Characteristics of the Mg-Zn-Ca-Gd Alloy after Mechanical Alloying

Abstract

:1. Introduction

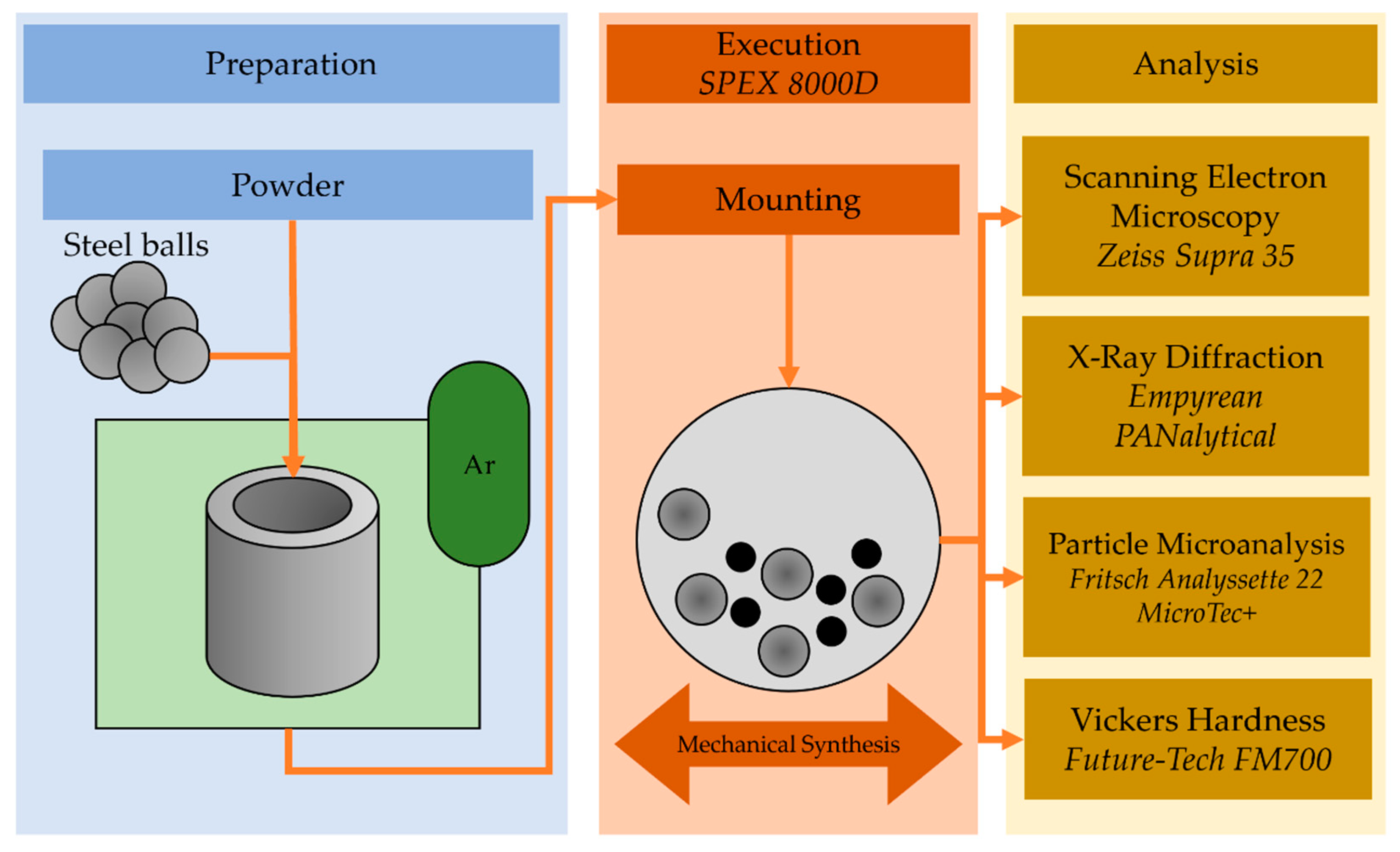

2. Materials and Methods

3. Results and Discussion

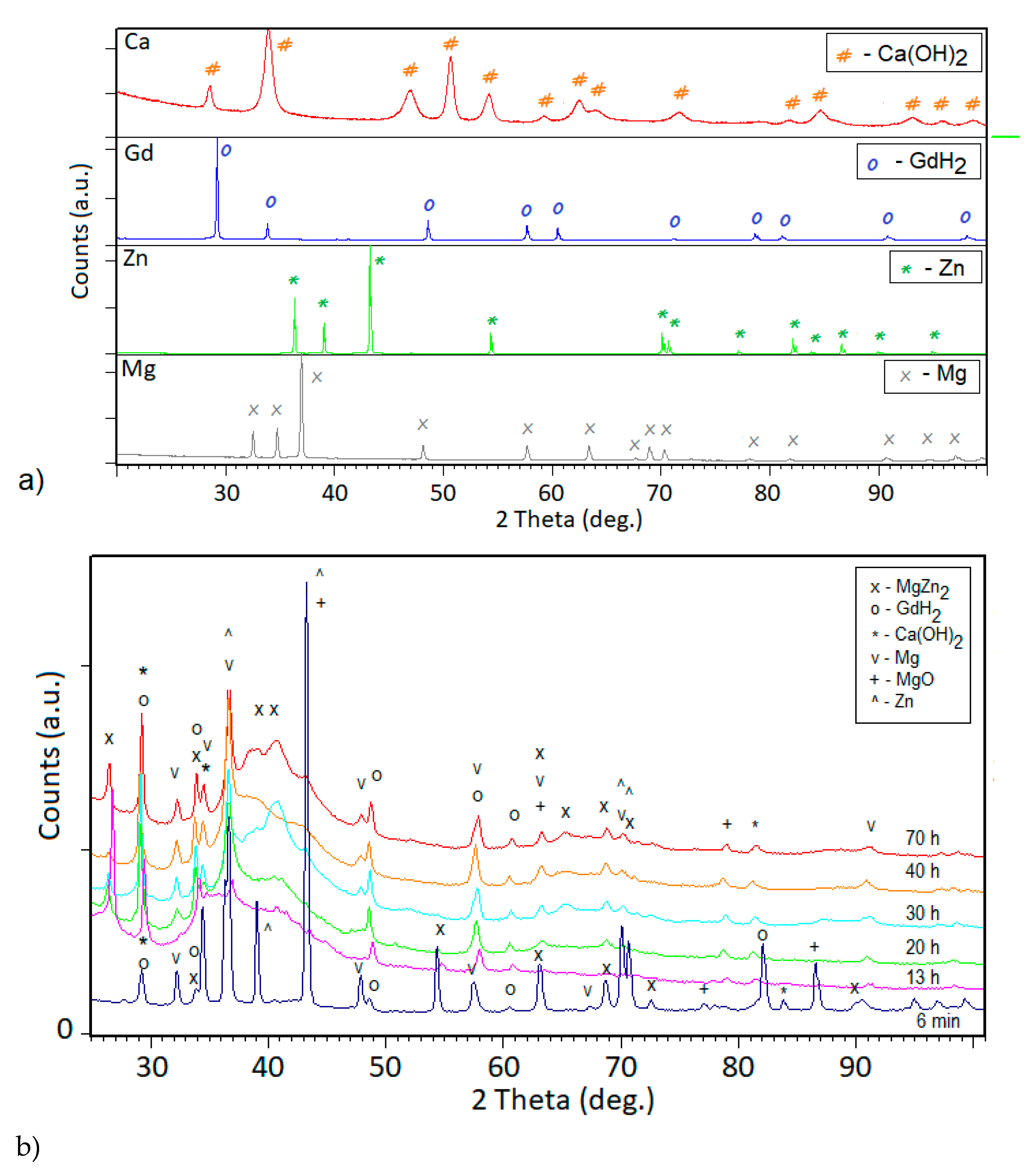

3.1. Phase Composition

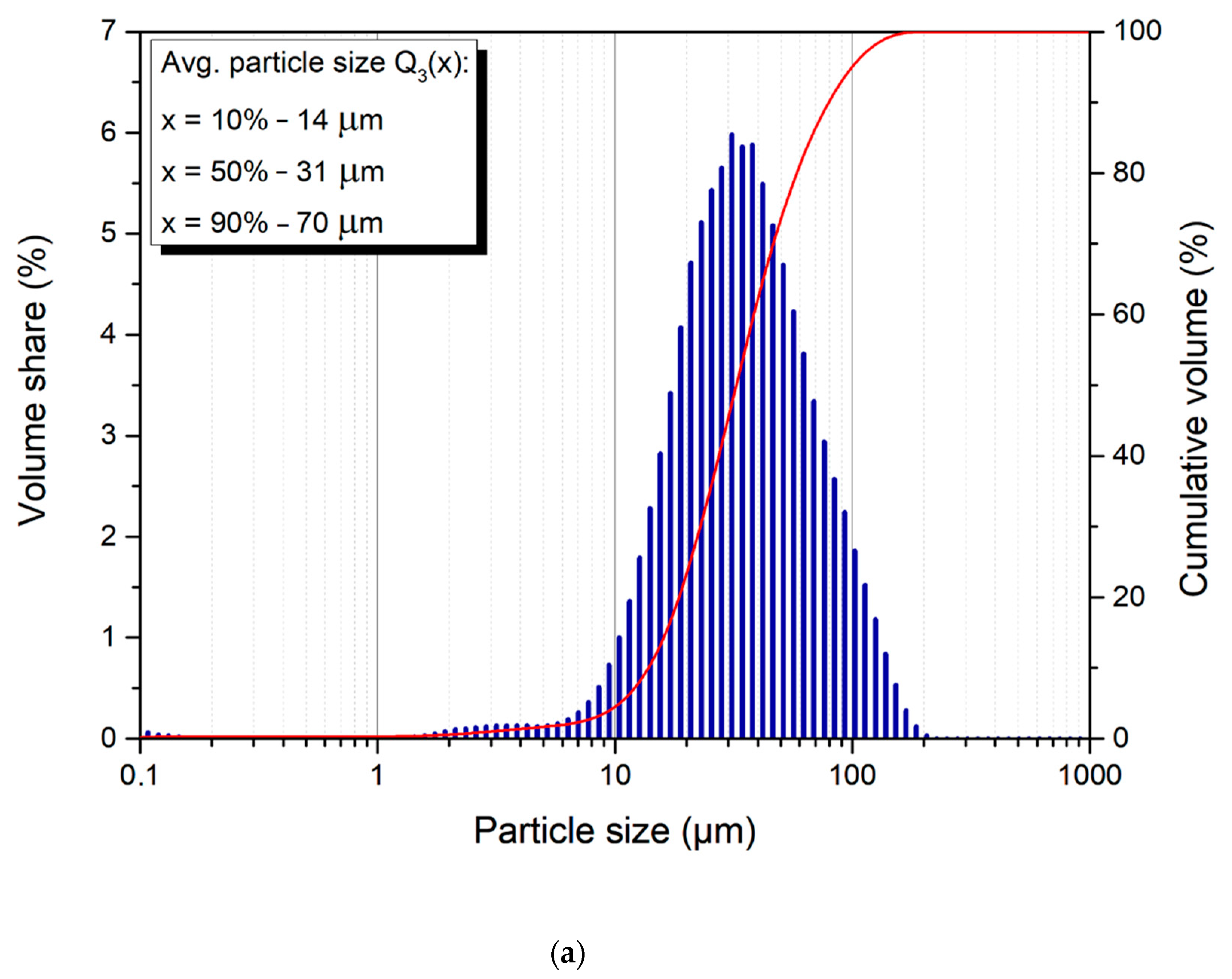

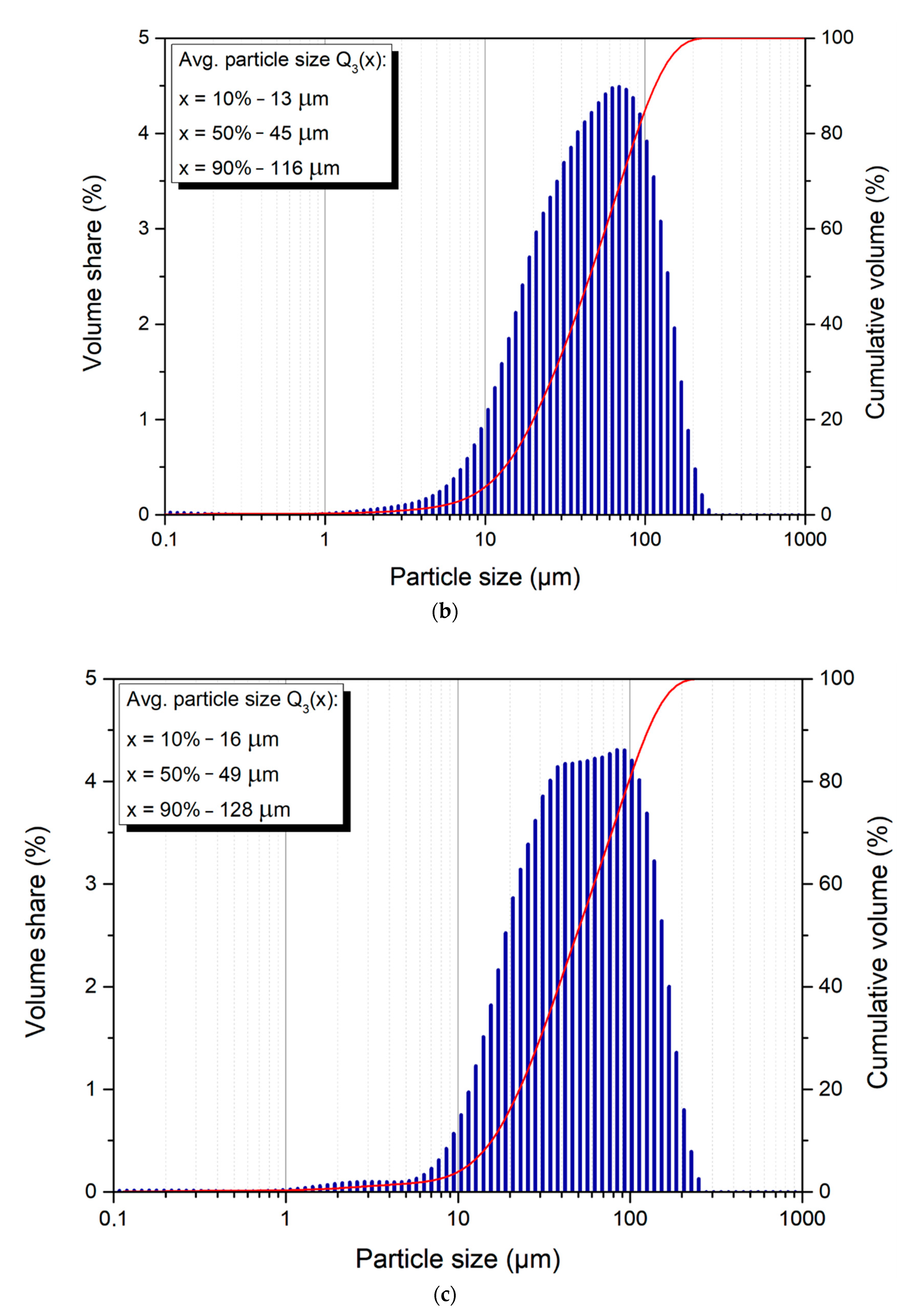

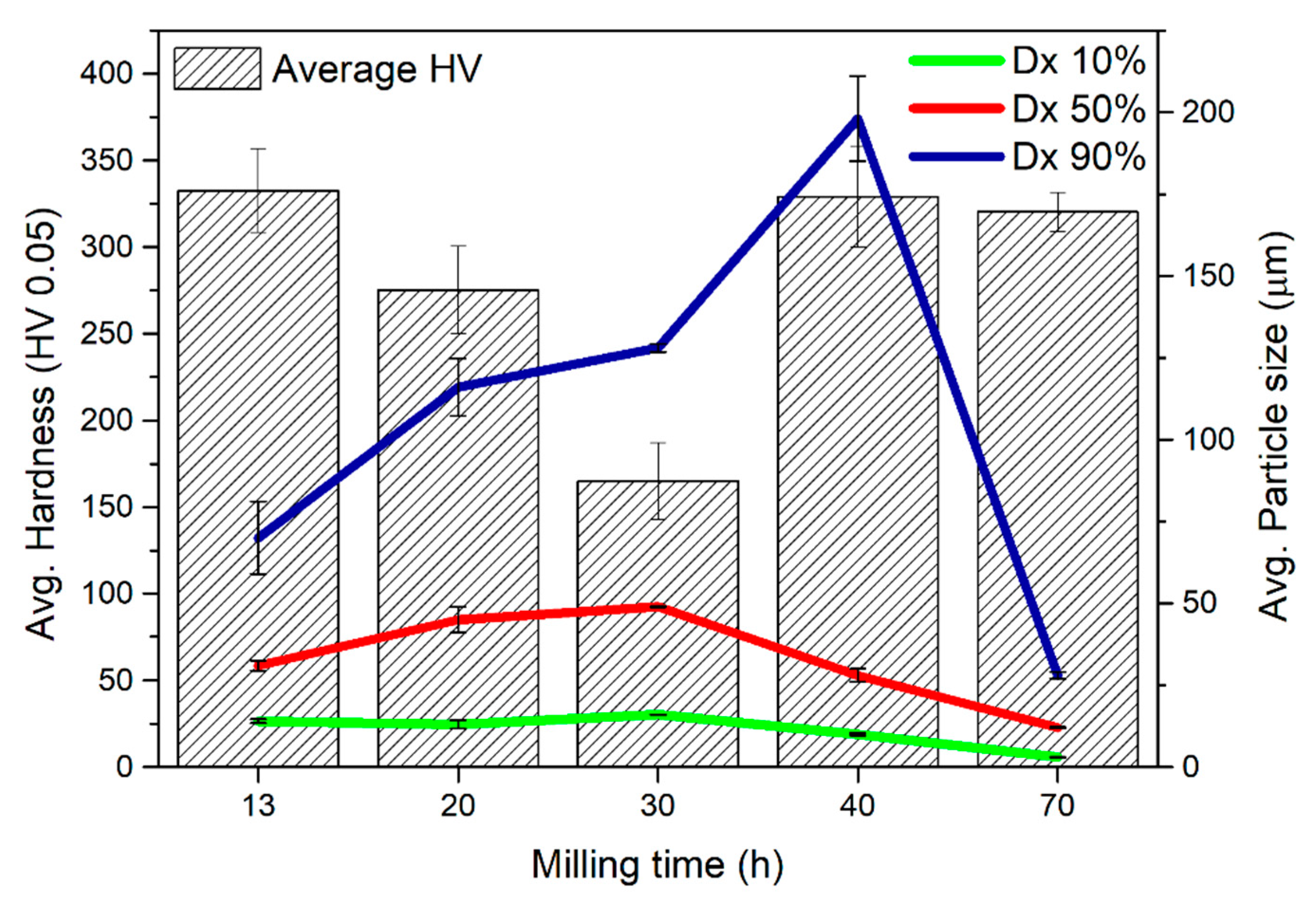

3.2. Granulometry and Hardness

3.3. Scanning Electron Microscopy: Morphology and Qualitative Chemical Composition Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Anderson, J.M. Biological performance of materials-fundamentals of biocompatibility (Vol. 8, Biomedical engineering and instrumentation series), by Jonathan Black, Marcel Dekker, New York, NY, 1981. J. Biomed. Mater. Res. 1983, 17, 557–558. [Google Scholar] [CrossRef]

- Dziki, J.L.; Badylak, S.F. Immunomodulatory biomaterials. Curr. Opin. Biomed. Eng. 2018, 6, 51–57. [Google Scholar] [CrossRef]

- Yang, K.; Zhou, C.; Fan, H.; Fan, Y.; Jiang, Q.; Song, P.; Fan, H.; Chen, Y.; Zhang, X. Bio-Functional Design, Application and Trends in Metallic Biomaterials. Int. J. Mol. Sci. 2017, 19, 24. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Amini, A.R.; Wallace, J.S.; Nukavarapu, S.P. Short-term and long-term effects of orthopedic biodegradable implants. J. Long. Term. Eff. Med. Implant. 2011, 21, 93–122. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, L.; Zhang, M.; Li, Y.; Zhao, J.; Qin, L.; Lai, Y. Corrosion and biocompatibility improvement of magnesium-based alloys as bone implant materials: A review. Regen. Biomater. 2017, 4, 129–137. [Google Scholar] [CrossRef] [Green Version]

- Sanchis-Moysi, J.; Dorado, C.; Vicente-Rodríguez, G.; Milutinovic, L.; Garces, G.L.; Calbet, J.A.L. Inter-arm asymmetry in bone mineral content and bone area in postmenopausal recreational tennis players. Maturitas 2004, 48, 289–298. [Google Scholar] [CrossRef]

- Chang, G.; Regatte, R.R.; Schweitzer, M.E. Olympic fencers: Adaptations in cortical and trabecular bone determined by quantitative computed tomography. Osteoporos. Int. 2009, 20, 779–785. [Google Scholar] [CrossRef]

- Iwamoto, J.; Takeda, T.; Sato, Y. Interventions to prevent bone loss in astronauts during space flight. Keio J. Med. 2005, 54, 55–59. [Google Scholar] [CrossRef] [Green Version]

- Okazaki, Y.; Gotoh, E.; Mori, J. Strength-Durability Correlation of Osteosynthesis Devices Made by 3D Layer Manufacturing. Materials 2019, 12, 436. [Google Scholar] [CrossRef] [Green Version]

- Shinya, A.; Ballo, A.M.; Lassila, L.V.J.; Shinya, A.; Närhi, T.O.; Vallittu, P.K. Stress and Strain Analysis of the Bone-Implant Interface: A Comparison of Fiber-Reinforced Composite and Titanium Implants Utilizing 3-Dimensional Finite Element Study. J. Oral Implant. 2011, 37, 133–140. [Google Scholar] [CrossRef]

- Ruff, C.; Holt, B.; Trinkaus, E. Who’s afraid of the big bad Wolff?: “Wolff’s law” and bone functional adaptation. Am. J. Phys. Anthr. 2006, 129, 484–498. [Google Scholar] [CrossRef] [PubMed]

- Frost, H.M. Wolff’s Law and bone’s structural adaptations to mechanical usage: An overview for clinicians. Angle Orthod. 1994, 64, 175–188. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.-N.; Hou, Z.-T.; Ye, X.; Xu, Z.-B.; Bai, X.-L.; Shang, P. The effect of selected alloying element additions on properties of Mg-based alloy as bioimplants: A literature review. Front. Mater. Sci. 2013, 7, 227–236. [Google Scholar] [CrossRef]

- Salleh, E.M.; Ramakrishnan, S.; Hussain, Z. Synthesis of Biodegradable Mg-Zn Alloy by Mechanical Alloying: Effect of Milling Time. Procedia Chem. 2016, 19, 525–530. [Google Scholar] [CrossRef] [Green Version]

- Matias, T.B.; Asato, G.H.; Ramasco, B.T.; Botta, W.J.; Kiminami, C.S.; Bolfarini, C. Processing and characterization of amorphous magnesium based alloy for application in biomedical implants. J. Mater. Res. Technol. 2014, 3, 203–209. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Huang, G.; Chen, X.; Deng, Q.; Tang, A.; Jiang, B.; Pan, F. Effects of Zn addition on the mechanical properties and texture of extruded Mg-Zn-Ca-Ce magnesium alloy sheets. Mater. Sci. Eng. A 2017, 705, 46–54. [Google Scholar] [CrossRef]

- Yuasa, M.; Hayashi, M.; Mabuchi, M.; Chino, Y. Improved plastic anisotropy of Mg–Zn–Ca alloys exhibiting high-stretch formability: A first-principles study. Acta Mater. 2014, 65, 207–214. [Google Scholar] [CrossRef]

- Plum, L.M.; Rink, L.; Haase, H. The essential toxin: Impact of zinc on human health. Int. J. Environ. Res. Public Health 2010, 7, 1342–1365. [Google Scholar] [CrossRef] [Green Version]

- Salahshoor, M.; Guo, Y. Biodegradable Orthopedic Magnesium-Calcium (MgCa) Alloys, Processing, and Corrosion Performance. Materials 2012, 5, 135–155. [Google Scholar] [CrossRef] [Green Version]

- Hort, N.; Huang, Y.; Fechner, D.; Störmer, M.; Blawert, C.; Witte, F.; Vogt, C.; Drücker, H.; Willumeit, R.; Kainer, K.U.; et al. Magnesium alloys as implant materials – Principles of property design for Mg–RE alloys. Acta Biomater. 2010, 6, 1714–1725. [Google Scholar] [CrossRef] [Green Version]

- Kawamura, Y.; Yamasaki, M. Formation and mechanical properties of Mg97Zn1RE 2 alloys with long-period stacking ordered structure. Mater. Trans. 2007, 48, 2986–2992. [Google Scholar] [CrossRef] [Green Version]

- Staiger, M.P.; Pietak, A.M.; Huadmai, J.; Dias, G. Magnesium and its alloys as orthopedic biomaterials: A review. Biomaterials 2006, 27, 1728–1734. [Google Scholar] [CrossRef] [PubMed]

- Song, G. Control of biodegradation of biocompatable magnesium alloys. Corros. Sci. 2007, 49, 1696–1701. [Google Scholar] [CrossRef]

- Zberg, B.; Uggowitzer, P.J.; Löffler, J.F. MgZnCa glasses without clinically observable hydrogen evolution for biodegradable implants. Nat. Mater. 2009, 8, 887. [Google Scholar] [CrossRef]

- Byrne, J.; O’Cearbhaill, E.; Browne, D. Comparison of crystalline and amorphous versions of a magnesium-based alloy: Corrosion and cell response. Eur. Cells Mater. 2015, 30, 75. [Google Scholar]

- Celarek, A.; Kraus, T.; Tschegg, E.K.; Fischerauer, S.F.; Stanzl-Tschegg, S.; Uggowitzer, P.J.; Weinberg, A.M. PHB, crystalline and amorphous magnesium alloys: Promising candidates for bioresorbable osteosynthesis implants? Mater. Sci. Eng. C 2012, 32, 1503–1510. [Google Scholar] [CrossRef]

- Abbasi, M.; Sajjadi, S.A.; Azadbeh, M. An investigation on the variations occurring during Ni3Al powder formation by mechanical alloying technique. J. Alloy. Compd. 2010, 497, 171–175. [Google Scholar] [CrossRef]

- Neves, F.; Fernandes, F.M.B.; Martins, I.; Correia, J.B. Parametric optimization of Ti–Ni powder mixtures produced by mechanical alloying. J. Alloy. Compd. 2011, 509, S271–S274. [Google Scholar] [CrossRef]

- Beaulieu, L.; Larcher, D.; Dunlap, R.; Dahn, J. Nanocomposites in the Sn–Mn–C system produced by mechanical alloying. J. Alloy. Compd. 2000, 297, 122–128. [Google Scholar] [CrossRef]

- Benjamin, J.S.; Volin, T.E. The mechanism of mechanical alloying. Metall. Trans. 1974, 5, 1929–1934. [Google Scholar] [CrossRef]

- Datta, M.K.; Chou, D.-T.; Hong, D.; Saha, P.; Chung, S.J.; Lee, B.; Sirinterlikci, A.; Ramanathan, M.; Roy, A.; Kumta, P.N. Structure and thermal stability of biodegradable Mg–Zn–Ca based amorphous alloys synthesized by mechanical alloying. Mater. Sci. Eng. B 2011, 176, 1637–1643. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Al-Aqeeli, N. Mechanically alloyed nanocomposites. Prog. Mater. Sci. 2013, 58, 383–502. [Google Scholar] [CrossRef]

- Dobrzański, L.A.; Drygała, A. Influence of Laser Processing on Polycrystalline Silicon Surface. Mater. Sci. Forum 2012, 2012, 829–834. [Google Scholar] [CrossRef]

- Velu, R.; Raspall, F.; Singamneni, S. 3D printing technologies and composite materials for structural applications. Green Compos. Automot. Appl. 2019, 171–196. [Google Scholar] [CrossRef]

- Hrapkowicz, B.; Lesz, S.T. Characterization of Ca 50 Mg 20 Zn 12 Cu 18 Alloy. Arch. Foundry Eng. 2019, 19, 75–82. [Google Scholar] [CrossRef]

- Toozandehjani, M.; Matori, K.A.; Ostovan, F.; Aziz, S.A.; Mamat, M.S. Effect of milling time on the microstructure, physical and mechanical properties of Al-Al2O3 nanocomposite synthesized by ball milling and powder metallurgy. Materials 2017, 10, 1232. [Google Scholar] [CrossRef] [Green Version]

- Broitman, E. Indentation Hardness Measurements at Macro-, Micro-, and Nanoscale: A Critical Overview. Tribol. Lett. 2017, 65, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Lesz, S.; Kremzer, M.; Gołombek, K.; Nowosielski, R. Influence of milling time on amorphization of mg-zn-ca powders synthesized by mechanical alloying technique. Arch. Metall. Mater. 2018, 63, 845–851. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical alloying and milling. Prog. Mater. Sci. 2001, 46, 1–184. [Google Scholar] [CrossRef]

- Lesz, S.; Kraczla, J.; Nowosielski, R. Structure and compression strength characteristics of the sintered Mg–Zn–Ca–Gd alloy for medical applications. Arch. Civ. Mech. Eng. 2018, 18, 1288–1299. [Google Scholar] [CrossRef]

- Dobrzański, L.A.; Tomiczek, B.; Matula, G.; Gołombek, K. Role of Halloysite Nanoparticles and Milling Time on the Synthesis of AA 6061 Aluminium Matrix Composites. Adv. Mater. Res. 2014, 939, 84–89. [Google Scholar] [CrossRef]

- Jurczyk, M. Bionanomaterials for Dental Applications; Pan Stanford Publishing: Singapore, 2012; ISBN 9789814303842. [Google Scholar]

- Jurczyk, M. Mechaniczna Synteza, Mechanical Alloying; Poznań University Press: Poznań, Poland, 2003; ISBN 9788371434778. [Google Scholar]

- Fogagnolo, J.; Velasco, F.; Robert, M.; Torralba, J. Effect of mechanical alloying on the morphology, microstructure and properties of aluminium matrix composite powders. Mater. Sci. Eng. A 2003, 342, 131–143. [Google Scholar] [CrossRef]

| Sample | Average Particle Size (μm) |

|---|---|

| 13 h | 31 ± 1.5 |

| 20 h | 45 ± 4.0 |

| 30 h | 49 ± 0.3 |

| 40 h | 28 ± 2.1 |

| 70 h | 12 ± 0.3 |

| Test Number | 13 h Sample (HV 0.05) | 20 h Sample (HV 0.05) | 30 h Sample (HV 0.05) | 40 h Sample (HV 0.05) | 70 h Sample (HV 0.05) |

|---|---|---|---|---|---|

| 1 | 305 | 273 | 179 | 359 | 333 |

| 2 | 305 | 253 | 141 | 348 | 316 |

| 3 | 343 | 249 | 151 | 348 | 316 |

| 4 | 367 | 282 | 153 | 285 | 303 |

| 5 | 343 | 319 | 201 | 305 | 333 |

| Average: | 333 ± 24 | 275 ± 25 | 168 ± 22 | 329 ± 29 | 320 ± 11 |

| Sample (Milling Time) | (wt.%) | (at.%) | ||||||

|---|---|---|---|---|---|---|---|---|

| Mg | Ca | Gd | Zn | Mg | Ca | Gd | Zn | |

| 13 | 39 ± 1.9 | 12 ± 0.6 | 4 ± 0.2 | 45 ± 2.2 | 61 ± 3.1 | 11 ± 0.6 | 1 | 27 ± 1.4 |

| 20 | 40 ± 2.0 | 6 ± 0.3 | 5 ± 0.3 | 50 ± 2.5 | 64 ± 3.2 | 6 ± 0.3 | 1 | 29 ± 1.5 |

| 30 | 40 ± 2.0 | 3 ± 0.1 | 4 ± 0.2 | 52 ± 2.6 | 65 ± 3.3 | 3 ± 0.1 | 1 | 31 ± 1.6 |

| 40 | 40 ± 2.0 | 3 ± 0.1 | 4 ± 0.2 | 52 ± 2.6 | 65 ± 3.3 | 3 ± 0.1 | 1 | 31 ± 1.6 |

| 70 | 43 ± 2.10 | 4 ± 0.2 | 4 ± 0.2 | 49 ± 2.5 | 67 ± 3.4 | 4 ± 0.1 | 1 | 28 ± 1.4 |

| Theoretical value | 40.94 | 4.15 | 4.08 | 50.83 | 65.00 | 4.00 | 1.00 | 30.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lesz, S.; Hrapkowicz, B.; Karolus, M.; Gołombek, K. Characteristics of the Mg-Zn-Ca-Gd Alloy after Mechanical Alloying. Materials 2021, 14, 226. https://doi.org/10.3390/ma14010226

Lesz S, Hrapkowicz B, Karolus M, Gołombek K. Characteristics of the Mg-Zn-Ca-Gd Alloy after Mechanical Alloying. Materials. 2021; 14(1):226. https://doi.org/10.3390/ma14010226

Chicago/Turabian StyleLesz, Sabina, Bartłomiej Hrapkowicz, Małgorzata Karolus, and Klaudiusz Gołombek. 2021. "Characteristics of the Mg-Zn-Ca-Gd Alloy after Mechanical Alloying" Materials 14, no. 1: 226. https://doi.org/10.3390/ma14010226

APA StyleLesz, S., Hrapkowicz, B., Karolus, M., & Gołombek, K. (2021). Characteristics of the Mg-Zn-Ca-Gd Alloy after Mechanical Alloying. Materials, 14(1), 226. https://doi.org/10.3390/ma14010226