, R.K. Mechanical response and texture evolution of AZ31 alloy at large strains for different strain rates and temperatures. Int. J. Plast. 2011, 27, 688–706. [Google Scholar] [CrossRef]

- Lee, E.-H.; Yoon, J.W.; Yang, D.-Y. Study on springback from thermal-mechanical boundary condition imposed to V-bending and L-bending processes coupled with infrared rays local heating. Int. J. Mater. Form. 2018, 11, 417–433. [Google Scholar] [CrossRef]

| Magnesium (Mg) | Aluminum (Al) | Zinc (Zn) | Manganese (Mn) | Silicon (Si) | Copper (Cu) | Calcium (Ca) | Iron (Fe) | Nickel (Ni) |

|---|---|---|---|---|---|---|---|---|

| 97% | 2.5–3.5% | 0.6–1.4% | 0.2% | 0.1% | 0.05% | 0.04% | 0.005% | 0.005% |

| 50% of UTS (ε50) | 75% of UTS (ε75) | 90% of UTS (ε90) | 100% of UTS (ε100) | e = 40% (ε40%) | |

|---|---|---|---|---|---|

| Pre-strain | 0.007 | 0.012 | 0.023 | 0.120 | 0.240 |

| Applied load (N) | 675.42 | 719.27 | 808.2 | 820.00 | 678.02 |

| The Time of Rupture (s) | 20 °C | 100 °C | 150 °C | 250 °C |

|---|---|---|---|---|

| ε50 (ε = 0.007) | - (Rupture did not occur) | - | - | 226 |

| ε75 (ε = 0.012) | - | - | 269 | 54 |

| ε90 (ε = 0.023) | - | 339 | 38 | 21 |

| Room Temperature | 150 °C | 250 °C | |

|---|---|---|---|

| Stress relaxation time (s) | - | 150 | 19 |

| The amount of the stress relaxation after 30 s (MPa) | 1.4 | 45.9 | 53.9 |

| Pre-Strain | 0.007 | 0.012 | 0.023 | 0.120 |

|---|---|---|---|---|

| Time of stress relaxation (s) | 46 | 26 | 19 | 10 |

| Amount of stress relaxation after 30 s (MPa) | 53.3 | 59.6 | 62.8 | 69.9 |

| Elastic Modulus © (GPa) | Poisson’s Ratio (υ) | Yield Stress (σy) (MPa) | Power Law Multiplier (A) | Stress Exponent (n) |

|---|---|---|---|---|

| 10.40 | 0.30 | 78.63 | 4.46 × 10−12 | 4.80 |

| Amount of Residual Force Reduction (N) | ||||

|---|---|---|---|---|

| Constant Displacement Holding Time | Pre-Strain of ε50 (ε = 0.007) | Pre-Strain of ε75 (ε = 0.012) | ||

| 0 s | 30 s | 0 s | 30 s | |

| Experiment | 675.42 | 205.90 | 719.27 | 195.27 |

| Simulation | 685.95 | 211.49 | 691.30 | 209.97 |

| Error based on experimental results | 1.08% | 2.71% | 3.89% | 7.53% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

YU, J.-H.; Lee, C.-W. Study on the Time-Dependent Mechanical Behavior and Springback of Magnesium Alloy Sheet (AZ31B) in Warm Conditions. Materials 2021, 14, 3856. https://doi.org/10.3390/ma14143856

YU J-H, Lee C-W. Study on the Time-Dependent Mechanical Behavior and Springback of Magnesium Alloy Sheet (AZ31B) in Warm Conditions. Materials. 2021; 14(14):3856. https://doi.org/10.3390/ma14143856

Chicago/Turabian StyleYU, Jae-Hyeong, and Chang-Whan Lee. 2021. "Study on the Time-Dependent Mechanical Behavior and Springback of Magnesium Alloy Sheet (AZ31B) in Warm Conditions" Materials 14, no. 14: 3856. https://doi.org/10.3390/ma14143856

APA StyleYU, J.-H., & Lee, C.-W. (2021). Study on the Time-Dependent Mechanical Behavior and Springback of Magnesium Alloy Sheet (AZ31B) in Warm Conditions. Materials, 14(14), 3856. https://doi.org/10.3390/ma14143856