Influence of Different Alloying Strategies on the Mechanical Behavior of Tool Steel Produced by Laser-Powder Bed Fusion

Abstract

:1. Introduction

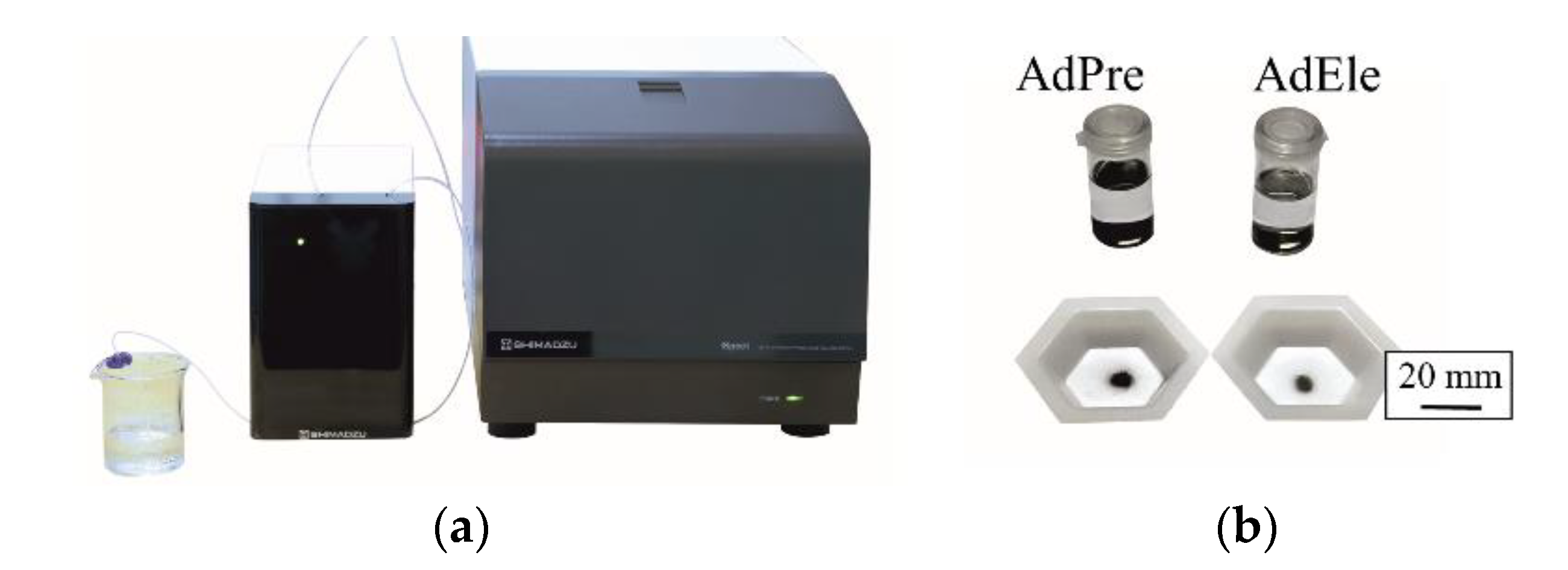

2. Materials and Methods

2.1. Powder Feed Stock Characterization

2.2. L-PBF Fabrication

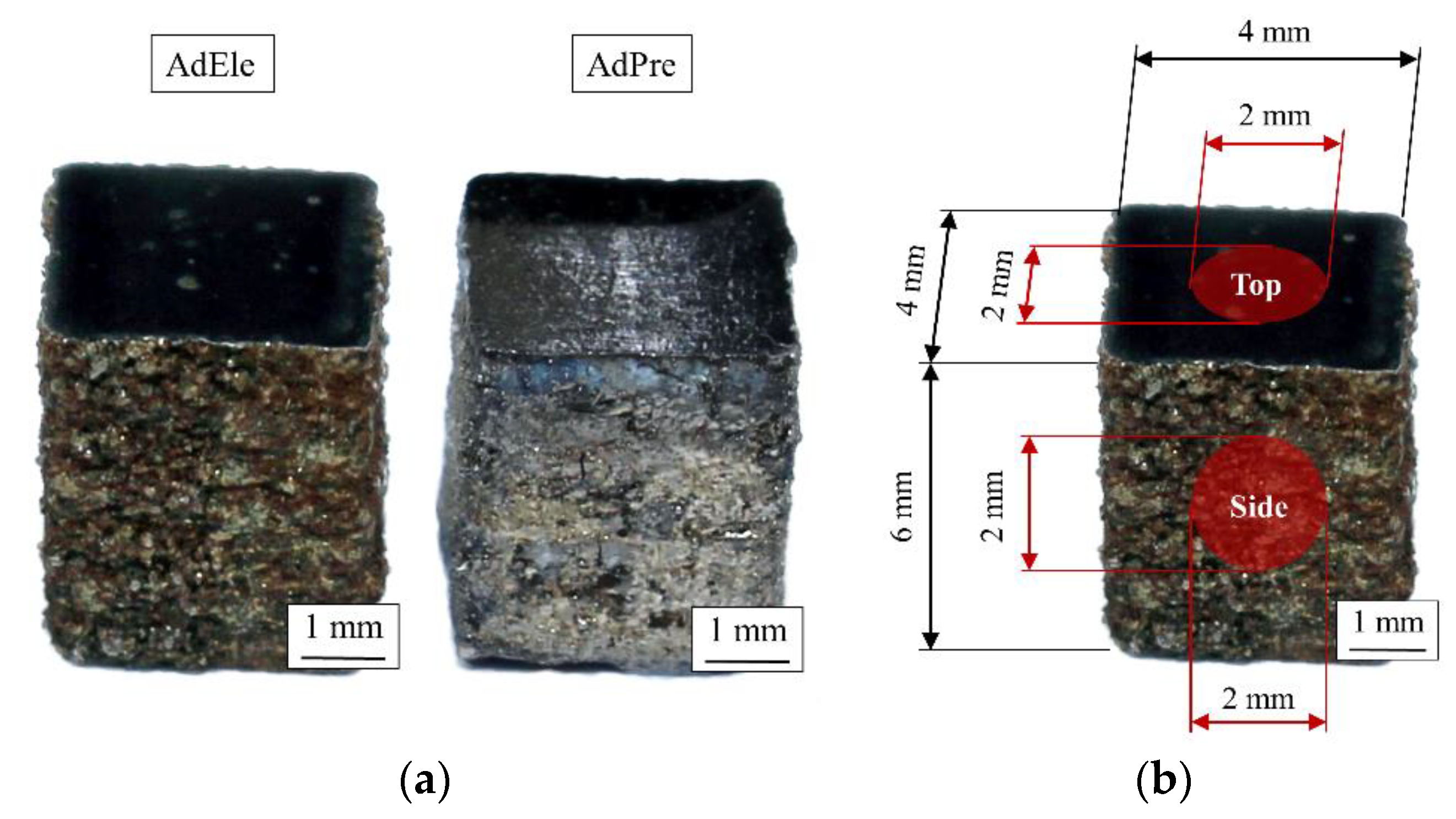

2.3. Residual Stress

2.4. Metallography and Microscopy

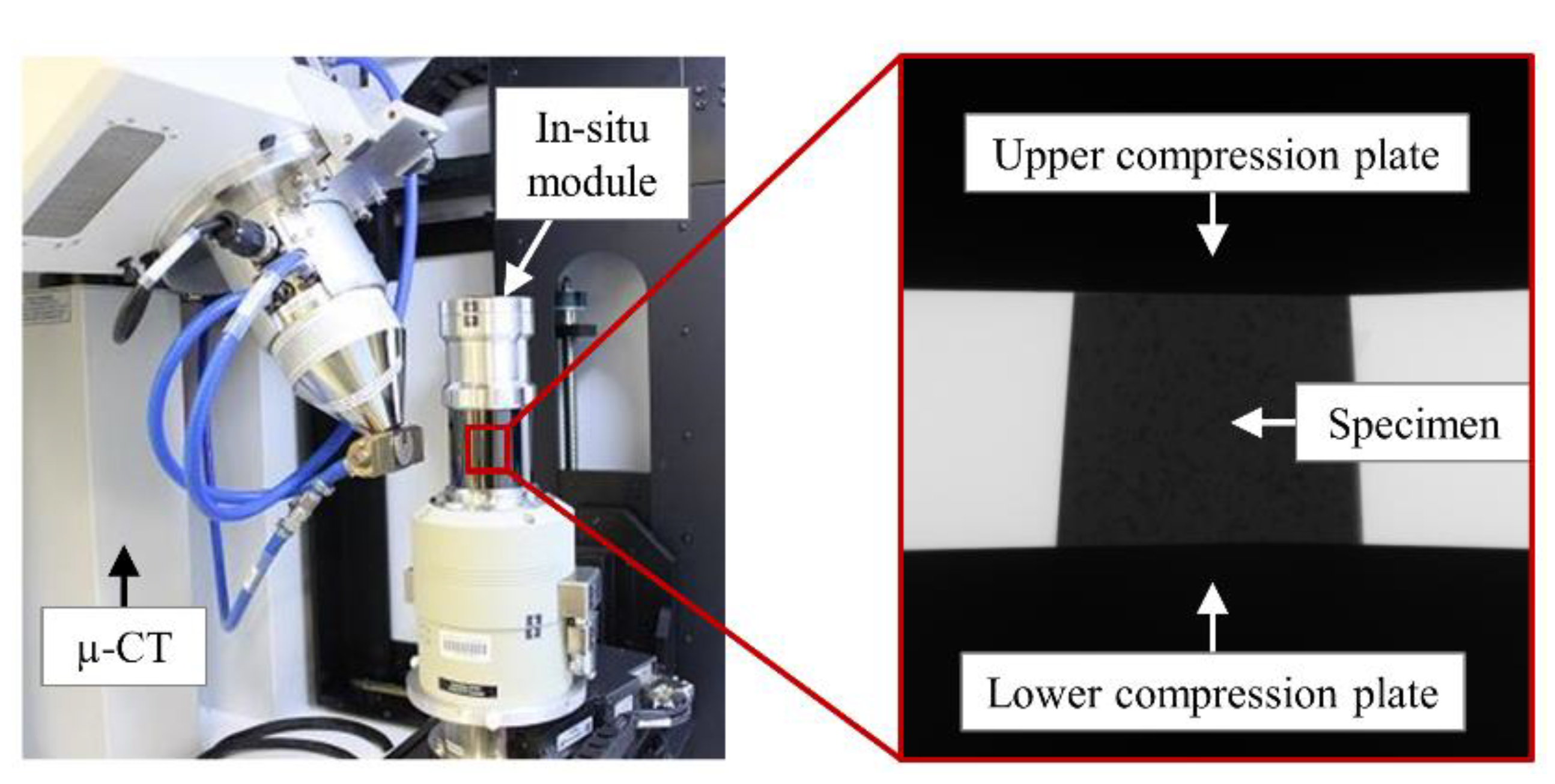

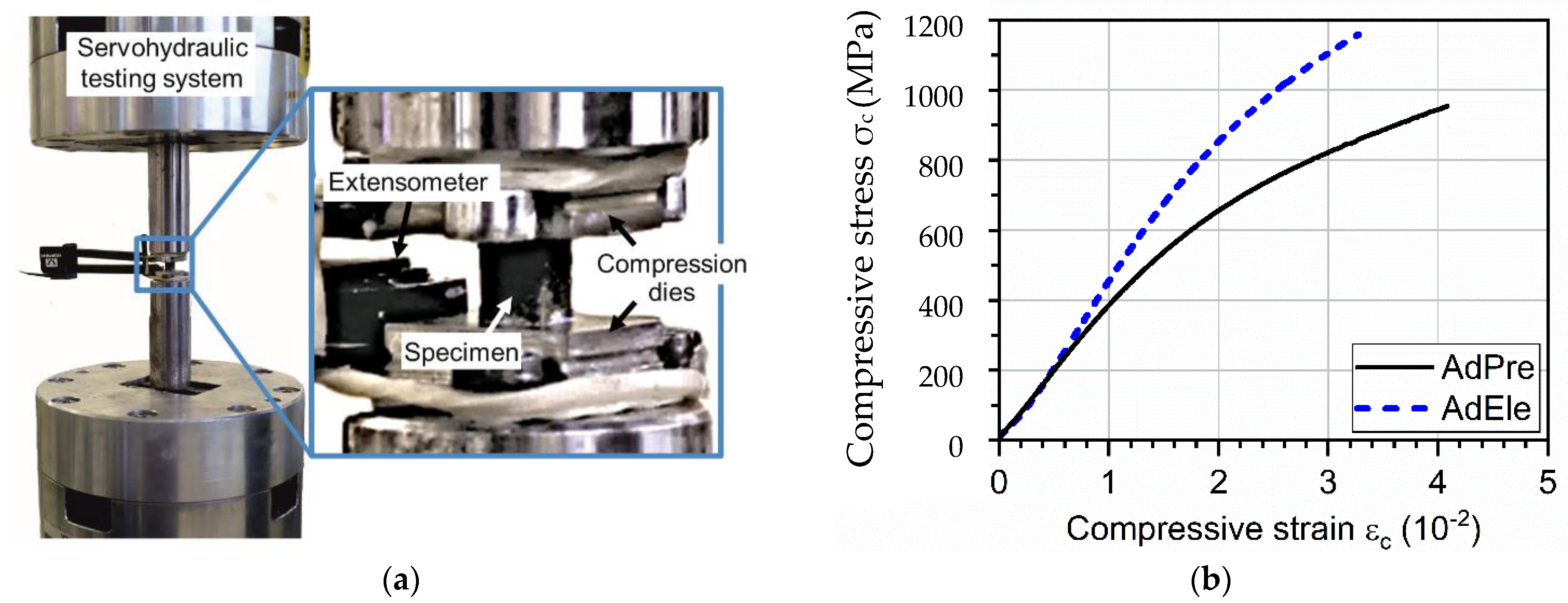

2.5. Mechanical Testing

3. Results and Discussion

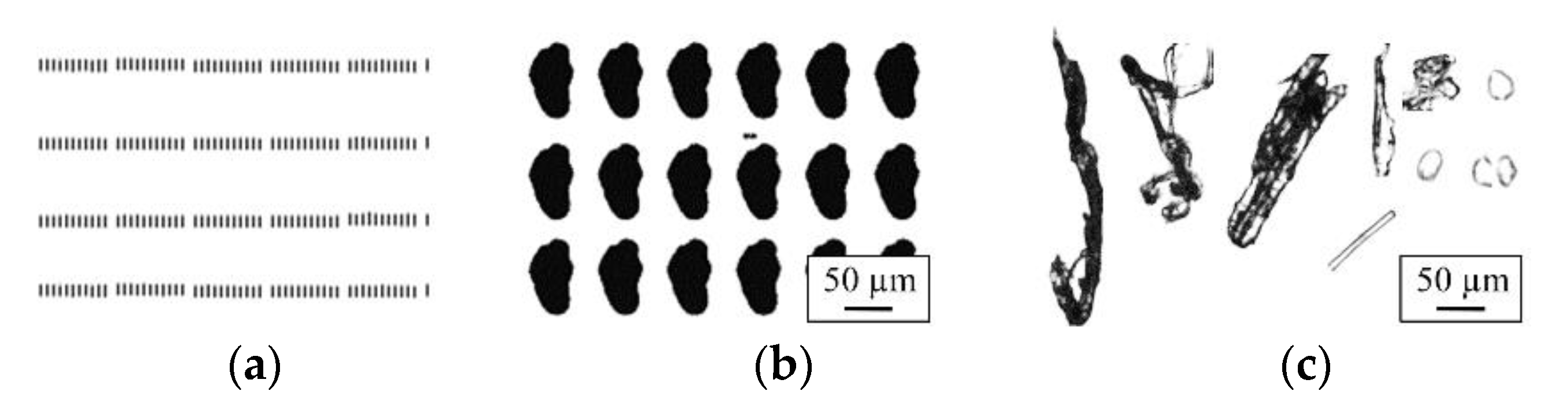

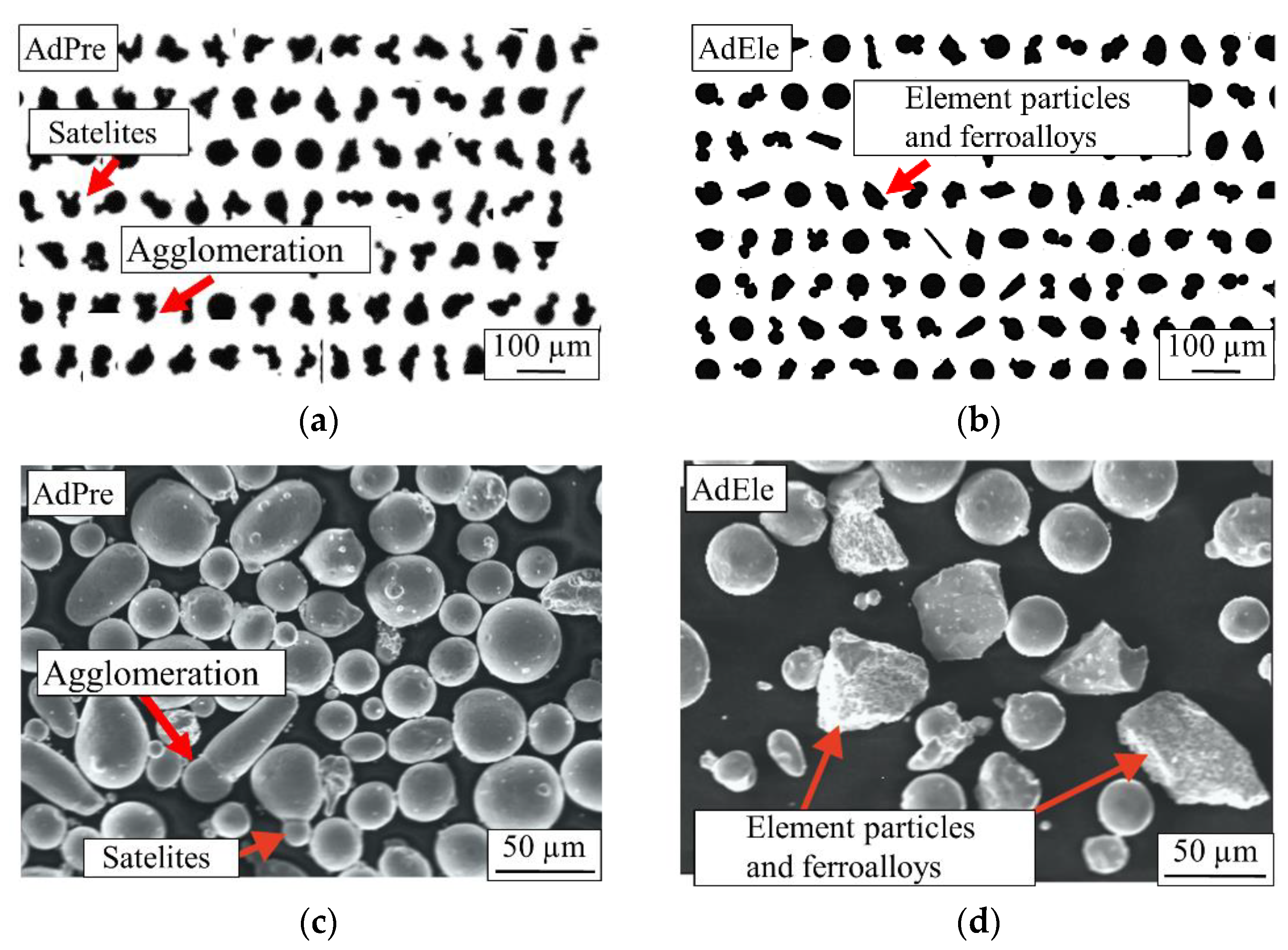

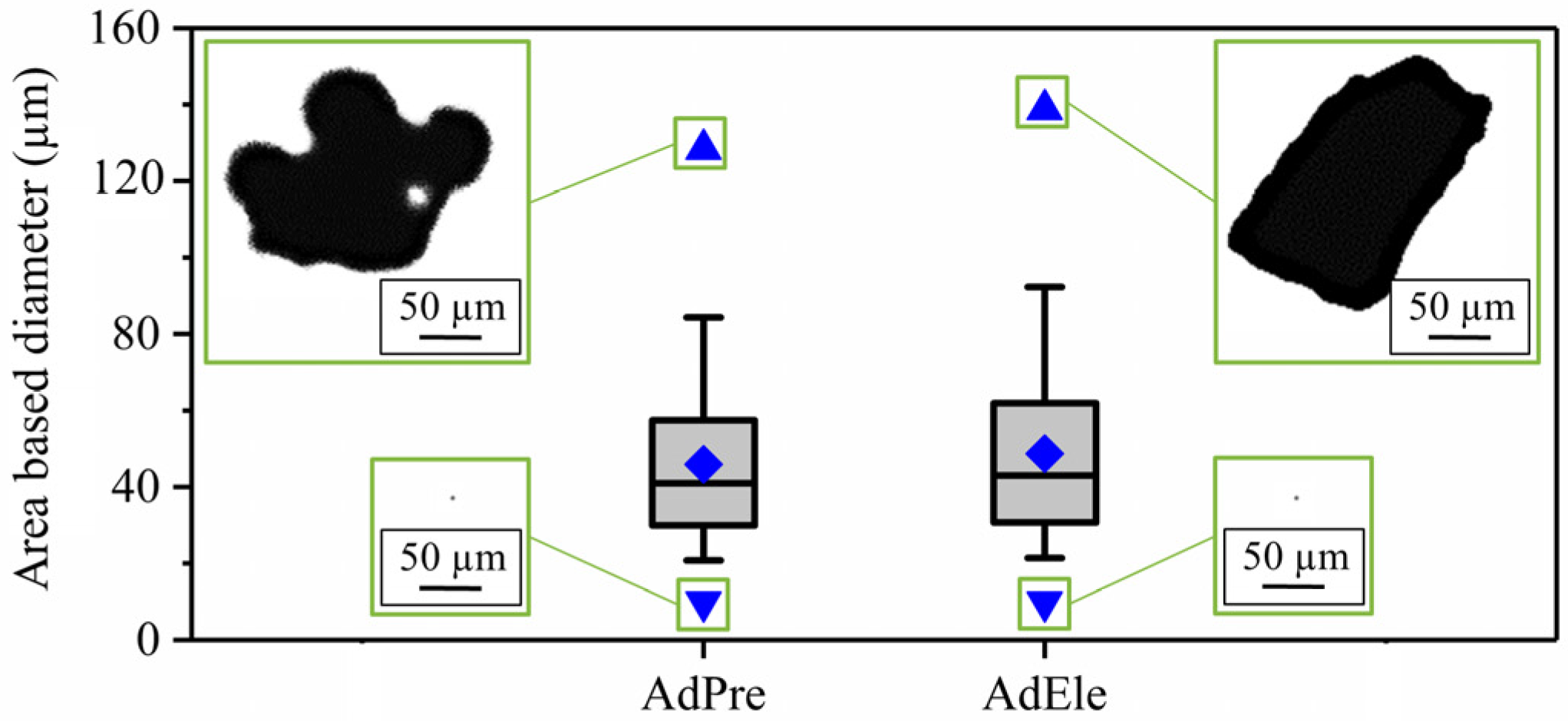

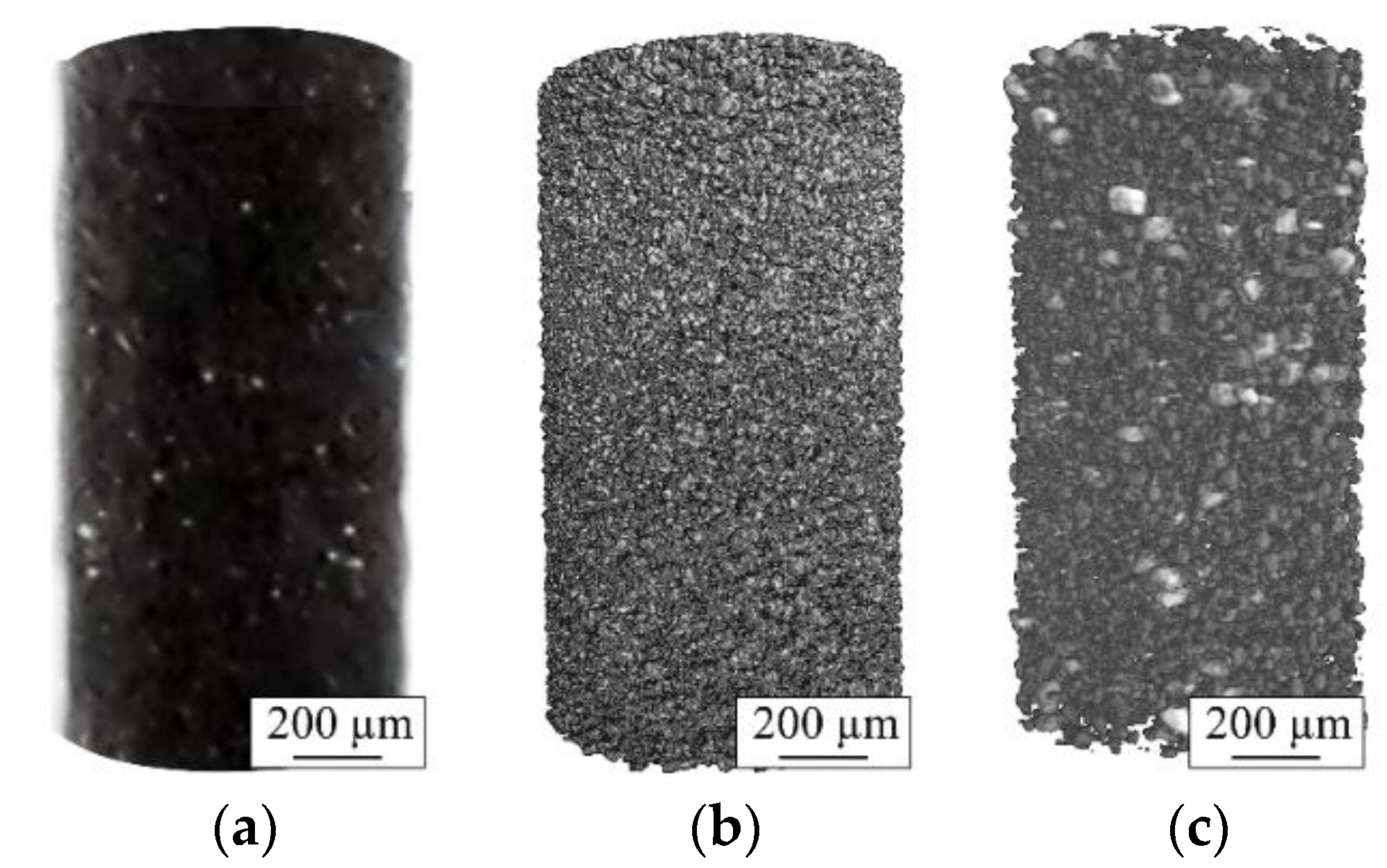

3.1. Powder Size Distribution and Morphology

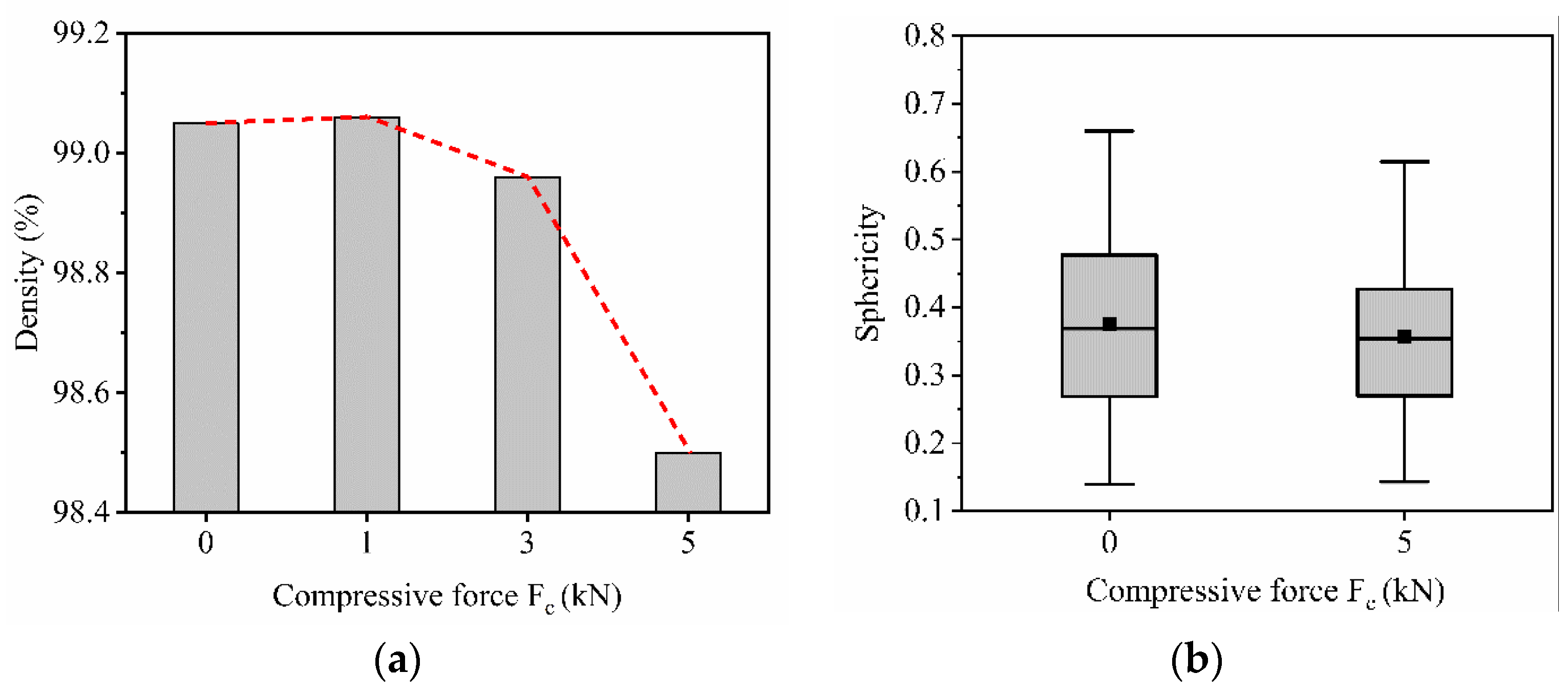

3.2. Defect Analysis of Powder Particles

3.3. Mechanical Testing of Powder Particles

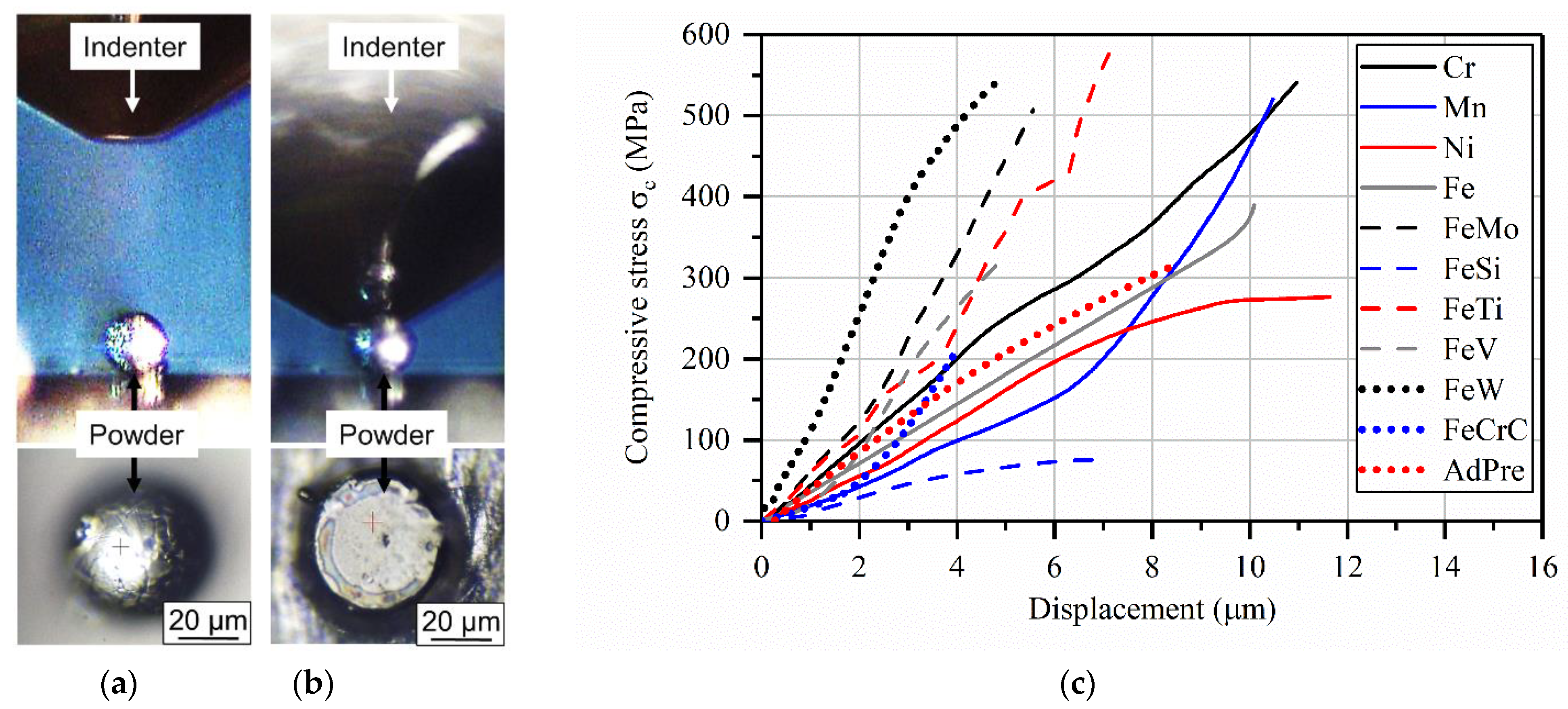

3.4. Defect Analysis of L-PBF Specimens

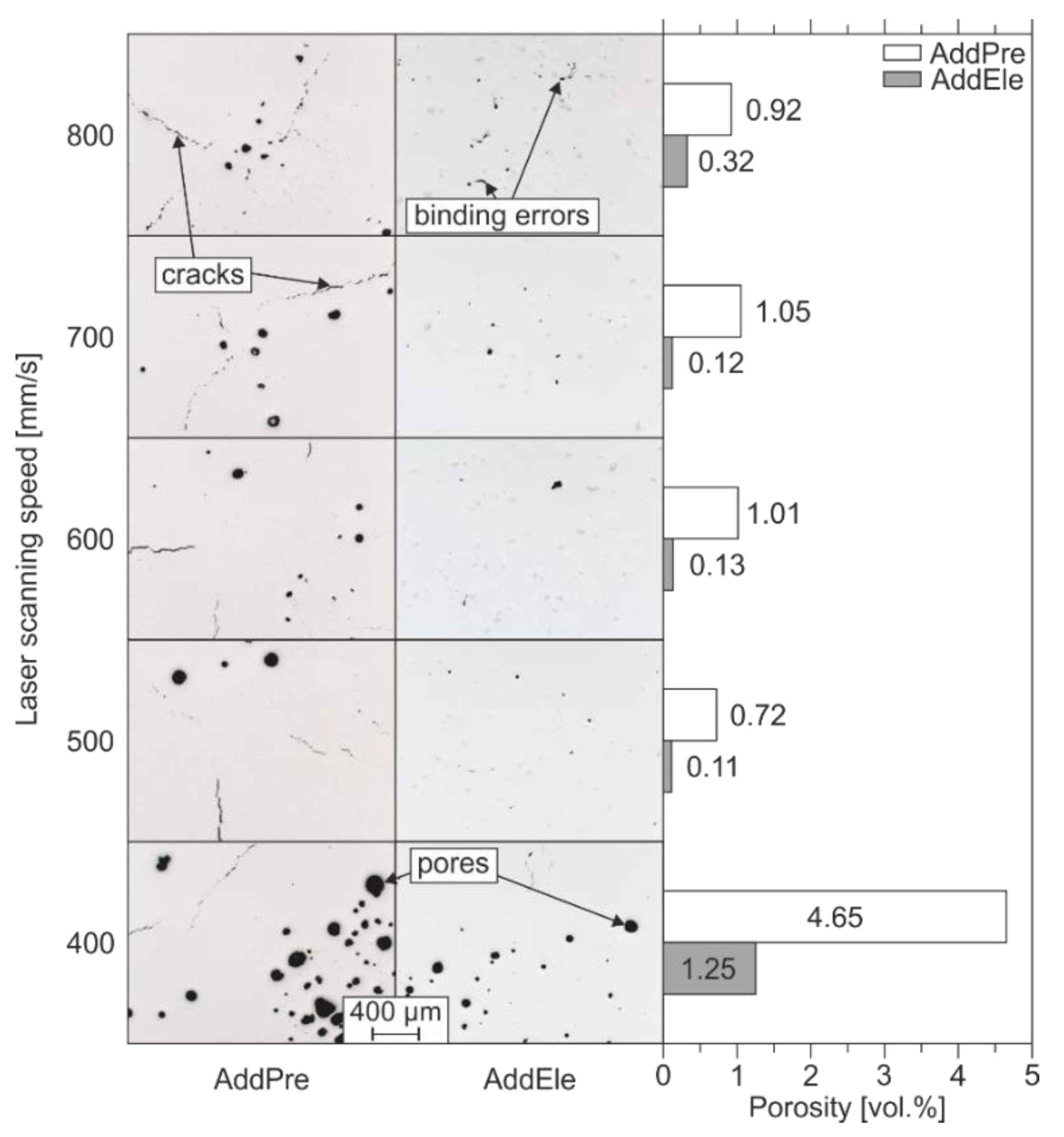

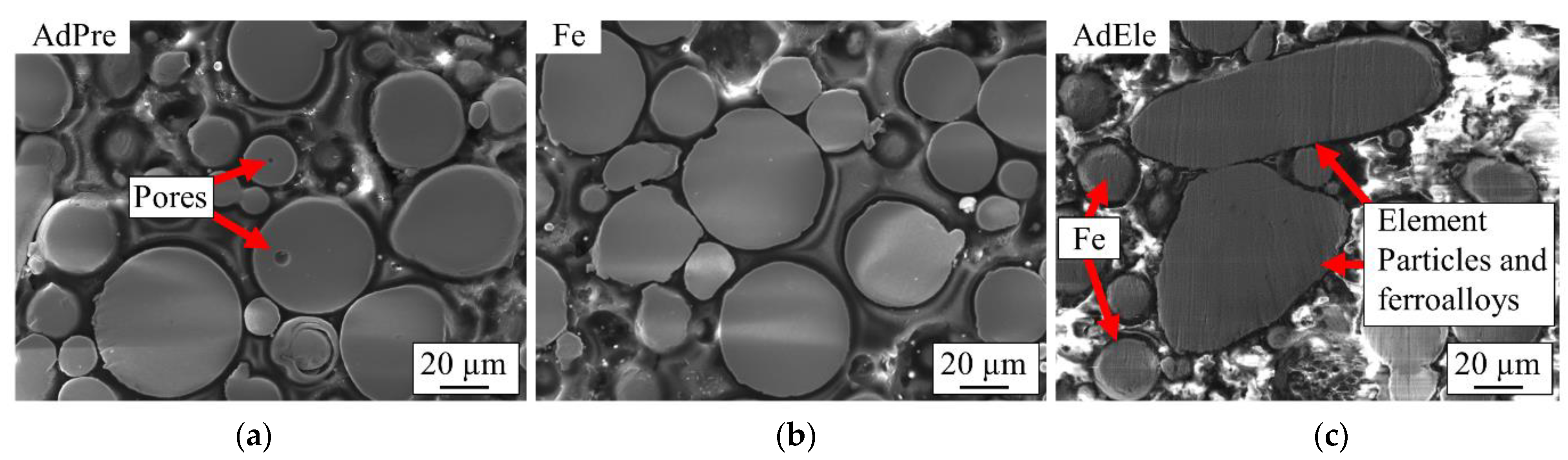

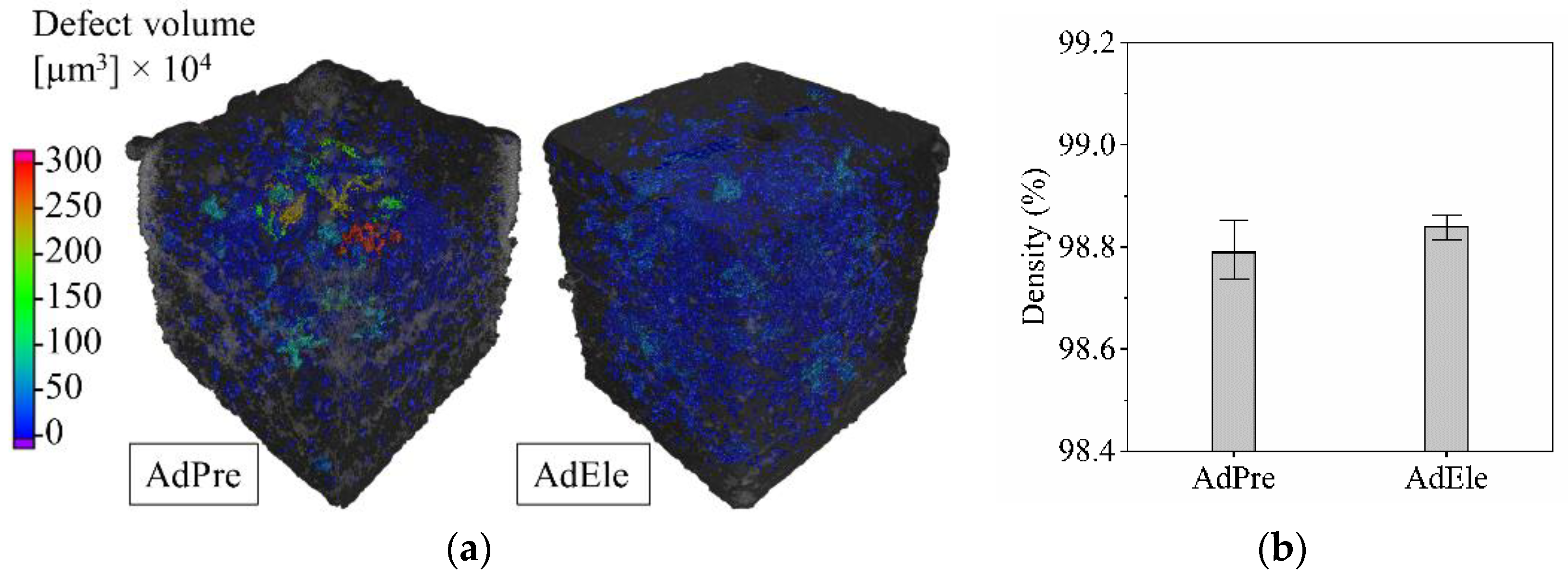

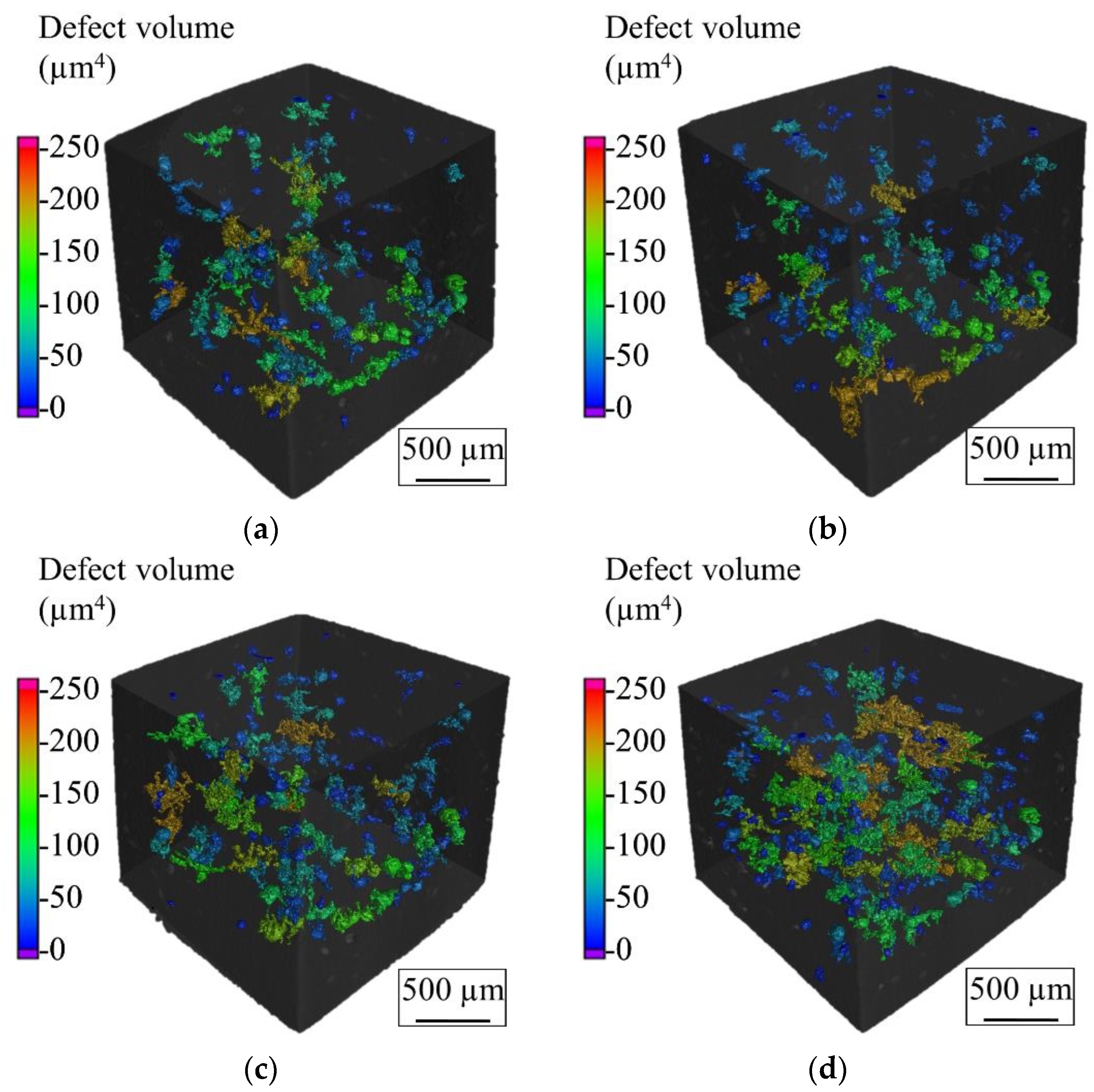

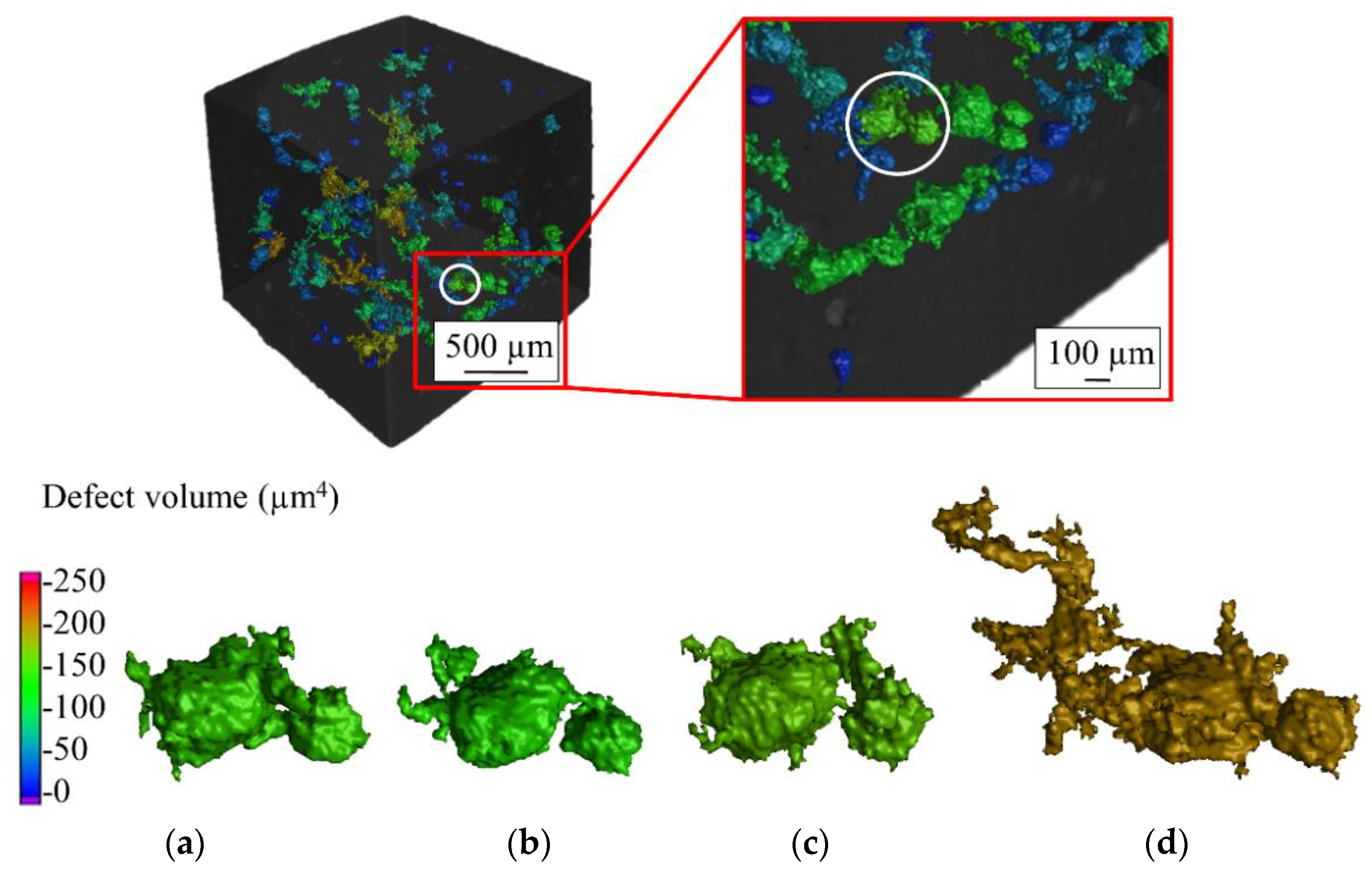

3.5. Residual Stress of L-PBF Specimens

3.6. Mechanical Testing of L-PBF Specimens

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandía, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of mechanical properties of AISI 316 stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int. J. Adv. Manuf. Technol. 2010, 51, 639–647. [Google Scholar] [CrossRef]

- Taruttis, A.; Hardes, C.; Röttger, A.; Uhlenwinkel, V.; Chehreh, A.B.; Theisen, W.; Walther, F.; Zoch, H.W. Laser additive manufacturing of hot work tool steel by means of a starting powder containing partly spherical pure elements and ferroalloys. Procedia CIRP 2020, 94, 46–51. [Google Scholar] [CrossRef]

- Kruth, J.P.; Levy, G.; Klocke, F.; Childs, T.H.C. Consolidation phenomena in laser and powder-bed based layered manufacturing. CIRP Annu. Manuf. Technol. 2007, 56, 730–759. [Google Scholar] [CrossRef]

- Riemer, A.; Leuders, S.; Thone, M.; Richard, H.A.; Troster, T.; Niendorf, T. On the fatigue crack growth behavior in 316L stainless steel manufactured by selective laser melting. Eng. Fract. Mech. 2014, 120, 15–25. [Google Scholar] [CrossRef]

- Krell, J.; Röttger, A.; Geenen, K.; Theisen, W. General investigations on processing tool steel X40CrMoV5-1 with selective laser melting. J. Mater. Proc. Technol. 2018, 255, 679–688. [Google Scholar] [CrossRef]

- Leal, R.; Barreiros, F.M.; Alves, L.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive manufacturing tooling for the automotive industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Bremen, S.; Meiners, W.; Diatlov, A. Selective laser melting: A manufacturing technology for the future? Laser Tech. J. 2012, 9, 33–38. [Google Scholar] [CrossRef]

- Boes, J.; Röttger, A.; Mutke, C.; Escher, C.; Theisen, W. Microstructure and mechanical properties of X65MoCrWV3-2 cold-work tool steel produced by selective laser melting. Addict. Manuf. 2018, 23, 170–180. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Aota, L.S.; Bajaj, P.; Sandim, H.R.Z.; Jägle, E.A. Laser powder-bed fusion as an alloy development tool: Parameter selection for in-situ alloying using elemental powders. Materials 2020, 13, 3922. [Google Scholar] [CrossRef]

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for additive manufacturing. CIRP Ann. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Konovalov, S.; Osintsev, K.; Golubeva, A.; Smelov, V.; Ivanov, Y.; Chen, X.; Komissarova, I. Surface modification of Ti-based alloy by selective laser melting of Ni-based superalloy powder. J. Mater. Res. Technol. 2020, 9, 8796–8807. [Google Scholar] [CrossRef]

- Chang, K.-C.; Zhao, J.-R.; Hung, F.-Y. Microstructure, mechanical properties, and fatigue fracture characteristics of high-fracture-resistance selective laser melting Al-Ni-Cu alloys. Metals 2021, 11, 87. [Google Scholar] [CrossRef]

- Panin, S.V.; Moiseenko, D.D.; Maksimov, P.V.; Vlasov, I.V.; Byakov, A.V.; Maruschak, P.O.; Berto, F.; Schmauder, S.; Vinogradov, A. Influence of energy dissipation at the interphase boundaries on impact fracture behaviour of a plain carbon steel. Theor. Appl. Fract. Mech. 2018, 97, 478–499. [Google Scholar] [CrossRef]

- Tan, J.H.; Wong, W.L.E.; Dalgarno, K.W. An overview of powder granulometry on feedstock and part performance in the selective laser melting process. Addict. Manuf. 2017, 18, 228–255. [Google Scholar] [CrossRef] [Green Version]

- Brandt, M. Laser Additive Manufacturing: Materials, Design, Technologies and Applications; Woodhead Publishing: Sawston, UK, 2017. [Google Scholar]

- Downing, L.; Kennedy, J.; O’Shaugnessy, S.; Trimble, D. A review of critical repeatability and reproducibility issues in powder bed fusion. Mater. Des. 2020, 186, 108346. [Google Scholar] [CrossRef]

- Schwendner, K.I.; Banerjee, R.; Collins, P.C.; Brice, C.A.; Fraser, H.L. Direct laser deposition of alloys from elemental powder blends. Scr. Mater. 2001, 45, 1123–1129. [Google Scholar] [CrossRef]

- Clayton, R.M. The Use of Elemental Powder Mixes in Laser-Based Additive Manufacturing. Master’s Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2013. [Google Scholar]

- Roberts, C.E.; Bourell, D.; Watt, T.; Cohen, J. A novel processing approach for additive manufacturing of commercial aluminum alloys. Phys. Proc. 2016, 83, 909–917. [Google Scholar] [CrossRef] [Green Version]

- Gorji, N.E.; O’Connor, R.; Brabazon, D. X-ray tomography, AFM and nanoindentation measurements for recyclability analysis of 316L powders in 3D printing process. Proc. Manuf. 2020, 47, 1113–1116. [Google Scholar]

- Andrews, K.W. Empirical formulae for calculation of some transformation temperatures. J. Iron Steel Inst. 1965, 203, 721–727. [Google Scholar]

- Sun, Z.; Tan, X.; Tor, S.B.; Yeong, W.Y. Selective laser melting of stainless steel 316L with low porosity and high build rates. Mater. Des. 2016, 104, 197–204. [Google Scholar] [CrossRef]

- Cunningham, R.; Narra, S.P.; Ozturk, T.; Beuth, J.; Rollett, A.D. Evaluating the effect of processing parameters on porosity in electron beam melted Ti-6Al-4V via synchrotron X-ray microtomography. J. Miner. 2016, 68, 765–771. [Google Scholar] [CrossRef]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. 2020, 772, 138633. [Google Scholar] [CrossRef]

- Dörfert, R.; Zhang, J.; Clausen, B.; Freiße, H.; Schumacher, J.; Vollertsen, F. Comparison of the fatigue strength between additively and conventionally fabricated tool steel 1.2344. Addict. Manuf. 2019, 27, 217–223. [Google Scholar] [CrossRef]

- Kempen, K.; Vrancken, B.; Buls, S.; Thijs, L.; Van Humbeeck, J.; Kruth, J.-P. Selective laser melting of crack-free high density M2 high speed steel parts by baseplate preheating. J. Manuf. Sci. Eng. 2014, 136, 061026. [Google Scholar] [CrossRef]

- Mazur, M.; Brincat, P.; Leary, M.; Brandt, M. Numerical and experimental evaluation of a conformally cooled H13 steel injection mold manufactured with selective laser melting. Int. J. Adv. Manuf. Technol. 2017, 93, 881–900. [Google Scholar] [CrossRef]

- Ooi, S.W.; Garnham, J.E.; Ramjaun, T.I. Review: Low transformation temperature weld filler for tensile residual stress reduction. Mater. Des. 2014, 56, 773–781. [Google Scholar] [CrossRef]

- Kromm, A.; Dixneit, J.; Kannengiesser, T. Residual stress engineering by low transformation temperature alloys—state of the art and recent developments. Weld. World 2014, 58, 729–741. [Google Scholar] [CrossRef]

- Thibault, D.; Bocher, P.; Thomas, M.; Gharghouri, M.; Côté, M. Residual stress characterization in low transformation temperature 13%Cr–4%Ni stainless steel weld by neutron diffraction and the contour method. Mater. Sci. Eng. 2010, 527, 6205–6210. [Google Scholar] [CrossRef]

- Murakami, Y.; Endo, M. Effects of hardness and crack geometries on ΔKth of small cracks emanating from small defects. In The Behaviour of Short Fatigue Cracks; Miller, K.J., de los Rios, E.R., Eds.; EGF Pub. 1; Mechanical Engineering Publications: London, UK, 1986; pp. 275–293. [Google Scholar]

- Murakami, Y. Material defects as the basis of fatigue design. Int. J. Fatigue 2012, 41, 2–10. [Google Scholar] [CrossRef]

| Material | Fe | C | Cr | Si | Mn | Ni | Mo | Ti | V | W |

|---|---|---|---|---|---|---|---|---|---|---|

| AdPre | Balance | 0.41 | 11.04 | 0.68 | 0.69 | 1.71 | 3.22 | 0.21 | 0.20 | 1.92 |

| AdEle | Balance | 0.47 | 9.89 | 0.73 | 0.67 | 1.95 | 3.36 | 0.13 | 0.29 | 2.17 |

| Target | Balance | 0.36 | 10.00 | 0.70 | 0.60 | 1.70 | 3.00 | 0.20 | 0.30 | 2.00 |

| Beam Energy (kV) | Beam Current (uA) | Power (W) | Exposure Time (ms) | Effective Pixel Size (µm) |

|---|---|---|---|---|

| 110 | 103 | 11.3 | 345 | 2.49 |

| Laser Power (W) | Scanning Speed (mm/s) | Spot Size (mm) | Hatch Distance (mm) | Layer Thickness (mm) | Strategy | Tilt Angle (°) | Gas |

|---|---|---|---|---|---|---|---|

| 250 | 500 | 0.05 | 0.08 | 0.05 | Checkerboard | 12 | Argon |

| Beam Energy (kV) | Beam Current (uA) | Power (W) | Exposure Time (ms) | Effective Pixel Size (µm) |

|---|---|---|---|---|

| 135 | 110 | 14.9 | 345 | 6.99 |

| Powder Characteristics | AdPre | AdEle |

|---|---|---|

| Characteristic particle sizes (μm) | ||

| d10 | 24.5 | 25.8 |

| d50 | 41.1 | 43.9 |

| d90 | 76.7 | 84.3 |

| dmin | 9.9 | 9.9 |

| dmax | 128.3 | 138.7 |

| Characteristic particle shapes | ||

| d10 | 0.69 | 0.68 |

| d50 | 0.87 | 0.86 |

| d90 | 0.96 | 0.95 |

| Flowability [3] | ||

| Hall flow (s/50 g) | 3.2 | 3.6 |

| Angle of repose (°) | 62 | 44 |

| Hausner ratio | 1.15 | 1.16 |

| Surface | AdPre (MPa) | AdEle (MPa) |

|---|---|---|

| Top surface (As-built) | 450 | 363 |

| Top surface (Polished) | −558 | −511 |

| Side surface (As-built) | −54 | −186 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baqerzadeh Chehreh, A.; Strauch, A.; Großwendt, F.; Röttger, A.; Fechte-Heinen, R.; Theisen, W.; Walther, F. Influence of Different Alloying Strategies on the Mechanical Behavior of Tool Steel Produced by Laser-Powder Bed Fusion. Materials 2021, 14, 3344. https://doi.org/10.3390/ma14123344

Baqerzadeh Chehreh A, Strauch A, Großwendt F, Röttger A, Fechte-Heinen R, Theisen W, Walther F. Influence of Different Alloying Strategies on the Mechanical Behavior of Tool Steel Produced by Laser-Powder Bed Fusion. Materials. 2021; 14(12):3344. https://doi.org/10.3390/ma14123344

Chicago/Turabian StyleBaqerzadeh Chehreh, Abootorab, Anna Strauch, Felix Großwendt, Arne Röttger, Rainer Fechte-Heinen, Werner Theisen, and Frank Walther. 2021. "Influence of Different Alloying Strategies on the Mechanical Behavior of Tool Steel Produced by Laser-Powder Bed Fusion" Materials 14, no. 12: 3344. https://doi.org/10.3390/ma14123344

APA StyleBaqerzadeh Chehreh, A., Strauch, A., Großwendt, F., Röttger, A., Fechte-Heinen, R., Theisen, W., & Walther, F. (2021). Influence of Different Alloying Strategies on the Mechanical Behavior of Tool Steel Produced by Laser-Powder Bed Fusion. Materials, 14(12), 3344. https://doi.org/10.3390/ma14123344