Microstructure and Wear Behavior of Laser Cladded Ni45 + High-Carbon Ferrochrome Composite Coatings

Abstract

1. Introduction

2. Experimental Materials and Procedure

3. Experimental Results and Analysis

4. Conclusions

- (1)

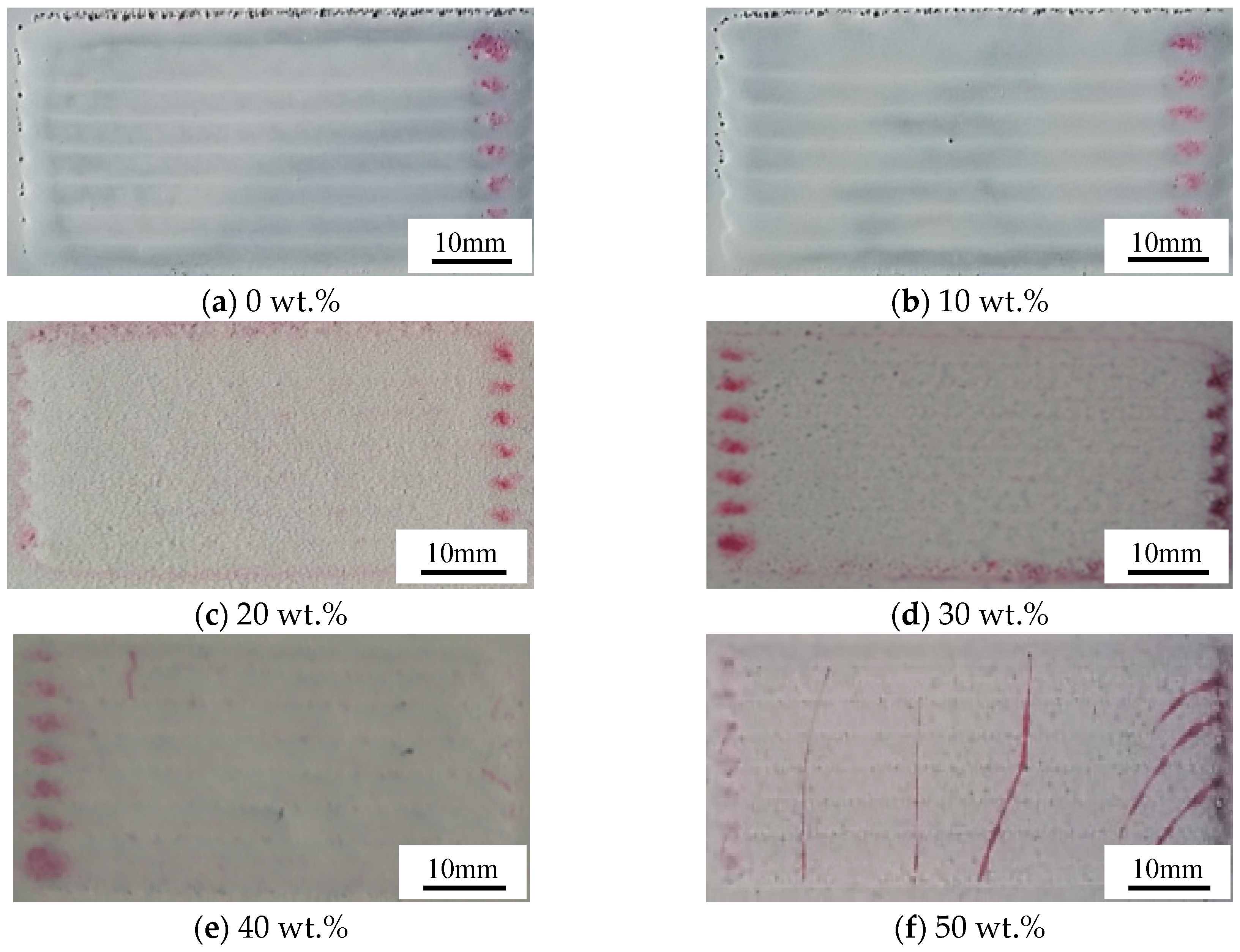

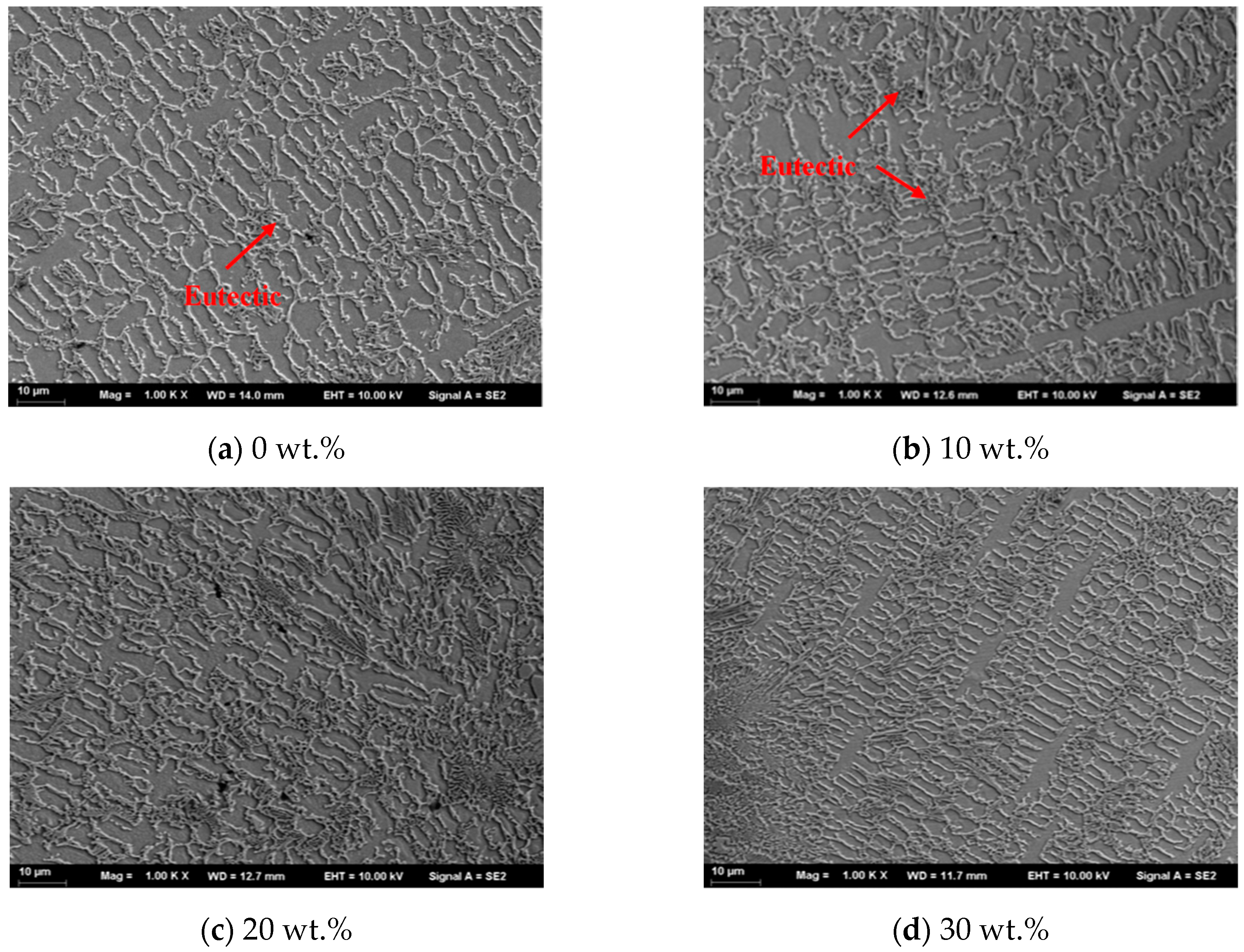

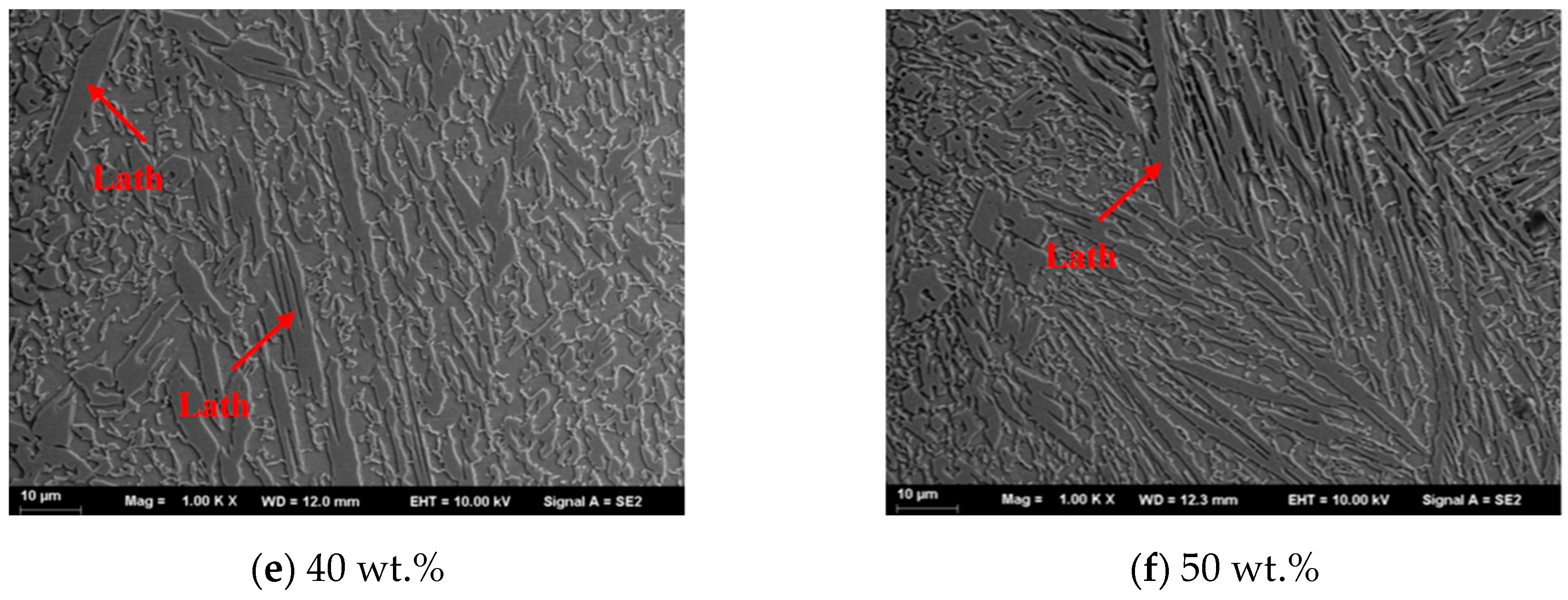

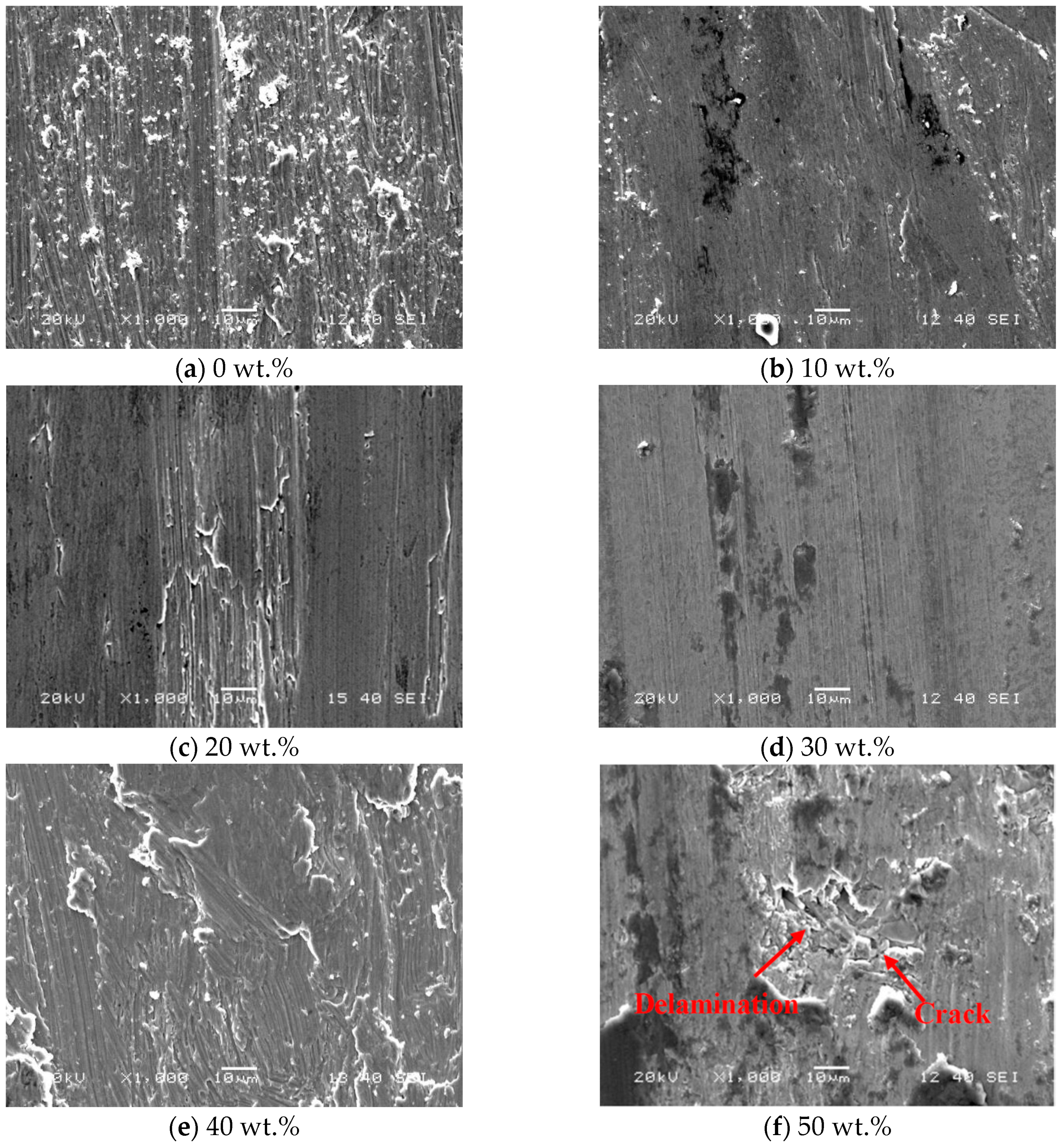

- Cracks appeared on the cladding surface when the added high-carbon ferrochrome content was higher than 40 wt.%. This could be related to the formation of hard phases including chromium carbides with increased C and Cr contents in the mixed powder.

- (2)

- The microhardness was enhanced remarkably by laser cladding Ni45 + high-carbon ferrochrome composite on the 1045 substrate, due to the existence of chromium carbides. It was found that with 30 wt.% high-carbon ferrochrome content, the microhardness of the composite coating was 2.4 times higher than that of the 1045 substrate.

- (3)

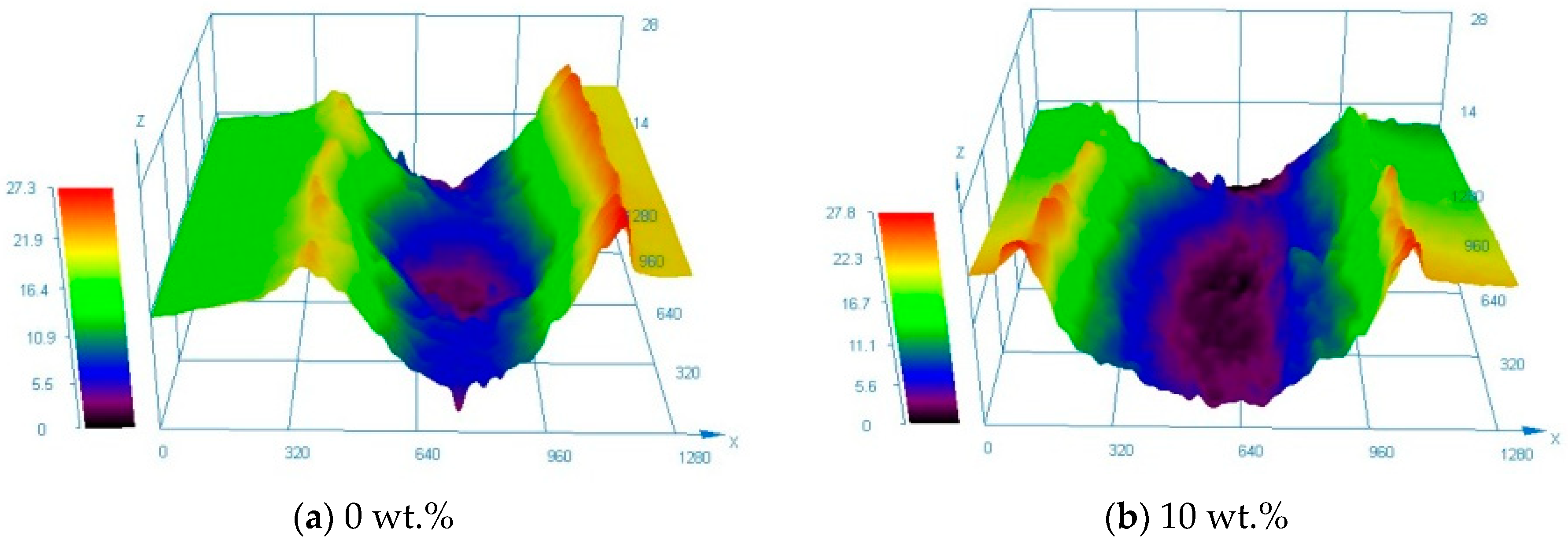

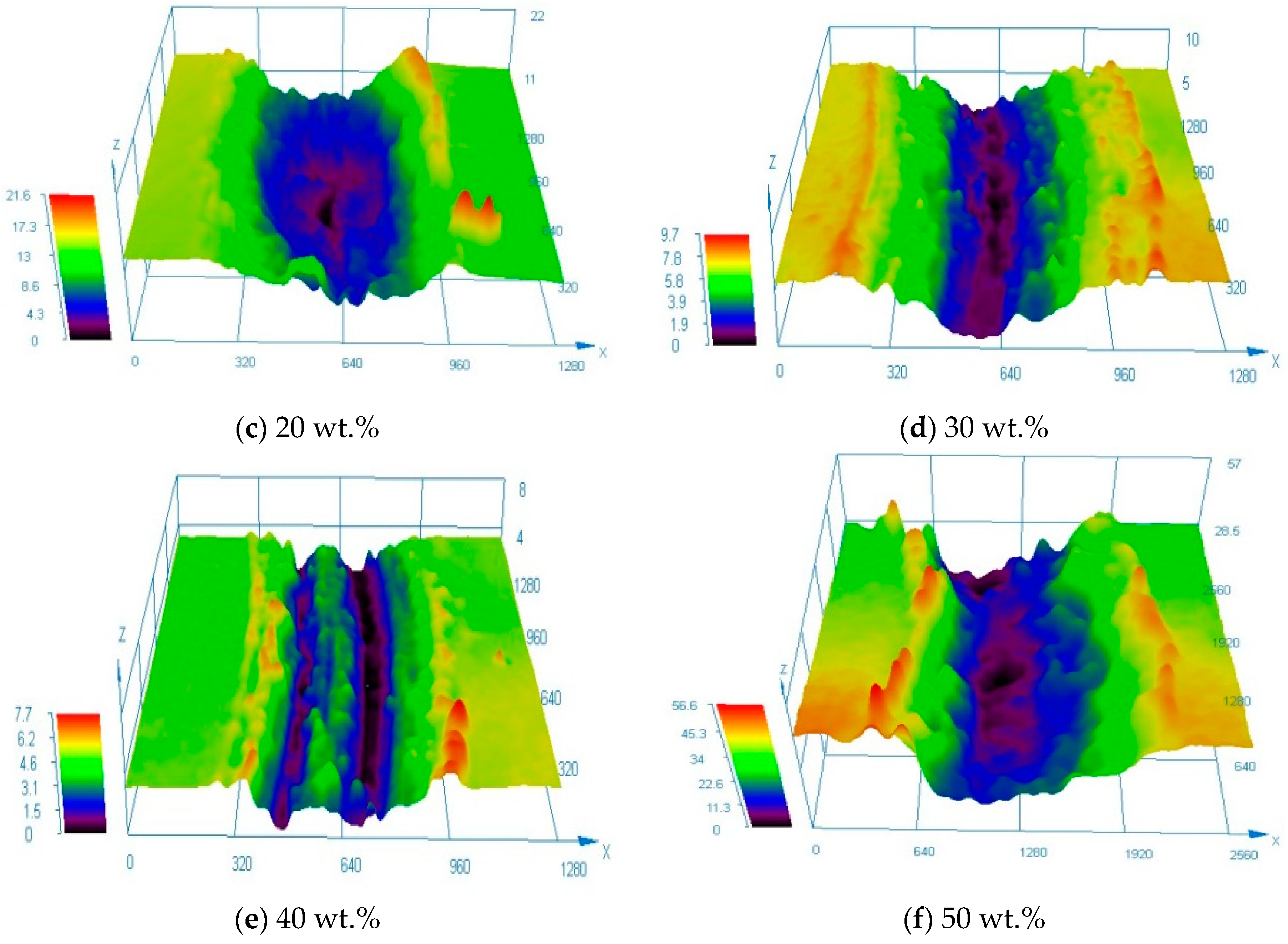

- The best wear performance was achieved when the high-carbon ferrochrome content was 30 wt.%, with the shallowest groove obtained lying along the wear track indicating the lowest wear rate. When further increasing the high-carbon ferrochrome content, microcracking and delamination were observed on the worn surfaces.

Author Contributions

Funding

Conflicts of Interest

References

- Farahmand, P.; Kovacevic, R. An experimental-numerical investigation of heat distribution and stress field in single-and multi-track laser cladding by a high-power direct diode laser. Opt. Lasers Technol. 2014, 63, 154–168. [Google Scholar] [CrossRef]

- Li, R.; Zheng, Q.; Zhu, Y.; Li, Z.; Feng, K.; Liu, C. Experimental study of the microstructure and micromechanical properties of laser cladded Ni-based amorphous composite coatings. J. Mater. Eng. Perform. 2018, 27, 80–88. [Google Scholar] [CrossRef]

- Liu, B.; Dong, S. Anisotropic structure affects thickness measurement of laser cladding coating with surface ultrasonic wave based on cross-correlation function. Mater. Res. Innov. 2015, 19, 1–5. [Google Scholar] [CrossRef]

- Cheng, J.; Feng, Y.; Yan, C.; Hu, X.; Li, R.; Liang, X. Development and characterization of Al-based amorphous coating. JOM 2020, 72, 745–753. [Google Scholar] [CrossRef]

- Quazi, M.M.; Fazal, M.A.; Haseeb, A.S.M.A.; Yusof, F.; Masjuki, H.H.; Arslan, A. A review to the laser cladding of self-lubricating composite coatings. Lasers Manuf. Mater. Process. 2016, 3, 67–99. [Google Scholar] [CrossRef]

- Weng, F.; Chen, C.; Yu, H. Research status of laser cladding on titanium and its alloys: A review. Mater. Des. 2014, 58, 412–425. [Google Scholar] [CrossRef]

- Guo, C.; Zhou, J.; Chen, J.; Zhao, J.; Yu, Y.; Zhou, H. High temperature wear resistance of laser cladding NiCrBSi and NiCrBSi/WC-Ni composite coatings. Wear 2011, 270, 492–498. [Google Scholar] [CrossRef]

- Navas, C.; Colaço, R.; de Damborenea, J.; Vilar, R. Abrasive wear behaviour of laser clad and flame sprayed-melted NiCrBSi coatings. Surf. Coat. Technol. 2006, 200, 6854–6862. [Google Scholar] [CrossRef]

- Wong, T.T.; Liang, G.Y.; He, B.L.; Woo, C.H. Wear resistance of laser-clad Ni–Cr–B–Si alloy on aluminium alloy. J. Mater. Process. Technol. 2000, 100, 142–146. [Google Scholar] [CrossRef]

- Fernández, E.; Cadenas, M.; González, R.; Navas, C.; Fernández, R.; de Damborenea, J. Wear behaviour of laser clad NiCrBSi coating. Wear 2005, 259, 870–875. [Google Scholar] [CrossRef]

- Wu, Q.; Li, W.; Zhong, N.; Gang, W.; Wang, H. Microstructure and wear behavior of laser cladding VC–Cr7C3 ceramic coating on steel substrate. Mater. Des. 2013, 49, 10–18. [Google Scholar] [CrossRef]

- Ye, F.; Hojamberdiev, M.; Xu, Y.; Zhong, L.; Yan, H.; Chen, Z. (Fe, Cr)7C3/Fe surface gradient composite: Microstructure, microhardness, and wear resistance. Mater. Chem. Phys. 2014, 147, 823–830. [Google Scholar] [CrossRef]

- Kaiming, W.; Yulong, L.; Hanguang, F.; Yongping, L.; Zhenqing, S.; Pengfei, M. A study of laser cladding NiCrBSi/Mo composite coatings. Surf. Eng. 2018, 34, 267–275. [Google Scholar] [CrossRef]

- Wang, K.; Fu, H.; Li, Y.; Lei, Y.; Wei, S.; Su, Z. Effect of power on microstructure and properties of laser cladding NiCrBSi composite coating. Int. J. Surf. Eng. Coat. 2017, 95, 328–336. [Google Scholar]

- Venkatesh, L.; Samajdar, I.; Tak, M.; Doherty, R.D.; Gundakaram, R.C.; Prasad, K.S.; Joshi, S.V. Microstructure and phase evolution in laser clad chromium carbide-NiCrMoNb. Appl. Surf. Sci. 2015, 357, 2391–2401. [Google Scholar] [CrossRef]

- Guo, L.J.; Wang, X.B.; Wang, F.H.; Wang, H.B. Modification of TiB2/Fe coating by SMAW with high carbon ferrochrome. Surf. Eng. 2013, 29, 642–646. [Google Scholar] [CrossRef]

- Cheng, F.J.; Wang, Y.S.; Yang, T.G. Microstructure and wear properties of Fe–VC–Cr7C3 composite coating on surface of cast steel. Mater. Charact. 2008, 59, 488–492. [Google Scholar] [CrossRef]

- Li, R.; Qiu, Y.; Zheng, Q.; Liu, B.; Chen, S.; Tian, Y. Finite element simulation of temperature and stress field for laser cladded nickel-based amorphous composite coatings. Coatings 2018, 8, 336. [Google Scholar] [CrossRef]

- Ma, L.; Huang, C.; Jiang, J.; Hui, R.; Xie, Y.; Liu, Z. Cracks formation and residual stress in chromium carbide overlays. Eng. Fail. Anal. 2013, 31, 320–337. [Google Scholar] [CrossRef]

- Wieczerzak, K.; Bala, P.; Stepien, M.; Cios, G.; Koziel, T. Formation of eutectic carbides in Fe-Cr-Mo-C alloy during non-equilibrium crystallization. Mater. Des. 2016, 94, 61–68. [Google Scholar] [CrossRef]

- Maslyuk, V.A.; Bondar, A.A.; Kuras, V.B.; Pidoprygora, M.I.; Varchenko, V.M. Structure and properties of iron–high-carbon ferrochrome powder composites. Powder Metall. Met. Ceram. 2013, 52, 291–297. [Google Scholar] [CrossRef]

- Lu, J.Z.; Cao, J.; Lu, H.F.; Zhang, L.Y.; Luo, K.Y. Wear properties and microstructural analyses of Fe-based coatings with various WC contents on H13 die steel by laser cladding. Surf. Coat. Technol. 2019, 369, 228–237. [Google Scholar] [CrossRef]

- Yu, J.; Song, B. Friction and wear behavior of a Ni-based alloy coating fabricated using a multistep induction cladding technique. Results Phys. 2018, 11, 105–111. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, X.; Yan, H. Phase composition, microstructure evolution and wear behavior of Ni-Mn-Si coatings on copper by laser cladding. Surf. Coat. Technol. 2017, 332, 504–510. [Google Scholar] [CrossRef]

- Amado, J.M.; Tobar, M.J.; Yáñez, A.; Amigó, V.; Candel, J.J. Crack free tungsten carbide feinforced Ni(Cr) layers obtained by laser cladding. Phys. Procedia 2011, 12, 338–344. [Google Scholar] [CrossRef]

- Li, Q.; Lei, Y.; Fu, H. Growth characteristics and reinforcing behavior of In-situ NbCp in laser cladded Fe-based composite coating. J. Mater. Sci. Technol. 2015, 31, 766–772. [Google Scholar] [CrossRef]

| C | Cr | Si | Mn | Fe | B | Ni |

|---|---|---|---|---|---|---|

| 0.45 | 12.00 | 4.00 | 0.10 | 10.00 | 2.40 | Balance |

| C | Cr | Si | P | S | Fe |

|---|---|---|---|---|---|

| ≤6.0 | ≥52.0 | ≤3.0 | ≤0.04 | ≤0.04 | Balance |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, J.; Li, R.; Chen, S.; Zhang, Y.; Chen, S.; Gu, H. Microstructure and Wear Behavior of Laser Cladded Ni45 + High-Carbon Ferrochrome Composite Coatings. Materials 2020, 13, 1611. https://doi.org/10.3390/ma13071611

Gu J, Li R, Chen S, Zhang Y, Chen S, Gu H. Microstructure and Wear Behavior of Laser Cladded Ni45 + High-Carbon Ferrochrome Composite Coatings. Materials. 2020; 13(7):1611. https://doi.org/10.3390/ma13071611

Chicago/Turabian StyleGu, Jiayang, Ruifeng Li, Shungao Chen, Yuhao Zhang, Shujin Chen, and Heng Gu. 2020. "Microstructure and Wear Behavior of Laser Cladded Ni45 + High-Carbon Ferrochrome Composite Coatings" Materials 13, no. 7: 1611. https://doi.org/10.3390/ma13071611

APA StyleGu, J., Li, R., Chen, S., Zhang, Y., Chen, S., & Gu, H. (2020). Microstructure and Wear Behavior of Laser Cladded Ni45 + High-Carbon Ferrochrome Composite Coatings. Materials, 13(7), 1611. https://doi.org/10.3390/ma13071611