Influence of Restrained Condition on Mechanical Properties, Frost Resistance, and Carbonation Resistance of Expansive Concrete

Abstract

1. Introduction

2. Experimental Program

2.1. Experimental Materials and Mix Proportions

2.2. Test Methods

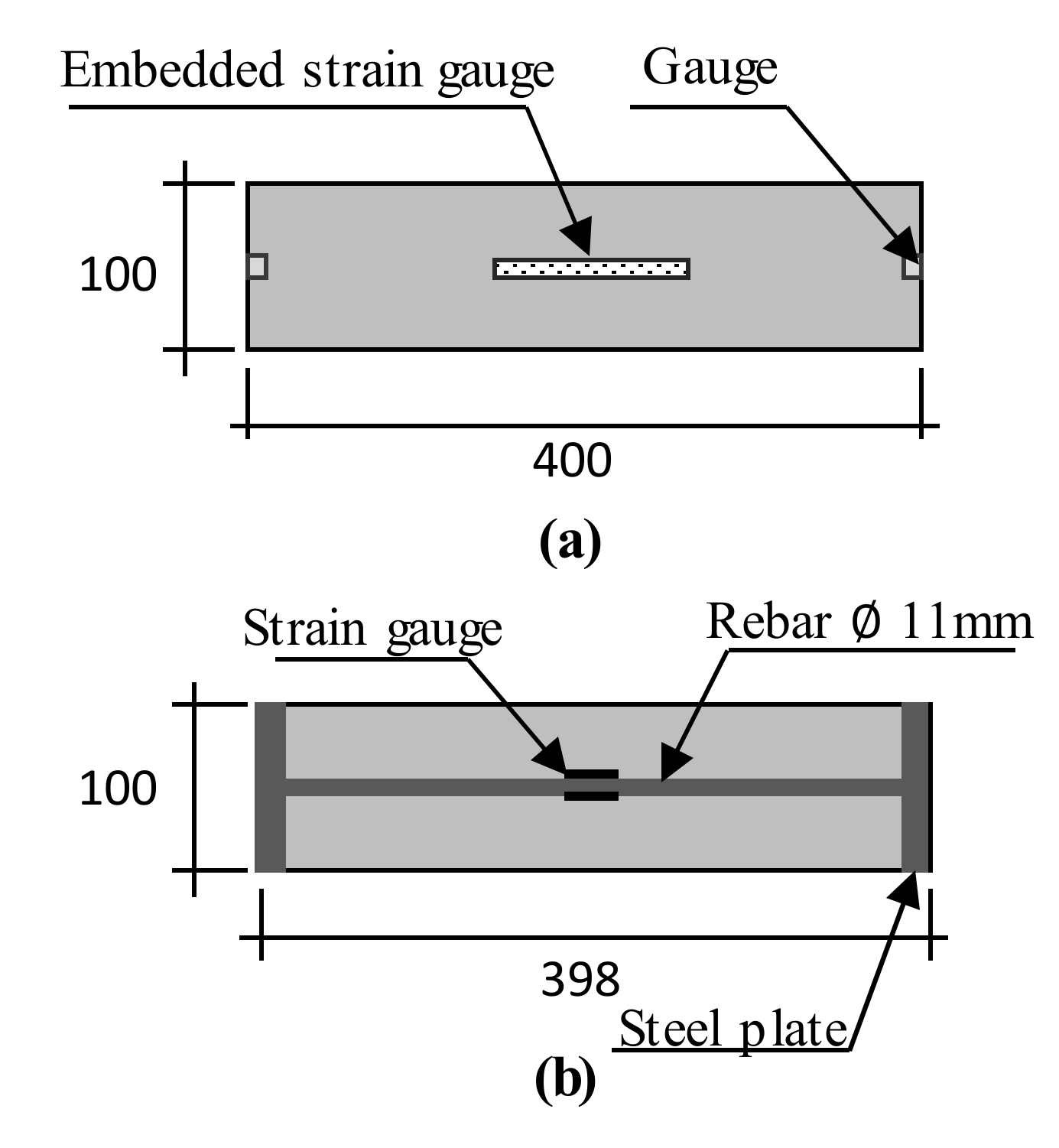

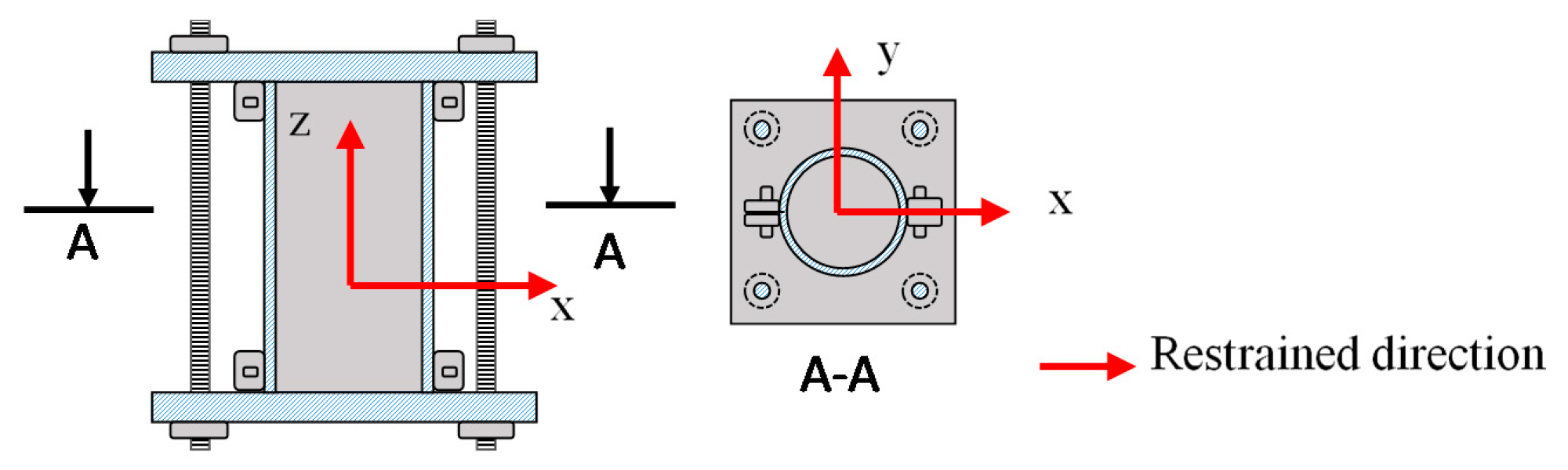

2.2.1. Length Change Ratio and Expansion Strain Tests

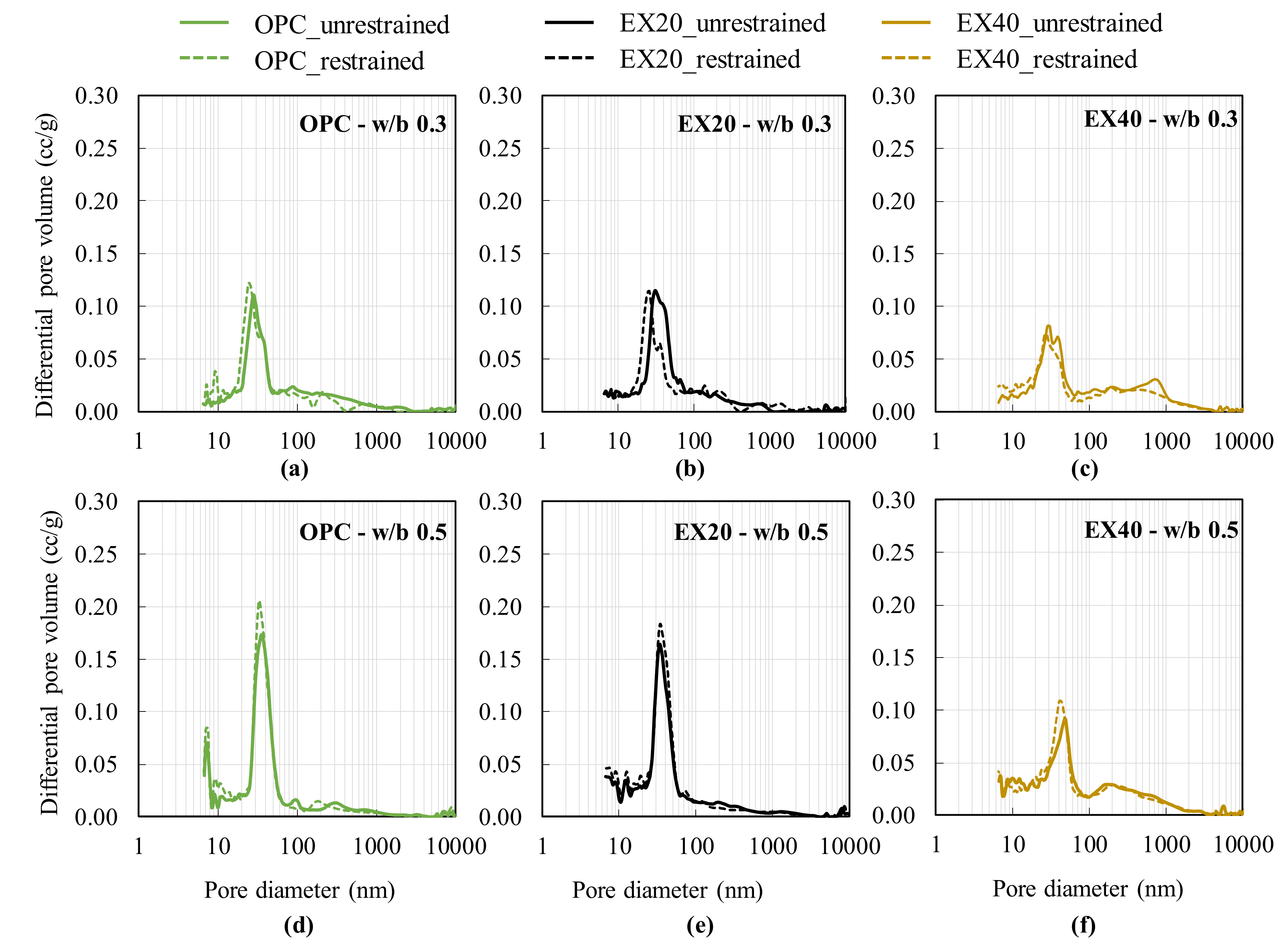

2.2.2. Mercury Intrusion Porosimetry Test

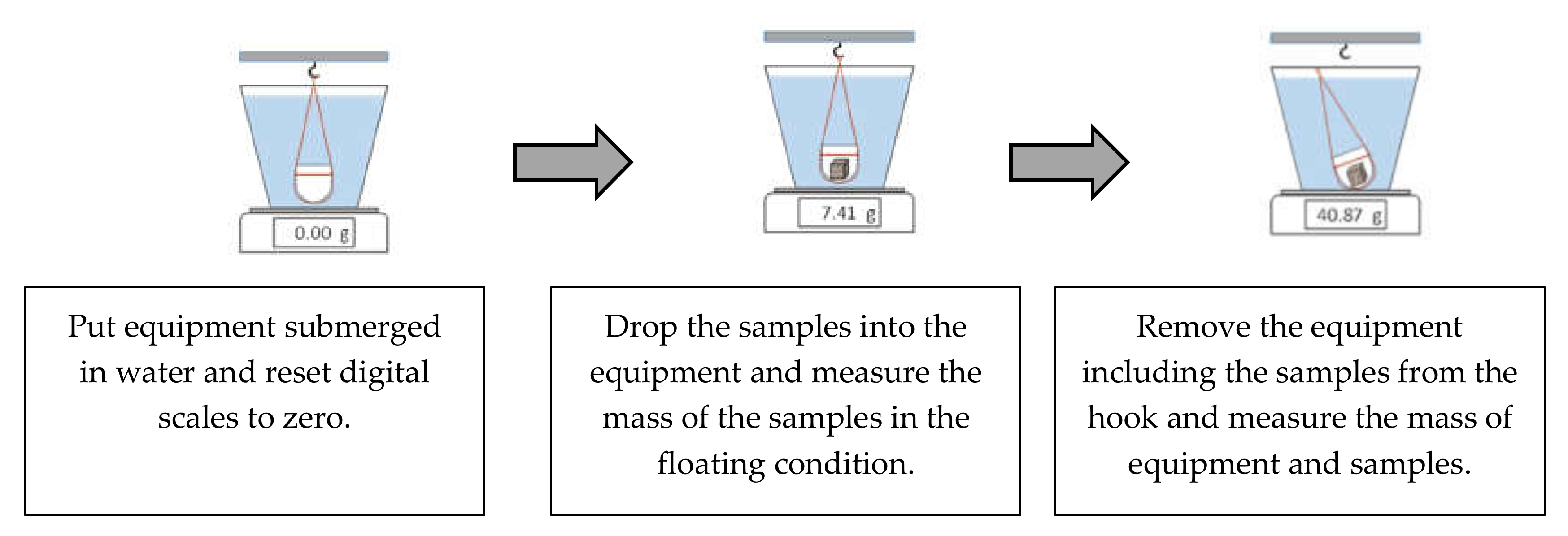

2.2.3. Underwater Weighing Test

2.2.4. Compressive Strength Test

2.2.5. Freeze–thaw Test

2.2.6. Accelerated Carbonation Test

3. Results and Discussion

3.1. Fresh Concrete

3.2. Length Change Ratio and Expansion

3.3. Pore Structure

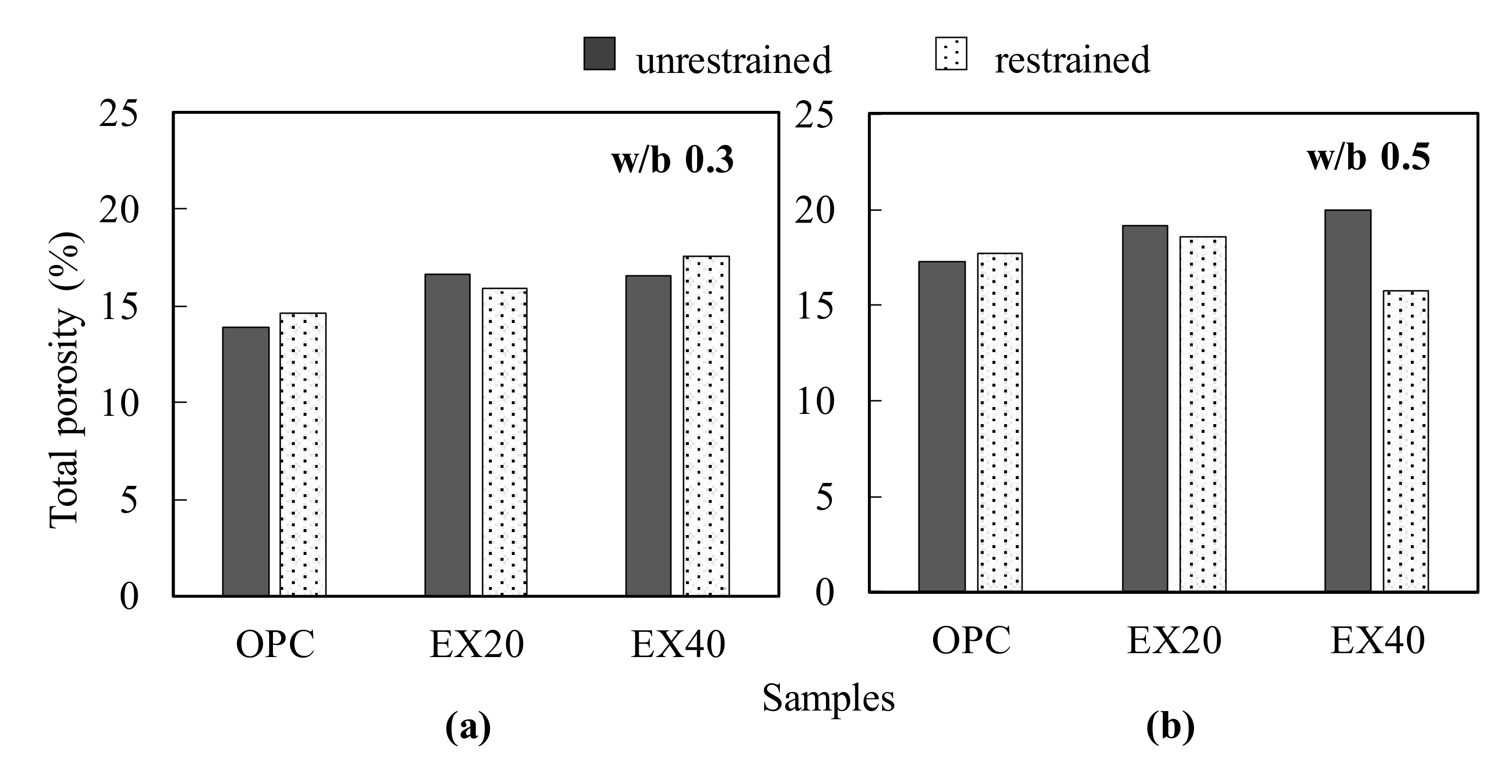

3.4. Total Porosity

3.5. Compressive Strength of Concrete

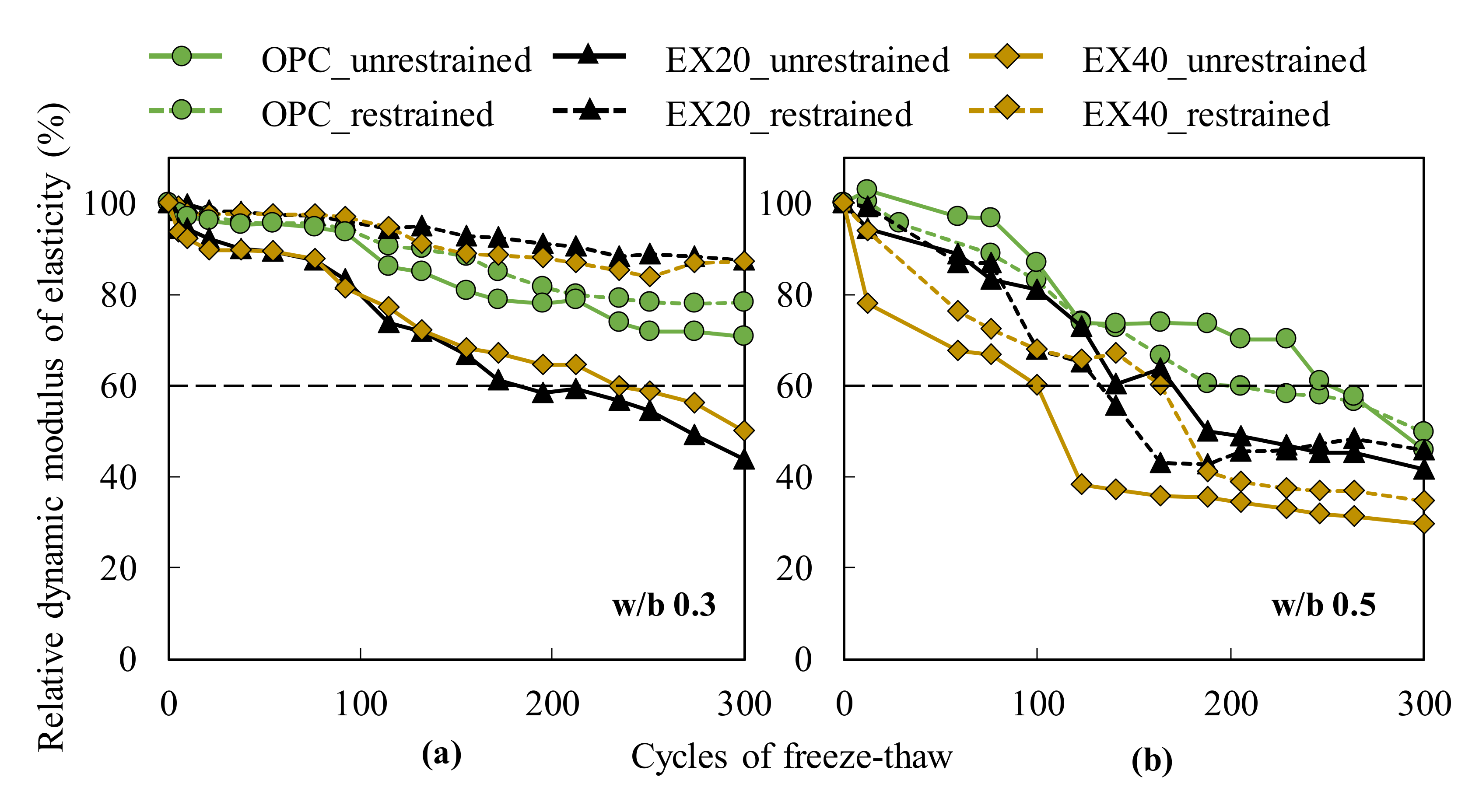

3.6. Frost Resistance of Concrete

3.7. Carbonation Depth of Concrete

4. Conclusions

- (1)

- The length change ratio and expansion strain of concrete with and without an expansive additive were controlled by the restrained condition.

- (2)

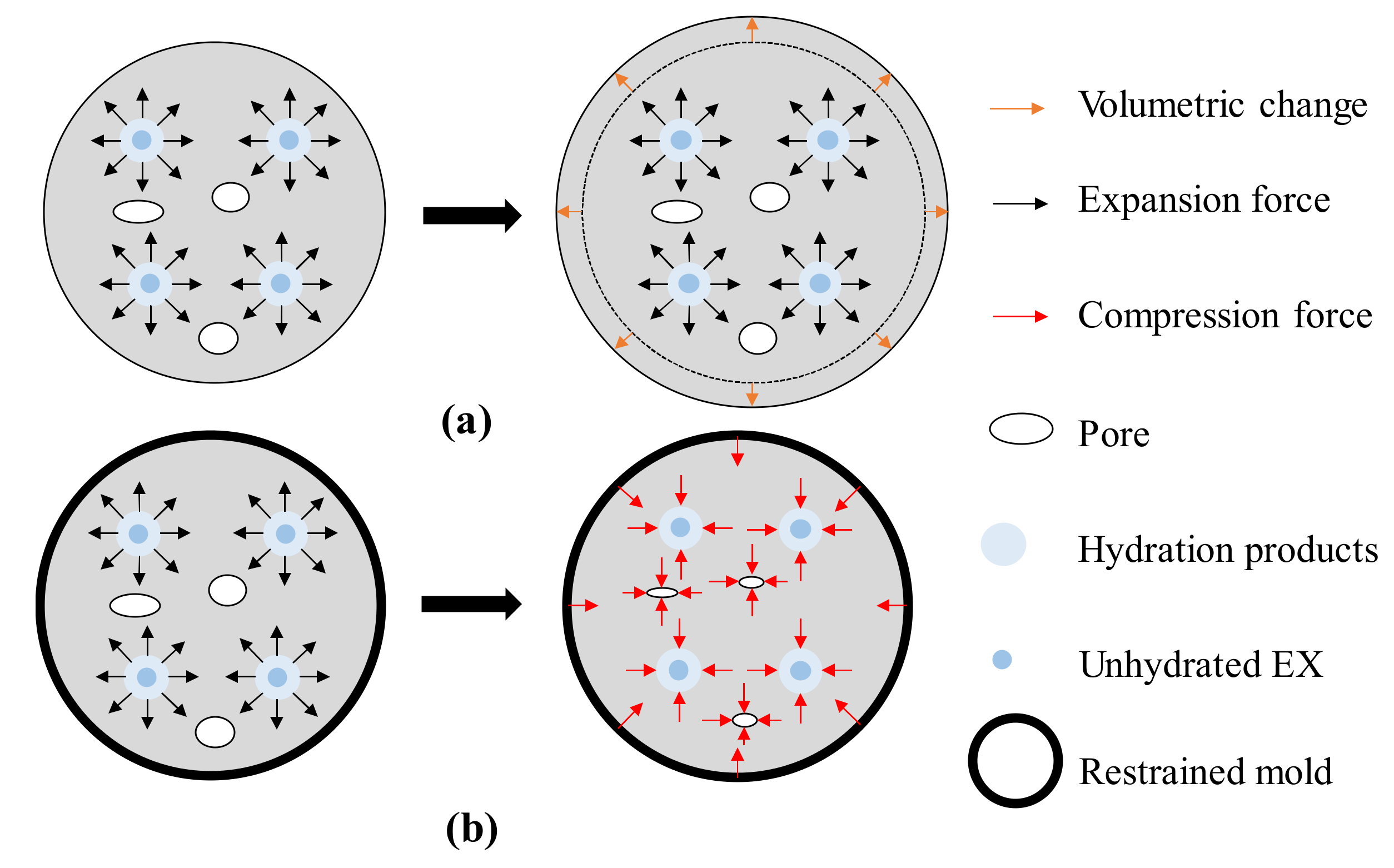

- Under the restrained condition, the pore size distribution of the expansive mortar shifted to a smaller size, which can be explained by two hypotheses. First, the microspore in the cement–expansive paste is filled with crystal ettringite. Second, the effect of chemical stress is caused by the expansive additive hydration.

- (3)

- The total porosity of the expansive concrete was decreased by the restraining when the amount of EX was 40 kg/m3 of concrete at a w/b ratio of 0.5. The compressive strength of the restrained concrete was 12% higher than that of the unrestrained concrete at 28 days.

- (4)

- The enhanced frost resistance of the expansive concrete was clearly observed at the w/b ratio of 0.3. However, at the w/b ratio of 0.5, the frost resistance of the expansive concrete was enhanced by restraining for EX40.

- (5)

- The concrete carbonation depth was not observed at the w/b ratio of 0.3. For the w/b of 0.5, the carbonation resistance of the expansive concrete was improved by restraining.

- (6)

- It is essential considering the effect of the restrained conditions in evaluating the various experimental results of the expansive concrete with a large expansive additive dosage (i.e., over 20 kg/m3 concrete) or concrete combining EX with other cement replacement materials (e.g., fly ash and blast furnace slag).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lam, N.T.; Sahamitmongkol, R.; Tangtermsirikul, S. Expansion and compressive strength of concrete with expansive additive. Res. Dev. J. 2008, 19, 40–49. [Google Scholar]

- Nguyen, T.B.T.; Chatchawan, R.; Saengsoy, W.; Tangtermsirikul, S.; Sugiyama, T. Influences of different types of fly ash and confinement on performances of expansive mortars and concretes. Constr. Build. Mater. 2019, 209, 176–186. [Google Scholar] [CrossRef]

- ACI Committee 223. Expansive cement concretes-Present state of knowledge. Aci J. 1970, 67, 583–610. [Google Scholar]

- Japanese Industrial Standard Committee. Expansive Additive for Concrete (Amendment 1); JIS A 6202; Japanese Standards Association: Tokyo, Japan, 2008. [Google Scholar]

- Sidney, M.L. Section 5-Calculations relating to concrete and masonry. In Construction Calculations Manual, 1st ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2012; pp. 211–264. [Google Scholar]

- Tsuji, Y.; Maruyama, H. A fundamental study on effect of restraint method on mechanical properties of expansive concrete. Annu. Conf. Concr. Eng. 1984, 86, 341–344. [Google Scholar]

- Harada, A. Influence of reinforcement restraint on the length change and frost damage during freezing-thawing action in structural concrete. Master Thesis, Muroran Institute of Technology, Hokkaido, Japan, March 2011. [Google Scholar]

- Lobo, C.; Cohen, M.D. Pore structure development in type K expansive cement pastes. Cem. Concr. Res. 1991, 21, 229–241. [Google Scholar] [CrossRef]

- Japanese Industrial Standard Committee. Methods Measurement for Length Change of Mortar and Concrete-Part 3: Method with Dial Gauge; JIS A 1129; Japanese Standards Association: Tokyo, Japan, 2010. [Google Scholar]

- Shen, J.; Xu, Q. Effect of moisture content and porosity on compressive strength of concrete during drying at 105 °C. Constr. Build. Mater. 2019, 195, 19–27. [Google Scholar] [CrossRef]

- Beaudoin, J.J. Porosity measurement of some hydrated cementitious systems by high pressure mercury intrusion-microstructural limitations. Cem. Concr. Res. 1979, 9, 771–781. [Google Scholar] [CrossRef]

- Marchand, J.; Hornain, H.; Diamond, S.; Pigeon, M.; Guiraud, H. The microstructure of dry concrete products. Cem. Concr. Res. 1996, 26, 427–438. [Google Scholar] [CrossRef]

- Aligizaki, K.K. Pore Structure of Cement-Based Material: Testing, Interpretation and Requirements, 1st ed.; CRC Press: Cleveland, OH, USA; Taylor & Francis, American: Milton Park, USA, 2005. [Google Scholar]

- Japanese Industrial Standard Committee. Method of Test for Compressive Strength of Concrete; JIS A 1108; Japanese Standards Association: Tokyo, Japan, 2018. [Google Scholar]

- Japanese Industrial Standard Committee. Method of Test for Resistance of Concrete of Freezing and Thawing; JIS A 1148; Japanese Standards Association: Tokyo, Japan, 2010. [Google Scholar]

- Japanese Industrial Standard Committee. Method of Accelerated Carbonation Test for Concrete; JIS A 1153; Japanese Standards Association: Tokyo, Japan, 2012. [Google Scholar]

- Japanese Industrial Standard Committee. Method of Test for Slump of Concrete; JIS A 1101; Japanese Standards Association: Tokyo, Japan, 2005. [Google Scholar]

- Japanese Industrial Standard Committee. Method of Test for Slump Flow of Concrete; JIS A 1150; Japanese Standards Association: Tokyo, Japan, 2007. [Google Scholar]

- Japanese Industrial Standard Committee. Method of Test for Air Content of Fresh Concrete by Pressure Method; JIS A 1128; Japanese Standards Association: Tokyo, Japan, 2019. [Google Scholar]

- Tsujino, M.; Yuasa, R.; Hashida, H. Method of test for restrained expansion of expansive concrete using a cylindrical mold. Conc. J. 2014, 52, 519–527. [Google Scholar] [CrossRef]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials, 1st ed.; CRC Press: Boca Raton, CA, USA, 2016. [Google Scholar]

- Van, N.D.; Choi, H.; Hama, Y. Modeling early age hydration reaction and predicting compressive strength of cement paste mixed with expansive additive. Constr. Build. Mater. 2019, 223, 994–1007. [Google Scholar] [CrossRef]

- Choi, H.; Noguchi, T. Modeling of Mechanical Properties of Concrete Mixed with Expansive Additive, Inter. J. Concr. Struc. Mater. 2015, 9, 391–399. [Google Scholar] [CrossRef]

- Kim, Y.Y.; Lee, K.M.; Bang, J.W.; Kwon, S.J. Effect of w/c ratio on durability and porosity in cement mortar with constant cement amount. Ad. Mater. Sci. Eng. 2014, 2014, 273460. [Google Scholar] [CrossRef]

- Nagataki, S.; Gomi, H. Expansive admixtures (mainly ettringite). Cem. Concr. Com. 1998, 20, 163–170. [Google Scholar] [CrossRef]

- Makoto, S.; Kentoro, S.; Yoshihiko, H.; Ryoetsu, Y. Frost Resistance of Expansive Concrete. In Proceedings of the 67th Annual Academic Lecture Meeting of the Japan Society of Civil Engineers, Nagoya, Japan, 5–7 September 2012; Japan Society of Civil Engineers: Nagoya, Japan (In Japanese). [Google Scholar]

- Singh, N.; Singh, S.P. Reviewing the Carbonation Resistance of Concrete. J. Mater. Eng. Struc. 2016, 3, 35–57. [Google Scholar]

| Materials | Symbol | Properties |

|---|---|---|

| Ordinary Portland cement | C | Density: 3.15 g/cm3; Specific surface area: 3490 cm2/g |

| Expansive additive | EX | Ettringite-gypsum type; Density: 3.05 g/cm3; Specific surface area: 3260 cm2/g |

| Coarse aggregate | G | Density: 2.68 g/cm3; Absorption: 2.17% |

| Fine aggregate | S | Density: 2.68 g/cm3; Absorption: 1.78% |

| Water | W | Tap water |

| Admixtures | Ads | w/b 0.5: AE water-reducing agent (Master Pozzolith No. 70) w/b 0.3: High-performance water-reducing agents (SP8SV) and AE agent (Master air 101) |

| Series | Symbol | w/b | Unit Weight, kg/m3 | Ads | ||||

|---|---|---|---|---|---|---|---|---|

| W | C | EX | S | A | ||||

| Series 1 | OPC | 0.3 | 175 | 583 | − | 616 | 981 | SP8SV (B × 1.2%) Master air 101 (B × 0.001%) |

| EX20 | 563 | 20 | ||||||

| EX40 | 543 | 40 | ||||||

| Series 2 | OPC | 0.5 | 185 | 370 | − | 855 | 959 | No. 70 (250 mL/B = 100 kg) |

| EX20 | 350 | 20 | ||||||

| EX40 | 330 | 40 | ||||||

| Series | Sample | w/b | Slump (cm) | Flow (cm) | Air Content (%) | |

|---|---|---|---|---|---|---|

| Series 1 | OPC | 0.3 | − | 66 | 4.7 | 19.5 |

| EX20 | − | 65.5 | 5.5 | 19.5 | ||

| EX40 | − | 66 | 5.8 | 20 | ||

| Series 2 | OPC | 0.5 | 20 | − | 4.8 | 15.0 |

| EX20 | 19.4 | − | 4.9 | 15.5 | ||

| EX40 | 19.5 | − | 4.9 | 16.2 |

| Sample | w/b 0.3 | w/b 0.5 | ||

|---|---|---|---|---|

| Unrestrained | Restrained | Unrestrained | Restrained | |

| OPC | 28.11 | 24.28 | 35.95 | 33.28 |

| EX20 | 30.77 | 26.05 | 33.89 | 33.89 |

| EX40 | 28.26 | 26.24 | 48.38 | 40.81 |

| Sample | w/b 0.3 | w/b 0.5 | ||

|---|---|---|---|---|

| Unrestrained | Restrained | Unrestrained | Restrained | |

| OPC | 0 | 0 | 1.15 | 0.95 |

| EX20 | 0 | 0 | 2.90 | 1.78 |

| EX40 | 0 | 0 | 3.60 | 2.80 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duc Van, N.; Kuroiwa, E.; Kim, J.; Choi, H.; Hama, Y. Influence of Restrained Condition on Mechanical Properties, Frost Resistance, and Carbonation Resistance of Expansive Concrete. Materials 2020, 13, 2136. https://doi.org/10.3390/ma13092136

Duc Van N, Kuroiwa E, Kim J, Choi H, Hama Y. Influence of Restrained Condition on Mechanical Properties, Frost Resistance, and Carbonation Resistance of Expansive Concrete. Materials. 2020; 13(9):2136. https://doi.org/10.3390/ma13092136

Chicago/Turabian StyleDuc Van, Nguyen, Emika Kuroiwa, Jihoon Kim, Hyeonggil Choi, and Yukio Hama. 2020. "Influence of Restrained Condition on Mechanical Properties, Frost Resistance, and Carbonation Resistance of Expansive Concrete" Materials 13, no. 9: 2136. https://doi.org/10.3390/ma13092136

APA StyleDuc Van, N., Kuroiwa, E., Kim, J., Choi, H., & Hama, Y. (2020). Influence of Restrained Condition on Mechanical Properties, Frost Resistance, and Carbonation Resistance of Expansive Concrete. Materials, 13(9), 2136. https://doi.org/10.3390/ma13092136