Analysis of Friction Stir Welding Tool Offset on the Bonding and Properties of Al–Mg–Si Alloy T-Joints

Abstract

:1. Introduction

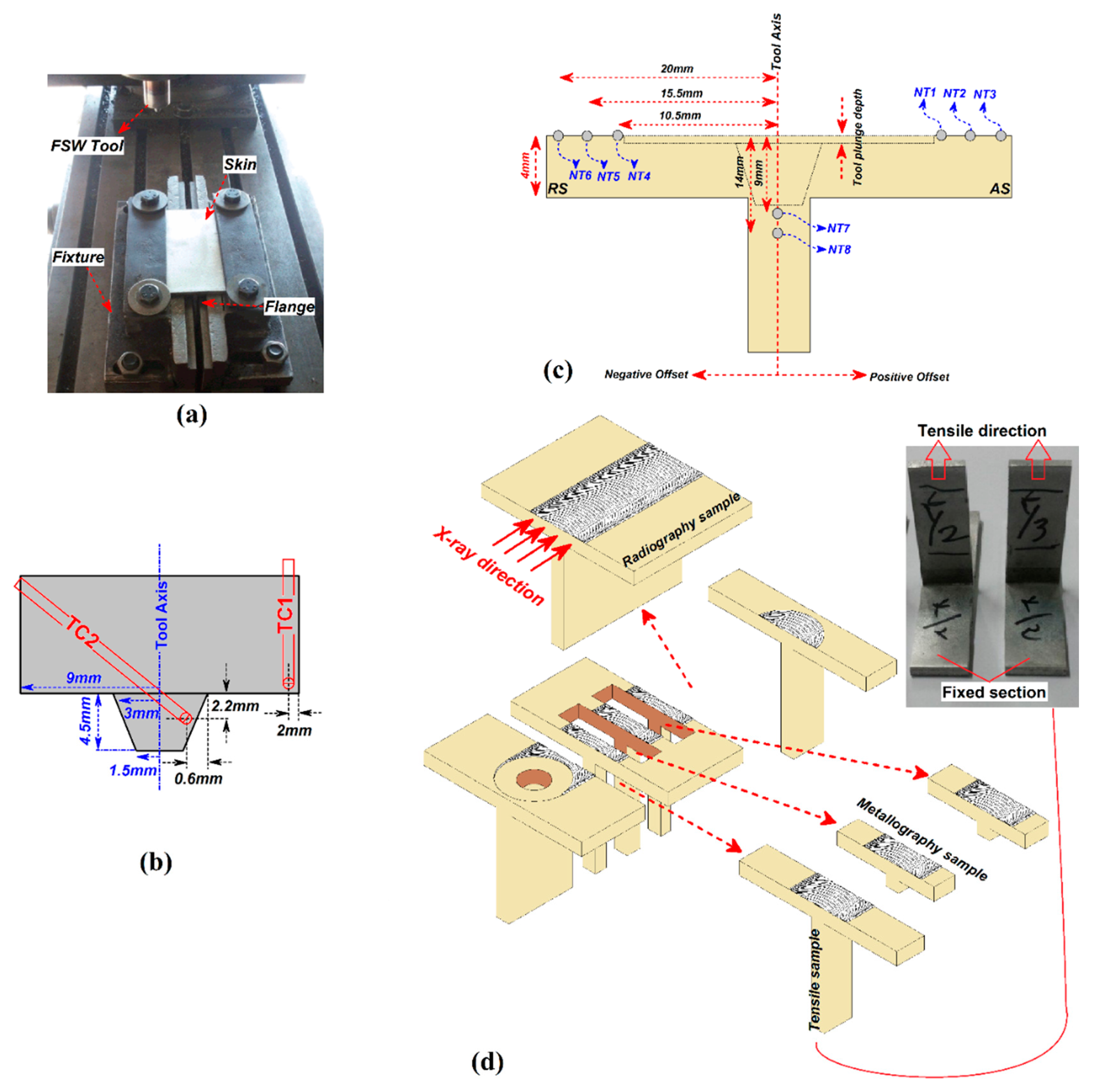

2. Experimental Procedure

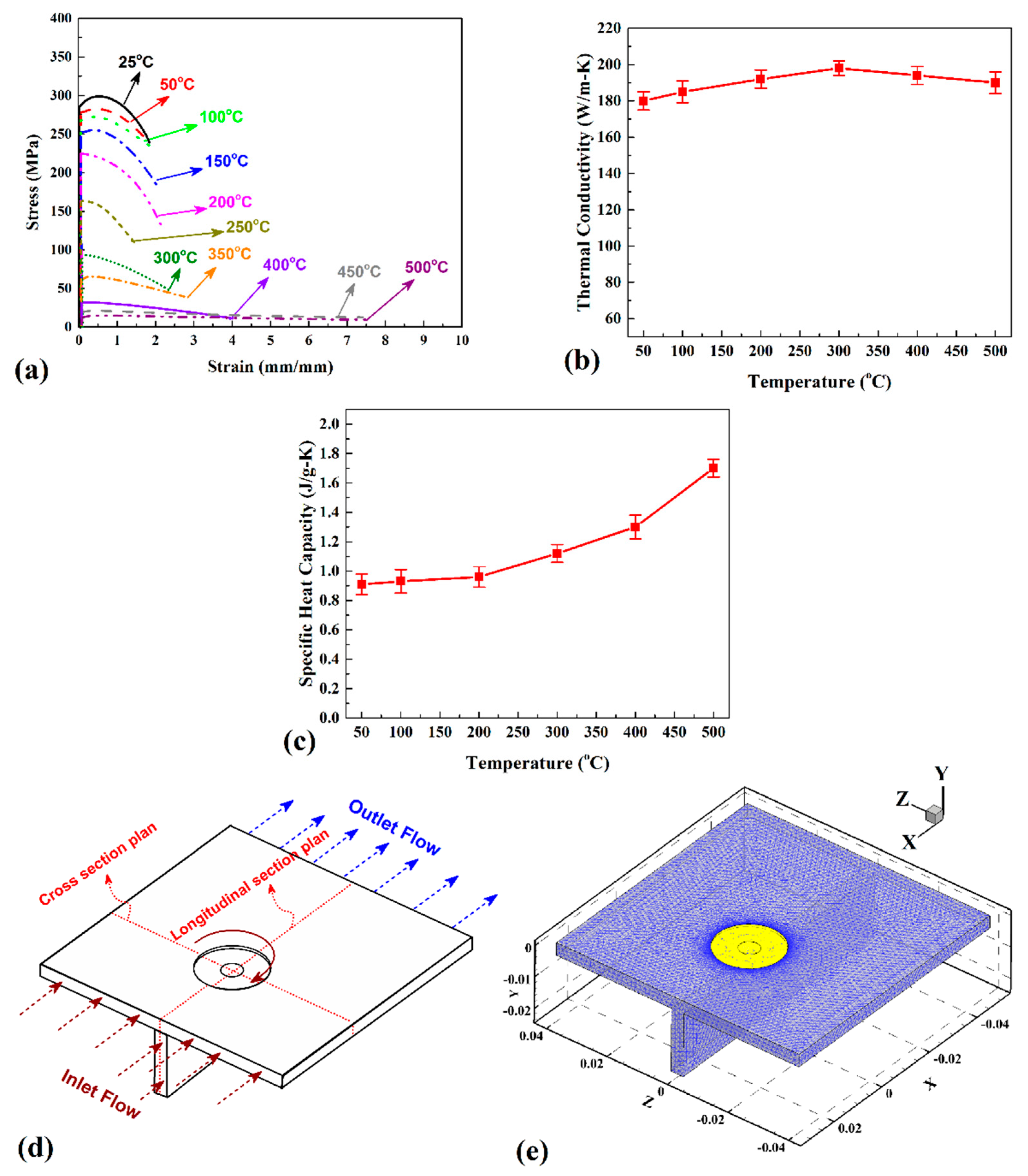

3. Process Modelling

4. Results and Discussion

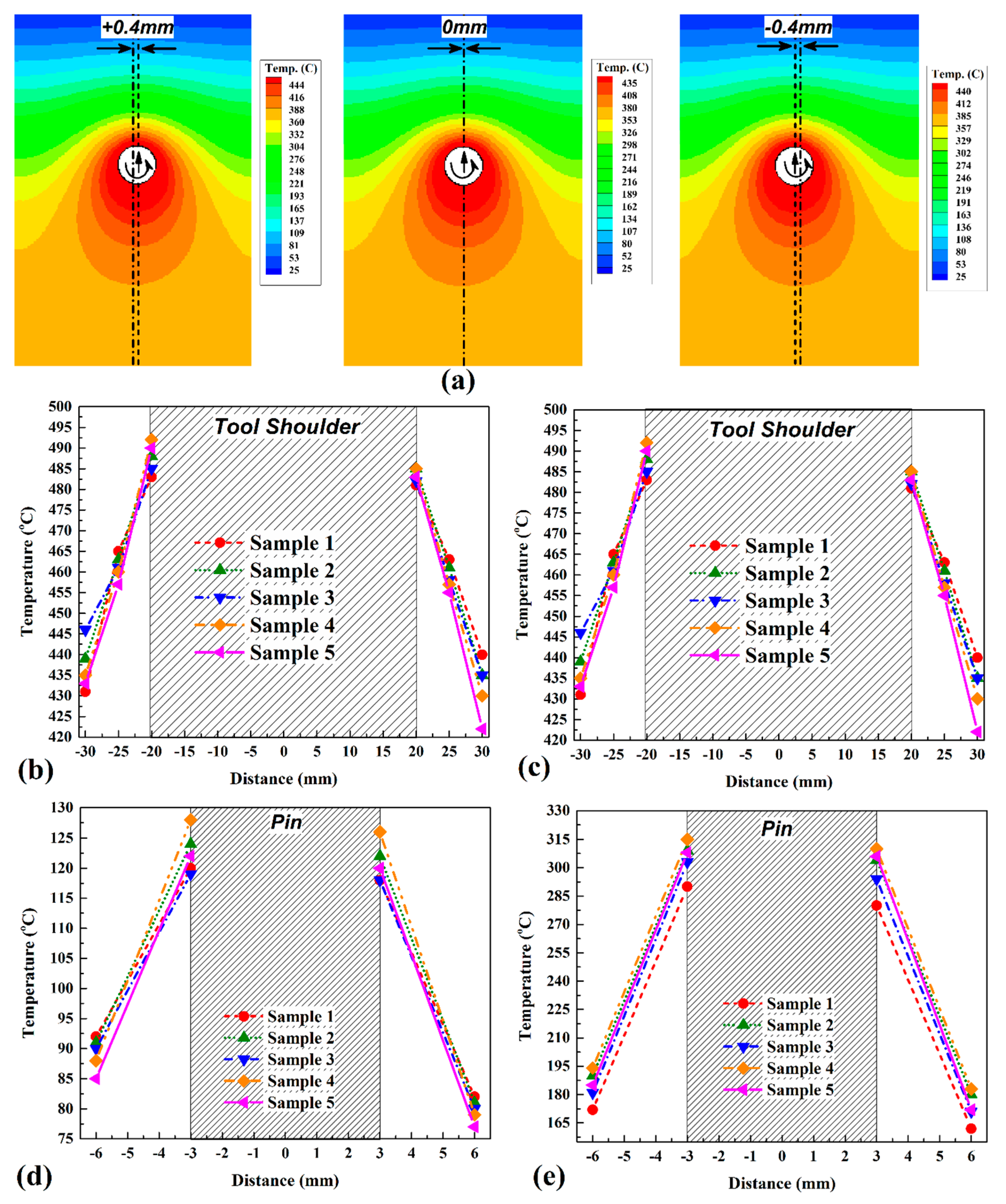

4.1. Thermal Study

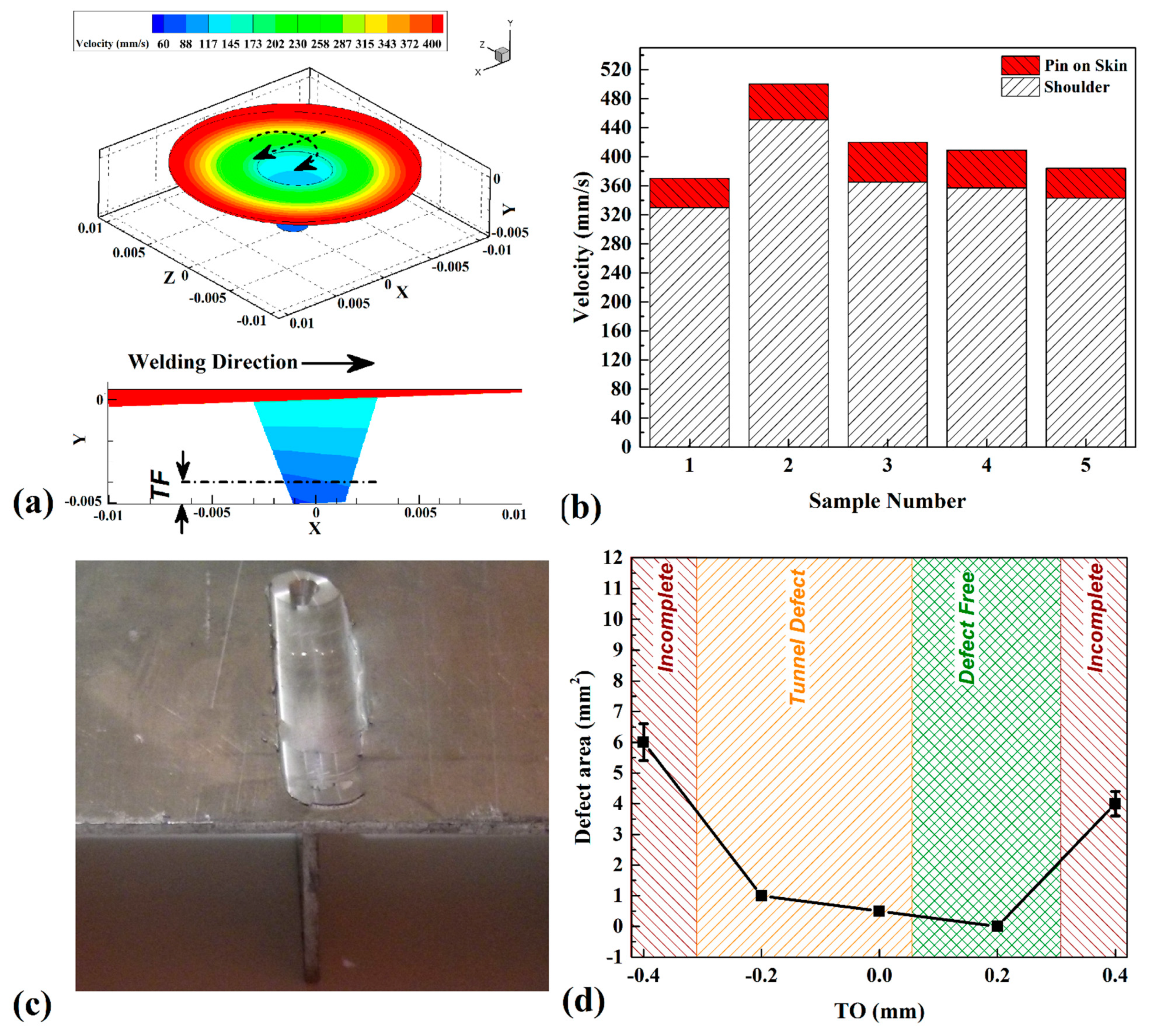

4.2. Material Velocity and Surface Flow

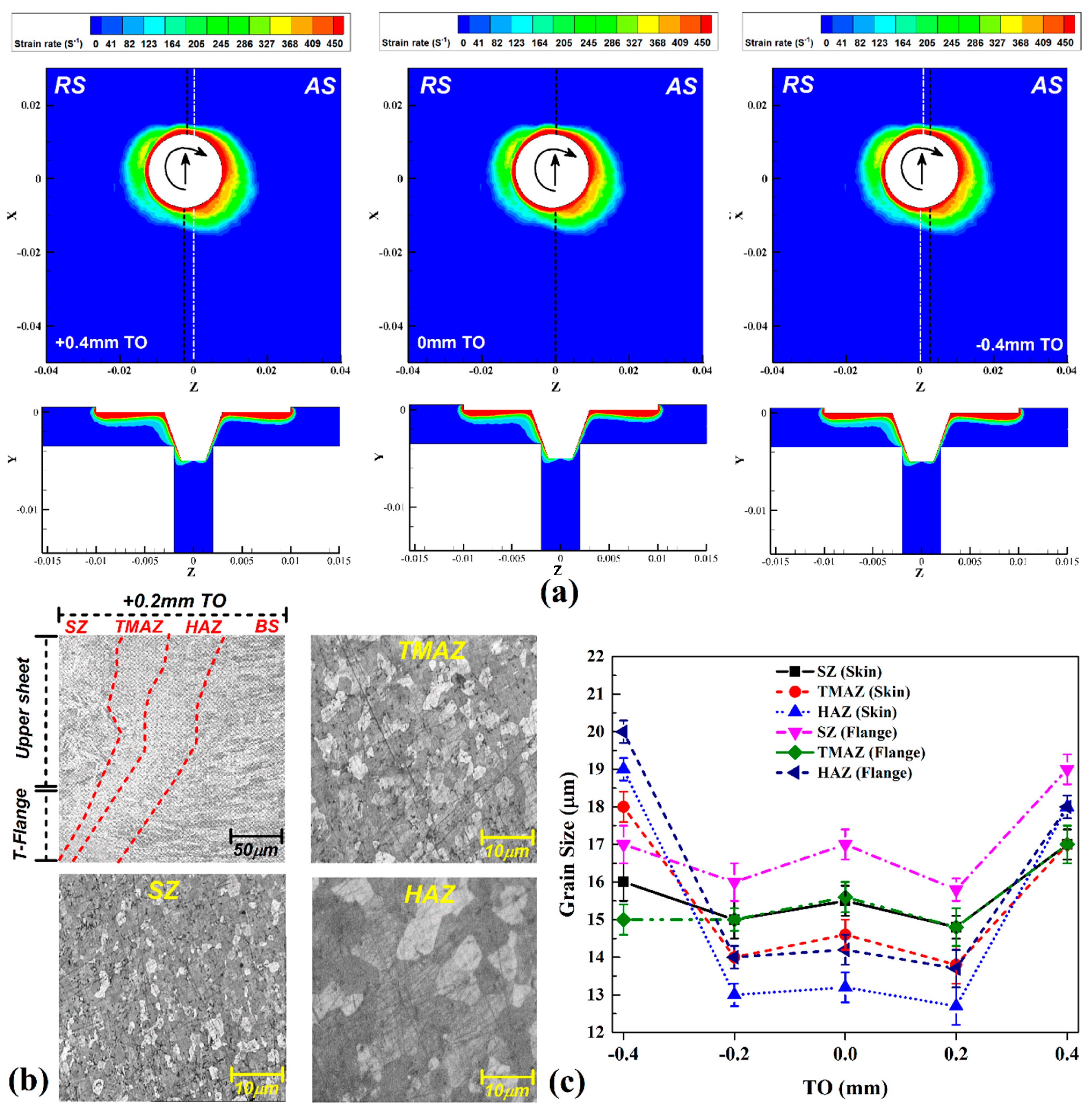

4.3. Strain Rate and Microstructure Changes

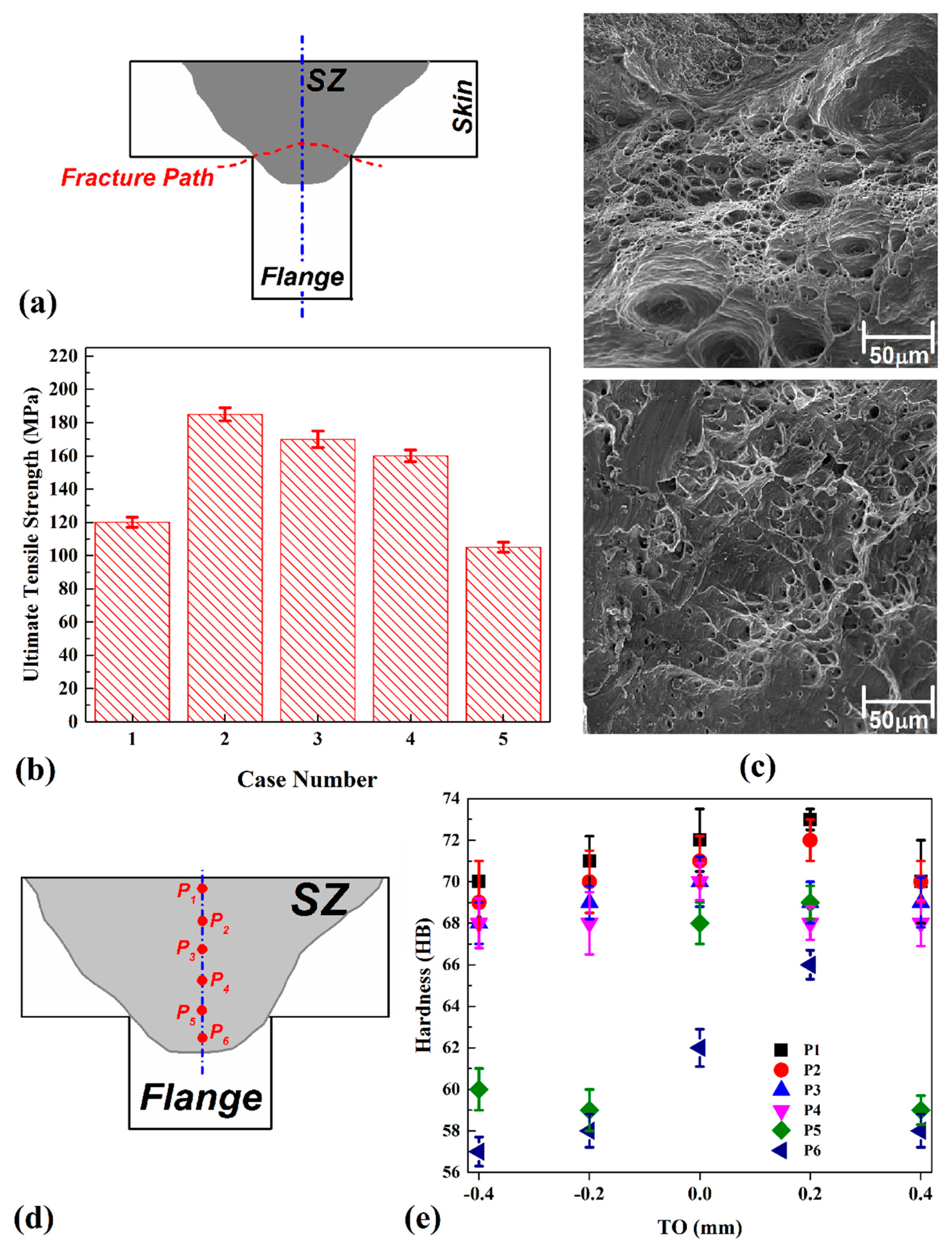

4.4. Tensile Strength and Micro-Hardness

5. Conclusions

- The maximum frictional heat was produced in Case 2 (~81% of the aluminium melting point) and the minimum frictional heat was produced in Case 5 (~77% of the aluminium melting point). The results show that at the optimum TO (in which mechanical properties are maximum), the heat generation by the tool pin in the flange side shows the highest value compared to other tool offsets.

- Thermal history and temperatures recorded by thermocouples revealed that due to the flange’s narrow area, the diffusion of heat is faster there than at the skin. For this reason, the stirring action of plasticized materials by the tool could be inconsistent at an inappropriate TO.

- The best materials velocity that produced a sound joint with appropriate material flow was predicted (~480 mm/s in +0.2 mm TO), and this setup results in enough materials stirring being produced from plasticized aluminium in the RS of the flange.

- The predicted strain rate in the AS was higher than at the RS in all analysed TOs. The higher strain rate leads to more stirring action and plastic flow. The best value was found in the case +0.2 mm of TO, which lead to a uniform grain size in all regions of the SZ. This behaviour results in a higher tensile strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Time | t |

| Coefficient of thermal conductivity | k |

| Mass-specific heat capacity | c |

| Density of the materials | ρ |

| Specific heat | ν |

| Yeild strength | τ |

| Material yield stress | σ y |

| Zener- hollomon Parameter | Z |

| Heat transfer coefficient | he |

| Initial temperature | Ta |

| Stefan–Boltzmann constant | B |

| Emissivity, | ε |

| Convective heat transfer coefficient | ht |

| Velocity, | u |

| Welding speed | U1 |

| Angular velocity | ω |

| Pressure | P |

| Flow stress | σe |

| Effective strain rate | ε |

| Material Constants | A = 5.18 × 1010 S−1 |

| Material Constants | a = 1 MPa−1 |

| Material Constants | n = 5.66 |

| Activation Energy | Q = 158.3 kJ/mol |

References

- Duong, H.D.; Okazaki, M.; Tran, T.H. Fatigue behavior of dissimilar friction stir welded T-lap joints between AA5083 and AA7075. Int. J. Fatigue 2021, 145, 106090. [Google Scholar] [CrossRef]

- Feistauer, E.; Bergmann, L.; Dos Santos, J. Effect of reverse material flow on the microstructure and performance of friction stir welded T-joints of an Al-Mg alloy. Mater. Sci. Eng. A 2018, 731, 454–464. [Google Scholar] [CrossRef]

- Salloomi, K.N. Fully coupled thermomechanical simulation of friction stir welding of aluminum 6061-T6 alloy T-joint. J. Manuf. Process. 2019, 45, 746–754. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Elyasi, M. The influence of process parameters in friction stir welding of Al-Mg alloy and polycarbonate. J. Manuf. Process. 2018, 35, 88–98. [Google Scholar] [CrossRef]

- Derazkola, H.A.; García, E.; Eyvazian, A.; Aberoumand, M. Effects of Rapid Cooling on Properties of Aluminum-Steel Friction Stir Welded Joint. Materials 2021, 14, 908. [Google Scholar] [CrossRef] [PubMed]

- Derazkola, H.A.; Khodabakhshi, F.; Gerlich, A. Friction-forging tubular additive manufacturing (FFTAM): A new route of solid-state layer-upon-layer metal deposition. J. Mater. Res. Technol. 2020, 9, 15273–15285. [Google Scholar] [CrossRef]

- Mehta, K.P.; Patel, R.; Vyas, H.; Memon, S.; Vilaça, P. Repairing of exit-hole in dissimilar Al-Mg friction stir welding: Process and microstructural pattern. Manuf. Lett. 2020, 23, 67–70. [Google Scholar] [CrossRef]

- Paidar, M.; Mehrez, S.; Babaei, B.; Memon, S.; Ojo, O.; Lankarani, H. Dissimilar welding of AA5083 to AZ31 Mg alloys using modified friction stir clinching brazing. Mater. Lett. 2021, 129764, 129764. [Google Scholar] [CrossRef]

- Memon, S.; Paidar, M.; Mehta, K.P.; Babaei, B.; Lankarani, H.M. Friction Spot Extrusion Welding on Dissimilar Materials AA2024-T3 to AA5754-O: Effect of Shoulder Plunge Depth. J. Mater. Eng. Perform. 2021, 30, 334–345. [Google Scholar] [CrossRef]

- Paidar, M.; Memon, S.; Samusenkov, V.O.; Babaei, B.; Ojo, O. Friction spot extrusion welding-brazing of copper to aluminum alloy. Mater. Lett. 2021, 285, 129160. [Google Scholar] [CrossRef]

- Memon, S.; Paidar, M.; Mehrez, S.; Cooke, K.; Ojo, O.; Lankarani, H. Effects of materials positioning and tool rotational speed on metallurgical and mechanical properties of dissimilar modified friction stir clinching of AA5754-O and AA2024-T3 sheets. Results Phys. 2021, 22, 103962. [Google Scholar] [CrossRef]

- Kredegh, A.; Sedmak, A.; Grbovic, A.; Milosevic, N.; Danicic, D. Numerical simulation of fatigue crack growth in friction stir welded T joint made of Al 2024 T351 alloy. Procedia Struct. Integr. 2016, 2, 3065–3072. [Google Scholar] [CrossRef] [Green Version]

- Jesus, J.; Costa, J.; Loureiro, A.; Ferreira, J. Assessment of friction stir welding aluminium T-joints. J. Mater. Process. Technol. 2018, 255, 387–399. [Google Scholar] [CrossRef]

- Elyasi, M.; Derazkola, H.A. Experimental and thermomechanical study on FSW of PMMA polymer T-joint. Int. J. Adv. Manuf. Technol. 2018, 97, 1445–1456. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Khodabakhshi, F. A novel fed friction-stir (FFS) technology for nanocomposite joining. Sci. Technol. Weld. Join. 2020, 25, 89–100. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Khodabakhshi, F. Development of fed friction-stir (FFS) process for dissimilar nanocomposite welding between AA2024 aluminum alloy and polycarbonate (PC). J. Manuf. Process. 2020, 54, 262–273. [Google Scholar] [CrossRef]

- Eyvazian, A.; Hamouda, A.M.; Derazkola, H.A.; Elyasi, M. Study on the effects of tool tile angle, offset and plunge depth on friction stir welding of poly(methyl methacrylate) T-joint. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 234, 773–787. [Google Scholar] [CrossRef]

- Zhou, G.; Yang, X.Q.; Cui, L.; Zhang, Z.H.; Xu, X.D. Study on the Microstructures and Tensile Behaviors of Friction Stir Welded T-joints for AA6061-T4 Alloys. J. Mater. Eng. Perform. 2012, 21, 2131–2139. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, L.; Wang, Q.; Yan, K.; Zou, J. Defects and tensile properties of 6013 aluminum alloy T-joints by friction stir welding. Mater. Des. 2014, 57, 146–155. [Google Scholar] [CrossRef]

- Zeng, S.; Chen, G.; Dinaharan, I.; Liu, Q.; Zhang, S.; Sahu, P.K.; Wu, J.; Zhang, G.; Shi, Q. Microstructure and Tensile Strength of AA6082 T-joints by Corner Stationary Shoulder Friction Stir Welding: Effect of Tool Rotation Speed. J. Mater. Eng. Perform. 2020, 29, 7094–7103. [Google Scholar] [CrossRef]

- Donati, L.; Tomesani, L.; Morri, A. Structural T-joint produced by means of friction stir welding (FSW) with filling material. Int. J. Mater. Form. 2009, 2, 295–298. [Google Scholar] [CrossRef]

- Cui, L.; Yang, X.; Xie, Y.; Hou, X.; Song, Y. Process parameter influence on defects and tensile properties of friction stir welded T-joints on AA6061-T4 sheets. Mater. Des. 2013, 51, 161–174. [Google Scholar] [CrossRef]

- Abidi, M.H.; Ali, N.; Ibrahimi, H.; Anjum, S.; Bajaj, D.; Siddiquee, A.N.; Alkahtani, M.; Rehman, A.U. T-FSW of Dissimilar Aerospace Grade Aluminium Alloys: Influence of Second Pass on Weld Defects. Metals 2020, 10, 525. [Google Scholar] [CrossRef] [Green Version]

- Derazkola, H.A.; Simchi, A. An investigation on the dissimilar friction stir welding of T-joints between AA5754 aluminum alloy and poly(methyl methacrylate). Thin-Walled Struct. 2019, 135, 376–384. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Simchi, A. Experimental and thermomechanical analysis of friction stir welding of poly(methyl methacrylate) sheets. Sci. Technol. Weld. Join. 2017, 23, 209–218. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Aval, H.J.; Elyasi, M. Analysis of process parameters effects on dissimilar friction stir welding of AA1100 and A441 AISI steel. Sci. Technol. Weld. Join. 2015, 20, 553–562. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Simchi, A. Processing and characterizations of polycarbonate/alumina nanocomposites by additive powder fed friction stir processing. Thin-Walled Struct. 2020, 157, 107086. [Google Scholar] [CrossRef]

- Mustafa, F.F.; Kadhym, A.H.; Yahya, H.H. Tool Geometries Optimization for Friction Stir Welding of AA6061-T6 Aluminum Alloy T-Joint Using Taguchi Method to Improve the Mechanical Behavior. J. Manuf. Sci. Eng. 2015, 137, 031018. [Google Scholar] [CrossRef]

- Buffa, G.; Fratini, L.; Micari, F.; Shivpuri, R. Material Flow in FSW of T-joints: Experimental and Numerical Analysis. Int. J. Mater. Form. 2008, 1, 1283–1286. [Google Scholar] [CrossRef]

- Fratini, L.; Buffa, G.; Micari, F.; Shivpuri, R. On the material flow in FSW of T-joints: Influence of geometrical and technological parameters. Int. J. Adv. Manuf. Technol. 2008, 44, 570–578. [Google Scholar] [CrossRef]

- Safeen, M.W.; Spena, P.R.; Buffa, G.; Campanella, D.; Masnata, A.; Fratini, L. Effect of position and force tool control in friction stir welding of dissimilar aluminum-steel lap joints for automotive applications. Adv. Manuf. 2020, 8, 59–71. [Google Scholar] [CrossRef]

- Astarita, A.; Squillace, A.; Scala, A.; Prisco, A. On the Critical Technological Issues of Friction Stir Welding T-Joints of Dissimilar Aluminum Alloys. J. Mater. Eng. Perform. 2011, 21, 1763–1771. [Google Scholar] [CrossRef]

- Krasnowski, K. Experimental Study of FSW T-joints of EN-AW 6082-T6 and Their Behavior under Static Loads. Arab. J. Sci. Eng. 2014, 39, 9083–9092. [Google Scholar] [CrossRef]

- Yan, X.; Ma, H.; Xiong, L.; Tian, Z.; Cao, X.; Zhang, Y. Effect of lateral offset on microstructure and strength of friction stir welded 2A14-T6 aluminum alloy. Int. J. Adv. Manuf. Technol. 2018, 97, 3893–3902. [Google Scholar] [CrossRef]

- Deng, Y.; Qiu, Z.; Zuo, D.; Zeng, J.; Zhang, W. Influence of tool offset on microstructure and properties of Mg/Al dissimilar alloys by friction stir welding joints at low heat input. Int. J. Adv. Manuf. Technol. 2020, 109, 2845–2853. [Google Scholar] [CrossRef]

- Tiwari, A.; Singh, P.; Pankaj, P.; Biswas, P.; Kore, S.D.; Pal, S. Effect of Tool Offset and Rotational Speed in Dissimilar Friction Stir Welding of AISI 304 Stainless Steel and Mild Steel. J. Mater. Eng. Perform. 2019, 28, 6365–6379. [Google Scholar] [CrossRef]

- Liu, H.; Chen, Y.; Yao, Z.; Luo, F. Effect of Tool Offset on the Microstructure and Properties of AA6061/AZ31B Friction Stir Welding Joints. Metals 2020, 10, 546. [Google Scholar] [CrossRef] [Green Version]

- Song, Q.; Ma, Z.-W.; Ji, S.-D.; Li, Q.-H.; Wang, L.-F.; Li, R. Influence of Pin Offset on Microstructure and Mechanical Properties of Friction Stir Welded Mg/Ti Dissimilar Alloys. Acta Met. Sin. 2019, 32, 1261–1268. [Google Scholar] [CrossRef] [Green Version]

- Talebizadehsardari, P.; Musharavati, F.; Khan, A.; Sebaey, T.A.; Eyvaziana, A.; Derazkola, H.A. Underwater friction stir welding of Al-Mg alloy: Thermo-mechanical modeling and validation. Mater. Today Commun. 2021, 26, 101965. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Kordani, N.; Derazkola, H.A. Effects of friction stir welding tool tilt angle on properties of Al-Mg-Si alloy T-joint. CIRP J. Manuf. Sci. Technol. 2021, 33, 264–276. [Google Scholar] [CrossRef]

- Guan, M.; Wang, Y.; Huang, Y.; Liu, X.; Meng, X.; Xie, Y.; Li, J. Non-weld-thinning friction stir welding. Mater. Lett. 2019, 255, 126506. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Khodabakhshi, F. Underwater submerged dissimilar friction-stir welding of AA5083 aluminum alloy and A441 AISI steel. Int. J. Adv. Manuf. Technol. 2019, 102, 4383–4395. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Garcia, E.; Elyasi, M. Underwater friction stir welding of PC: Experimental study and thermo-mechanical modelling. J. Manuf. Process. 2021, 65, 161–173. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Khodabakhshi, F. Intermetallic compounds (IMCs) formation during dissimilar friction-stir welding of AA5005 aluminum alloy to St-52 steel: Numerical modeling and experimental study. Int. J. Adv. Manuf. Technol. 2019, 100, 2401–2422. [Google Scholar] [CrossRef]

- Caseiro, J.; Valente, R.; Andrade-Campos, A.; Yoon, J.W. On the elasto-plastic buckling of Integrally Stiffened Panels (ISP) joined by Friction Stir Welding (FSW): Numerical simulation and optimization algorithms. Int. J. Mech. Sci. 2013, 76, 49–59. [Google Scholar] [CrossRef]

- Marciniak, Z.; Kuczyński, K. Limit strains in the processes of stretch-forming sheet metal. Int. J. Mech. Sci. 1967, 9, 609–620. [Google Scholar] [CrossRef]

- Mirzaei, M.; Asadi, P.; Fazli, A. Effect of Tool Pin Profile on Material Flow in Double Shoulder Friction Stir Welding of AZ91 Magnesium Alloy. Int. J. Mech. Sci. 2020, 183, 105775. [Google Scholar] [CrossRef]

- Muhammad, N.A.; Wu, C. Evaluation of capabilities of ultrasonic vibration on the surface, electrical and mechanical behaviours of aluminium to copper dissimilar friction stir welds. Int. J. Mech. Sci. 2020, 183, 105784. [Google Scholar] [CrossRef]

- Andrade, D.; Leitão, C.; Dialami, N.; Chiumenti, M.; Rodrigues, D. Modelling torque and temperature in friction stir welding of aluminium alloys. Int. J. Mech. Sci. 2020, 182, 105725. [Google Scholar] [CrossRef]

- Iqbal, P.; Tripathi, A.; Jain, R.; Mahto, R.P.; Pal, S.; Mandal, P. Numerical modelling of microstructure in friction stir welding of aluminium alloys. Int. J. Mech. Sci. 2020, 185, 105882. [Google Scholar] [CrossRef]

- Zhao, W.; Wu, C.; Shi, L. Acoustic induced antifriction and its effect on thermo-mechanical behavior in ultrasonic assisted friction stir welding. Int. J. Mech. Sci. 2021, 190, 106039. [Google Scholar] [CrossRef]

- Su, H.; Wu, C. Numerical Simulation for the Optimization of Polygonal Pin Profiles in Friction Stir Welding of Aluminum. Acta Met. Sin. 2021, 34, 1065–1078. [Google Scholar] [CrossRef]

- Yu, P.; Wu, C.; Shi, L. Analysis and characterization of dynamic recrystallization and grain structure evolution in friction stir welding of aluminum plates. Acta Mater. 2021, 207, 116692. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Eyvazian, A.; Simchi, A. Modeling and experimental validation of material flow during FSW of polycarbonate. Mater. Today Commun. 2020, 22, 100796. [Google Scholar] [CrossRef]

- Khodabakhshi, F.; Derazkola, H.A.; Gerlich, A.P. Monte Carlo simulation of grain refinement during friction stir processing. J. Mater. Sci. 2020, 55, 13438–13456. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Simchi, A. Experimental and thermomechanical analysis of the effect of tool pin profile on the friction stir welding of poly(methyl methacrylate) sheets. J. Manuf. Process. 2018, 34, 412–423. [Google Scholar] [CrossRef]

- Gale, W.F.; Totemeier, T.C.B.T.-S.M.R.B. (Eds.) Gas–metal systems. In Smithells Metals Reference Book, 8th ed.; Butterworth-Heinemann: Oxford, UK, 2004; pp. 12–28. ISBN 978-0-7506-7509-3. [Google Scholar]

- Gale, W.F.; Totemeier, T.C.B.T.-S.M.R.B. (Eds.) General physical and chemical constants. In Smithells Metals Reference Book, 8th ed.; Butterworth-Heinemann: Oxford, UK, 2004; pp. 3–11. ISBN 978-0-7506-7509-3. [Google Scholar]

- Gale, W.F.; Totemeier, T.C.B.T.-S.M.R.B. (Eds.) General physical properties. In Smithells Metals Reference Book, 8th ed.; Butterworth-Heinemann: Oxford, UK, 2004; pp. 14–45. ISBN 978-0-7506-7509-3. [Google Scholar]

- Eyvazian, A.; Hamouda, A.; Tarlochan, F.; Derazkola, H.A.; Khodabakhshi, F. Simulation and experimental study of underwater dissimilar friction-stir welding between aluminium and steel. J. Mater. Res. Technol. 2020, 9, 3767–3781. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Khodabakhshi, F.; Simchi, A. Friction-stir lap-joining of aluminium-magnesium/poly-methyl-methacrylate hybrid structures: Thermo-mechanical modelling and experimental feasibility study. Sci. Technol. Weld. Join. 2018, 23, 35–49. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Eyvazian, A.; Simchi, A. Submerged friction stir welding of dissimilar joints between an Al-Mg alloy and low carbon steel: Thermo-mechanical modeling, microstructural features, and mechanical properties. J. Manuf. Process. 2020, 50, 68–79. [Google Scholar] [CrossRef]

- Kasman, Ş.; Ozan, S. Effects of overlapping formed via pin-offsetting on friction stir weldability of AA7075-T651 aluminum alloy. J. Mech. Sci. Technol. 2019, 33, 819–828. [Google Scholar] [CrossRef]

- Lambiase, F.; Derazkola, H.A.; Simchi, A. Friction Stir Welding and Friction Spot Stir Welding Processes of Polymers—State of the Art. Materials 2020, 13, 2291. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Simchi, A.; Lambiase, F. Friction stir welding of polycarbonate lap joints: Relationship between processing parameters and mechanical properties. Polym. Test. 2019, 79, 105999. [Google Scholar] [CrossRef]

- Kar, A.; Vicharapu, B.; Morisada, Y.; Fujii, H. Elucidation of interfacial microstructure and properties in friction stir lap welding of aluminium alloy and mild steel. Mater. Charact. 2020, 168, 110572. [Google Scholar] [CrossRef]

- Kumar, R.A.; Thansekhar, M.R. Mechanical and wear properties of friction stir welded dissimilar AA6101-T6 and AA1350 alloys: Effect of offset distance and number of passes. J. Mech. Sci. Technol. 2018, 32, 3299–3307. [Google Scholar] [CrossRef]

- Hou, W.; Shah, L.H.A.; Huang, G.; Shen, Y.; Gerlich, A. The role of tool offset on the microstructure and mechanical properties of Al/Cu friction stir welded joints. J. Alloy. Compd. 2020, 825, 154045. [Google Scholar] [CrossRef]

- Bhattacharya, T.; Das, H.; Pal, T. Influence of welding parameters on material flow, mechanical property and intermetallic characterization of friction stir welded AA6063 to HCP copper dissimilar butt joint without offset. Trans. Nonferrous Met. Soc. China 2015, 25, 2833–2846. [Google Scholar] [CrossRef]

- Krishna, G.G.; Mahender, T.; Reddy, S.; Rao, R.U. The effect of offset tools on aluminum AA6351 alloy friction stir welds. Mater. Today Proc. 2021, 46, 320–324. [Google Scholar] [CrossRef]

- Sahu, P.K.; Pal, S.; Pal, S.K.; Jain, R. Influence of plate position, tool offset and tool rotational speed on mechanical properties and microstructures of dissimilar Al/Cu friction stir welding joints. J. Mater. Process. Technol. 2016, 235, 55–67. [Google Scholar] [CrossRef]

| Parameter | Density | Melting Point | Thermal Conductivity | Ultimate Tensile Strength | Shear Strength | Yield Strength | Vickers Hardness |

|---|---|---|---|---|---|---|---|

| Units | kg/m3 | °C | W/m·k | MPa | MPa | MPa | HB |

| Value | 2700 | 555 | 180 | 300 | 460 | 200 | 91 |

| Element | Cu | Mg | Mn | Si | Fe | Cr | Zn | Al |

|---|---|---|---|---|---|---|---|---|

| wt.% | 0.1 | 1.2 | 1 | 1.3 | 0.5 | 0.25 | 0.2 | 95.4 |

| Parameter | Tool Rotation Speed | Welding Speed | Tool Tilt Angle | Tool Plunge Depth | Tool Offset |

|---|---|---|---|---|---|

| Sample Number/Units | rpm | mm/min | Degree | mm | mm |

| 1 | 1400 | 40 | 2 | 0.2 | +0.4 |

| 2 | 1400 | 40 | 2 | 0.2 | +0.2 |

| 3 | 1400 | 40 | 2 | 0.2 | 0 |

| 4 | 1400 | 40 | 2 | 0.2 | −0.2 |

| 5 | 1400 | 40 | 2 | 0.2 | −0.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Memon, S.; Murillo-Marrodán, A.; Lankarani, H.M.; Aghajani Derazkola, H. Analysis of Friction Stir Welding Tool Offset on the Bonding and Properties of Al–Mg–Si Alloy T-Joints. Materials 2021, 14, 3604. https://doi.org/10.3390/ma14133604

Memon S, Murillo-Marrodán A, Lankarani HM, Aghajani Derazkola H. Analysis of Friction Stir Welding Tool Offset on the Bonding and Properties of Al–Mg–Si Alloy T-Joints. Materials. 2021; 14(13):3604. https://doi.org/10.3390/ma14133604

Chicago/Turabian StyleMemon, Shabbir, Alberto Murillo-Marrodán, Hamid M. Lankarani, and Hesamoddin Aghajani Derazkola. 2021. "Analysis of Friction Stir Welding Tool Offset on the Bonding and Properties of Al–Mg–Si Alloy T-Joints" Materials 14, no. 13: 3604. https://doi.org/10.3390/ma14133604

APA StyleMemon, S., Murillo-Marrodán, A., Lankarani, H. M., & Aghajani Derazkola, H. (2021). Analysis of Friction Stir Welding Tool Offset on the Bonding and Properties of Al–Mg–Si Alloy T-Joints. Materials, 14(13), 3604. https://doi.org/10.3390/ma14133604