Characterizing Micromechanical Properties of Friction Welding Interface between TiAl Alloy and GH3039 Superalloy

Abstract

1. Introduction

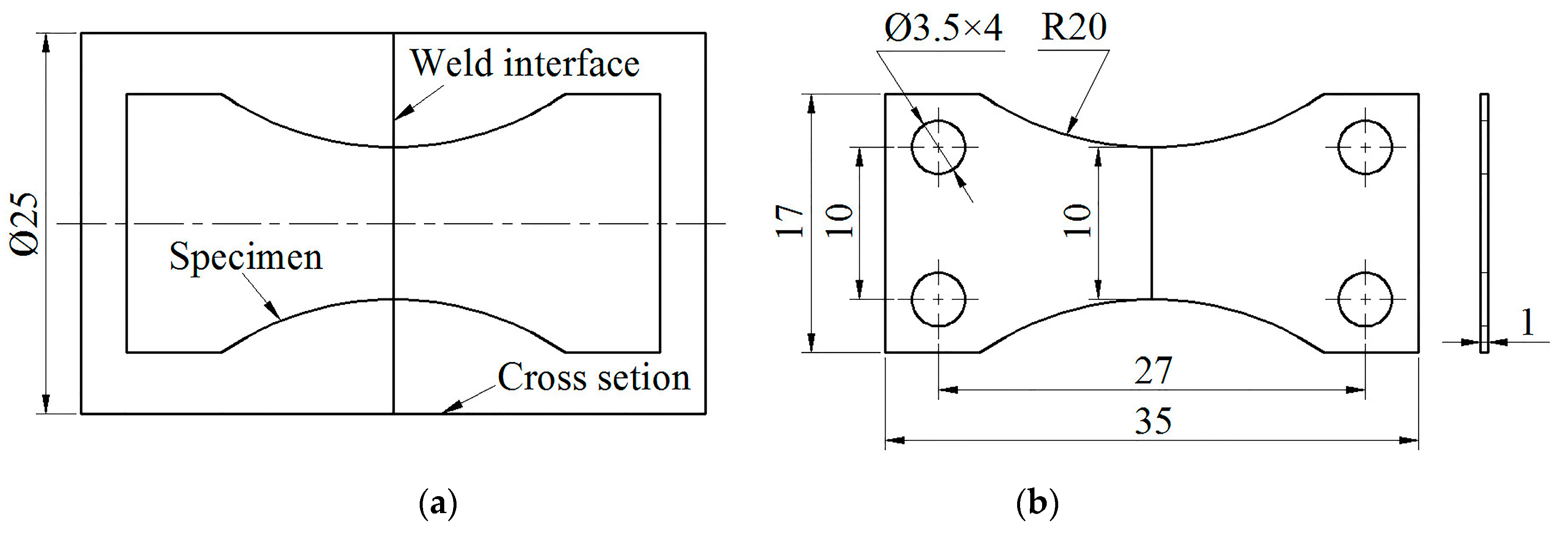

2. Experimental Procedures

2.1. Materials and Process

2.2. Characterization Methods

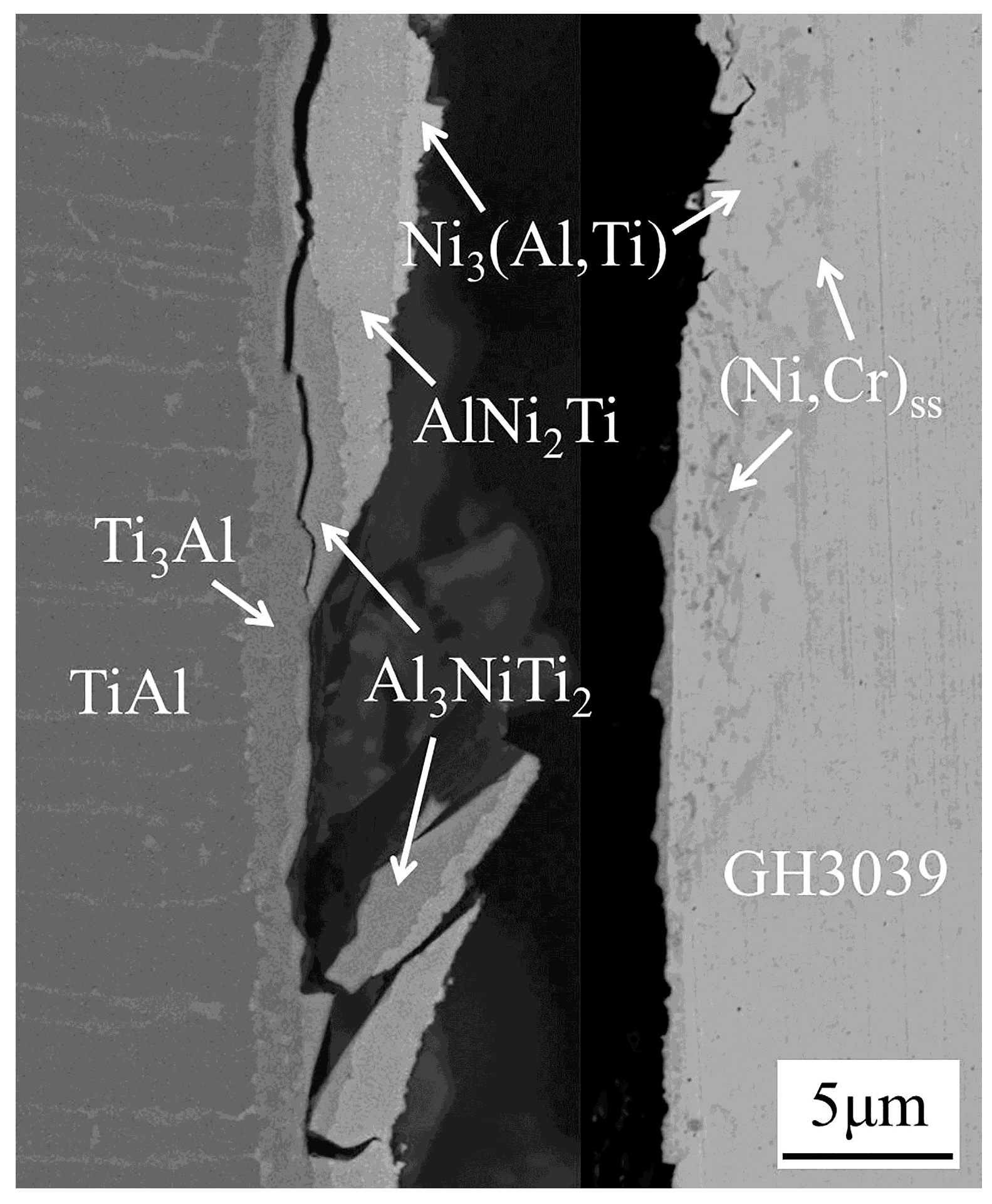

3. Results and Discussion

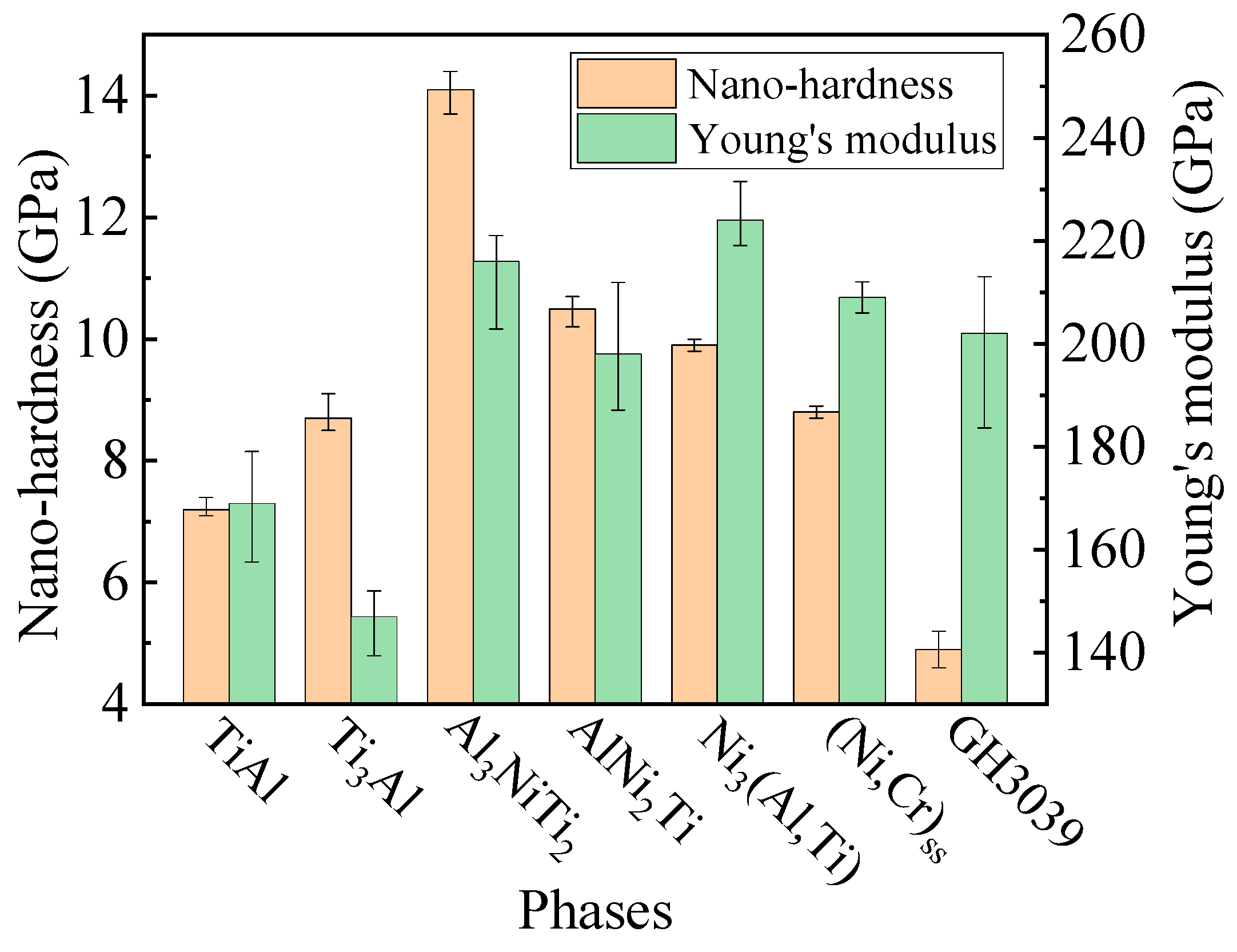

3.1. Nanoindentation

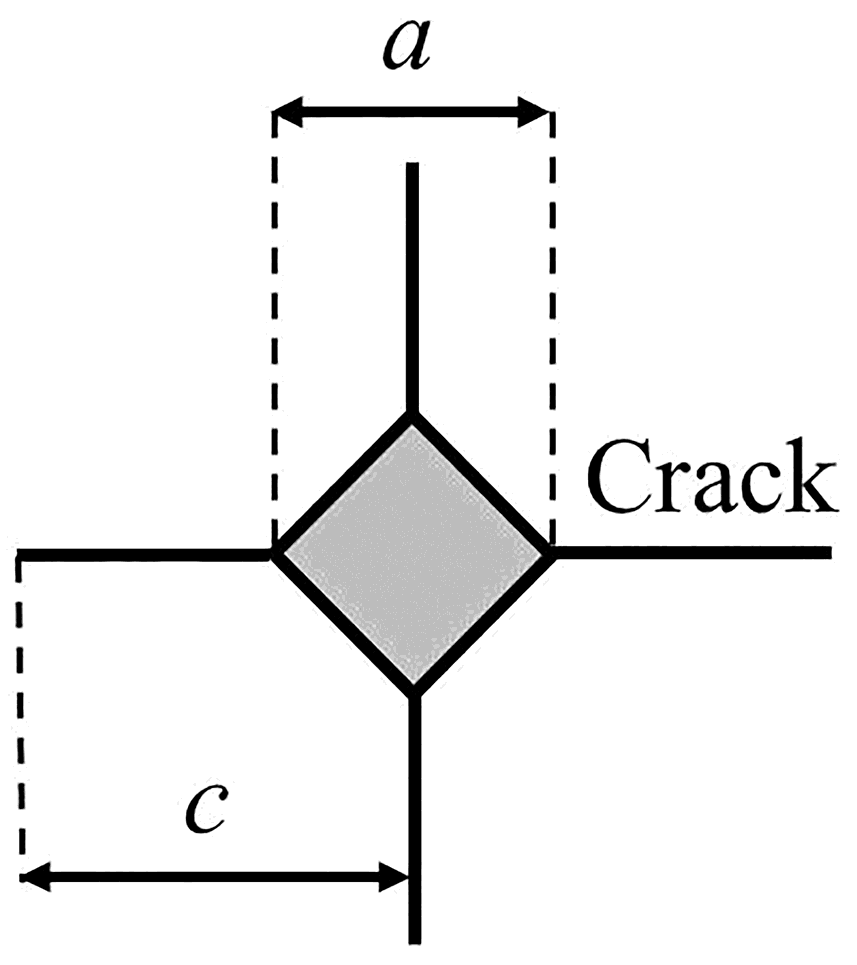

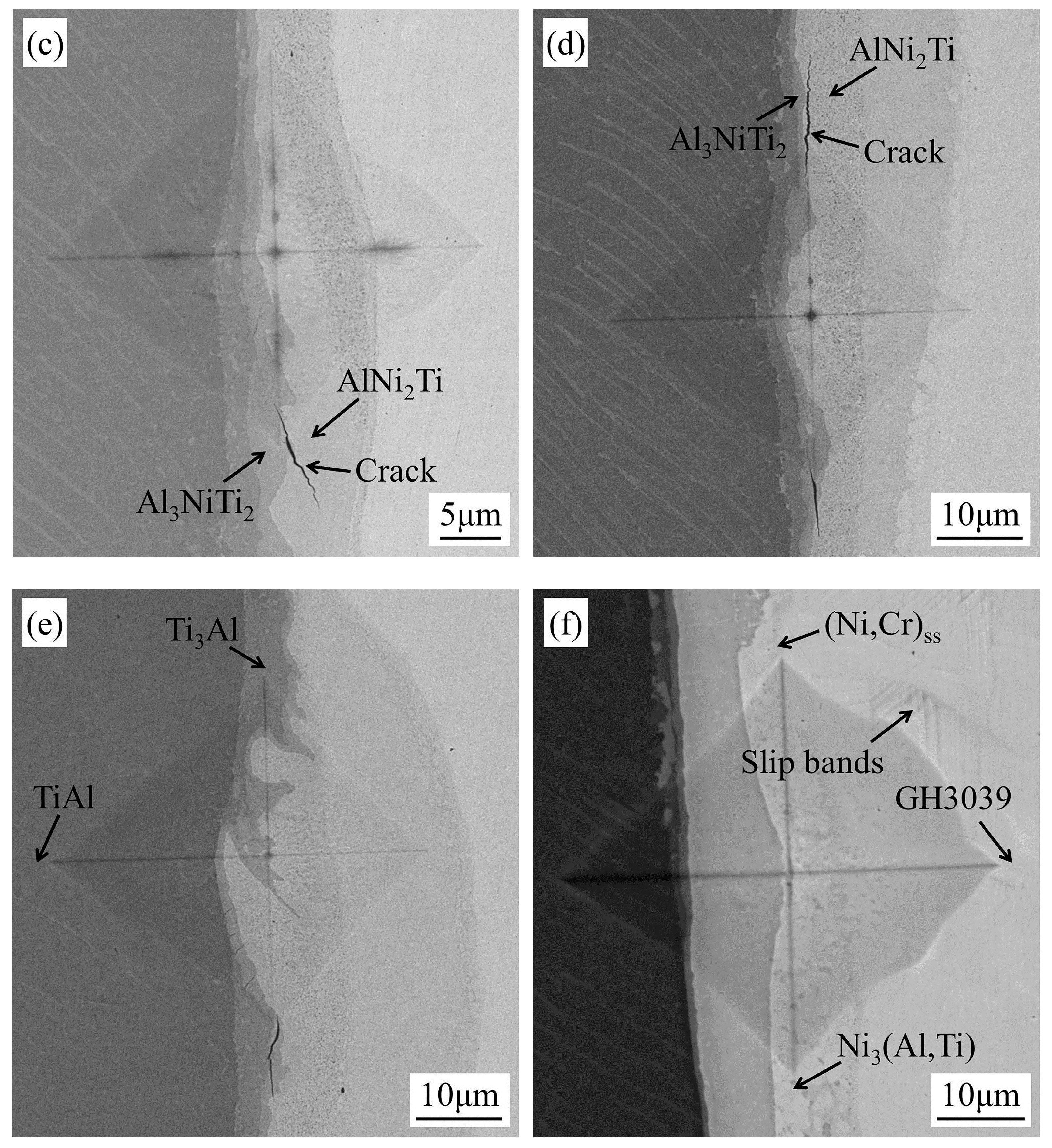

3.2. Fracture Toughness

3.3. In-Situ Tensile

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Du, Z.; Zhang, K.; Lu, Z.; Jiang, S. Microstructure and mechanical properties of vacuum diffusion bonding joints for γ-TiAl based alloy. Vacuum 2018, 150, 96–104. [Google Scholar] [CrossRef]

- Song, Y.; Dou, Z.; Zhang, T.; Liu, Y. A novel continuous and controllable method for fabrication of as-cast TiAl alloy. J. Alloy. Compd. 2019, 789, 266–275. [Google Scholar] [CrossRef]

- Hauschildt, K.; Stark, A.; Schell, N.; Müller, M.; Pyczak, F. The transient liquid phase bonding process of a γ-TiAl alloy with brazing solders containing Fe or Ni. Intermetallics 2019, 106, 48–58. [Google Scholar] [CrossRef]

- Cai, X.; Sun, D.; Li, H.; Guo, H.; Gu, X.; Zhao, Z. Microstructure characteristics and mechanical properties of laser-welded joint of γ-TiAl alloy with pure Ti filler metal. Opt. Laser Technol. 2017, 97, 242–247. [Google Scholar] [CrossRef]

- Dong, H.; Yang, Z.; Wang, Z.; Deng, D.; Dong, C. CuTiNiZrV Amorphous Alloy Foils for Vacuum Brazing of TiAl Alloy to 40Cr Steel. J. Mater. Sci. Technol. 2015, 31, 217–222. [Google Scholar] [CrossRef]

- Li, Y.; He, P.; Feng, J. Interface structure and mechanical properties of the TiAl/42CrMo steel joint vacuum brazed with Ag-Cu/Ti/Ag-Cu filler metal. Scr. Mater. 2006, 55, 171–174. [Google Scholar] [CrossRef]

- Du, S.; Wang, S.; Ding, K. A novel method of friction-diffusion welding between TiAl alloy and GH3039 high temperature alloy. J. Manuf. Process. 2020. under review. [Google Scholar]

- Iracheta, O.; Bennett, C.J.; Sun, W. Characterization of material property variation across an inertia friction welded CrMoV steel component using the inverse analysis of nanoindentation data. Int. J. Mech. Sci. 2016, 107, 253–263. [Google Scholar] [CrossRef]

- Hsueh, C.; Liao, M.; Wang, S.; Tsai, Y.; Yang, J.; Wu, R.; Lee, W. Size effect and strain induced double twin by nanoindentation in DSS weld metal of vibration-assisted GTAW. Mater. Chem. Phys. 2018, 219, 40–50. [Google Scholar] [CrossRef]

- Liu, W.; Wang, Y.; Ma, Y.; Yu, Q.; Huang, Y. Nanoindentation study on micromechanical behaviors of Au–Ni–Sn intermetallic layers in Au–20Sn/Ni solder joints. Mater. Sci. Eng. A 2016, 653, 13–22. [Google Scholar] [CrossRef]

- Cabibbo, M.; Forcellese, A.; Mehtedi, M.E.; Simoncini, M. Double side friction stir welding of AA6082 sheets: Microstructure and nanoindentation characterization. Mater. Sci. Eng. A 2014, 590, 209–217. [Google Scholar] [CrossRef]

- Chu, Q.; Li, J.; Tong, X.; Xu, S.; Zhang, M.; Yan, C. Nanoindentation and microstructure analysis of Ti/Fe dissimilar joint. Mater. Lett. 2019, 238, 98–101. [Google Scholar] [CrossRef]

- Yu, W.; Fan, M.; Shi, J.; Xue, F.; Chen, X.; Liu, H. A comparison between fracture toughness at different locations of SMAW and GTAW welded joints of primary coolant piping. Eng. Fract. Mech. 2018, 202, 135–146. [Google Scholar] [CrossRef]

- Li, X.; Li, K.; Li, S.; Wu, Y.; Cai, Z.; Pan, J. Microstructure and high temperature fracture toughness of NG-TIG welded Inconel 617B superalloy. J. Mater. Sci. Technol. 2020, 39, 173–182. [Google Scholar] [CrossRef]

- Sebastiani, M.; Johanns, K.E.; Herbert, E.G.; Pharr, G.M. Measurement of fracture toughness by nanoindentation methods: Recent advances and future challenges. Curr. Opin. Solid State Mater. Sci. 2015, 19, 324–333. [Google Scholar] [CrossRef]

- Munther, M.; Palma, T.; Tavangarian, F.; Beheshti, A.; Davami, K. Nanomechanical properties of additively and traditionally manufactured nickel-chromium-based superalloys through instrumented nanoindentation. Manuf. Lett. 2020, 23, 39–43. [Google Scholar] [CrossRef]

- Cai, X.; Xu, Y.; Zhong, L.; Liu, M. Fracture toughness of WC-Fe cermet in W-WC-Fe composite by nanoindentation. J. Alloys Compd. 2017, 728, 788–796. [Google Scholar] [CrossRef]

- Casellas, D.; Caro, J.; Molas, S.; Prado, J.; Valls, I. Fracture toughness of carbides in tool steels evaluated by nanoindentation. Acta Mater. 2007, 55, 4277–4286. [Google Scholar] [CrossRef]

- Chu, Q.; Zhang, M.; Li, J.; Yan, F.; Yan, C. Investigation of microstructure and fracture toughness of Fe-Zr welded joints. Mater. Lett. 2018, 231, 134–136. [Google Scholar] [CrossRef]

- Ahn, J.; He, E.; Chen, L.; Dear, J.; Shao, Z.; Davies, C. In-situ micro-tensile testing of AA2024-T3 fibre laser welds with digital image correlation as a function of welding speed. Int. J. Light. Mater. Manuf. 2018, 1, 179–188. [Google Scholar] [CrossRef]

- Yang, B.; Xuan, F.; Chen, J. Evaluation of the microstructure related strength of CrMoV weldment by using the in-situ tensile test of miniature specimen. Mater. Sci. Eng. A 2018, 736, 193–201. [Google Scholar] [CrossRef]

- Zhang, K.; Ni, L.; Lei, Z.; Chen, Y.; Hu, X. In situ investigation of the tensile deformation of laser welded Ti2AlNb joints. Mater. Charact. 2017, 123, 51–57. [Google Scholar] [CrossRef]

- Li, Y.; Lv, M.; Feng, J.; He, P. Characteristics of reaction phases and effects of phases on mechanical properties of TiAl/42CrMo steel brazed joint. Trans. China Weld. Inst. 2014, 35, 41–44. [Google Scholar]

- Anstis, G.R.; Chantikul, P.; Lawn, B.R.; Marshall, D.B. A Critical Evaluation of Indentation Techniques for Measuring Fracture Toughness: I, Direct Crack Measurements. J. Am. Ceram. Soc. 1981, 64, 533–538. [Google Scholar] [CrossRef]

- Ji, S. Generalized means as an approach for predicting Young’s moduli of multiphase materials. Mater. Sci. Eng. A 2004, 366, 195–201. [Google Scholar] [CrossRef]

- Fang, X.; Li, C.; Sun, L.; Sun, H.; Jiang, Z. Hardness and friction coefficient of fused silica under scratching considering elastic recovery. Ceram. Int. 2020, 46, 8200–8208. [Google Scholar] [CrossRef]

- Shim, S.; Bei, H.; George, E.P.; Pharr, G.M. A different type of indentation size effect. Scr. Mater. 2008, 59, 1095–1098. [Google Scholar] [CrossRef]

- Tetsui, T. Effects of brazing filler on properties of brazed joints between TiAl and metallic materials. Intermetallics 2001, 9, 253–260. [Google Scholar] [CrossRef]

| Materials | Chemical Composition (at.%) | |||||||

|---|---|---|---|---|---|---|---|---|

| Ti | Al | Ni | Cr | V | Fe | Mo | Nb | |

| TiAl | 49.0 | 47.5 | − | 1.0 | 2.5 | − | − | − |

| GH3039 | 0.6 | 1.1 | 69.6 | 22.6 | − | 2.9 | 1.2 | 0.7 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, S.; Wang, S.; Xu, W. Characterizing Micromechanical Properties of Friction Welding Interface between TiAl Alloy and GH3039 Superalloy. Materials 2020, 13, 2072. https://doi.org/10.3390/ma13092072

Du S, Wang S, Xu W. Characterizing Micromechanical Properties of Friction Welding Interface between TiAl Alloy and GH3039 Superalloy. Materials. 2020; 13(9):2072. https://doi.org/10.3390/ma13092072

Chicago/Turabian StyleDu, Suigeng, Songlin Wang, and Wanting Xu. 2020. "Characterizing Micromechanical Properties of Friction Welding Interface between TiAl Alloy and GH3039 Superalloy" Materials 13, no. 9: 2072. https://doi.org/10.3390/ma13092072

APA StyleDu, S., Wang, S., & Xu, W. (2020). Characterizing Micromechanical Properties of Friction Welding Interface between TiAl Alloy and GH3039 Superalloy. Materials, 13(9), 2072. https://doi.org/10.3390/ma13092072