Effect of Au-Coating on the Laser Spot Cutting on Spring Contact Probe (SCP) for Semi-Conductor Inspection

Abstract

1. Introduction

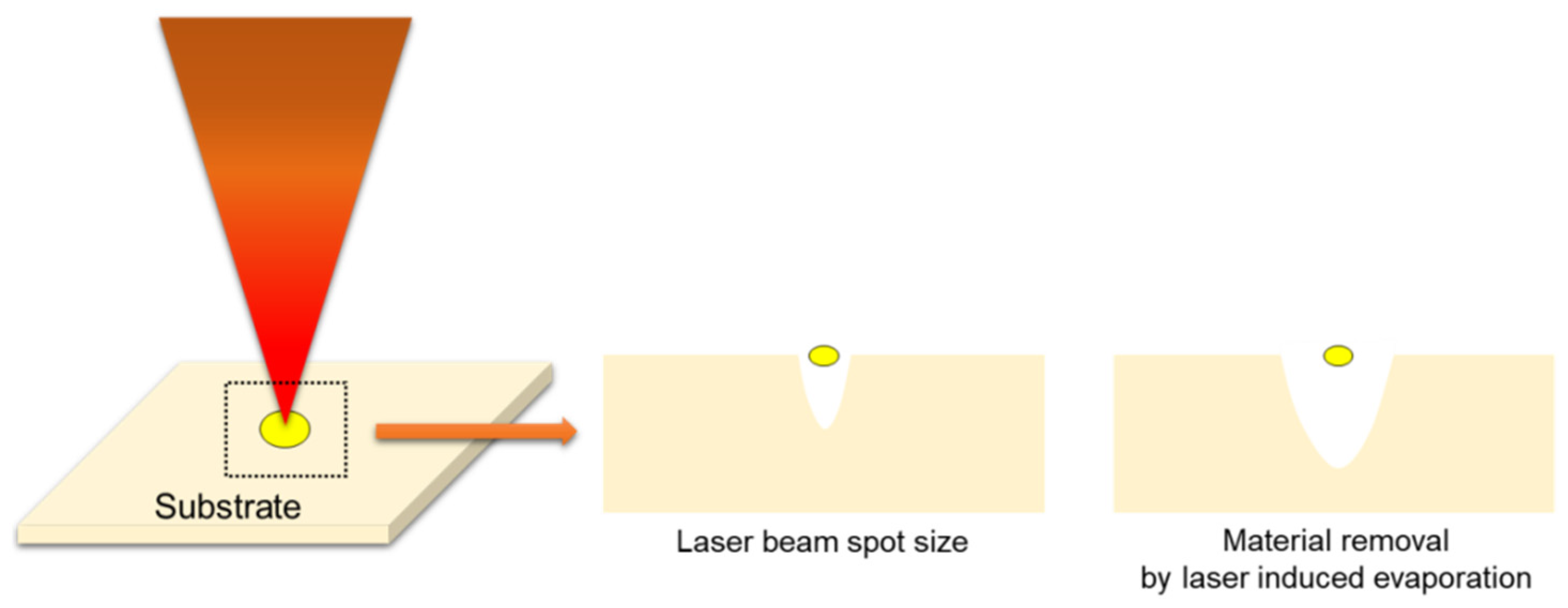

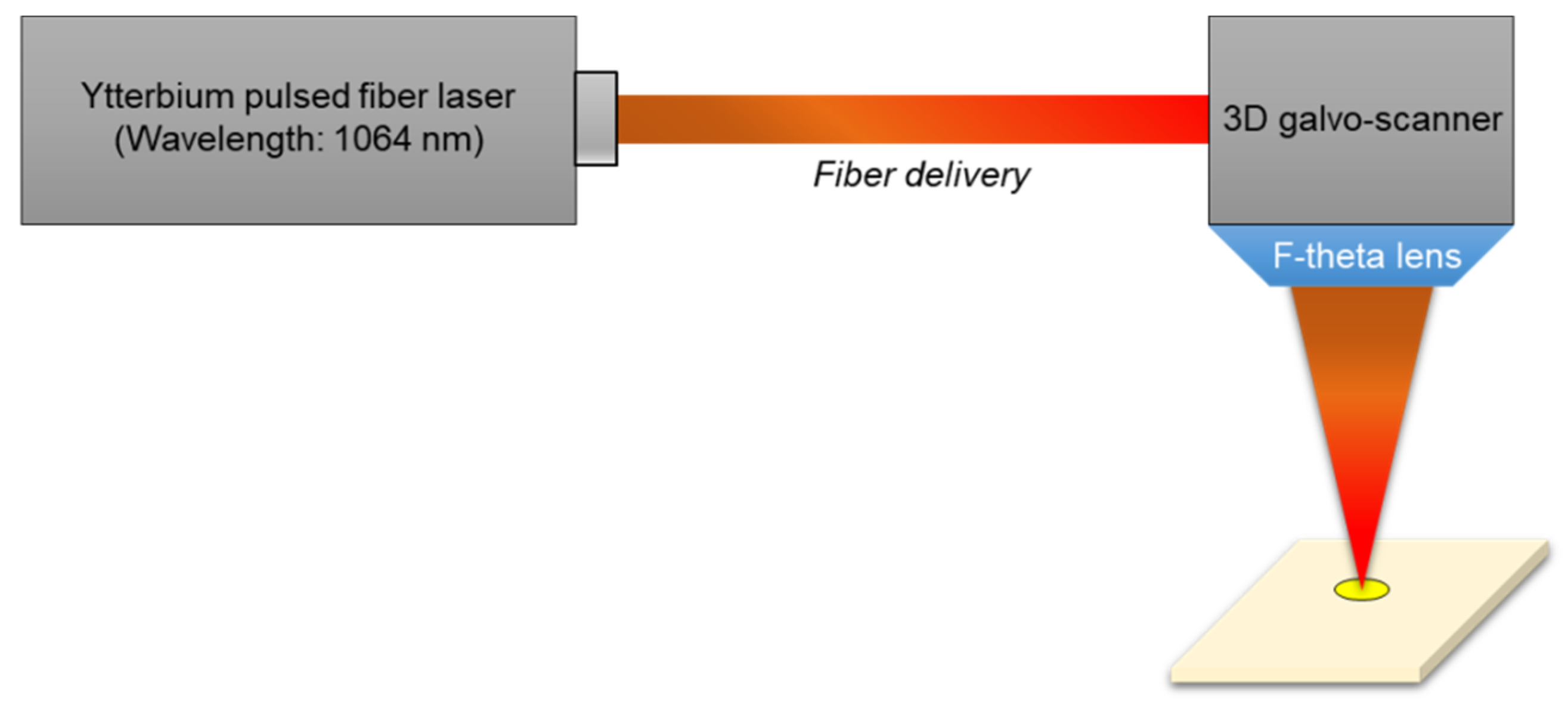

2. Experimental Setup and Design

3. Experimental Results and Analysis

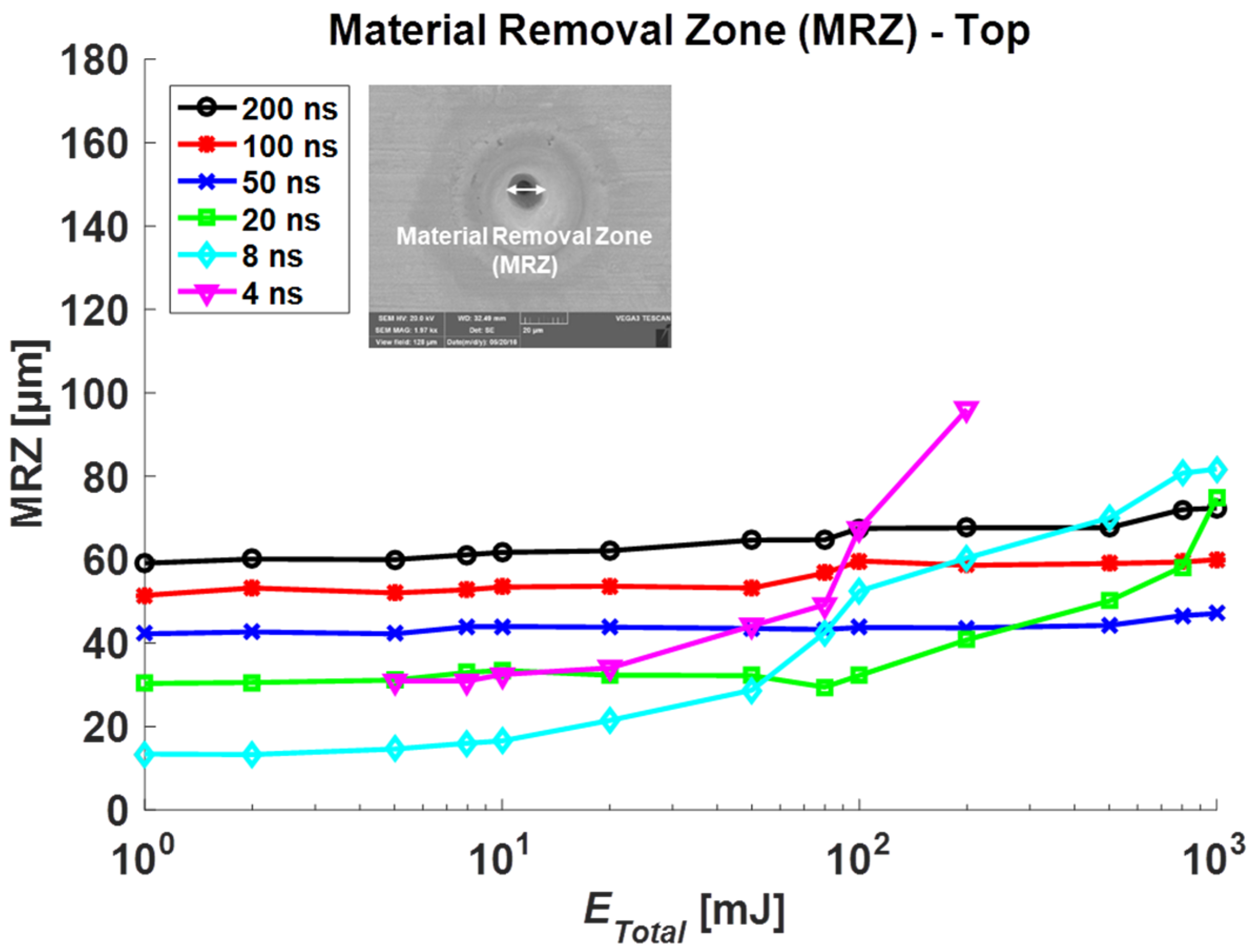

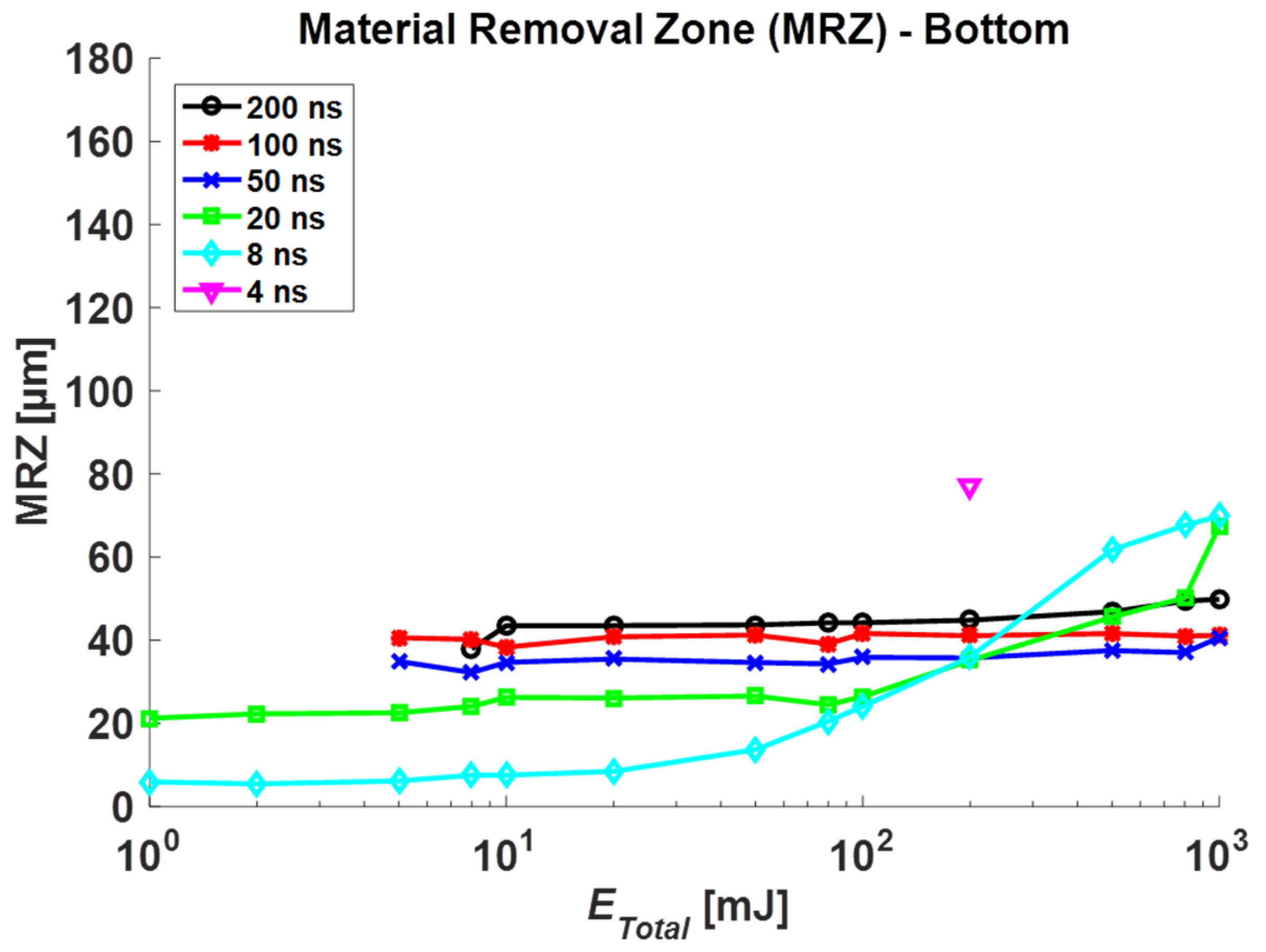

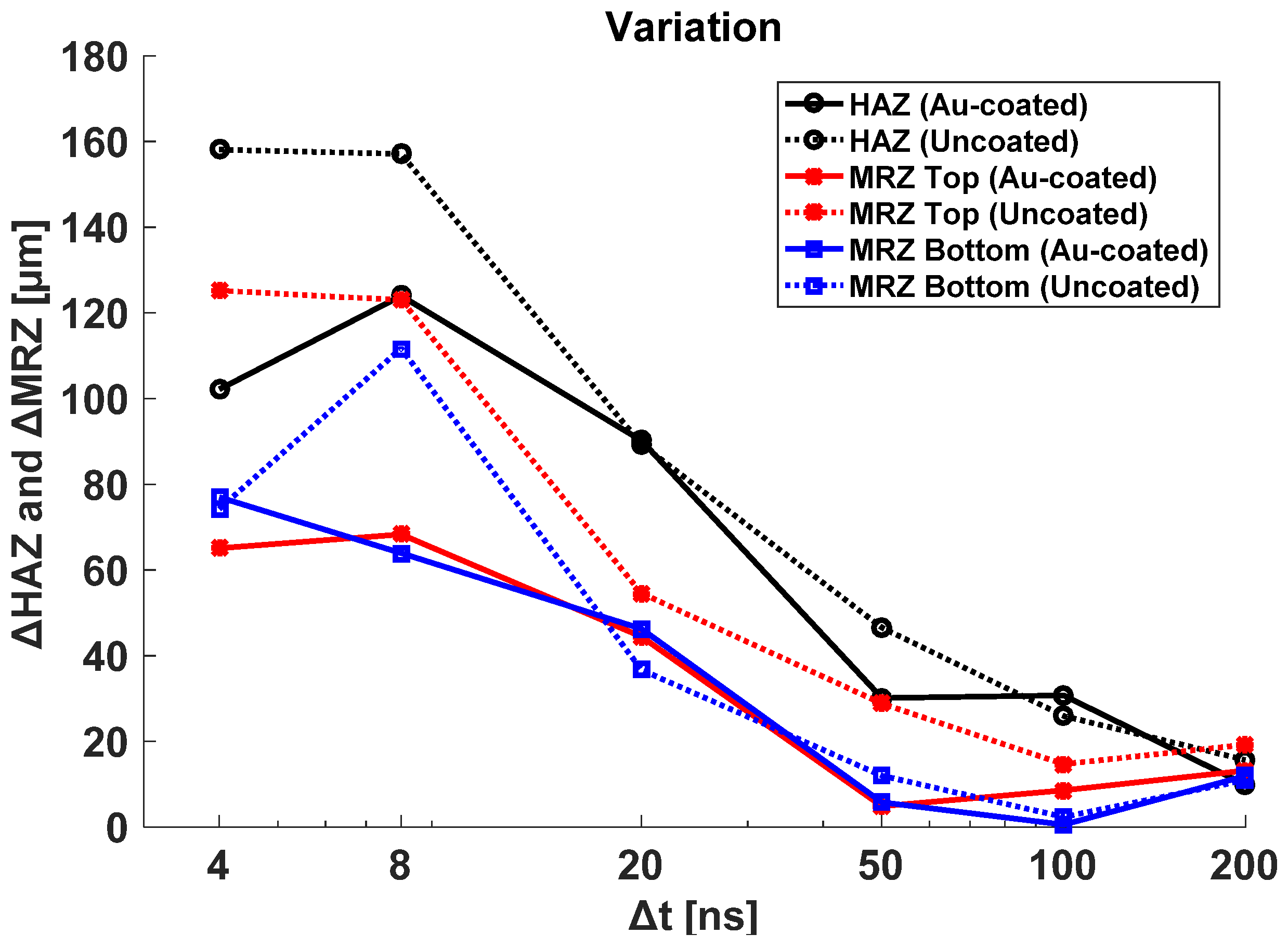

3.1. Analysis of HAZ and MRZ Results

3.2. HAZ and MRZ Change Rate Analysis

3.3. Roundness

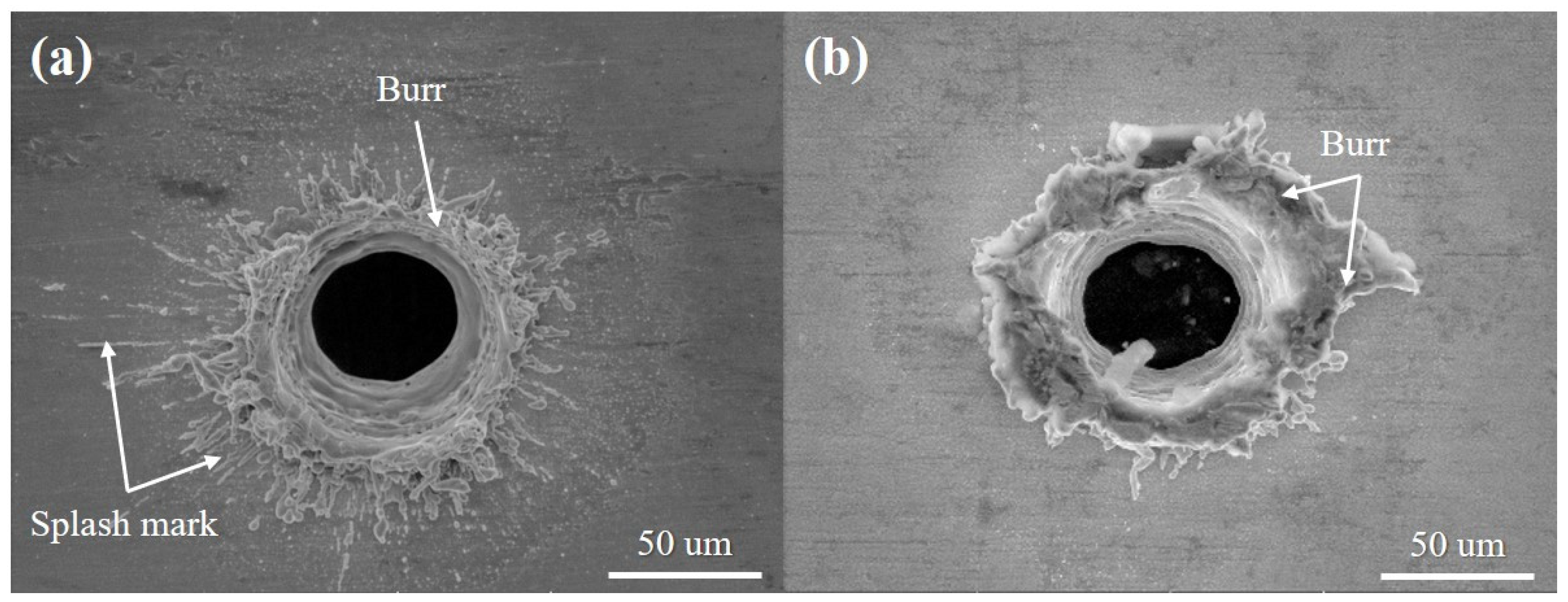

3.4. Surface Morphology

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kang, M.; Ahn, Y.-N.; Kim, C. Porosity Reduction during Gas Tungsten Arc-Gas Metal Arc Hybrid Welding of Zinc Coated Steel Sheets (I)—Effect of Preceding Gas Tungsten Arc. J. Weld. Join. 2016, 34, 40–47. [Google Scholar] [CrossRef]

- Kang, M.; Kim, C.; Kim, Y.-M. Evaluation of the Laser Weldability of Inconel 713C alloy. J. Weld. Join. 2017, 35, 68–73. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B. Dross-free submerged laser cutting of AZ31 Mg alloy for biodegradable stents. J. Laser Appl. 2016, 28, 032001. [Google Scholar] [CrossRef]

- Lee, D.; Patwa, R.; Herfurth, H.; Mazumder, J. Parameter optimization for high speed remote laser cutting of electrodes for lithium-ion batteries. J. Laser Appl. 2016, 28, 022006. [Google Scholar] [CrossRef]

- Lee, D.; Patwa, R.; Herfurth, H.; Mazumder, J. Three dimensional simulation of high speed remote laser cutting of cathode for lithium-ion batteries. J. Laser Appl. 2016, 28, 032010. [Google Scholar] [CrossRef]

- Lee, D. Experimental Investigation of Laser Spot Welding of Ni and Au-Sn-Ni Alloy. J. Weld. Join. 2017, 35, 1–5. [Google Scholar] [CrossRef]

- Lee, D.; Patwa, R.; Herfurth, H.; Mazumder, J. High speed remote laser cutting of electrodes for lithium-ion batteries: Anode. J. Power Sources 2013, 240, 368–380. [Google Scholar] [CrossRef]

- Lee, D.; Patwa, R.; Herfurth, H.; Mazumder, J. Computational and experimental studies of laser cutting of the current collectors for lithium-ion batteries. J. Power Sources 2012, 210, 327–338. [Google Scholar] [CrossRef]

- Lutey, A.H.A.; Fortunato, A.; Ascari, A.; Carmignato, S.; Leone, C. Laser cutting of lithium iron phosphate battery electrodes: Characterization of process efficiency and quality. Opt. Laser Technol. 2015, 65, 164–174. [Google Scholar] [CrossRef]

- Lutey, A.H.A.; Fortunato, A.; Carmignato, S.; Ascari, A.; Liverani, E.; Guerrini, G. Quality and Productivity Considerations for Laser Cutting of LiFePO4 and LiNiMnCoO2 Battery Electrodes. In Proceedings of the 18th CIRP Conference on Electro Physical and Chemical Machining (ISEM XVIII), Tokyo, Japan, 18–22 April 2016. [Google Scholar]

- Schmieder, B. Analytical model of the laser ablation mechanism of lithium-ion battery coatings. In Proceedings of the Laser-based Micro- and Nanoprocessing IX, San Francisco, CA, USA, 21 April 2015. [Google Scholar]

- Staehr, R.; Bluemel, S.; Jaeschke, P.; Suttmann, O.; Overmeyer, L. Laser cutting of composites—Two approaches toward an industrial establishment. J. Laser Appl. 2016, 28, 022203. [Google Scholar] [CrossRef]

- Canisius, M.; Herzog, D.; Schmidt-Lehr, M.; Oberlander, M.; Direnga, J.; Emmelmann, C. Laser cutting of carbon fiber-reinforced plastic with an absorber transparent for visible spectrum. J. Laser Appl. 2015, 27, 032003. [Google Scholar] [CrossRef]

- Herzog, D.; Schmidt-Lehr, M.; Oberlander, M.; Canisius, M.; Radek, M.; Emmelmann, C. Laser cutting of carbon fibre reinforced plastics of high thickness. Mater. Des. 2016, 92, 742–749. [Google Scholar] [CrossRef]

- Herzog, D.; Schmidt-Lehr, M.; Canisius, M.; Oberlander, M.; Tasche, J.-P.; Emmelmann, C. Laser cutting of carbon fiber reinforced plastic using a 30 kW fiber laser. J. Laser Appl. 2015, 27, S28001. [Google Scholar] [CrossRef]

- Wu, C.W.; Wu, X.Q.; Huang, C.G. Ablation behaviors of carbon reinforced polymer composites by laser of different operation modes. Opt. Laser Technol. 2015, 73, 23–28. [Google Scholar] [CrossRef]

- Choubey, A.; Jain, R.K.; Ali, S.; Singh, R.; Vishwakarma, S.C.; Agrawal, D.K.; Arya, R.; Kaul, R.; Upadhyaya, B.N.; Oak, S.M. Studies on pulsed Nd:YAG laser cutting of thick stainless steel in dry air and underwater environment for dismantling applications. Opt. Laser Technol. 2015, 71, 6–15. [Google Scholar] [CrossRef]

- Phi Long, N.; Matsunaga, Y.; Hanari, T.; Yamada, T.; Muramatsu, T. Experimental investigation of transient temperature characteristic in high power fiber laser cutting of a thick steel plate. Opt. Laser Technol. 2016, 84, 134–143. [Google Scholar] [CrossRef]

- Hilton, P.A.; Lloyd, D.; Tyrer, J.R. Use of a diffractive optic for high power laser cutting. J. Laser Appl. 2016, 28, 012014. [Google Scholar] [CrossRef]

- Orishich, A.M.; Shulyatyev, V.B.; Filon, A.E. Craterlike structures on the cut surface after oxygen-assisted laser cutting of steel. J. Laser Appl. 2016, 28, 012007. [Google Scholar] [CrossRef]

- Lee, D. Experimental Investigation of Laser Ablation Characteristics on Nickel-Coated Beryllium Copper. Metals 2018, 8, 211. [Google Scholar] [CrossRef]

- Lee, D.; Cho, J.; Kim, C.H.; Lee, S.H. Application of laser spot cutting on spring contact probe for semiconductor package inspection. Opt. Laser Technol. 2017, 97, 90–96. [Google Scholar] [CrossRef]

| Pulse Duration [ns] | Rep. Rate [kHz] | Pulse E [µJ] | Total E [mJ] | ||||||||||||

| 1000 | 800 | 500 | 200 | 100 | 80 | 50 | 20 | 10 | 8 | 5 | 2 | 1 | |||

| Number of Pulse [#] | |||||||||||||||

| 200 | 20 | 1000 | 1000 | 800 | 500 | 200 | 100 | 80 | 50 | 20 | 10 | 8 | 5 | 2 | 1 |

| 100 | 40 | 500 | 2000 | 1600 | 1000 | 400 | 200 | 160 | 100 | 40 | 20 | 16 | 10 | 4 | 2 |

| 50 | 60 | 333.3 | 3000 | 2400 | 1500 | 600 | 300 | 240 | 150 | 60 | 30 | 24 | 15 | 6 | 3 |

| 20 | 105 | 190.5 | 5250 | 4200 | 2625 | 1050 | 525 | 420 | 263 | 105 | 53 | 42 | 26 | 11 | 5 |

| 8 | 200 | 100 | 10,000 | 8000 | 5000 | 2000 | 1000 | 800 | 500 | 200 | 100 | 80 | 50 | 20 | 10 |

| 4 | 500 | 40 | 25,000 | 20,000 | 12,500 | 5000 | 2500 | 2000 | 1250 | 500 | 250 | 200 | 125 | 50 | 25 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seo, Y.; Nam, J.; Yun, H.; Jun, M.B.G.; Lee, D. Effect of Au-Coating on the Laser Spot Cutting on Spring Contact Probe (SCP) for Semi-Conductor Inspection. Materials 2021, 14, 3300. https://doi.org/10.3390/ma14123300

Seo Y, Nam J, Yun H, Jun MBG, Lee D. Effect of Au-Coating on the Laser Spot Cutting on Spring Contact Probe (SCP) for Semi-Conductor Inspection. Materials. 2021; 14(12):3300. https://doi.org/10.3390/ma14123300

Chicago/Turabian StyleSeo, Youngjin, Jungsoo Nam, Huitaek Yun, Martin Byung Guk Jun, and Dongkyoung Lee. 2021. "Effect of Au-Coating on the Laser Spot Cutting on Spring Contact Probe (SCP) for Semi-Conductor Inspection" Materials 14, no. 12: 3300. https://doi.org/10.3390/ma14123300

APA StyleSeo, Y., Nam, J., Yun, H., Jun, M. B. G., & Lee, D. (2021). Effect of Au-Coating on the Laser Spot Cutting on Spring Contact Probe (SCP) for Semi-Conductor Inspection. Materials, 14(12), 3300. https://doi.org/10.3390/ma14123300