Freeze–Thaw Resistance and Air-Void Analysis of Concrete with Recycled Glass–Pozzolan Using X-ray Micro-Tomography

Abstract

1. Introduction

2. Materials and Experimental Program

2.1. Experimental Program

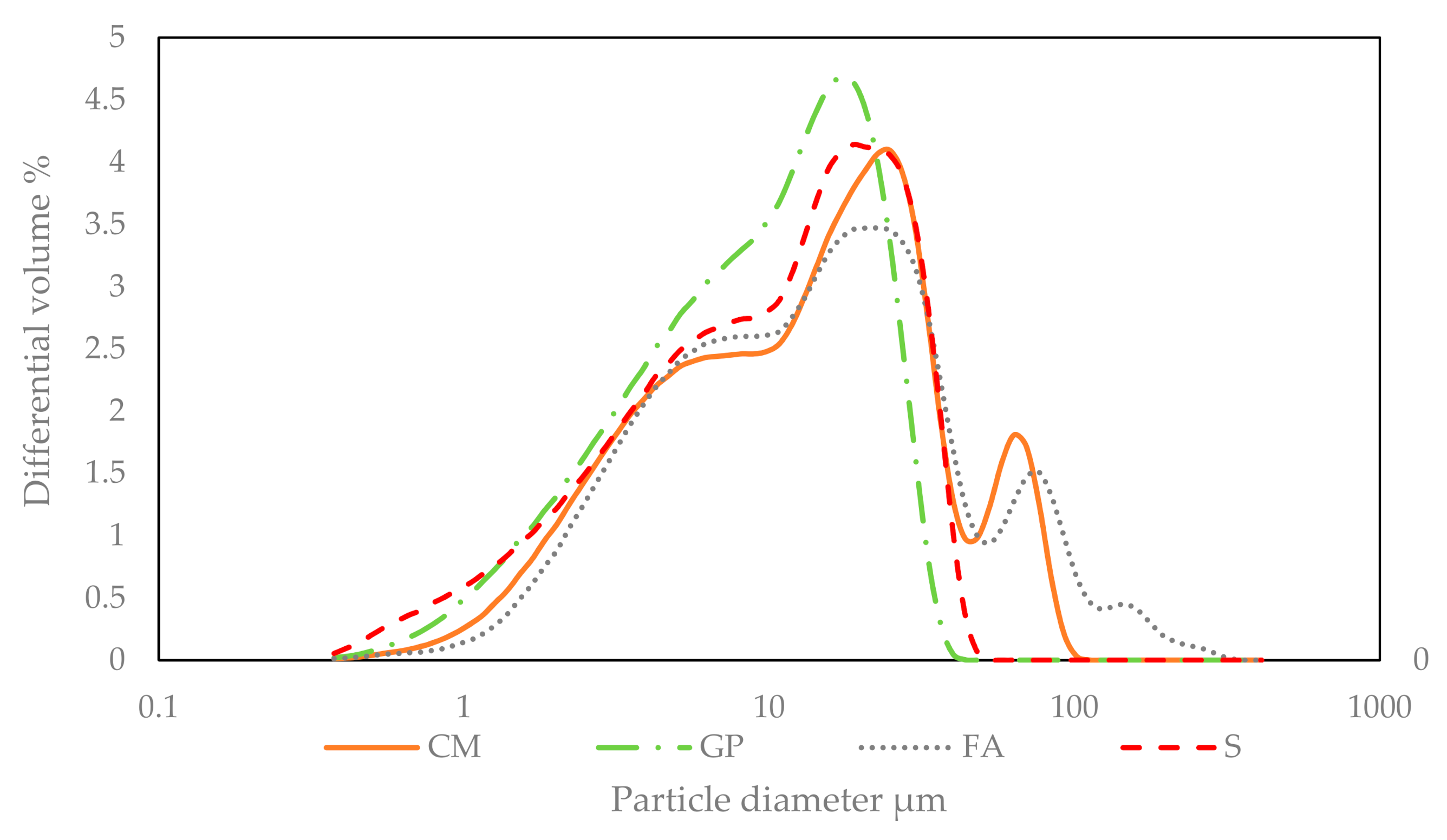

2.2. Materials and Mixtures

2.3. Characterization Methods

2.3.1. Air Content of fresh Concrete

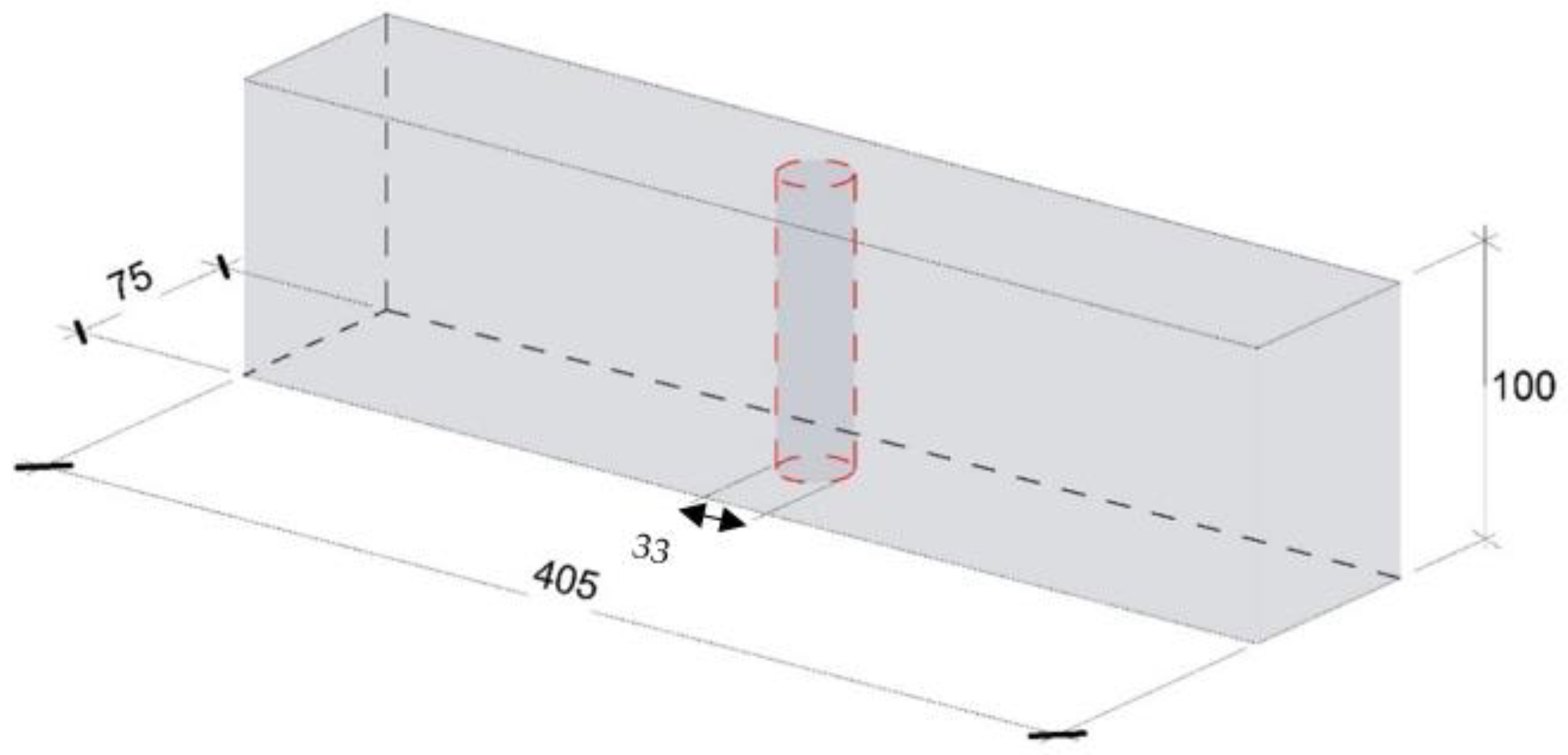

2.3.2. Dynamic Modulus of Elasticity (Ed)

2.3.3. Freeze–Thaw Cycles

2.4. Multi-Scale Characterization of Pore Structure and Micro-Cracks

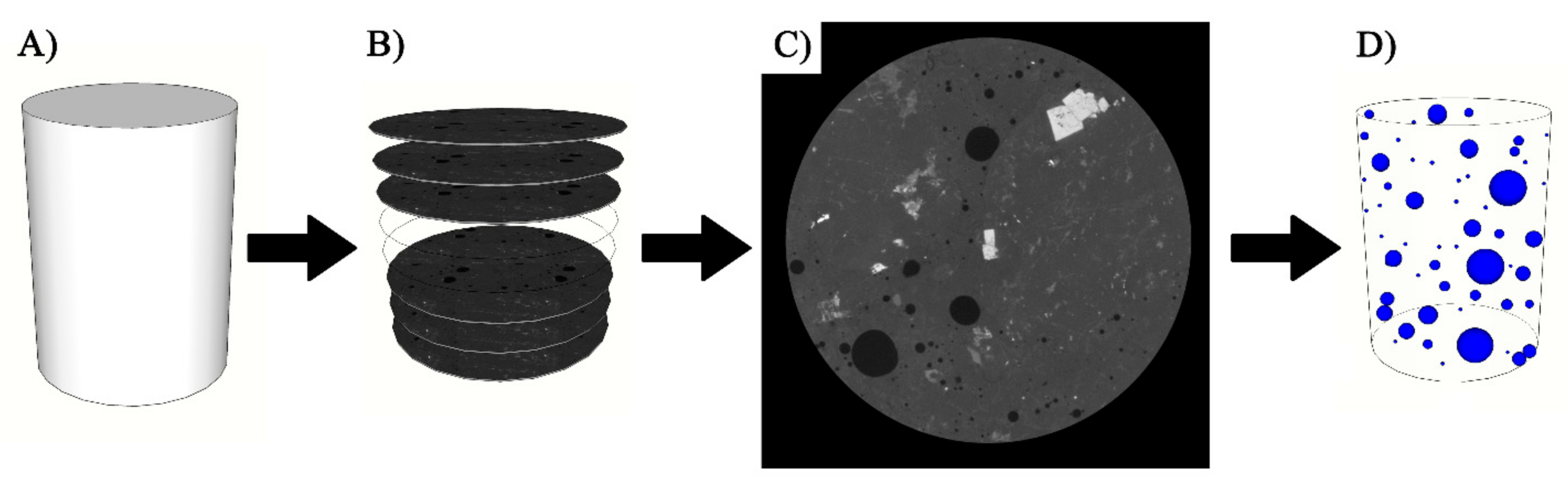

2.4.1. X-ray Micro-Computerized Tomography (Micro-CT) for Air Void System Analysis

2.4.2. Mercury Intrusion Porosimetry (MIP)

2.4.3. Nitrogen Adsorption

2.5. Thermogravimetric Analysis (TGA)

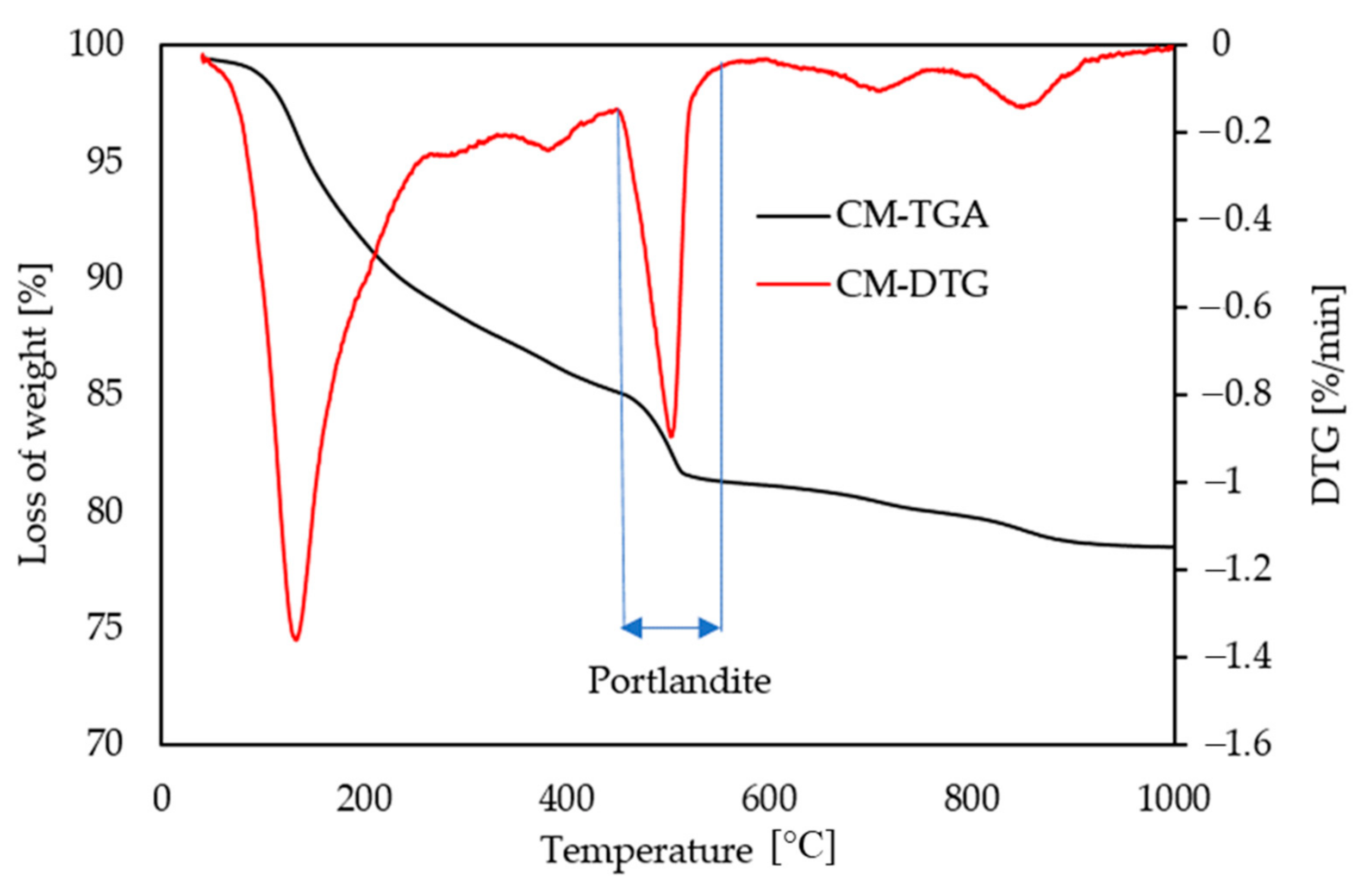

- 40 to 430 °C: Water loss from AFm, AFt (aluminate ferrite mono sulfate, and tri-sulfate, respectively) and C-S-H phases;

- 430 to 550 °C: Water loss from portlandite;

- 550 to 800 °C: Carbon dioxide loss from calcium carbonate minerals.

3. Results and Discussion

3.1. Results

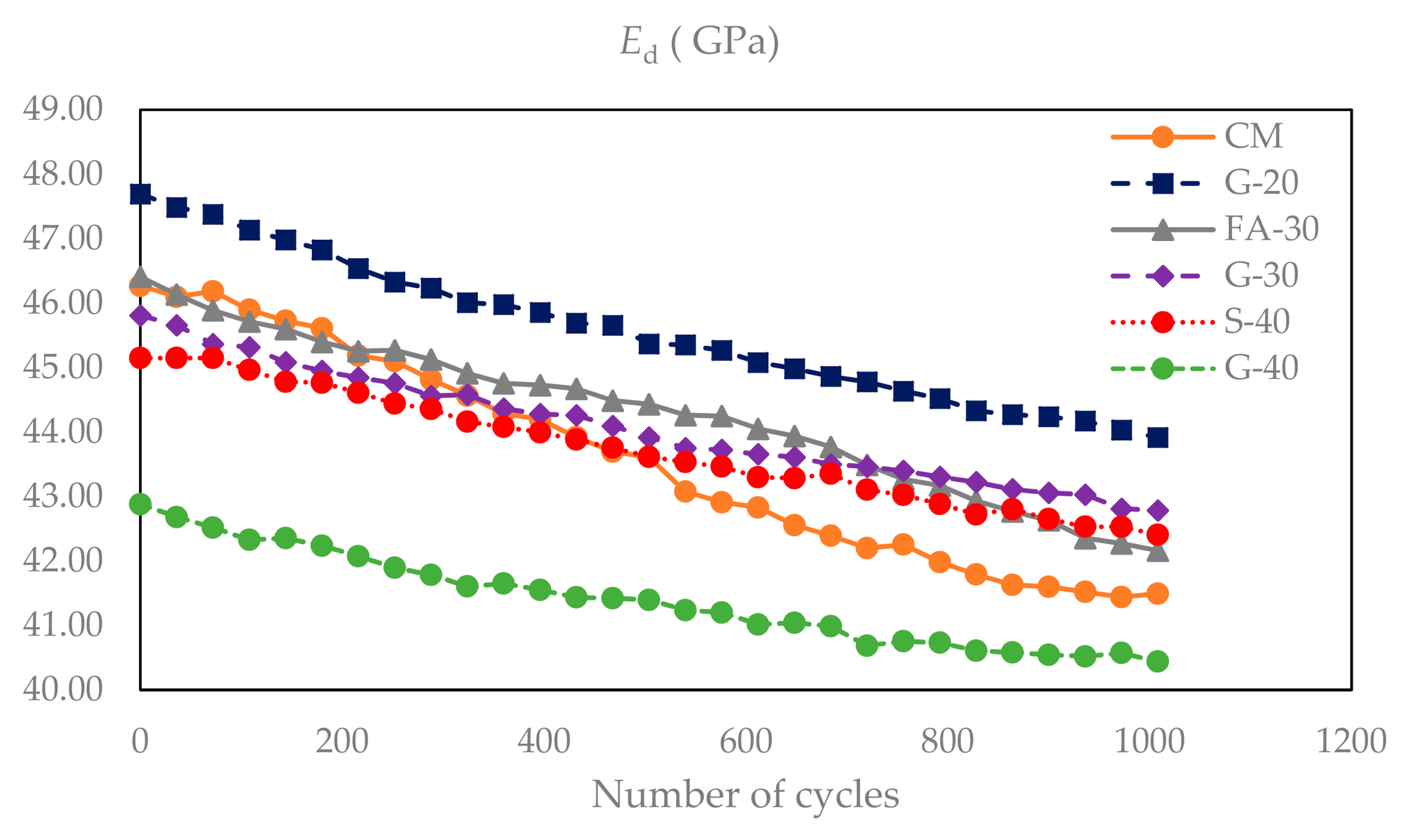

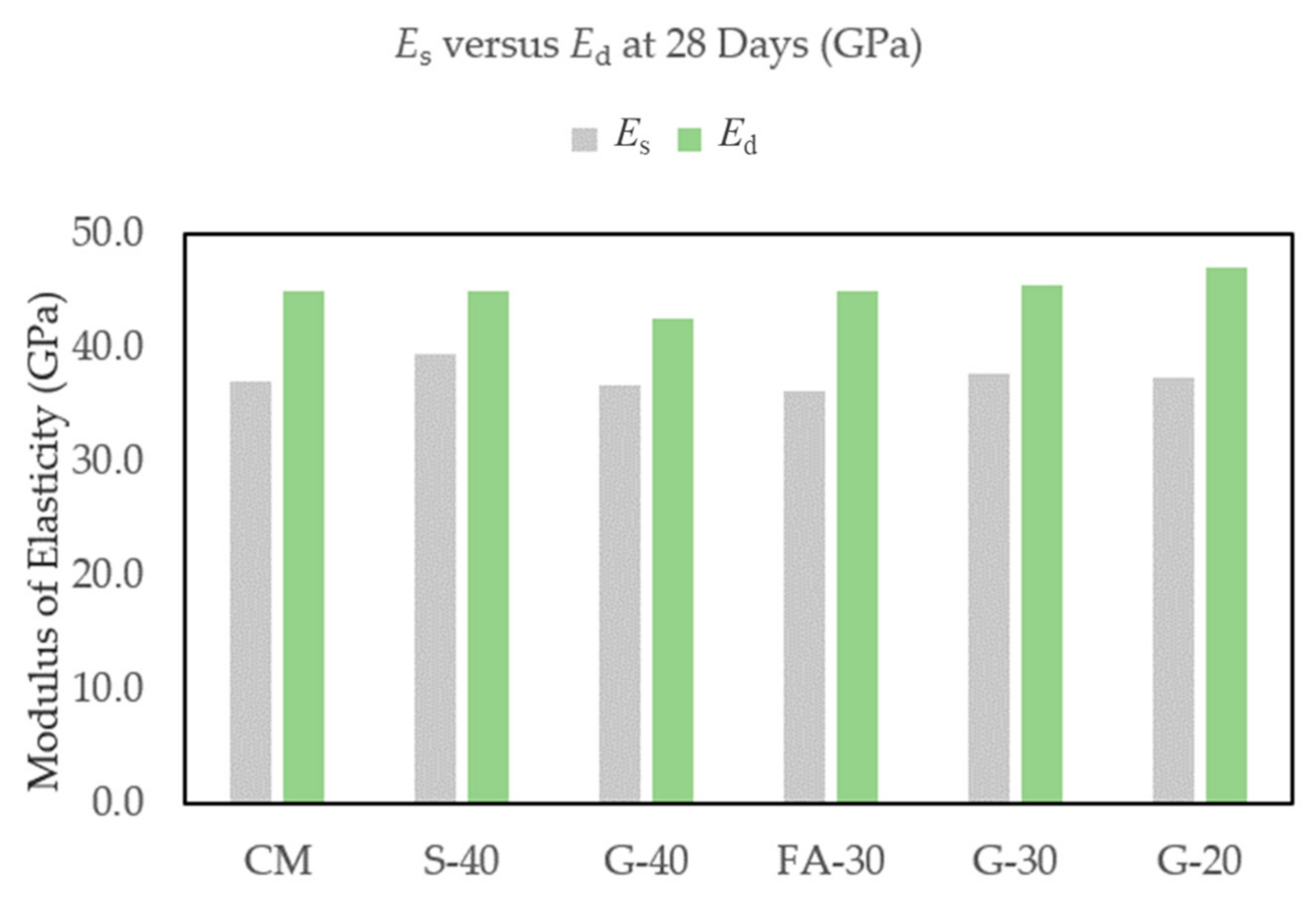

3.1.1. Dynamic Modulus of Elasticity (Ed)

| for Cement 100% | |

| for Slag 40% | |

| for Glass 40% | |

| for Fly Ash 30% | |

| for Glass 30% | |

| for Glass 20% |

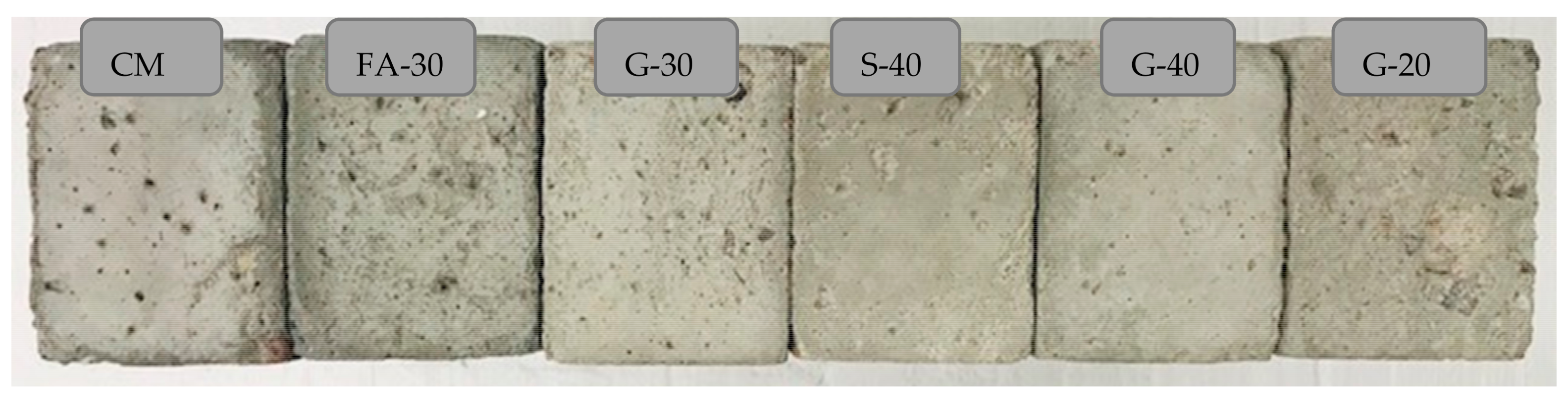

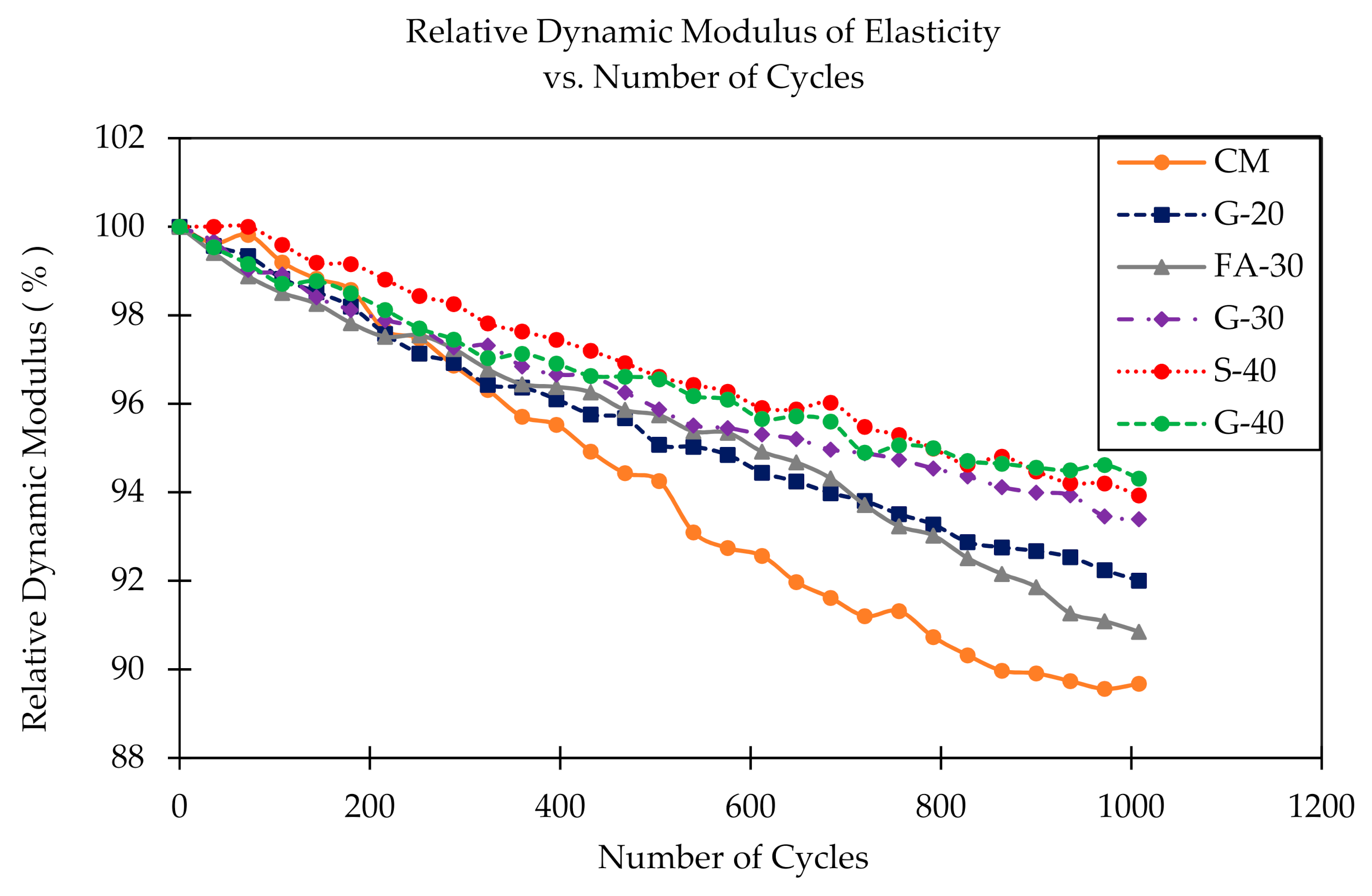

3.1.2. Freeze–Thaw Cycling

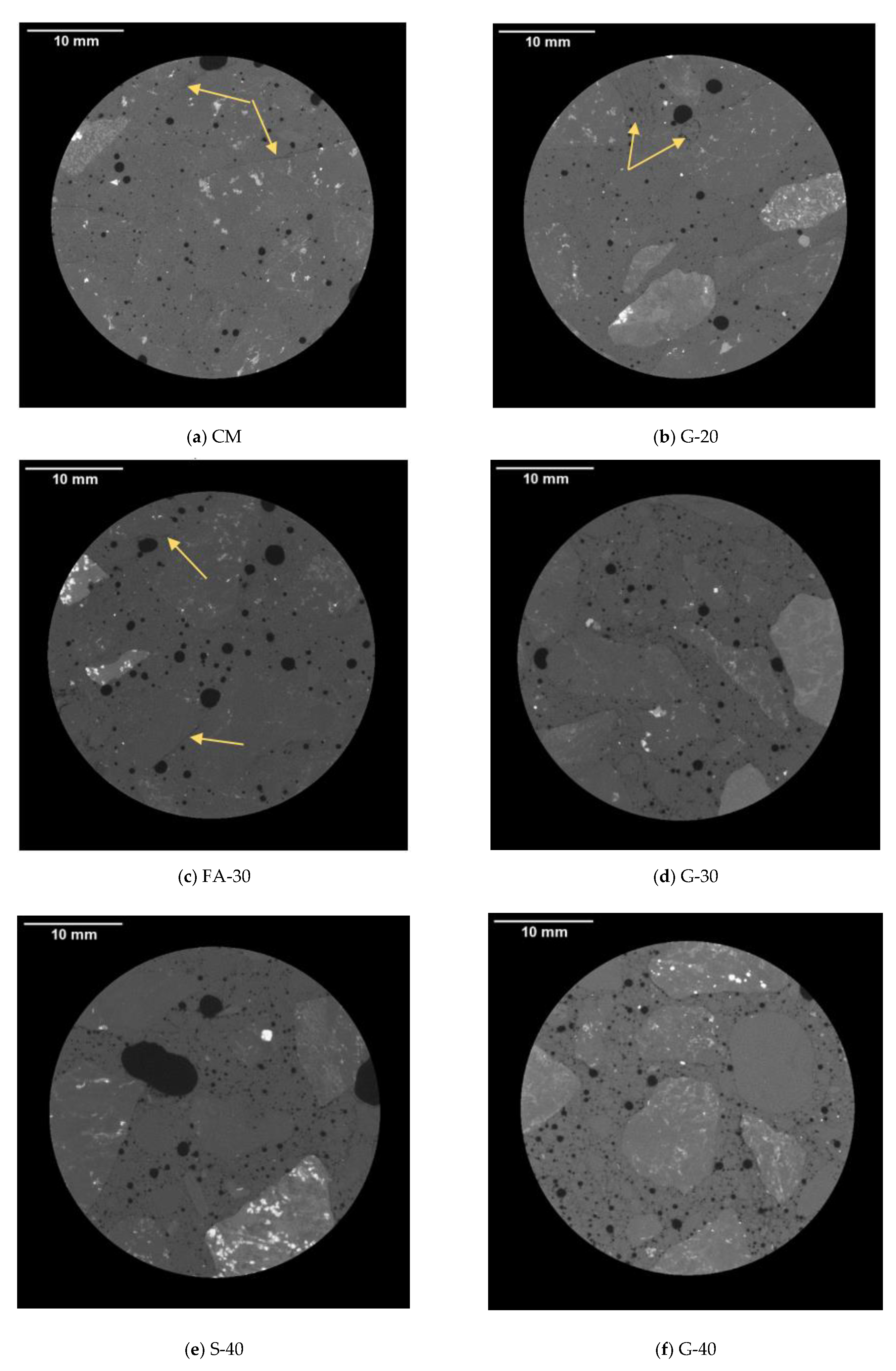

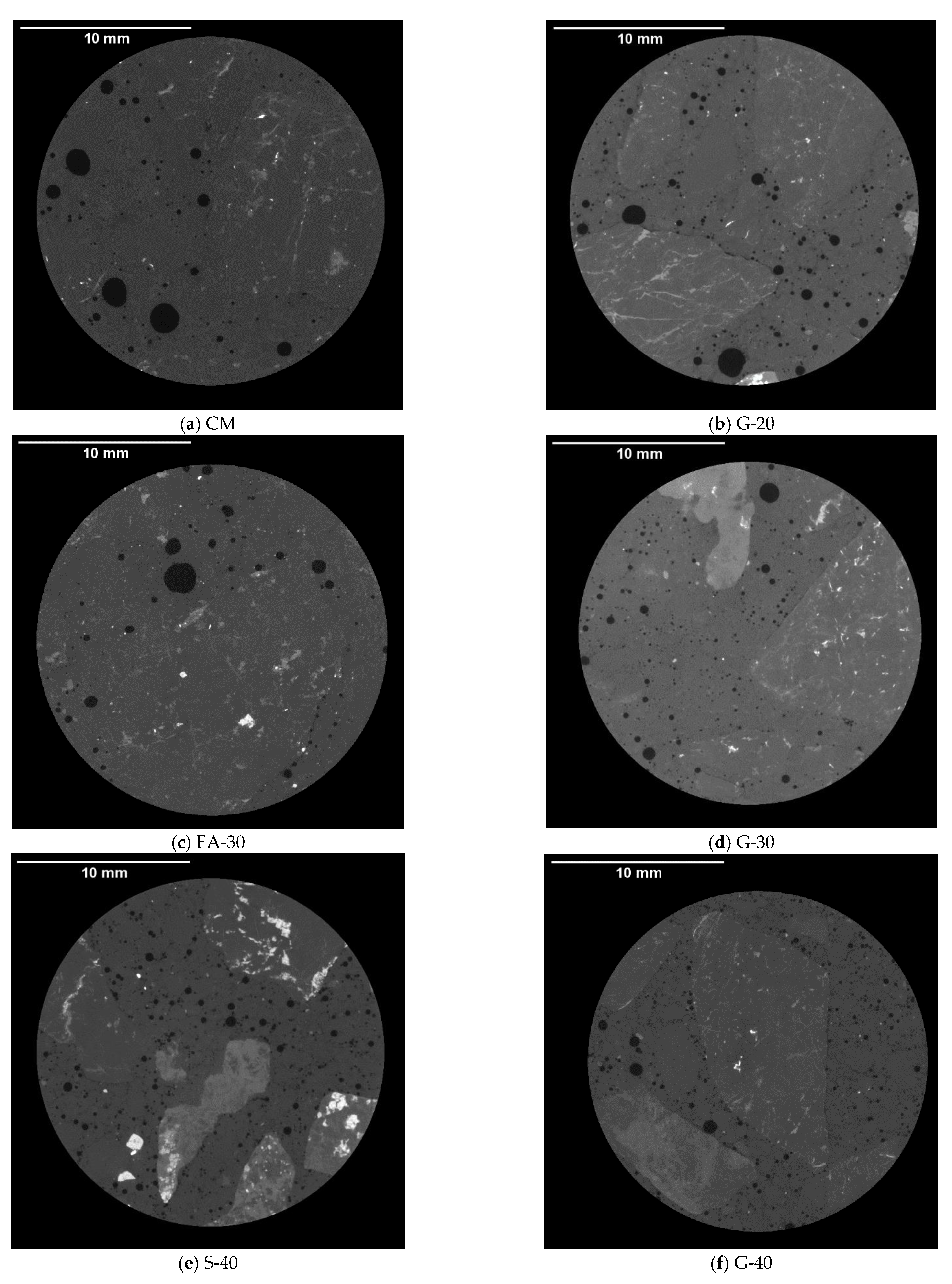

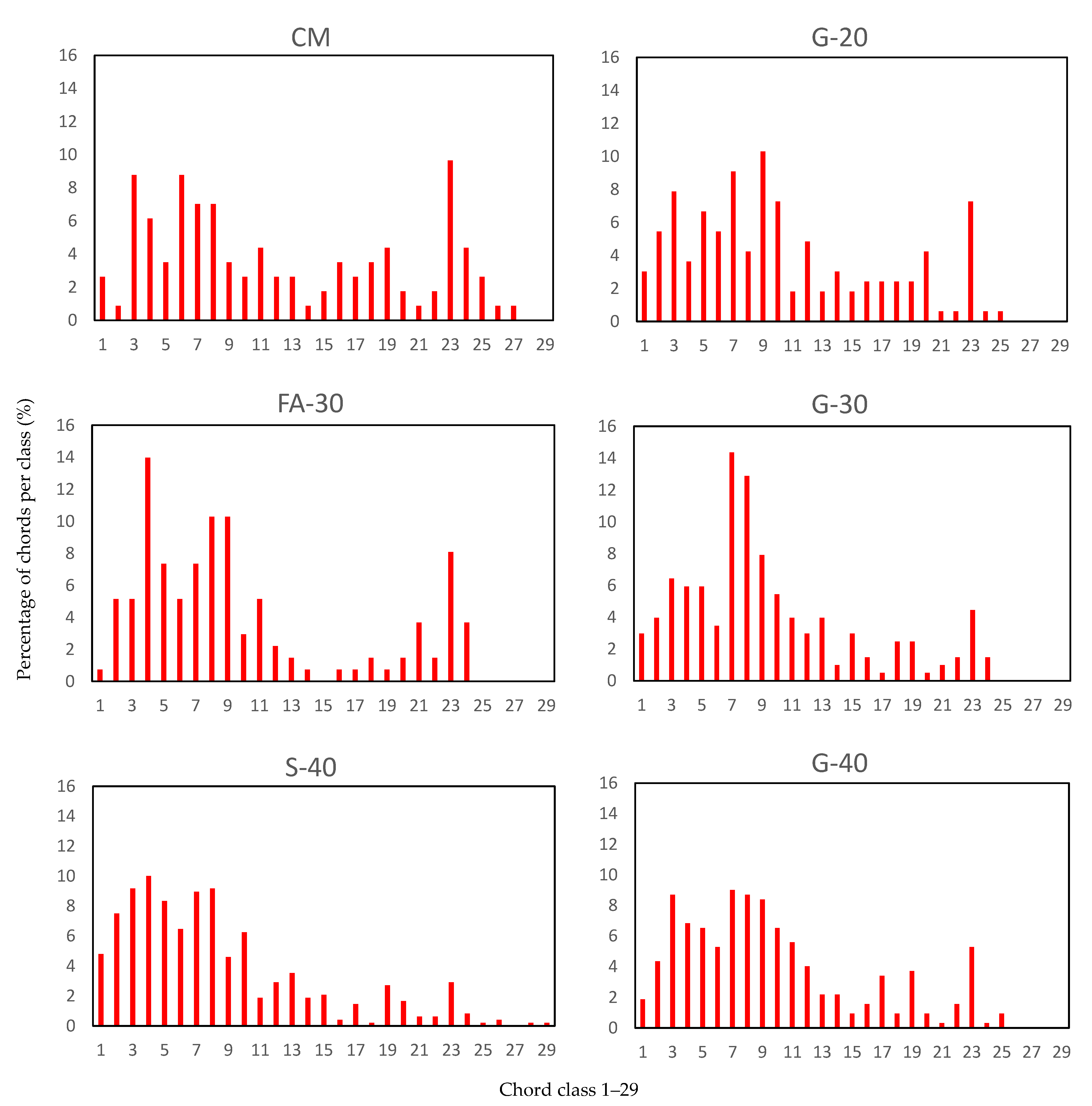

3.1.3. Air Void Analysis of Hardened Concrete Using X-ray Computed Tomography

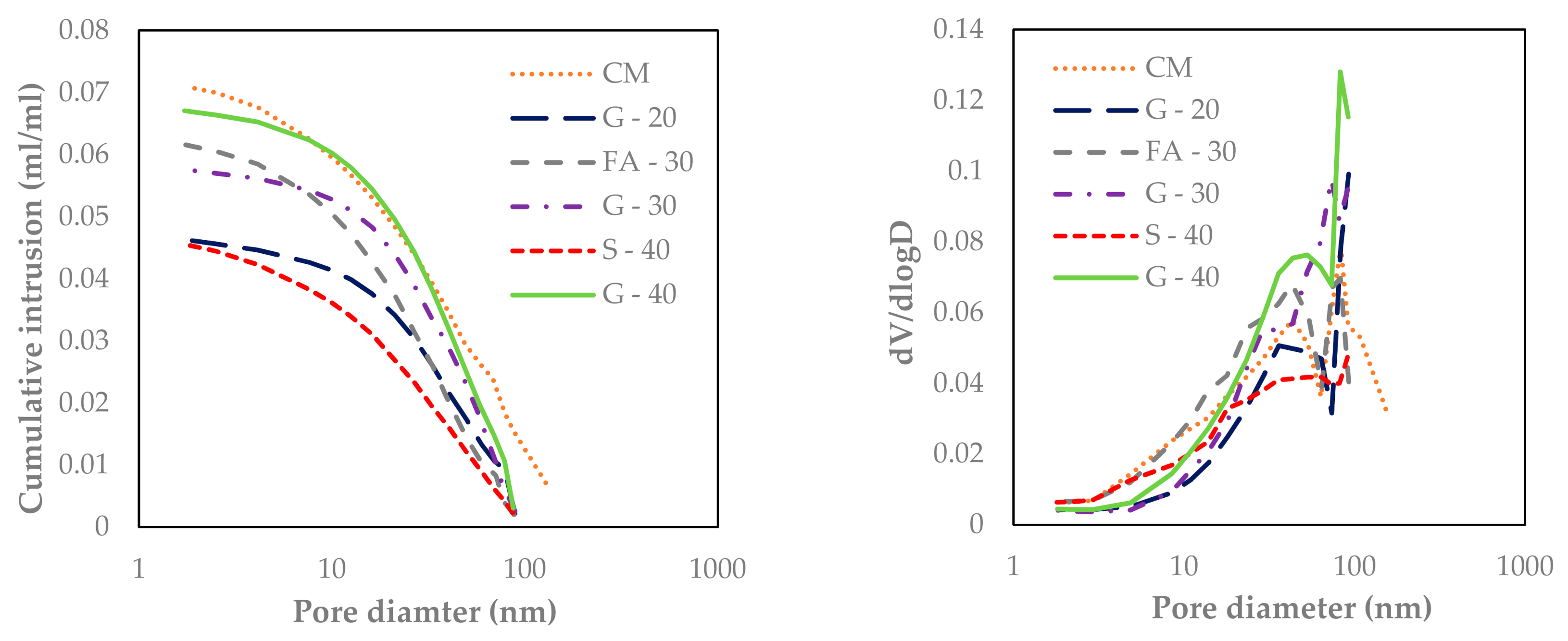

3.1.4. Mercury Intrusion Porosimetry (MIP)

3.1.5. Nitrogen Adsorption

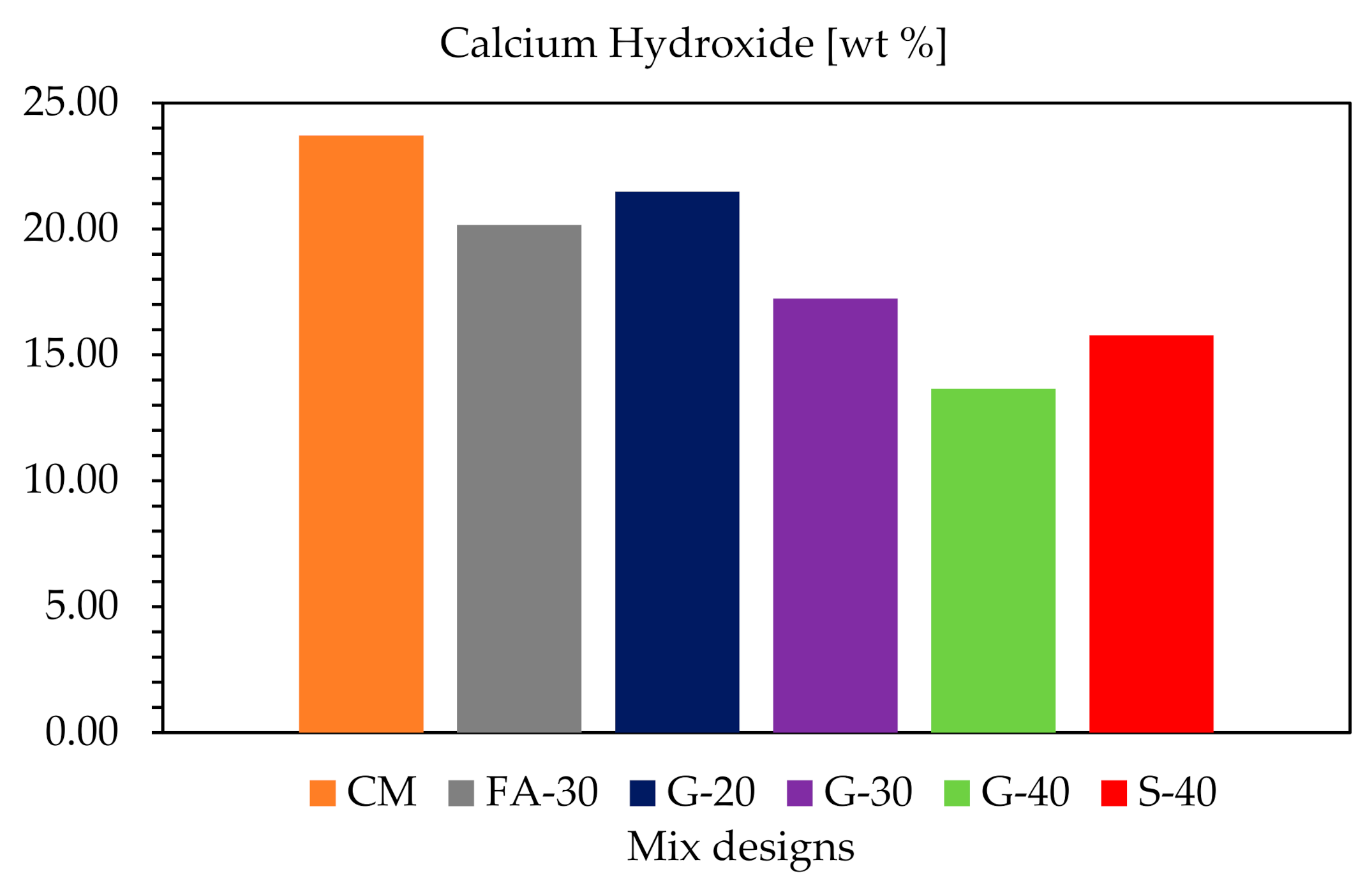

3.1.6. Thermogravimetric Analysis (TGA)

3.2. Discussion

4. Conclusions

- The samples were simultaneously tested for freeze–thaw cycles and dynamic modulus, which decreased continuously up to about 10% at 1000 freeze–thaw cycles, indicating deterioration of the samples.

- A durability factor of above 90%, and mass loss of ~1% for all concretes except for CM (1.6%), indicated improved freeze–thaw resistance with increased of cement replacements by GP, due to its pozzolanic activity, and perhaps consuming more CH for C-S-H formation.

- Using GP as an alternate SCM, serves as nucleation for air bubbles due to its angularity and finer particle size than CM, and consequently its larger specific surface area. Spacing factor decreases and specific surface increases with higher cement replacement by GP, which are favorable for FT resistance.

- Based on MIP and N2, higher replacement of cement by GP results in slightly higher total porosity, but also more refined pore structure. By increasing the GP content, the pore size gets more refined (gel pores and pore size distribution increase).

- Calcium hydroxide (CH) was quantified by TGA. Even though binary systems containing SCMs had less cement content for creating CH, when G-30 was compared to FA-30 and G-40 to S-40, results showed that CH was consumed more in the systems when adding higher contents of GP, leading to C-S-H formation. G-40 showed the least portlandite present at all times, which clearly indicates the pozzolanic reactivity of GP.

- The air void analysis by X-ray micro-tomography coupled with ImageJ can be successfully used to evaluate the microstructure of cementitious materials. It is a nondestructive method, and it can provide 3D information that is especially useful for air void analysis. This method requires minimum sample preparation, unlike the standard method ASTM C457; however, it has a limitation on sample size.

- Micro-cracks after 1000 FT cycles were almost unnoticeable. This implies a good FT resistance which is in agreement with the overall analyses results, and/or it could mean that there were very small cracks which coalesced probably due to self-healing of concrete over time.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Class | From | To |

|---|---|---|

| 1 | 0 | 10 |

| 2 | 15 | 20 |

| 3 | 25 | 30 |

| 4 | 35 | 40 |

| 5 | 45 | 50 |

| 6 | 55 | 60 |

| 7 | 65 | 80 |

| 8 | 85 | 100 |

| 9 | 105 | 120 |

| 10 | 125 | 140 |

| 11 | 145 | 160 |

| 12 | 165 | 180 |

| 13 | 185 | 200 |

| 14 | 205 | 220 |

| 15 | 225 | 240 |

| 16 | 245 | 260 |

| 17 | 265 | 280 |

| 18 | 285 | 300 |

| 19 | 305 | 350 |

| 20 | 355 | 400 |

| 21 | 405 | 450 |

| 22 | 455 | 500 |

| 23 | 505 | 1000 |

| 24 | 1005 | 1500 |

| 25 | 1505 | 2000 |

| 26 | 2005 | 2500 |

| 27 | 2505 | 3000 |

| 28 | 3005 | 4000 |

| 29 | > | 4005 |

References

- Pawlowicz, J. Evaluation of Air Entraining Behaviour in Concrete Using Computer Aided Methods on Hardened Samples. Master’s Thesis, TU Delft University, Delft, The Netherlands, 2019. [Google Scholar]

- Hanjari, K.Z.; Utgenannt, P.; Lundgren, K. Experimental study of the material and bond properties of frost-damaged concrete. Cem. Concr. Res. 2011, 41, 244–254. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Pearson Education Limited: London, UK, 2011; ISBN 978-0-273-75580-7. [Google Scholar]

- Shang HS, S.Y. Experimental study of strength and deformation of plain concrete under biaxial compression after freezing and thawing cycles. Cem. Concr. Res. 2006, 36, 1857–1864. [Google Scholar] [CrossRef]

- Keleştemur, O.; Yildiz, S.; Gökçer, B.; Arici, E. Statistical analysis for freeze-thaw resistance of cement mortars containing marble dust and glass fiber. Mater. Des. 2014, 60, 548–555. [Google Scholar] [CrossRef]

- Gagne, R. Science and Technology of Concrete Admixtures; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 9780081006931. [Google Scholar]

- Whiting, D.; Nagi, M. Control of Air Content in Concrete; Office of Field Services, Department of Commerce: New York, NY, USA, 1998.

- Saucier, F.; Pigeon, M.; Cameron, M. Air-void stability-part V: Temperature, general analysis, and performance index. ACI Mater. J. 1991, 88, 25–36. [Google Scholar]

- Peterson, K.; Sutter, L.; Radlinski, M. The practical of application a flatbed scanner for air-void characterization of hardened concrete. J. ASTM Int. 2009, 6, 1–15. [Google Scholar]

- Peterson, K.W.; Anzalone, G.C.; Nezami, S.; Oh, C.Y.S.; Lu, H. Robust Test of the Flatbed Scanner for Air-Void Characterization in Hardened Concrete. J. Test. Eval. 2016, 44, 20140432. [Google Scholar] [CrossRef]

- ASTM C 457/C 457M-12. Standard Test Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete 1; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Kim, K.Y.; Yun, T.S.; Choo, J.; Kang, D.H.; Shin, H.S. Determination of air-void parameters of hardened cement-based materials using X-ray computed tomography. Constr. Build. Mater. 2012, 37, 93–101. [Google Scholar] [CrossRef]

- Lanzón, M.; Cnudde, V.; De Kock, T.; Dewanckele, J. X-ray microtomography (μ-CT) to evaluate microstructure of mortars containing low density additions. Cem. Concr. Compos. 2012, 34, 993–1000. [Google Scholar] [CrossRef]

- Kosmatka, S.H.; Wilson, M.L. Design and Control of Concrete Mixtures, 15th ed.; Portlan Cement Association: Skokie, IL, USA, 2014; ISBN 978-0-89312-272-0. [Google Scholar]

- Nedeljković, M.; Li, Z.; Ye, G. Setting, strength, and autogenous shrinkage of alkali-activated fly ash and slag pastes: Effect of slag content. Materials (Basel) 2018, 11, 2121. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Chatham House. Making Concrete Change: Innovation in Low-Carbon Cement and Concrete. 2018. Available online: https://www.chathamhouse.org/2018/06/making-concrete-change-innovation-low-carbon-cement-and-concrete (accessed on 28 December 2020).

- U.S. Geological Survey. Cement Statistics and Information. 2018. Available online: http://minerals.usgs.gov/minerals/pubs/commodity/cement/ (accessed on 18 January 2020).

- Kamali, M.; Ghahremaninezhad, A. Effect of glass powders on the mechanical and durability properties of cementitious materials. Constr. Build. Mater. 2015, 98, 407–416. [Google Scholar] [CrossRef]

- Sheikh, V. Limited Availability of Cementitious Materials Could Impact the Value Chain. Appl. Sci. Sustain. Coal Ash 2018, 34–36. [Google Scholar]

- Roston, E.; Migliozzi, B. Obama’s EPA Rule Is Redrawing the U.S. Coal Map. Bloomberg New Energy Finance-US Coal Retirements Database. 2015. Available online: http://www.bloomberg.com/graphics/2015-coal-plants/ (accessed on 18 January 2020).

- Hodge, T. Power Generation from Coal and Natural Gas Expected to Temporarily Converge This Spring. U.S. Energy Information Administration. 2015. Available online: http://www.eia.gov/todayinenergy/detail.cfm?id=21232 (accessed on 18 January 2020).

- Ober, J.E.; U.S. Geological Survey. Mineral Commodity Summaries. 2017. Available online: https://www.usgs.gov/centers/nmic/arsenic-statistics-and-information#mcs (accessed on 18 December 2019).

- Kamali, M.; Ghahremaninezhad, A. An investigation into the hydration and microstructure of cement pastes modified with glass powders. Constr. Build. Mater. 2016, 112, 915–924. [Google Scholar] [CrossRef]

- Kaminsky, A.; Krstic, M.; Rangaraju, P.; Hamou, A.T.; Thomas, M. Ground-Glass Pozzolan for Use in Concrete, Members of ASTM Subcommittee C09.24 summarize industry context behind new ASTM standard specification. Concr. Int. 2020, 42, 24–32. [Google Scholar]

- Shayan, A. Value-added utilization of waste glass in concrete. In Proceedings of the IABSE Symposium, Melbourne, Australia, 11–13 September 2002; pp. 1–11. [Google Scholar]

- Omran, A.; Tagnit-hamou, A. Performance of glass-powder concrete in field applications. Constr. Build. Mater. 2016, 109, 84–95. [Google Scholar] [CrossRef]

- ASTM C33. Standard Specifications for Concrete Aggregates; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM C128. Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Fine Aggregate; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM C127. Standard Test Method for Density, Relative Density (Specific Gravity), and Absorption of Coarse Aggregate; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM C494. Standard Specification for Chemical Admixtures for Concrete; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- NYC. D.D.C. of Standard Highway Specifications Volume I of II; ASTM: West Conshohocken, PA, USA, 2015; Volume I. [Google Scholar]

- ASTM C192. Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory; ASTM: West Conshohocken, PA, USA, 2015; Volume 4.02, pp. 1–8. [Google Scholar]

- ASTM C231. Standard Test Method for Air Content of Freshly Mixed Concrete by the PressureMethod; ASTM: West Conshohocken, PA, USA, 2015; Volume 4.02, pp. 1–9. [Google Scholar]

- ASTM C215. Standard Test Method for Fundamental Transverse, Longitudinal, and Torsional Resonant Frequencies of Concrete Specimens; ASTM: West Conshohocken, PA, USA, 2015; Volume 4.02, pp. 1–7. [Google Scholar]

- ASTM C666. Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing; ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Rueden, C.T.; Schindelin, J.; Hiner, M.C.; DeZonia, B.E.; Walter, A.E.; Arena, E.T.; Eliceiri, K.W. ImageJ2: ImageJ for the next generation of scientific image data. BMC Bioinform. 2017, 18, 1–26. [Google Scholar] [CrossRef]

- BS EN 480-11:2005. Admixtures for Concrete, Mortar and Grout- Test Methods Part 11: Determination of Air Void Characteristics in Hardened Concrete; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- Kaufmann, J. Pore space analysis of cement-based materials by combined Nitrogen sorption-Wood’s metal impregnation and multi-cycle mercury intrusion. Cem. Concr. Compos. 2010, 32, 514–522. [Google Scholar] [CrossRef]

- Zhang, J.; Scherer, G.W. Comparison of methods for arresting hydration of cement. Cem. Concr. Res. 2011, 41, 1024–1036. [Google Scholar] [CrossRef]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cmenetitious Materials; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- YE, G. Experimental Study and Numerical Simulation of the Development of the Microstructure and Permeability of Cementitious Materials. Ph.D. Thesis, TU Delft University, Delft, The Netherlands, 2003. [Google Scholar]

- Diamond, S. Mercury porosimetry. An inappropriate method for the measurement of pore size distributions in cement-based materials. Cem. Concr. Res. 2000, 30, 1517–1525. [Google Scholar] [CrossRef]

- Gerhardt, R. As Review of Conventional and Non-Conventional Pore Characterization Techniques. MRS Proc. 1988, 137, 75. [Google Scholar] [CrossRef]

- Barrett, E.P.; Joyner, L.G.; Halenda, P.P. The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J. Am. Chem. Soc. 1951, 73, 373–380. [Google Scholar] [CrossRef]

- Nassar, R.; Soroushian, P. Strength and durability of recycled aggregate concrete containing milled glass as partial replacement for cement. Constr. Build. Mater. 2012, 29, 368–377. [Google Scholar] [CrossRef]

- Roels, S.; Vandersteen, K.; Carmeliet, J. Measuring and simulating moisture uptake in a fracturedporous medium. Adv. Water Resour. 2003, 26, 237–246. [Google Scholar] [CrossRef]

- Šavija, B.; Luković, M.; Schlangen, E. Influence of cracking on moisture uptake in strain-hardening cementitious composites. J. Nanomech. Micromech. 2017, 7, 1–8. [Google Scholar] [CrossRef]

- Cook, R.A.; Hover, K.C. Mercury porosimetry of hardened cement pastes. Cem. Concr. Res. 1999, 29, 933–943. [Google Scholar] [CrossRef]

- Feldman, F. Pore structure damage in blended cements caused by mercury intrusion. J. Am. Ceram. Soc. 1984, 67, 30–33. [Google Scholar] [CrossRef]

- Yu, Z. Microstructure Development and Transport Properties of Portland Cement-fly Ash Binary Systems. Ph.D. Thesis, TU Delft University, Delft, The Netherlands, 2015. [Google Scholar]

- Hongjian Du and Kiang Hwee Tan Transport Properties of Concrete with Glass Powder as Supplementary Cementitious Material. ACI Mater. J. 2015, 112, 429–438.

- Du, H.; Tan, K.H. Waste glass powder as cement replacement in concrete. J. Adv. Concr. Technol. 2014, 12, 468–477. [Google Scholar] [CrossRef]

- Krstic, M.; Davalos, J.F. Field application of recycled glass pozzolan for concrete. ACI Mater. J. 2019, 116, 123–131. [Google Scholar] [CrossRef]

- Krstic, M. Macro- and Micro-structure Evaluations and Field Applications of Concrete with Recycled Glass. Ph.D. Thesis, The CIty College of New York, CUNY, New York, NY, USA, 2020. [Google Scholar]

- Krstic, M.; Davalos, J.F. Macro-and Micro-structure Evaluations of Recycled Post-consumer Glass Cementitious Material for Concrete. In Proceedings of the Interdisciplinary Approaches for Cement-Based Materials and Structural Concrete: Synergizing Expertise and Bridging Scales of Space and Time; Miguel, A., Dirk Schlicke, F.B., Jędrzejewska, A., Eds.; RILEM Publications: Madeira Island, Portugal, 2018; pp. 261–266. [Google Scholar]

| Chemical Composition | Glass Pozzolan (GP) | Fly Ash Class F (FA) | Slag (S) | Portland Cement (PC) |

|---|---|---|---|---|

| SiO2, % | 72.5 | 47.58 | 38.00 | 20.2 |

| Na2O, % | 13.7 | 1.5 | 0.32 | 0.19 |

| CaO, % | 9.7 | 5.54 | 39.84 | 61.9 |

| Al2O3, % | 0.4 | 26.42 | 7.52 | 4.7 |

| MgO, % | 3.3 | 0.9 | 10.54 | 2.6 |

| K2O, % | 0.1 | 1.9 | 0.38 | 0.82 |

| Fe2O3, % | 0.2 | 12.19 | 0.31 | 3.0 |

| SO3, % | 0.1 | 1.08 | 0.16 | 3.9 |

| Total alkalis Na2O + 0.658K2O, % | 13.77 | 2.75 | 0.6 | 0.73 |

| LOI, % | 0.4 | 2.5 | 1.2 | 1.5 |

| Physical Properties | Portland Cement | Glass Pozzolan | Fly Ash Class F | Slag |

|---|---|---|---|---|

| % Passing #325 Mesh % | 90.00 | 100 | 81.50 | 99 |

| Specific Gravity | 3.15 | 2.46 | 2.52 | 3 |

| Median Particle Size (micron) | 14 | 10 | 15 | 11 |

| Strength Activity Index, 28d, % | - | 102 | - | - |

| Water Requirement, % of Control % | - | 97 | - | - |

| Soundness % | - | 0.05 | - | - |

| Moisture Content % | - | 0.10 | - | - |

| Brightness % | - | 80–87 | - | - |

| Specific Area cm2/g | - | 4840 | - | - |

| Ingredients | CM | G-20 | FA-30 | G-30 | S-40 | G-40 |

|---|---|---|---|---|---|---|

| Cement type I/II, kg/m3 | 341 | 273 | 237 | 237 | 205 | 205 |

| Glass pozzolan, kg/m3 | - | 68 | - | 104 | - | 137 |

| Class F fly ash, kg/m3 | - | - | 104 | - | - | - |

| Slag, kg/m3 | - | - | - | - | 137 | - |

| Coarse aggregate kg/m3 | 1196 | 1193 | 1171 | 1187 | 1196 | 1187 |

| Fine aggregate, kg/m3 | 640 | 631 | 631 | 631 | 632 | 630 |

| Water content, kg/m3 | 138.2 | 138.2 | 138.8 | 139.4 | 140 | 140.6 |

| Water-reducing admixture, ml/m3 | 660 | 695 | 735 | 775 | 815 | 850 |

| Air-entraining admixture, ml/m3 | 620 | 660 | 1150 | 735 | 775 | 810 |

| Water-cement ratio (w/c) | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 | 0.41 |

| Slump, in. mm | 115 | 100 | 100 | 100 | 115 | 100 |

| Air content, % | 5.9 | 5.2 | 5.6 | 5.2 | 6.2 | 5.8 |

| Temperature, °C | 24 | 24 | 26 | 23 | 22 | 22 |

| Characterization of Raw Materials | Standard | Specimen | |

|---|---|---|---|

| Particle size distribution | - | powder | |

| X-ray fluorescence | - | powder | |

| Test Methods of Fresh Concrete | |||

| Air content pressure method | ASTM C 231 | - | - |

| Slump | ASTM C 143 | - | - |

| Temperature of fresh concrete | ASTM C 1064 | - | - |

| Test Methods of Hardened Concrete | |||

| Static modulus of elasticity | ASTM C 469 | Cylinder 100 mm × 200 mm | |

| Dynamic modulus of elasticity | ASTM C215 | Prism 75 mm × 100 mm × 405 mm | |

| Freeze–thaw resistance test | ASTM C 666 | Prism 75 mm × 100 mm × 405 mm | |

| Air-void analysis (modified) CT | ASTM C 457 | Cylinder 20 mm × 23 mm | |

| Micro-cracking analysis CT | - | Cylinder 33 mm × 50 mm | |

| Mercury intrusion porosimetry | - | Prism 10 mm × 10 mm × 3 mm | |

| Nitrogen adsorption | - | powder | |

| Thermogravimetric Analysis | - | powder | |

| CM | G-20 | FA-30 | G-30 | S-40 | G-40 | |

|---|---|---|---|---|---|---|

| Durability factor | 0.90 | 0.920 | 0.91 | 0.93 | 0.94 | 0.94 |

| Mass Loss % | 1.58 | 0.75 | 1.01 | 0.6 | 0.56 | 0.52 |

| % | CM | G-20 | G-30 | G-40 | S-40 | FA-30 |

|---|---|---|---|---|---|---|

| Air voids-Traverse method | 3.0 | 2.3 | 2.5 | 4.3 | 5.4 | 2.4 |

| Air voids-Threshold | 2.9 | 1.1 | 2.2 | 3.9 | 4.5 | 1.8 |

| Air content-Air-pressure | 5.9 | 5.2 | 5.2 | 5.8 | 6.2 | 5.6 |

| CM | G-20 | G-30 | G-40 | S-40 | FA-30 | |

|---|---|---|---|---|---|---|

| α (1/mm) | 11.9 | 20.7 | 24.2 | 23.8 | 26.2 | 21.3 |

| P (%) | 20.7 | 20.8 | 20.9 | 21.0 | 20.9 | 21.0 |

| A (%) | 3.0 | 2.3 | 2.5 | 4.3 | 5.4 | 2.4 |

| R | 6.9 | 8.9 | 8.4 | 4.9 | 3.9 | 8.8 |

| L (mm) | 0.45 | 0.29 | 0.24 | 0.19 | 0.15 | 0.28 |

| CM | G-20 | FA-30 | G-30 | S-40 | G-40 | |

|---|---|---|---|---|---|---|

| Bulk density (%) | 1.79 | 1.66 | 1.74 | 1.64 | 1.73 | 1.55 |

| Total Porosity (%) | 17.8 | 19.1 | 17.6 | 18.5 | 13.9 | 21.3 |

| Ink-Bottle Porosity (%) | 11.7 | 12.8 | 10.3 | 11.9 | 9.8 | 13.9 |

| Effective Porosity (%) | 6.1 | 6.3 | 7.4 | 6.6 | 4.1 | 7.4 |

| Critical Pore Diameter (µm) | 0.0465 | 0.0465 | 0.035 | 0.043 | 0.0433 | 0.0435 |

| Pore Connectivity (%) | 34.4 | 33.0 | 41.7 | 35.7 | 29.6 | 34.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krstic, M.; Davalos, J.F.; Rossi, E.; Figueiredo, S.C.; Copuroglu, O. Freeze–Thaw Resistance and Air-Void Analysis of Concrete with Recycled Glass–Pozzolan Using X-ray Micro-Tomography. Materials 2021, 14, 154. https://doi.org/10.3390/ma14010154

Krstic M, Davalos JF, Rossi E, Figueiredo SC, Copuroglu O. Freeze–Thaw Resistance and Air-Void Analysis of Concrete with Recycled Glass–Pozzolan Using X-ray Micro-Tomography. Materials. 2021; 14(1):154. https://doi.org/10.3390/ma14010154

Chicago/Turabian StyleKrstic, Marija, Julio F. Davalos, Emanuele Rossi, Stefan C. Figueiredo, and Oguzhan Copuroglu. 2021. "Freeze–Thaw Resistance and Air-Void Analysis of Concrete with Recycled Glass–Pozzolan Using X-ray Micro-Tomography" Materials 14, no. 1: 154. https://doi.org/10.3390/ma14010154

APA StyleKrstic, M., Davalos, J. F., Rossi, E., Figueiredo, S. C., & Copuroglu, O. (2021). Freeze–Thaw Resistance and Air-Void Analysis of Concrete with Recycled Glass–Pozzolan Using X-ray Micro-Tomography. Materials, 14(1), 154. https://doi.org/10.3390/ma14010154