Improvement of Resistive Switching Performance in Sulfur-Doped HfOx-Based RRAM

Abstract

1. Introduction

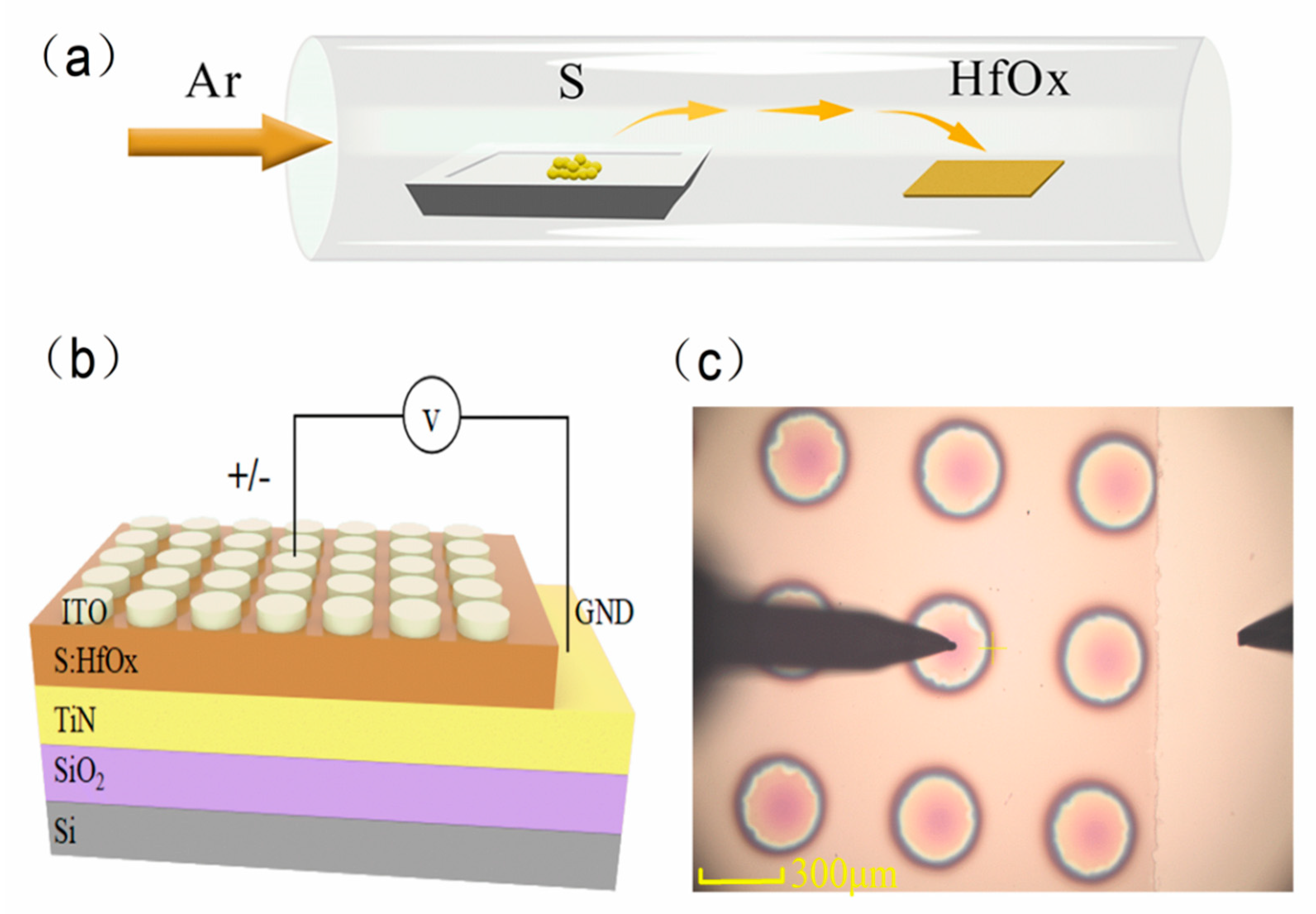

2. Experimental Section

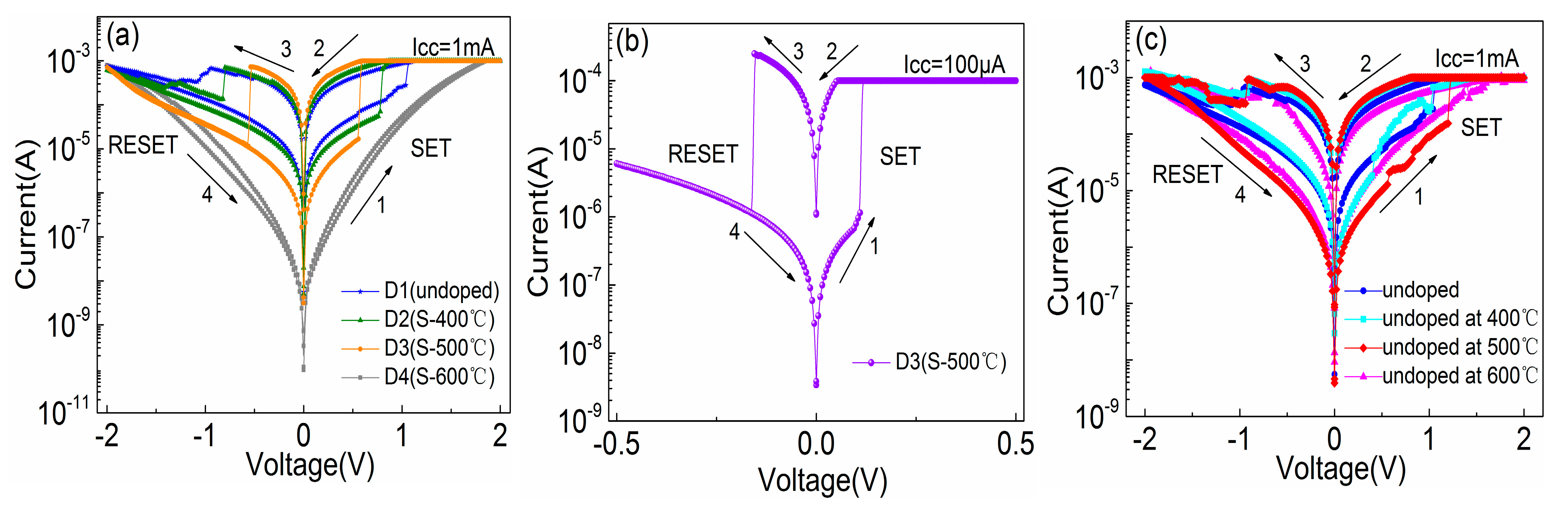

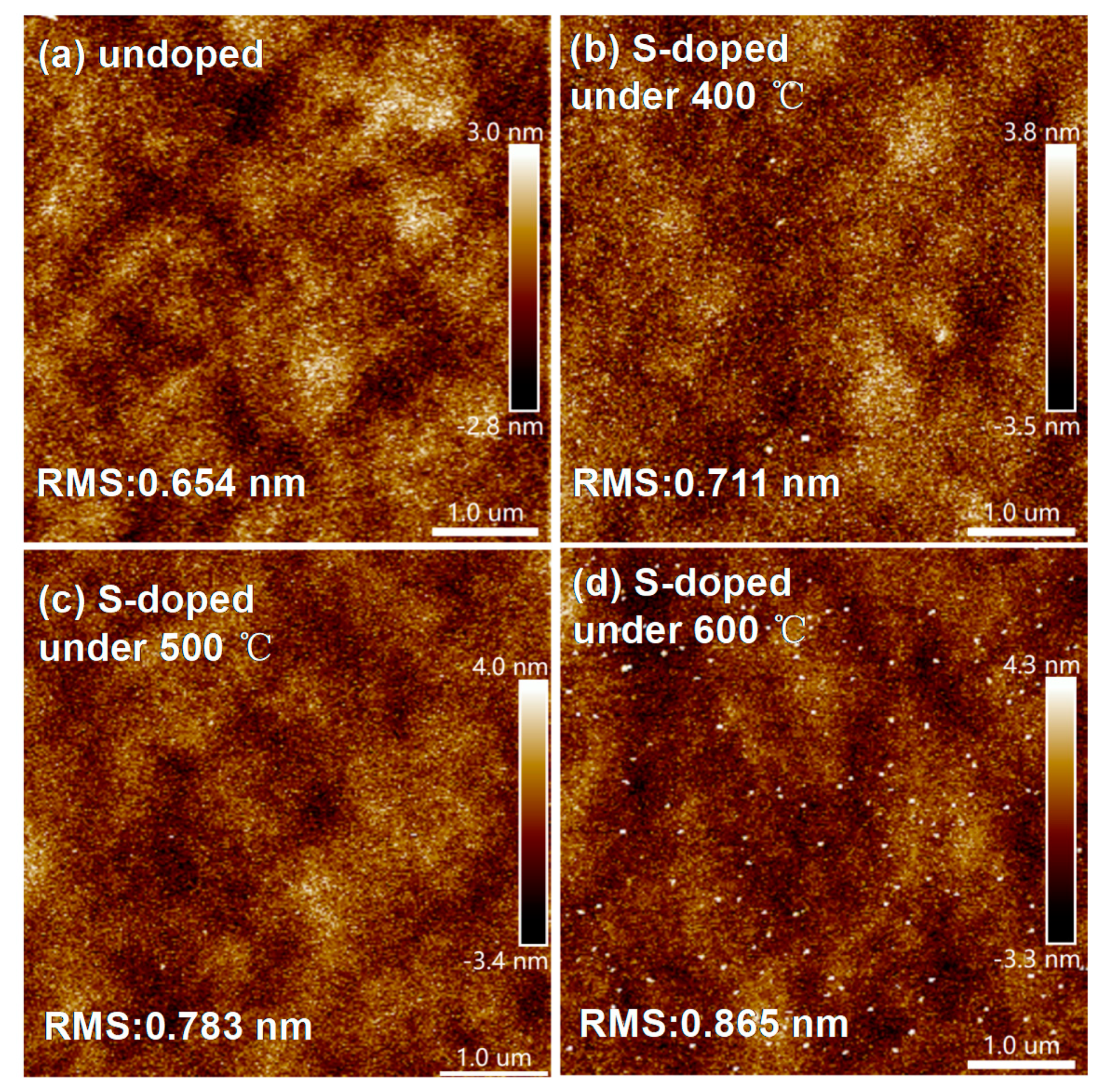

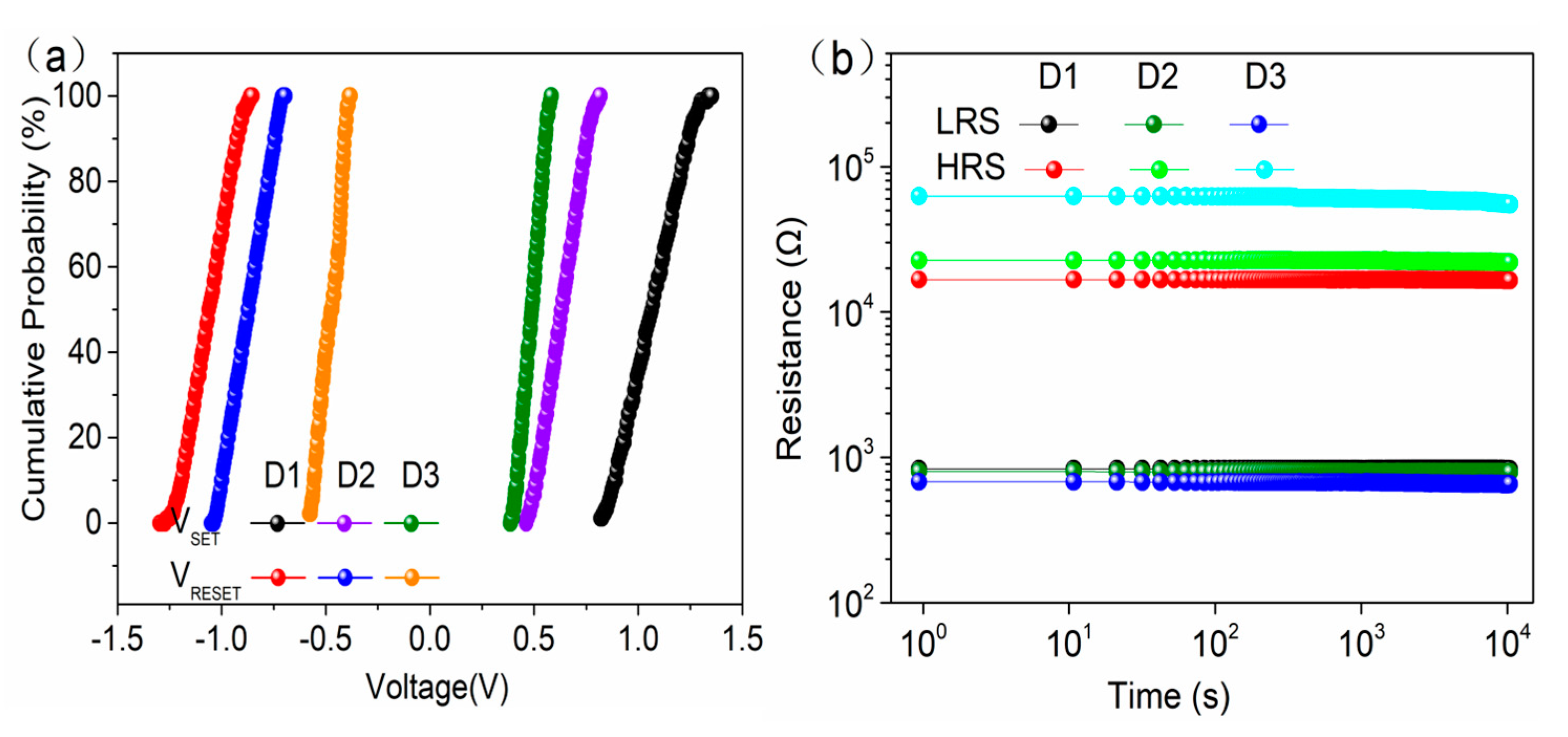

3. Results and Discussions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, S.-T.; Zhou, Y.; Roy, V.A.L. Towards the Development of Flexible Non-Volatile Memories. Adv. Mater. 2013, 25, 5425–5449. [Google Scholar] [CrossRef]

- Lee, J.; Schell, W.; Zhu, X.; Kioupakis, E.; Lu, W.D. Charge Transition of Oxygen Vacancies during Resistive Switching in Oxide-Based RRAM. ACS Appl. Mater. Interfaces 2019, 11, 11579–11586. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Feng, J.; Bae, D. Drastic reduction of RRAM reset current via plasma oxidization of TaOx film. Appl. Surf. Sci. 2015, 324, 275–279. [Google Scholar] [CrossRef]

- Ku, B.; Abbas, Y.; Sokolov, A.S.; Choi, C. Interface engineering of ALD HfO2-based RRAM with Ar plasma treatment for reliable and uniform switching behaviors. J. Alloy. Compd. 2018, 735, 1181–1188. [Google Scholar] [CrossRef]

- Tan, T.; Guo, T.; Liu, Z. Au doping effects in HfO2-based resistive switching memory. J. Alloy. Compd. 2014, 610, 388–391. [Google Scholar] [CrossRef]

- Wu, Q.; Banerjee, W.; Cao, J.; Ji, Z.; Li, L.; Liu, M. Improvement of durability and switching speed by incorporating nanocrystals in the HfOx based resistive random access memory devices. Appl. Phys. Lett. 2018, 113, 023105. [Google Scholar] [CrossRef]

- Michalas, L.; Stathopoulos, S.; Khiat, A.; Prodromakis, T. Conduction mechanisms at distinct resistive levels of Pt/TiO2-x/Pt memristors. Appl. Phys. Lett. 2018, 113, 143503. [Google Scholar] [CrossRef]

- Zhuge, F.; Peng, S.; He, C.; Zhu, X.; Chen, X.; Liu, Y.; Li, R.-W. Improvement of resistive switching in Cu/ZnO/Pt sandwiches by weakening the randomicity of the formation/rupture of Cu filaments. Nanotechnology 2011, 22, 275204. [Google Scholar] [CrossRef]

- He, P.; Ye, C.; Wu, J.; Wei, W.; Wei, X.; Wang, H.; Zhang, R.; Zhang, L.; Xia, Q.; Wang, H. Effect of sputtering atmosphere on the characteristics of ZrOx resistive switching memory. Semicond. Sci. Technol. 2017, 32, 055016. [Google Scholar] [CrossRef]

- Lee, M.-J.; Lee, C.B.; Lee, D.; Lee, S.R.; Chang, M.; Hur, J.H.; Kim, Y.-B.; Kim, C.-J.; Seo, D.H.; Seo, S.; et al. A fast, high-endurance and scalable non-volatile memory device made from asymmetric Ta2O5−x/TaO2−x bilayer structures. Nat. Mater. 2011, 10, 625–630. [Google Scholar] [CrossRef] [PubMed]

- Lin, Y.; Zeng, T.; Xu, H.; Wang, Z.; Zhao, X.; Liu, W.; Ma, J.; Liu, Y. Transferable and Flexible Artificial Memristive Synapse Based on WO x Schottky Junction on Arbitrary Substrates. Adv. Electron. Mater. 2018, 4, 1–8. [Google Scholar] [CrossRef]

- Xie, H.; Liu, Q.; Li, Y.; Lv, H.; Wang, M.; Liu, X.; Sun, H.; Yang, X.; Long, S.; Liu, S.; et al. Nitrogen-induced improvement of resistive switching uniformity in a HfO2-based RRAM device. Semicond. Sci. Technol. 2012, 27, 125008. [Google Scholar] [CrossRef]

- Chang, T.-C.; Chang, K.-C.; Tsai, T.-M.; Chu, T.-J.; Sze, S.M. Resistance random access memory. Mater. Today 2016, 19, 254–264. [Google Scholar] [CrossRef]

- Wong, H.-S.P.; Lee, H.-Y.; Yu, S.; Chen, Y.-S.; Wu, Y.; Chen, P.-S.; Lee, B.; Chen, F.T.; Tsai, M.-J. Metal–Oxide RRAM. Proc. IEEE Inst. Electr. Electron Eng. 2012, 100, 1951–1970. [Google Scholar] [CrossRef]

- Sokolov, A.S.; Son, S.K.; Lim, D.; Han, H.H.; Jeon, Y.-R.; Lee, J.H.; Choi, C. Comparative study of Al2O3, HfO2, and HfAlOxfor improved self-compliance bipolar resistive switching. J. Am. Ceram. Soc. 2017, 100, 5638–5648. [Google Scholar] [CrossRef]

- Qi, M.; Cao, S.; Yang, L.; You, Q.; Shi, L.; Wu, Z. Uniform multilevel switching of graphene oxide-based RRAM achieved by embedding with gold nanoparticles for image pattern recognition. Appl. Phys. Lett. 2020, 116, 163503. [Google Scholar] [CrossRef]

- Tang, L.; Maruyama, H.; Han, T.; Nino, J.C.; Chen, Y.; Zhang, D. Resistive switching in atomic layer deposited HfO2/ZrO2 nanolayer stacks. Appl. Surf. Sci. 2020, 515, 146015. [Google Scholar] [CrossRef]

- Kim, S.; Abbas, Y.; Jeon, Y.-R.; Sokolov, A.S.; Ku, B.; Choi, C. Engineering synaptic characteristics of TaOx/HfO2 bi-layered resistive switching device. Nanotechnology 2018, 29, 415204. [Google Scholar] [CrossRef] [PubMed]

- Zhang, K.; Sun, K.; Wang, F.; Han, Y.; Jiang, Z.; Zhao, J.; Wang, B.; Zhang, H.; Jian, X.; Wong, H.-S.P.; et al. Ultra-Low Power Ni/HfO2/TiOx/TiN Resistive Random Access Memory With Sub-30-nA Reset Current. IEEE Electron. Device Lett. 2015, 36, 1018–1020. [Google Scholar] [CrossRef]

- Sun, C.; Lu, S.; Jin, F.; Mo, W.; Song, J.; Dong, K. Control the switching mode of Pt/HfO2/TiN RRAM devices by tuning the crystalline state of TiN electrode. J. Alloy. Compd. 2018, 749, 481–486. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Chen, P.-H.; Chang, T.-C.; Chang, K.-C.; Zhang, S.-D.; Tsai, T.-M.; Pan, C.-H.; Chen, M.-C.; Po-Hsun, C.; Tseng, Y.-T.; et al. Attaining resistive switching characteristics and selector properties by varying forming polarities in a single HfO2-based RRAM device with a vanadium electrode. Nanoscale 2017, 9, 8586–8590. [Google Scholar] [CrossRef] [PubMed]

- Tan, T.; Guo, T.; Chen, X.; Li, X.; Liu, Z. Impacts of Au-doping on the performance of Cu/HfO2/Pt RRAM devices. Appl. Surf. Sci. 2014, 317, 982–985. [Google Scholar] [CrossRef]

- Jang, J. Effect of electrode material on characteristics of non-volatile resistive memory consisting of Ag2S nanoparticles. AIP Adv. 2016, 6, 75006. [Google Scholar] [CrossRef]

- Li, N.; Wang, Y.; Sun, H.; Hu, J.; Zheng, M.; Ye, S.; Wang, Q.; Li, Y.; He, D.; Wang, J.; et al. Resistive switching behaviors and mechanisms of HfS2 film memory devices studied by experiments and density functional theory calculations. Appl. Phys. Lett. 2020, 116, 063503. [Google Scholar] [CrossRef]

- Zheng, J.; Cheng, B.; Wu, F.; Su, X.; Xiao, Y.; Guo, R.; Lei, S. Modulation of Surface Trap Induced Resistive Switching by Electrode Annealing in Individual PbS Micro/Nanowire-Based Devices for Resistance Random Access Memory. ACS Appl. Mater. Interfaces 2014, 6, 20812–20818. [Google Scholar] [CrossRef]

- Chen, P.-H.; Chang, K.-C.; Chang, T.-C.; Tsai, T.-M.; Pan, C.-H.; Chu, T.-J.; Chen, M.-C.; Huang, H.-C.; Lo, I.; Zheng, J.-C.; et al. Bulk Oxygen–Ion Storage in Indium–Tin–Oxide Electrode for Improved Performance of HfO2-Based Resistive Random Access Memory. IEEE Electron. Device Lett. 2016, 37, 280–283. [Google Scholar] [CrossRef]

- Naumkin, A.V.; Kraut-Vass, A.; Gaarenstroom, S.W.; Powell, C.J. NIST X-Ray Photoelectron Spectroscopy (XPS) Database. 2012. Available online: https://srdata.nist.gov/xps/selEnergyType.aspx (accessed on 25 March 2021).

- Qi, M.; Tao, Y.; Wang, Z.; Xu, H.; Zhao, X.; Liu, W.; Ma, J.; Liu, Y. Highly uniform switching of HfO2−x based RRAM achieved through Ar plasma treatment for low power and multilevel storage. Appl. Surf. Sci. 2018, 458, 216–221. [Google Scholar] [CrossRef]

- Tan, T.; Du, Y.; Cao, A.; Sun, Y.; Zha, G.; Lei, H.; Zheng, X. The resistive switching characteristics of Ni-doped HfO film and its application as a synapse. J. Alloy. Compd. 2018, 766, 918–924. [Google Scholar] [CrossRef]

- Balatti, S.; Larentis, S.; Gilmer, D.C.; Ielmini, D. Multiple Memory States in Resistive Switching Devices through Controlled Size and Orientation of the Conductive Filament. Adv. Mater. 2013, 25, 1474–1478. [Google Scholar] [CrossRef]

- Clima, S.; Govoreanu, B.; Jurczak, M.; Pourtois, G. HfOx as RRAM material – First principles insights on the working principles. Microelectron. Eng. 2014, 120, 13–18. [Google Scholar] [CrossRef]

- Dean, J.A. Lange’s Handbook of Chemistry, 13th ed.; McGraw-Hill Book Company: New York, NY, USA, 1985. [Google Scholar]

- Guo, T.; Tan, T.; Liu, Z.; Liu, B. Oxygen vacancy modulation and enhanced switching behavior in HfOx film induced by Al doping effect. J. Alloy. Compd. 2016, 686, 669–674. [Google Scholar] [CrossRef]

- Wang, M.-H.; Chang, T.-C.; Shih, C.-C.; Tseng, Y.-T.; Tsai, T.-M.; Zheng, H.-X.; Wu, P.-Y.; Huang, H.-C.; Chen, W.-C.; Huang, J.-W.; et al. Performance improvement after nitridation treatment in HfO2-based resistance random-access memory. Appl. Phys. Express 2018, 11, 084101. [Google Scholar] [CrossRef]

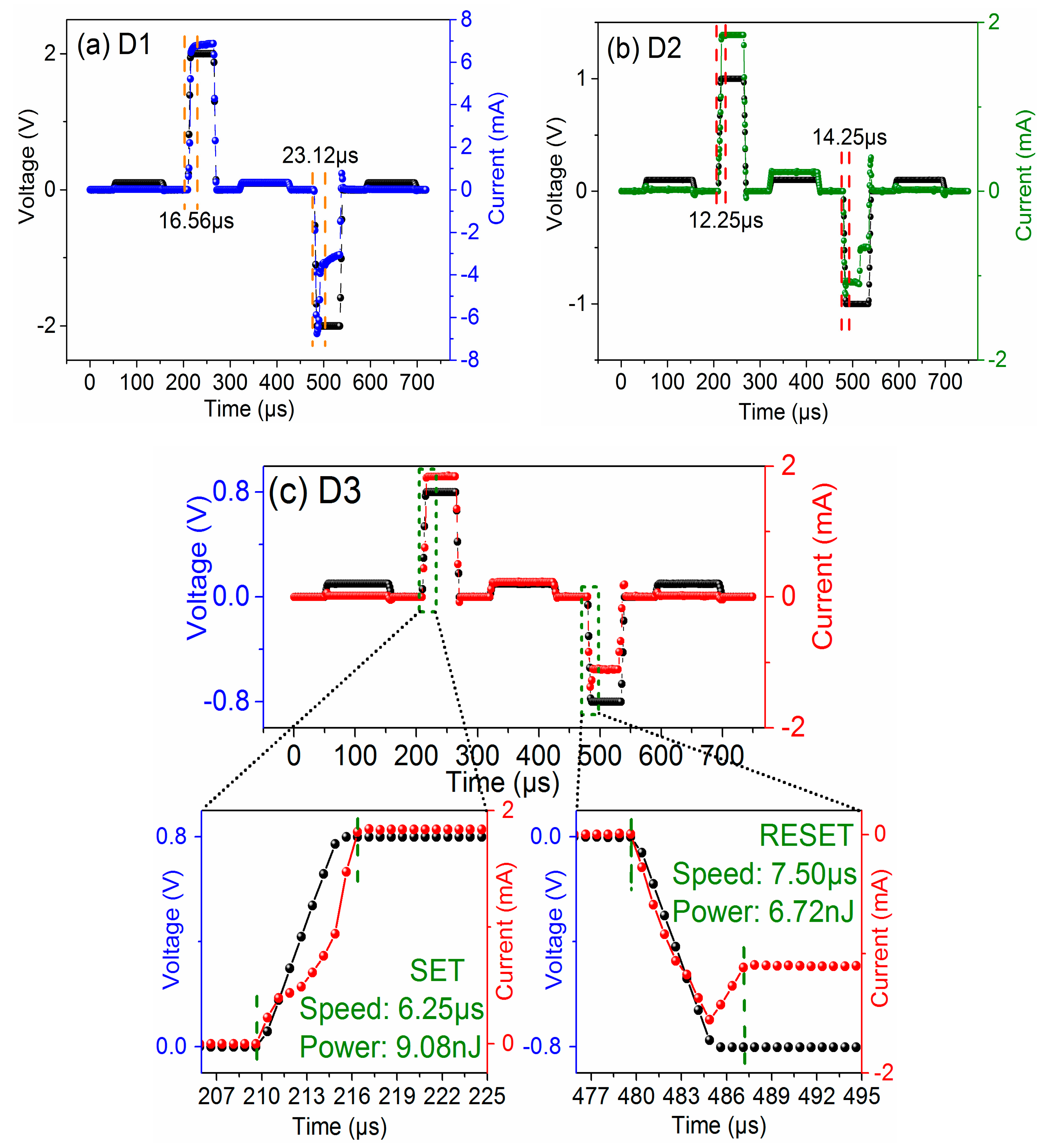

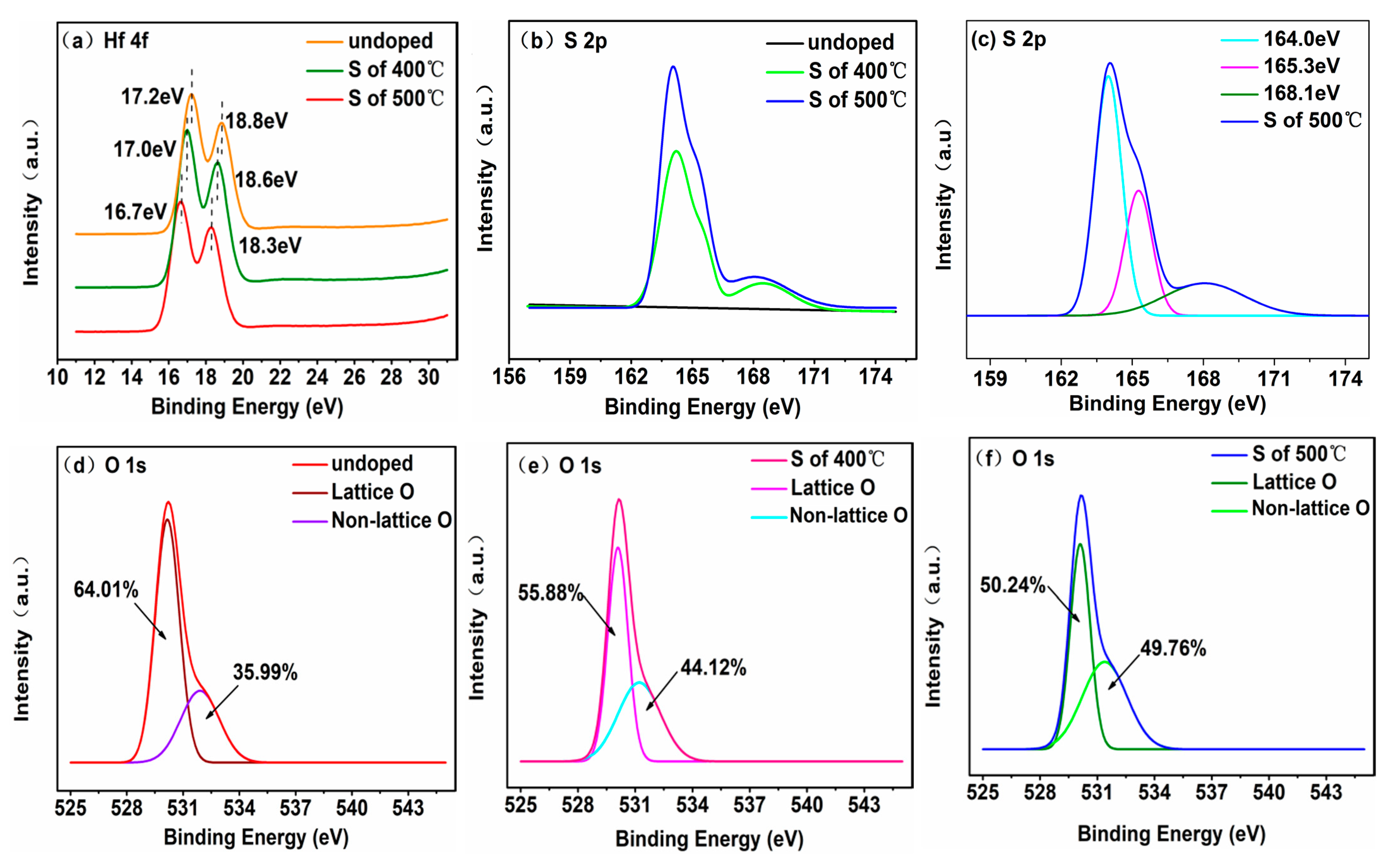

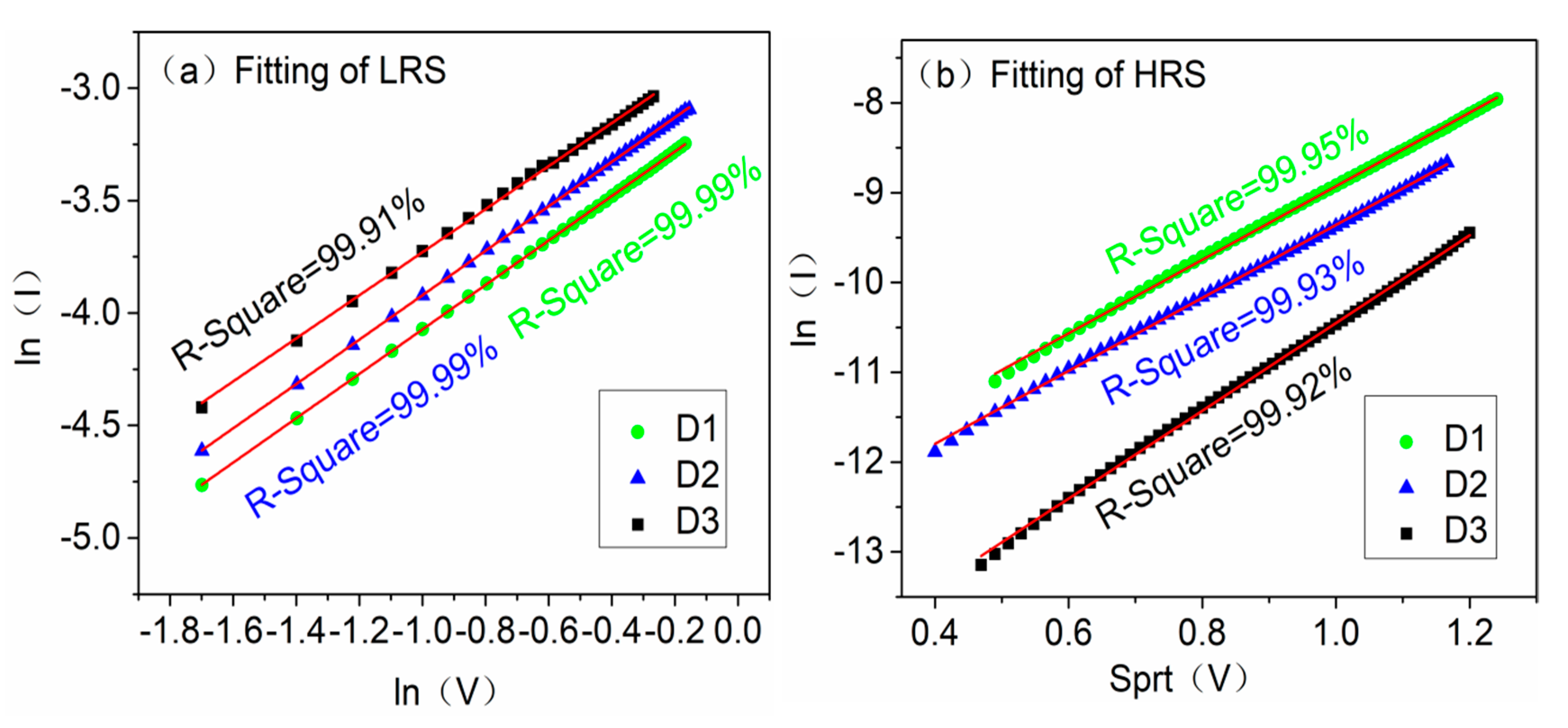

| Devices | Vforming (V) | Voltage (V) | HRS/LRS Ratio | Endurance (AC cycles) | Retention at 85 °C (s) | Switching Speed (μs) | Energy Consumption (nJ) |

|---|---|---|---|---|---|---|---|

| SET/RESET | |||||||

| D1 | +2.18 | +1.05/ −0.94 | ~12 | 106 (Degradation) | 104 | ~16.56/~23.12 | 224.2/155.8 |

| D2 | +1.32 | +0.76/ −0.78 | ~30 | 106 | 104 | ~12.25/~14.25 | 22.54/15.25 |

| D3 | +0.85 | +0.11/ −0.15 | ~90 | 106 (Uniformity) | 104 (Uniformity) | ~6.25/~7.50 | 9.08/6.72 |

| D4 | - | +2/−2 | ~2 | - | - | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Wang, F.; Hu, K.; She, Y.; Song, S.; Song, Z.; Zhang, K. Improvement of Resistive Switching Performance in Sulfur-Doped HfOx-Based RRAM. Materials 2021, 14, 3330. https://doi.org/10.3390/ma14123330

Zhang Z, Wang F, Hu K, She Y, Song S, Song Z, Zhang K. Improvement of Resistive Switching Performance in Sulfur-Doped HfOx-Based RRAM. Materials. 2021; 14(12):3330. https://doi.org/10.3390/ma14123330

Chicago/Turabian StyleZhang, Zhenzhong, Fang Wang, Kai Hu, Yu She, Sannian Song, Zhitang Song, and Kailiang Zhang. 2021. "Improvement of Resistive Switching Performance in Sulfur-Doped HfOx-Based RRAM" Materials 14, no. 12: 3330. https://doi.org/10.3390/ma14123330

APA StyleZhang, Z., Wang, F., Hu, K., She, Y., Song, S., Song, Z., & Zhang, K. (2021). Improvement of Resistive Switching Performance in Sulfur-Doped HfOx-Based RRAM. Materials, 14(12), 3330. https://doi.org/10.3390/ma14123330