The Influence of Polymer Composition on the Hydrolytic and Enzymatic Degradation of Polyesters and Their Block Copolymers with PDMAEMA

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Hydrolytic Degradation

2.3. Enzymatic Degradation

3. Characterization

3.1. Nuclear Magnetic Resonance (1H NMR)

3.2. Size Exclusion Chromatography (SEC)

4. Results and Discussion

4.1. Polymer Characterization before Degradation

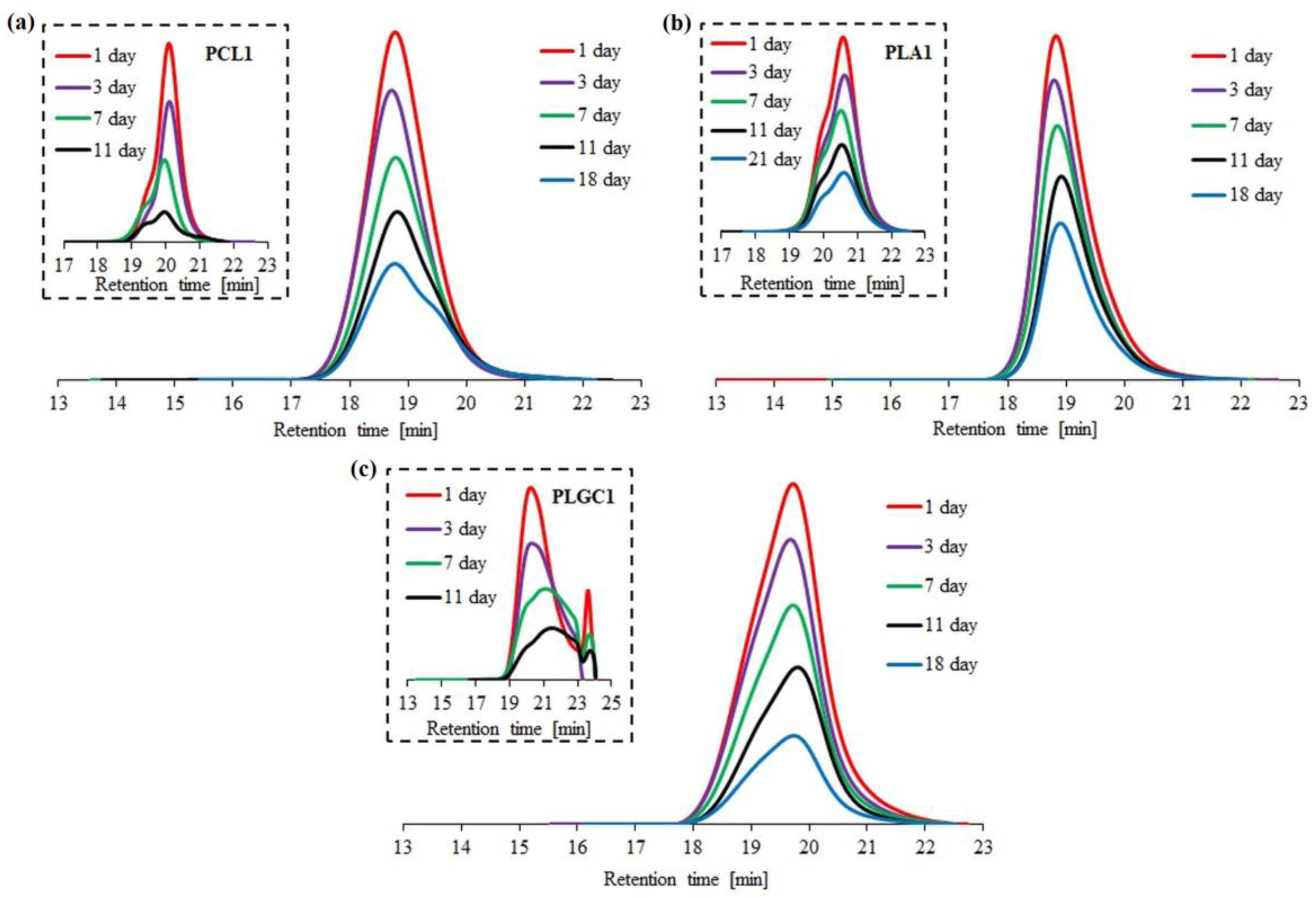

4.2. Hydrolytic Degradation

4.3. Enzymatic Degradation

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Namazi, H. Polymers in our daily life. BioImpacts 2017, 7, 73–74. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ilyas, M.; Ahmad, W.; Khan, H.; Yousaf, S.; Khan, K.; Nazir, S. Plastic waste as a significant threat to environment—A systematic literature review. Rev. Environ. Health 2018, 33, 383–406. [Google Scholar] [CrossRef] [PubMed]

- Heidbreder, L.M.; Bablok, I.; Drews, S.; Menzel, C. Tackling the plastic problem: A review on perceptions, behaviors, and interventions. Sci. Total Environ. 2019, 668, 1077–1093. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.-C.; Anseth, K.S. The Biodegradation of Biodegradable Polymeric Biomaterials. In Biomaterials Science; Elsevier: Amsterdam, The Netherlands, 2013; pp. 716–728. ISBN 9780123746269. [Google Scholar]

- Rydz, J.; Sikorska, W.; Kyulavska, M.; Christova, D. Polyester-Based (Bio)degradable Polymers as Environmentally Friendly Materials for Sustainable Development. Int. J. Mol. Sci. 2014, 16, 564–596. [Google Scholar] [CrossRef] [Green Version]

- McKeen, L.W. Environmentally Friendly Polymers. In Permeability Properties of Plastics and Elastomers; Elsevier: Amsterdam, The Netherlands, 2017; pp. 305–323. [Google Scholar]

- Lakshmi, S.N.; Cato, T.L. Biodegradable polymers as biomaterials. Prog. Polym. Sci. 2007, 32, 762–798. [Google Scholar] [CrossRef]

- Schindler, A.; Jeffcoat, R.; Kimmel, G.L.; Pitt, C.G.; Wall, M.E.; Zweidinger, R. Biodegradable Polymers for Sustained Drug Delivery. In Contemporary Topics in Polymer Science; Springer: Boston, MA, USA, 1977; pp. 251–289. [Google Scholar]

- Bartnikowski, M.; Dargaville, T.R.; Ivanovski, S.; Hutmacher, D.W. Degradation mechanisms of polycaprolactone in the context of chemistry, geometry and environment. Prog. Polym. Sci. 2019, 96, 1–20. [Google Scholar] [CrossRef]

- MacDonald, R.T.; McCarthy, S.P.; Gross, R.A. Enzymatic Degradability of Poly(lactide): Effects of Chain Stereochemistry and Material Crystallinity. Macromolecules 1996, 29, 7356–7361. [Google Scholar] [CrossRef]

- Elsawy, M.A.; Kim, K.-H.; Park, J.-W.; Deep, A. Hydrolytic degradation of polylactic acid (PLA) and its composites. Renew. Sustain. Energy Rev. 2017, 79, 1346–1352. [Google Scholar] [CrossRef]

- Kemme, M.; Prokesch, I.; Heinzel-Wieland, R. Comparative study on the enzymatic degradation of poly(lactic-co-glycolic acid) by hydrolytic enzymes based on the colorimetric quantification of glycolic acid. Polym. Test. 2011, 30, 743–748. [Google Scholar] [CrossRef]

- Turek, A.; Kasperczyk, J.; Jelonek, K.; Borecka, A.; Janeczek, H.; Libera, M.; Gruchlik, A.; Dobrzyński, P. Thermal properties and morphology changes in degradation process of poly(L-lactide-co-glycolide) matrices with risperidone. Acta Bioeng. Biomech. 2015, 17, 11–20. [Google Scholar] [CrossRef]

- Jaworska, J.; Kasperczyk, J.; Dobrzyński, P. Degradation Process of Bioresorbable Copolyesters. Microstructure Investigation by NMR and ESI-MS. Macromol. Symp. 2007, 253, 40–46. [Google Scholar] [CrossRef]

- Stefani, M.; Coudane, J.; Vert, M. In vitro ageing and degradation of PEG–PLA diblock copolymer-based nanoparticles. Polym. Degrad. Stab. 2006, 91, 2554–2559. [Google Scholar] [CrossRef]

- Yang, L.; El Ghzaoui, A.; Li, S. In vitro degradation behavior of poly(lactide)–poly(ethylene glycol) block copolymer micelles in aqueous solution. Int. J. Pharm. 2010, 400, 96–103. [Google Scholar] [CrossRef]

- Wang, Z.; Yu, L.; Ding, M.; Tan, H.; Li, J.; Fu, Q. Preparation and rapid degradation of nontoxic biodegradable polyurethanes based on poly(lactic acid)-poly(ethylene glycol)-poly(lactic acid) and l-lysine diisocyanate. Polym. Chem. 2011, 2, 601–607. [Google Scholar] [CrossRef]

- Kunii, R.; Onishi, H.; Machida, Y. Preparation and antitumor characteristics of PLA/(PEG-PPG-PEG) nanoparticles loaded with camptothecin. Eur. J. Pharm. Biopharm. 2007, 67, 9–17. [Google Scholar] [CrossRef]

- Blackwell, C.; Haernvall, K.; Guebitz, G.; Groombridge, M.; Gonzales, D.; Khosravi, E. Enzymatic Degradation of Star Poly(ε-Caprolactone) with Different Central Units. Polymers 2018, 10, 1266. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Tong, D.; Wang, L.; Chen, L.; Yu, N.; Li, Z. A facile strategy for fabricating PCL/PEG block copolymer with excellent enzymatic degradation. Polym. Degrad. Stab. 2017, 140, 64–73. [Google Scholar] [CrossRef]

- Hoque, M.E.; Hutmacher, D.W.; Feng, W.; Li, S.; Huang, M.-H.; Vert, M.; Wong, Y.S. Fabrication using a rapid prototyping system and in vitro characterization of PEG-PCL-PLA scaffolds for tissue engineering. J. Biomater. Sci. Polym. Ed. 2005, 16, 1595–1610. [Google Scholar] [CrossRef] [PubMed]

- Xiong, L.; Jiang, H.W.; Wang, D.Z. Synthesis, characterization and degradation of poly(dl-lactide)-block-polyvinylpyrrolidone-block-poly(dl-lactide) copolymers. J. Polym. Res. 2009, 16, 191–197. [Google Scholar] [CrossRef]

- Kupczak, M.; Mielańczyk, A.; Neugebauer, D. PDMAEMA/polyester miktopolymers: Synthesis via in-out approach, physicochemical characterization and enzymatic degradation. Materials 2021, 14, 1277. [Google Scholar] [CrossRef]

- Larrañaga, A.; Aldazabal, P.; Martin, F.J.; Sarasua, J.R. Hydrolytic degradation and bioactivity of lactide and caprolactone based sponge-like scaffolds loaded with bioactive glass particles. Polym. Degrad. Stab. 2014, 110, 121–128. [Google Scholar] [CrossRef]

- Little, U.; Buchanan, F.; Harkin-Jones, E.; McCaigue, M.; Farrar, D.; Dickson, G. Accelerated degradation behaviour of poly(ε-caprolactone) via melt blending with poly(aspartic acid-co-lactide) (PAL). Polym. Degrad. Stab. 2009, 94, 213–220. [Google Scholar] [CrossRef]

- Mielańczyk, A.; Kupczak, M.; Burek, M.; Mielańczyk, Ł.; Klymenko, O.; Wandzik, I.; Neugebauer, D. Functional (mikto)stars and star-comb copolymers from D-gluconolactone derivative: An efficient route for tuning the architecture and responsiveness to stimuli. Polymer 2018, 146, 331–343. [Google Scholar] [CrossRef]

- Utrata-Wesołek, A.; Trzebicka, B.; Dworak, A. Polimery wrażliwe na bodźce (I). Polimery 2008, 53, 717–724. [Google Scholar]

- Burkersroda, F.; Schedl, L.; Gopferich, A. Why degradable polymers undergo surface erosion or bulk erosion. Biomaterials 2002, 23, 4221–4231. [Google Scholar] [CrossRef]

- Aris, M.; Annuar, M.; Ling, T. Lipase-mediated degradation of poly-ε-caprolactone in toluene: Behavior and its action mechanism. Polym. Degrad. Stab. 2016, 133, 182–191. [Google Scholar] [CrossRef]

- Ciolkowski, M.; Rozanek, M.; Bryszewska, M.; Klajnert, B. The influence of PAMAM dendrimers surface groups on their interaction with porcine pepsin. Biochim. Biophys. Acta 2013, 1834, 1982–1987. [Google Scholar] [CrossRef]

- Rae, J.M.; Jachimska, B. Analysis of dendrimer-protein interactions and their implications on potential applications of dendrimers in nanomedicine. Nanoscale 2021, 13, 2703–2713. [Google Scholar] [CrossRef] [PubMed]

| Polymer | Initiator | DPCL a | DPLA a | DPGA a | Mn,NMR a (g/mol) | Mn,SEC b (g/mol) | Mw/Mn b |

|---|---|---|---|---|---|---|---|

| PCL1 | MTEG | 82 | - | - | 9400 | 11,300 | 1.15 |

| PLA1 | - | 204 | - | 14,700 | 13,400 | 1.17 | |

| PLGC1 | 22 | 125 | 30 | 13,300 | 13,300 | 1.49 | |

| PCL2 | HEBiB | 112 | - | - | 12,800 | 21,100 | 1.38 |

| PLA2 | - | 112 | - | 8100 | 11,200 | 1.24 | |

| PLGC2 | 17 | 94 | 24 | 10,100 | 15,000 | 1.55 |

| Polymer | DPPolyester a/DPDMAEMA b | Fhydrophilic c | Mn,theo d (g/mol) | Mn,SEC e (g/mol) | Mw/Mn e |

|---|---|---|---|---|---|

| 1PCL2-b-PDMAEMA | 112/44 | 0.32 | 19,700 | 32,000 | 1.21 |

| 2PCL2-b-PDMAEMA | 112/40 | 0.26 | 19,100 | 33,000 | 1.24 |

| PLA2-b-PDMAEMA | 112/76 | 0.40 | 20,000 | 26,600 | 1.22 |

| PLGC-b-PDMAEMA | 135/31 | 0.19 | 15,000 | 19,400 | 1.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kupczak, M.; Mielańczyk, A.; Neugebauer, D. The Influence of Polymer Composition on the Hydrolytic and Enzymatic Degradation of Polyesters and Their Block Copolymers with PDMAEMA. Materials 2021, 14, 3636. https://doi.org/10.3390/ma14133636

Kupczak M, Mielańczyk A, Neugebauer D. The Influence of Polymer Composition on the Hydrolytic and Enzymatic Degradation of Polyesters and Their Block Copolymers with PDMAEMA. Materials. 2021; 14(13):3636. https://doi.org/10.3390/ma14133636

Chicago/Turabian StyleKupczak, Maria, Anna Mielańczyk, and Dorota Neugebauer. 2021. "The Influence of Polymer Composition on the Hydrolytic and Enzymatic Degradation of Polyesters and Their Block Copolymers with PDMAEMA" Materials 14, no. 13: 3636. https://doi.org/10.3390/ma14133636

APA StyleKupczak, M., Mielańczyk, A., & Neugebauer, D. (2021). The Influence of Polymer Composition on the Hydrolytic and Enzymatic Degradation of Polyesters and Their Block Copolymers with PDMAEMA. Materials, 14(13), 3636. https://doi.org/10.3390/ma14133636