Mechanical Properties of Chopped Basalt Fiber-Reinforced Lightweight Aggregate Concrete and Chopped Polyacrylonitrile Fiber Reinforced Lightweight Aggregate Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mixture Proportion

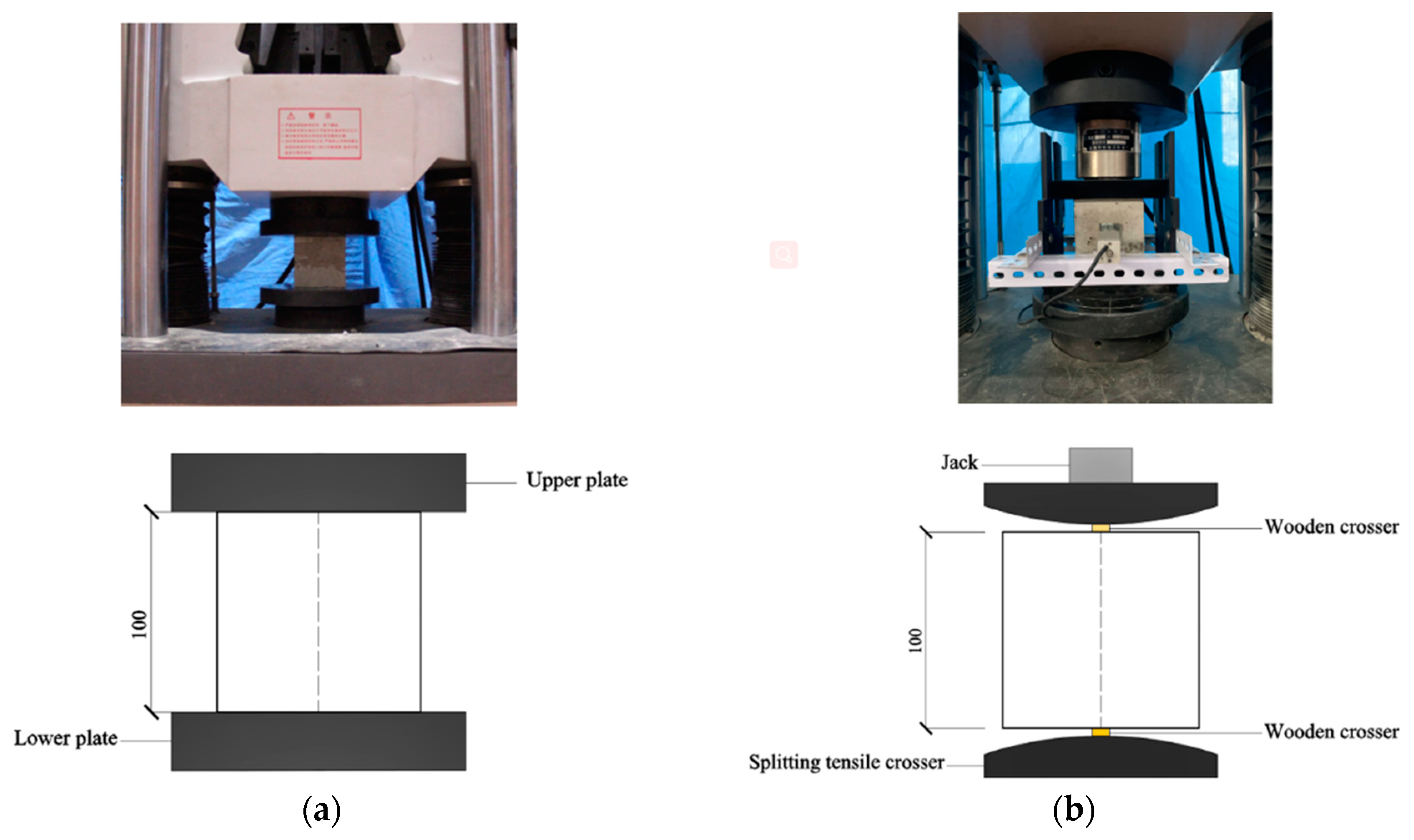

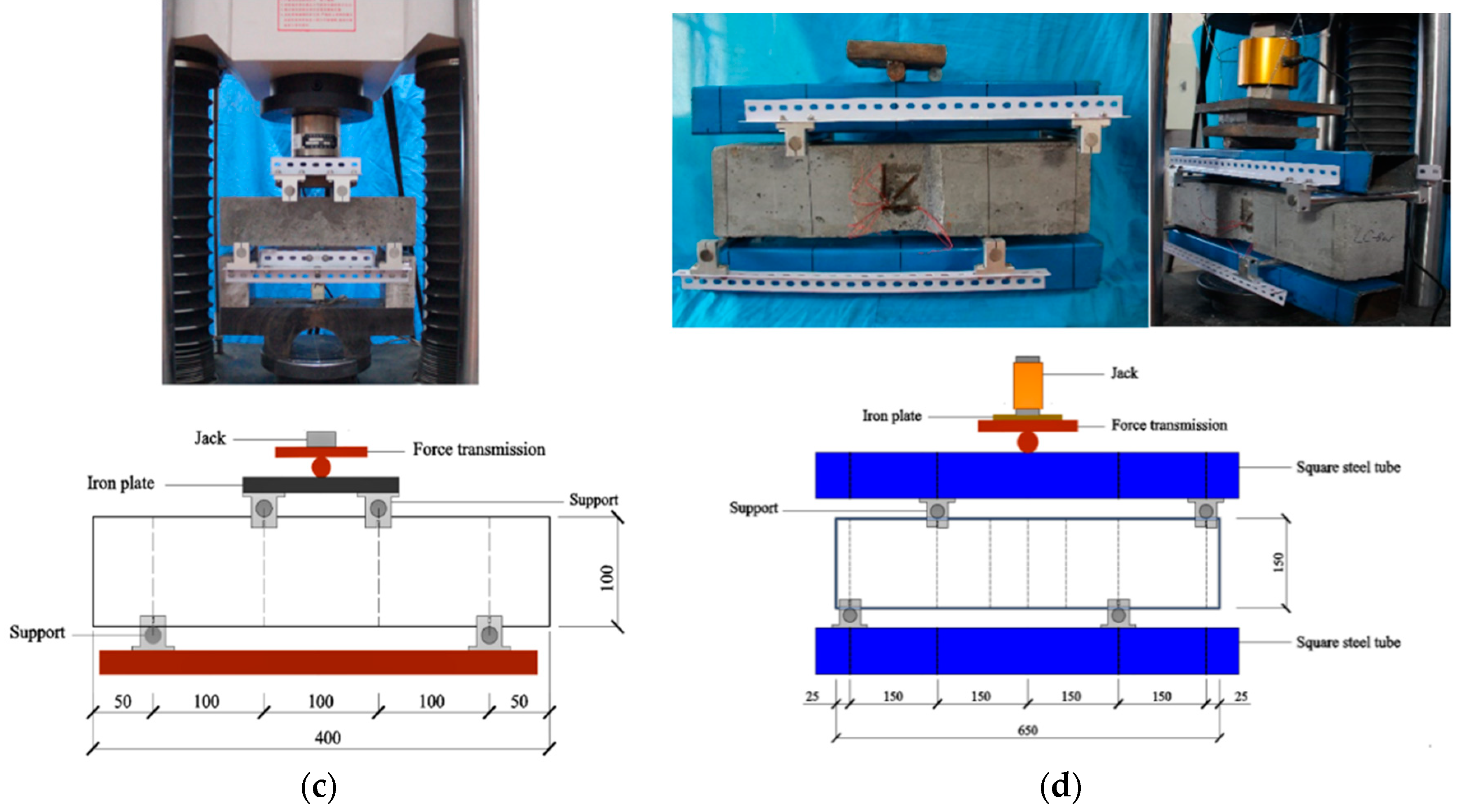

2.3. Testing Methods

3. Test Results and Discussion

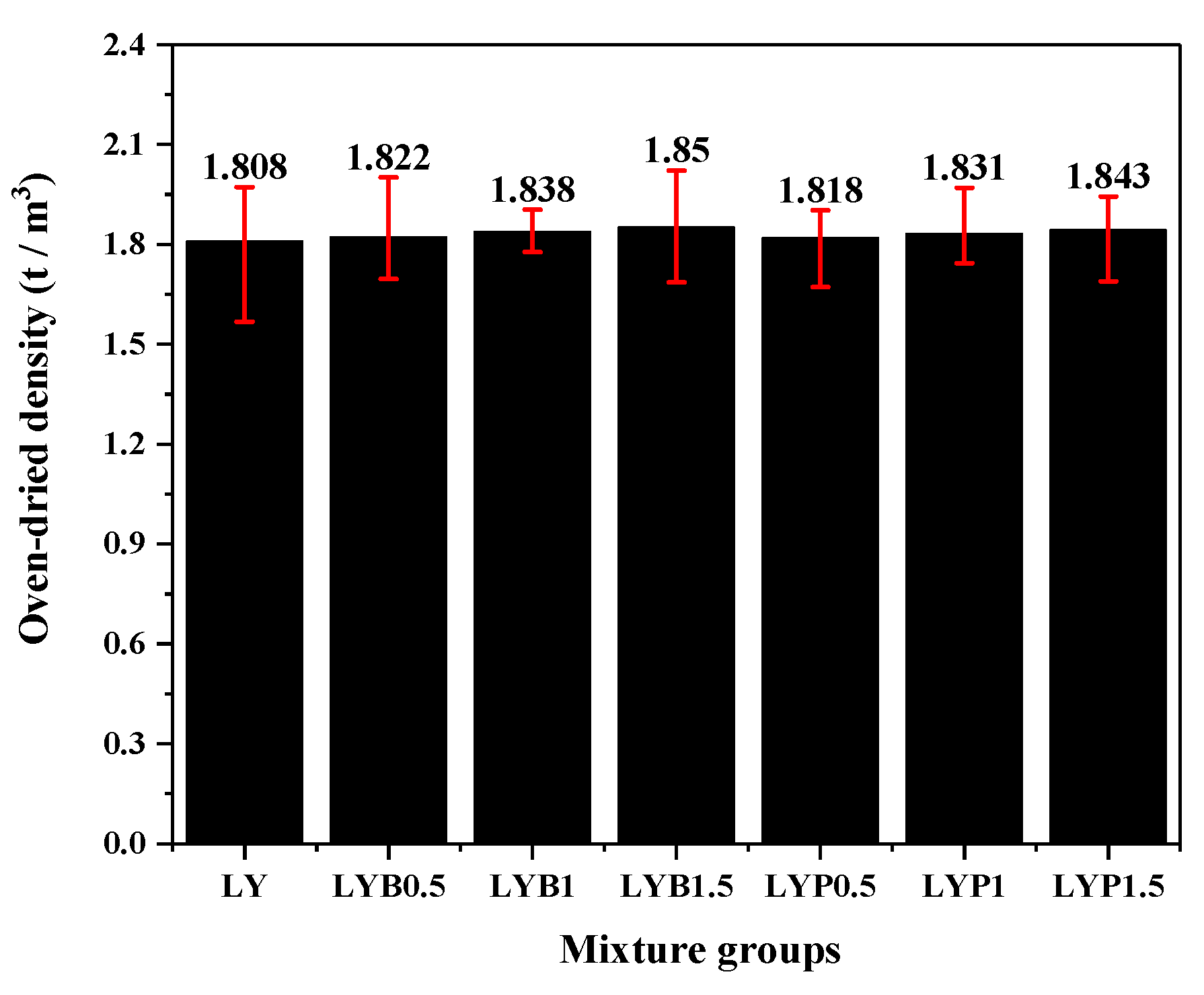

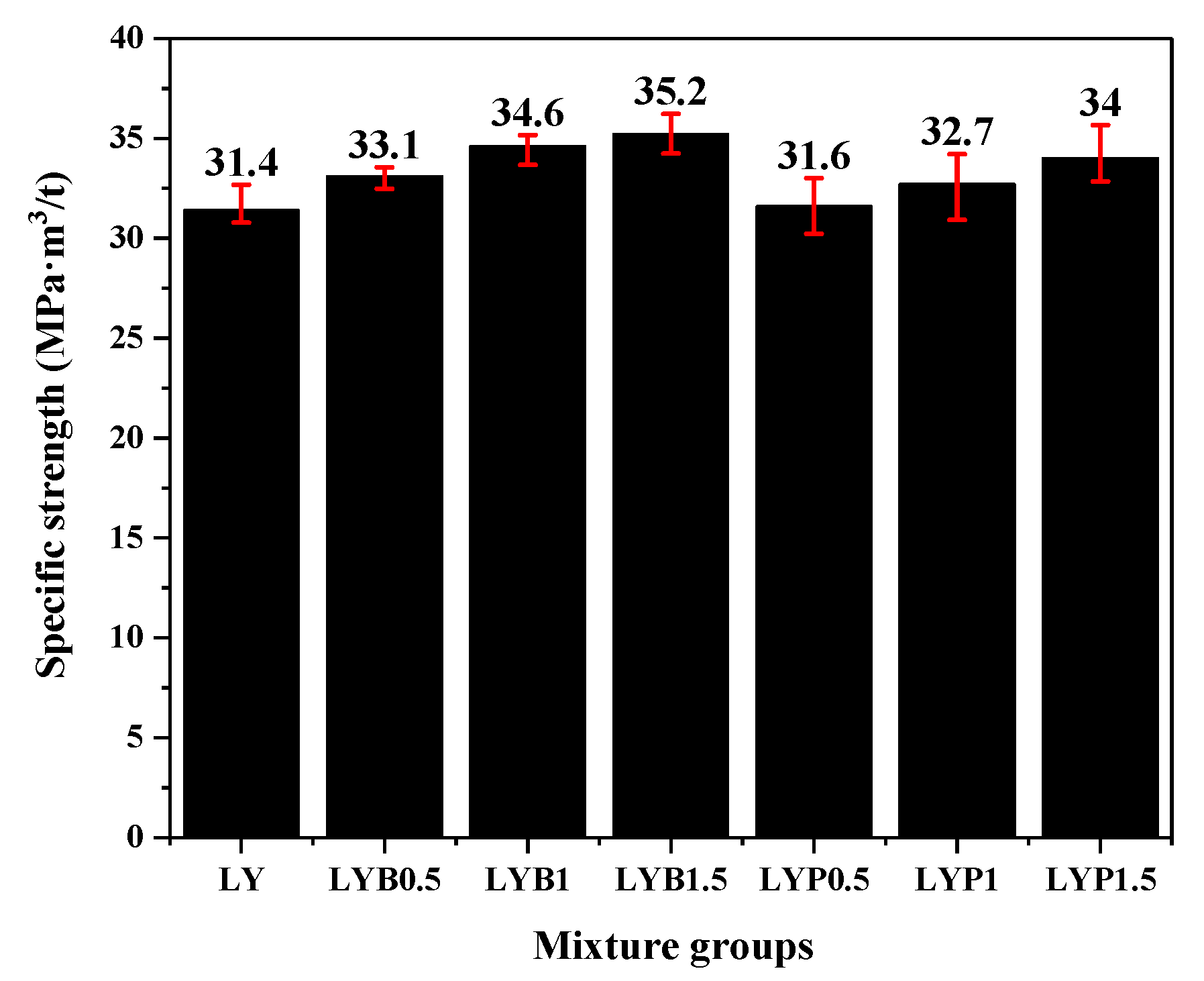

3.1. Oven-dried Density and Specific Strength

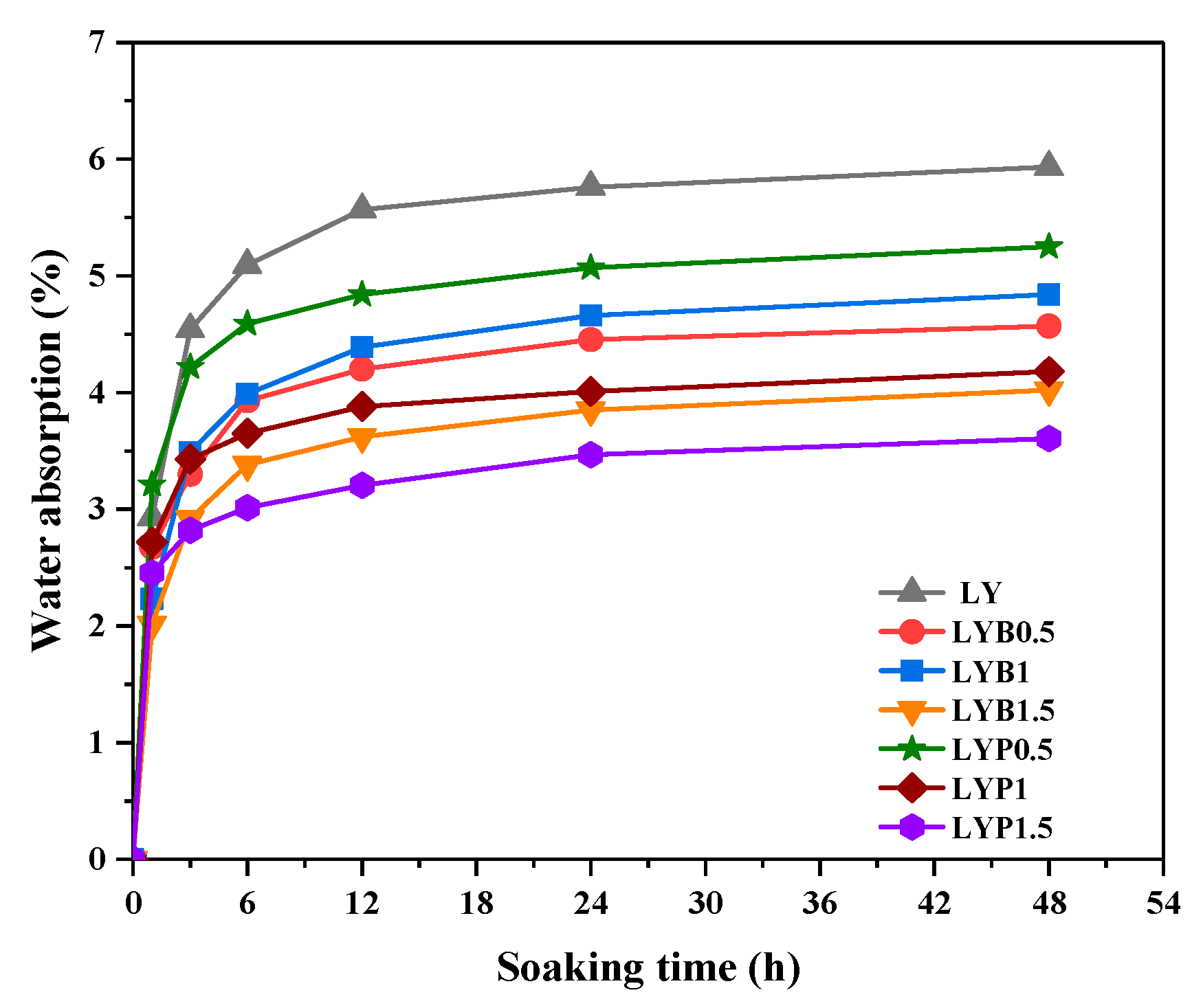

3.2. Water Absorption

3.3. Cube Compressive Strength

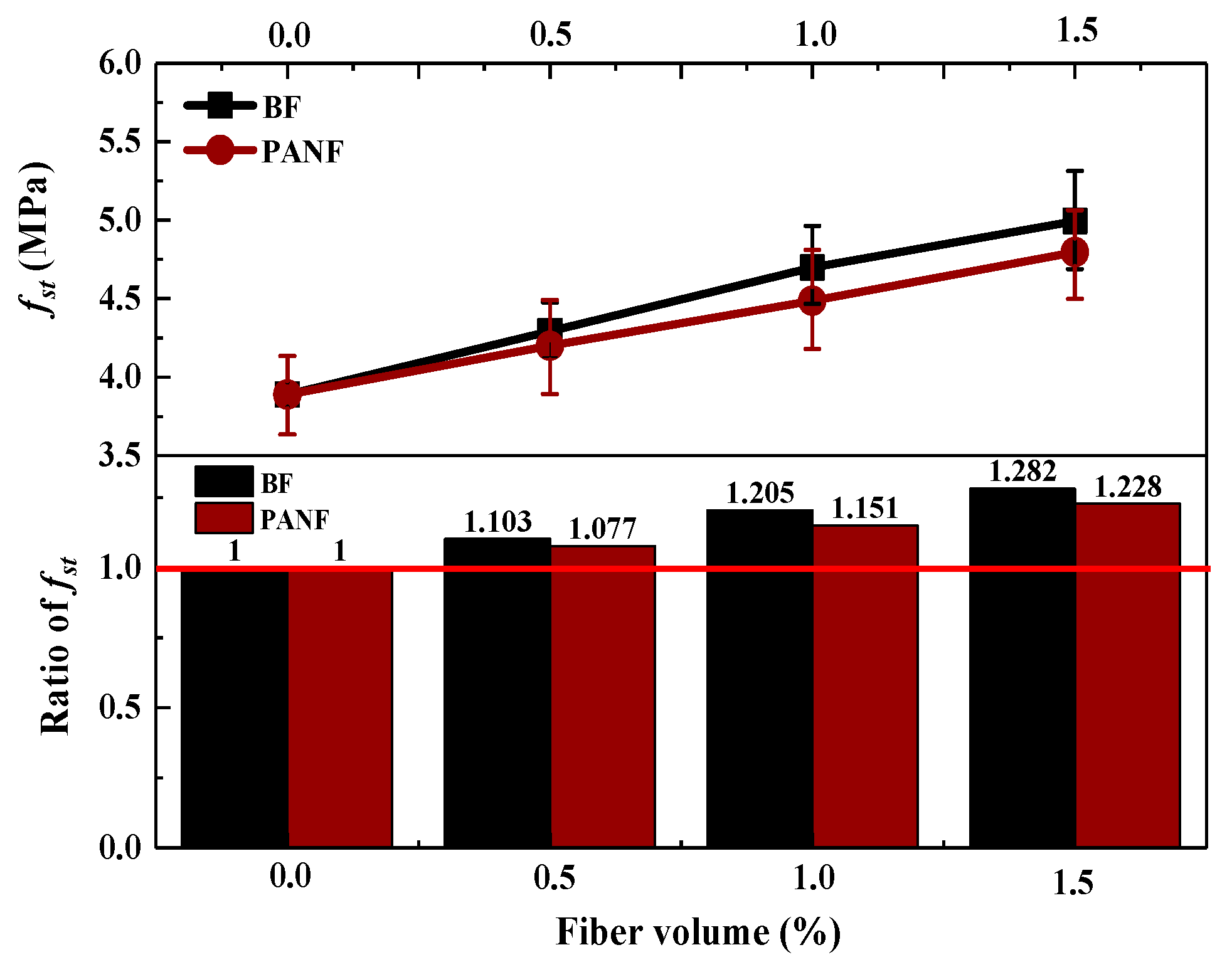

3.4. Splitting Tensile Strength

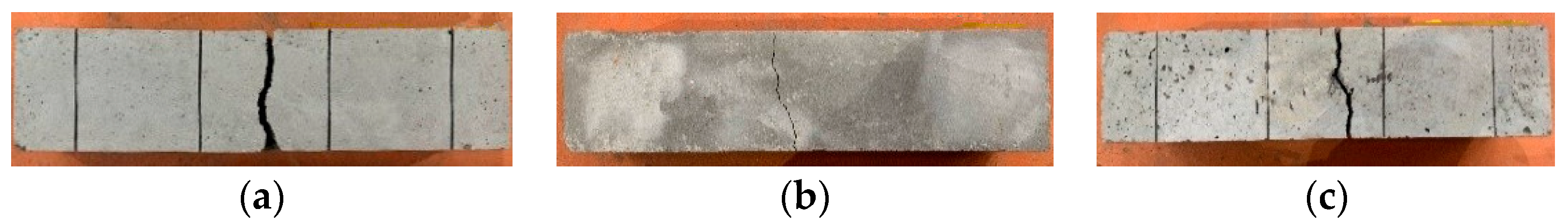

3.5. Flexural Strength

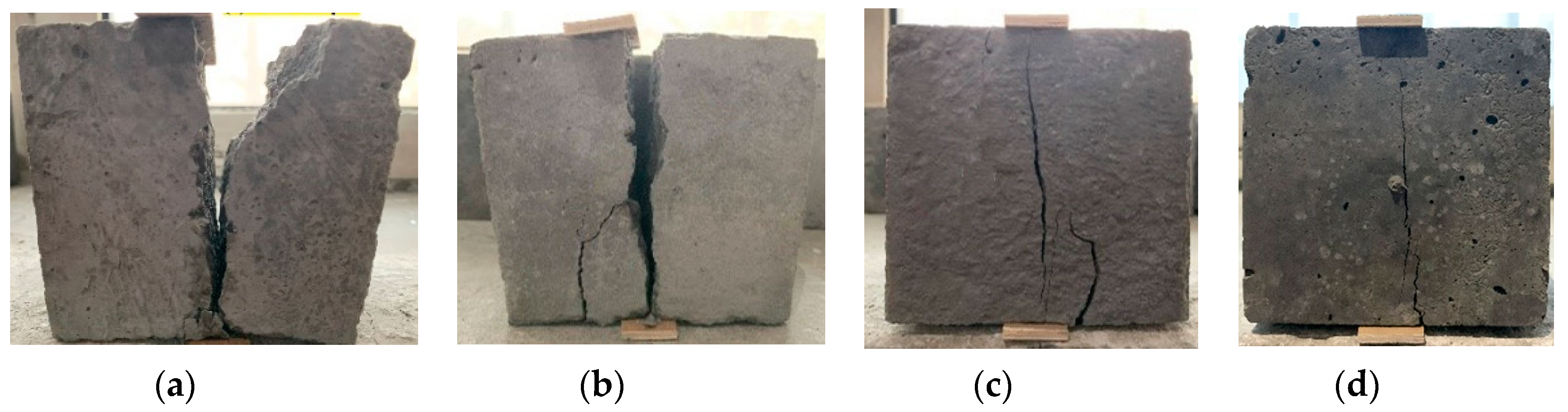

3.6. Shear Strength

4. Strength Calculation Method

4.1. Calculation Method for Cube Compressive Strength

4.2. Calculation Models for Splitting Tensile Strength

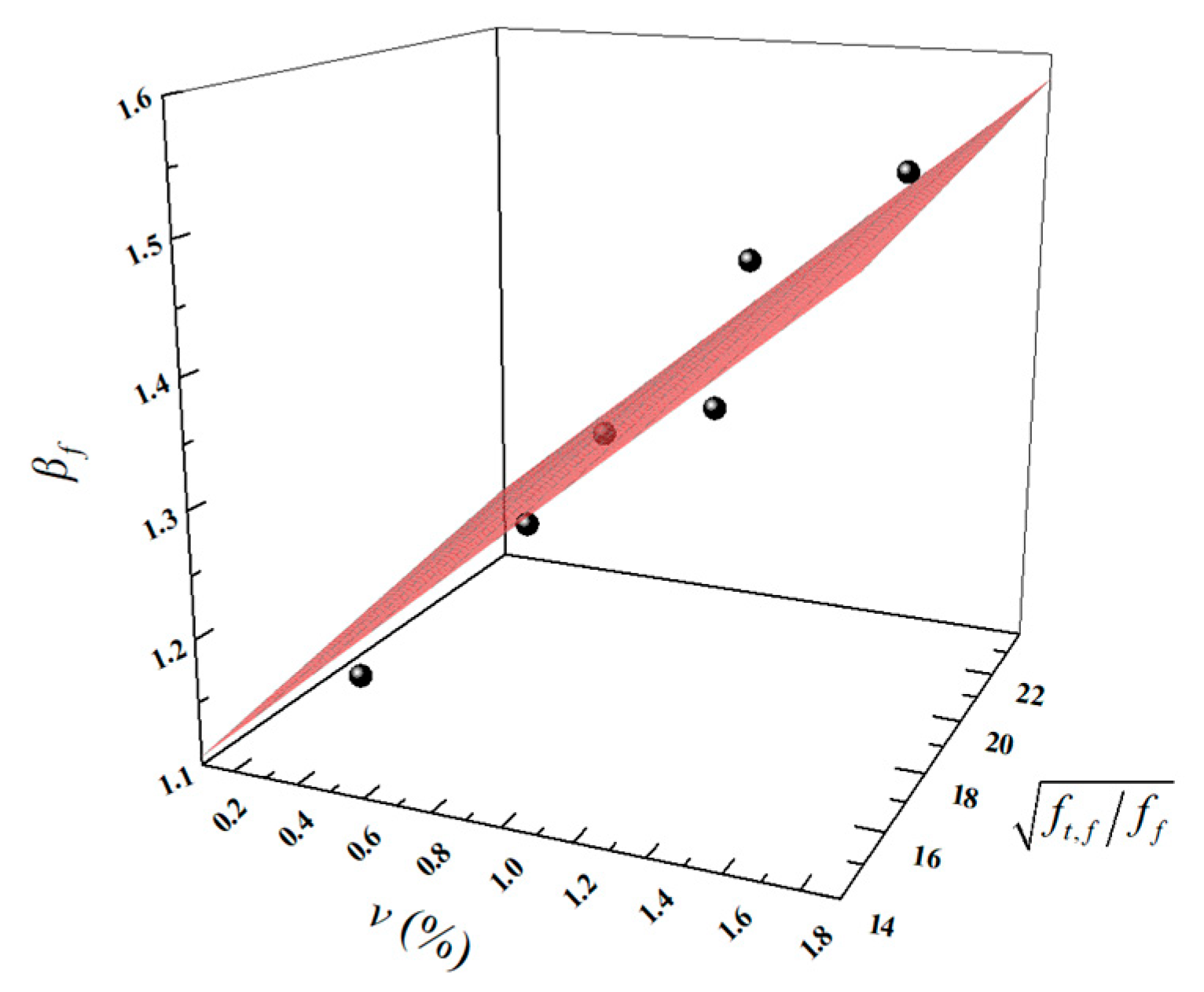

4.3. Calculation Models for Flexural Strength

4.4. Calculation Models for Shear Strength

5. Conclusions

- Both BF and PANF have effects on the improvement of oven-dried density and the reduction of water absorption with the increase of volume fraction due to the role of filling internal pores. The specific strength showed a similar change tendency with cube compressive strength, which increases with the increase of the fiber content respectively, indicating that fiber play a more important role in crack-resistance than in filling in concrete.

- The addition of BF and PANF into LWAC samples showed a slight influence on the cube compressive strength but had significant effects on the splitting tensile strength, flexural strength and shear strength improvement, relatively. The flexural strength was the most sensitive to fiber addition. In that regard, synthesizing the fiber effect on strength enhancement, a 1.5% volume fraction of BF or PANF is suggested to obtain the optimal improvement in mechanical properties.

- BF and PANF had effects on the failure morphology changes of splitting tensile and flexural destruction but had almost no effect on the shear failure morphology.

- The strength enhancement parameters β can describe the fiber effects on strength enhancement of LWACs when subjected to different loading types. Moreover, the strength calculation Equations (3), (5), (7) and (9) were established and the results of calculation agree well with the testing results.

Author Contributions

Funding

Conflicts of Interest

Appendix A

| Mixtures | Cube Compressive Strength (MPa) | Splitting Tensile Strength (MPa) | Flexural Strength (MPa) | Shear Strength (MPa) |

|---|---|---|---|---|

| LY | 57.11 | 3.90 | 3.58 | 2.80 |

| LYB0.5 | 60.25 | 4.32 | 4.54 | 3.14 |

| LYB1 | 63.70 | 4.70 | 5.06 | 3.48 |

| LYB1.5 | 65.14 | 5.00 | 5.37 | 3.64 |

| LYP0.5 | 57.56 | 4.20 | 4.20 | 3.06 |

| LYP1 | 60.10 | 4.49 | 4.69 | 3.24 |

| LYP1.5 | 62.48 | 4.79 | 5.05 | 3.51 |

References

- Huiskes, D.M.A.; Keulen, A.; Yu, Q.L.; Brouwers, H.J.H. Design and performance evaluation of ultra-lightweight geopolymer concrete. Mater. Design. 2016, 89, 516–526. [Google Scholar] [CrossRef]

- Domagała, L. Size Effect in compressive strength tests of cored specimens of lightweight aggregate concrete. Materials 2020, 13, 1183. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Thienel, K.C.; Haller, T.; Beuntner, N. Lightweight concrete—From basics to innovations. Materials 2020, 13, 1120. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dulsang, N.; Kasemsiri, P.; Posi, P.; Hiziroglu, S.; Chindaprasirt, P. Characterization of an environment friendly lightweight concrete containing ethyl vinyl acetate waste. Mater. Design. 2016, 96, 350–356. [Google Scholar] [CrossRef]

- Chen, H.J.; Hsueh, Y.C.; Peng, Y.C.; Tang, C.W. Paper sludge reuse in lightweight aggregates manufacturing. Materials 2016, 9, 876. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Farías, R.D.; García, C.M.; Palomino, T.C.; Arellano, M.M. Effects of wastes from the brewing industry in lightweight aggregates manufactured with clay for green roofs. Materials 2017, 10, 527. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tang, C.W. Uniaxial bond stress-slip behavior of reinforcing bars embedded in lightweight aggregate concrete. Struct. Eng. Mech. 2017, 62, 651–661. [Google Scholar]

- Tang, C.W. Effect of presoaking degree of lightweight aggregate on the properties of lightweight aggregate concrete. Comput. Concr. 2017, 19, 69–78. [Google Scholar] [CrossRef]

- Bacinskas, D.; Rumsys Sokolov, A.; Kaklauskas, G. Deformation analysis of reinforced beams made of lightweight aggregate concrete. Materials 2020, 13, 20. [Google Scholar] [CrossRef] [Green Version]

- Dong, W.; Shen, X.D.; Xue, H.J.; He, J.; Liu, Y. Research on the freeze-thaw cyclic test and damage model of aeolian sand lightweight aggregate concrete. Constr. Build. Mater. 2016, 123, 792–799. [Google Scholar] [CrossRef]

- Ma, H.L.; Cui, C.; Li, X.; Hu, S.L. Study on mechanical properties of steel fiber reinforced autoclaved lightweight shell-aggregate concrete. Mater. Des. 2013, 52, 565–571. [Google Scholar] [CrossRef]

- Toverud, L.; Moe, T.T.; Hovland, E. Use of lightweight aggregate concrete gives a cheaper bridge. In Proceedings of the 2nd international symposium on structural lightweight aggregate concrete, Kristiansand, Norway, 18–22 June 2000. [Google Scholar]

- Sohel, K.M.A.; Al-Jabri, K.; Zhang, M.H.; Richard Liew, J.Y. Flexural fatigue behavior of ultralightweight cement composite and high strength lightweight aggregate. Constr. Build. Mater. 2018, 173, 90–100. [Google Scholar] [CrossRef]

- Smadi, M.; Migdady, E.S. Properties of high strength tuff lightweight aggregate concrete. Cem. Concr. Compos. 1991, 13, 129–135. [Google Scholar] [CrossRef]

- Domagała, L. Modification of properties of structural lightweight concrete with steel fibers. J. Civ. Eng. Manag. 2011, 17, 36–44. [Google Scholar] [CrossRef]

- Ferdous, W.; Almutairi, A.D.; Huang, Y. Short-term flexural behaviour of concrete filled pultruded GFRP cellular and tubular sections with pin-eye connections for modular retaining wall construction. Compos. Struct. 2018, 206, 1–10. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Manalo, A.C.; Ferdous, W.; Yan, Z.G.; Vijayd, P.V. Experimental and numerical evaluations on the behaviour of structures repaired using prefabricated FRP composites jacket. Eng. Struct. 2020, 210, 110358. [Google Scholar] [CrossRef]

- Al-Rubaye, M.; Manalo, A.; Alajarmeh, O.; Ferdous, W.; Lokuge, W.; Benmokrane, B.; Edoo, A. Flexural behaviour of concrete slabs reinforced with GFRP bars and hollow composite reinforcing systems. Compos. Struct. 2020, 236, 111836. [Google Scholar] [CrossRef] [Green Version]

- Barros, J.A.O.; SenaCruz, J.M. Fracture energy of steel fibre reinforced concrete. Mech. Compos. Mater. Struct. 2001, 8, 29–45. [Google Scholar] [CrossRef]

- Hassanpour, M.; Shafigh, P. Mahmud, H.B. Lightweight aggregate concrete fiber reinforcement—A review. Constr. Build. Mater. 2012, 37, 452–461. [Google Scholar] [CrossRef]

- Li, J.J.; Wan, C.J.; Niu, J.G.; Wu, L.F.; Wu, Y.C. Investigation on flexural toughness evaluation method of steel fiber reinforced lightweight aggregate concrete. Constr. Build. Mater. 2017, 131, 449–458. [Google Scholar] [CrossRef]

- Li, X.K.; Li, C.Y.; Zhao, M.L.; Yang, H.; Zhou, S.Y. Testing and prediction of shear performance for steel fiber reinforced expanded-shale lightweight concrete beams without web reinforcements. Materials 2019, 12, 1594. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, T.; Yang, X.; Wei, H.; Liu, X. Mechanical properties and microstructure of lightweight aggregate concrete with and without fibers. Constr. Build. Mater. 2019, 199, 526–539. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Bella, G.D.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Chairman, C.A.; Babu, S.P.K. Mechanical and abrasive wear behavior of glass and basalt fabric-reinforced epoxy composites. J. Appl. Polym. Sci. 2013, 130, 120–130. [Google Scholar] [CrossRef]

- Irine, F. Strength aspects of basalt fiber reinforced concrete. Int. J. Innov. Res. Adv. Eng. 2014, 1, 192–198. [Google Scholar]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part B 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Asprone, D.; Cadoni, E.; Iucolano, F.; Prota, A. Analysis of the strain-rate behavior of a basalt fiber reinforced natural hydraulic mortar. Cem. Concr. Compos. 2014, 53, 52–58. [Google Scholar] [CrossRef]

- Rahaman, M.S.A.; Ismail, A.F.; Mustafa, A. A review of heat treatment on polyacrylonitrile fiber. Polym. Degrad. Stab. 2007, 92, 1421–1432. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Z.Y.; Liu, X.H. Experimental research on anti-cracking ability of polyacrylonitrile fiber mortar. Adv. Mater. Res. 2015, 1095, 237–241. [Google Scholar]

- Chen, Y.; Cen, G.P.; Cui, Y.H. Comparative study on the effect of synthetic fiber on the preparation and durability of airport pavement concrete. Constr. Build. Mater. 2018, 184, 34–44. [Google Scholar] [CrossRef]

- Xu, G.Q.; Chen, S.H. Experimental study on mechanics property of synthetic fiber concrete. J. Hebei. North. Univ. 2011, 27, 78–82. [Google Scholar]

- Zhang, M.H.; Gjorv, O.E. Mechanical properties of high-strength lightweight aggregate concrete. ACI Mater. J. 1991, 88, 240–247. [Google Scholar]

- Bremner, T.W.; Holm, T.A. Elastic compatibility and the behavior of concrete. ACI J. 1986, 83, 244–250. [Google Scholar]

- Liu, B.; Feng, C.; Deng, Z.H. Shear behavior of three types of recycled aggregate concrete. Constr. Build. Mater. 2019, 217, 557–572. [Google Scholar] [CrossRef]

- Zhang, Q.; Guo, Z.H. Investigation on shear strength and shear strain of concrete. J. Build. Struct. 1992, 13, 379–390. [Google Scholar]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Technical Specification for Lightweight Aggregate Concrete; China Building Industry Press: Beijing, China, 2002.

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Test Method of Mechanical Properties on Ordinary Concrete; China Building Industry Press: Beijing, China, 2002.

- Liu, Y.F.; Li, T.C.; Zeng, X.H.; Wang, Y.J.; Gao, J.X.; Zhou, S.N. Mechanical strength and water absorption capability of fiber-reinforced foamed concrete. J. Civil. Environ. Eng. 2019, 41, 120–126. [Google Scholar]

- Karahan, O.; Atiş, C.D. The durability properties of polypropylene fiber reinforced fly ash concrete. Mater. Design. 2011, 32, 1044–1049. [Google Scholar] [CrossRef]

- Mauricio, Z.; Lawrence, F.K.; Kimberly, E.K. Creep and shrinkage of high-performance lightweight concrete. ACI Mater. J. 2004, 101, 391–399. [Google Scholar]

- Wu, L.; Farzadnia, N.; Shi, C.; Zhang, Z.; Wang, H. Autogenous shrinkage of high performance concrete: A review. Constr. Build. Mater. 2017, 149, 62–75. [Google Scholar] [CrossRef]

- Romualdi, J.P.; Batson, G.B. Mechanics of crack arrest in concrete. Proc. ASCE 1963, 89, 147–168. [Google Scholar]

- Li, J.J.; Niu, J.G.; Wan, C.J. Comparison of flexural property between high performance polypropylene fiber reinforced lightweight aggregate concrete and steel fiber reinforced lightweight aggregate concrete. Constr. Build. Mater. 2017, 157, 729–736. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Ding, J.P.; Guo, Y.S. Stress-strain curves of structural lightweight aggregate concretes. Concrete 2005, 3, 39–41. [Google Scholar]

- Gao, D.Y.; Zhu, H.T.; Tang, J.Y. Experimental study on shear strength of fiber reinforced high-strength concrete. Build. Sci. 2004, 20, 69–73. [Google Scholar]

- Alzyoud, S.; Ziadat, A. Effect of fibers on concrete fresh, mechanical and transport properties. In Proceedings of the 2018 Advances in Science and Engineering Technology International Conferences (ASET). IEEE, Abu Dhabi, UAE, 6 February–5 April 2018. [Google Scholar]

- Jalasutram, S.; Sahoo, D.R.; Matsagar, V. Experimental investigation on mechanical properties of basalt fibre-reinforced concrete. Struct. Concr. 2016, 18, 1–22. [Google Scholar] [CrossRef]

- Algburi, A.H.M.; Sheikh, M.N.; Hadi, M.N.S. Mechanical properties of steel, glass and hybrid fiber reinforced reactive powder concrete. Front. Struct. Civ. Eng. 2019, 13, 998–1006. [Google Scholar] [CrossRef] [Green Version]

| Materials | Density (kg/m3) | Mean Diameter (μm) | Loss on Ignition (%) | SiO2 (%) | CaO (%) | Al2O3 (%) | Fe2O3 (%) | MgO (%) |

|---|---|---|---|---|---|---|---|---|

| Cement | 2234 | 18–24 | - | 22.1 | 62.39 | 5.72 | 3.05 | 2.02 |

| Fly ash | 2420 | 23–25 | 1.5 | 55.0 | 1.2 | 34.2 | 5.1 | 1.3 |

| Silica fume | 1700 | 0.1–0.3 | 3 | 95.0 | 0.2 | 0.7 | 0.6 | 0.5 |

| Types of Aggregates | Size (mm) | Bulk Density (kg/m3) | Cylinder Compressive Strength (MPa) | 1h Water Absorption (%) | Softening Coefficient |

|---|---|---|---|---|---|

| Lytag | 5-10 | 877 | 12.1 | 8.1 | 0.9 |

| Types of Fibers | Length (mm) | Density (kg/m3) | Tensile Strength (MPa) | Elongation(%) | Melting Point (°C) | Diameter (mm) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|---|---|

| BF | 6 | 2699 | 2000 | 2.5 | 1450 | 17.4 | 85 |

| PANF | 3 | 1190 | 800 | 1 | 245 | 10 | ≥10 |

| Groups | Cement (kg/m3) | Fly ash (kg/m3) | Silica Fume (kg/m3) | Coarse Aggregate (kg/m3) | Fine Aggregate (kg/m3) | Volume (%) | Super (kg/m3) | Water (kg/m3) | w/b |

|---|---|---|---|---|---|---|---|---|---|

| LY | 440 | 66 | 44 | 656 | 602 | - | 1.7 | 143 | 0.29 |

| LYB0.5 | 440 | 66 | 44 | 656 | 602 | 0.5 | 1.7 | 143 | 0.29 |

| LYB1 | 440 | 66 | 44 | 656 | 602 | 1 | 1.7 | 143 | 0.29 |

| LYB1.5 | 440 | 66 | 44 | 656 | 602 | 1.5 | 1.7 | 143 | 0.29 |

| LYP0.5 | 440 | 66 | 44 | 656 | 602 | 0.5 | 1.7 | 143 | 0.29 |

| LYP1 | 440 | 66 | 44 | 656 | 602 | 1 | 1.7 | 143 | 0.29 |

| LYP1.5 | 440 | 66 | 44 | 656 | 602 | 1.5 | 1.7 | 143 | 0.29 |

| Mixtures | v | βcu,t | βcu,c | βcu,t/βcu,c | |

|---|---|---|---|---|---|

| LY | 0 | 0 | 1 | 1 | 1.00 |

| LYB0.5 | 0.5 | 22.774 | 1.055 | 1.046 | 1.01 |

| LYB1 | 1 | 22.774 | 1.115 | 1.091 | 1.02 |

| LYB1.5 | 1.5 | 22.774 | 1.141 | 1.137 | 1.00 |

| LYP0.5 | 0.5 | 14.404 | 1.008 | 1.029 | 0.98 |

| LYP1 | 1 | 14.404 | 1.052 | 1.058 | 0.99 |

| LYP1.5 | 1.5 | 14.404 | 1.094 | 1.086 | 1.01 |

| 0.3C [23] | 0.3 | 29.193 | 1.027 | 1.035 | 0.99 |

| 0.6C [23] | 0.6 | 29.193 | 1.057 | 1.070 | 0.99 |

| 0.9C [23] | 0.9 | 29.193 | 1.122 | 1.105 | 1.02 |

| PF0.6 [46] | 0.6 | 8.54 | 1.027 | 1.020 | 1.01 |

| PF0.9 [46] | 0.9 | 8.54 | 1.034 | 1.031 | 1.00 |

| PF1.2 [46] | 1.2 | 8.54 | 1.052 | 1.041 | 1.01 |

| Mixtures | v | βst,t | βst,c | βst,t/βst,c | |

|---|---|---|---|---|---|

| LY | 0 | 0 | 1 | 1 | 1.00 |

| LYB0.5 | 0.5 | 22.680 | 1.108 | 1.102 | 1.01 |

| LYB1 | 1 | 22.680 | 1.205 | 1.204 | 1.00 |

| LYB1.5 | 1.5 | 22.680 | 1.282 | 1.306 | 0.98 |

| LYP0.5 | 0.5 | 14.344 | 1.077 | 1.064 | 1.01 |

| LYP1 | 1 | 14.344 | 1.151 | 1.129 | 1.02 |

| LYP1.5 | 1.5 | 14.344 | 1.228 | 1.194 | 1.03 |

| 0.3C [23] | 0.3 | 29.193 | 1.123 | 1.063 | 1.06 |

| 0.6C [23] | 0.6 | 29.193 | 1.200 | 1.125 | 1.07 |

| 0.9C [23] | 0.9 | 29.193 | 1.323 | 1.188 | 1.11 |

| FG [47] | 0.5 | 15.182 | 1.091 | 1.068 | 1.02 |

| FP [47] | 0.5 | 15.528 | 1.112 | 1.070 | 1.04 |

| SF [47] | 0.5 | 20.628 | 1.178 | 1.093 | 1.08 |

| Mixtures | v | βf,t | βf,c | βf,t/βf,c | |

|---|---|---|---|---|---|

| LY | 0 | 0 | 1 | 1 | 1.00 |

| LYB0.5 | 0.5 | 23.629 | 1.268 | 1.257 | 1.01 |

| LYB1 | 1 | 23.629 | 1.412 | 1.372 | 1.03 |

| LYB1.5 | 1.5 | 23.629 | 1.499 | 1.487 | 1.01 |

| LYP0.5 | 0.5 | 14.944 | 1.172 | 1.205 | 0.97 |

| LYP1 | 1 | 14.944 | 1.310 | 1.320 | 0.99 |

| LYP1.5 | 1.5 | 14.944 | 1.410 | 1.435 | 0.98 |

| 0.3C [23] | 0.3 | 31.623 | 1.371 | 1.259 | 1.09 |

| 0.6C [23] | 0.6 | 31.623 | 1.428 | 1.328 | 1.07 |

| 0.9C [23] | 0.9 | 31.623 | 1.486 | 1.397 | 1.06 |

| BFRC2 [48] | 0.5 | 9.287 | 1.150 | 1.170 | 0.98 |

| BFRC3 [48] | 1 | 9.287 | 1.390 | 1.286 | 1.08 |

| BFRC4 [48] | 1.5 | 9.287 | 1.500 | 1.401 | 1.07 |

| BFRC5 [48] | 2 | 9.287 | 1.633 | 1.516 | 1.08 |

| Mixtures | v | l | βs,t | βs,c | βs,t/βs,c |

|---|---|---|---|---|---|

| LY | 0 | 6 | 1 | 1 | 1.00 |

| LYB0.5 | 0.5 | 6 | 1.120 | 1.107 | 1.01 |

| LYB1 | 1 | 6 | 1.242 | 1.213 | 1.02 |

| LYB1.5 | 1.5 | 6 | 1.300 | 1.319 | 0.98 |

| LYP0.5 | 0.5 | 3 | 1.093 | 1.083 | 1.01 |

| LYP1 | 1 | 3 | 1.156 | 1.165 | 0.99 |

| LYP1.5 | 1.5 | 3 | 1.251 | 1.248 | 1.00 |

| PF0.6 [46] | 0.6 | 12 | 1.079 | 1.185 | 0.91 |

| PF0.9 [46] | 0.9 | 12 | 1.206 | 1.278 | 0.94 |

| PF1.2 [46] | 1.2 | 12 | 1.286 | 1.371 | 0.94 |

| GFR-RPC [49] | 1.5 | 13 | 1.600 | 1.487 | 1.07 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Y.; Zhou, X.; Tang, A.; Sun, P. Mechanical Properties of Chopped Basalt Fiber-Reinforced Lightweight Aggregate Concrete and Chopped Polyacrylonitrile Fiber Reinforced Lightweight Aggregate Concrete. Materials 2020, 13, 1715. https://doi.org/10.3390/ma13071715

Zeng Y, Zhou X, Tang A, Sun P. Mechanical Properties of Chopped Basalt Fiber-Reinforced Lightweight Aggregate Concrete and Chopped Polyacrylonitrile Fiber Reinforced Lightweight Aggregate Concrete. Materials. 2020; 13(7):1715. https://doi.org/10.3390/ma13071715

Chicago/Turabian StyleZeng, Yusheng, Xianyu Zhou, Aiping Tang, and Peng Sun. 2020. "Mechanical Properties of Chopped Basalt Fiber-Reinforced Lightweight Aggregate Concrete and Chopped Polyacrylonitrile Fiber Reinforced Lightweight Aggregate Concrete" Materials 13, no. 7: 1715. https://doi.org/10.3390/ma13071715

APA StyleZeng, Y., Zhou, X., Tang, A., & Sun, P. (2020). Mechanical Properties of Chopped Basalt Fiber-Reinforced Lightweight Aggregate Concrete and Chopped Polyacrylonitrile Fiber Reinforced Lightweight Aggregate Concrete. Materials, 13(7), 1715. https://doi.org/10.3390/ma13071715