Process–Structure–Property Relationships of Copper Parts Manufactured by Laser Powder Bed Fusion

Abstract

1. Introduction

2. Experimental Procedure

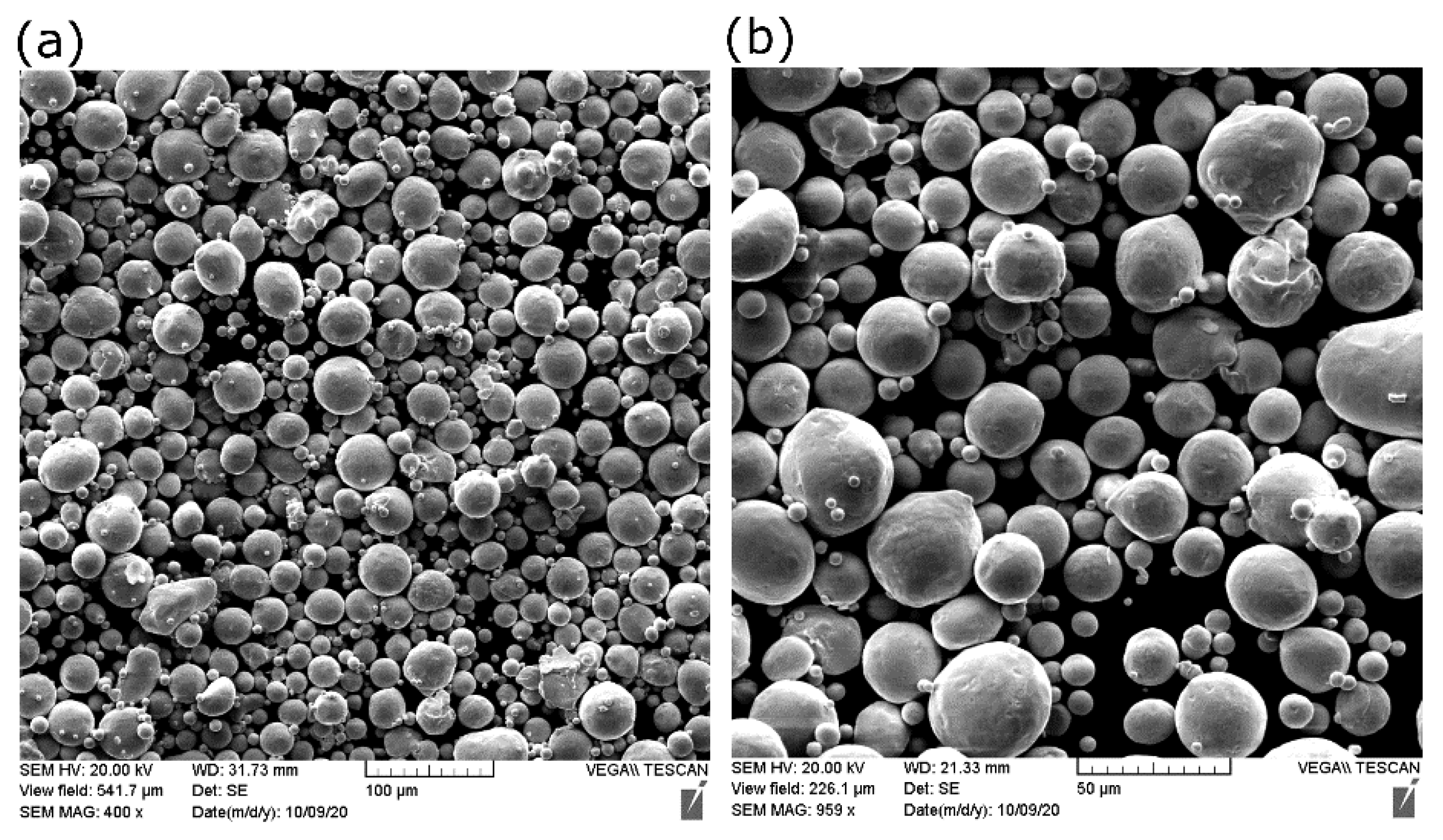

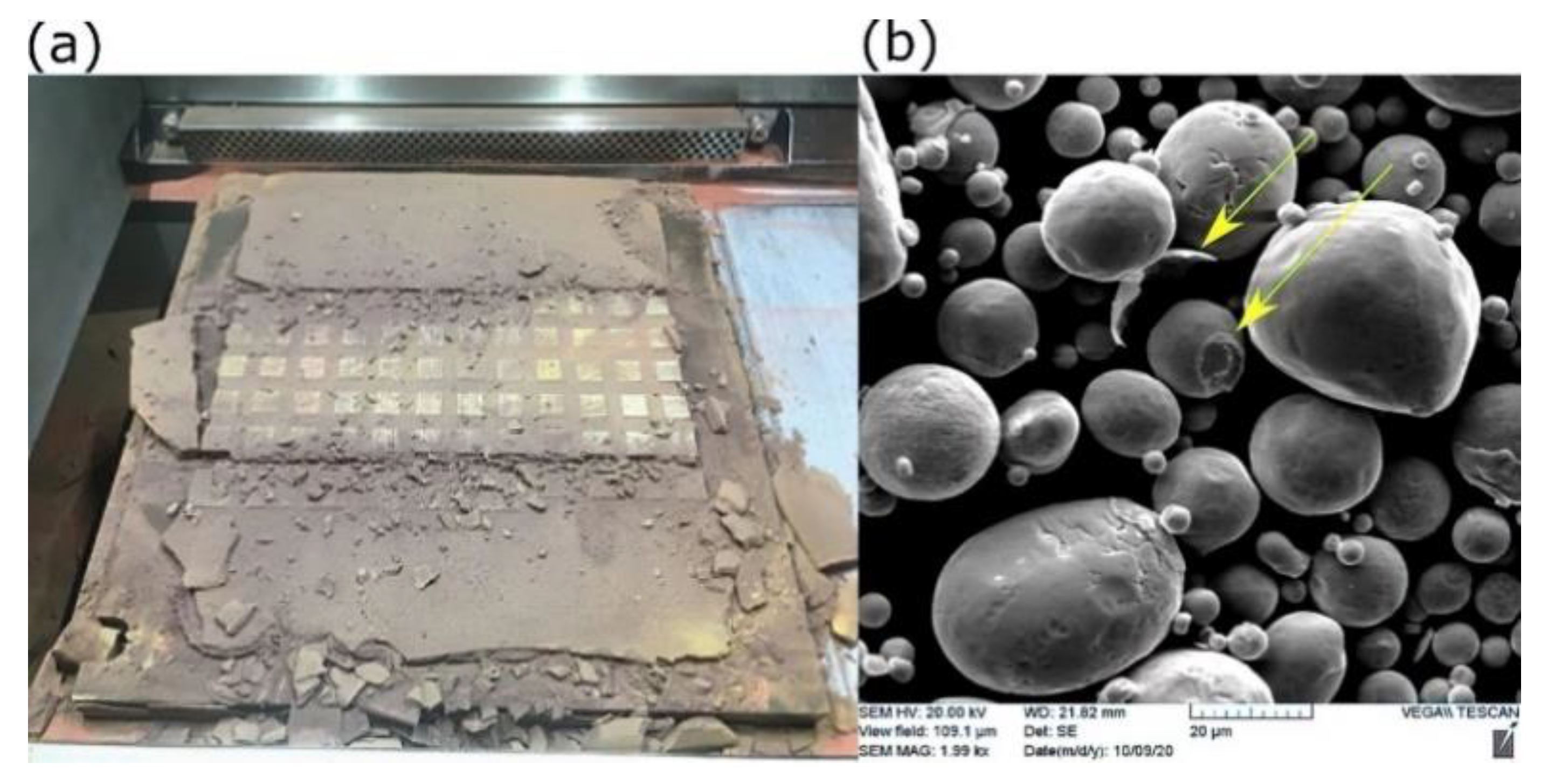

2.1. Feedstock Material

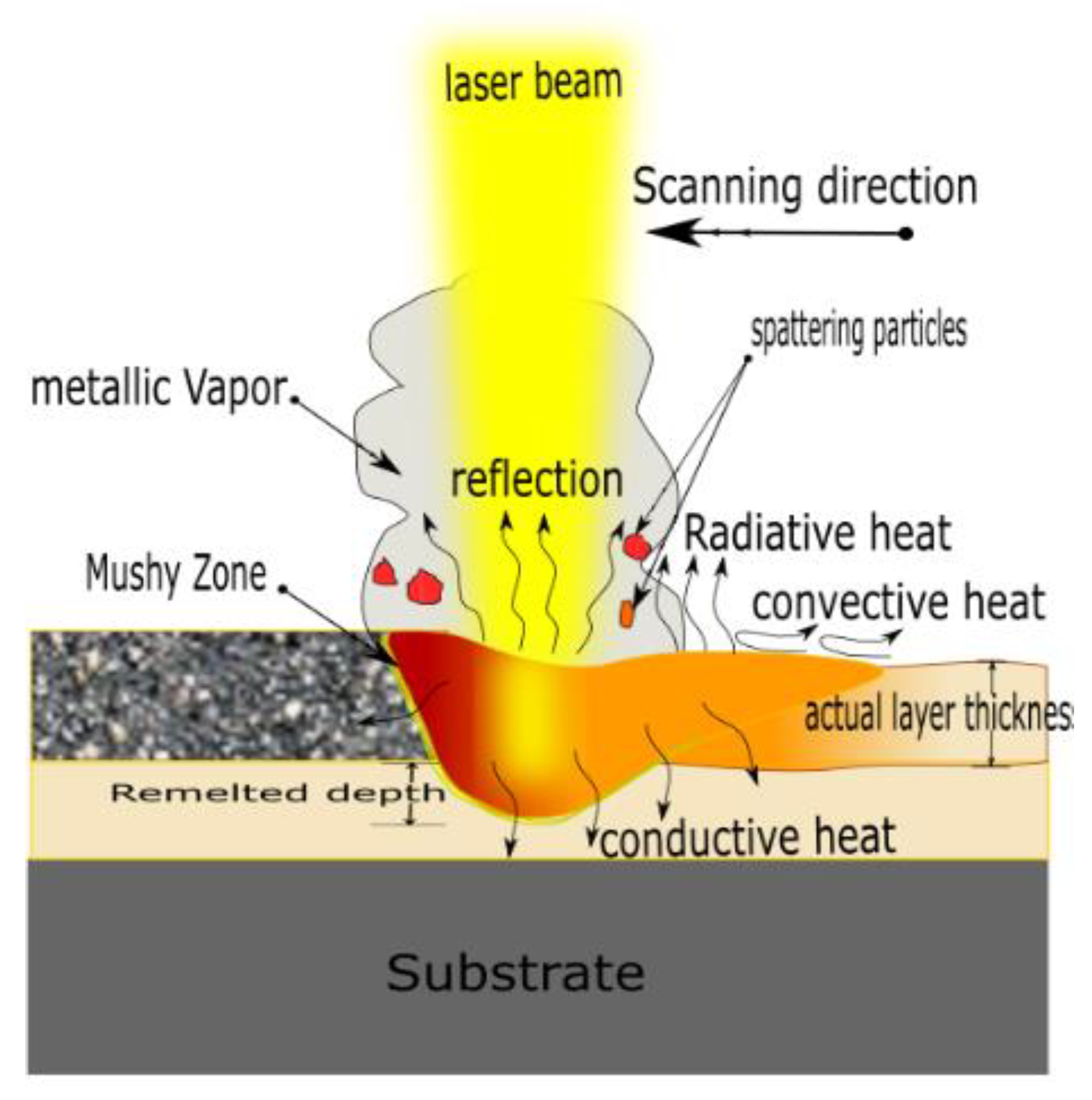

2.2. L-PBF Process

2.3. Sample Characterization

3. Results and Discussion

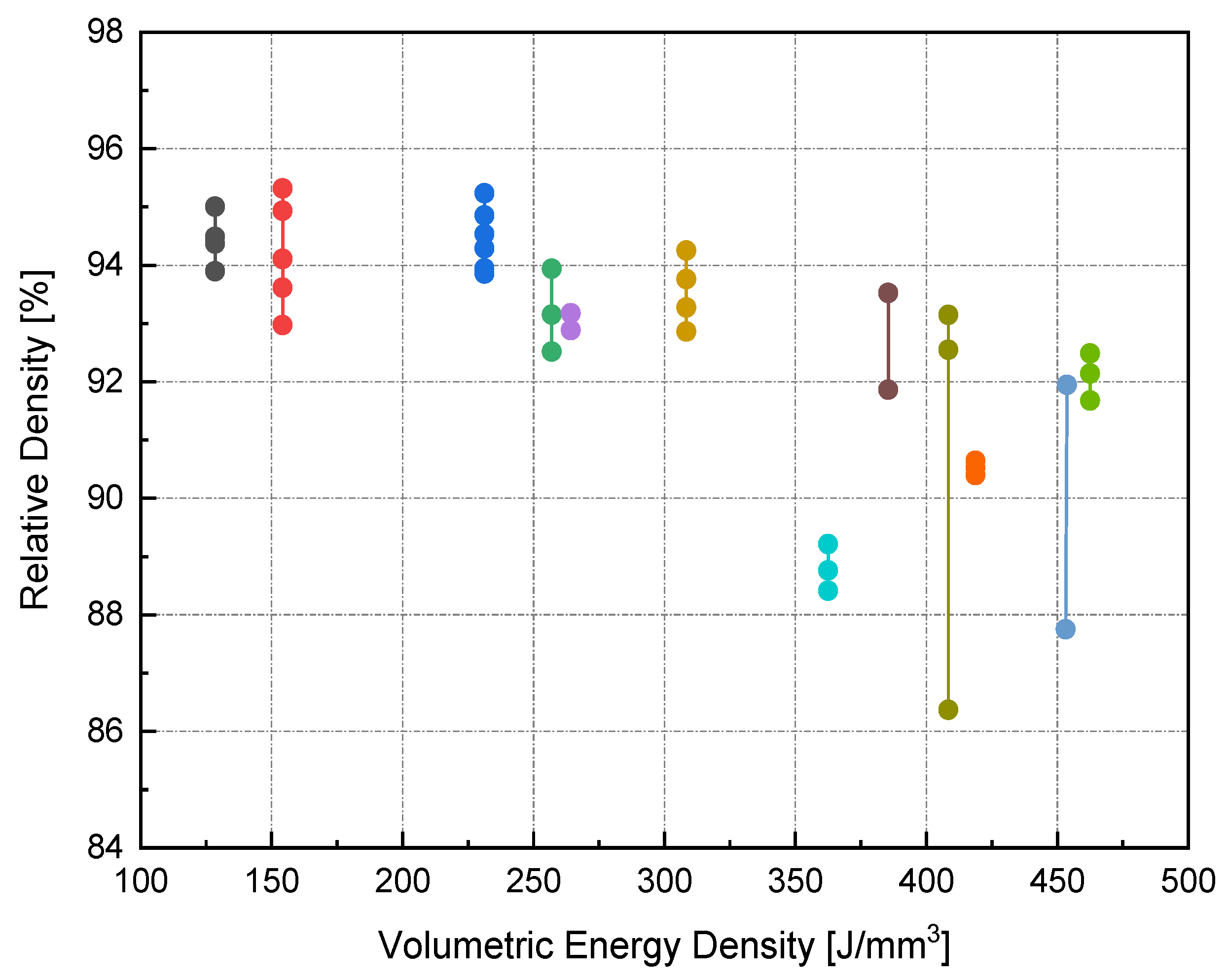

3.1. Required Volumetric Energy Density

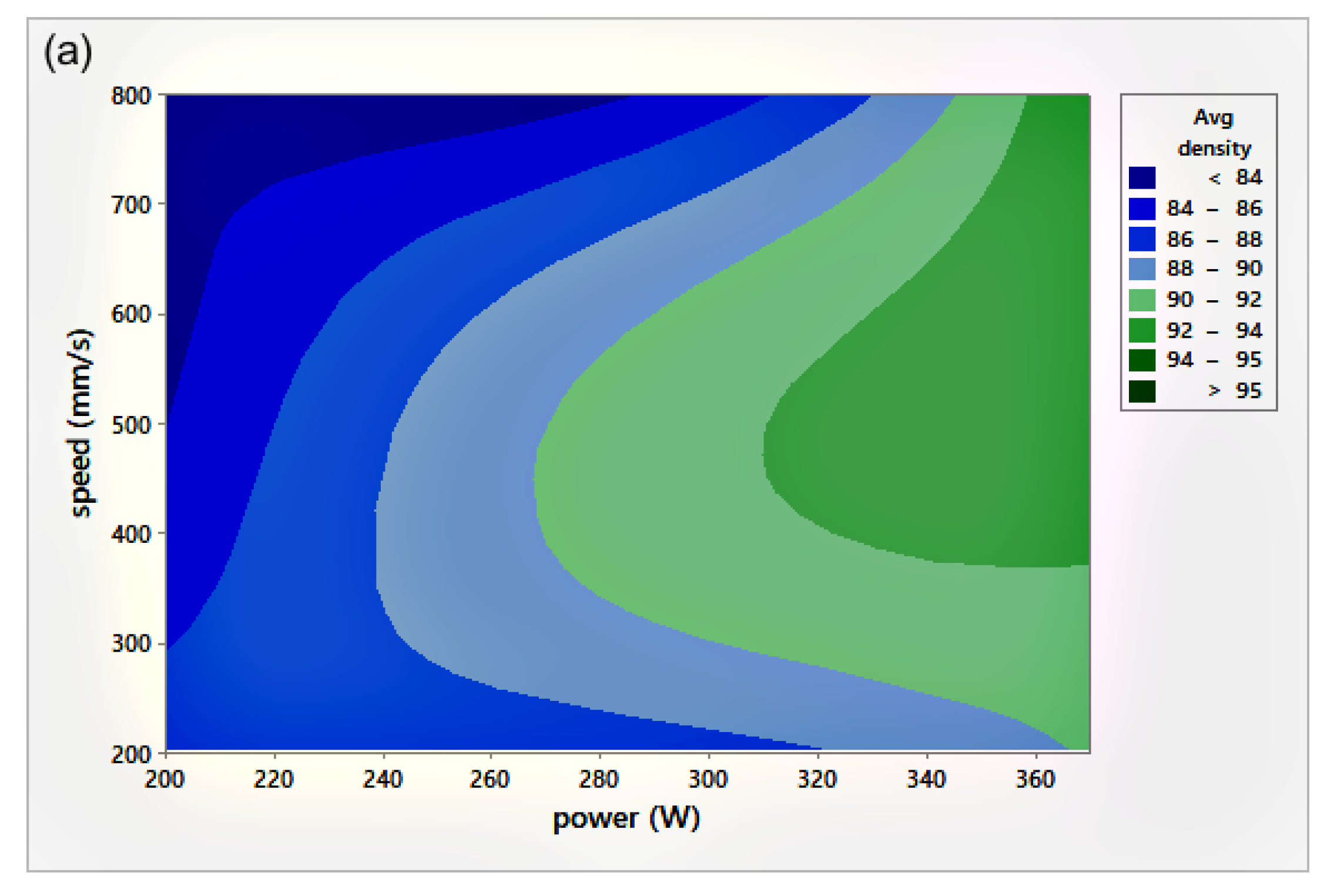

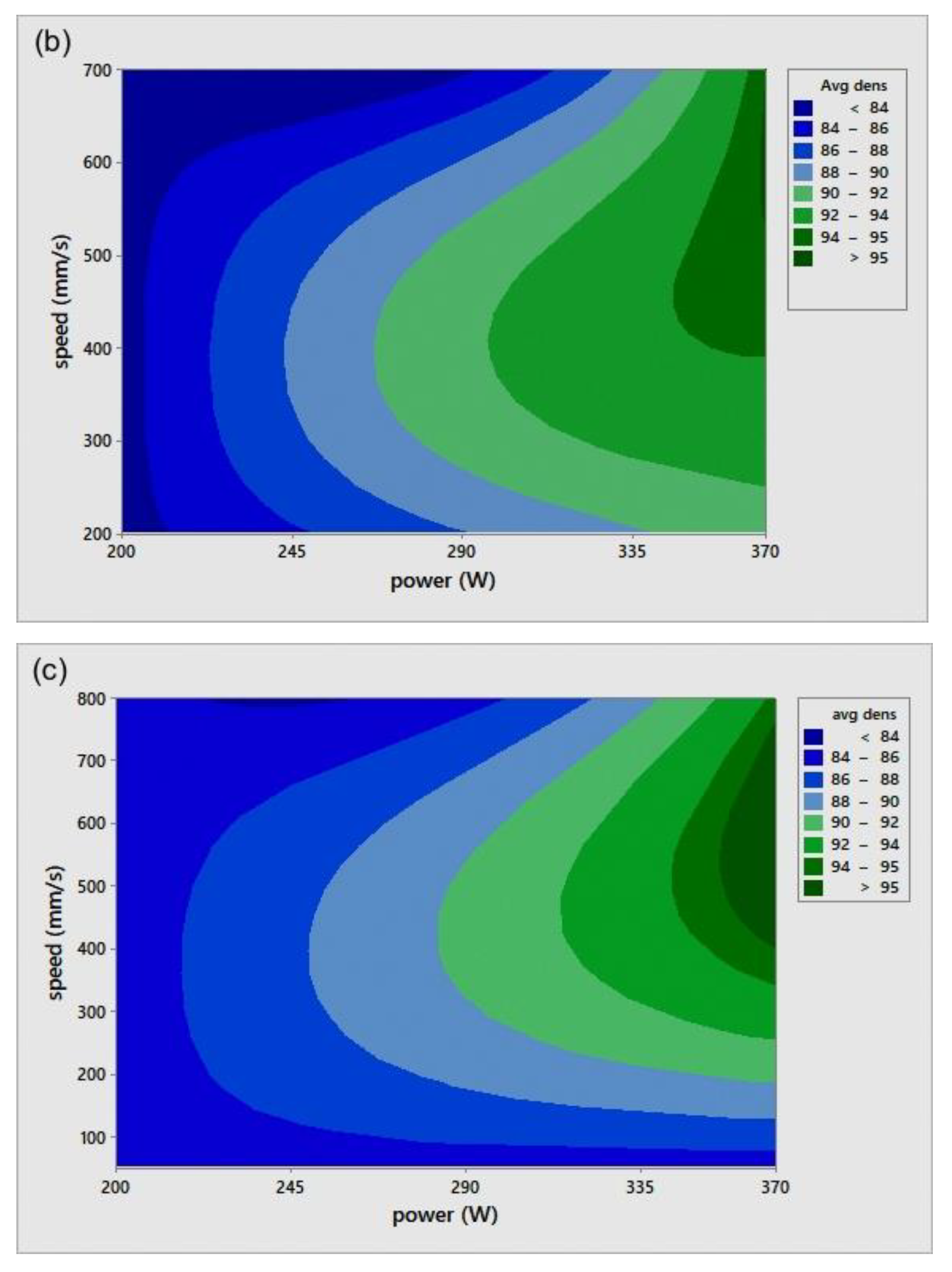

3.2. Density Measurement

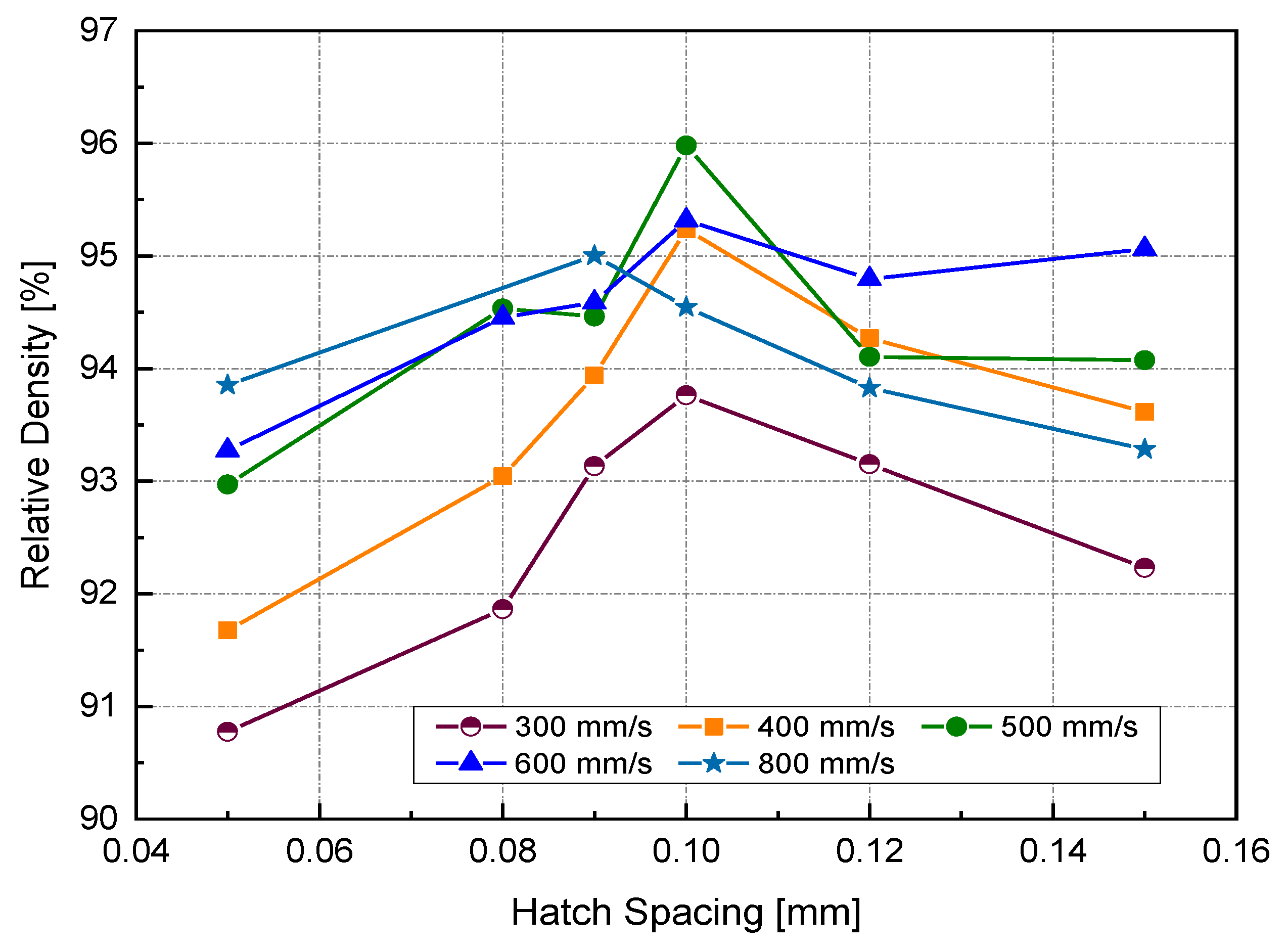

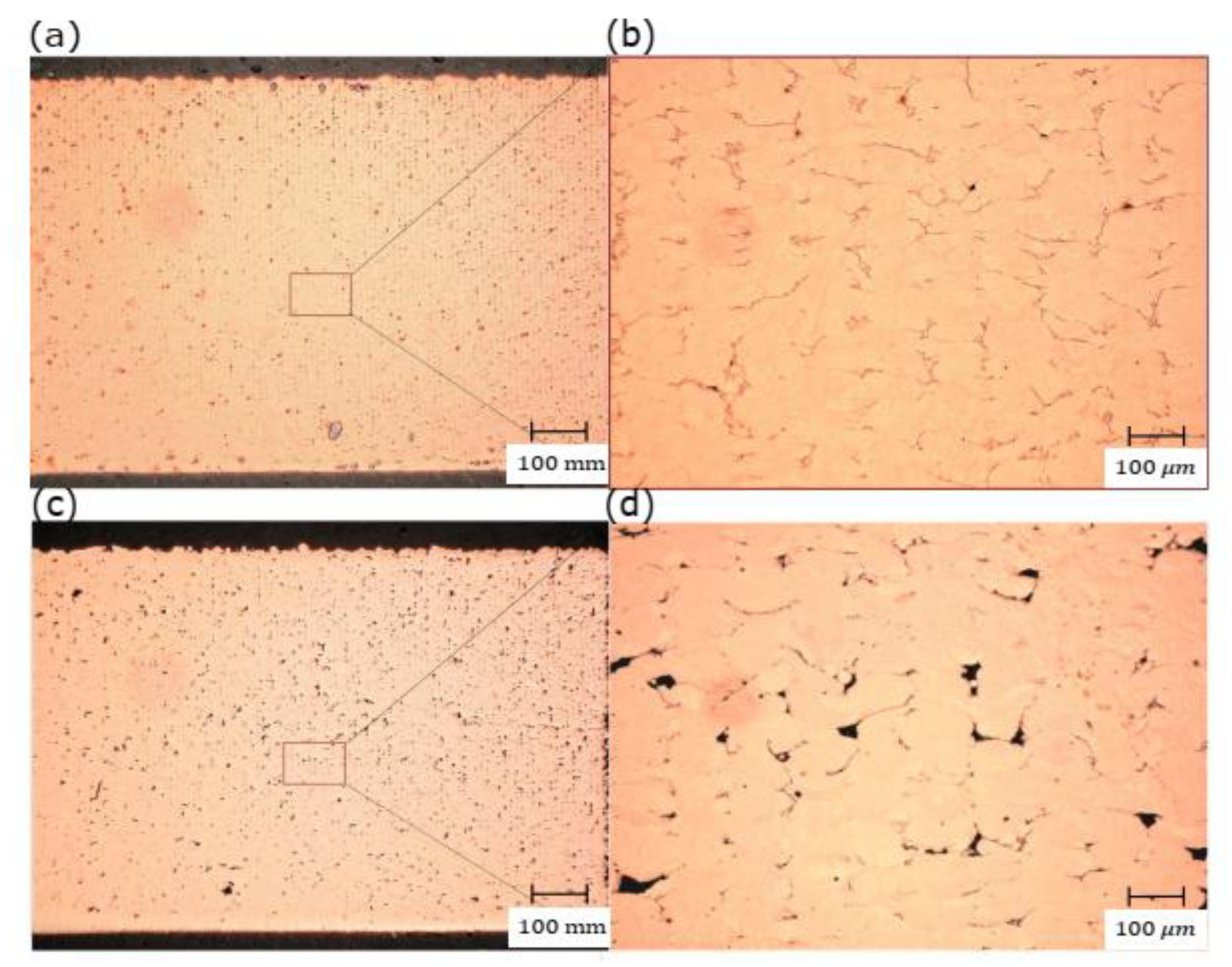

3.3. Effect of Hatch Spacing

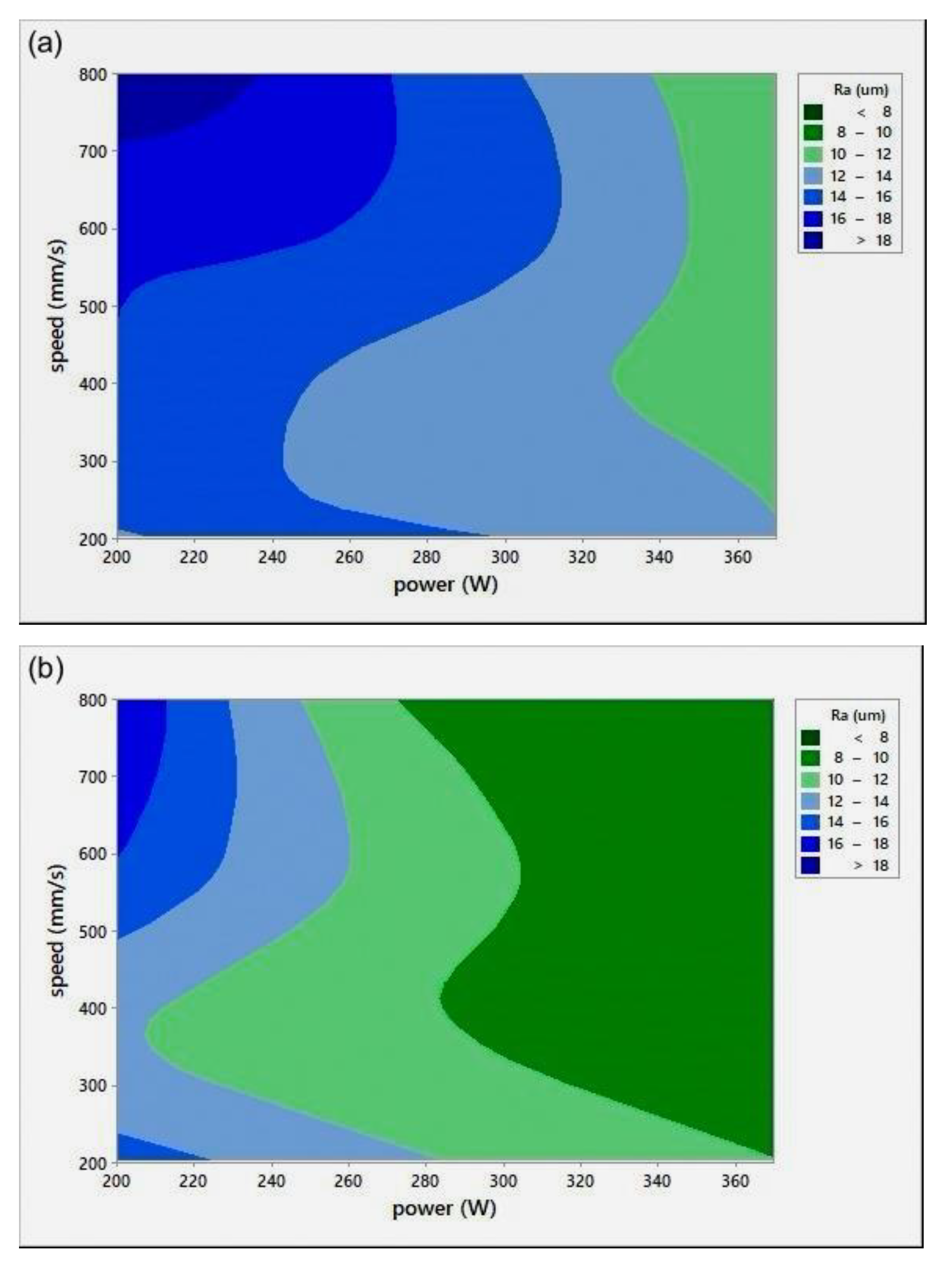

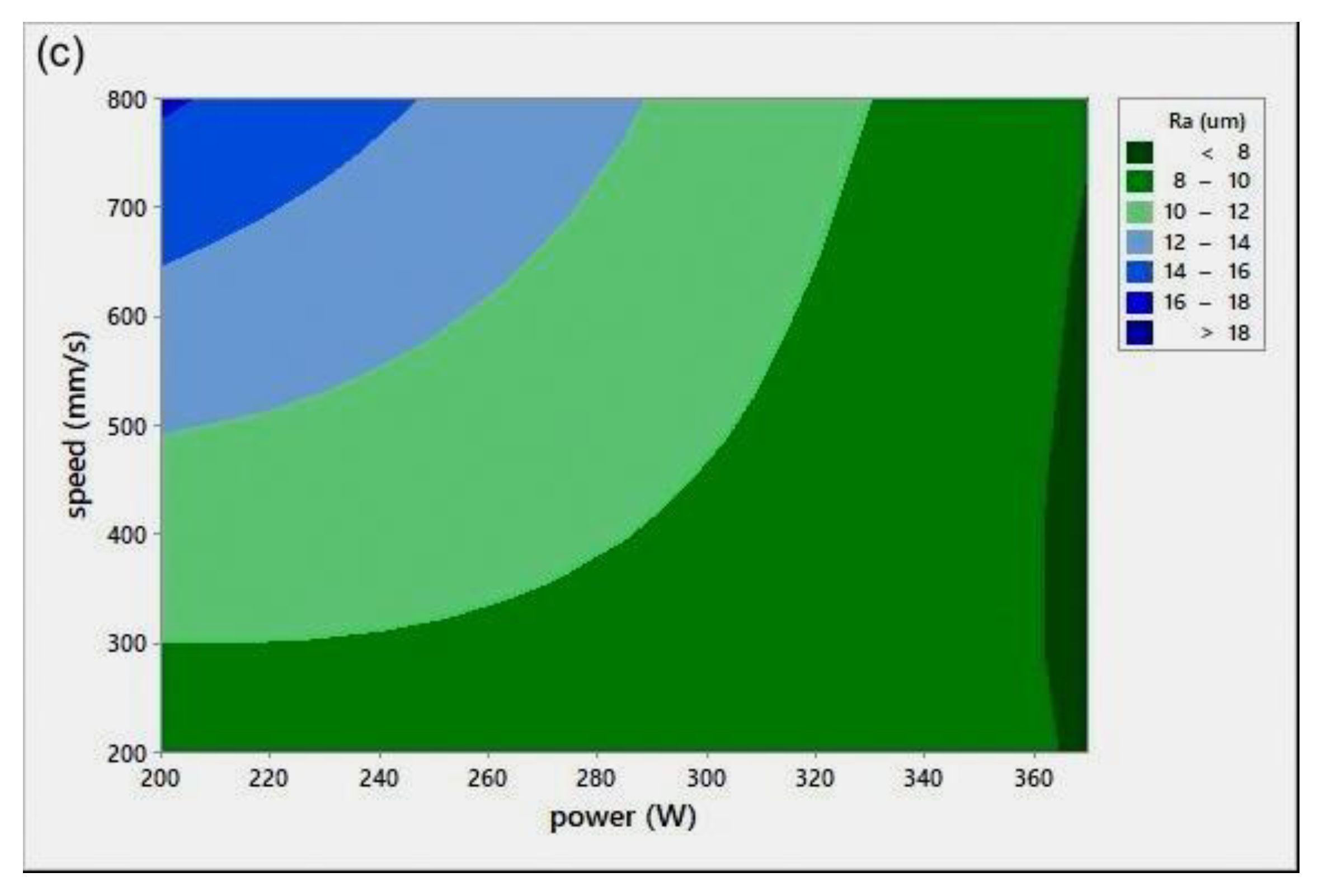

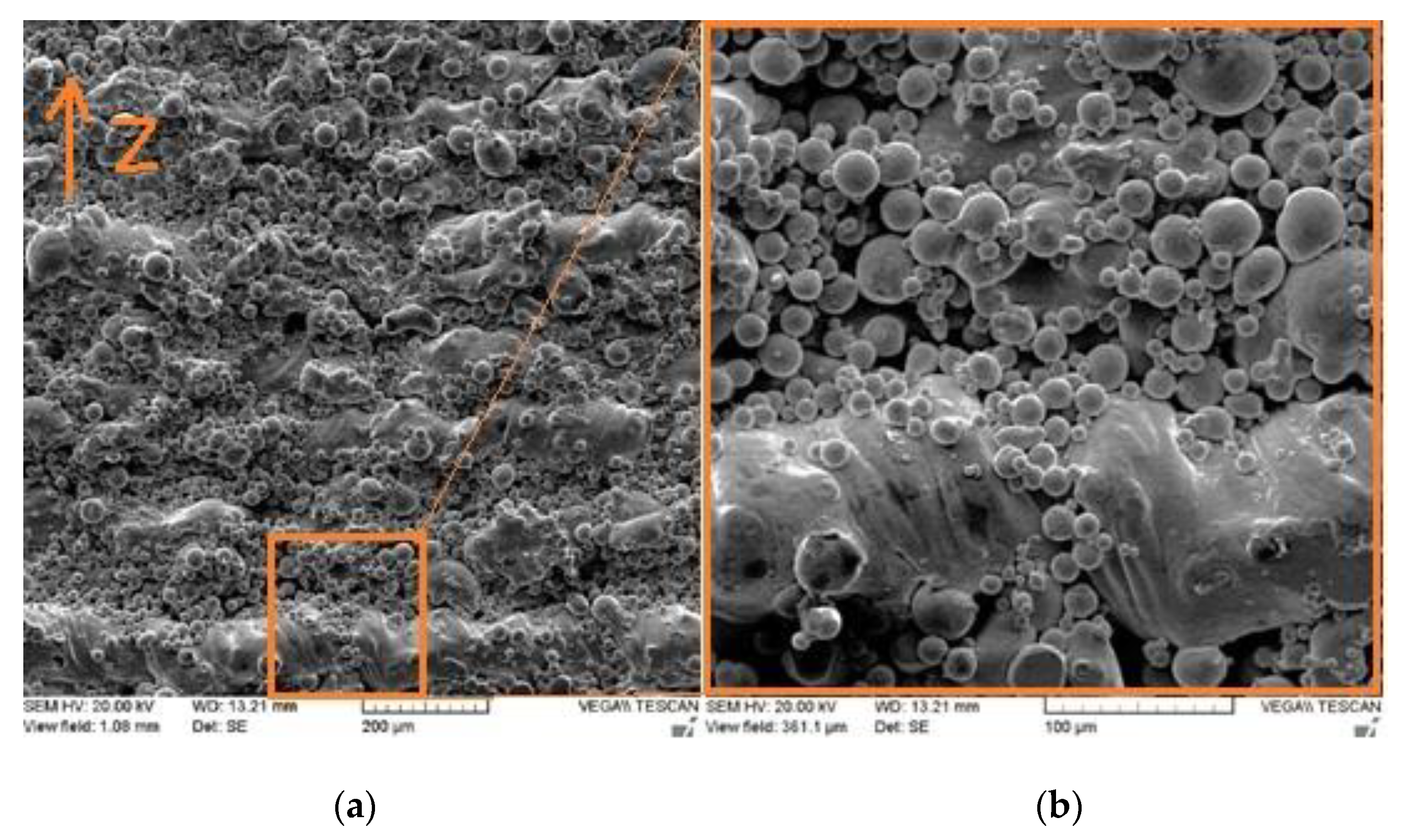

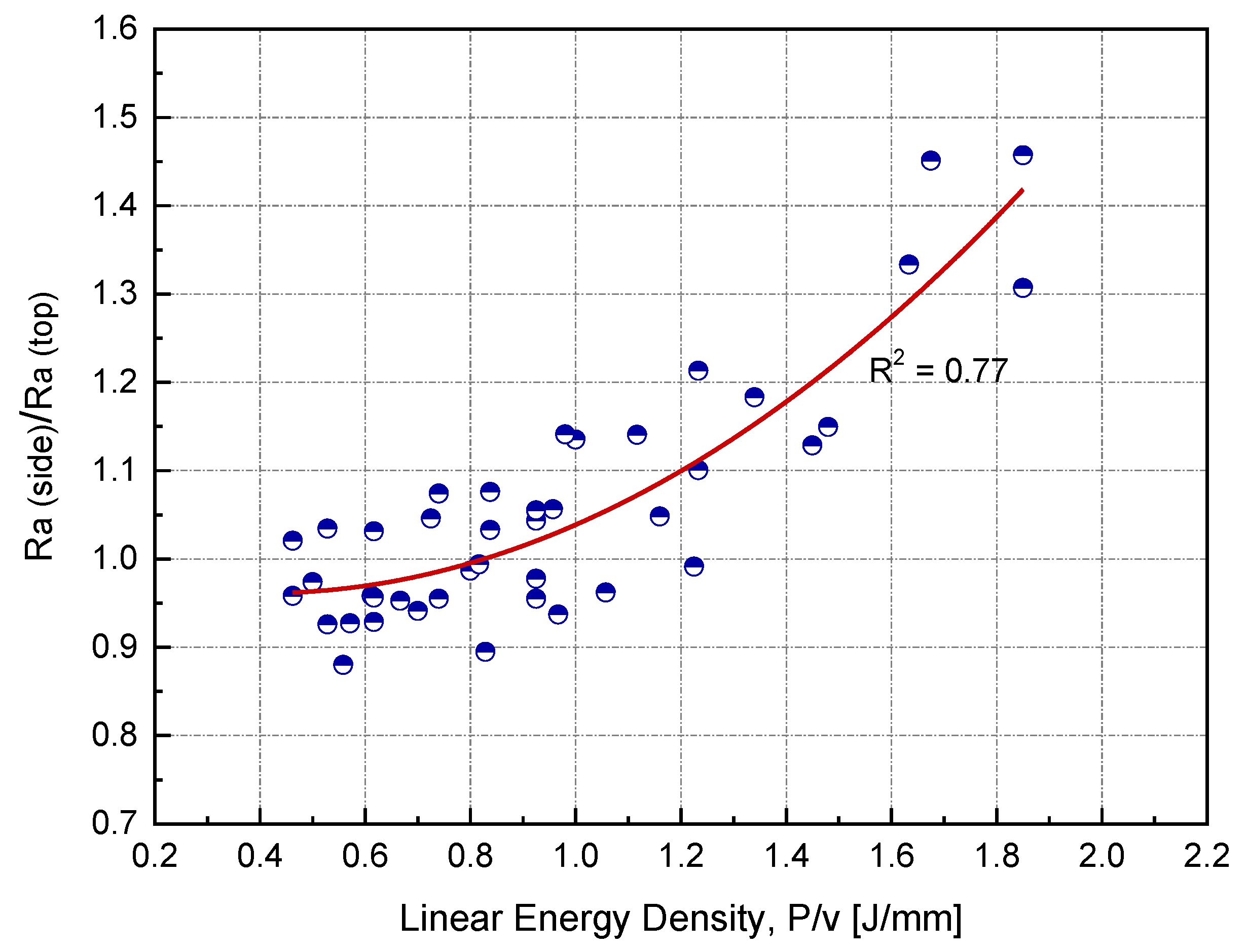

3.4. Surface Roughness and Dimensional Accuracy

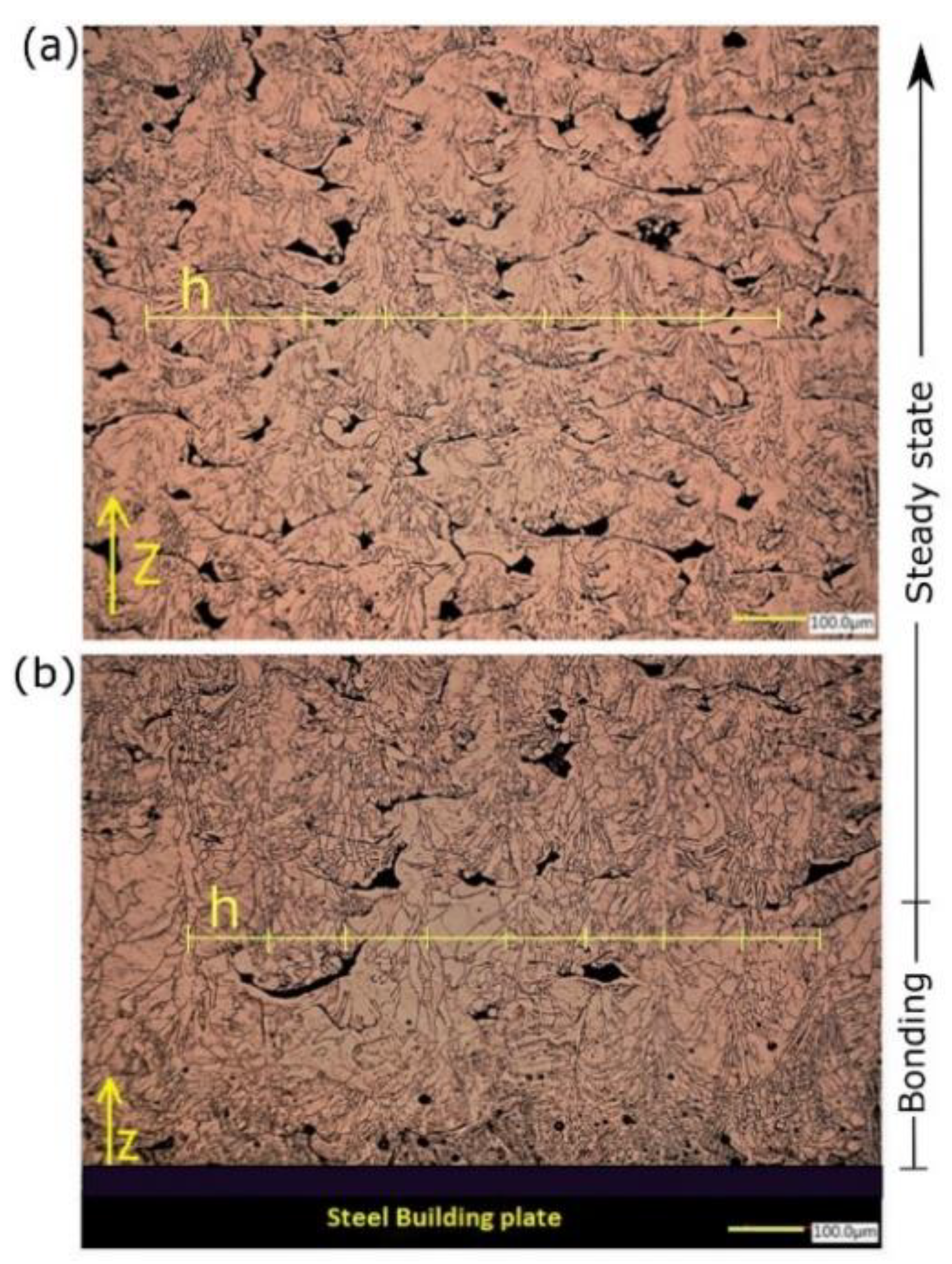

3.5. Microstructure

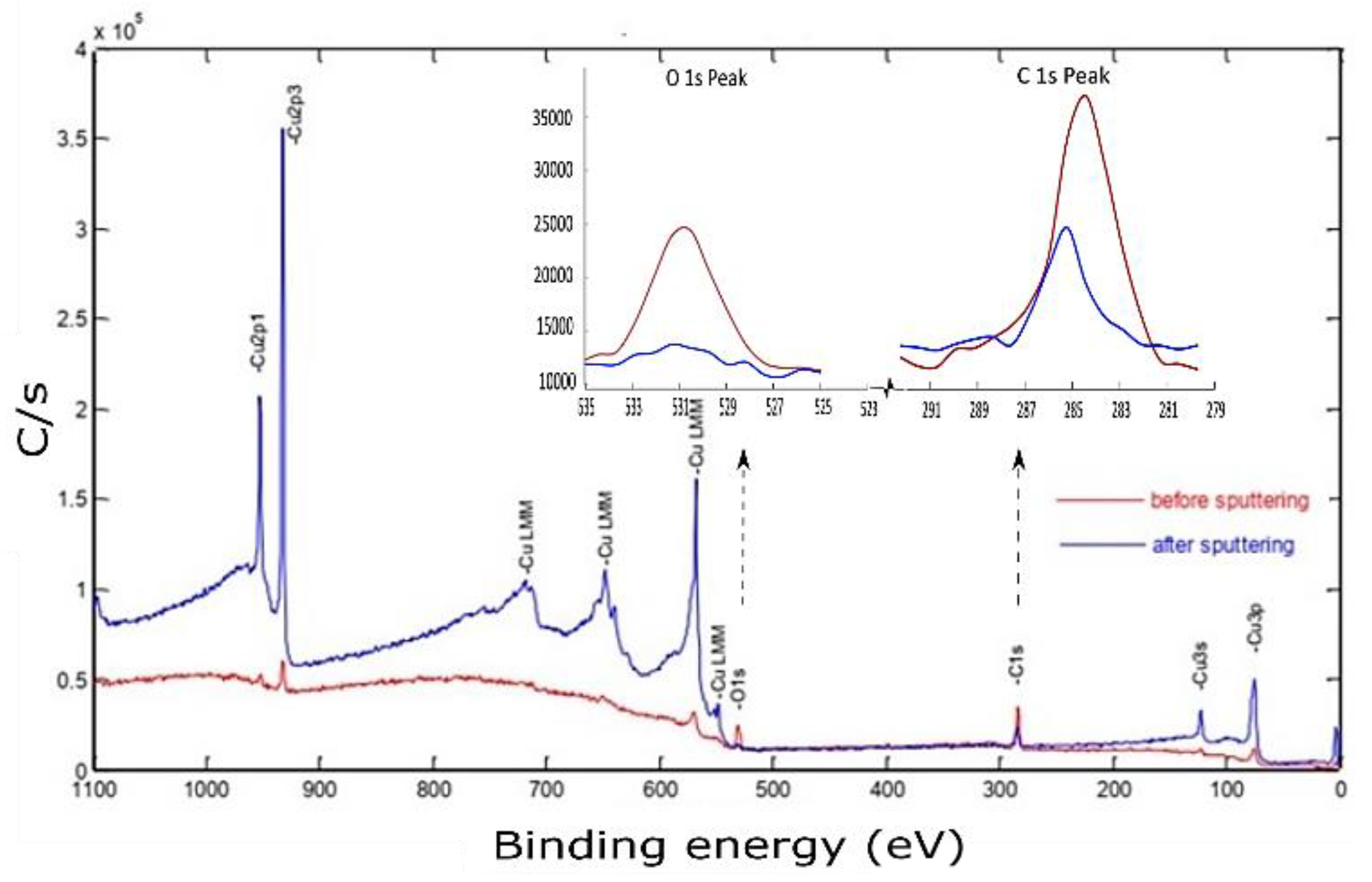

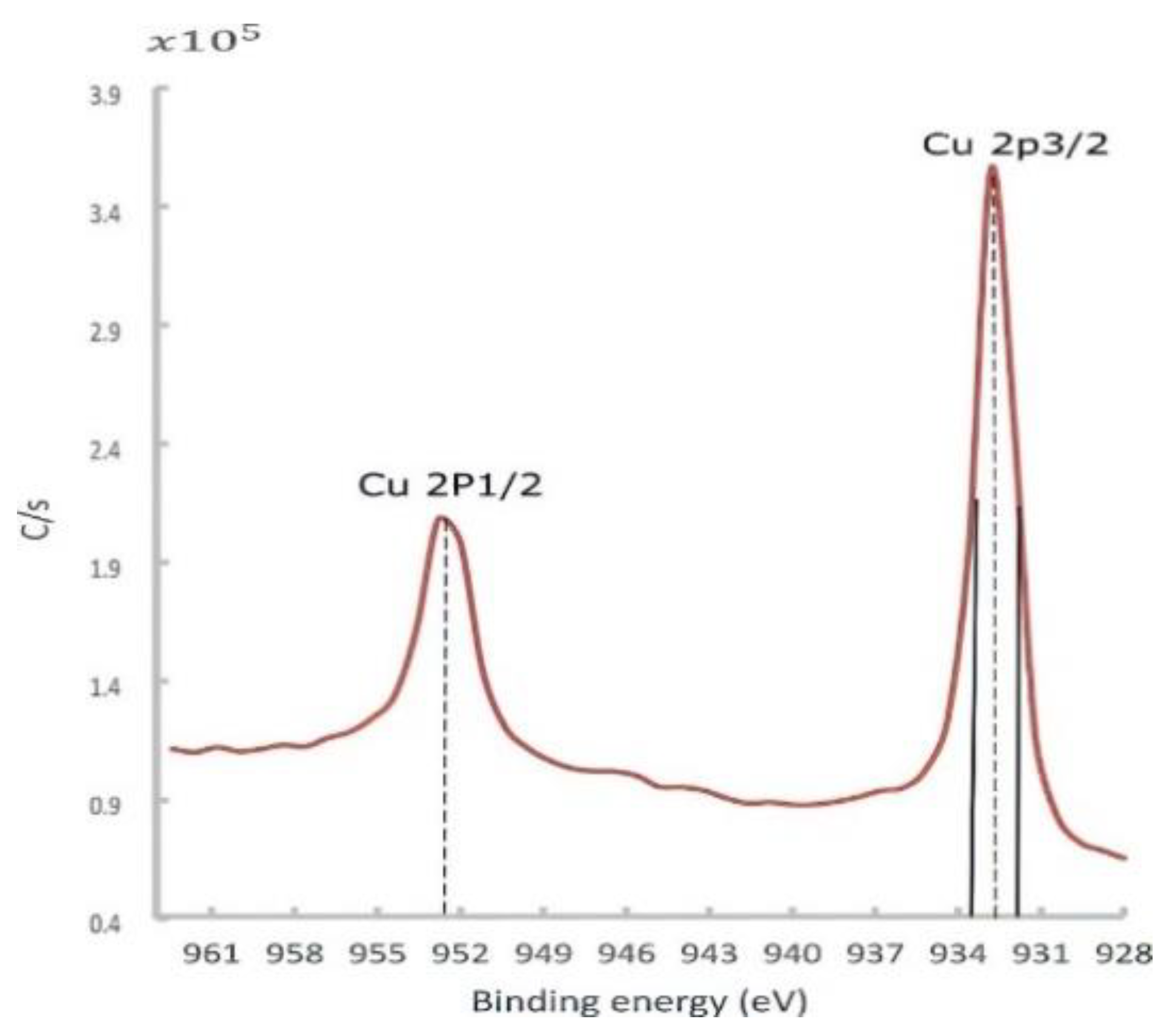

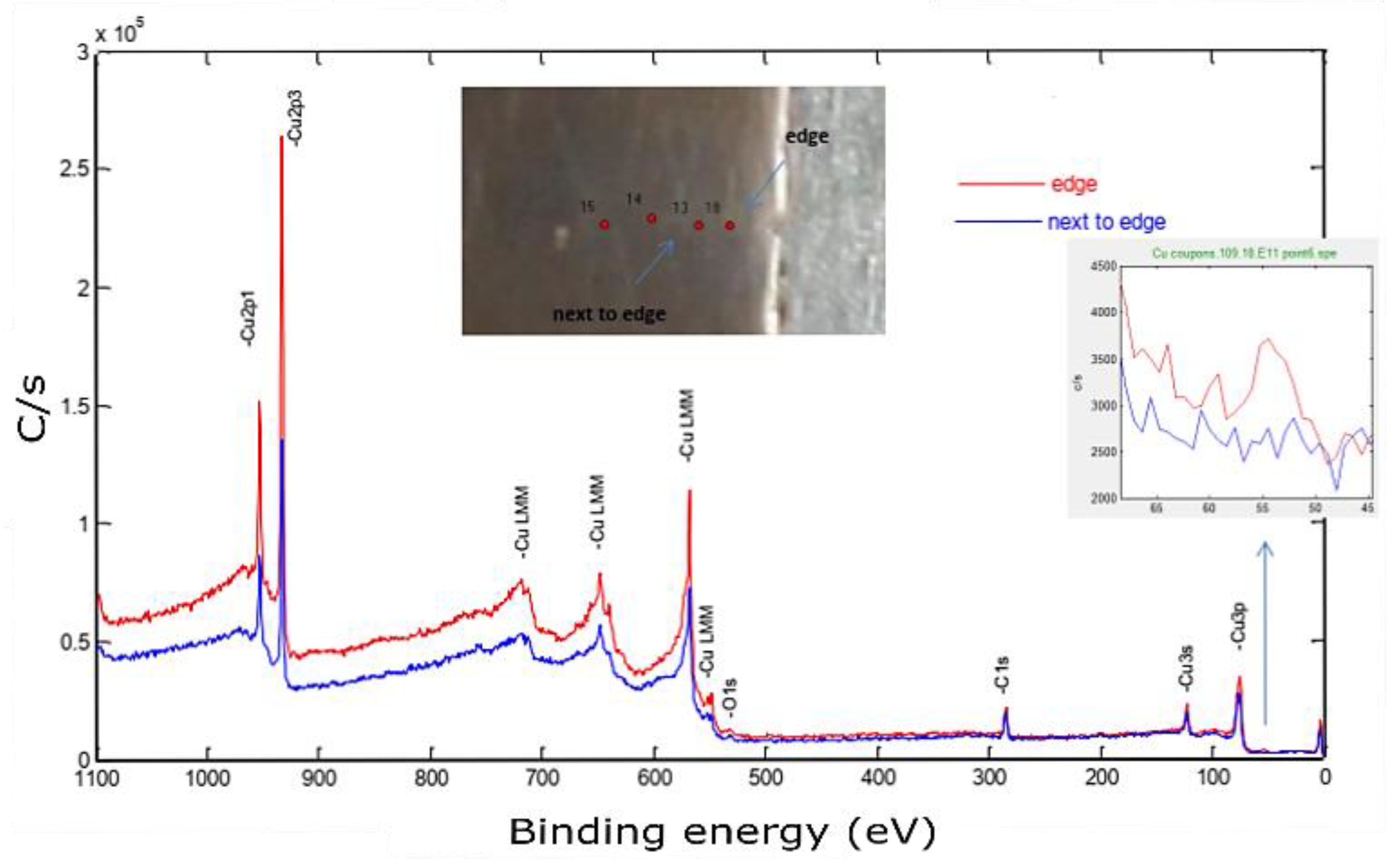

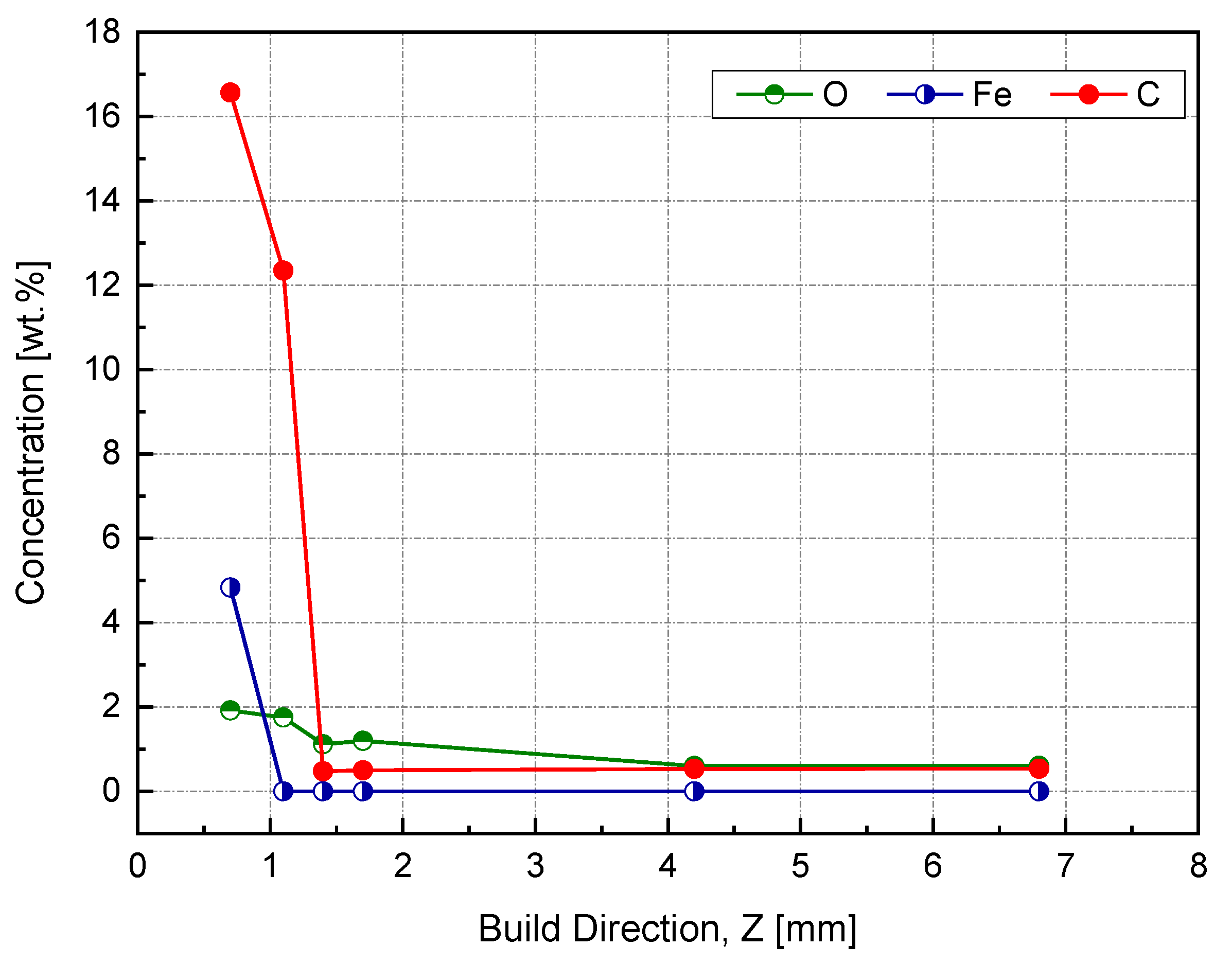

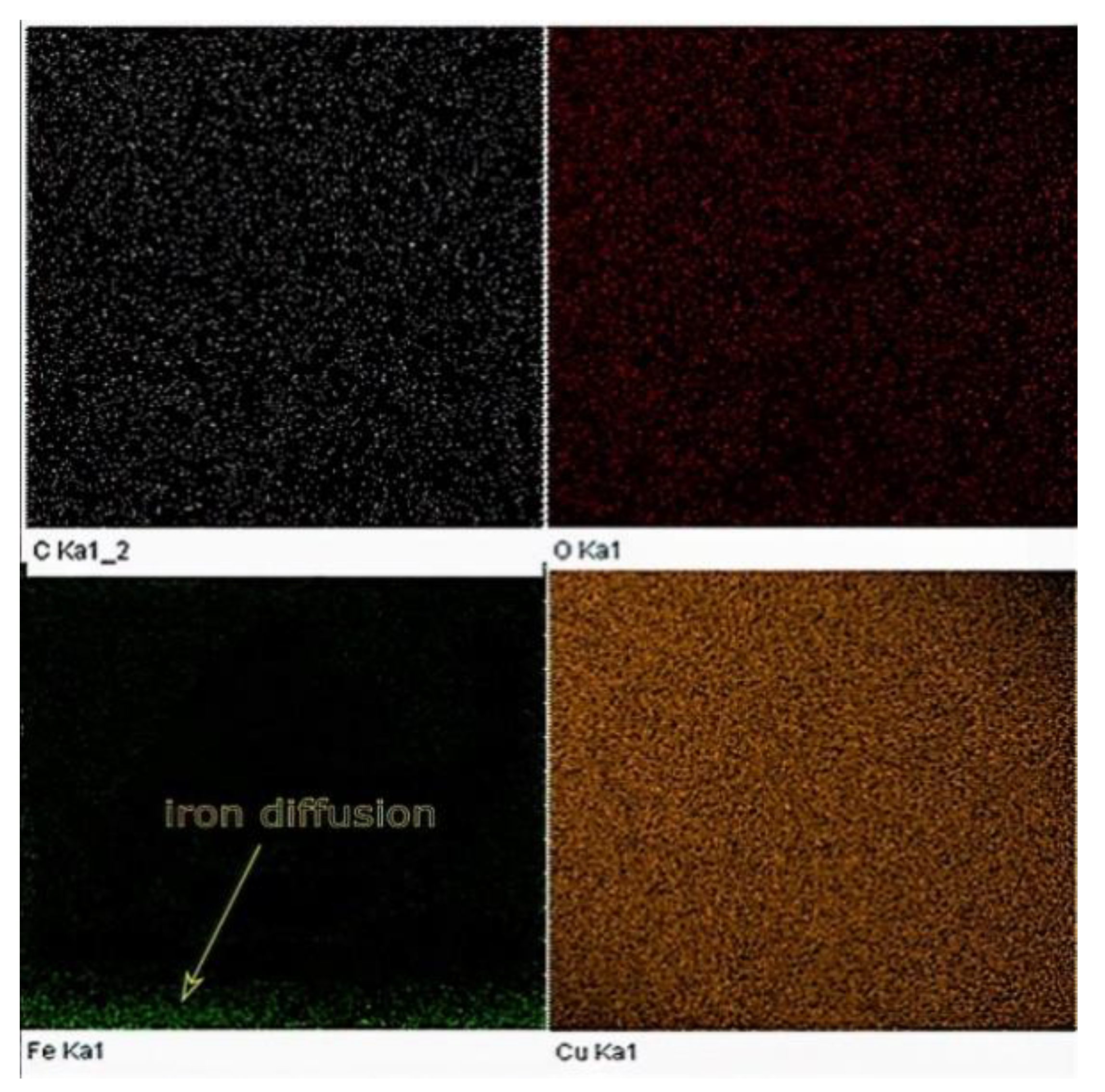

3.6. Chemical Composition

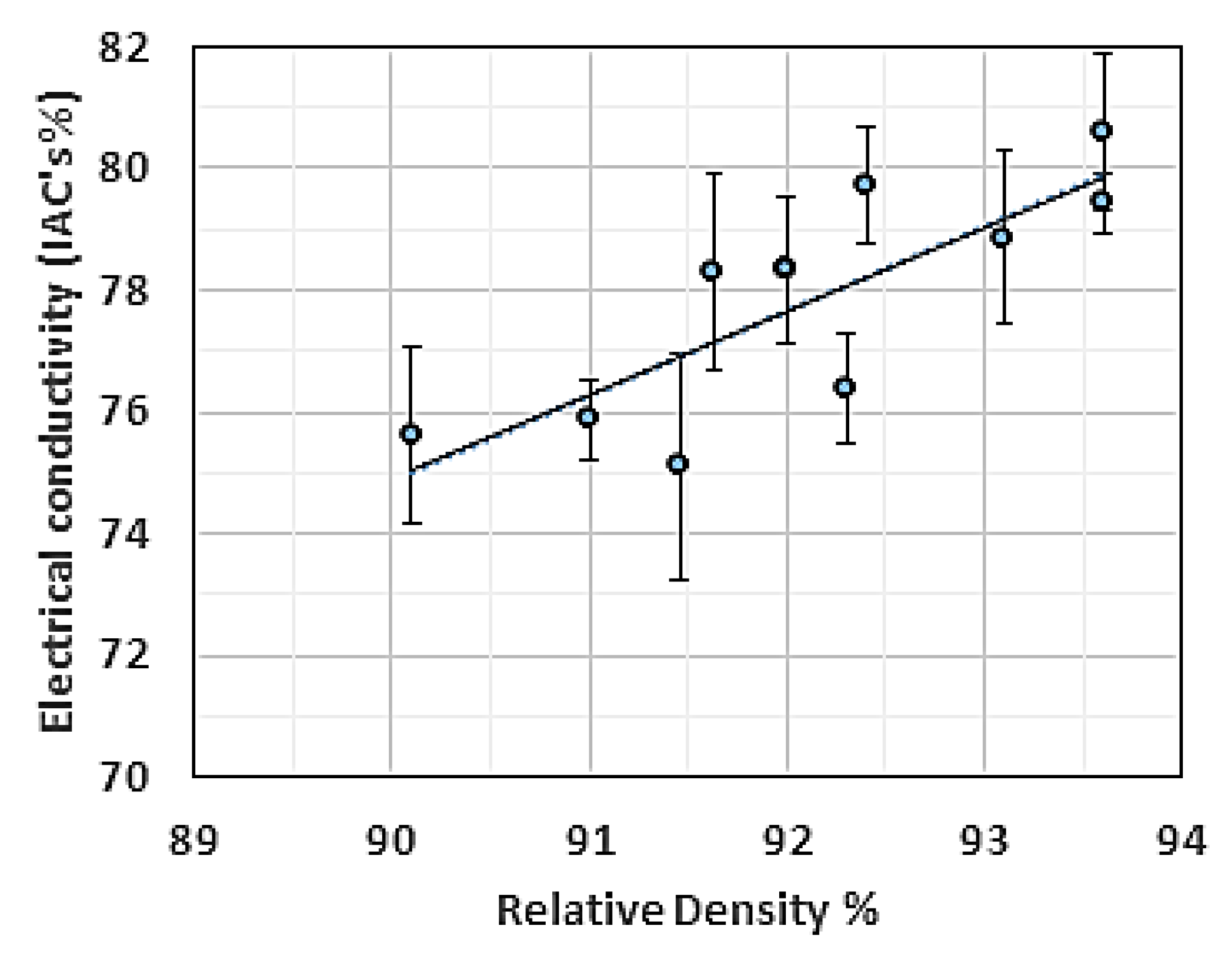

3.7. Electrical Conductivity

4. Conclusions

- The highest relative density obtained was 96% when a laser power of 370 W, scanning speed of 600 mm/s, hatch spacing of 100 μm, and layer thickness of 40 μm were employed.

- Using a maximum permitted laser power of 370 W and different scanning speeds, the relative density was found to increase with hatch spacing until reaching its peak at a hatch spacing of 100 μm, above which further increases in the hatch spacing resulted in relative density deterioration.

- The minimum surface roughness obtained was 8 ± 0.5 μm, which was comparable to the surface roughness of machined surfaces. At the optimum hatch spacing of 100 μm, the side-to-top surface roughness ratio increased when increasing the input linear energy density.

- The grain morphology was found to vary depending on the investigated location along the building direction. Close to the building plate (bonding zone), the grain structure inside the melt pool (MP) consisted of two distinct zones owning obvious characteristic shapes, starting with columnar-dendritic formed perpendicular to MP boundaries and directed inwards. The equiaxed grains were formed at the melt pool center. At mid-height of the sample (steady-state zone), a mix of cellular and columnar grains was identified. The average size of grain remarkably varied from 10 μm up to 100 μm.

- Two types of porosity were detected: spherical (type I) due to entrapped vapor, as well as lack of fusion and unmelted powder porosity (type II). Types I and II of porosity were detected in the bonding and steady-state zones, respectively. However, type II was observed to be more intense in the steady-state zone.

- The relative density of all samples investigated increased when a preheating of 200 °C was employed during the printing of samples by laser powder bed fusion.

- During the XPS testing conducted on the polished and cleaned Cu samples, the spectrum peaks corresponding to the electronic state of the constitutional element were hardly distinguishable. However, after sputtering, the characteristic XPS peaks of Cu were revealed.

- The maximum electrical conductivity (EC) of Cu samples printed by L-PBF was 81% IACS. The impurities in L-PBF were more significant on EC than the porosities presented when using the optimum process parameters.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Franz, R.; Wiedemann, G. Ueber die Wärme-Leitungsfähigkeit der Metalle. Ann. Phys. 1853, 165, 497–531. [Google Scholar] [CrossRef]

- Hummel, R.E. Electronic Properties of Materials; Springer Science & Business Media: New York, NY, USA, 2011. [Google Scholar]

- Kaden, L.; Matthäus, G.; Ramm, R.; Ullsperger, T.; Seyfarth, B.; Nolte, S. Additive manufacturing of pure copper using ultrashort laser pulses. Laser 3D Manuf. VI 2019, 10909, 109090D. [Google Scholar]

- Santos, E.C.; Shiomi, M.; Osakada, K.; Laoui, T. Rapid manufacturing of metal components by laser forming. Int. J. Mach. Tools Manuf. 2006, 46, 1459–1468. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Dadbakhsh, S.; Goossens, L.; Kruth, J.P.; van Humbeeck, J.; Vanmeensel, K. Influence of selective laser melting process parameters on texture evolution in pure copper. J. Mater. Process. Technol. 2019, 270, 47–58. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Vleugels, J.; Kruth, J.; van Humbeeck, J.; Vanmeensel, K. Mechanical and electrical properties of selective laser-melted parts produced from surface-oxidized copper. Mater. Des. Process. Commun. 2020, 2, e94. [Google Scholar] [CrossRef]

- Ikeshoji, T.-T.; Nakamura, K.; Yonehara, M.; Imai, K.; Kyogoku, H. Selective laser melting of pure copper. JOM 2018, 70, 396–400. [Google Scholar] [CrossRef]

- Colopi, M.; Caprio, L.; Demir, A.G.; Previtali, B. Selective laser melting of pure Cu with a 1 kW single mode fiber laser. Procedia Cirp. 2018, 74, 59–63. [Google Scholar] [CrossRef]

- Zhang, S.; Zhu, H.; Hu, Z.; Zeng, X.; Zhong, F. Selective laser melting of Cu10Zn alloy powder using high laser power. Powder Technol. 2019, 342, 613–620. [Google Scholar] [CrossRef]

- Kaden, L.; Matthäus, G.; Ullsperger, T.; Seyfarth, B.; Nolte, S. Selective laser melting of copper using ultrashort laser pulses at different wavelengths. Laser 3D Manuf. V 2018, 10523, 1052312. [Google Scholar]

- Hönl, R. World Premiere at Formnext: Green Laser from TRUMPF Prints Copper and Gold; TRUMPF Global Press Release; TRUMPF GmbH + Co. KG: Ditzingen, Germany, 2018. [Google Scholar]

- Kaiser, E.; Dold, E.; Killi, A.; Zaske, S.; Pricking, S. Application benefits of welding copper with a 1 kW, 515 nm continuous wave laser. In Proceedings of the 10th CIRP Conference on Photonic Technologies—LANE 2018, Fürth, Germany, 3–6 September 2018. [Google Scholar]

- El-Wardany, T.I.; She, Y.; Jagdale, V.N.; Garofano, J.K.; Liou, J.J.; Schmidt, W.R. Challenges in three-dimensional printing of high-conductivity copper. J. Electron. Packag. 2018, 140, 020907. [Google Scholar] [CrossRef]

- Lindström, V.; Liashenko, O.; Zweiacker, K.; Derevianko, S.; Morozovych, V.; Lyashenko, Y.; Leinenbach, C. Laser powder bed fusion of metal coated copper powders. Materials 2020, 13, 3493. [Google Scholar] [CrossRef] [PubMed]

- Silbernagel, C.; Gargalis, L.; Ashcroft, I.; Hague, R.; Galea, M.; Dickens, P. Electrical resistivity of pure copper processed by medium-powered laser powder bed fusion additive manufacturing for use in electromagnetic applications. Addit. Manuf. 2019, 29, 100831. [Google Scholar] [CrossRef]

- Trevisan, F.; Flaviana, C.; Diego, M.; Paolo, F. Selective laser melting of chemical pure copper powders. In Proceedings of the Euro PM2017 Congress & Exhibition, Milan, Italy, 1–5 October 2017; pp. 1–5. [Google Scholar]

- Lykov, P.A.; Safonov, E.V.; Akhmedianov, A.M. Selective laser melting of copper. Mater. Sci. Forum 2016, 843, 284–288. [Google Scholar] [CrossRef]

- Huang, J.; Yan, X.; Chang, C.; Xie, Y.; Ma, W.; Huang, R.; Zhao, R.; Li, S.; Liu, M.; Liao, H. Pure copper components fabricated by cold spray (CS) and selective laser melting (SLM) technology. Surf. Coat. Technol. 2020, 395, 125936. [Google Scholar] [CrossRef]

- Yan, X.; Chang, C.; Dong, D.; Gao, S.; Ma, W.; Liu, M.; Liao, H.; Yin, S. Microstructure and mechanical properties of pure copper manufactured by selective laser melting. Mater. Sci. Eng. A 2020, 789, 139615. [Google Scholar] [CrossRef]

- Constantin, L.; Wu, Z.; Li, N.; Fan, L.; Silvain, J.-F.; Lu, Y.F. Laser 3D printing of Complex Copper Structures. Addit. Manuf. 2020, 35, 101268. [Google Scholar] [CrossRef]

- Yakout, M.; Elbestawi, M.A.; Veldhuis, S.C. On the characterization of stainless steel 316L parts produced by selective laser melting. Int. J. Adv. Manuf. Technol. 2018, 95, 1953–1974. [Google Scholar] [CrossRef]

- ASTM B193—20: Standard Test Method for Resistivity of Electrical Conductor Materials. In Book of Standards V. 02.03; ASTM International: West Conshohocken, PA, USA, 2020.

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.D.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Davis, J.R. Copper and Copper Alloys. In ASM Specialty Handbook; ASM International: Materials Park, OH, USA, 2001. [Google Scholar]

- Yan, S.P.; Zhang, A.F.; Liang, S.D.; Wang, T. Measurement of laser light absorptivity of commonly used metals in laser additive manufacturing technique. Aeronaut. Manuf. Technol. 2017, 536, 97–100. [Google Scholar]

- Dong, Z.; Liu, Y.; Wen, W.; Ge, J.; Liang, J. Effect of hatch spacing on melt Pool and as-built quality during selective laser melting of stainless steel: Modeling and experimental approaches. Materials 2019, 12, 50. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, T.; Manvatkar, V.; De, A.; DebRoy, T. Dimensionless numbers in additive manufacturing. J. Appl. Phys. 2017, 121, 64904. [Google Scholar] [CrossRef]

- Harrison, D.A.; Yan, D.; Blairs, S. The surface tension of liquid copper. J. Chem. Thermodyn. 1977, 9, 1111–1119. [Google Scholar] [CrossRef]

- Simson, T.; Emmel, A.; Dwars, A.; Böhm, J. Residual stress measurements on AISI 316L samples manufactured by selective laser melting. Addit. Manuf. 2017, 17, 183–189. [Google Scholar] [CrossRef]

- Sharma, P.C. A Textbook of Production Engineering; S. Chand Publishing: Ram Nagar, New Delhi, India, 2009. [Google Scholar]

- Kurz, W.; Giovanola, B.; Trivedi, R. Theory of microstructural development during rapid solidification. Acta Metall. 1986, 34, 823–830. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy; Jonn Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Guo, M.; Wang, F.; Yi, L. The microstructure controlling and deformation behaviors of Cu–Fe–C alloy prepared by rapid solidification. Mater. Sci. Eng. A 2016, 657, 197–209. [Google Scholar] [CrossRef]

- Wei, H.L.; Elmer, J.W.; DebRoy, T. Origin of grain orientation during solidification of an aluminum alloy. Acta Mater. 2016, 115, 123–131. [Google Scholar] [CrossRef]

- Johnson, D.L. Solid-state sintering. In Concise Encyclopedia of Advanced Ceramic Materials; Elsevier: Amsterdam, The Netherlands, 1991; pp. 454–458. [Google Scholar]

- Kruth, J.; Mercelis, P.; van Vaerenbergh, J.; Froyen, L.; Rombouts, M. Binding mechanisms in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2005, 11, 26–36. [Google Scholar] [CrossRef]

- German, R. Sintering: From Empirical Observations to Scientific Principles; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- Colin, S.; Beche, E.; Berjoan, R.; Jolibois, H.; Chambaudet, A. An XPS and AES study of the free corrosion of Cu-, Ni-and Zn-based alloys in synthetic sweat. Corros. Sci. 1999, 41, 1051–1065. [Google Scholar] [CrossRef]

- Rhodin, T.N., Jr. Low temperature oxidation of copper. I. Physical mechanism1a. J. Am. Chem. Soc. 1950, 72, 5102–5106. [Google Scholar] [CrossRef]

- Lenglet, M.; Kartouni, K.; Machefert, J.; Claude, J.M.; Steinmetz, P.; Beauprez, E.; Heinrich, J.; Celati, N. Low temperature oxidation of copper: The formation of CuO. Mater. Res. Bull. 1995, 30, 393–403. [Google Scholar] [CrossRef]

- Ghijsen, J.; Tjeng, L.H.; van Elp, J.; Eskes, H.; Westerink, J.; Sawatzky, G.A.; Czyzyk, M.T. Electronic structure of Cu2O and CuO. Phys. Rev. B Condens. Matter 1988, 38, 11322–11330. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Santino, L.M.; Acharya, S.; Anandarajah, H.; D’Arcy, J.M. Studying Electrical Conductivity Using a 3D Printed Four-Point Probe Station; ACS Publications: Washington, DC, USA, 2017. [Google Scholar]

- Grootenhuis, P.; Powell, R.W.; Tye, R.P. Thermal and electrical conductivity of porous metals made by powder metallurgy methods. Proc. Phys. Soc. Sect. B 1952, 65, 502. [Google Scholar] [CrossRef]

- Taubenblat, P.W.; Smith, W.E.; Evans, C.E. Production of p/m parts from cu powders. Precis. Met. 1972, 30, 41–43. [Google Scholar]

- Dyos, G. The Handbook of Electrical Resistivity: New Materials and Pressure Effects; The Institution of Engineering and Technology: London, UK, 2012. [Google Scholar]

| Ref. | L-PBF Machine | Process Parameters | Optimum Properties | |||||

|---|---|---|---|---|---|---|---|---|

| P (W) | v (mm/s) | h (mm) | t (mm) | Ev (J/mm3) | RD% | EC (IAC’s%) | ||

| [13] | Phenix ProX 200 | 250 | 800 | - | - | - | 91 | 16 |

| [15] | Renishaw PLC AM125 | 200 | 300 | 0.1 | 0.045 | 148 | 86 | 50.3 |

| [16] | EOSINT M270 | 195 | 400 | 0.08 | 0.03 | 203 | 83 | NA |

| [17] | Sinterstation Pro DM125 | 200 | 100 | 0.12 | 0.05 | 333 | 88.1 | NA |

| [18,19] | EOS M290 | 200, 300 | 400, 600 | 0.08 | 0.03 | 208 | 99 | 41 |

| [20] | SLM® 125 | 400 | 400 | 0.12 | 0.03 | 278 | 95 | 98 |

| Test | Value | ASTM Standard |

|---|---|---|

| Sieve analysis (+45 μm) | 1.62 wt % | ASTM B214 |

| Laser size diffraction | Dv (10) = 16 μm | ASTM B822 |

| Dv (50) = 31 μm | ||

| Dv (90) = 51 μm | ||

| Hall flow | 11 s/50 g | ASTM B213 |

| Apparent density | 5.07 g/cm3 | ASTM B212 |

| Process Variables | Levels |

|---|---|

| Laser power (W) | 200, 245, 290, 335, 370 |

| Scanning speed (mm/s) | 200–400 (steps of 50), 500–800 (steps of 100) |

| Hatch spacing () | 50, 80, 100, 120, 150 |

| Exposure type | Single, presintering, remelting |

| Preheating (K) | 393, 473 |

| Scanning orientation of each layer | 67°, X-axis, Y-axis |

| Layer thickness () | 30, 40 |

| Scanning pattern | Serpentine (zigzag) |

| Strip width (mm) | 100 |

| −0.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdelhafiz, M.; Al-Rubaie, K.S.; Emadi, A.; Elbestawi, M.A. Process–Structure–Property Relationships of Copper Parts Manufactured by Laser Powder Bed Fusion. Materials 2021, 14, 2945. https://doi.org/10.3390/ma14112945

Abdelhafiz M, Al-Rubaie KS, Emadi A, Elbestawi MA. Process–Structure–Property Relationships of Copper Parts Manufactured by Laser Powder Bed Fusion. Materials. 2021; 14(11):2945. https://doi.org/10.3390/ma14112945

Chicago/Turabian StyleAbdelhafiz, Mohamed, Kassim S. Al-Rubaie, Ali Emadi, and Mohamed A. Elbestawi. 2021. "Process–Structure–Property Relationships of Copper Parts Manufactured by Laser Powder Bed Fusion" Materials 14, no. 11: 2945. https://doi.org/10.3390/ma14112945

APA StyleAbdelhafiz, M., Al-Rubaie, K. S., Emadi, A., & Elbestawi, M. A. (2021). Process–Structure–Property Relationships of Copper Parts Manufactured by Laser Powder Bed Fusion. Materials, 14(11), 2945. https://doi.org/10.3390/ma14112945