Experimental and Numerical Analyses of the Failure of Prestressed Concrete Railway Sleepers

Abstract

1. Introduction

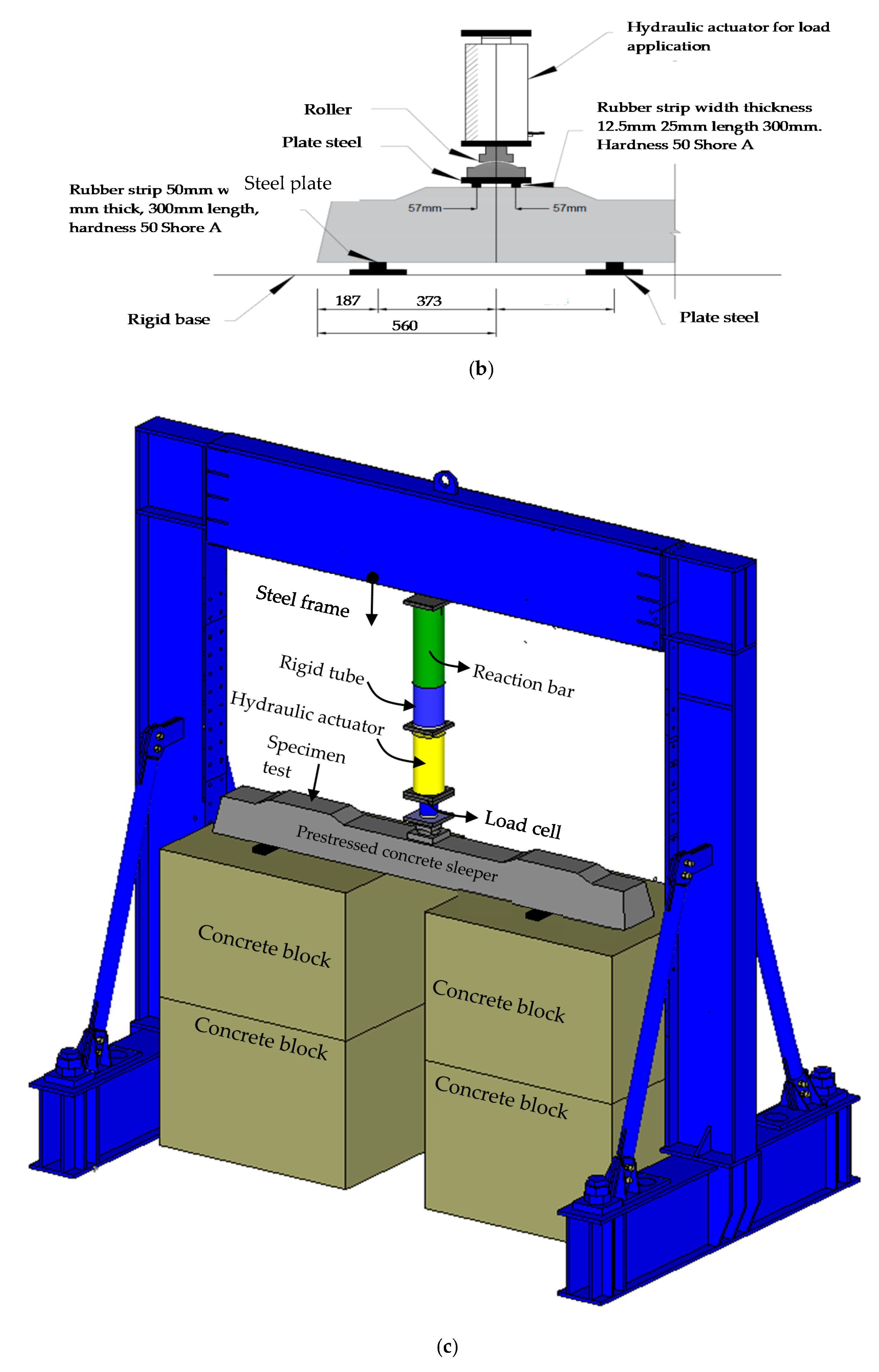

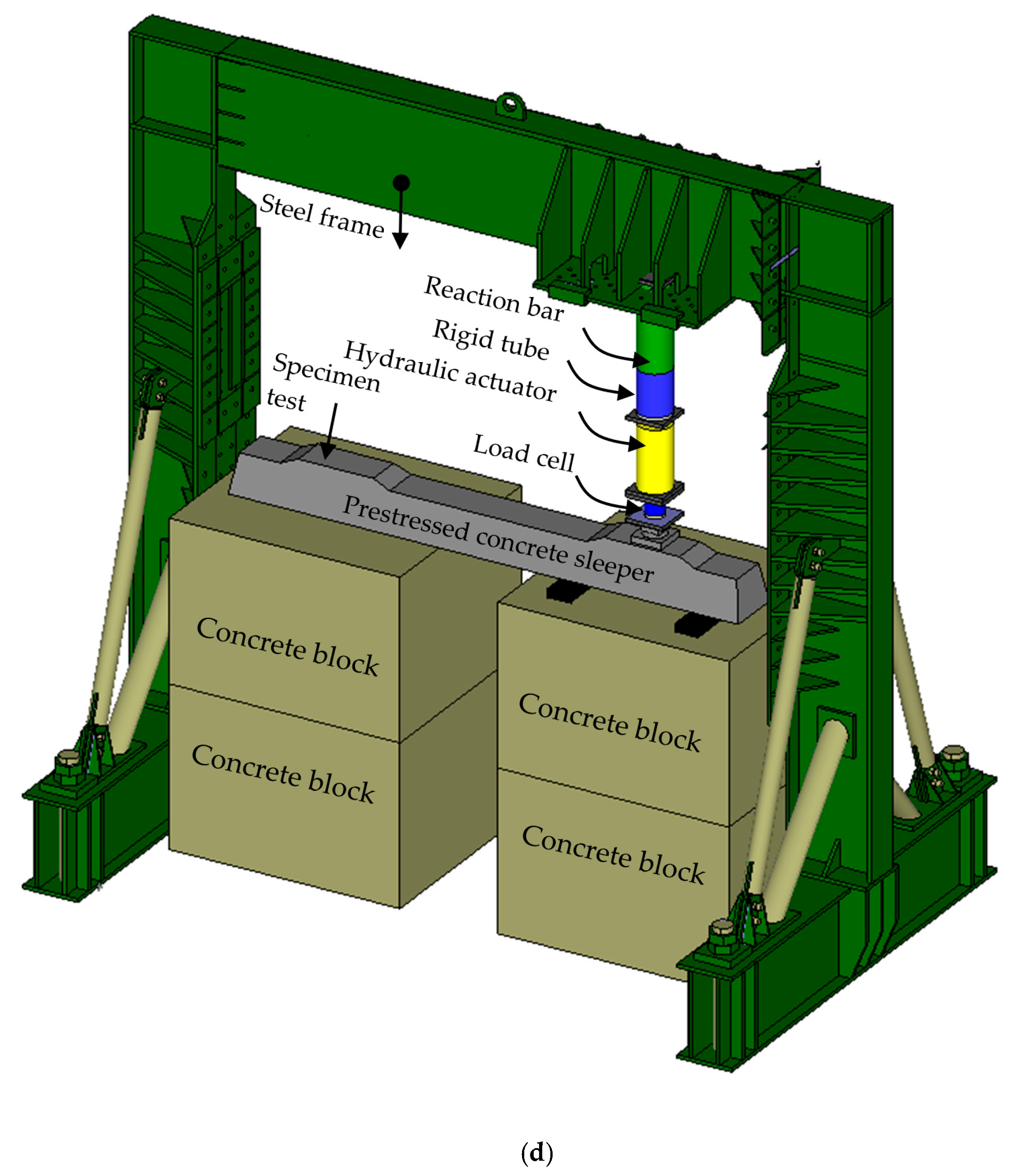

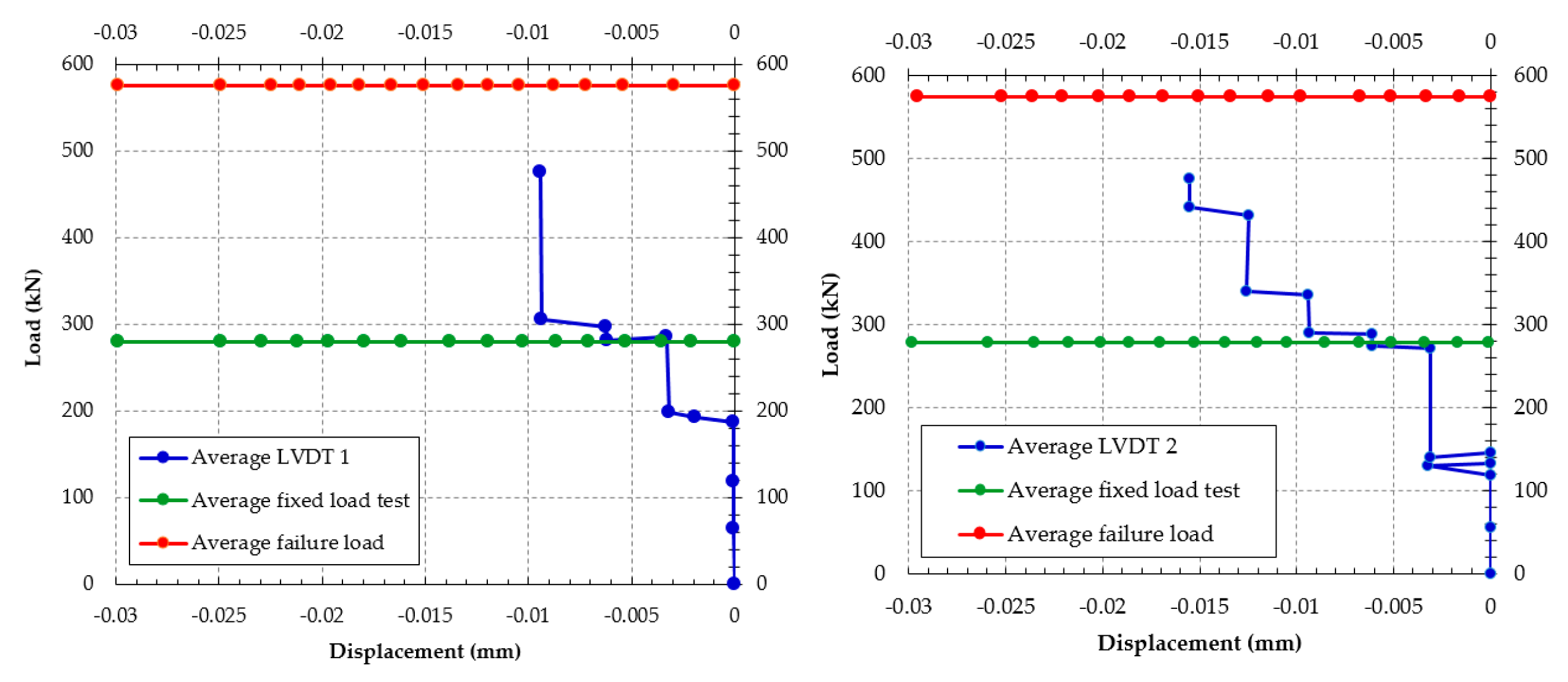

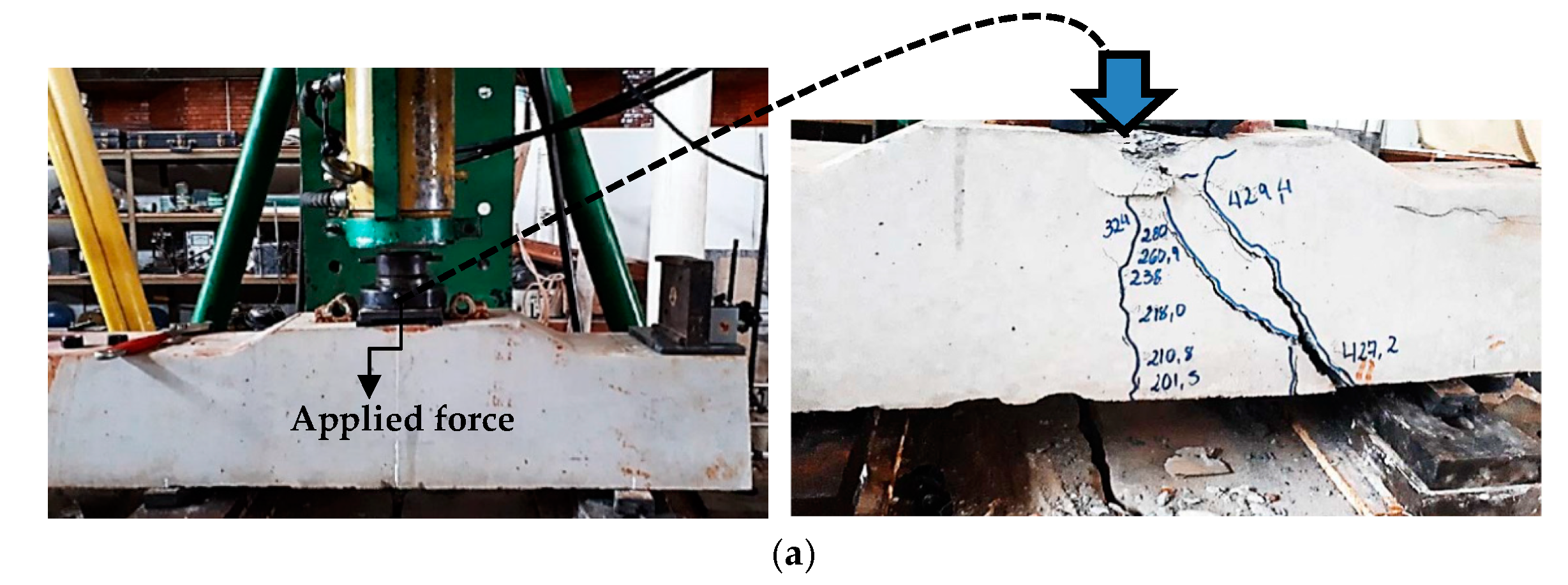

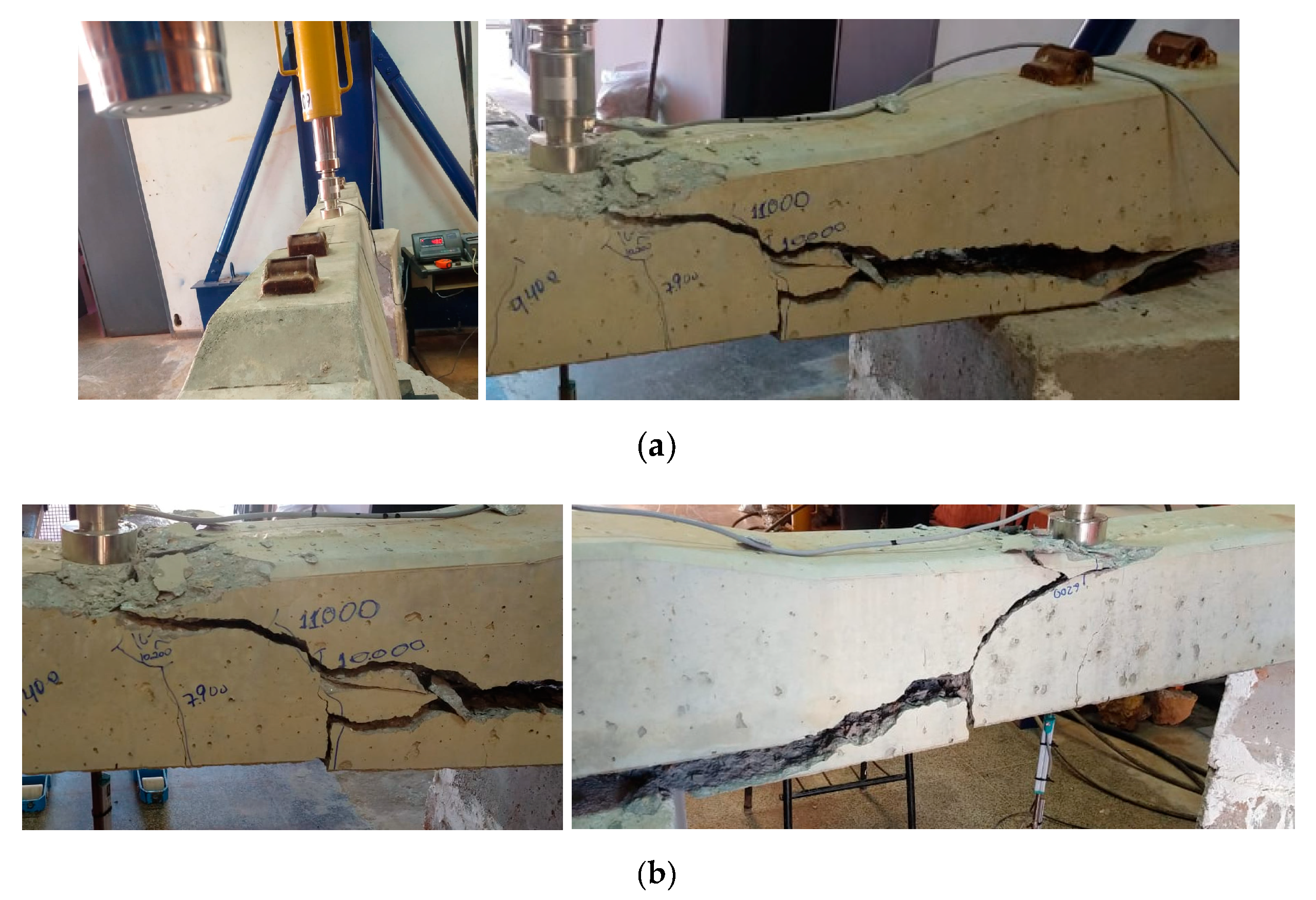

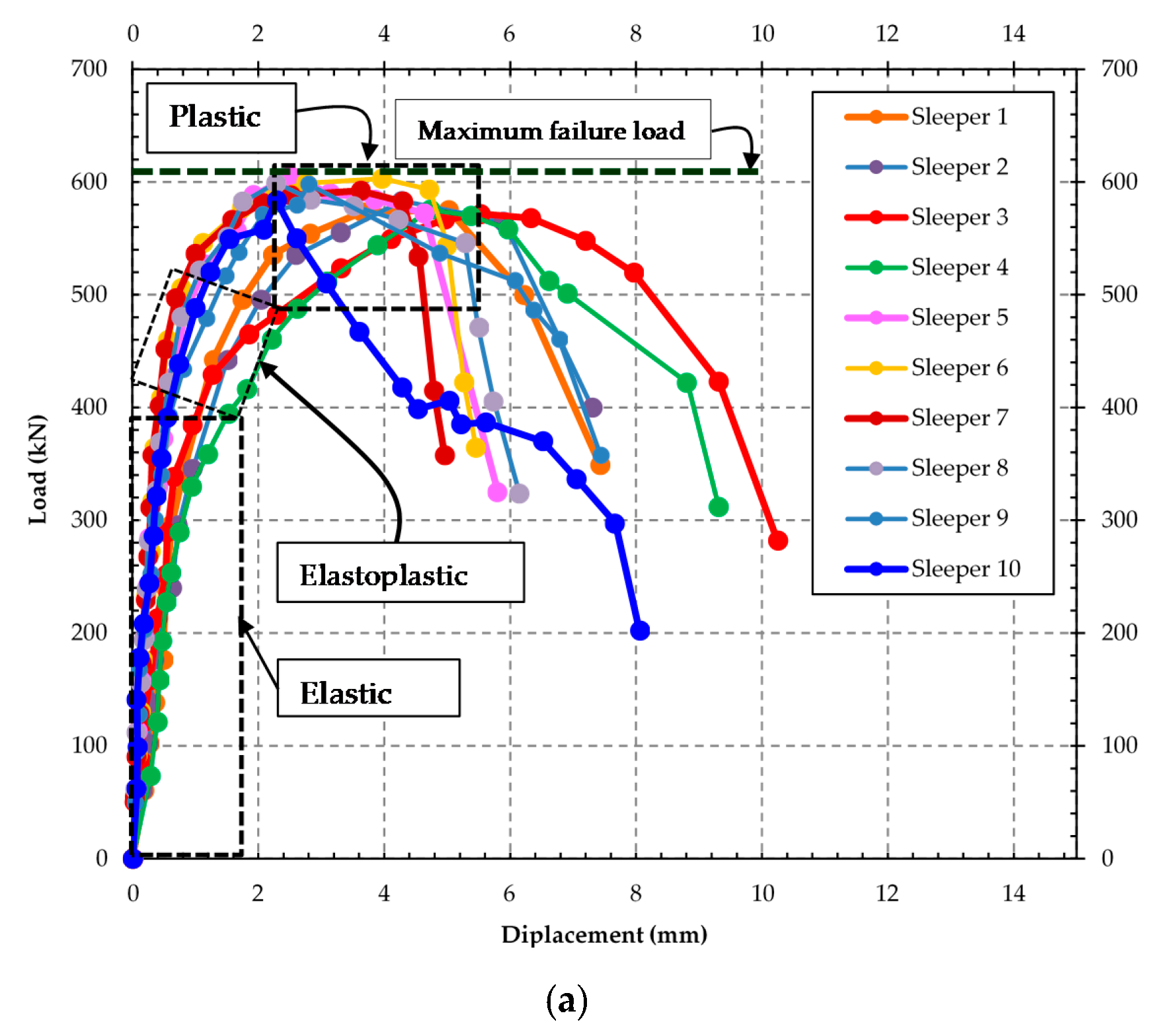

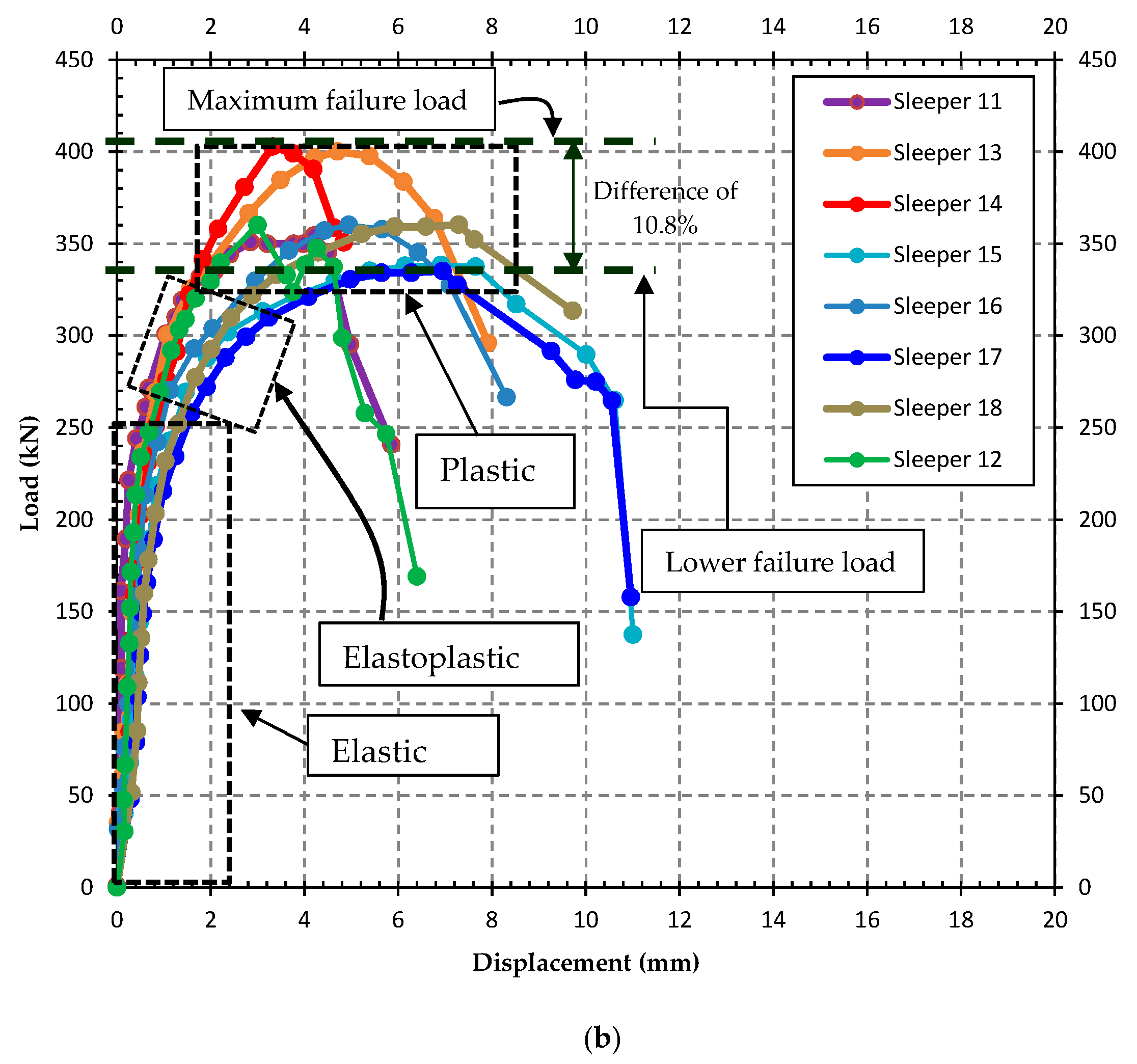

2. Experimental Investigations

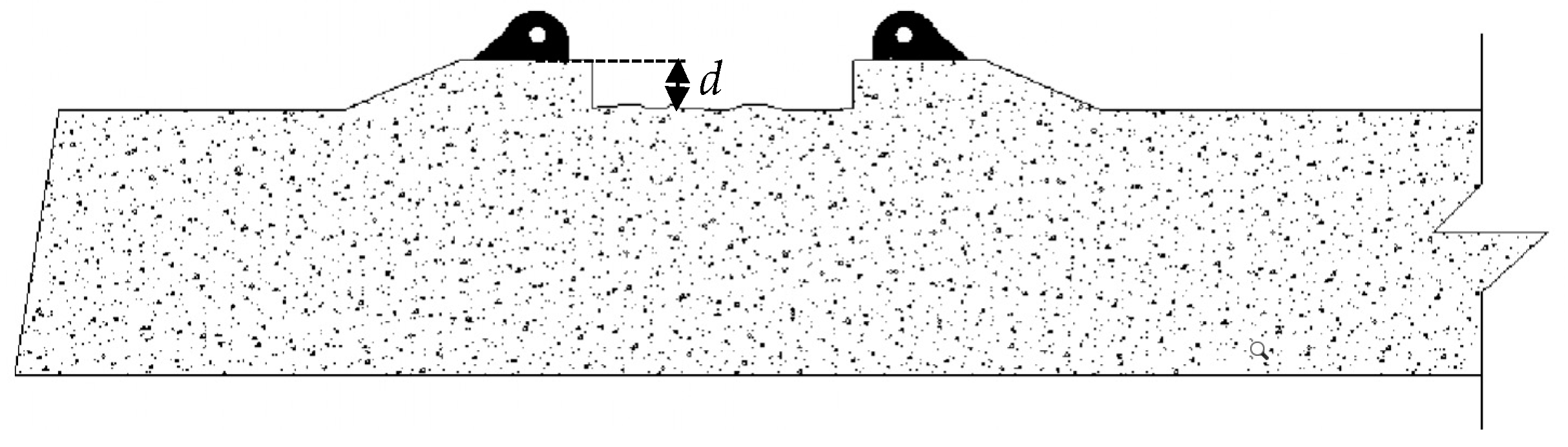

2.1. Details of Prestressed Sleeper

2.2. Compressive Strength Test of Concrete and Experimental Procedures

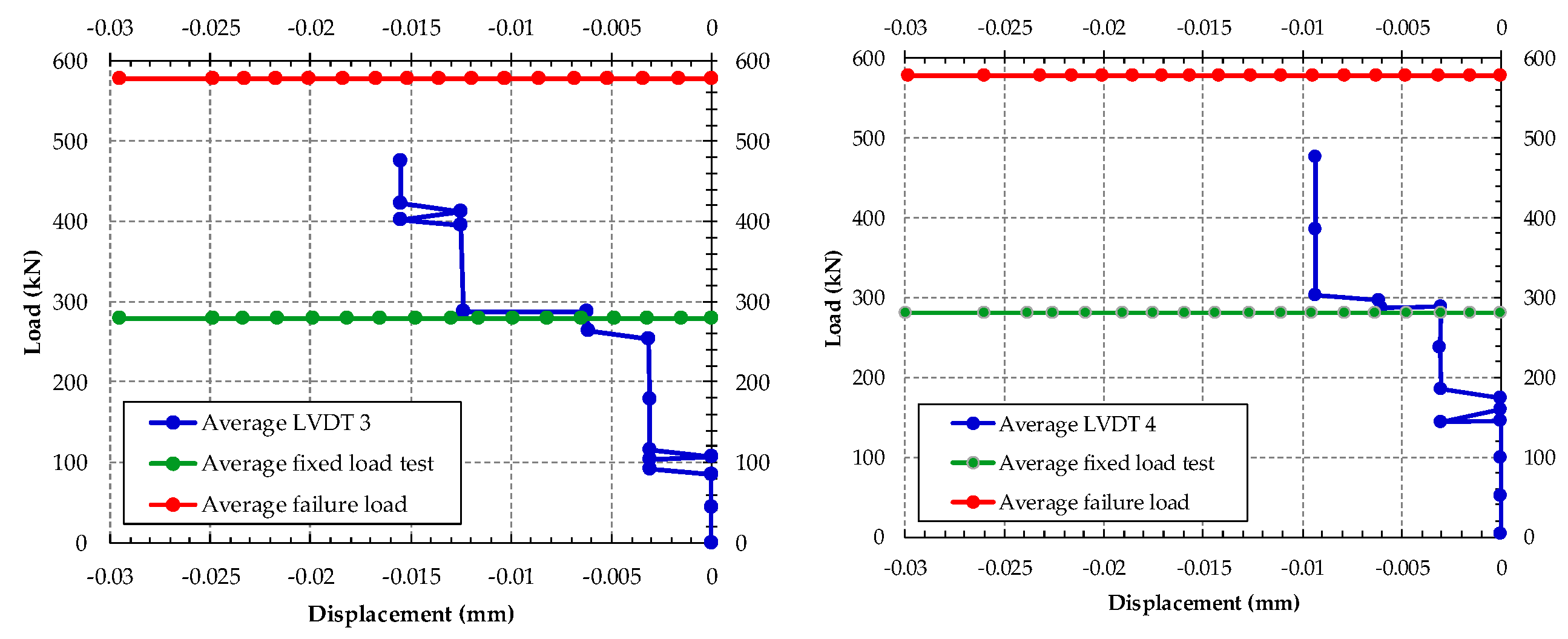

3. Experimental Results and Discussion

4. Finite Element Analysis

4.1. Numerical Model of the Concrete Sleeper

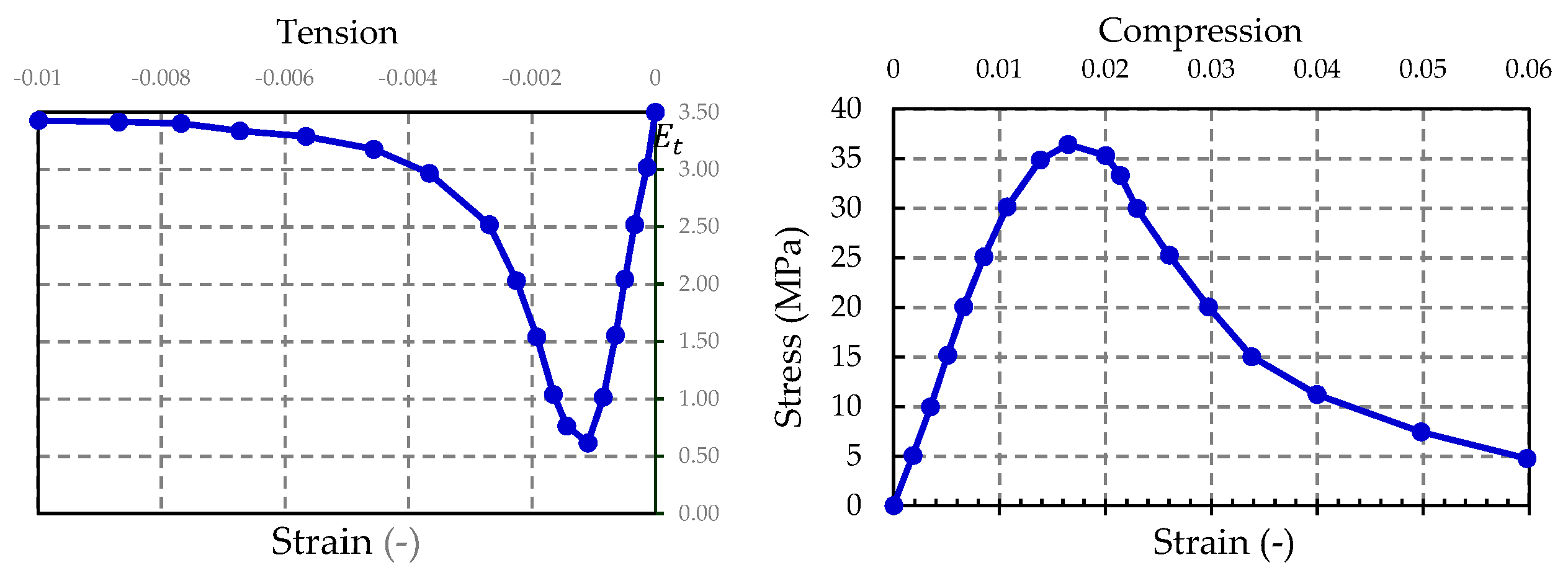

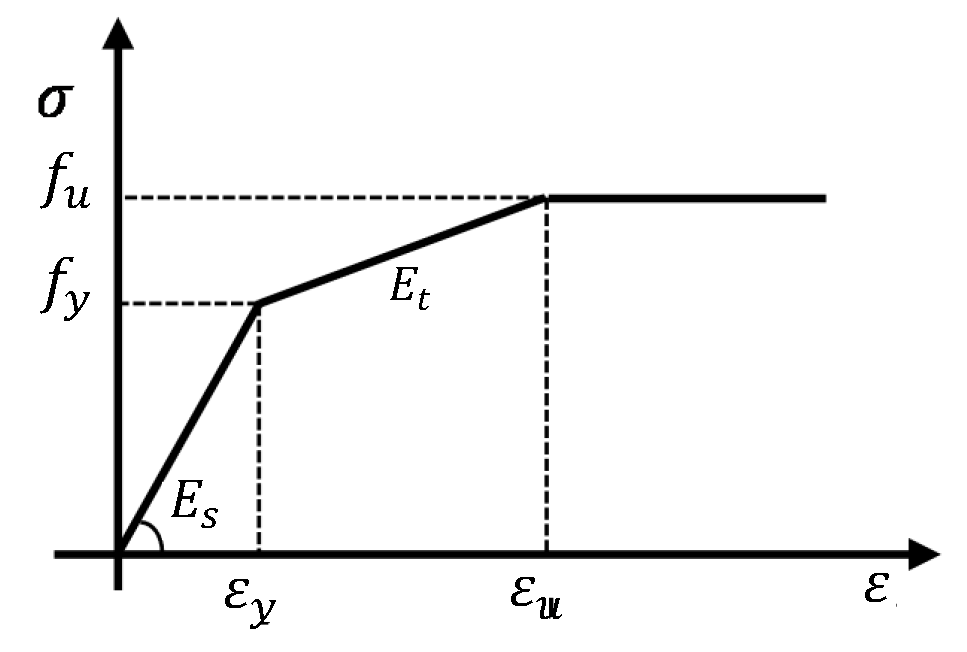

4.2. Material Models

4.3. Loading Application and Boundary Conditions

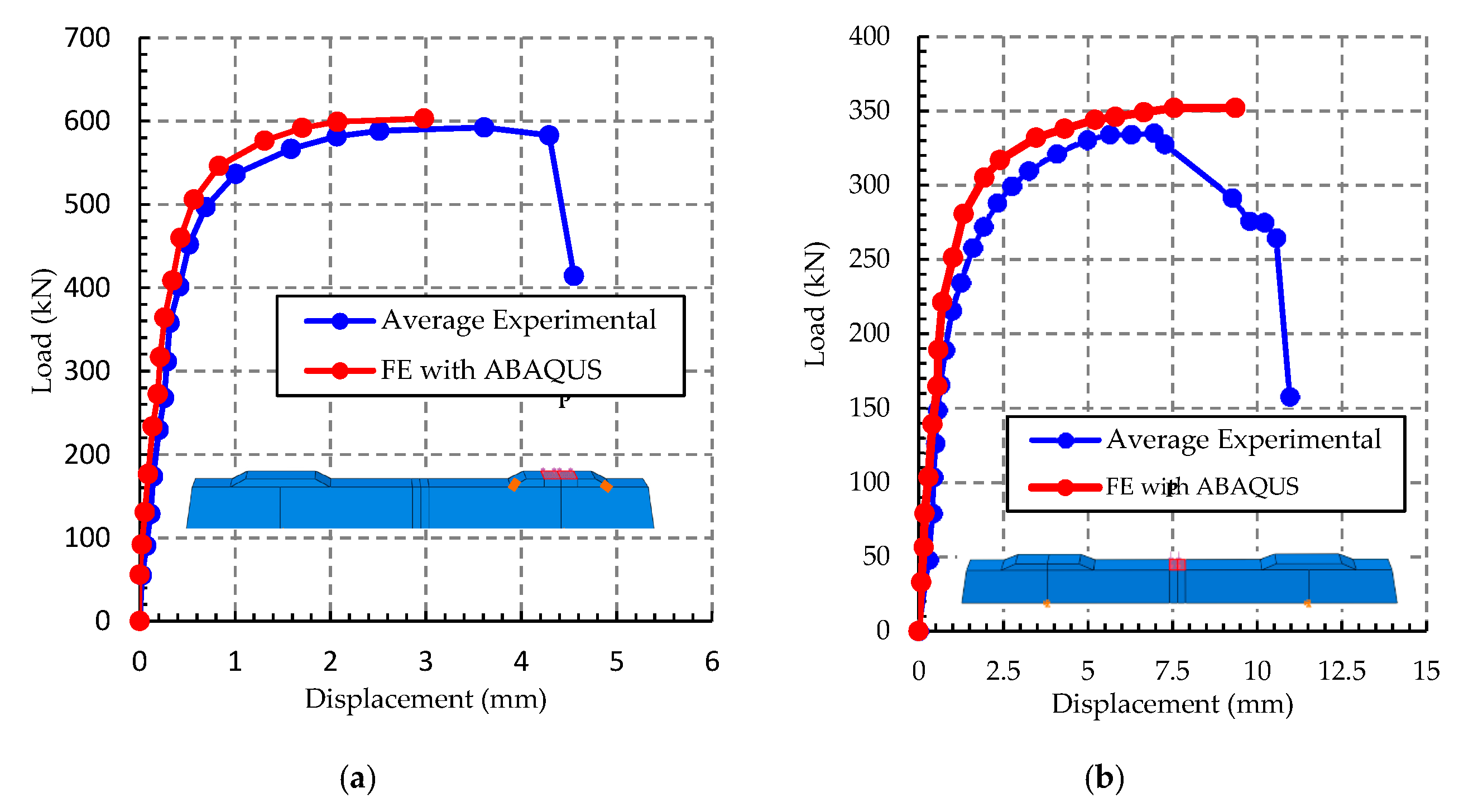

4.4. Validation of Numerical Models

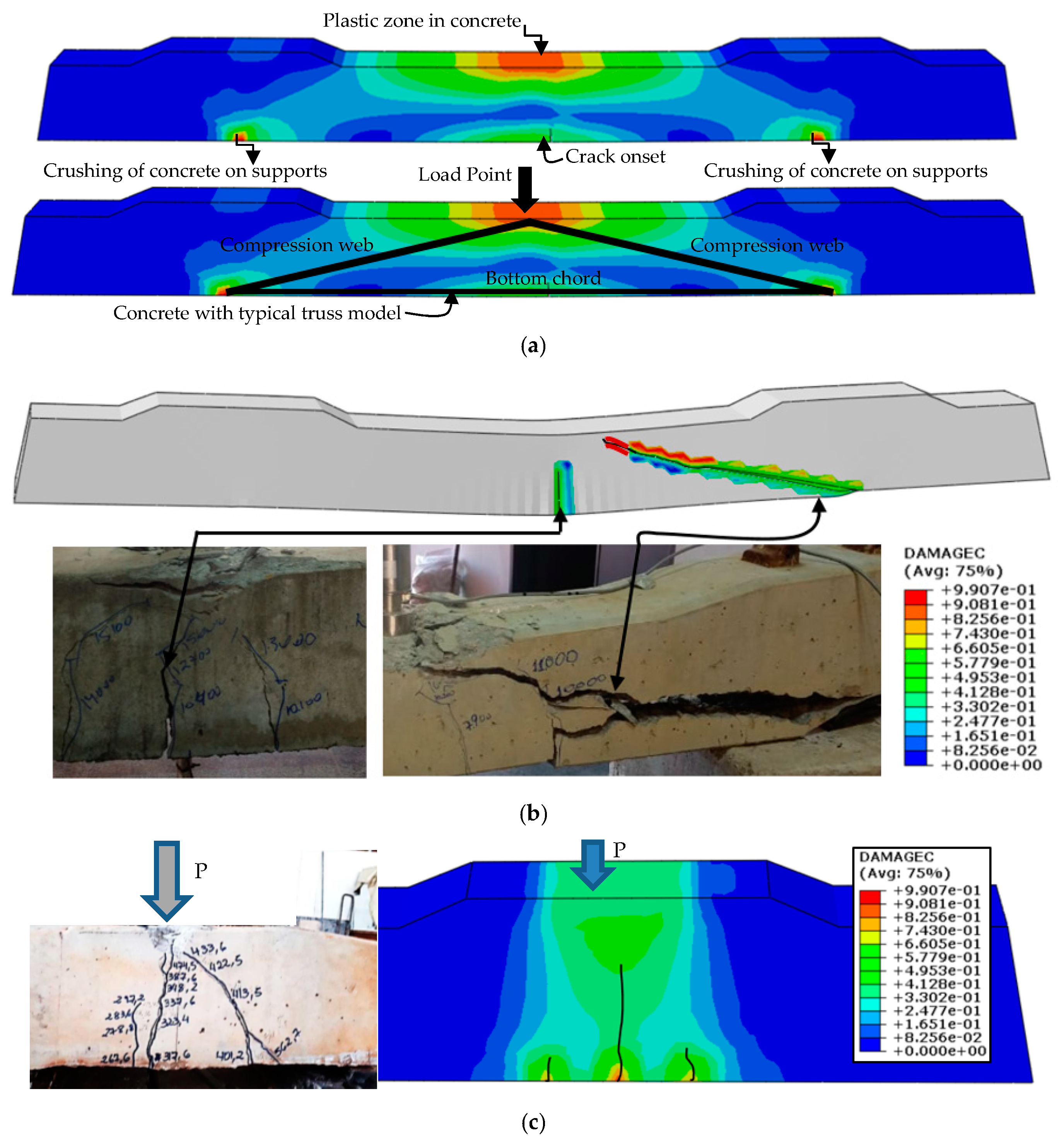

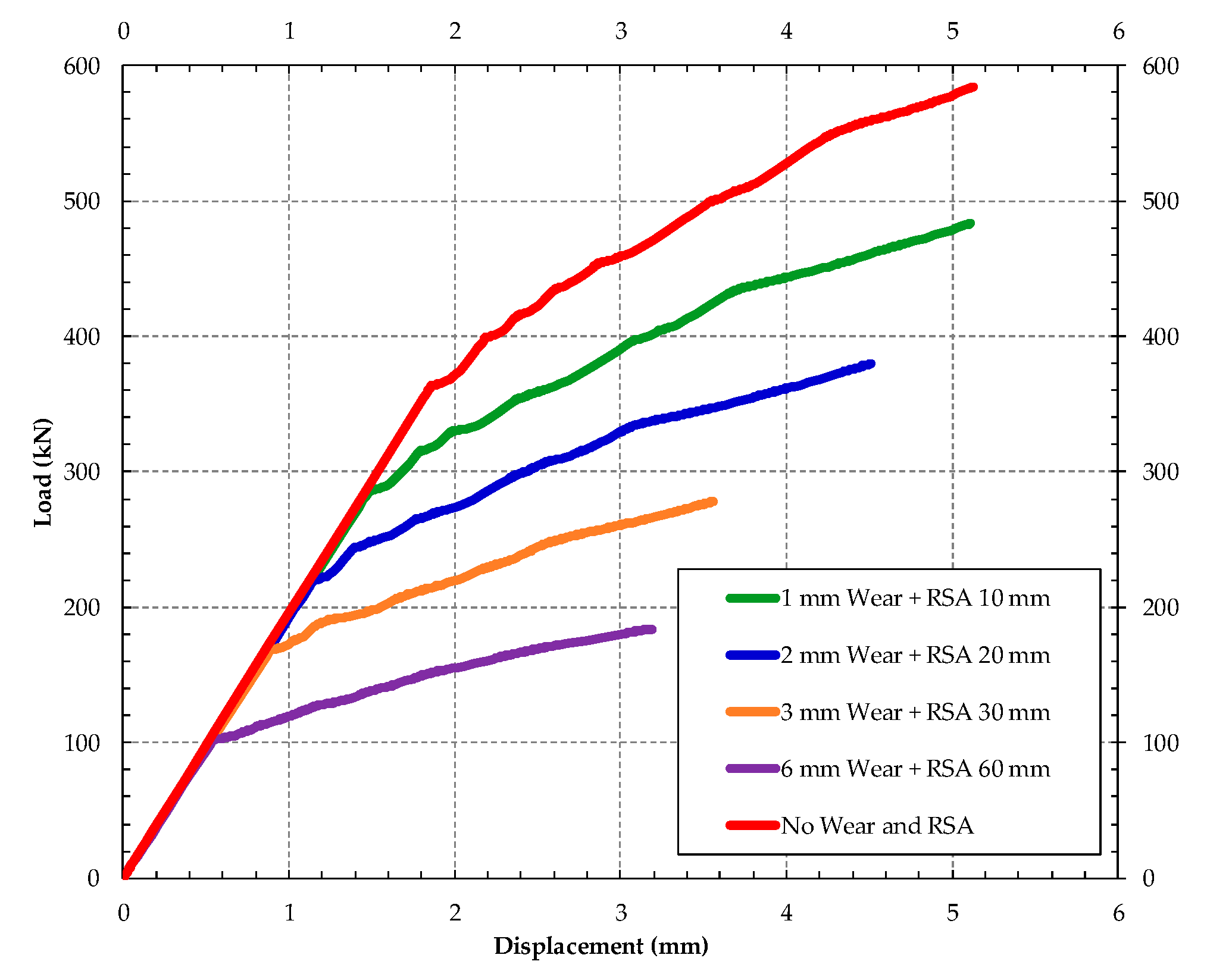

5. Pathologies Simulation

6. Conclusions

- The experimental results pointed out that the sleepers were designed in accordance with Brazilian standards.

- The use of the CDP model for concrete behavior was considered satisfactory. The numerical mechanical behavior was similar to experimental ones from the beginning of plastification up to the final failure stage.

- Simulations of the post-buckling behavior of the structure (in post-critical states) were carried out, using the Riks analysis available in the Abaqus software [26], which enables “passing” through the bifurcation point. In this way, it was possible not only increase but also decrease the force in order to meet the static equilibrium criterion.

- The size of the calculation step in the modified Riks method [43] depends on the “Arc Length”, measured along the static equilibrium path in the load–displacement space.

- It was also possible to evaluate the impact of local pathologies in the sleeper’s load-carrying capacity. These deleterious effects of reinforcement degradation are responsible for reducing the sleeper strength, which may lead to a loss of more than 50% of the load-carrying capacity.

- It is important to highlight the relevance of prestressing, good construction practices (well-performed cure and low water/cement ratio) and other anti-cracking mechanisms in the durability of the sleeper in order to get a good response from the sleepers over their service life.

- The numerical model carried out could be used to predict static responses of prestressed concrete sleepers.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Remennikov, A.; Kaewunruen, S. Experimental load rating of aged railway concrete sleepers. Eng. Struct. 2014, 76, 147–162. [Google Scholar] [CrossRef]

- Farnam, S.M.; Rezaei, F. Part A- experimental: experimental analysis of crack propagation in pre-stressed concrete sleepers by fracture mechanics. Int. J. Transp. Eng. 2017, 5, 17–29. [Google Scholar]

- Farnam, S.; Rezaie, F. Simulation of crack propagation in prestressed concrete sleepers by fracture mechanics. Eng. Fail. Anal. 2019, 96, 109–117. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Gamage, E.K.; Remennikov, A. Structural Behaviours of Railway Prestressed Concrete Sleepers (Crossties) With Hole and Web Openings. Procedia Eng. 2016, 161, 1247–1253. [Google Scholar] [CrossRef]

- Farnam, S.M.; Rezaei, F. Experimental analysis of fracture and damage mechanics of pre-stressed concrete sleepers B70: part B- analysis. Int. J. Transp. Eng. 2017, 5, 163–177. [Google Scholar]

- Karihaloo, B.; Nallathambi, P. Fracture toughness of plain concrete from three-point bend specimens. Mater. Struct. 1989, 22, 185–193. [Google Scholar] [CrossRef]

- Zi, G.; Moon, D.Y.; Lee, S.-J.; Jang, S.Y.; Yang, S.C.; Kim, S.-S. Investigation of a concrete railway sleeper failed by ice expansion. Eng. Fail. Anal. 2012, 26, 151–163. [Google Scholar] [CrossRef]

- Dugarte, M.; Martinez-Arguelles, G.; Torres, J. Experimental Evaluation of Modified Sulfur Concrete for Achieving Sustainability in Industry Applications. Sustainability 2018, 11, 70. [Google Scholar] [CrossRef]

- Smith, P. Design and specification of marine concrete structures. Mar. Concr. Struct. 2016, 65–114. [Google Scholar] [CrossRef]

- PKoteš, P.; Strieška, M.; Bahleda, F.; Bujňáková, P. Prediction of RC Bridge Member Resistance Decreasing in Time under Various Conditions in Slovakia. Materials 2020, 13, 1125. [Google Scholar] [CrossRef]

- Bastos, P.S.S.; Pinheiro, L.M. Prestressed concrete sleepers reinforced with steel fibers. Cad. Eng. Estruturas. 2007, 9, 117–150. [Google Scholar]

- Rezaie, F.; Farnam, S. Fracture mechanics analysis of pre-stressed concrete sleepers via investigating crack initiation length. Eng. Fail. Anal. 2015, 58, 267–280. [Google Scholar] [CrossRef]

- Kaewunruen, S. Experimental and Numerical Studies for Evaluating Dynamic Behaviour of Prestressed Concrete Sleepers Subject to Severe Impact Loading. Ph.D Thesis, University of Wollongong, Wollongong, Australia, 2007; p. 412. Available online: http://ro.uow.edu.au/theses/277 (accessed on 3 April 2020).

- Sadeghi, J. Field Investigation on Dynamics of Railway Track Pre-Stressed Concrete Sleepers. Adv. Struct. Eng. 2010, 13, 139–151. [Google Scholar] [CrossRef]

- Sadeghi, J. Experimental evaluation of accuracy of current practices in analysis and design of railway track sleepers. Can. J. Civ. Eng. 2008, 35, 881–893. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Remennikov, A.M. Experimental and Numerical Studies of Railway Prestressed Concrete Sleepers under Static and Impact Loads. Civ. Comput. 2007, 3, 25–28. Available online: www.uow.edu.au (accessed on 3 April 2020).

- Remennikov, A.M.; Kaewunruen, S. Investigation of Vibration Characteristics of Prestressed Concrete Sleepers in Free-free and In-situ Conditions. Aust. Struct. Eng. Conf. 2005, 2005, 11–14. [Google Scholar]

- Kernes, R.G.; A Shurpali, A.; Edwards, J.R.; Dersch, M.; Lange, D.; Barkan, C.P.L. Investigation of the mechanics of rail seat deterioration and methods to improve the abrasion resistance of concrete sleeper rail seats. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2014, 228, 581–589. [Google Scholar] [CrossRef]

- ABNT NBR 11709, Concrete sleepers—Design, materials and components. Brazilian Assoc. Tech. Stand. 2015, 137.

- AREMA. Concrete Ties. In Evalution Tests for Tie Systems; AREMA: Lanham, MD, USA, 2010; Volume 1, Chapter 30, Part 4. [Google Scholar]

- Taherinezhad, J.; Sofi, M.; Mendis, P.A.; Ngo, T. A review of behaviour of Prestressed concrete sleepers, Electron. J. Struct. Eng. 2013, 13, 1–16. [Google Scholar]

- You, R.; Goto, K.; Ngamkhanong, C.; Kaewunruen, S. Nonlinear finite element analysis for structural capacity of railway prestressed concrete sleepers with rail seat abrasion. Eng. Fail. Anal. 2019, 95, 47–65. [Google Scholar] [CrossRef]

- Remennikov, A.M.; Murray, M.H.; Kaewunruen, S. Conversion of AS1085. 14 for Prestressed Concrete Sleeepers to Limit States Design Format, AusRAIL PLUS. 2007, pp. 1–18. Available online: www.uow.edu.au (accessed on 3 April 2020).

- ABNT NBR 5739. Concrete—Compression test of cylindrical specimens ABNT NBR 5739. Brazilian Assoc. Tech. Stand. 2018, 71.

- ABNT NBR 7680. Concrete—Sampling, preparing, testing and result analysis of concrete cores Part 1: Axial compressive strength. Brazilian Assoc. Tech. Stand. 2015, 28.

- ABAQUS. Theory Manual; Version 6.11; Dassault Systèmes Simulia Corp: Providence, RI, USA, 2011. [Google Scholar]

- Chen, Z.; Shin, M.; Wei, S.; Andrawes, B.; A Kuchma, D. Finite element modeling and validation of the fastening systems and concrete sleepers used in North America. Proc. Inst. Mech. Eng. Part F: J. Rail Rapid Transit 2014, 228, 590–602. [Google Scholar] [CrossRef]

- Rezaie, F.; Farnam, S.M. Sensitivity analysis of pre-stressed concrete sleepers for longitudinal crack prorogation effective factors. Eng. Fail. Anal. 2016, 66, 385–397. [Google Scholar] [CrossRef]

- Inc., A. ABAQUS; Dassault Systèmes Simulia Corp: Josnton, RI, USA, 2016. [Google Scholar]

- Śledziewski, K.; Górecki, M. Finite Element Analysis of the Stability of a Sinusoidal Web in Steel and Composite Steel-Concrete Girders. Materials 2020, 13, 1041. [Google Scholar] [CrossRef]

- Alfarah, B.; López-Almansa, F.; Oller, S. New methodology for calculating damage variables evolution in Plastic Damage Model for RC structures. Eng. Struct. 2017, 132, 70–86. [Google Scholar] [CrossRef]

- Lubliner, J.; Oliver, J.; Oller, S.; Onate, E. A plastic-damage model for concrete. Int. J. Solids Struct. 1989, 25, 299–326. [Google Scholar] [CrossRef]

- Oller, S.; Onate, E.; Oliver, J.; Lubliner, J. Finite element nonlinear analysis of concrete structures using a “plastic-damage model”. Eng. Fract. Mech. 1990, 35, 219–231. [Google Scholar] [CrossRef]

- ABAQUS. User’s Manual; Version 6.14-1; Dassault Systèmes Simulia Corp: Providence, RI, USA, 2014. [Google Scholar]

- Farias, M.M.; Naylor, D.J. Safety analysis using finite elements. Comput. Geotech. 1998, 22, 165–181. [Google Scholar] [CrossRef]

- Zeman, J.C.; Edwards, J.R.; Lange, D.A.; Barkan, C.P.L. Investigation of Potential Concrete Tie Rail Seat Deterioration Mechanisms: Cavitation Erosion and Hydraulic Pressure Cracking. In Proceedings of the Transportation Research Board 89th Annual Meeting, Washington, DC, USA, 10–14 January 2009; pp. 1–13. [Google Scholar]

- Jin, Z.; Yuan, L.; Pei, S. Efficient evaluation of bridge deformation for running safety of railway vehicles using simplified models. Adv. Struct. Eng. 2019, 23, 454–467. [Google Scholar] [CrossRef]

- Jankowiak, T.; Łodygowski, T. Quasi-Static Failure Criteria for Concrete/Quasi-Statyczne Kryteria Zniszczenia Betonu. Arch. Civ. Eng. 2010, 56, 123–154. [Google Scholar] [CrossRef]

- Yu, T.; Teng, J.-G.; Wong, Y.; Dong, S. Finite element modeling of confined concrete-II: Plastic-damage model. Eng. Struct. 2010, 32, 680–691. [Google Scholar] [CrossRef]

- Kmiecik, P.; Kaminski, M. Modelling of reinforced concrete structures and composite structures with concrete strength degradation taken into consideration. Arch. Civ. Mech. Eng. 2011, 11, 623–636. [Google Scholar] [CrossRef]

- Śledziewski, K. Selection of appropriate concrete model in numerical calculation. ITM Web Conf. 2017, 15, 7012. [Google Scholar] [CrossRef]

- Lee, J.; Fenves, G.L. Plastic-Damage Model for Cyclic Loading of Concrete Structures. J. Eng. Mech. 1998, 124, 892–900. [Google Scholar] [CrossRef]

- Riks, E. An incremental approach to the solution of snapping and buckling problems. Int. J. Solids Struct. 1979, 15, 529–551. [Google Scholar] [CrossRef]

- Aslani, F.; Jowkarmeimandi, R. Stress—Strain model for concrete under cyclic loading. Mag. Concr. Res. 2012, 64, 673–685. [Google Scholar] [CrossRef]

| Sleeper Specimen | d (mm) | h (mm) | h/d (--) | k1 (--) | k2 (--) | k3 (--) | k4 (--) | Area (mm²) | Load (kN) | Stress (MPa) |

|---|---|---|---|---|---|---|---|---|---|---|

| CP1 | 68 | 121.1 | 1.78 | 0.01 | 0.12 | 0 | 0.04 | 3631.7 | 79.4 | 85.0 |

| CP2 | 68 | 121.0 | 1.78 | 0.01 | 0.12 | 0 | 0.04 | 3631.7 | 64.6 | 69.1 |

| CP3 | 68 | 132.4 | 1.95 | 0.01 | 0.12 | 0 | 0.04 | 3631.7 | 57.7 | 61.7 |

| CP4 | 68 | 132.9 | 1.96 | 0.01 | 0.12 | 0 | 0.04 | 3631.7 | 58.1 | 62.1 |

| CP5 | 68 | 120.6 | 1.77 | 0.01 | 0.12 | 0 | 0.04 | 3631.7 | 49.2 | 52.6 |

| CP6 | 68 | 110.7 | 1.63 | 0.02 | 0.12 | 0 | 0.04 | 3631.7 | 59.3 | 62.9 |

| CP7 | 68 | 132.4 | 1.95 | 0.01 | 0.12 | 0 | 0.04 | 3631.7 | 57.7 | 61.7 |

| CP8 | 68 | 132.9 | 1.96 | 0.01 | 0.12 | 0 | 0.04 | 3631.7 | 58.1 | 62.1 |

| CP9 | 68 | 120.6 | 1.77 | 0.01 | 0.12 | 0 | 0.04 | 3631.7 | 49.2 | 52.6 |

| CP10 | 68 | 110.7 | 1.63 | 0.02 | 0.12 | 0 | 0.04 | 3631.7 | 59.3 | 62.9 |

| Sleeper Specimen | Reference Load (kN) | Average Load Applied (kN) | Load Time Applied (min) | Crack Load of the Sleeper (kN) | Failure Load (kN) |

|---|---|---|---|---|---|

| SS1 | 278.24 | 278.24 | 8 | 267.60 | 576 |

| SS2 | 278.24 | 278.31 | 8 | 233.10 | 566 |

| SS3 | 278.24 | 278.02 | 8 | 210.50 | 490 |

| SS4 | 278.24 | 278.21 | 8 | 262.20 | 578 |

| SS5 | 278.24 | 278.22 | 8 | 254.4 | 601 |

| SS6 | 278.24 | 278.24 | 8 | 248.1 | 608 |

| SS7 | 278.24 | 278.27 | 8 | 234.41 | 589 |

| SS8 | 278.24 | 278.18 | 8 | 241.17 | 589 |

| SS9 | 278.24 | 278.31 | 8 | 238.11 | 583 |

| SS10 | 278.24 | 278.26 | 8 | 238.10 | 597 |

| Internal Friction Angle | Eccentricity of the Plastic Potential | fb0/fc0 | Shape of the Plastic Potential Surface Kc | Viscosity Parameter |

|---|---|---|---|---|

| 36° | 0.1 | 1.16 | 0.667 | 0.005 |

| Elastic Modulus, Es (MPa) | Hardening Modulus Et (MPa) | Yield Stress, fy (MPa) | Poison Coefficient, (-) | Density (kN/m3) |

|---|---|---|---|---|

| 205.000 MPa | 200 MPa | 1700 MPa | 0.3 | 78 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, R.; Silva, W.V.; Farias, J.Y.d.; Santos, M.A.A.; Neiva, L.O. Experimental and Numerical Analyses of the Failure of Prestressed Concrete Railway Sleepers. Materials 2020, 13, 1704. https://doi.org/10.3390/ma13071704

Silva R, Silva WV, Farias JYd, Santos MAA, Neiva LO. Experimental and Numerical Analyses of the Failure of Prestressed Concrete Railway Sleepers. Materials. 2020; 13(7):1704. https://doi.org/10.3390/ma13071704

Chicago/Turabian StyleSilva, Ramon, Welington V. Silva, Jonas Yamashita de Farias, Marcos Aires A. Santos, and Leonardo O. Neiva. 2020. "Experimental and Numerical Analyses of the Failure of Prestressed Concrete Railway Sleepers" Materials 13, no. 7: 1704. https://doi.org/10.3390/ma13071704

APA StyleSilva, R., Silva, W. V., Farias, J. Y. d., Santos, M. A. A., & Neiva, L. O. (2020). Experimental and Numerical Analyses of the Failure of Prestressed Concrete Railway Sleepers. Materials, 13(7), 1704. https://doi.org/10.3390/ma13071704