Prediction of Crack Resistance of LFSMA-13 with and without Anti-Rut Agent Using Parameters of FTIR Spectrum under Different Aging Degrees

Abstract

1. Introduction

2. Materials and Gradation Design

2.1. Materials

2.1.1. Asphalt

2.1.2. Lignin Fiber

2.1.3. Anti-Rut Agent

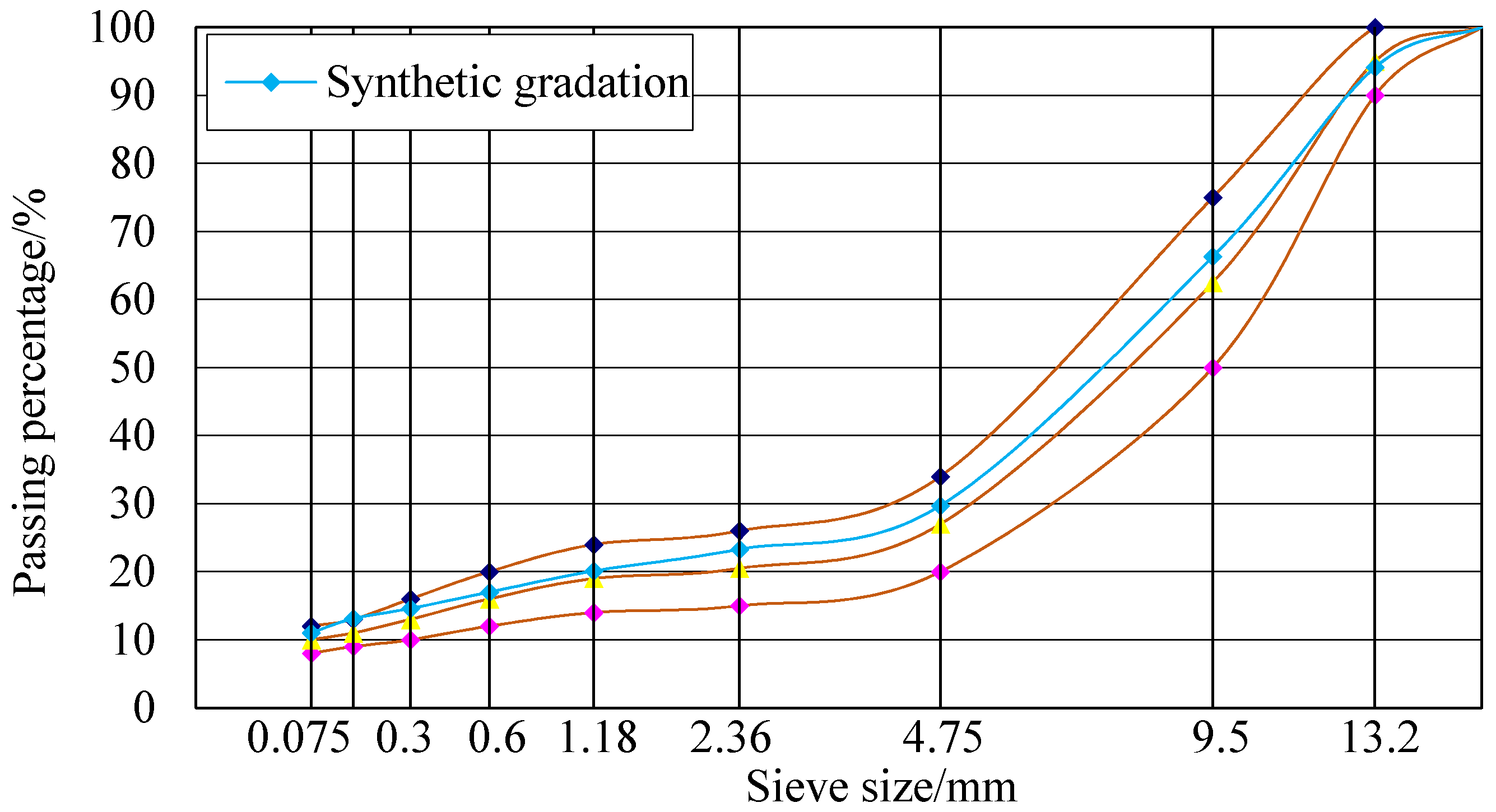

2.2. Gradation Design of SMA-13 Asphalt Mixtures with LF and ARA

2.3. Sample Preparation

3. Test and Analysis Methods

3.1. Test Methods

3.1.1. IDEAL-CT Test

3.1.2. FTIR Spectroscopy Measurements

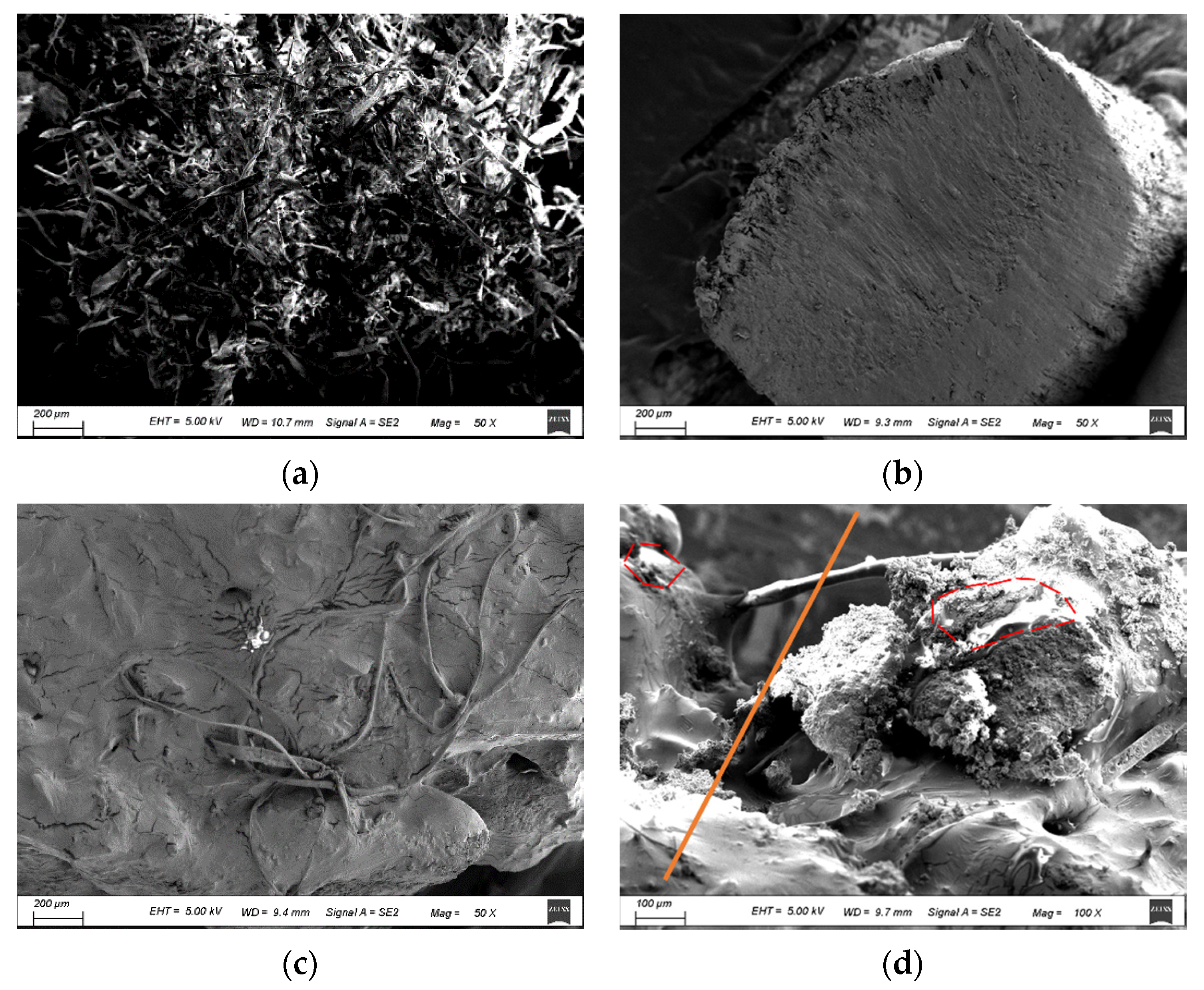

3.1.3. SEM Observations

3.2. Grey Correlation Analysis

4. Results and Discussion

4.1. IDEAL-CT Test

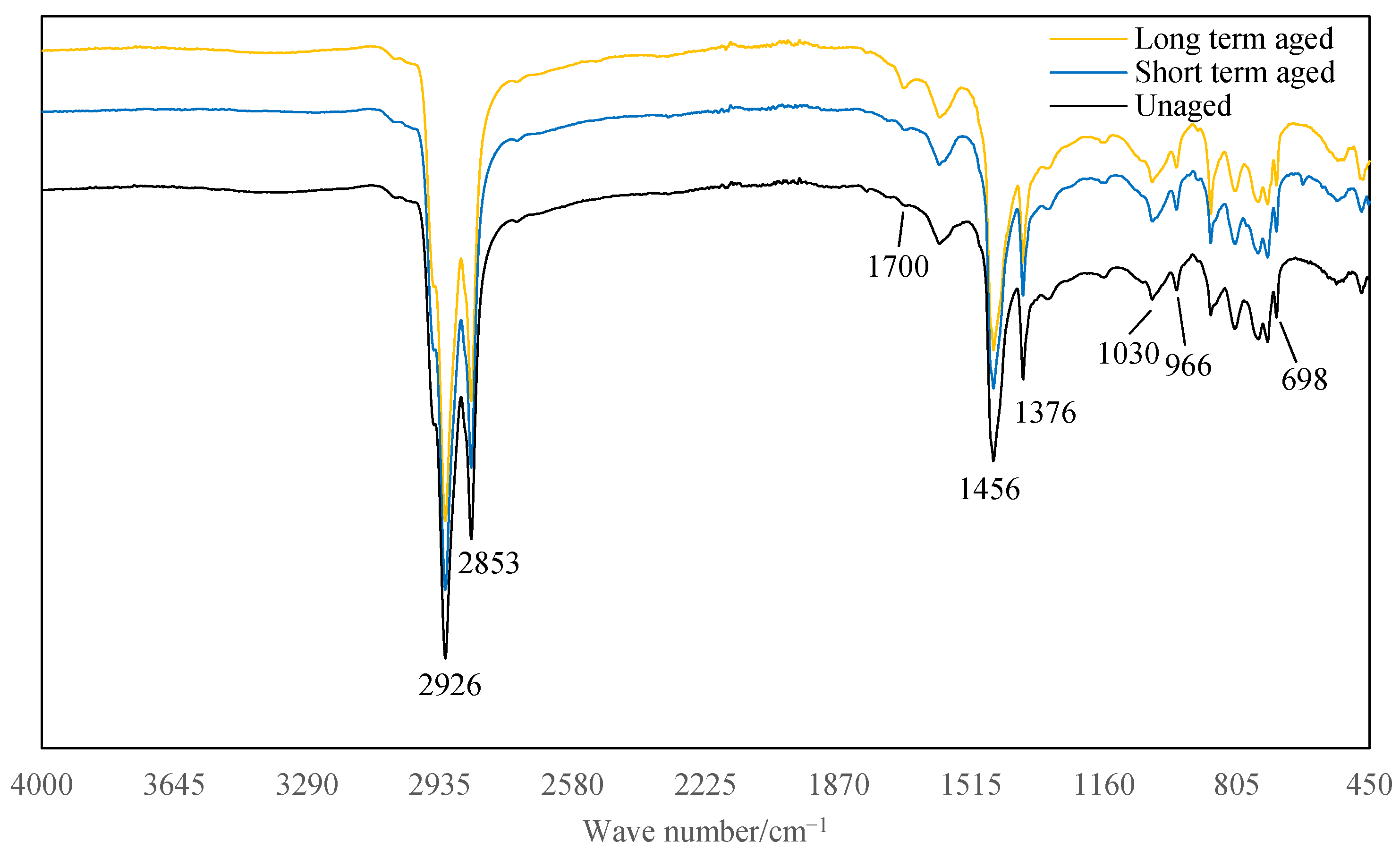

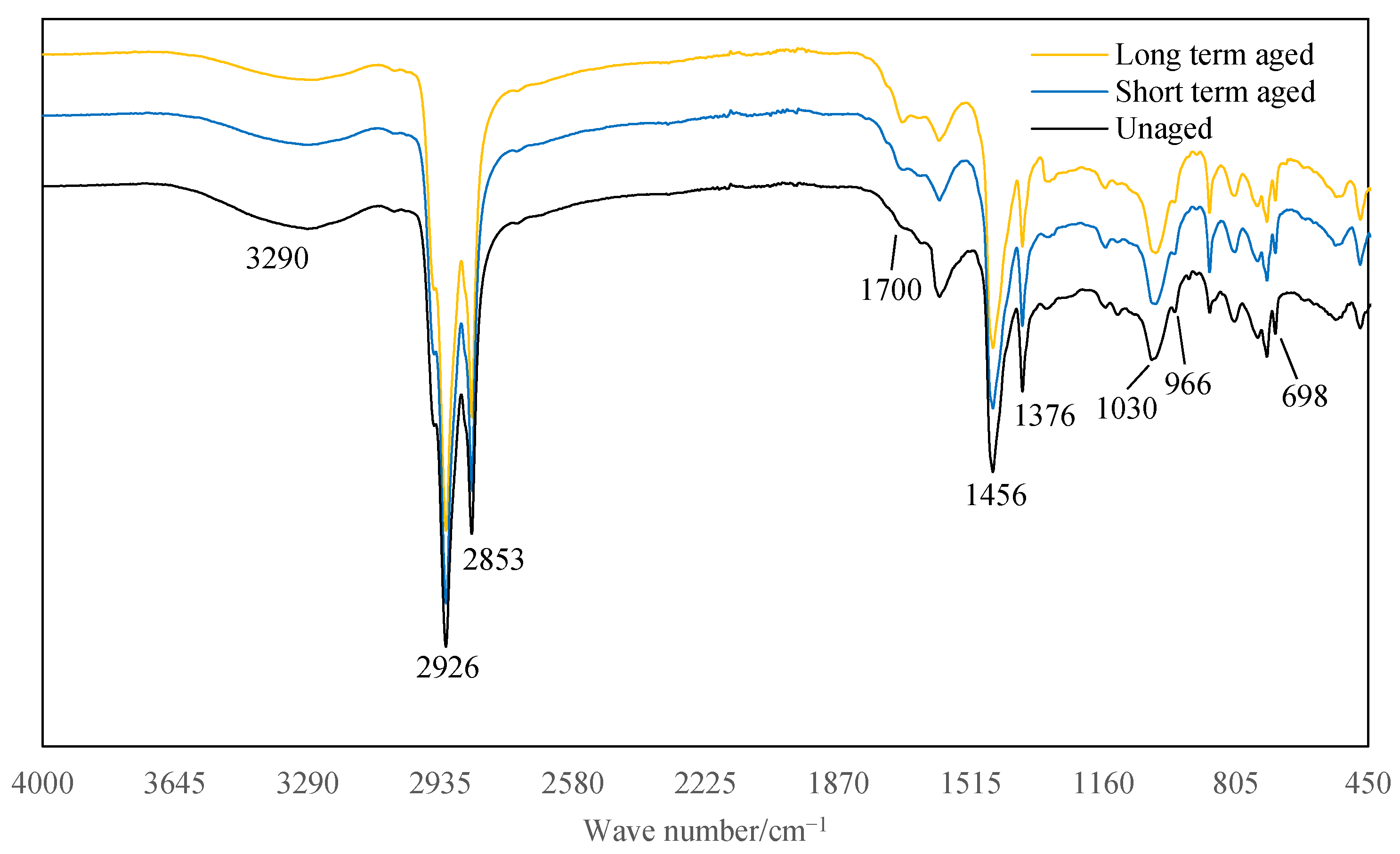

4.2. FTIR Spectroscopy Measurements

4.3. Grey Correlation Analysis

4.4. Preliminary Prediction Model and Application Method

4.5. SEM Observations Result

5. Conclusions

- (1)

- The sensitivity of ALSMA-13 to aging is slightly lower than that of LFSMA-13. The crack formation work, Winitial, and the crack propagation index, CTIndex, of ALSMA-13 are higher than those of LFSMA-13. The difference between the crack resistances of LFSMA-13 and ALSMA-13 will be higher when the aging degree increases.

- (2)

- When the aging degree increase, the peak area of the imino group in ALSMA-13 decreases, the peak areas of methylene of all the samples are relatively stable, the peak areas of the carbonyl and sulfoxide groups increase, and the peak areas of trans butadiene and styrene in the samples decrease.

- (3)

- Grey correlation analysis could be adopted to select suitable indexes of the FTIR spectra to derive prediction models of CTIndex and Winitial of LFSMA-13 and ALSMA-13. The ternary linear prediction models could also well predict the crack resistance.

- (4)

- A convenient method or procedure to quickly test the crack resistance of the LFSMA-13, with and without anti-rut agent, was provided in the research. SEM images showed that LF curled in the mixtures and ARA melted in the asphalt.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, C.; Wang, L.; Wang, X.X. Crack and crack growth behavior analysis of asphalt mixtures based on the digital speckle correla-tion method. Constr. Build. Mater. 2017, 147, 227–238. [Google Scholar] [CrossRef]

- Xiao, F.; Li, R.; Amirkhanian, S.; Yuan, J. Rutting-Resistance Investigation of Alternative Polymerized Asphalt Mixtures. J. Mater. Civ. Eng. 2018, 30, 04018116. [Google Scholar] [CrossRef]

- Kringos, N.; Scarpas, A. Raveling of asphaltic mixes due to water damage: Computational identification of controlling pa-rameters. Transport. Res. Rec. 2005, 1929, 79–87. [Google Scholar] [CrossRef]

- Liao, M.-C.; Lin, Y.-Y.; Tseng, M.-Y. Laboratory Evaluation of Aging on Engineering Properties of Fine-Graded Porous-Asphalt Concrete. J. Test. Eval. 2017, 46, 215–226. [Google Scholar] [CrossRef]

- Sirin, O.; Paul, D.K.; Kassem, E. State of the Art Study on Aging of Asphalt Mixtures and Use of Antioxidant Additives. Adv. Civ. Eng. 2018, 2018, 1–18. [Google Scholar] [CrossRef]

- Sirin, O.; Ohiduzzaman, M.; Kassem, E.; Paul, D.K. Comprehensive evaluation of long-term aging of asphalt mixtures in hot climatic condition. Road Mater. Pavement Des. 2018, 21, 1–23. [Google Scholar] [CrossRef]

- Lv, S.; Hu, L.; Xia, C.; Wang, X.; Cabrera, M.B.; Guo, S.; Chen, J. Development of fatigue damage model of asphalt mixtures based on small-scale accelerated pavement test. Constr. Build. Mater. 2020, 260, 119930. [Google Scholar] [CrossRef]

- Hou, Y.; Wang, L.; Pauli, T.; Sun, W. Investigation of the Asphalt Self-Healing Mechanism Using a Phase-Field Model. J. Mater. Civ. Eng. 2015, 27, 04014118. [Google Scholar] [CrossRef]

- Hou, Y.; Sun, W.; Das, P.; Song, X.; Wang, L.; Ge, Z.; Huang, Y. Coupled Navier–Stokes Phase-Field Model to Evaluate the Microscopic Phase Separation in Asphalt Binder under Thermal Loading. J. Mater. Civ. Eng. 2016, 28, 04016100. [Google Scholar] [CrossRef]

- Harmelink, D.; Shuler, S.; Aschenbrener, T. Top-Down Cracking in Asphalt Pavements: Causes, Effects, and Cures. J. Transp. Eng. 2008, 134, 1–6. [Google Scholar] [CrossRef]

- Wu, S.; Xue, Y.; Ye, Q.; Chen, Y. Utilization of steel slag as aggregates for stone mastic asphalt (SMA) mixtures. Build. Environ. 2007, 42, 2580–2585. [Google Scholar] [CrossRef]

- Ameri, M.; Mohammadi, R.; Vamegh, M.; Molayem, M. Evaluation the effects of nanoclay on permanent deformation behavior of stone mastic asphalt mixtures. Constr. Build. Mater. 2017, 156, 107–113. [Google Scholar] [CrossRef]

- Chen, H.; Xu, Q.; Chen, S.; Zhang, Z. Evaluation and design of fiber-reinforced asphalt mixtures. Mater. Des. 2009, 30, 2595–2603. [Google Scholar] [CrossRef]

- Sheng, Y.; Li, H.; Guo, P.; Zhao, G.; Chen, H.; Xiong, R. Effect of Fibers on Mixture Design of Stone Matrix Asphalt. Appl. Sci. 2017, 7, 297. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, Y.; Xue, J.; Deng, C.; Tian, T. Performance of Stone Mastic Asphalt Mixtures Fabricated by Different Com-paction Methods. Appl. Sci. 2020, 10, 2523. [Google Scholar] [CrossRef]

- Liu, K.Y.; Dong, J.Z.; Liu, R.M.; Zheng, L. Rheological and Fatigue Properties of Asphalt Binders Containing Anti-Rut Agents. Key Eng. Mater. 2014, 599, 239–243. [Google Scholar] [CrossRef]

- Li, P.; Wang, X.; Li, H.; Qian, Y. Influence Factors and Anti-Rutting Agent of High-Temperature Stability of Asphalt Mixture. In Proceedings of the Traffic and Transportation Studies 2010, Kunming, China, 3–5 August 2010; pp. 1293–1302. [Google Scholar]

- Yiluo, Z.; Ning, L. Research on Applicability of Anti-rutting Agent LY to Different Asphalt Mixtures. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Dalian, China, 21–23 August 2020; Volume 587, p. 012029. [Google Scholar]

- Wang, J.; Yuan, J.; Xiao, F.; Li, Z.; Wang, J.; Xu, Z. Performance investigation and sustainability evaluation of multiple-polymer asphalt mixtures in airfield pavement. J. Clean. Prod. 2018, 189, 67–77. [Google Scholar] [CrossRef]

- Zhou, F.; Im, S.; Sun, L.; Scullion, T. Development of an IDEAL cracking test for asphalt mix design and QC/QA. Road Mater. Pavement Des. 2017, 18, 405–427. [Google Scholar] [CrossRef]

- Sirin, O.; Paul, D.K.; Kassem, E.; Ohiduzzaman, M. Evaluation of Short-Term Aging Protocol for Asphalt Mixtures. Appl. Sci. 2019, 9, 2783. [Google Scholar] [CrossRef]

- Crucho, J.M.L.; das Neves, J.M.C.; Capitão, S.D.; de Picado-Santos, L.G. Evaluation of the durability of asphalt concrete modified with nanomaterials using the TEAGE aging method. Constr. Build. Mater. 2019, 214, 178–186. [Google Scholar] [CrossRef]

- Singh, D.; Zaman, M.; Commuri, S. Effect of long term oven aging on dynamic modulus of hot mix asphalt. Geo-Front. 2011 Adv. Geotech. Eng. 2011, 4773–4781. [Google Scholar]

- Yan, C.; Zhang, Y.; Bahia, H.U. Comparison between SCB-IFIT, un-notched SCB-IFIT and IDEAL-CT for measuring cracking resistance of asphalt mixtures. Constr. Build. Mater. 2020, 252, 119060. [Google Scholar] [CrossRef]

- Mohammad, L.N.; Kim, M.; Elseifi, M. Characterization of Asphalt Mixture’s Fracture Resistance Using the Semi-Circular Bending (SCB) Test. In Proceedings of the 7th RILEM International Conference on Cracking in Pavements, Delft, The Netherlands, 20–22 June 2012; pp. 1–10. [Google Scholar]

- Zhao, Y.; Ni, F.; Zhou, L.; Jiang, J. Heterogeneous fracture simulation of asphalt mixture under SCB test with cohesive crack model. Road Mater. Pavement Des. 2017, 18, 1411–1422. [Google Scholar] [CrossRef]

- Hofko, B.; Porot, L.; Cannone, A.F.; Poulikakos, L.; Huber, L.; Lu, X.; Mollenhauer, K.; Grothe, H. FTIR spectral analysis of bituminous binders: Reproducibility and impact of ageing temperature. Mater. Struct. 2018, 51, 45. [Google Scholar] [CrossRef]

- Cong, P.; Hao, H.; Luo, W. Investigation of carbonyl of asphalt binders containing antiaging agents and waste cooking oil using FTIR spectroscopy. J. Test. Eval. 2019, 47, 1147–1162. [Google Scholar] [CrossRef]

- Wu, X.; Kang, A.H.; Wu, Z.G. Application of a new instrument testing the adhesion between fibers and asphalt mortar. Exp. Technol. Manag. 2021, 38, 58–63. (In Chinese) [Google Scholar]

- Kou, C.; Wu, X.; Xiao, P.; Liu, Y.; Wu, Z. Physical, Rheological, and Morphological Properties of Asphalt Reinforced by Basalt Fiber and Lignin Fiber. Materials 2020, 13, 2520. [Google Scholar] [CrossRef]

- Xue, Y.; Hou, H.; Zhu, S.; Zha, J. Utilization of municipal solid waste incineration ash in stone mastic asphalt mixture: Pavement performance and environmental impact. Constr. Build. Mater. 2009, 23, 989–996. [Google Scholar] [CrossRef]

- Technical Specification for Construction of Highway Asphalt Pavements. JTG F40-2004. Occupation Standard of China.

- Liu, Z.; Zhao, J. Research on material composition and construction technology of SMA. Road Constr. Mach. 2015, 32, 43–46. [Google Scholar]

- Zhou, C.; Fan, W.; Jing, G. Comparative study on improving the low temperature performance measures of asphalt pave-ment. J. Wuhan Univ. Technol. 2013, 37, 630–633. [Google Scholar]

- Zhang, J.; Tan, H.; Pei, J.; Qu, T.; Liu, W. Evaluating Crack Resistance of Asphalt Mixture Based on Essential Fracture Energy and Fracture Toughness. Int. J. Géoméch. 2019, 19, 06019005. [Google Scholar] [CrossRef]

- Nishikawa, M.; Mima, H.; Kanzawa, T. Infrared Spectra of Thiourea and its Inclusion Compounds. I. Vibrational Spectrum of Rhombohedral Thiourea. Chem. Pharm. Bull. 1962, 10, 1199–1204. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Zhao, Y.; Gu, F.; Xu, J.; Jin, J. Analysis of aging mechanism of SBS polymer modified asphalt based on Fourier transform in-frared spectrum. J. Wuhan. Univ. Technol.-Mater. Sci. Ed. 2010, 25, 1047–1052. [Google Scholar] [CrossRef]

- Alam, M.; Alandis, N.M. Corn oil based poly(ether amide urethane) coating material—Synthesis, characterization and coating properties. Ind. Crop. Prod. 2014, 57, 17–28. [Google Scholar] [CrossRef]

- Li, S.-Y.; Zou, D.-H.; Luo, Y.-W.; Sun, Q.-R.; Deng, K.-F.; Chen, Y.-J.; Huang, P. Characteristics of electrically injured skin from human hand tissue samples using Fourier transform infrared microspectroscopy. Sci. Justice 2014, 54, 98–104. [Google Scholar] [CrossRef] [PubMed]

- Rieppo, L.; Saarakkala, S.; Närhi, T.; Helminen, H.J.; Jurvelin, J.S.; Rieppo, J. Application of second derivative spectroscopy for increasing molecular specificity of fourier transform infrared spectroscopic imaging of articular cartilage. Osteoarthr. Cartil. 2012, 20, 451–459. [Google Scholar] [CrossRef] [PubMed]

- Sato, N.; Zhang, Q.; Ma, C.-M.; Hattori, M. Anti-human Immunodeficiency Virus-1 Protease Activity of New Lanostane-Type Triterpenoids from Ganoderma sinense. Chem. Pharm. Bull. 2009, 57, 1076–1080. [Google Scholar] [CrossRef]

- Ongel, A.; Hugener, M. Impact of rejuvenators on aging properties of bitumen. Constr. Build. Mater. 2015, 94, 467–474. [Google Scholar] [CrossRef]

| Index | Value |

|---|---|

| Penetration (25 °C, 100 g, 5 s), 0.1 mm | 71 |

| Softening point, °C | 64 |

| Ductility (5 °C, 5 cm/min), cm | 48 |

| PI index | 0.5 |

| Solubility, % | 99.9 |

| Elastic recovery (25 °C), % | 76 |

| Rotational viscosity (135 °C), Pa·s | 2.302 |

| Relative density (25 °C) | 1.031 |

| Index | Lignin Fiber |

|---|---|

| Specific surface area, m2/g | 1.93 |

| Aspect ratio | 100 |

| Hygroscopic rate, % | 28.70 |

| Heat resistance, °C | 260 |

| Ph value | 7.6 |

| Fracture strength, MPa | <300 |

| Index | Anti-Rut Agent |

|---|---|

| Density, g/cm3 | 0.96 |

| Diameter, mm | 2–3 |

| Melting point, °C | 135–150 |

| Polymer content, % | ≥95 |

| Index | Optimum Asphalt Content (OAC)/% | Air Voids (VV)/% | Voids in Mineral Aggregate (VMA)/% | Voids Filled with Asphalt (VFA)/% | Stability/kN | Flow Value/mm |

|---|---|---|---|---|---|---|

| LFSMA-13 | 6.0 | 3.8 | 17.2 | 78.0 | 11.93 | 2.8 |

| ALSMA-13 | 6.0 | 3.9 | 17.3 | 77.5 | 14.38 | 2.6 |

| Specification requirements | / | 3~4.5 | ≥16.5 | 70~85 | ≥6 | 2.0~4.0 |

| Aging Degree | Mixture | 3290 cm−1 | 2926 cm−1 | 2853 cm−1 | 1700 cm−1 | 1456 cm−1 | 1376 cm−1 | 1030 cm−1 | 966 cm−1 | 698 cm−1 |

|---|---|---|---|---|---|---|---|---|---|---|

| Peak area (unaged) | ALSMA-13 | 814.043 | 1301.605 | 399.881 | 9.118 | 739.81 | 140.834 | 204.736 | 15.495 | 21.255 |

| LFSMA-13 | / | 1370.071 | 415.502 | 6.236 | 754.708 | 145.334 | 129.157 | 34.395 | 24.767 | |

| Peak area (short term) | ALSMA-13 | 558.818 | 1344.04 | 422.75 | 21.106 | 865.316 | 131.556 | 236.645 | 13.543 | 20.138 |

| LFSMA-13 | / | 1384.12 | 422.454 | 7.997 | 837.843 | 134.164 | 167.747 | 28.416 | 23.093 | |

| Peak area (long term) | ALSMA-13 | 511.145 | 1337.038 | 414.275 | 46.824 | 848.767 | 111.202 | 254.31 | 11.997 | 20.114 |

| LFSMA-13 | / | 1361.256 | 413.794 | 26.378 | 859.53 | 119.484 | 184.64 | 27.330 | 22.754 |

| Aging Degree | Unaged | Short Term | Long Term |

|---|---|---|---|

| CTIndex (X0) | 215 | 168 | 142 |

| Peak area at 2926 cm−1 (X1) | 1370.071 | 1384.120 | 1361.256 |

| Peak area at 2853 cm−1 (X2) | 415.502 | 422.454 | 413.794 |

| Peak area at 1700 cm−1 (X3) | 6.236 | 7.997 | 26.378 |

| Peak area at 1456 cm−1 (X4) | 754.708 | 837.843 | 859.530 |

| Peak area at 1376 cm−1 (X5) | 145.334 | 134.164 | 119.484 |

| Peak area at 1030 cm−1 (X6) | 129.157 | 167.747 | 184.640 |

| Peak area at 966 cm−1 (X7) | 34.395 | 28.416 | 27.330 |

| Peak area at 698 cm−1 (X8) | 24.767 | 23.093 | 22.754 |

| Aging Degree | Unaged | Short Term | Long Term |

|---|---|---|---|

| CTIndex (X0) | 1 | 0.781395 | 0.660465 |

| Peak area at 2926 cm−1 (X1) | 1 | 1.010254 | 0.993566 |

| Peak area at 2853 cm−1 (X2) | 1 | 1.016732 | 0.995889 |

| Peak area at 1700 cm−1 (X3) | 1 | 1.282393 | 4.229955 |

| Peak area at 1456 cm−1 (X4) | 1 | 1.110155 | 1.138891 |

| Peak area at 1376 cm−1 (X5) | 1 | 0.923143 | 0.822134 |

| Peak area at 1030 cm−1 (X6) | 1 | 1.298784 | 1.429578 |

| Peak area at 966 cm−1 (X7) | 1 | 0.826167 | 0.794592 |

| Peak area at 698 cm−1 (X8) | 1 | 0.932410 | 0.918722 |

| Aging Degree | Unaged | Short Term | Long Term |

|---|---|---|---|

| X1 − X0 | 0 | 0.228859 | 0.333101 |

| X2 − X0 | 0 | 0.235336 | 0.335424 |

| X3 − X0 | 0 | 0.500997 | 3.569490 |

| X4 − X0 | 0 | 0.328760 | 0.478426 |

| X5 − X0 | 0 | 0.141747 | 0.161669 |

| X6 − X0 | 0 | 0.517388 | 0.769113 |

| X7 − X0 | 0 | 0.044771 | 0.134127 |

| X8 − X0 | 0 | 0.151015 | 0.258257 |

| Aging Degree | Unaged | Short Term | Long Term | Average Value |

|---|---|---|---|---|

| Peak area at 2926 cm−1 | 1 | 0.886344 | 0.842717 | 0.909687 |

| Peak area at 2853 cm−1 | 1 | 0.883502 | 0.841794 | 0.908432 |

| Peak area at 1700 cm−1 | 1 | 0.780816 | 0.333333 | 0.704717 |

| Peak area at 1456 cm−1 | 1 | 0.844448 | 0.788604 | 0.877684 |

| Peak area at 1376 cm−1 | 1 | 0.926422 | 0.91694 | 0.947787 |

| Peak area at 1030 cm−1 | 1 | 0.775257 | 0.698843 | 0.824700 |

| Peak area at 966 cm−1 | 1 | 0.975528 | 0.930101 | 0.968543 |

| Peak area at 698 cm−1 | 1 | 0.921987 | 0.873589 | 0.931859 |

| Aging Degree | Unaged | Short Term | Long Term | Average Value |

|---|---|---|---|---|

| Peak area at 2926 cm−1 | 1 | 0.93551 | 0.905517 | 0.947009 |

| Peak area at 2853 cm−1 | 1 | 0.932201 | 0.904402 | 0.945534 |

| Peak area at 1700 cm−1 | 1 | 0.814109 | 0.333333 | 0.715814 |

| Peak area at 1456 cm−1 | 1 | 0.886956 | 0.840715 | 0.909224 |

| Peak area at 1376 cm−1 | 1 | 0.982403 | 0.996087 | 0.99283 |

| Peak area at 1030 cm−1 | 1 | 0.807795 | 0.735441 | 0.847746 |

| Peak area at 966 cm−1 | 1 | 0.962566 | 0.987944 | 0.983503 |

| Peak area at 698 cm−1 | 1 | 0.977192 | 0.942948 | 0.97338 |

| Aging Degree | Unaged | Short Term | Long Term | Average Value |

|---|---|---|---|---|

| Peak area at 3290 cm−1 | 1 | 0.950345 | 0.97141 | 0.973918 |

| Peak area at 2926 cm−1 | 1 | 0.906132 | 0.869296 | 0.925143 |

| Peak area at 2853 cm−1 | 1 | 0.897133 | 0.866321 | 0.921151 |

| Peak area at 1700 cm−1 | 1 | 0.594929 | 0.333333 | 0.642754 |

| Peak area at 1456 cm−1 | 1 | 0.858152 | 0.830282 | 0.896145 |

| Peak area at 1376 cm−1 | 1 | 0.944063 | 0.958436 | 0.967499 |

| Peak area at 1030 cm−1 | 1 | 0.862749 | 0.801848 | 0.888199 |

| Peak area at 966 cm−1 | 1 | 0.968811 | 0.964825 | 0.977879 |

| Peak area at 698 cm−1 | 1 | 0.938745 | 0.897723 | 0.945489 |

| Aging Degree | Unaged | Short Term | Long Term | Average Value |

|---|---|---|---|---|

| Peak area at 3290 cm−1 | 1 | 0.908617 | 0.914101 | 0.940906 |

| Peak area at 2926 cm−1 | 1 | 0.943197 | 0.916142 | 0.953113 |

| Peak area at 2853 cm−1 | 1 | 0.933143 | 0.912734 | 0.948626 |

| Peak area at 1700 cm−1 | 1 | 0.603914 | 0.333333 | 0.645749 |

| Peak area at 1456 cm−1 | 1 | 0.889767 | 0.871607 | 0.920458 |

| Peak area at 1376 cm−1 | 1 | 0.985733 | 0.981491 | 0.989075 |

| Peak area at 1030 cm−1 | 1 | 0.894869 | 0.839367 | 0.911412 |

| Peak area at 966 cm−1 | 1 | 0.986733 | 0.974671 | 0.987135 |

| Peak area at 698 cm−1 | 1 | 0.979754 | 0.948812 | 0.976189 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Kang, A.; Wu, B.; Lou, K.; Fan, Z. Prediction of Crack Resistance of LFSMA-13 with and without Anti-Rut Agent Using Parameters of FTIR Spectrum under Different Aging Degrees. Materials 2021, 14, 3209. https://doi.org/10.3390/ma14123209

Wu X, Kang A, Wu B, Lou K, Fan Z. Prediction of Crack Resistance of LFSMA-13 with and without Anti-Rut Agent Using Parameters of FTIR Spectrum under Different Aging Degrees. Materials. 2021; 14(12):3209. https://doi.org/10.3390/ma14123209

Chicago/Turabian StyleWu, Xing, Aihong Kang, Bangwei Wu, Keke Lou, and Zhao Fan. 2021. "Prediction of Crack Resistance of LFSMA-13 with and without Anti-Rut Agent Using Parameters of FTIR Spectrum under Different Aging Degrees" Materials 14, no. 12: 3209. https://doi.org/10.3390/ma14123209

APA StyleWu, X., Kang, A., Wu, B., Lou, K., & Fan, Z. (2021). Prediction of Crack Resistance of LFSMA-13 with and without Anti-Rut Agent Using Parameters of FTIR Spectrum under Different Aging Degrees. Materials, 14(12), 3209. https://doi.org/10.3390/ma14123209