Numerical Investigation of Deposition Characteristics of PLA on an ABS Plate Using a Material Extrusion Process

Abstract

1. Introduction

2. Finite Element Analysis and Experiments of Material Extrusion Process

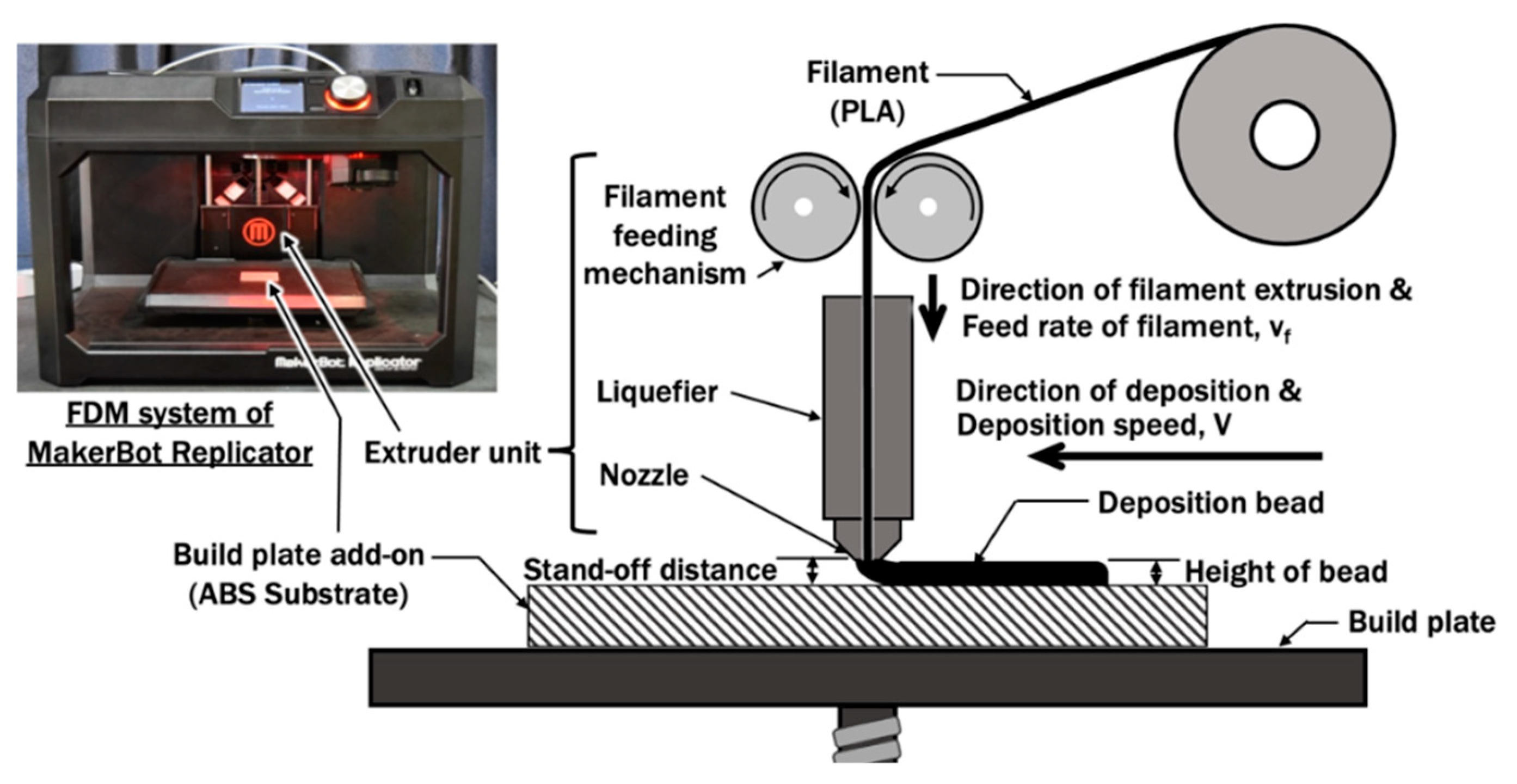

2.1. Material Extrusion Process of Extruder Unit

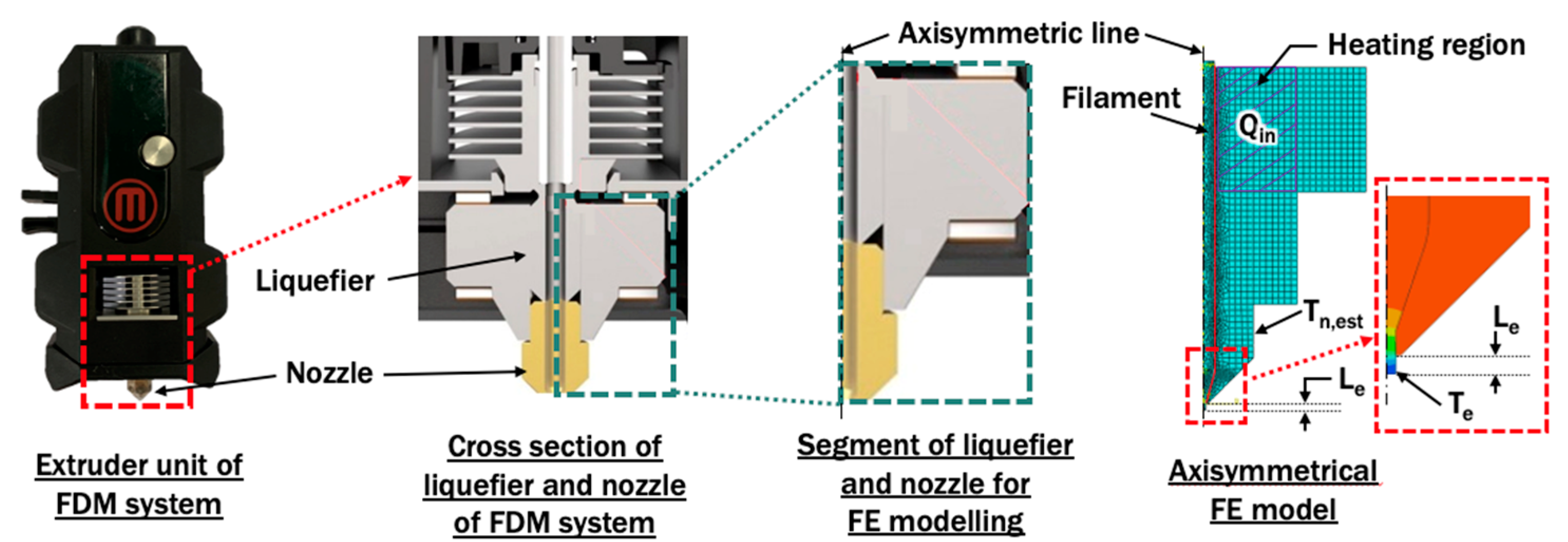

2.1.1. Finite Element Model for Extrusion Process of Filament

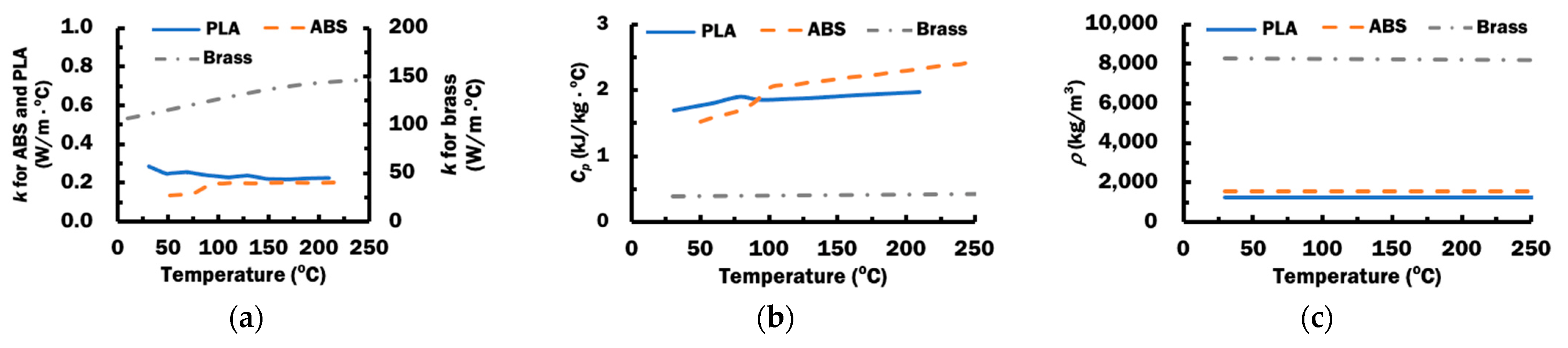

2.1.2. Material Properties

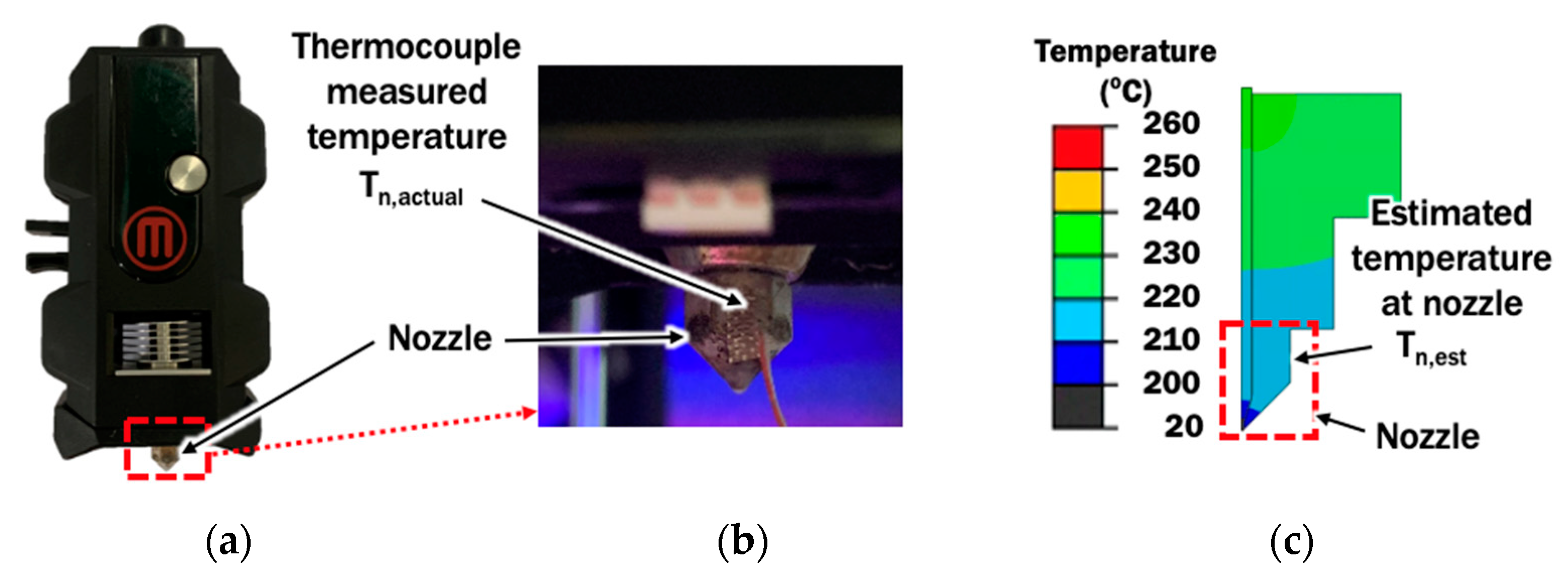

2.1.3. Validation of Finite Element Model Using Temperature Measurement at Nozzle

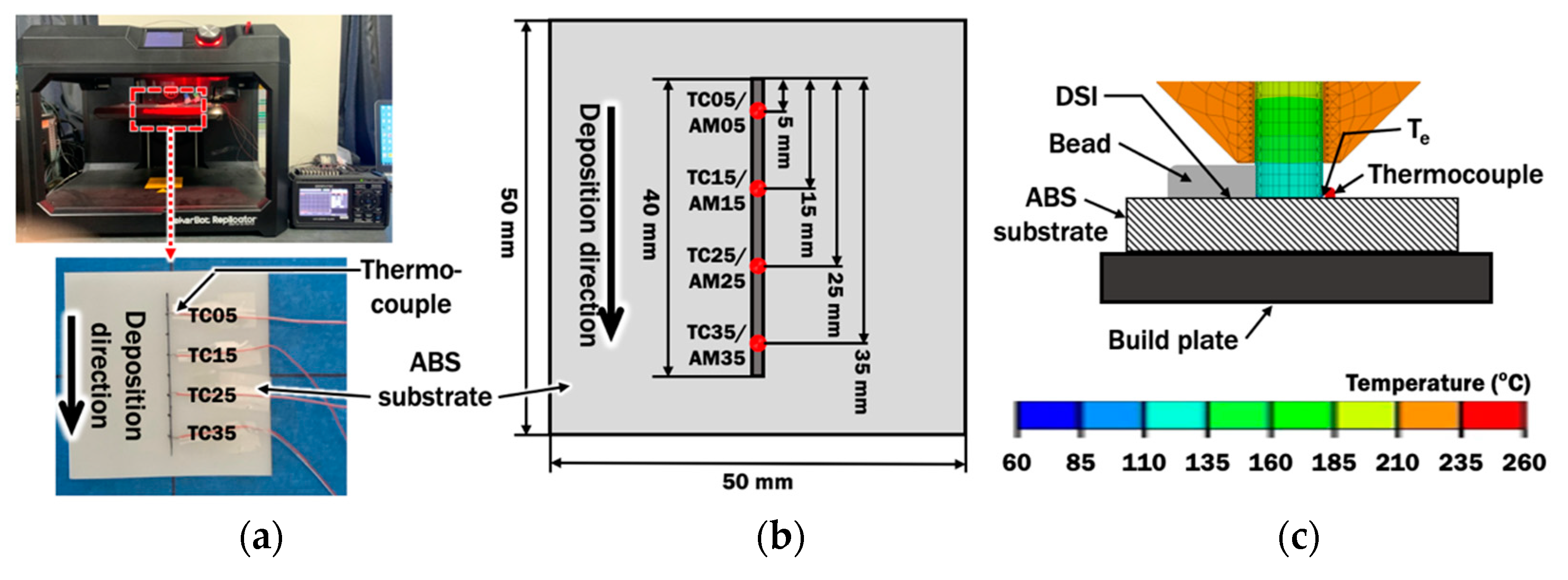

2.1.4. Verification of Proper Extruded Length Using Temperature Measurement at Deposit-Substrate Interface (DSI) during Deposition Process

2.2. Deposition Process of PLA on ABS Plate

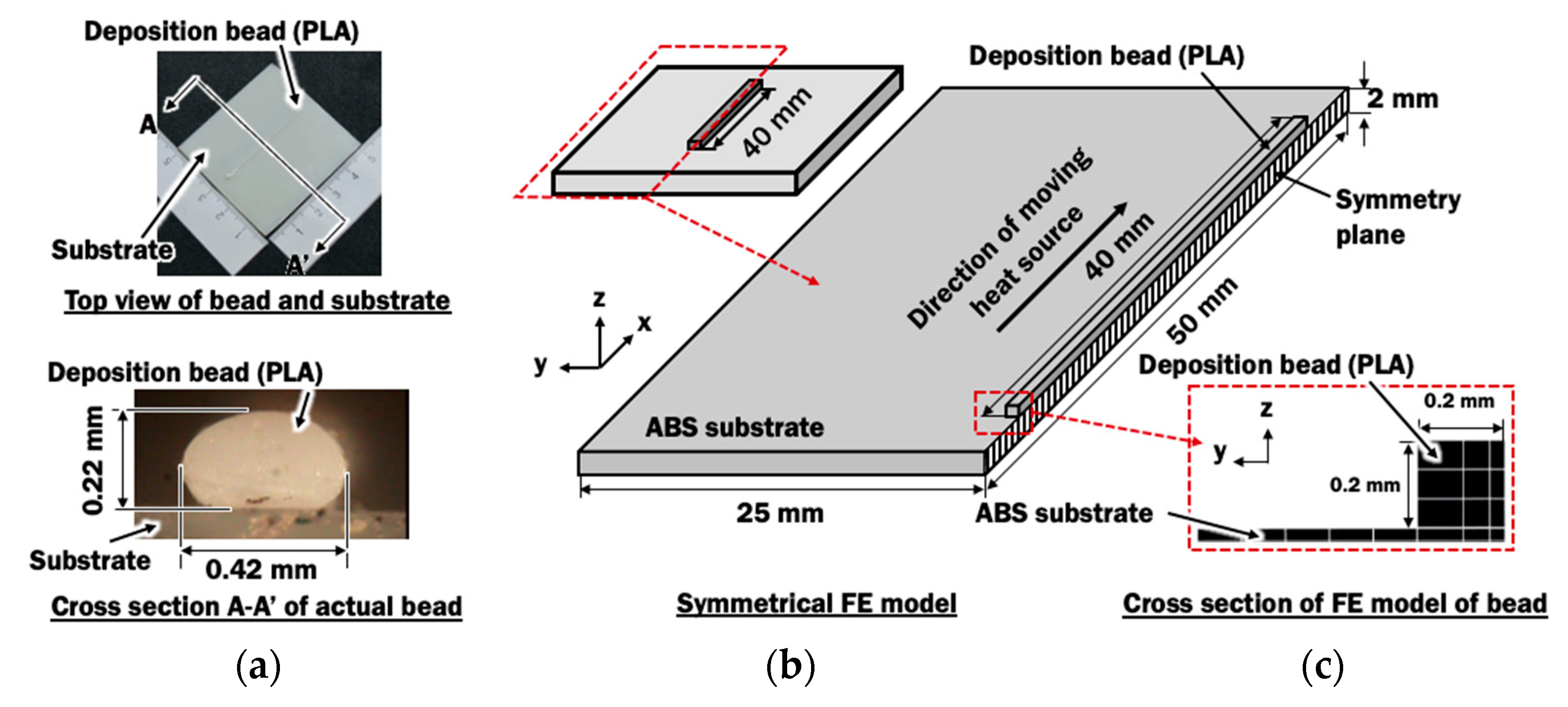

2.2.1. Finite Element Model for Deposition Process

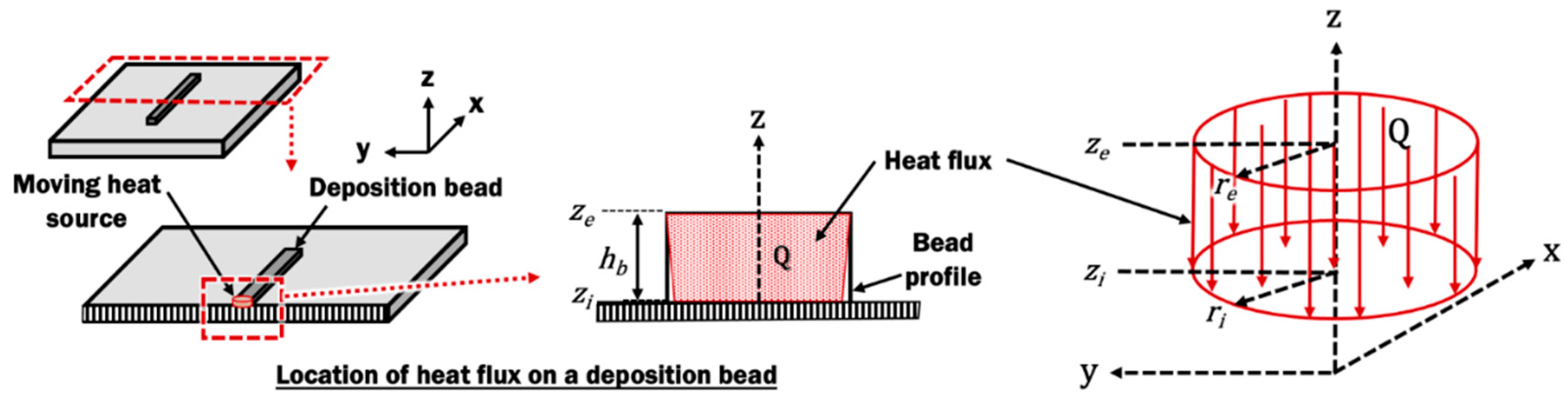

2.2.2. Heat Source Model

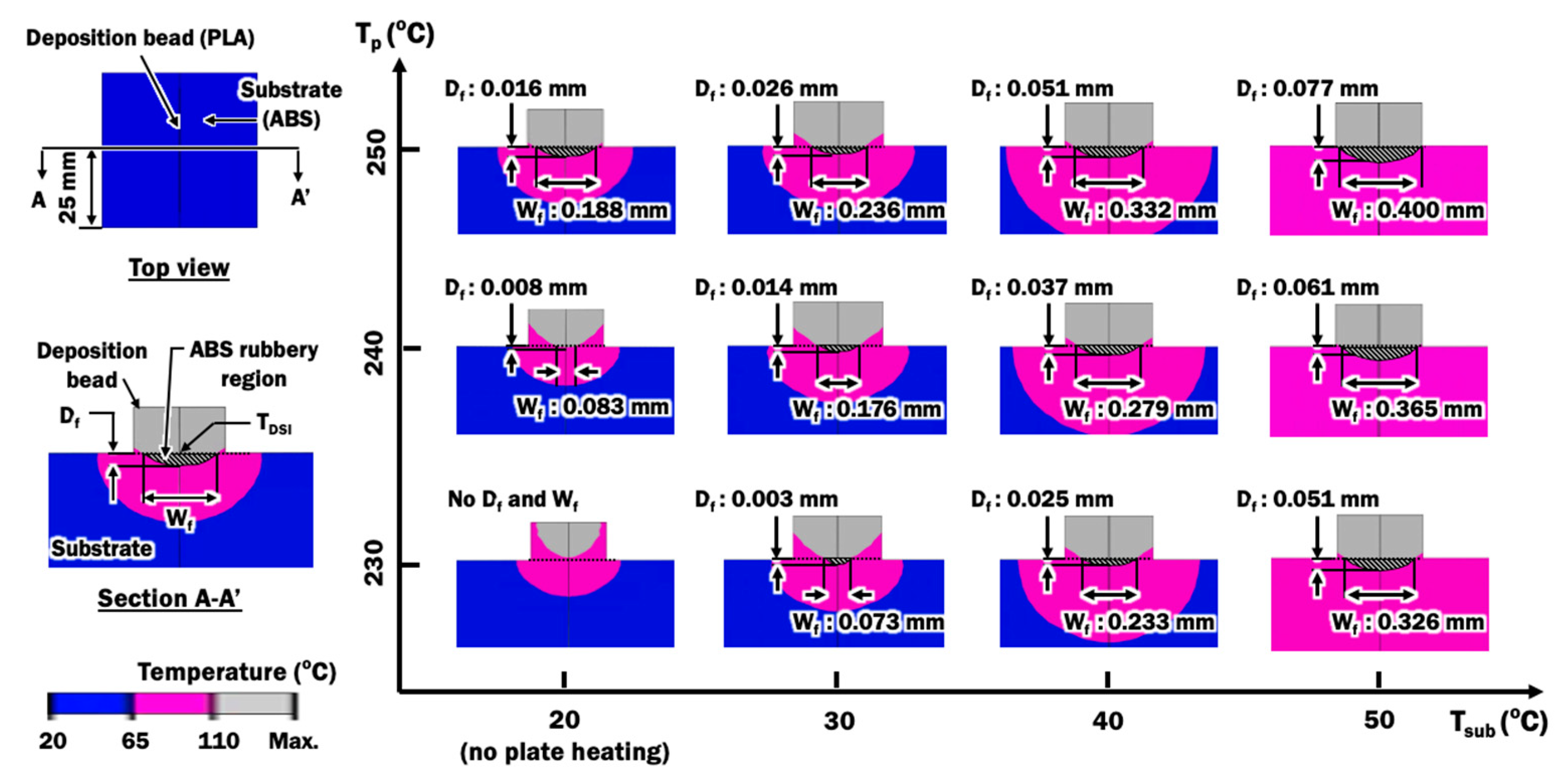

2.2.3. Numerical Investigation of Deposition Process with Plate Heating

3. Results and Discussion

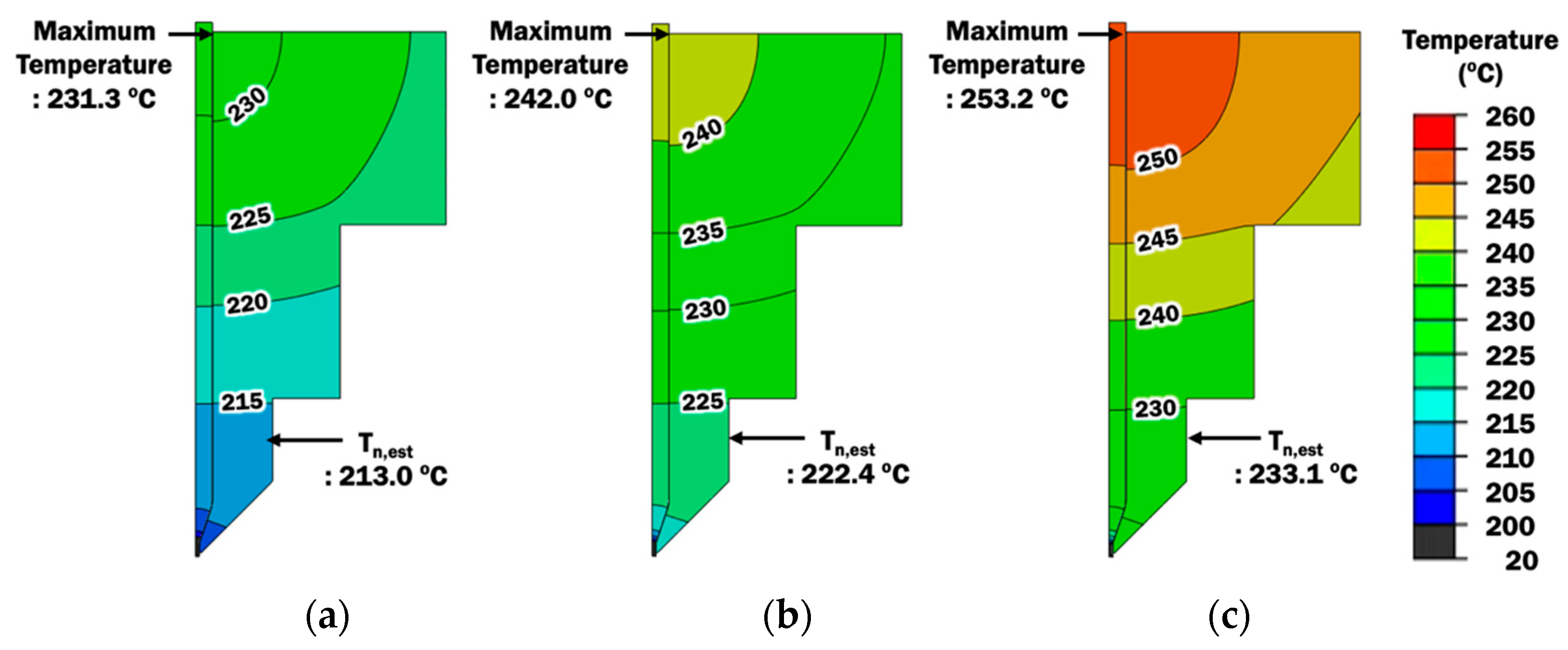

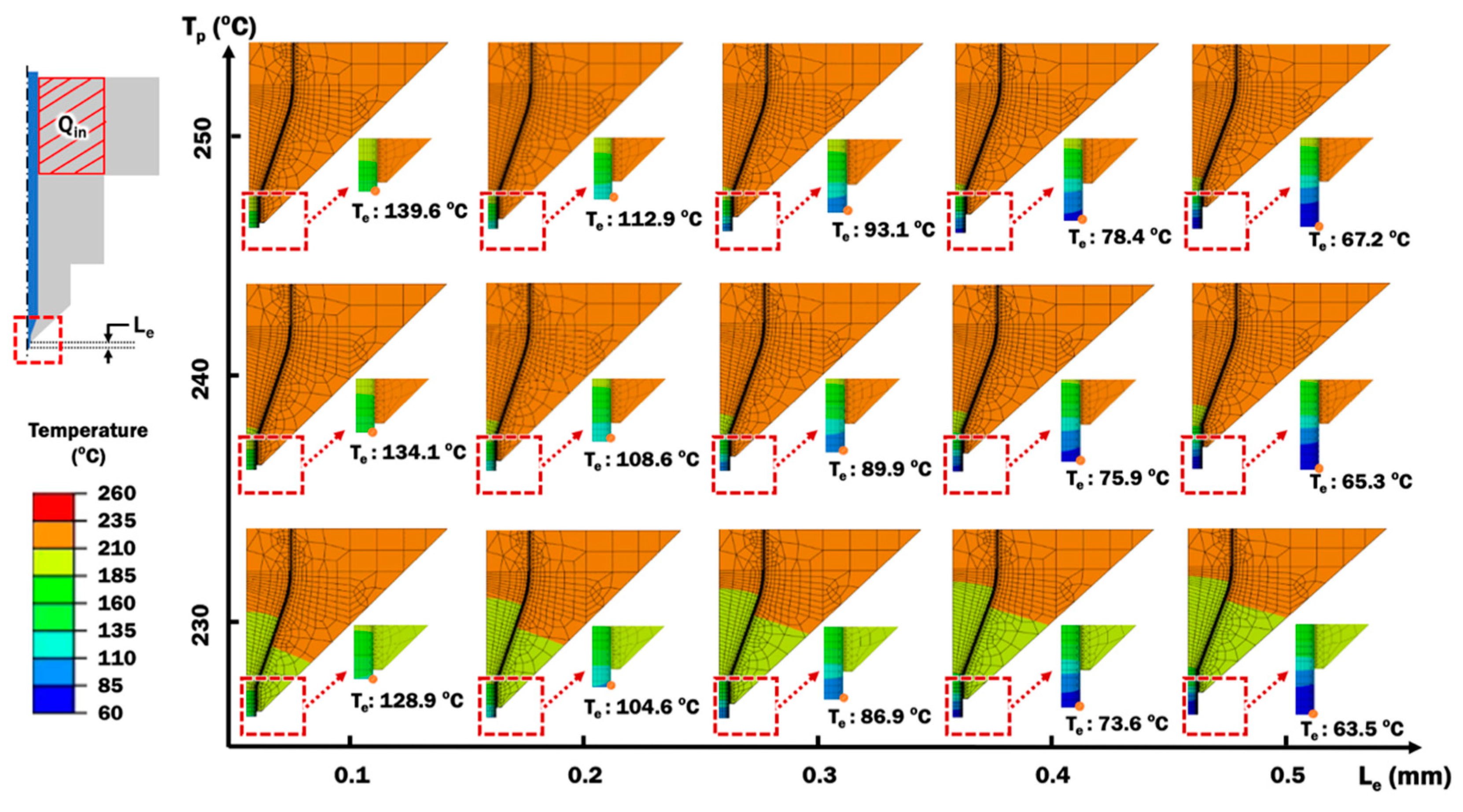

3.1. Effects of Printing Temperature and Stand-Off Distance on Temperature Distributions of Extruder Unit

3.1.1. Validation of FE Model for Extrusion Process

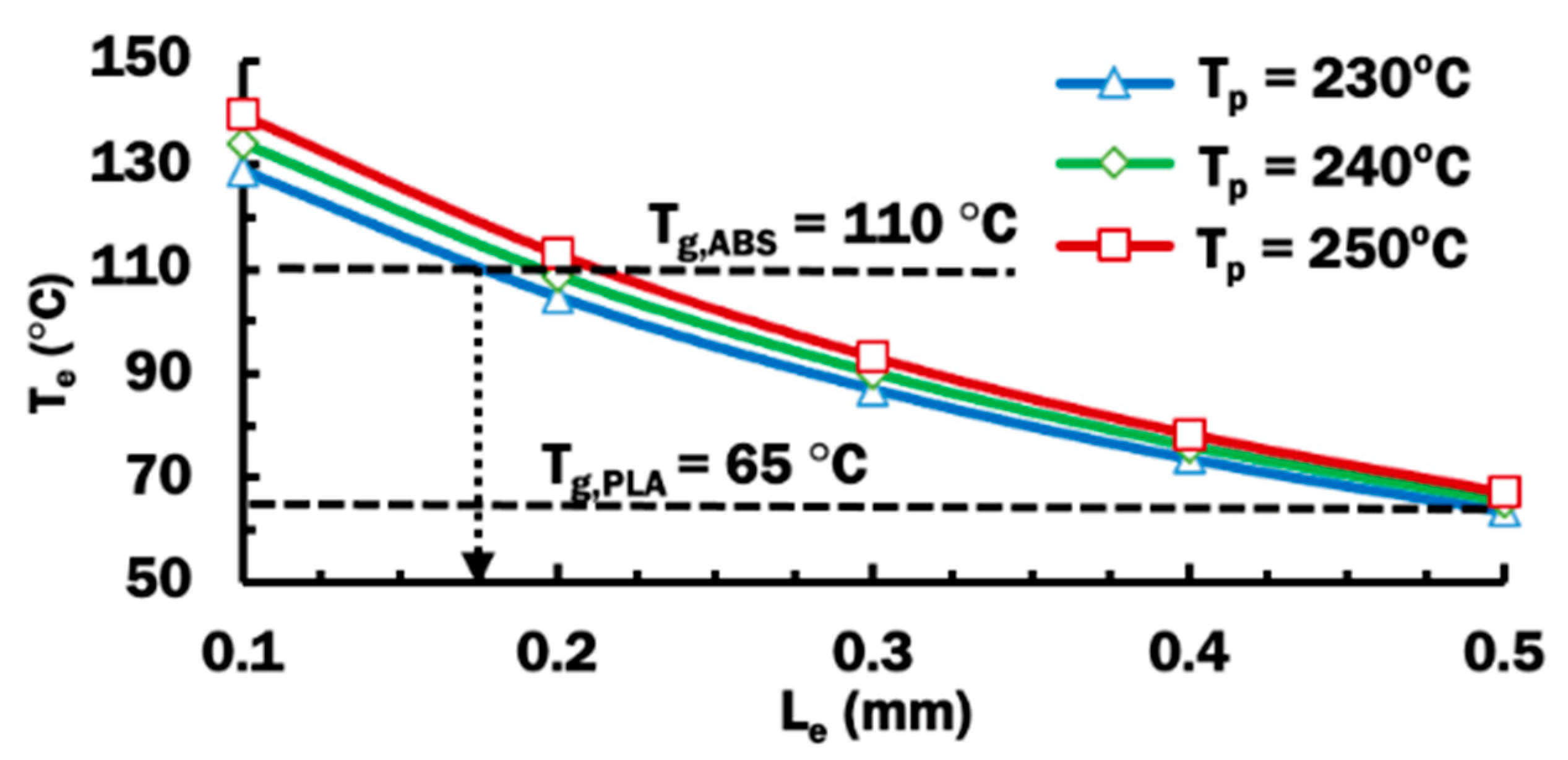

3.1.2. Effects of Printing Temperature and Extruded Length of PLA Filament on Temperature Distributions and Selection of Stand-Off Distance

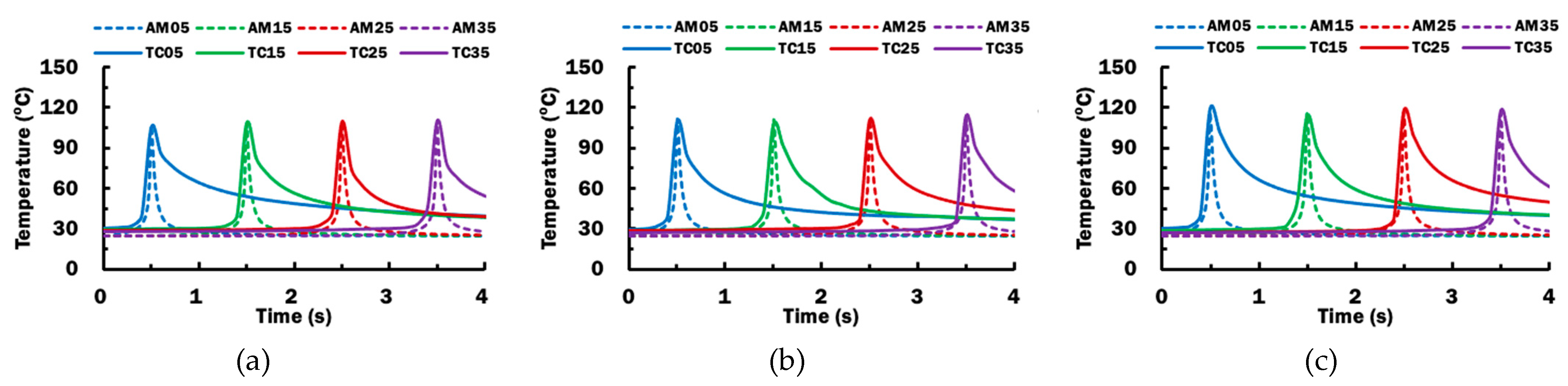

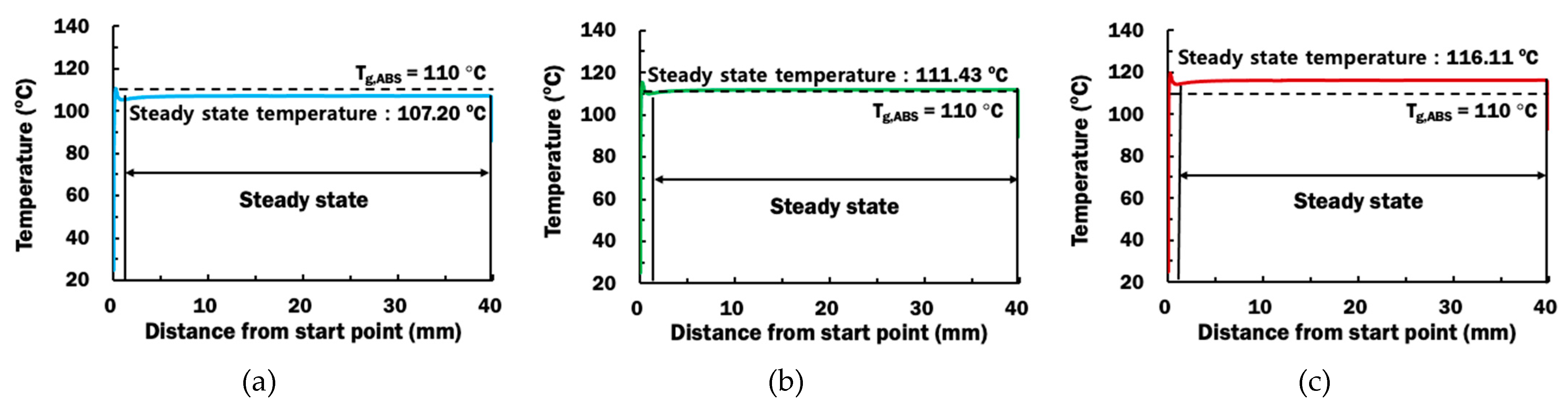

3.1.3. Relationship Between Estimated Temperature at End of Extruded Material and Measured Temperature at DSI during Deposition Process

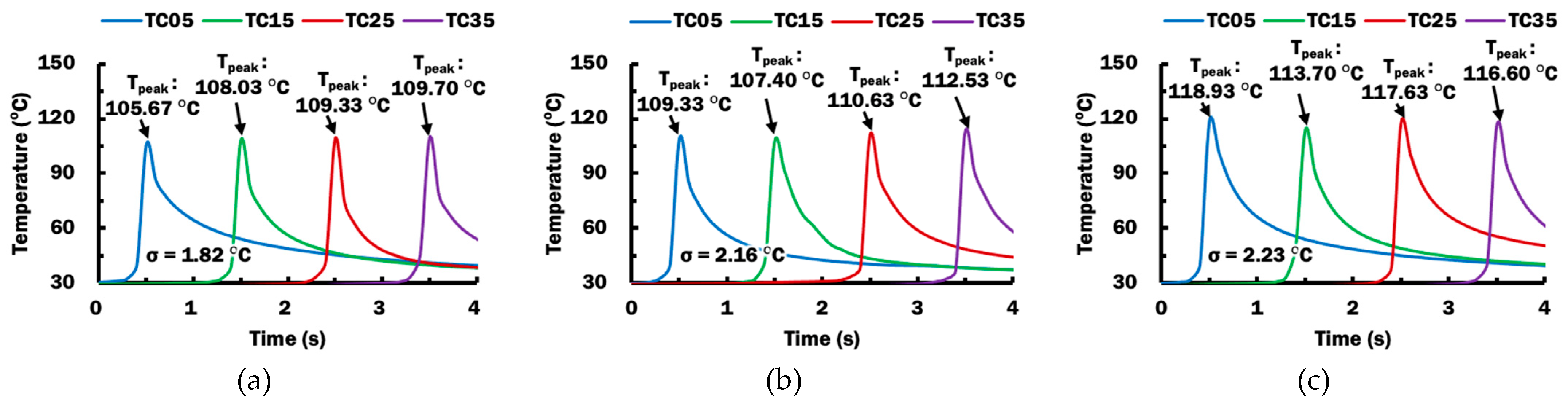

3.2. Effects of Printing Temperature on the Temperature Histories during Deposition Process

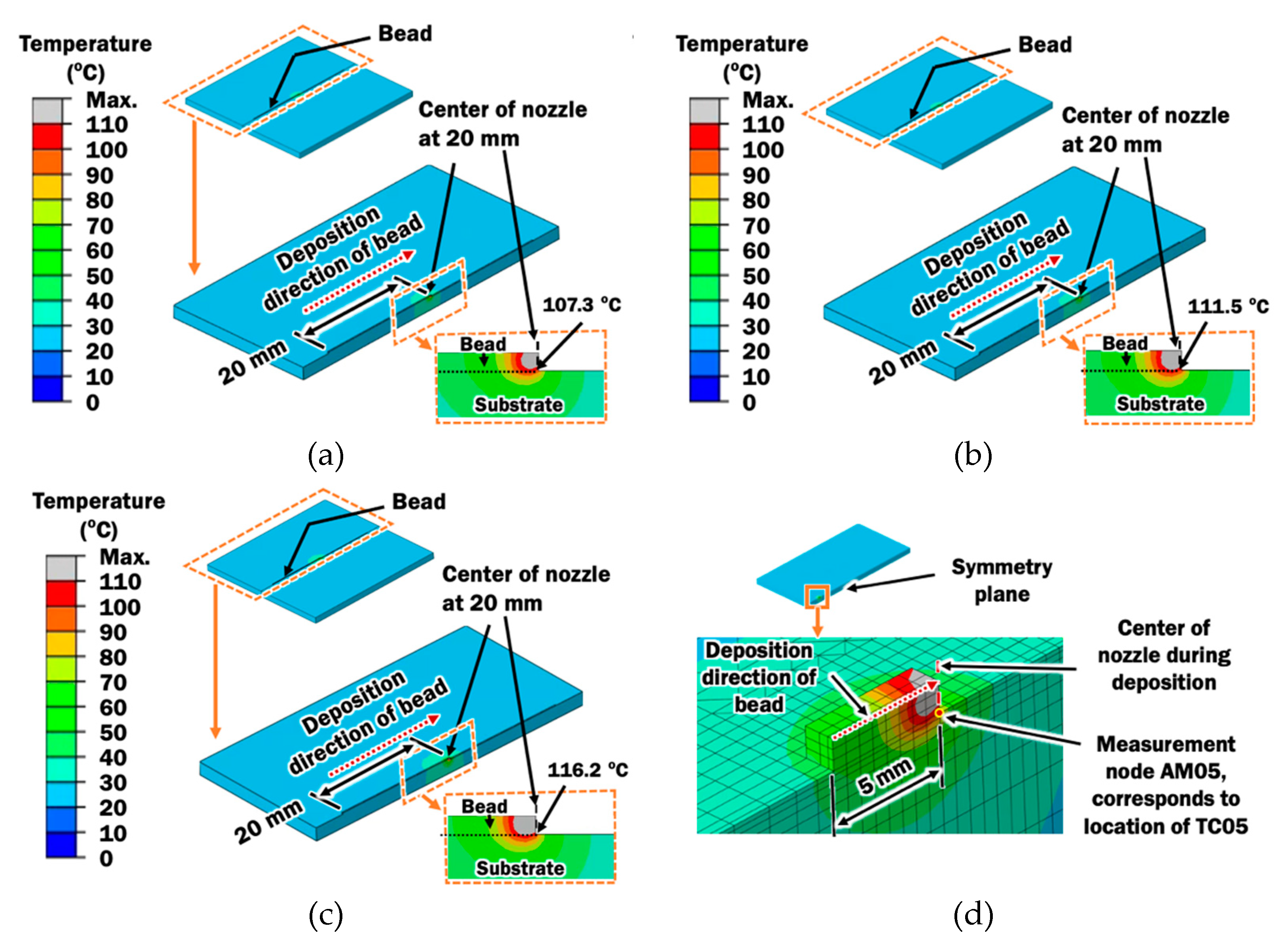

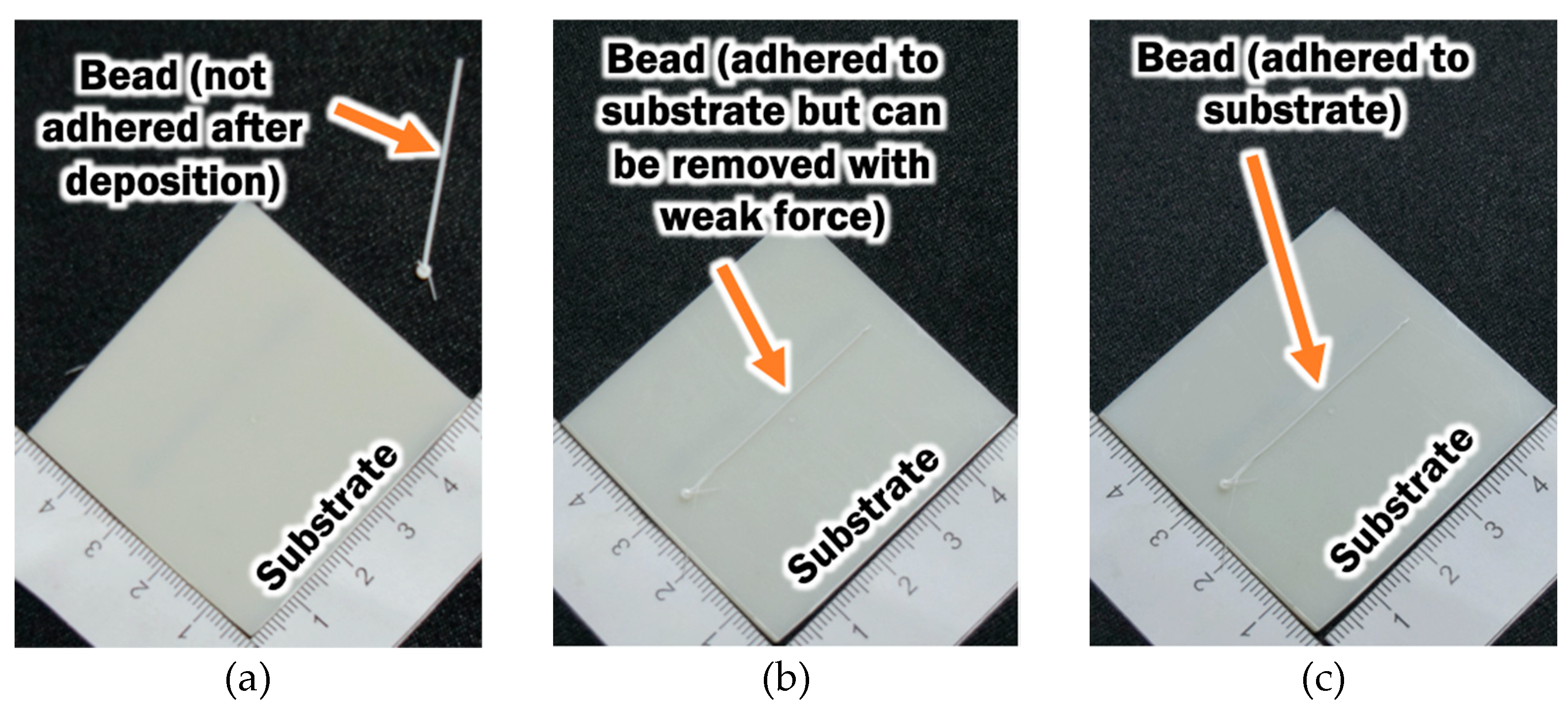

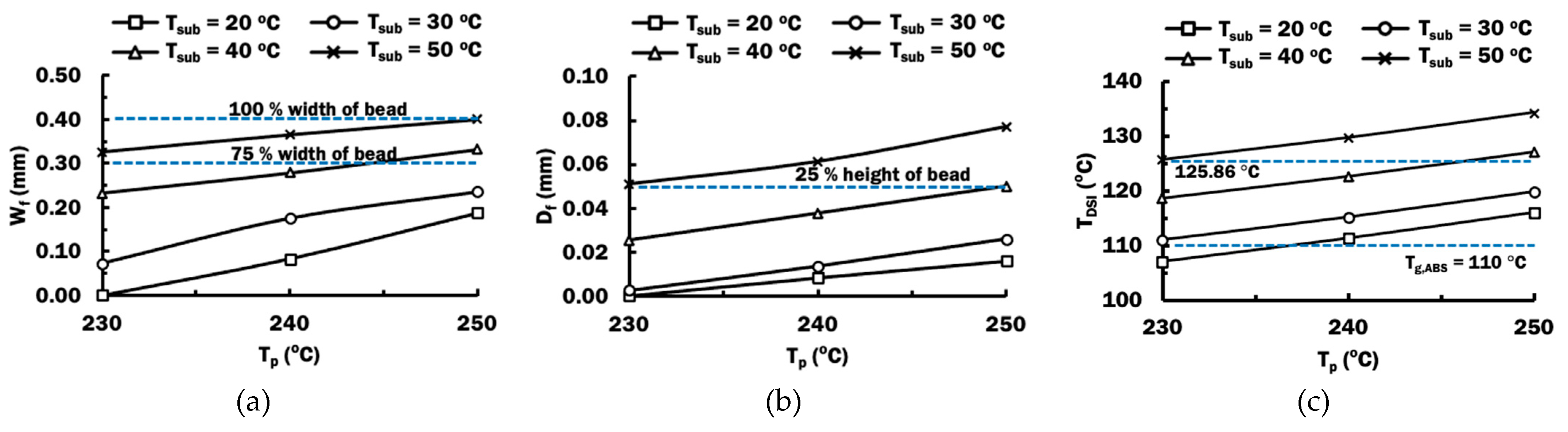

3.3. Effects of Plate Heating Temperature on the Temperature Distributions of Deposited Bead and Substrate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ME | Material Extrusion |

| FDM | Fused Deposition Modelling |

| ABS | Acrylonitrile Butadiene Styrene |

| PLA | Polylactic Acid |

| mFFF | Metallic Fused Filament Fabrication |

| SLA | Stereolithography |

| FE | Finite Element |

| FEA | Finite Element Analysis |

| DED | Directed Energy Deposition |

| DSI | Deposit–Substrate Interface |

References

- Sun, Q.; Rizvi, G.M.; Bellehumeur, C.T.; Gu, P. Effect of Processing Conditions on the Bonding Quality of FDM Polymer Filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Masood, S.H. Advances in Fused Deposition Modeling. In Comprehensive Materials Processing; Elsevier: Amsterdam, The Netherlands, 2014; pp. 69–91. ISBN 978-0-08-096533-8. [Google Scholar]

- Vanaei, H.; Shirinbayan, M.; Deligant, M.; Raissi, K.; Fitoussi, J.; Khelladi, S.; Tcharkhtchi, A. Influence of Process Parameters on Thermal and Mechanical Properties of Polylactic Acid Fabricated by Fused Filament Fabrication. Polym. Eng. Sci. 2020, 60, 1822–1831. [Google Scholar] [CrossRef]

- Abeykoon, C.; Sri-Amphorn, P.; Fernando, A. Optimization of Fused Deposition Modeling Parameters for Improved PLA and ABS 3D Printed Structures. Int. J. Lightweight Mater. Manuf. 2020, 3, 284–297. [Google Scholar] [CrossRef]

- Günay, E.E.; Velineni, A.; Park, K.; Okudan Kremer, G.E. An Investigation on Process Capability Analysis for Fused Filament Fabrication. Int. J. Precis. Eng. Manuf. 2020, 21, 759–774. [Google Scholar] [CrossRef]

- Torrado Perez, A.R.; Roberson, D.A.; Wicker, R.B. Fracture Surface Analysis of 3D-Printed Tensile Specimens of Novel ABS-Based Materials. J. Fail. Anal. Preven. 2014, 14, 343–353. [Google Scholar] [CrossRef]

- Dhinesh, S.K.; Arun, P.S.; Senthil, K.K.L.; Megalingam, A. Study on Flexural and Tensile Behavior of PLA, ABS and PLA-ABS Materials. Mater. Today Proc. 2021, 45, 1175–1180. [Google Scholar] [CrossRef]

- Rahim, T.N.A.T.; Abdullah, A.M.; Md Akil, H. Recent Developments in Fused Deposition Modeling-Based 3D Printing of Polymers and Their Composites. Polym. Rev. 2019, 59, 589–624. [Google Scholar] [CrossRef]

- Han, S.; Xiao, Y.; Qi, T.; Li, Z.; Zeng, Q. Design and Analysis of Fused Deposition Modeling 3D Printer Nozzle for Color Mixing. Adv. Mater. Sci. Eng. 2017, 2017, 1–12. [Google Scholar] [CrossRef]

- Prasad, A.; Kandasubramanian, B. Fused Deposition Processing Polycaprolactone of Composites for Biomedical Applications. Polym.-Plast. Technol. Mater. 2019, 58, 1365–1398. [Google Scholar] [CrossRef]

- Jeon, S.; Han, J.; Jeong, W.; Son, J.; Kim, J.B.; Kang, H.-W. Flexibility Enhancement of Poly(Lactide-Co-Glycolide) for Fused Deposition Modeling Technology. Int. J. Precis. Eng. Manuf.-Green Tech. 2019, 6, 465–475. [Google Scholar] [CrossRef]

- Han, S.; Sung, J.; So, H. Simple Fabrication of Water Harvesting Surfaces Using Three-Dimensional Printing Technology. Int. J. Precis. Eng. Manuf.-Green Tech. 2020. [Google Scholar] [CrossRef]

- Ertay, D.S.; Yuen, A.; Altintas, Y. Synchronized Material Deposition Rate Control with Path Velocity on Fused Filament Fabrication Machines. Addit. Manuf. 2018, 19, 205–213. [Google Scholar] [CrossRef]

- Reddy, V.; Flys, O.; Chaparala, A.; Berrimi, C.E.; V, A.; Rosen, B. Study on Surface Texture of Fused Deposition Modeling. Procedia Manuf. 2018, 25, 389–396. [Google Scholar] [CrossRef]

- Turner, B.N.; Gold, S.A. A Review of Melt Extrusion Additive Manufacturing Processes: II. Materials, Dimensional Accuracy, and Surface Roughness. Rapid Prototyp. J. 2015, 21, 250–261. [Google Scholar] [CrossRef]

- Kim, M.K.; Lee, I.H.; Kim, H.-C. Effect of Fabrication Parameters on Surface Roughness of FDM Parts. Int. J. Precis. Eng. Manuf. 2018, 19, 137–142. [Google Scholar] [CrossRef]

- Rane, R.; Kulkarni, A.; Prajapati, H.; Taylor, R.; Jain, A.; Chen, V. Post-Process Effects of Isothermal Annealing and Initially Applied Static Uniaxial Loading on the Ultimate Tensile Strength of Fused Filament Fabrication Parts. Materials 2020, 13, 352. [Google Scholar] [CrossRef]

- Yah Aw; Cheow Yeoh; Muhammad Idris; Pei Teh; Khairul Hamzah; Shulizawati Sazali Effect of Printing Parameters on Tensile, Dynamic Mechanical, and Thermoelectric Properties of FDM 3D Printed CABS/ZnO Composites. Materials 2018, 11, 466. [CrossRef]

- Song, X.; He, W.; Qin, H.; Yang, S.; Wen, S. Fused Deposition Modeling of Poly (Lactic Acid)/Macadamia Composites—Thermal, Mechanical Properties and Scaffolds. Materials 2020, 13, 258. [Google Scholar] [CrossRef] [PubMed]

- Penumakala, P.K.; Santo, J.; Thomas, A. A Critical Review on the Fused Deposition Modeling of Thermoplastic Polymer Composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Li, F.; Macdonald, N.P.; Guijt, R.M.; Breadmore, M.C. Increasing the Functionalities of 3D Printed Microchemical Devices by Single Material, Multimaterial, and Print-Pause-Print 3D Printing. Lab Chip 2019, 19, 35–49. [Google Scholar] [CrossRef]

- De Santis, R.; Gloria, A.; Russo, T.; D’Amora, U.; Zeppetelli, S.; Tampieri, A.; Herrmannsdörfer, T.; Ambrosio, L. A Route toward the Development of 3D Magnetic Scaffolds with Tailored Mechanical and Morphological Properties for Hard Tissue Regeneration: Preliminary Study: A Basic Approach toward the Design of 3D Rapid Prototyped Magnetic Scaffolds for Hard-Tissue Regeneration Is Presented and Validated in This Paper. Virtual Phys. Prototyp. 2011, 6, 189–195. [Google Scholar] [CrossRef]

- Gloria, A.; Frydman, B.; Lamas, M.L.; Serra, A.C.; Martorelli, M.; Coelho, J.F.J.; Fonseca, A.C.; Domingos, M. The Influence of Poly(Ester Amide) on the Structural and Functional Features of 3D Additive Manufactured Poly(ε-Caprolactone) Scaffolds. Mater. Sci. Eng. C 2019, 98, 994–1004. [Google Scholar] [CrossRef] [PubMed]

- Duarte, L.C.; Chagas, C.L.S.; Ribeiro, L.E.B.; Coltro, W.K.T. 3D Printing of Microfluidic Devices with Embedded Sensing Electrodes for Generating and Measuring the Size of Microdroplets Based on Contactless Conductivity Detection. Sens. Actuators B Chem. 2017, 251, 427–432. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H.; Chen, Q.; Advincula, R.C. Mechanical Characterization of 3D-Printed Polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Melenka, G.W.; Cheung, B.K.O.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation and Prediction of the Tensile Properties of Continuous Fiber-Reinforced 3D Printed Structures. Compos. Struct. 2016, 153, 866–875. [Google Scholar] [CrossRef]

- Caminero, M.; Chacón, J.; García-Plaza, E.; Núñez, P.; Reverte, J.; Becar, J. Additive Manufacturing of PLA-Based Composites Using Fused Filament Fabrication: Effect of Graphene Nanoplatelet Reinforcement on Mechanical Properties, Dimensional Accuracy and Texture. Polymers 2019, 11, 799. [Google Scholar] [CrossRef]

- Rigoussen, A.; Raquez, J.-M.; Dubois, P.; Verge, P. A Dual Approach to Compatibilize PLA/ABS Immiscible Blends with Epoxidized Cardanol Derivatives. Eur. Polym. J. 2019, 114, 118–126. [Google Scholar] [CrossRef]

- Zhang, Y.; Chou, Y.K. Three-Dimensional Finite Element Analysis Simulations of the Fused Deposition Modelling Process. Proc. Inst. Mech.Eng. Part B J. Eng. Manuf. 2006, 220, 1663–1671. [Google Scholar] [CrossRef]

- Costa, S.; Duarte, F.; Covas, J.A. Using MATLAB to Compute Heat Transfer in Free Form Extrusion. In MATLAB-A Ubiquitous Tool for the Practical Engineer; Ionescu, C., Ed.; InTech: Munich, Germany, 2011; ISBN 978-953-307-907-3. [Google Scholar]

- Li, L.; Sun, Q.; Bellehumeur, C.; Gu, P. Investigation of Bond Formation in FDM Process; The University of Texas: Austin, TX, USA, 2002; pp. 400–407. [Google Scholar]

- Chua, B.L.; Lee, H.J.; Ahn, D.G.; Wang, Y. A Study on Activation Algorithm of Finite Elements for Three-Dimensional Transient Heat Transfer Analysis of Directed Energy Deposition Process. Int. J. Precis. Eng. Manuf. 2019, 20, 863–869. [Google Scholar] [CrossRef]

- MakerBot Replicator (5th Generation): Manuals and Guides. Available online: https://support.makerbot.com/s/article/User-Guides-Replicator-Fifth-Generation-English-and-translations (accessed on 22 March 2021).

- Logan, D.L. A First Course in the Finite Element Method, 5th ed.; Cengage Learning: Stamford, CT, USA, 2012; ISBN 978-0-495-66825-1. [Google Scholar]

- Vasileiou, A.; Vosniakos, G.-C.; Pantelis, D. Determination of Local Heat Transfer Coefficients in Precision Castings by Genetic Optimisation Aided by Numerical Simulation. Proc. Inst. Mech.Eng. Part C J. Mech. Eng. Sci. 2015, 229, 735–750. [Google Scholar] [CrossRef]

- Beanumont Moldflow Material Characterization. Available online: https://www.beaumontinc.com/moldflow-material-characterization/ (accessed on 1 March 2020).

- Pandey, A.K.; Kumar, R.; Kachhavah, V.S.; Kar, K.K. Mechanical and Thermal Behaviours of Graphite Flake-Reinforced Acrylonitrile–Butadiene–Styrene Composites and Their Correlation with Entanglement Density, Adhesion, Reinforcement and C Factor. RSC Adv. 2016, 6, 50559–50571. [Google Scholar] [CrossRef]

- Awaja, F.; Gilbert, M.; Kelly, G.; Fox, B.; Pigram, P.J. Adhesion of Polymers. Prog. Polym. Sci. 2009, 34, 948–968. [Google Scholar] [CrossRef]

- Ravi, A.K.; Deshpande, A.; Hsu, K.H. An In-Process Laser Localized Pre-Deposition Heating Approach to Inter-Layer Bond Strengthening in Extrusion Based Polymer Additive Manufacturing. J. Manuf. Process. 2016, 24, 179–185. [Google Scholar] [CrossRef]

| Printing Temperature (Tp, °C) | Extruded Length of PLA from the End of Nozzle Orifice (Le, mm) |

|---|---|

| 230, 240, 250 | 0.1, 0.2, 0.3, 0.4, 0.5 |

| Printing Temperature (Tp, °C) | ABS Substrate Initial Temperature (Ts, °C) | Deposition Speed (V, mm/s) | Height of Bead (hb, mm) |

|---|---|---|---|

| 230, 240, 250 | 20 | 10 | 0.2 |

| Penetration Depth (hb, mm) | Effective Heat Radius at Surface of Bead (re, mm) | Effective Heat Radius at hb (ri, mm) |

|---|---|---|

| 0.2 | 0.2 | 0.199 |

| Printing Temperature (Tp, °C) | Calibrated Efficiency (η, %) |

|---|---|

| 230, 240, 250 | 100 |

| Printing Temperature (Tp, °C) | ABS Substrate Heating Temperature (Ts, °C) | Deposition Speed (V, mm/s) | Height of Bead (hb, mm) |

|---|---|---|---|

| 230, 240, 250 | 30, 40, 50 | 10 | 0.2 |

| Printing Temperature (Tp, °C) | Measured Temperature at Nozzle (Tn,actual, °C) | Estimated Temperature at Nozzle (Tn,est, °C) |

|---|---|---|

| 230 | 215.0 | 213.0 |

| 240 | 223.2 | 222.4 |

| 250 | 233.4 | 233.1 |

| Printing Temperature (Tp, °C) | Mean Peak Temperature of TC05, TC15, TC25, and TC35 (Tdeposit, °C) | Estimated Temperature at End of Extruded Material for Le = 0.2 mm (Te, °C) |

|---|---|---|

| 230 | 108.18 | 104.6 |

| 240 | 109.98 | 108.6 |

| 250 | 116.72 | 112.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chua, B.-L.; Baek, S.-H.; Park, K.; Ahn, D.-G. Numerical Investigation of Deposition Characteristics of PLA on an ABS Plate Using a Material Extrusion Process. Materials 2021, 14, 3404. https://doi.org/10.3390/ma14123404

Chua B-L, Baek S-H, Park K, Ahn D-G. Numerical Investigation of Deposition Characteristics of PLA on an ABS Plate Using a Material Extrusion Process. Materials. 2021; 14(12):3404. https://doi.org/10.3390/ma14123404

Chicago/Turabian StyleChua, Bih-Lii, Sun-Ho Baek, Keun Park, and Dong-Gyu Ahn. 2021. "Numerical Investigation of Deposition Characteristics of PLA on an ABS Plate Using a Material Extrusion Process" Materials 14, no. 12: 3404. https://doi.org/10.3390/ma14123404

APA StyleChua, B.-L., Baek, S.-H., Park, K., & Ahn, D.-G. (2021). Numerical Investigation of Deposition Characteristics of PLA on an ABS Plate Using a Material Extrusion Process. Materials, 14(12), 3404. https://doi.org/10.3390/ma14123404