1. Introduction

Textile-reinforced concrete (TRC) is composed of textile reinforcement and a matrix and has a much thinner layer than conventional reinforced concrete (RC). The textile reinforcement generally takes the form of a two-dimensional (2D) grid of carbon fibers, and the matrix is commonly made of concrete or cementitious mortar. If the matrix contains no coarse aggregates, we refer to it as textile reinforced mortar (TRM). TRC is more popularly used than TRM. The TRC system can be fabricated either by on-site cast-in-place (CIP) installation or off-site precast element.

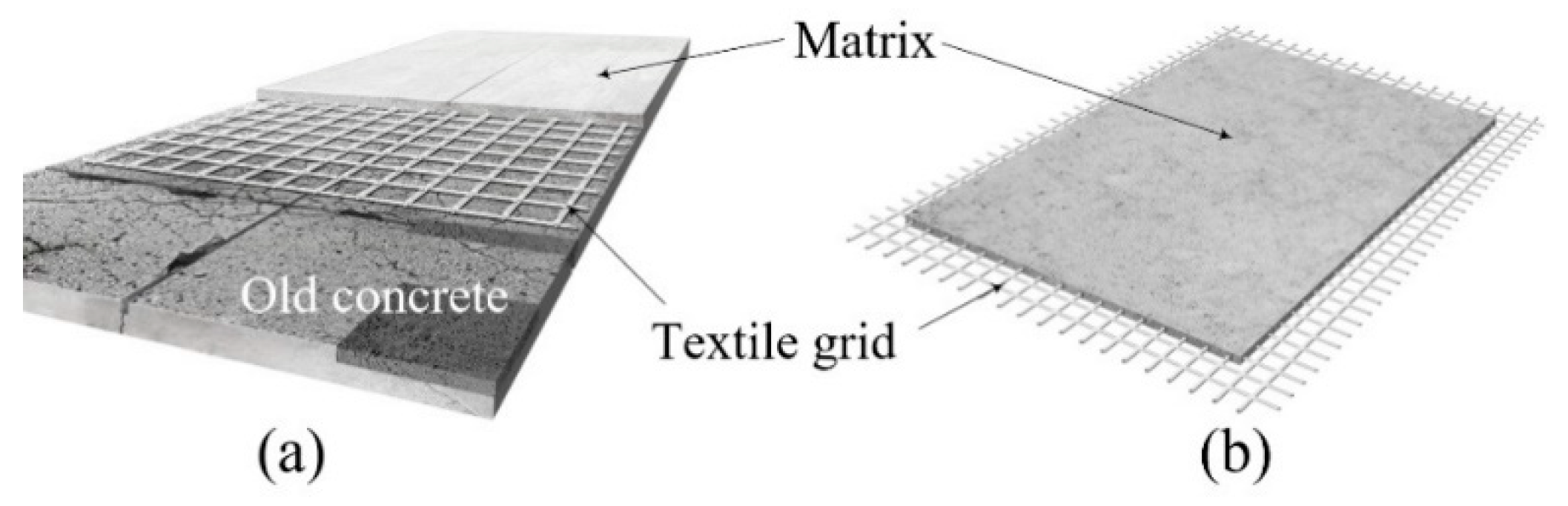

Figure 1a,b respectively illustrate a TRC system installed over an existing concrete element and a precast TRC element.

Over the past two decades, the TRC system has been widely studied for both construction of new structural components and strengthening of existing structures. Early developments are well summarised in the literature [

1,

2,

3,

4], and recent developments and applications of the TRC system can be found in References. [

5,

6,

7,

8,

9,

10,

11,

12,

13]. More recently, a research group in the Korea Institute of Civil Engineering and Building Technology (KICT) conducted a series of experimental investigations to utilise a TRC system for a new structural component and strengthening for deteriorated concrete elements. In KICT, slab-type concrete elements were strengthened with a precast TRC panel with grout [

14], as well as a CIP TRC system [

15,

16]. A precast TRC panel was also used for stay-in-place permanent formwork in the new construction of a reinforced concrete slab [

17]. Moreover, the long-term tensile performance of the TRC system was investigated through collaboration by research groups in KICT and ITA RWTH Aachen University (Aachen, Germany) [

18].

In earlier applications, lack of testing methods and design guidelines for TRC systems was one of the technical barriers to enter construction markets. However, the testing methods and design guidelines for TRC systems in building and construction have been relatively slow, but successfully established in recent years [

19,

20,

21,

22]. Although roughly specified in the design guidelines for TRC systems [

22], designers dealing with the TRC system must pay attention to overlap or lap splice length of the textile reinforcements. Every commercially available 2D textile grid reinforcement is fabricated either by a warp-weaving or warp-knitting method, where the knitting method is more popular these days. Although technically there is no limitation of textile fabrication in length, e.g., warp direction, the width of textile is generally limited by the machine size. Therefore, the textile grid often requires on-site overlap in the weft direction of the textile.

The overlapped textile grid has a mechanical discontinuity, and is a weak point for the TRC system. The induced tensile stress within the TRC system should be transferred from one textile grid to another through the matrix. To safely transfer tensile stress of the lap-spliced textile, the overlap length (hereafter, lap splice length) of the textile grid must be greater than the minimum lap splice length of the textile grid. The minimum lap splice length of the textile grid is usually evaluated by a tensile test in accordance with a testing protocol, such as that specified in [

22]. Numerous research groups [

23,

24,

25] conducted direct tensile tests for TRC coupon specimens fabricated with lap-spliced textile grids. Overall, longer lap-spliced length of the textile grid gave better tensile performance than the shorter length.

The strengthening of concrete structures with TRC system is usually carried out on-site, but on-site casting methods need to be modified for sites with a narrow working space. A fast installation of TRC system can be obtained if a precast TRC panel can be externally bonded to an existing concrete structure, as presented by KICT [

14,

26,

27,

28]. As illustrated in

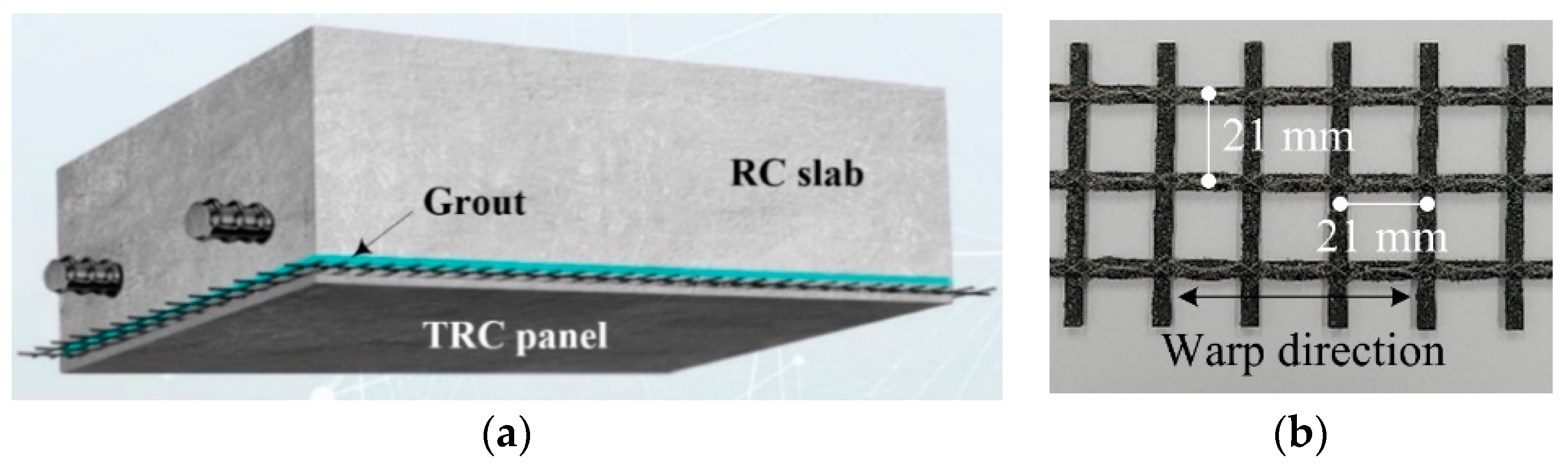

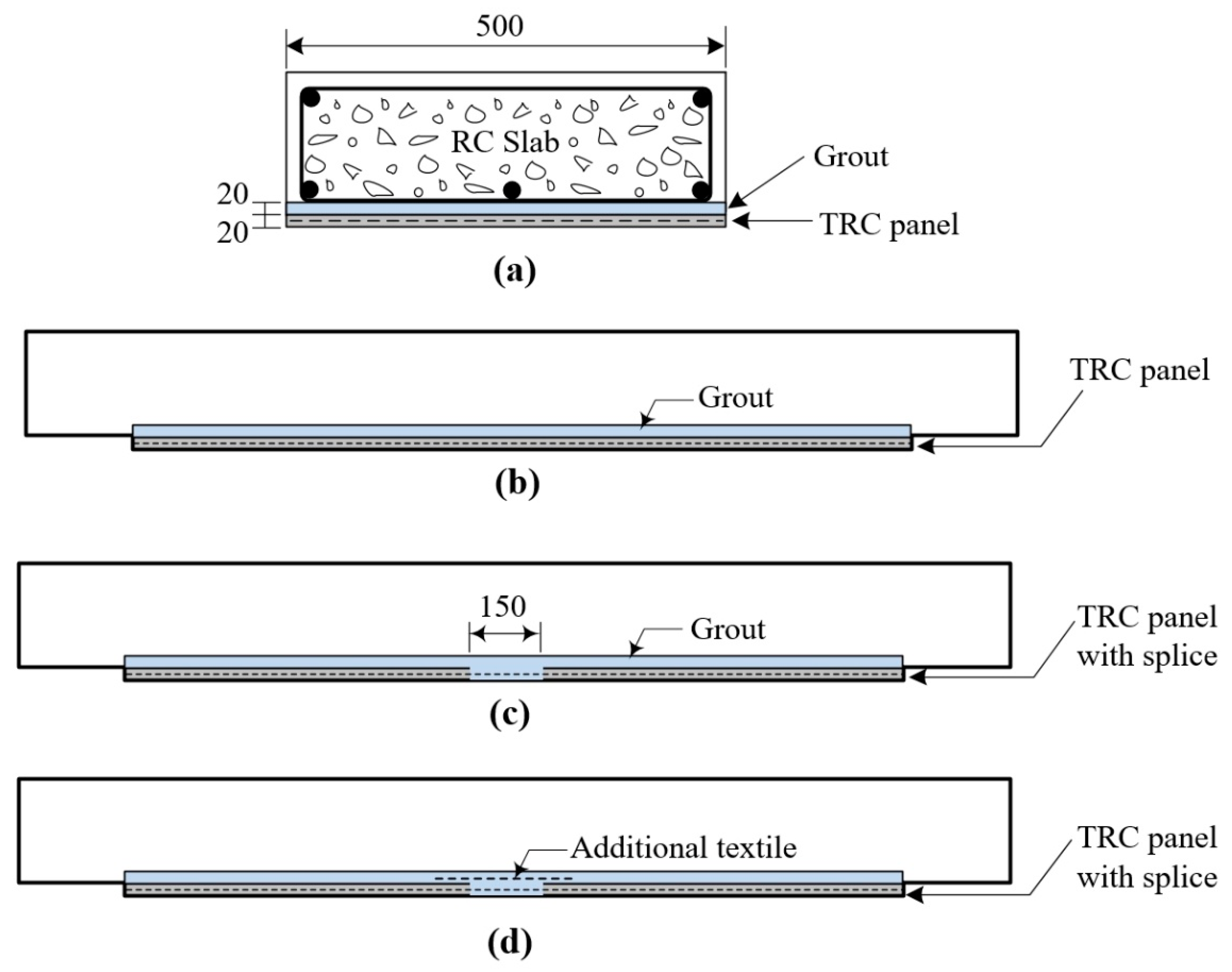

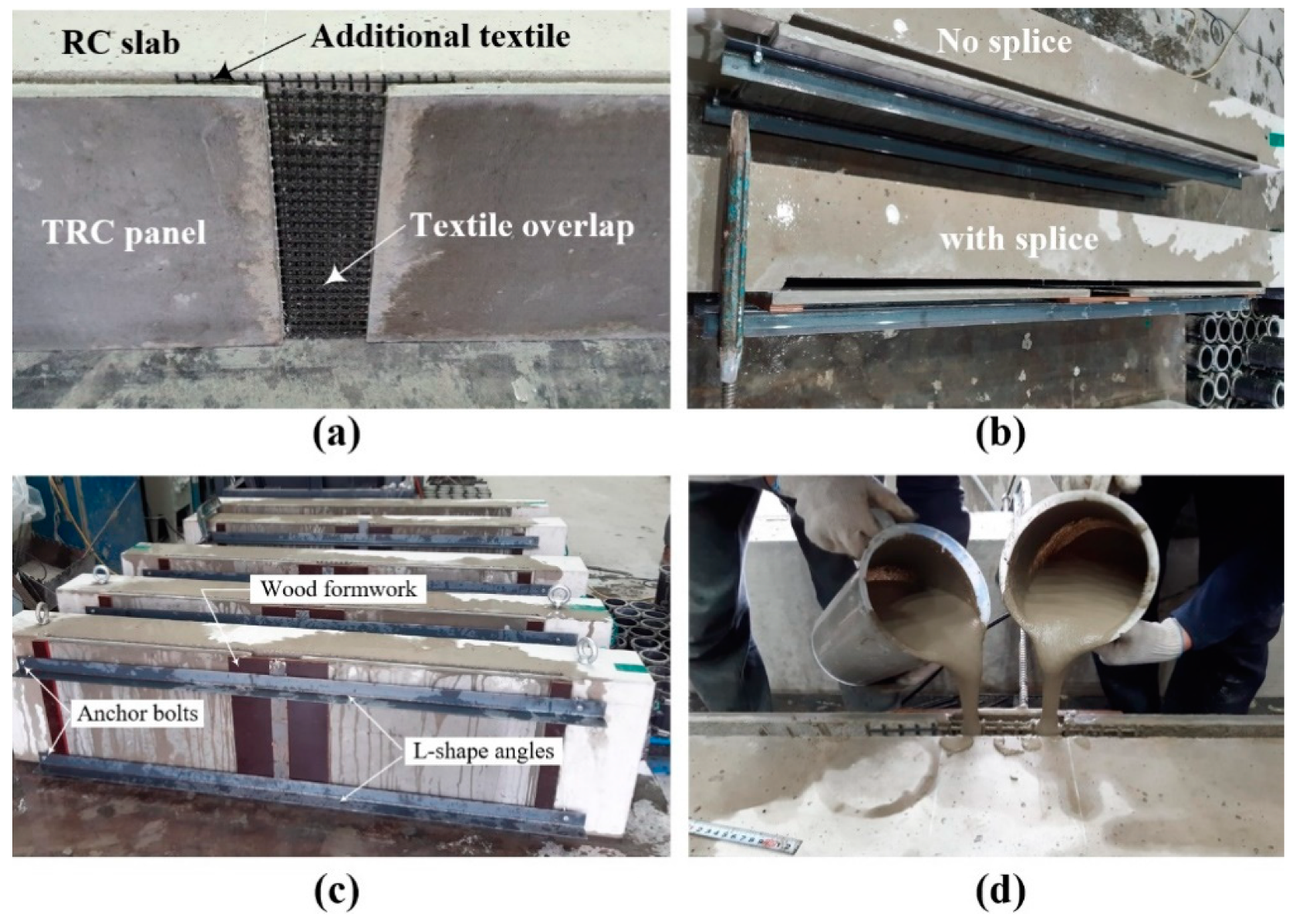

Figure 2, the TRC panel can be installed underneath concrete elements by anchor bolts with a grouting space between the panel and the concrete. Several air vents and grouting inlets are also installed. The grout is then injected until the grout completely fills the space between the panel and the concrete. A preceding paper [

14] reported the development and validation of an externally bonding method using a precast TRC panel and cementitious grout for the strengthening of concrete elements, such as the slab deck of an open-type wharf structure, and its effectiveness was demonstrated by a trial construction [

26,

27,

28]. Note that the bottom reinforcement of slab deck of an open-type wharf structure is usually severely corroded due to chloride attack, if steel corrosion is not prevented, but the bottom surface of the deck is extremely difficult to repair or strengthen due to high water levels and narrow working space. Furthermore, an off-site method of repair or strengthening methods are highly recommended for these type of structures to avoid marine pollution during on-site construction. However, construction with precast or prefabricated elements always involves unavoidable structural joints, and requires connecting methods for the joints. Therefore, as suggested in the preceding study [

14], an effective connecting method for the precast TRC panel joints should be developed for the externally bonded strengthening method by precast TRC panels and cementitious grout.

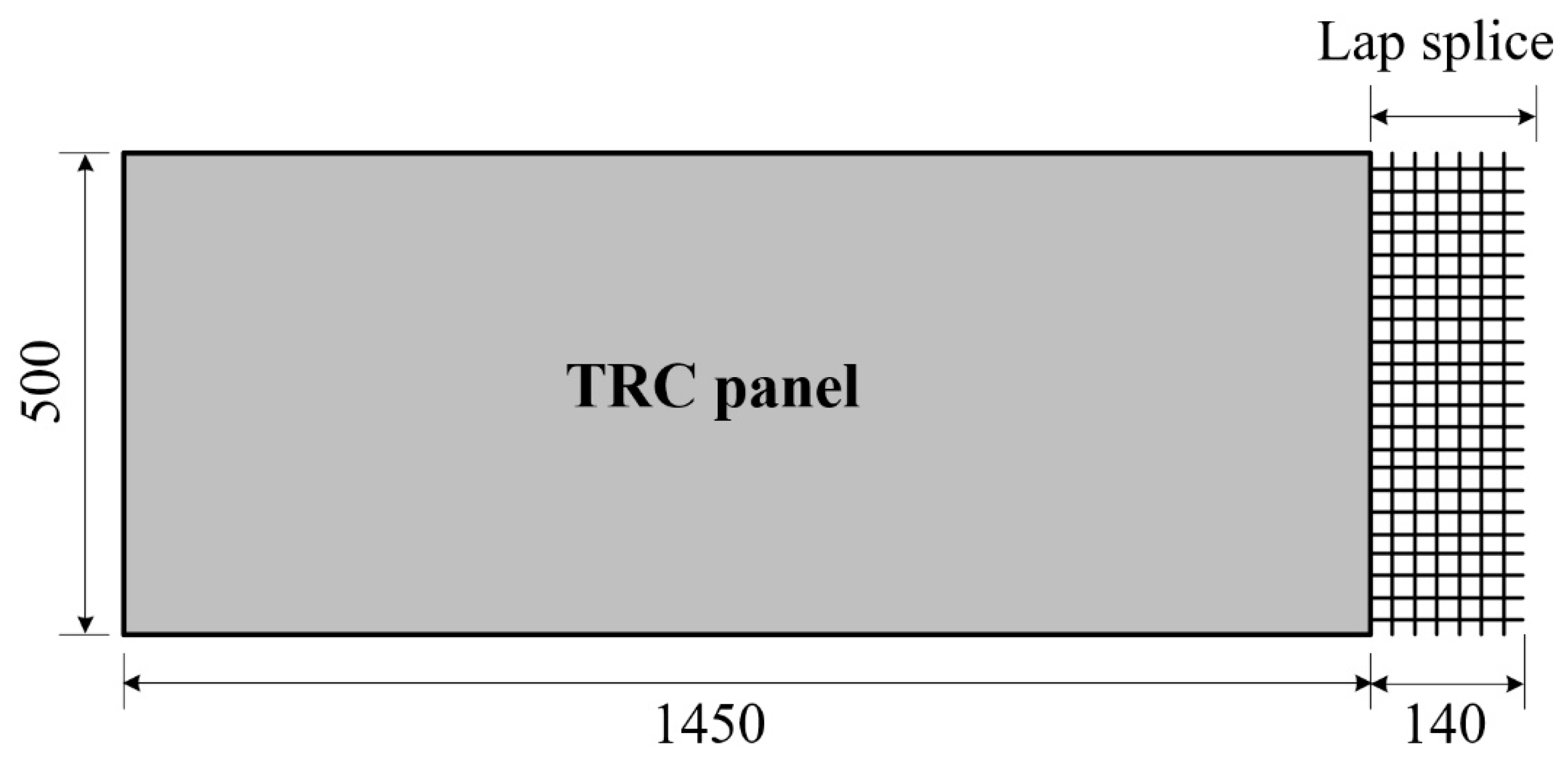

This paper deals with the development of an on-site connecting method for precast TRC panels with a lap-spliced textile grid. The objectives of this study are to identify the tensile behavior of the TRC system with lap-spliced textiles and to experimentally validate the performance of the proposed connecting method by flexural failure tests for concrete slabs strengthened by TRC panels with lap-spliced textile.

To examine the tensile behavior of a TRC system with lap-spliced textiles, prismatic TRC coupon specimens with lap-spliced carbon textile grids at the middle of the specimens were fabricated and tested under tension. Two different cementitious binders, e.g., mortar and non-shrink grout, were considered for the matrix system. Three different lap splice lengths were considered for the TRC system with mortar, while two different lap splice lengths were considered for the TRC system with grout. Twenty-one coupon specimens were tested in tension. Tensile properties of the lap-spliced specimens compared with those of the specimen without lap splice.

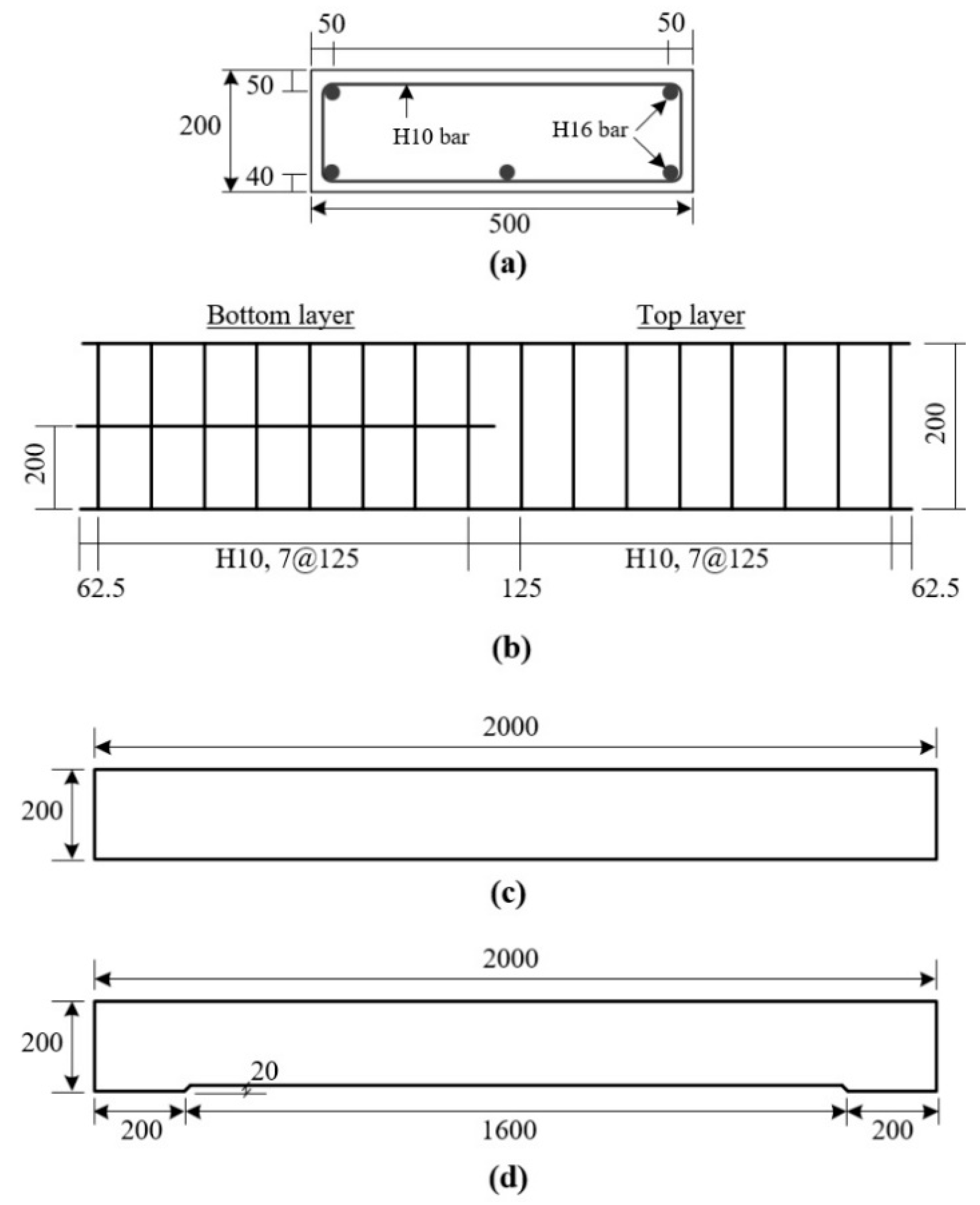

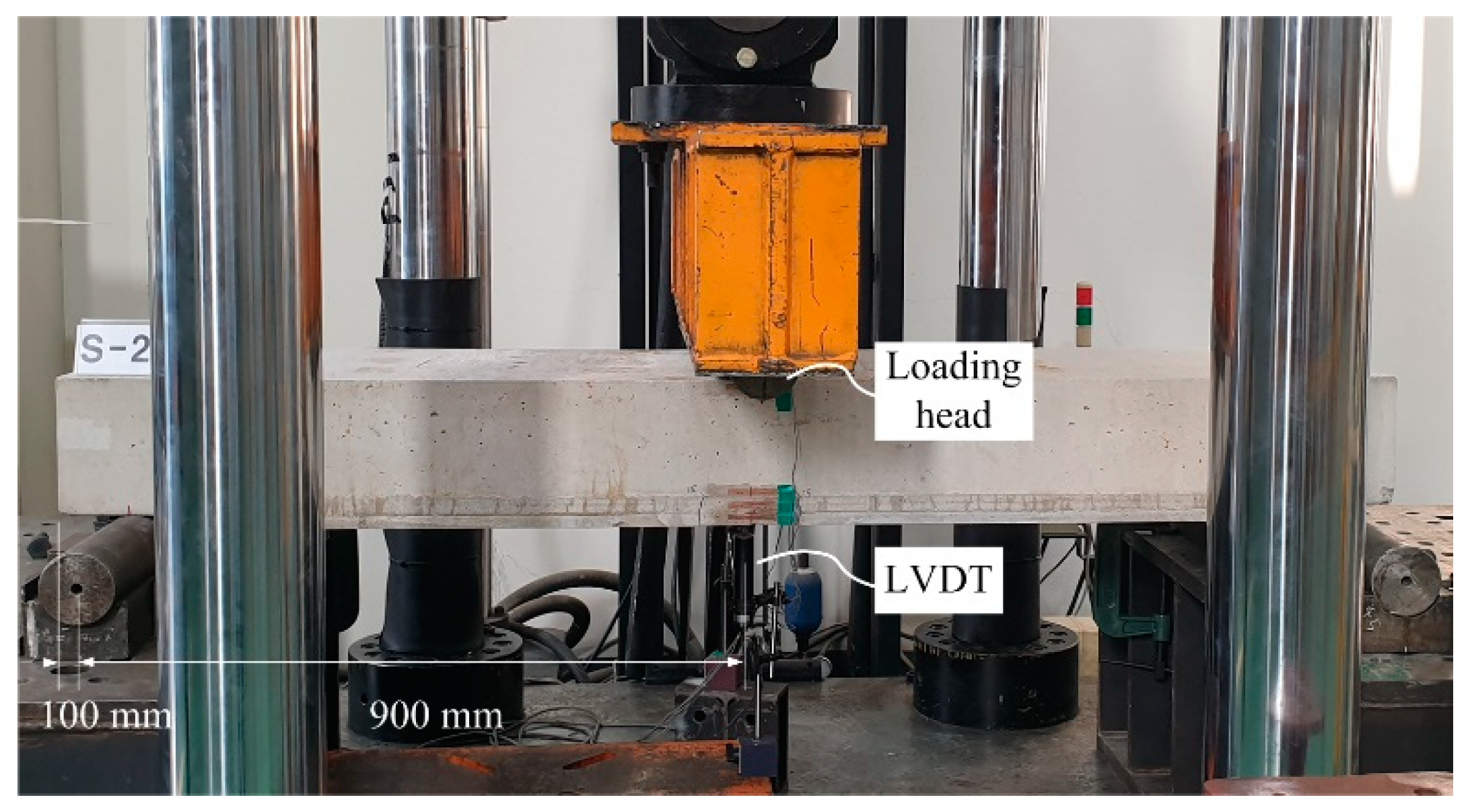

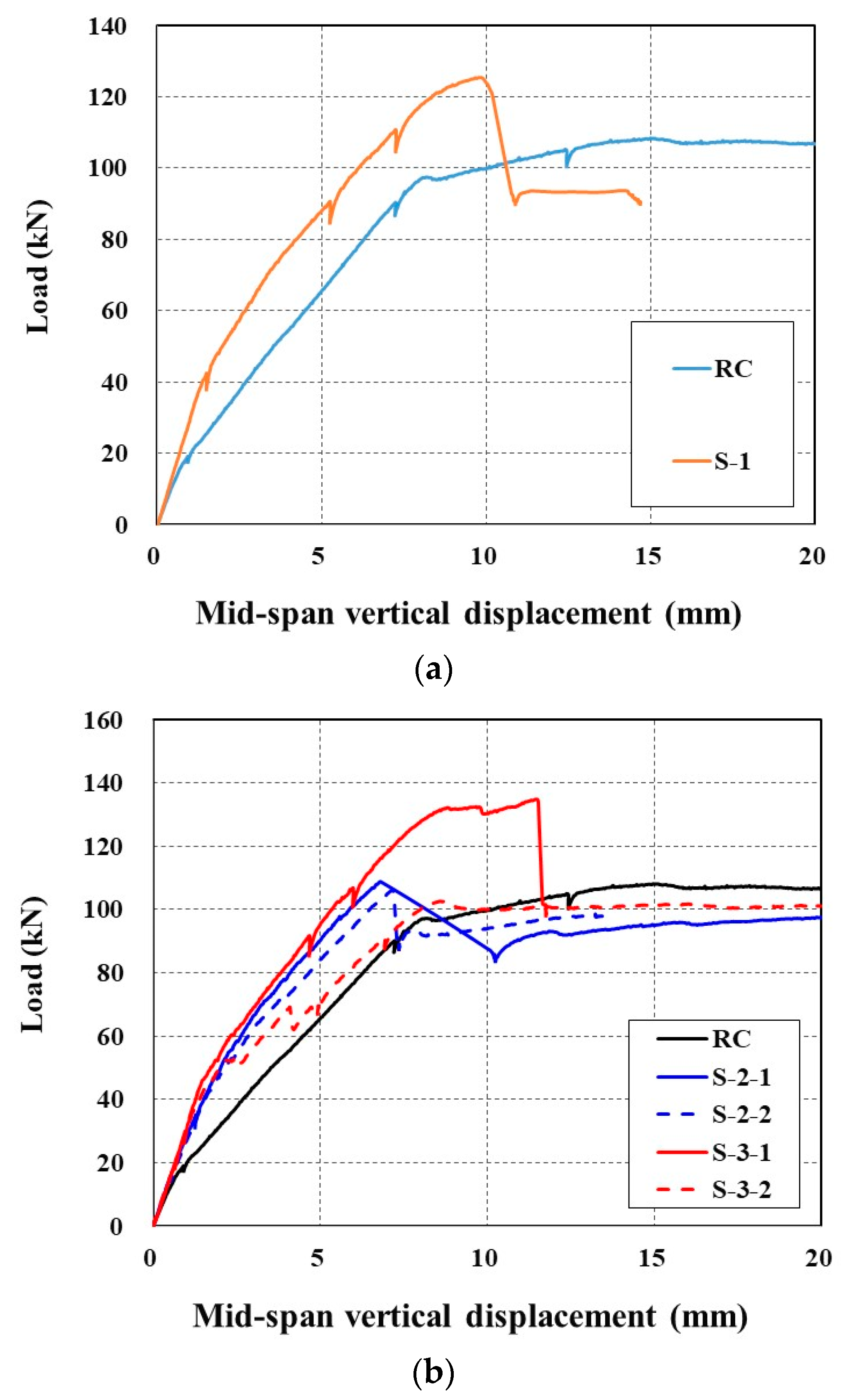

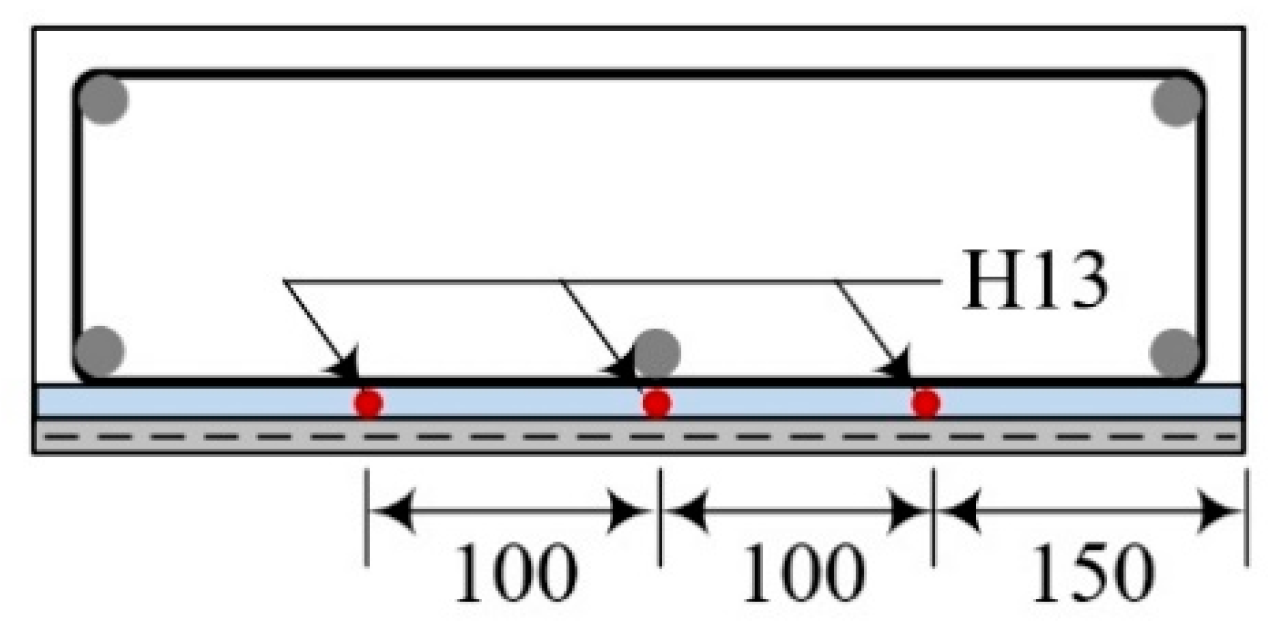

Six 2000.0 mm-long full-scale RC concrete slabs were fabricated and TRC panels (20.0 mm-thick) with one ply of carbon grid textile and mortar were also fabricated: one full-length (1600.0 mm) panel has no lap splice; four sets of the panels have a textile lap splice at the middle of the panel. Five RC slabs were strengthened with precast TRC panels and grout. Among these, one of the slabs was strengthened by a full-length TRC panel (no lap splice), two of the slabs were strengthened by a set of lap-spliced TRC panels at the mid span only and the other two slabs were strengthened by lap-spliced TRC panels with an additional textile grid within the grouting space to reinforced the joint. The full-scale strengthened slab specimens were tested by a three-point bending test. The load-deflection behavior and failure mode of the strengthened specimens is compared with those of the unstrengthened RC slab specimen.

2. Tensile Behavior of TRC System with Lap Splice

2.1. Materials

The carbon textile grid (

Figure 2b) is employed in this study.

Table 1 summarises the mechanical properties of the grid, which is sand-coated (grain size of 0.3–0.8 mm) [

29]. The sand-coated textile is employed in this study, as the surface coated textiles showed better bonding performance than uncoated textiles [

15,

16,

17,

23,

24,

25].

The mix composition of the mortar [

16] is summarised in

Table 2. PVA (polyvinyl alcohol, KURALON K-II REC100L, Kuraray, Japan) short fibers (10%, length = 6.0 mm) was mixed with the mortar. Detailed explanations of the purpose and the process of the mix design of mortar for the TRC panel can be found in a previous paper [

16]. The mean compressive strength of the air-cured mortar (ten cubic samples) at the age of 28 days was 63.9 MPa, with a standard deviation of 6.7.

On the other hand, a commercially available cementitious non-shrink grout (MR5000, Jetcon Ltd. Co., Seoul, Korea) was used as a grouting material in the fabrication of the specimens. The mean compressive strengths of the air-cured grout (ten cubic samples) at the time of the test was 81.6 MPa, with a standard deviation of 6.6 at the age of 28 days.

Furthermore, a ready-mixed concrete with a design strength of 27 MPa was used for the fabrication of full-scale RC slabs. The mix composition of the ready-mixed concrete is provided in

Table 3.

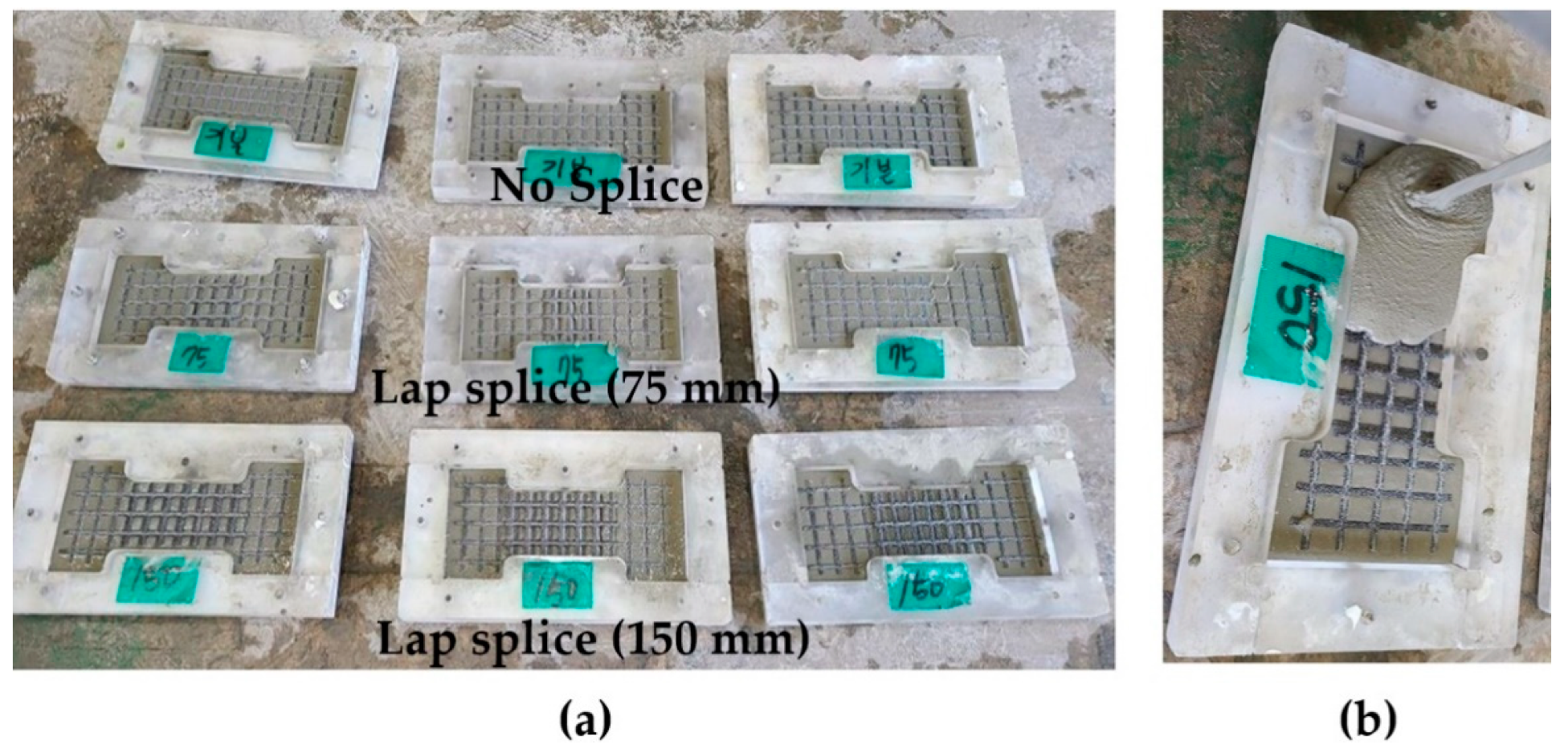

2.2. Fabrication of Tensile Test Specimens

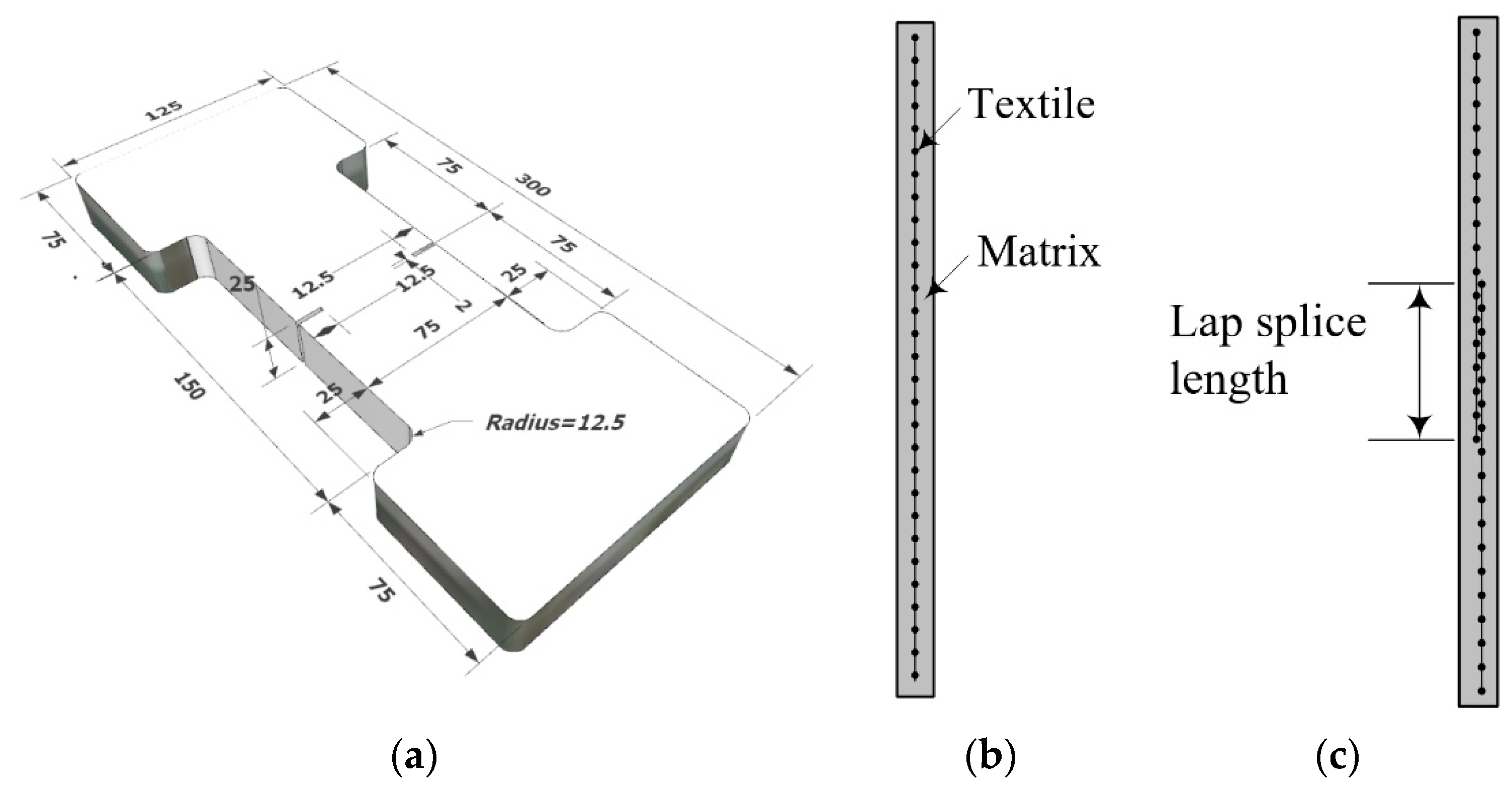

In this study, a direct tensile test was used to evaluate the tensile properties of the TRC system. Preliminary tests conducted in KICT indicate that the dumbbell-type coupon specimen (

Figure 3a) provided more consistent test results than the clevis-type specimen specified in [

20,

22]. Two 12.5 mm-deep notches were provided at the middle of the specimen to induce a crack in this region.

Figure 3b,c respectively show a side view of the specimen without a textile lap splice and with a lap splice.

Table 4 summarises the characteristics of two groups of coupon specimens tested under tension. The design variables considered in the test were type of matrix and lap splice length (

). The first group of specimens (TM series) used a cementitious mortar, while the second group of specimens (TG series) used a cementitious grout. The maximum

was set to 150 mm by considering the length of the load transition zone of the coupon specimen, e.g., 150 mm. For both groups, textiles with no lap splice (TM-0 and TG-0 series) and with different lap splice length (

) (0 mm–150 mm) were considered. Note that AC434 codes [

22] recommends the minimum

of textile as 51 mm.

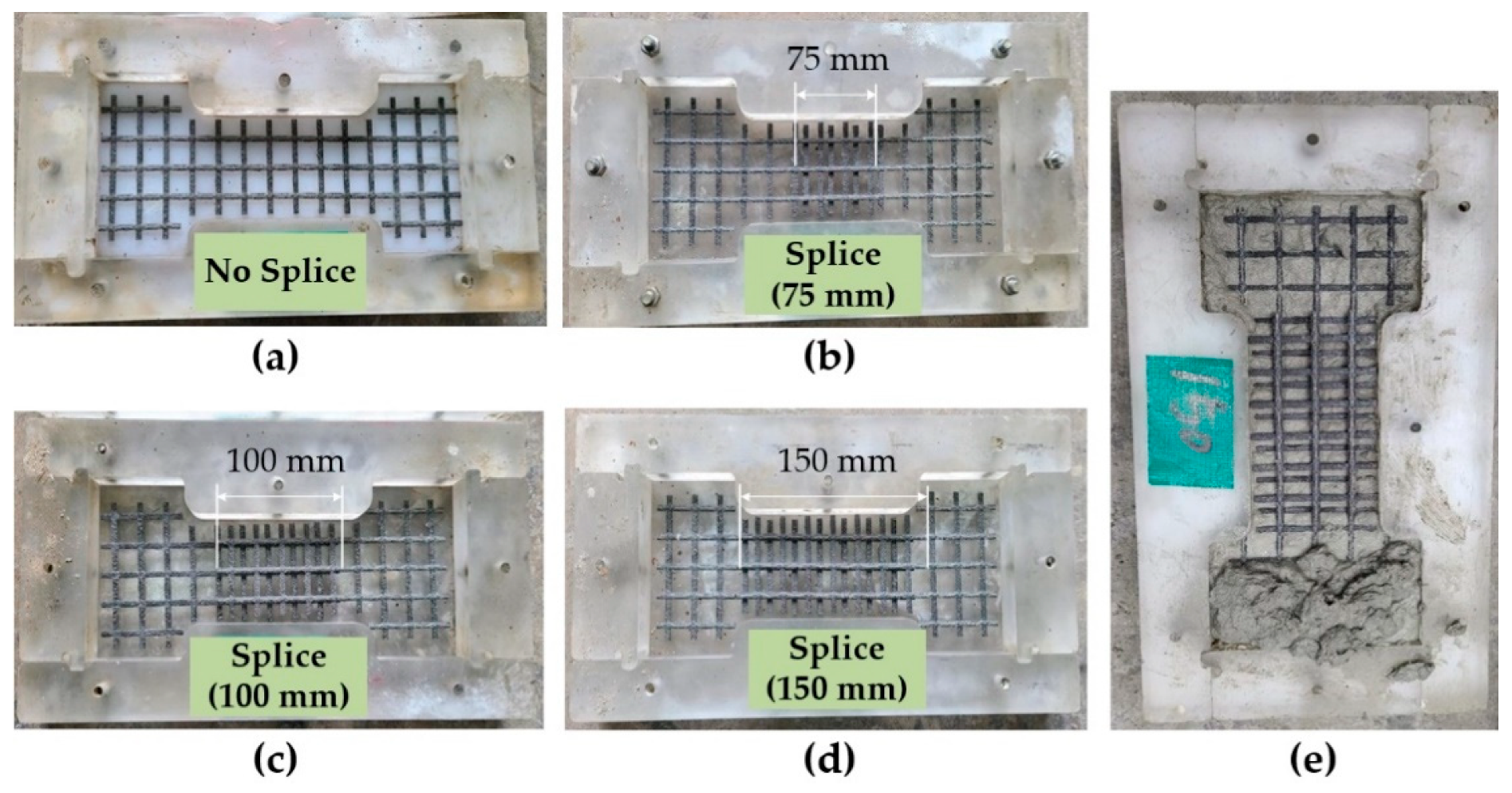

Figure 4a–d show the placement of textile within a plastic mold for the fabrication of the TM series coupon specimens. As illustrated in

Figure 4e, the lap-spliced textile grid was placed mid-plane of the mortar layer.

Figure 5a,b respectively illustrate the placement of textile and the grouting within a mold for the fabrication of the TG series coupon specimens. First, the grout was poured onto the mold to form a half the thickness of the specimen (

Figure 5b). The carbon textile was placed onto the first layer of the grout surface, and then the top surface of the specimen was finished by grouting.

2.3. Results of Tensile Tests and Discussion

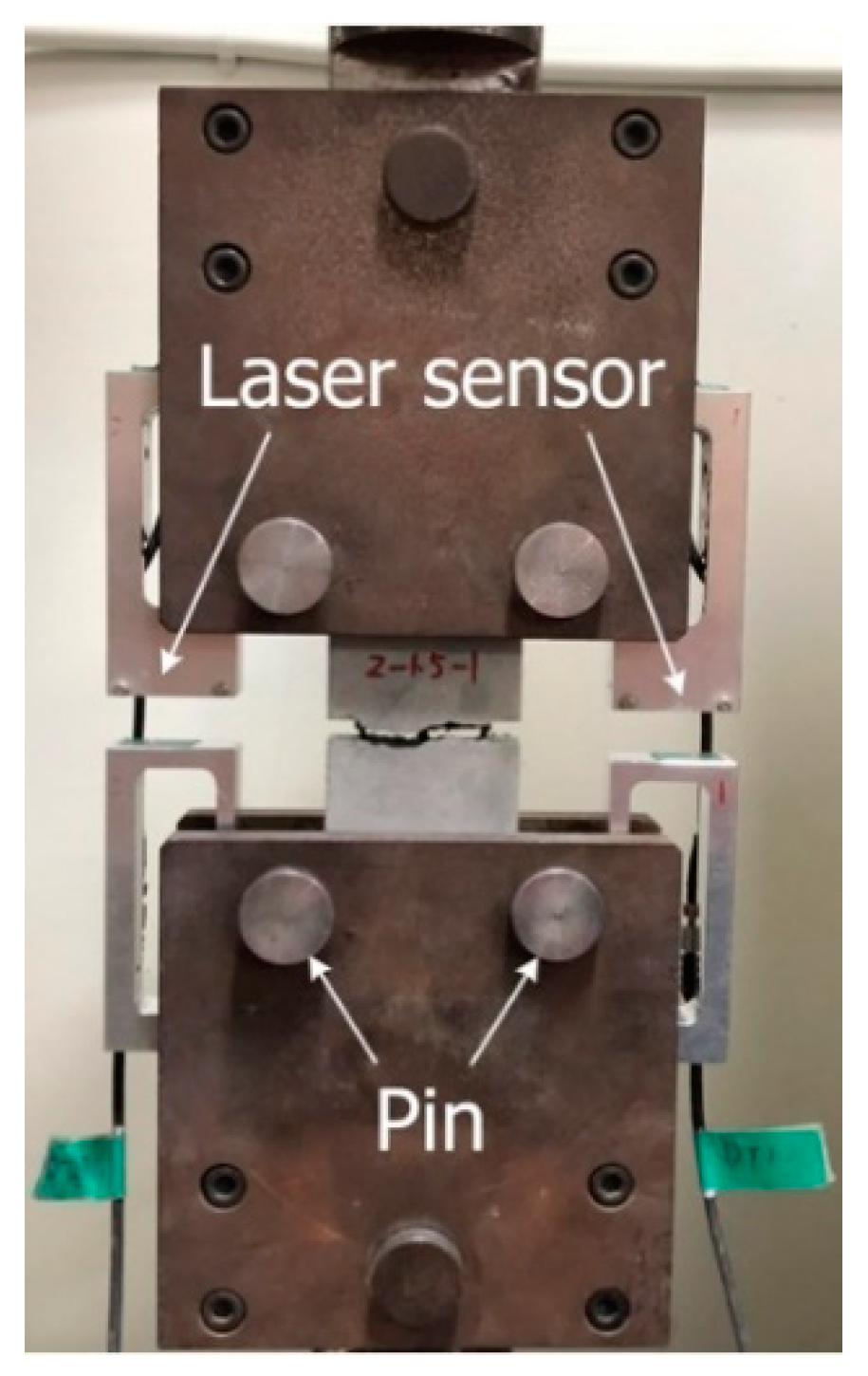

Figure 6 shows the set-up for the direct tensile test. Vertical monotonic loading with a displacement control of 0.4 mm/min was applied to the specimens using a 300 kN capacity universal testing machine. Laser sensors mounted at both sides of the specimen measured the vertical displacement of the specimens.

The results of the direct tensile tests were summarised in

Table 5.

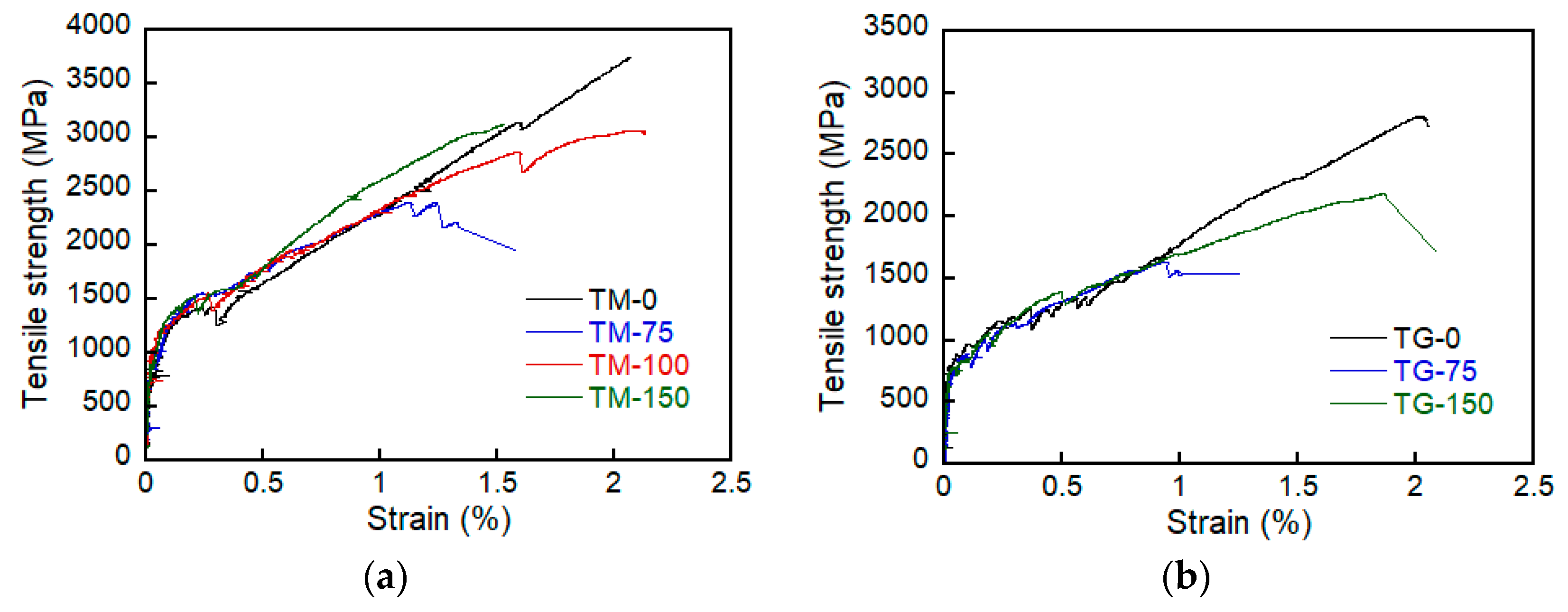

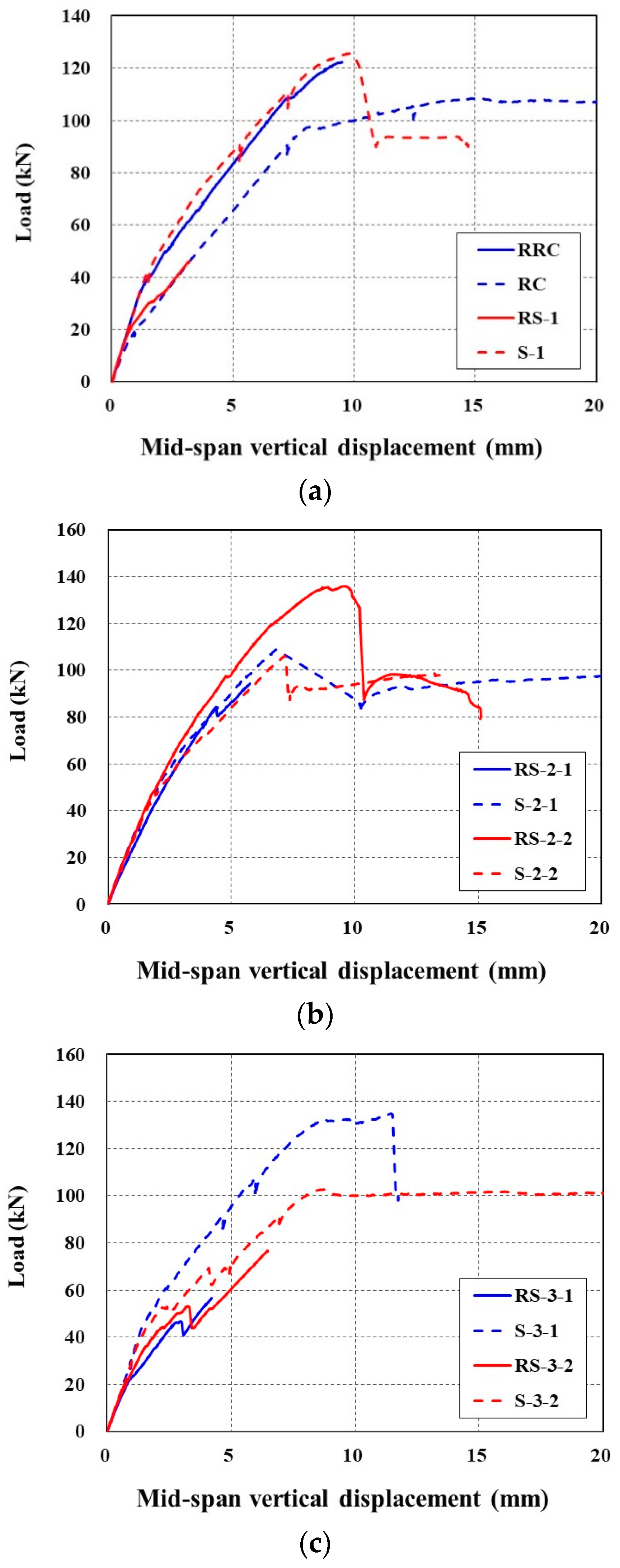

Figure 7 shows the axial stress-strain curve of the specimens. The ultimate tensile strength (

) of the TRC system was significantly affected by the lap splice lengths. In the early stage of loading, the stress increased linearly until a matrix crack occurred. The sudden stress drop after matrix cracking is due to a local slip between the textile and matrix. The slope of the stress-strain curve then decreased, but the stress continued to increase until failure occurred.

Overall, of the TM series specimens increased as increased. However, did not increase further for the lap splice length that was greater than 100 mm. Therefore, the minimum of the TM series specimens can be considered as 100 mm. On the other hand, the initial cracking strength () and the ultimate tensile strain () did not give consistent results with respect to . Similar behavior was also observed for the TG series specimens, but the testing variable () was not sufficient to clearly identify the minimum . The maximum value of of the TM and TG series specimens with the lap-spliced panel is at most 84.6% and 78.6% of the specimen with the full-length panel (no lap splice).

Although the compressive strength of the mortar (TM series) is about 78% of that of the grout (TG series), for the same value of , of the TM series specimens was almost two times greater than that of the TG series specimens. Furthermore, of the TM series was at least 27% greater than that of the TG series. Note that is the initial cracking load divided by the cross-sectional area of the matrix (transition zone). Therefore, the influence of the matrix properties on and is significant.

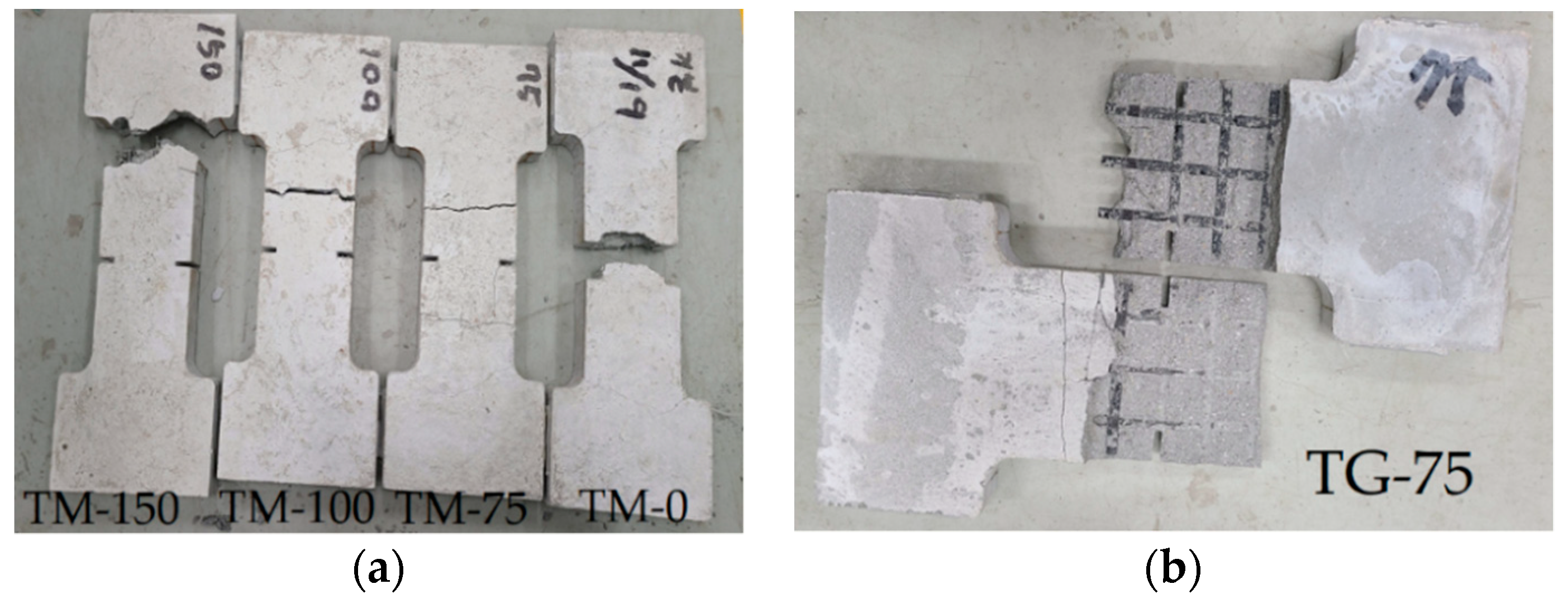

Figure 8 shows the failure modes of the tensile tested specimens. It can be clearly seen that failure of the TM-0 and TM-150 specimens is associated with tensile rupture of the textile grids, while failure of the TM-75 and TM-100 specimens is slippage of the textile within the matrix. On the other hand, failure of the TG series specimens is associated with splitting, and finally delamination along the lap-spliced face of the textile. As shown in

Figure 8, few specimens were failed at 12.5 mm-deep notches that were placed at both sides of the coupons induce a crack in this region notches. Although an attempt was not made in this study, an analytical model in terms of stress intensity factor and fracture mechanics criteria needs to be developed to analyse the matrix cracking and design the notches.

The mortar used for the TM series specimens was reinforced with short dispersed PVA fibers. It should be further noted that the TM series specimens showed fewer stress drops than the TG specimens. Therefore, the results of direct tensile test indicated that the presence of PVA fibers in the mortar provided a crack-bridging force that prevented the TM series specimens from splitting failure.

To connect the joint of lap-spliced TRC panels on-site, grout is a preferred material over dense mortar. Therefore, a viable grouting material should be developed in a future study for the proposed method of on-site installation.

5. Conclusions and Future Study

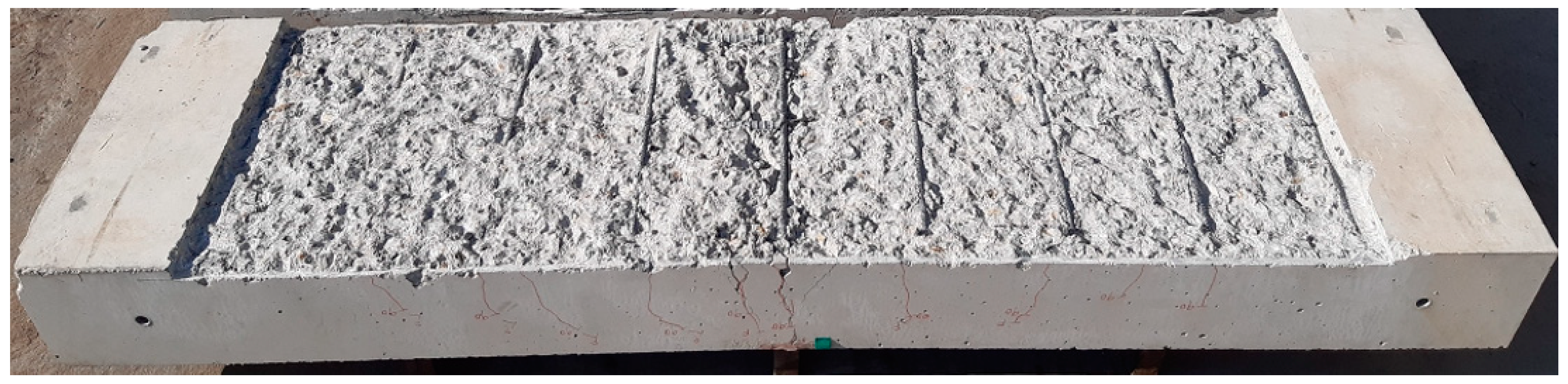

This paper proposed an on-site connecting method for precast TRC panels by the lap splicing of textile grids. The tensile behavior of a TRC system with lap-spliced textile was experimentally investigated by a direct tensile test. Full-scale concrete slabs were strengthened by the lap-spliced TRC panel and CIP grout, and tested under flexure to validate the performance of the proposed connecting method. Moreover, the failure-tested specimens were re-strengthened by a new TRC panel system, and tested again under flexure to investigate whether the TRC panel can replace the yielded steel reinforcement. The following conclusions and recommendation for a future study can be drawn.

From the results of the direct tensile test conducted for the lap-spliced TRC system, the minimum lap splice length is considered to be 100 mm. The maximum value of the ultimate tensile strength of the lap-spliced TRC system is at most 78.6% of the non-lap-spliced case. The influence of matrix properties on the ultimate tensile strength of the lap-spliced TRC system is significant. Although the compressive strength of the mortar used is about 78% of that of the grout, for the same lap splice length, the ultimate tensile strength of the TRC system with mortar is almost two-fold greater than that of the TRC system with grout. Furthermore, the lap-spliced TRC specimens with grout failed by splitting, and finally delamination along the lap-spliced face of the textile.

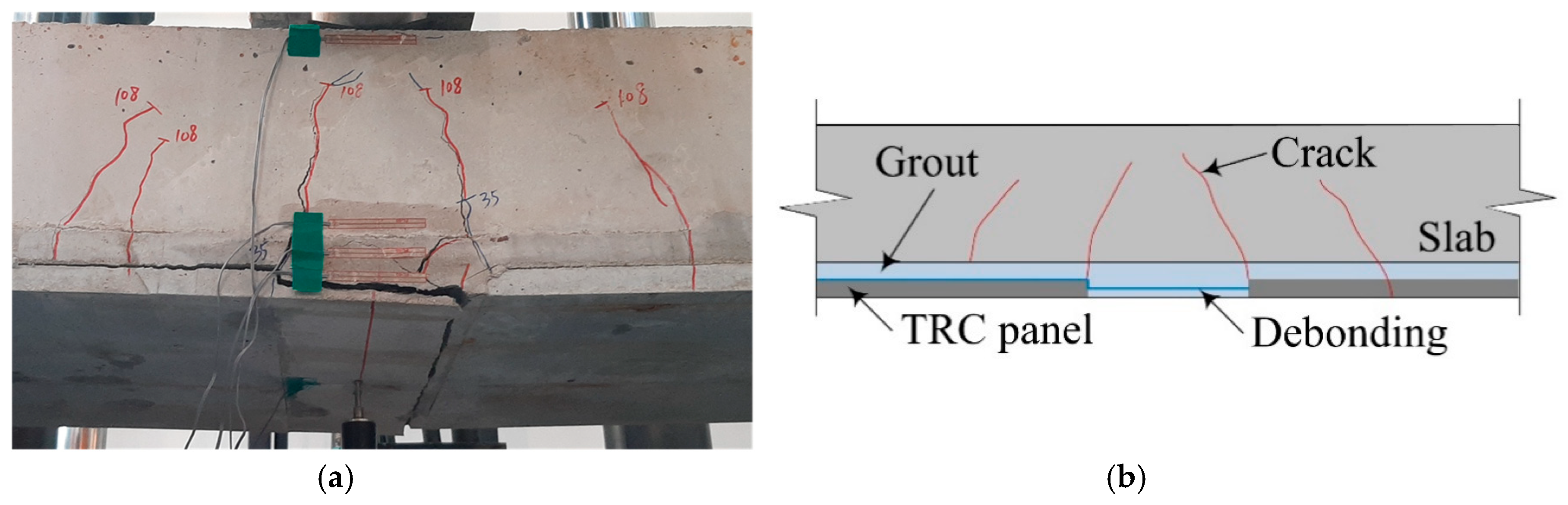

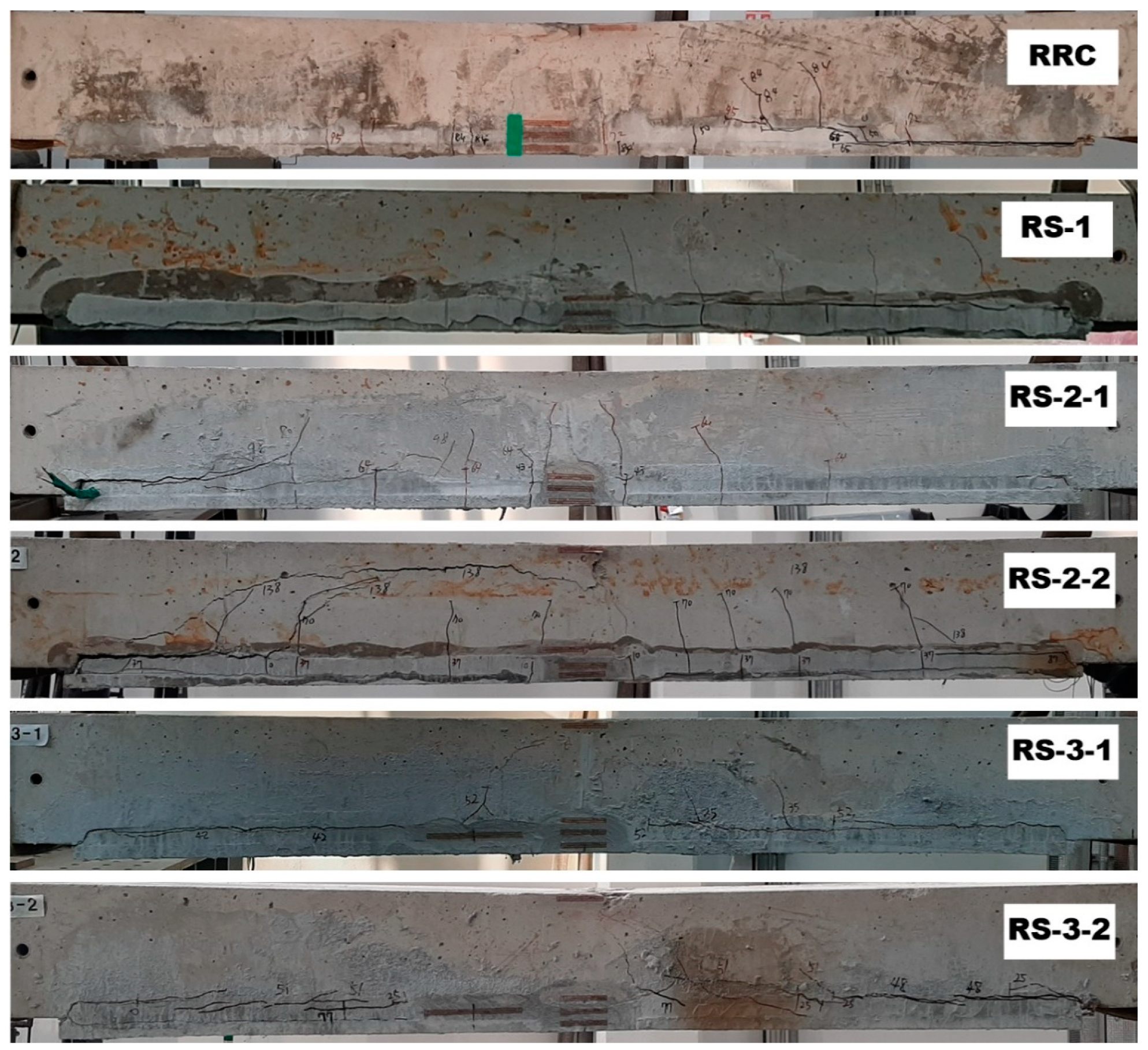

Six full-scale RC slab specimens were strengthened by TRC panels with and without lap splice, and failure tested in flexure. The results of the failure test indicated that the initial cracking load and the stiffness of the slab were somewhat increased by the strengthening with the TRC panel. However, five strengthened specimens out of six failed mainly by the debonding of the TRC panel from the slab. The debonding of the panel caused premature failure, and thus the TRC panel bonded to the slabs was unable to develop a sufficient composite action, and thus strengthening effect.

The failure-tested specimens (damaged slabs) were re-strengthened by the TRC panel and grout to investigate whether the yielded steel reinforcement in the damaged slab can be replaced by a TRC panel. Although the same grouting material was used, the bottom face of the panel was mounted to the slab. The results of the failure test for the re-strengthened slabs indicated that the initial cracking load and the stiffness of the damaged slabs were significantly increased by re-strengthening. Furthermore, the failure of the re-strengthened specimens was mainly associated with the delamination and separation of the grouted section from the concrete substrate. Moreover, no severe cracking or failure was observed at the lap-spliced joint. Therefore, an on-site connecting method proposed in this study for precast TRC panels by lap splicing of textile grids can be considered as an effective method.

When dealing with externally bonding strengthening methods, including a strengthening method by the precast TRC panel with grout, the debonding failure is an undesirable failure mode, as it usually causes sudden catastrophic failure. Therefore, a viable grouting material needs to be developed for the proposed method of strengthening. This paper presents the experimental study only. However, as a bonding model between the concrete slab and the precast TRC panel is developed, the behavior of the structural elements strengthened with the precast TRC panel and the CIP grout can be analysed by numerical methods.

It should be noted that the numbers of strengthened and re-strengthened specimens tested in this study were very limited, in order to obtain reliable test results. Thus, an increased number of specimens needs to be considered for a test program to evaluate the strengthening performance of CIP TRC panel.

The proposed strengthening method can also be used to build or to strengthen RC protective structures subject to direct impact loads such as projectile firing. Recently, a testing method has been proposed for TRC under impact load [

31]. Therefore, if the proposed strengthening method is to be employed in military applications, the evaluation of the material and structural performance of the CIP TRC panel under impact loadings needs to be conducted.